Page 1

Pro-Tuner Users Guide

Edelbrock Corporation

2700 California Street

Torrance, CA 90503

Toll Free Tech Line: 800-416-8628

Office: 310-781-2222

Tech e-mail: edelbrock@edelbrock.com

Page 2

2

Table of Contents

Part I

Part II

Part III

Introduction

Kit Contents

Installation and Setup

................................................................................................................................... 101 Engine Management Concepts

.......................................................................................................................................................... 12Strategies and Methods

................................................................................................................................... 152 Vehicle Installation

.......................................................................................................................................................... 22Fuel System Installation

.......................................................................................................................................................... 30ECU and Main Harness Installation

.......................................................................................................................................................... 36Component and Sensor Installation

......................................................................................................................................................... 37Distributor and Ignition

......................................................................................................................................................... 41Intake Air Temperature Sensor (IAT)

......................................................................................................................................................... 42Engine Coolant Temperature Sensor (ECT)

......................................................................................................................................................... 43Manifold Absolute Pressure Sensor (MAP)

......................................................................................................................................................... 45Idle Air Control Valve (IAC)

......................................................................................................................................................... 46Fuel Pressure Sensor (optional)

......................................................................................................................................................... 47Oil Pressure Sensor (optional)

......................................................................................................................................................... 48Mass Air Flow (MAF) Sensor (optional)

......................................................................................................................................................... 50Throttle Position Sensor (TPS)

......................................................................................................................................................... 51Main Wiring Harness and Engine Wiring

......................................................................................................................................................... 54Oxygen Sensors

......................................................................................................................................................... 59Malfunction Indicator Light

................................................................................................................................... 603 Installing and Configuring the Software

.......................................................................................................................................................... 62System Requirements

.......................................................................................................................................................... 64Installing the Software

