Page 1

PERFORMER 454 TBIINTAKE MANIFOLD

For 1987-1990 454 c.i.d. Chevrolet V8

CATALOG #3764

INSTALLATION INSTRUCTIONS

PLEASE study these instructions carefully before beginning this installation. Most installations can be accomplished with common

tools and procedures. However, you should be familiar with and comfortable working on your vehicle. If you do not feel comfortable

performing this installation, it is recommended to have the installation completed by a mechanic. If you have any questions or

problems, please call our Technical Hotline at: 1-800-416-8628, 7:00 am - 5:00 pm, Pacific Standard Time, Monday through

Friday or e-mail us at edelbrock@edelbrock.com.. PLEASE complete and mail your warranty card. Be sure to write the model

number of this product in the "Part #____" space. THANK YOU.

• DESCRIPTION: The Edelbrock Performer 454 TBI intake manifold is designed for 454 c.i.d. throttle body injected Chevrolet V8s.

It delivers outstanding performance for the street with complete emissions compatibility. Manifold is a stock replacement/street

legal part for 1987-1990 Chevy/GMC trucks with Mark IV, 454 c.i.d. throttle body-injected V8 engines.

• PARTS SUPPLIED WITH MANIFOLD:

Qty. Description

1 3/8”-18 NPTF to 5/8” hose fitting (Front water core)

1 3/8”-18 NPTF to 3/4” hose fitting (Rear water core)

1 1/4”-18 NPTF male to female 90° elbow fitting (Power brake vacuum elbow)

1 3/8”-18 NPTF to 1/4”-18 NPTF adapter fitting (Power brake vacuum)

1 5/16”-18 x 1/2” grade 2 hex cap screw (For throttle cable bracket)

1 1/4” plastic hose vacuum tee (For MAP sensor and transmission vacuum modulator)

1 Spacer; 11/16” O.D. x 7/16” I.D. x .3" (For MAP sensor)

• ACCESSORIES & INSTALLATION ITEMS: Major recommendations are listed below. See our catalog for details. To order a

catalog, call (800) FUN-TEAM, or visit www.edelbrock.com.

• EXHAUST EMISSIONS SYSTEMS: Edelbrock EGR-equipped Performer T.B.I. manifolds are intended as a direct replacement for

their O.E.M. counterparts. All exhaust emissions or emissions-related stock components will be retained and functional.

• THROTTLE BODY INJECTORS: Use only OEM-type throttle body fuel injectors and base gasket. Label all vacuum lines removed

for re-attachment to the T.B.I. The use of aftermarket throttle body injection units is not recommended.

• BRACKETS: The throttle cable bracket from a 1991 454SS truck is required. Use Edelbrock #8019 or GM #10111685. On some

applications, the end of the bracket will need to be cut off. Use a hacksaw to remove about two inches from the end where the

cable housing mounts.

• CRUISE CONTROL: If the factory cruise control rod will not fit, use GM part #14009160.

• EGR VALVE: Manifold will accept OEM EGR valve. If a replacement valve is needed, use GM #17090051.

• WATER JACKET: Do not use the OEM water jacket plate between the injector base and the Performer T.B.I. manifold, as this

water cavity is already cast into the manifold. Use the OEM formed hose from the front water outlet (just below the T.B.I.) to the

front water passage, and the original fitting in the front water passage. It is important to use the correct mixture of anti-freeze

and water in your cooling system, as water only will quickly corrode the intake manifold.

• GASKETS AND SEALANT: Do not use high-performance or competition-type intake gaskets for street applications. Due to

material deterioration under street conditions, internal leakage of both vacuum and oil may occur.

