Page 1

Street/Strip Camshafts for

Honda/Acura B-Series VTEC Engines

,

Proper installation is the responsibility of the customer. Improper or incomplete installation could result in poor

performance, related component damage, potentially severe engine damage, and will void your warranty. If you do not feel

Catalog # 4730

INSTALLATION INSTRUCTIONS

PLEASE study these instructions carefully before installing your new Street/Strip Camshafts for Honda/Acura B-Series VTEC

Engines. If you have any questions or problems, do not hesitate to contact our Technical Hotline at: 1-800-416-8628

from 7am-5pm PST, Mon-Fri, or via e-mail at: Edelbrock@Edelbrock.com. Please fill out and mail your warranty card.

• Note:

comfortable installing these parts, we recommend having the installation performed by a professional mechanic.

• Description: The Street/Strip camshafts for Honda/Acura B-Series VTEC engines provide best performance up to 9000

RPM. They are ground from chilled iron and nitride hardened for outstanding durability. Due to the increased lift of these

camshafts, changing valve springs is required.

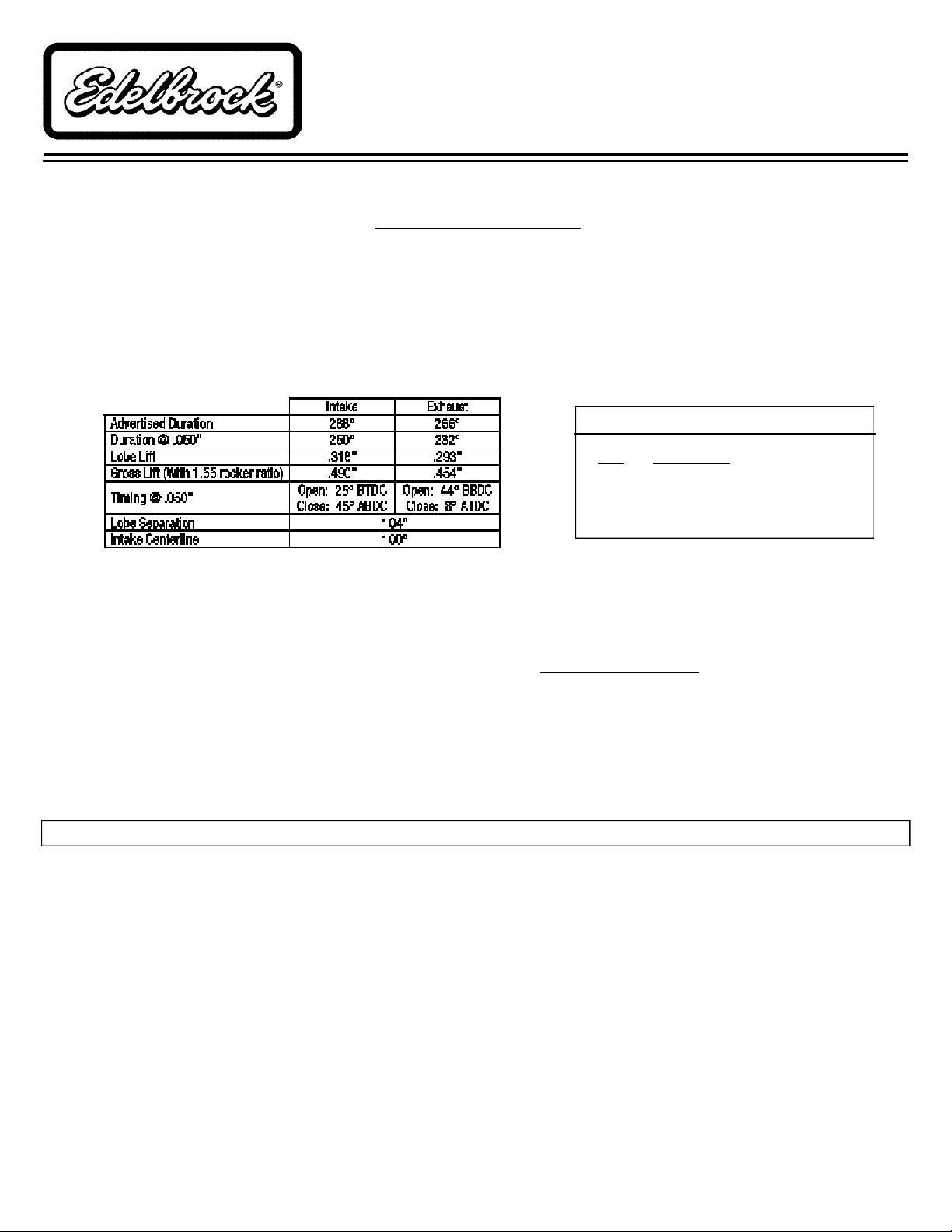

Cam Specifications (Vtec Lobe):

Kit Contents

Qty. Description

❑ 1 Intake Camshaft

❑ 1 Exhaust Camshaft

❑ 1 Container of Assembly Lube

• Recommended Related Products:

Due to the high rpm nature of the Street/Strip Camshafts, a programmable or modified ECU is recommended to overcome

the rev limiter for off-highway race vehicles only. Fine tuning on a dyno is recommended for maximum performance. We

recommend the use of Edelbrock Adjustable Cam Gears, #4721 (silver) or #4723 (red), to adjust cam timing for best

performance. To order a catalog, call (800) FUN-TEAM, or visit www.Edelbrock.com.

• Tools and Additional Parts Required:

1. Edelbrock #4737 - Street/Strip Valve Spring Kit

2. Honda #07AA-PR3020A - Tappet Adjuster Wrench

3. Socket Wrench with 10, 12, 14 & 19mm Sockets

(Long sockets or extentions may be required.)

4. 5/8” Spark Plug Socket Wrench

5. Long Feeler Gauges (.006” & .008”)

6. Adjustable Torque Wrench

7. Automotive Sensor Safe Silicone Sealant

INSTALLATION NOTES

• Note: Make sure your engine is in good running condition before installing the Edelbrock Street/Strip Camshafts. If your