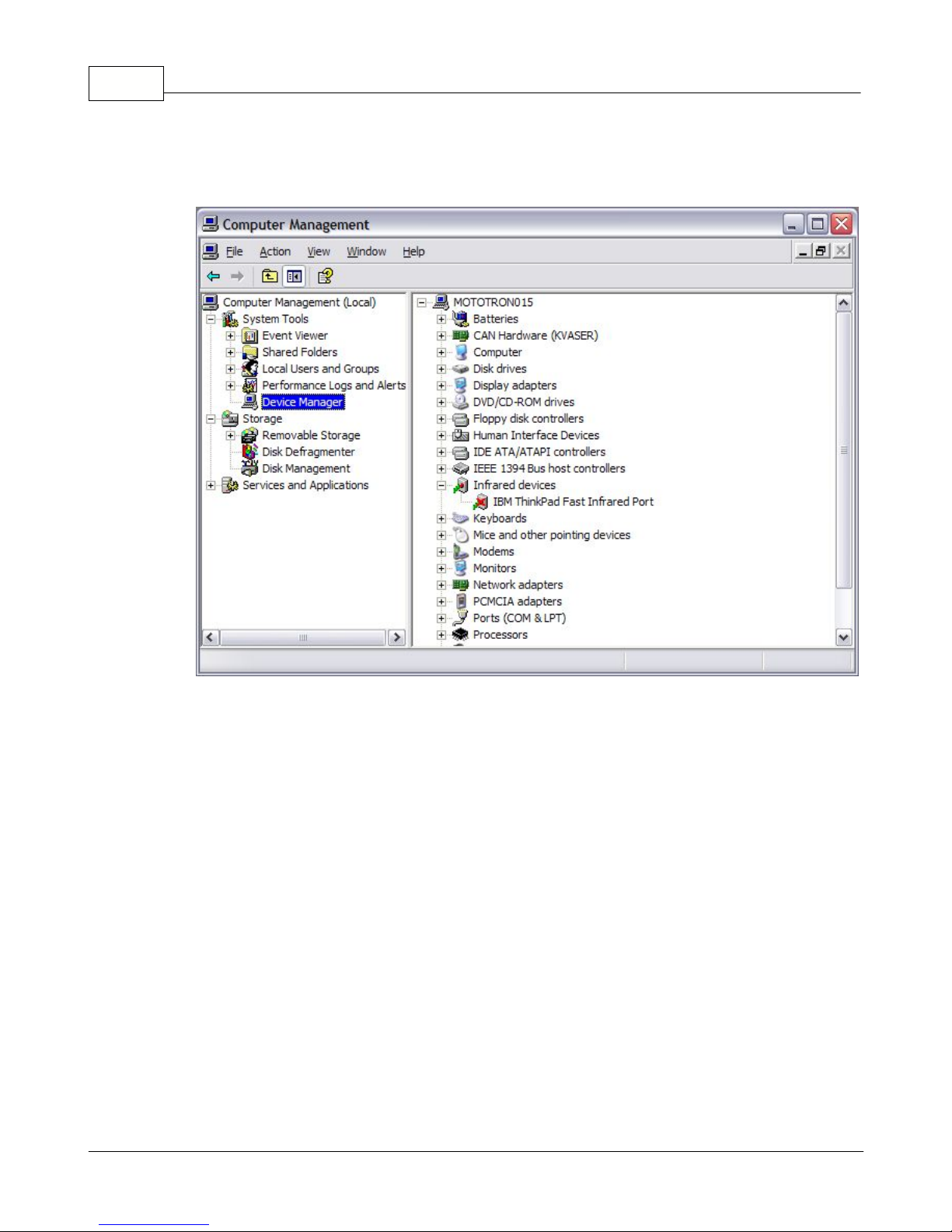

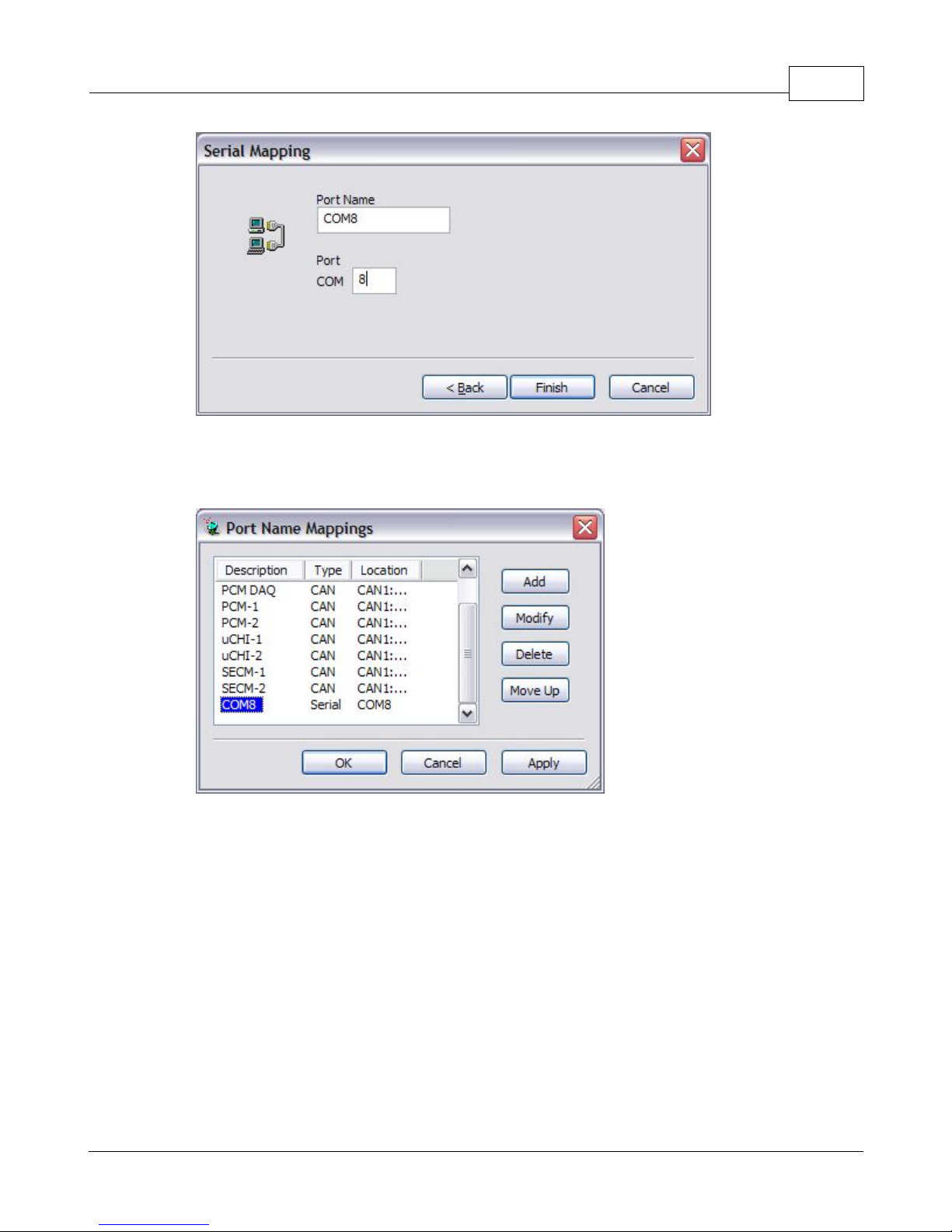

.......................................................................................................................................................... 70Installing the Communications Hardware