INTAKE MANIFOLD REFERENCE RECOMMENDED GASKET

3764 (None) GM #10181398

Catalog #3764

Rev. 5/05 - RS/mc

©2005 Edelbrock Corporation

Brochure #63-0403Page 1 of 2

Page 2

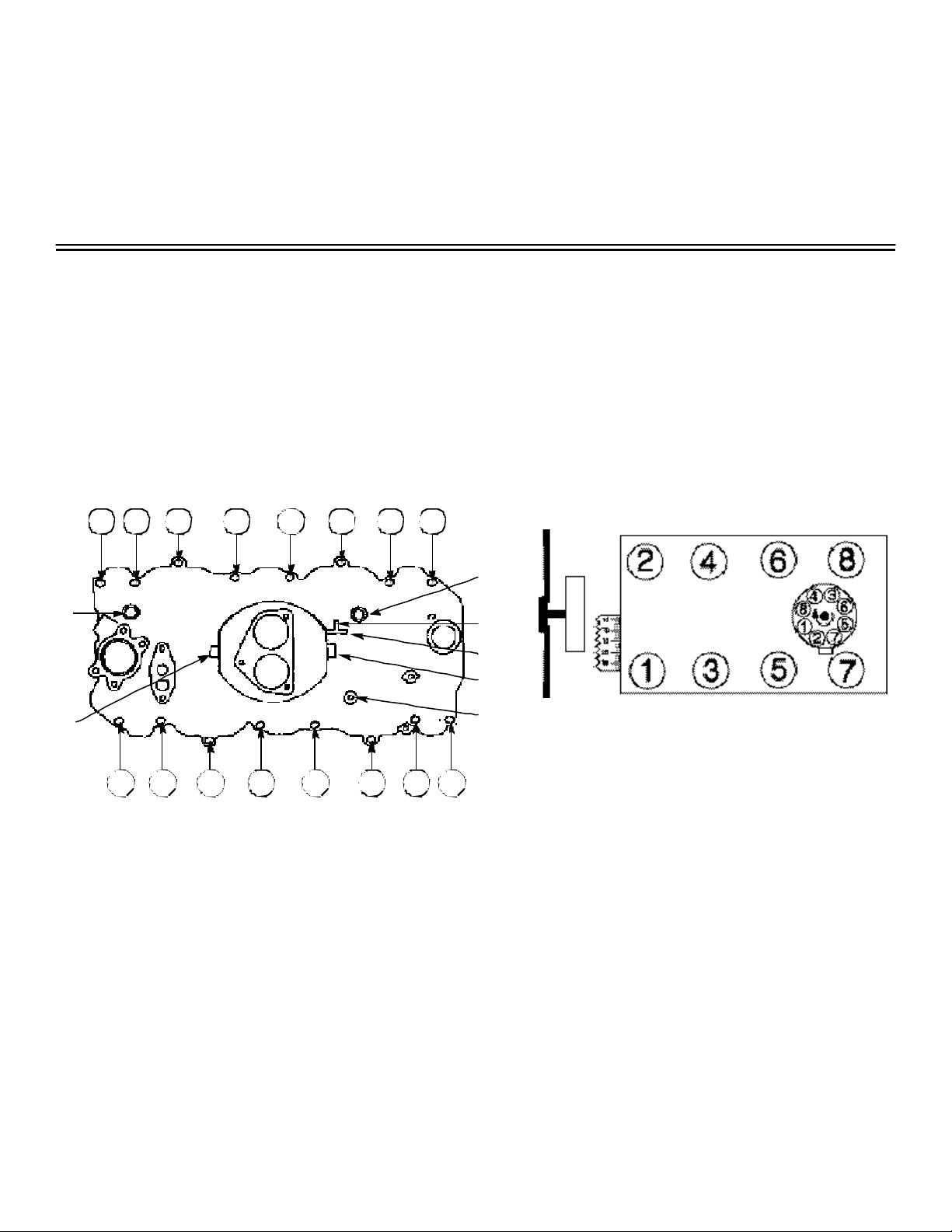

• FIRING ORDER AND CYLINDER NUMBERING: For cylinder numbering and firing order, see Figure 2.

• FINAL TUNING: NOTE: Local emission laws must be checked for legality of injector or ignition changes.

Performer manifolds deliver excellent driveability and power utilizing the factory OEM distributor settings.

• CAMSHAFTS AND HEADERS: Use only parts that are compatible with computer-controlled engines, such as Edelbrock

camshaft #2162 and Edelbrock Tubular Exhaust Systems. Do not use other header systems which are not tested for compatibility

with computer-controlled TBI systems. Those headers may not position the O2 sensor in the correct location, causing improper

operation of the injector.

INSTALLATION INSTRUCTIONS

1) Use only recommended intake gaskets set when installing this intake manifold.

2) Fully clean the cylinder head intake flanges and the engine block end seal surfaces.

3) Apply Edelbrock Gasgacinch sealant P/N 9300 to both cylinder head flanges and to the cylinder head side of the gaskets,

allow to air dry, and attach the intake gaskets.

4) Do not use cork or rubber end seals. Use RTV silicone sealer instead. Apply a ¼" high bead across each block end seal

surface, overlapping the intake gasket at the four corners. This method will eliminate end seal slippage.

5) WARNING: There is no gasket support for the manifold on the four bolt holes which are numbered 5, 10, 11, and 16 in

Figure 1. Damage to the manifold will occur if these four bolts are over-tightened. Hand tighten them with a 6” boxend wrench. Do not use a torque wrench. Torque all of the remaining manifold bolts in two steps by the sequence

shown in Figure 1 to 25 ft/lbs. For ease of installation, we recommend using Edelbrock Manifold Bolt & Washer Kit

#8564.

9

A

B

7 6 5 1 4 16 14

Figure 1 - Intake Manifold Tightening Sequence and Plumbing

DO NOT USE A TORQUE WRENCH ON BOLTS 5, 10, 11, &16

Hand Tighten Bolts using a 6” box end wrench.

Tighten remaining bolts to 25 ft./lbs. in sequence shown.

A - Water from water core (Use original 1/2"-14 NPTF to 5/8" hose fitting)

B - Water out (3/8"-18 NPTF to 5/8" hose fitting)

C - Power Brakes (1/4"-18 90° elbow & 3/8"-18 to 1/4"-18 adapter)

D - To Transmission vacuum modulator

E - To MAP Sensor (1/4" vacuum tee)

F - Water in (3/8"-18 NPT to 3/4" hose)

G - 5/16”-18 x 1/2” bolt

13121132108

C

D

E

F

G

15

Figure 2 - 454 c.i.d. Chevrolet Firing Order

Firing Order: 1-8-4-3-6-5-7-2

Turn Distributor Counter-Clockwise to Advance Timing

Catalog #3764

Rev. 5/05 - RS/mc

Edelbrock Corporation • 2700 California St. • Torrance, CA 90503

Tech-Line: 800-416-8628 • E-Mail: Edelbrock@Edelbrock.com

©2005 Edelbrock Corporation

Brochure #63-0403Page 2 of 2

Loading...

Loading...