engine is not in good working order, installation of these high performance camshafts could result in premature engine

wear. It is recommended to check the wear of the camshaft journals before installation by checking the oil clearance as

shown in the factory service manual. Checking the camshaft end-play, and rocker arm wear is also recommended.

• Remember: When working on your engine, especially when oil or fuel is present, always work in a well-

ventilated area. Keep all sparks, open flames, or other sources of ignition away from the work area. Failure

to do so could result in a fire or explosion causing vehicle or property damage, personal injury, and/or death.

• Before Beginning: This installation can be accomplished using common tools and procedures. However, you should have

a basic knowledge of automotive repair and modification and be familiar with and comfortable working on your vehicle. If

you do not feel comfortable working on your vehicle, it is recommended to have the installation completed by a professional

mechanic. Keeping your specific vehicle’s Service Manual on hand for reference is helpful.

©2003 Edelbrock Corporation

Rev. 10/03

Page 1 of 4

Catalog #4730

Brochure #63-0210

Page 2

INSTALLATION PROCEDURE

1. Make sure the engine is cool and the vehicle is on level

ground. Set the parking brake. If you have an original

equipment radio with anti-theft protection, make sure to

write down the code before disconnecting the battery.

After installation, you will need this code to restore radio

operation. It is recommended to clean the valve cover, as

well as the area surrounding the valve cover, to avoid

getting dirt or debris into the engine. Disconnect the

negative cable from the battery.

2. Disconnect the PCV hose and ground wire from the valve

cover. Using a 10mm socket, remove the four cap nuts

holding the spark plug wire cover. Remove the spark

plug wire cover and remove the spark plug wire boots

from the spark plugs. Using a 5/8” spark plug socket,

remove the spark plugs. This will make turning the

engine over in step 5 easier. Using a 10mm socket,

remove the remaining eight nuts and washers holding

the valve cover, and carefully lift off the valve cover.

(Note: Inspect the valve cover gasket and rubber

seals surrounding the spark plug holes. If they are

in good condition, they may be re-used). Set the

cover, gasket, and seals aside.

Check that the no. 1 cylinder is still at TDC. If not,

continue to rotate the crankshaft pulley counterclockwise until the no. 1 cylinder is again at TDC.

7. Remove the timing belt tensioner access plug and loosen

the belt tensioner adjusting bolt 1/2 turn using a 14mm

socket. Push on the belt tensioner to remove tension

from the timing belt, then tighten the adjusting bolt to

hold the tensioner in place.

8. You may now slide the timing belt off of the camshaft

sprockets.

9. Remove the cam sprocket bolts and remove the cam

sprockets, being very careful not to lose the cam keys

that locate the sprockets onto the camshafts. You may

now remove the bolt holding the back timing cover using

a 10mm socket. Remove the cover and inspect the seal

between the cover and the cylinder head; if it is in good

condition, it may be re-used.

10. Using the Tappet Adjuster Wrench, loosen the tappet

adjusting screws on all rockers.

3. Loosen and remove the three distributor mounting bolts

using a 12mm socket. Remove the distributor from the

cylinder head and rest it carefully next to the head, you

do not need to unplug the distributor from the wiring

harness. Be careful not to lose the o-ring seal. Inspect

the seal for damage. If it is in good condition, it may be

re-used.

4. Remove the two bolts holding the middle timing belt

cover using a 10mm socket. Remove the middle timing

cover and set aside.

5. Turn the steering wheel so the front tires are pointing to

the left. Now you can access the crankshaft pulley bolt

through the fender liner. Rotate the engine counterclockwise using a 19mm socket until the no. 1 cylinder is

at top dead center (TDC) on the compression cycle. The

no. 1 cylinder is at TDC when the white TDC mark on the

crankshaft pulley is aligned with the pointer on the lower

timing belt cover.

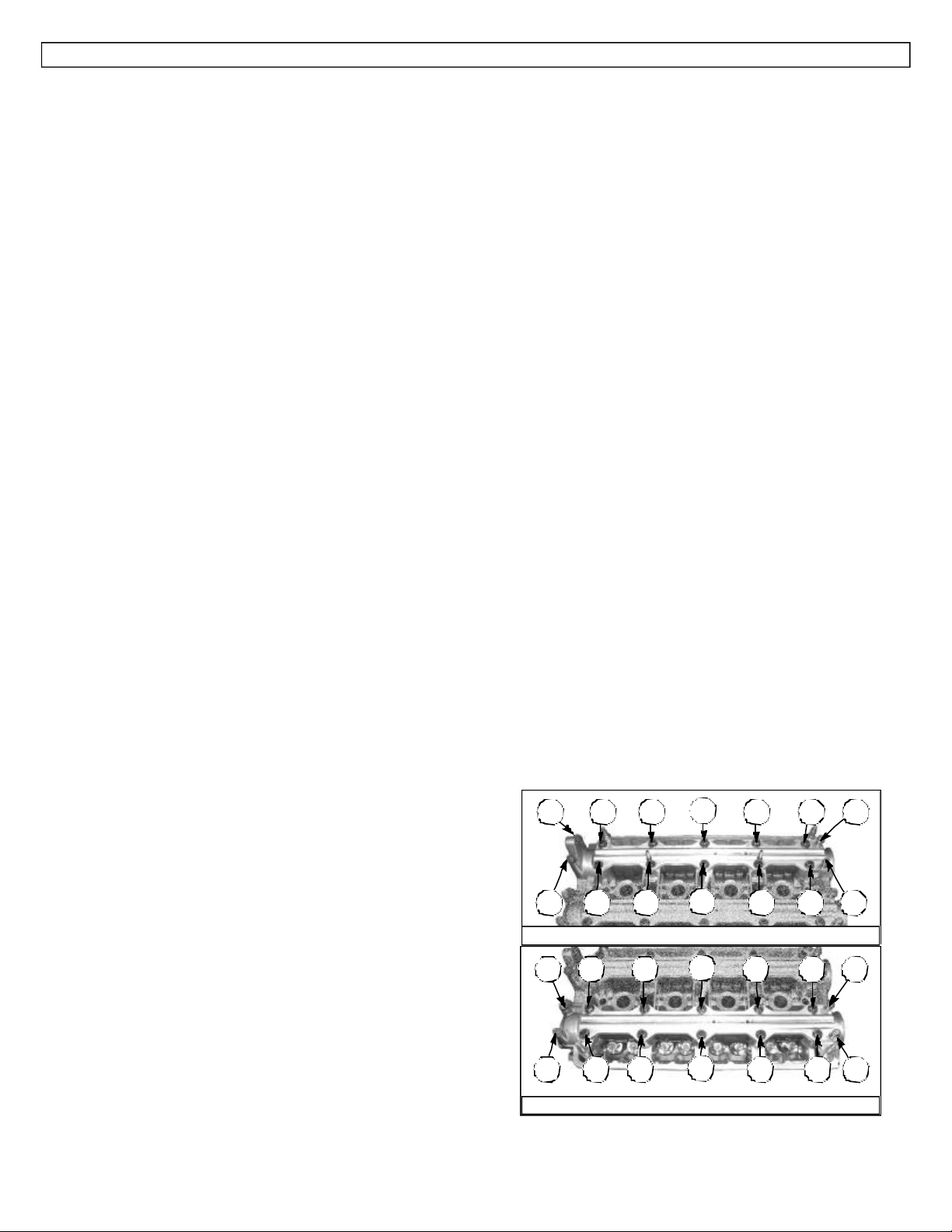

11. Loosen the bolts holding the camshaft holder plates and

camshaft holders (cam caps) using a 12mm socket on

bolts 1-10 and a 10mm socket on bolts 11-14 of each

set of camshaft holder plates (See Fig. 1-A & 1-B). To

prevent any possible warpage of the plates and cam

caps, loosen each bolt 1/3 turn at a time in the sequence

shown. Repeat until all bolts are fully loosened.

1

14 10 6

Fig. 1-A - Intake Cam Plate Torque Sequence

14 10 6

2

1

2

3 7

4 8 12

3 7

4 8 12

11913 5

11913 5

6. Using a 14mm socket, loosen the camshaft sprocket

bolts approximately 1/2 turn. Do not remove the bolts.

©2003 Edelbrock Corporation

Rev. 10/03

Fig. 1-B - Exhaust Cam Plate Torque Sequence

Catalog #4730

Brochure #63-0210Page 2 of 4

Page 3

12. Remove each plate carefully, keeping the intake cam

plate and exhaust plate in order, allowing the bolts to

remain in their positions in the plates. This will allow the

bolts to go back into their original positions and is an

easy way to keep them in order. Set the plates aside.

Carefully lift the cam caps off of the camshafts keeping

them in order. You will notice that each cap is marked

with an arrow and number that corresponds to its

location. The arrows point toward the timing belt, and

they are numbered with no. 1 being closest to the timing

belt and no. 5 being closest to the distributor. Make sure

to keep the bolts that hold the end cam caps in order as

well. (Note: You may need to pry the cam caps

loose before lifting them off. Carefully use a flat

blade screwdriver to pry the cam caps loose. See

Fig. 2). There is an oil seal and dowel pin under the no.

3 cam cap. Inspect the oil seal and replace, if necessary.

Carefully use a flat blade

screwdriver to lift cam caps.

DO NOT pry near the cam

journal surface. Wrap the end

of the screwdriver with tape

to protect the cam caps.

liberal coating of lube to the rocker arm contact surface

and to the journal suface in the cylinder head and on the

cam caps.

16. Set the camshafts into the head with the keyways facing

up. Apply some automotive sensor safe silicone to the

mating surfaces of the no. 1 and no. 5 cam caps (See

Fig. 3). Make sure the cam caps are in order and set

them down on top of the camshafts. Now install the cam

holder plates, and torque bolts #1 - 10 to 20 ft/lbs, and

bolts #11 - 14 to 7 ft/lbs (See Fig. 1).

No. 5 Cam Caps

Apply

automotive

sensor safe

silicone to

the lightened

areas shown.

No. 1 Cam Caps

Fig. 3

17. Install the back timing cover and gasket. Torque bolt to

7 ft/lbs. Install the cam sprockets, making sure to use

the cam keys. Hand tighten the cam sprocket bolts at

this time.

Fig. 2

13. Remove the camshafts one at a time, keeping them in

order. (Note: The oil seals will come out with the

camshafts. Take care not to damage the oil seals).

Now is a good time to inspect the rubber cap near the

end of the exhaust cam, opposite the timing belt. If it is

in good condition, it may be re-used. Make sure the oring sealing surface is clean and dry.

14. Remove the oil seals from the camshafts. If they are in

good condition, they may be re-used. Install the oil seals

onto the new Edelbrock Street/Strip Camshafts with the

spring side facing in towards the camshafts.

15. Apply a liberal coating of assembly lube to the journals

and lobes of the Edelbrock camshafts. Also, apply a

18. Slip the timing belt over the cam sprockets. Loosen the

belt tensioner adjusting bolt to allow it to tighten the belt.

Tighten the tensioner adjusting bolt to 40 ft/lbs. Tighten

the cam sprocket bolts to 40 ft/lbs. Make sure the cam

sprockets are aligned properly (See Fig. 4). If you can

rotate the belt more than 90° by hand, the belt is too

loose. Make sure the tensioner is not stuck by loosening

the tensioner adjusting bolt and pulling up on the

tensioner with a hook or bent wire hanger, then retighten the bolt. Replace the tensioner adjusting bolt

access plug.

Make sure sprockets are aligned

as shown. Stock sprocket “Up”

marks should point up with TDC

mark aligned as shown.

Fig. 4

©2003 Edelbrock Corporation

Rev. 10/03

Catalog #4730

Brochure #63-0210Page 3 of 4

Page 4

19. Rotate the engine 5-6 revolutions to seat the belt. Bring

the engine around to TDC as in step 5. Make sure the

cam sprockets are still aligned properly (See Fig. 4).

20. Replace the middle timing cover. Torque bolts to 7 ft/lbs.

24. Install the spark plugs and wires. Install the wire cover.

Tighten cap nuts to 7 ft/lbs. Connect the PCV hose and

the ground wire. Connect the negative battery cable.

21. Coat the distributor o-ring with clean engine oil, and

install the distributor. Tighten mounting bolts to 17 ft/lbs.

(Note: The distribitor shaft and end of camshaft

are notched to elimiinate the possibility of

installing the distributor 180° out of time).

22. Before installing the valve cover, you will need to adjust

the valves. Set the no. 1 cylinder at TDC as explained in

step 5. Make sure the cam sprockets are aligned

properly (See Fig. 4). Using the tappet adjuster wrench,

adjust the valve lash on the no. 1 cylinder. The intake

valve clearances should be set at .006” and the exhaust

valve clearances at .008”. The feeler gauge should slide

between the rocker arm and the camshaft with a slight

amount of drag. Tighten the lock nut and re-check the

clearance. It should stay at .006” (intake) and .008”

(exhaust). Turn the crankshaft 180° counter-clockwise.

The cams should have rotated by 90°. Repeat the valve

adjustment on the no. 3 cylinder. Rotate the engine 180°

again, and repeat the adjustment on the no. 4 cylinder.

Rotate again by 180° and repeat the adjustment on the

no. 2 cylinder. The valves are now adjusted. After

adjusting the valves, re-torque the crankshaft bolt to 130

ft/lbs.

Apply Here Apply Here

Apply automotive sensor safe

silicone to the corners of the seal

on both ends of the valve cover.

7

3

8

4 2

Fig. 5

5

1

6

23. Thoroughly clean the valve cover mating surface, being

careful not to get any old silicone or dirt into the engine.

Clean off the rubber cap near the exhaust cam, put a thin

coat of automotive sensor safe silicone around it and

install it. Clean the groove in the valve cover and press

the valve cover gasket into the groove in the valve cover.

Apply a bit of automotive sensor safe silicone at the

corners of the gasket that go around the camshafts (See

Fig. 5). Set the valve cover onto the cylinder head and

press down lightly to make sure the gasket is seated.

Install the four nuts and washers that go under the plug

wire cover and the four cap nuts and washers. Tighten

nuts to 7 ft/lbs (See Fig. 6 for torque sequence).

Edelbrock Corporation • 2700 California St. • Torrance, CA 90503

Tech Line: 1-800-416-8628 • Office: (310) 781-2222 • E-Mail: Edelbrock@Edelbrock.com

©2003 Edelbrock Corporation

Rev. 10/03

Fig. 6

• Camshaft Run-In Procedure:

Edelbrock recommends performing a Run-In procedure

after installing new camshafts. Make sure the oil level in

the engine is at the proper level, and the oil is clean. We

recommend using a non-synthetic oil during the break in.

Start the vehicle and immediately bring the engine above

2500 rpm for at least 20 minutes. Vary the engine speed

constantly to help sling oil around the camshafts. After

the run-in, change the oil to remove any assembly lube.

Catalog #4730

Brochure #63-0210Page 4 of 4

Page 5

CAMSHAFT: Street/Strip

Rev. 10/03

Rev. 10/03

CATALOG #: 4730

ENGINE: Honda, B-Series VTEC

RPM RANGE: Idle - 9000 RPM

CAMSHAFT: Street/Strip

CATALOG #: 4730

ENGINE: Honda, B-Series VTEC

RPM RANGE: Idle - 9000 RPM

Advertised Duration: Int. 288° Exh. 266°

Duration at .050” Lift: Int. 250° Exh. 232°

Lift at Cam: Int. .316” Exh. .293”

Lift at Valve: Int. .490” Exh. .454”

Intake Centerline: 100°

Lobe Separation: 104°

Timing at .050” Lift:

Open Close

Intake: 25° BTDC 45° ABDC

Exhaust: 44° BBDC 8° BTDC

Advertised Duration: Int. 288° Exh. 266°

Duration at .050” Lift: Int. 250° Exh. 232°

Lift at Cam: Int. .316” Exh. .293”

Lift at Valve: Int. .490” Exh. .454”

Intake Centerline: 100°

Lobe Separation: 104°

Timing at .050” Lift:

Open Close

Intake: 25° BTDC 45° ABDC

Exhaust: 44° BBDC 8° BTDC

Rev. 10/03

CAMSHAFT: Street/Strip

CATALOG #: 4730

ENGINE: Honda, B-Series VTEC

RPM RANGE: Idle - 9000 RPM

Advertised Duration: Int. 288° Exh. 266°

Duration at .050” Lift: Int. 250° Exh. 232°

Lift at Cam: Int. .316” Exh. .293”

Lift at Valve: Int. .490” Exh. .454”

Intake Centerline: 100°

Lobe Separation: 104°

Timing at .050” Lift:

Open Close

Intake: 25° BTDC 45° ABDC

Exhaust: 44° BBDC 8° BTDC

CAMSHAFT: Street/Strip

CATALOG #: 4730

ENGINE: Honda, B-Series VTEC

RPM RANGE: Idle - 9000 RPM

Advertised Duration: Int. 288° Exh. 266°

Duration at .050” Lift: Int. 250° Exh. 232°

Lift at Cam: Int. .316” Exh. .293”

Lift at Valve: Int. .490” Exh. .454”

Intake Centerline: 100°

Lobe Separation: 104°

Timing at .050” Lift:

Open Close

Intake: 25° BTDC 45° ABDC

Exhaust: 44° BBDC 8° BTDC

Rev. 10/03

Loading...

Loading...