......................................................................................................................................................... 72USB/Serial Converters

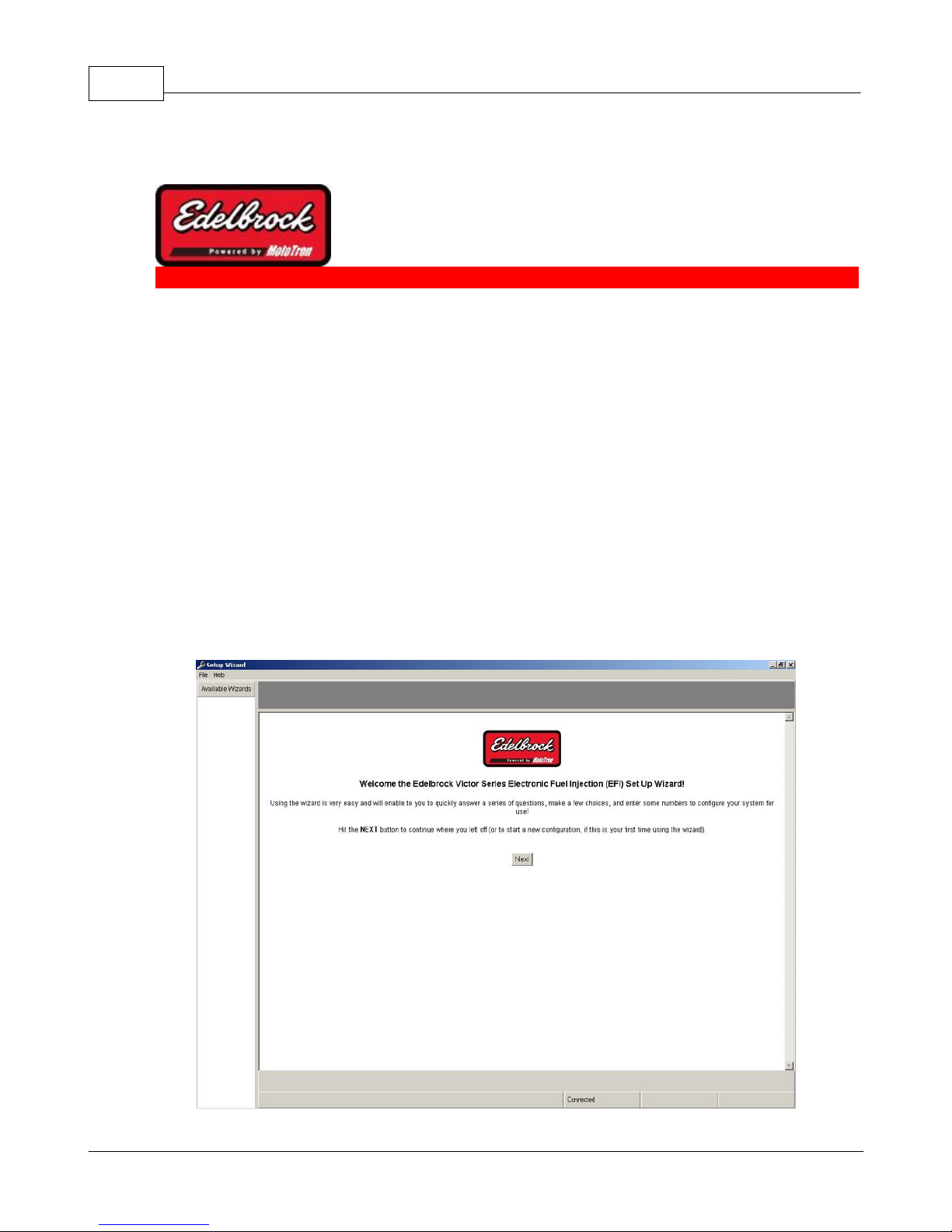

.......................................................................................................................................................... 80Connecting to the Vehicle

.......................................................................................................................................................... 87Application Settings and Preferences

5

7

10

Part IV

Basic Tuning with the Pro Tuner System

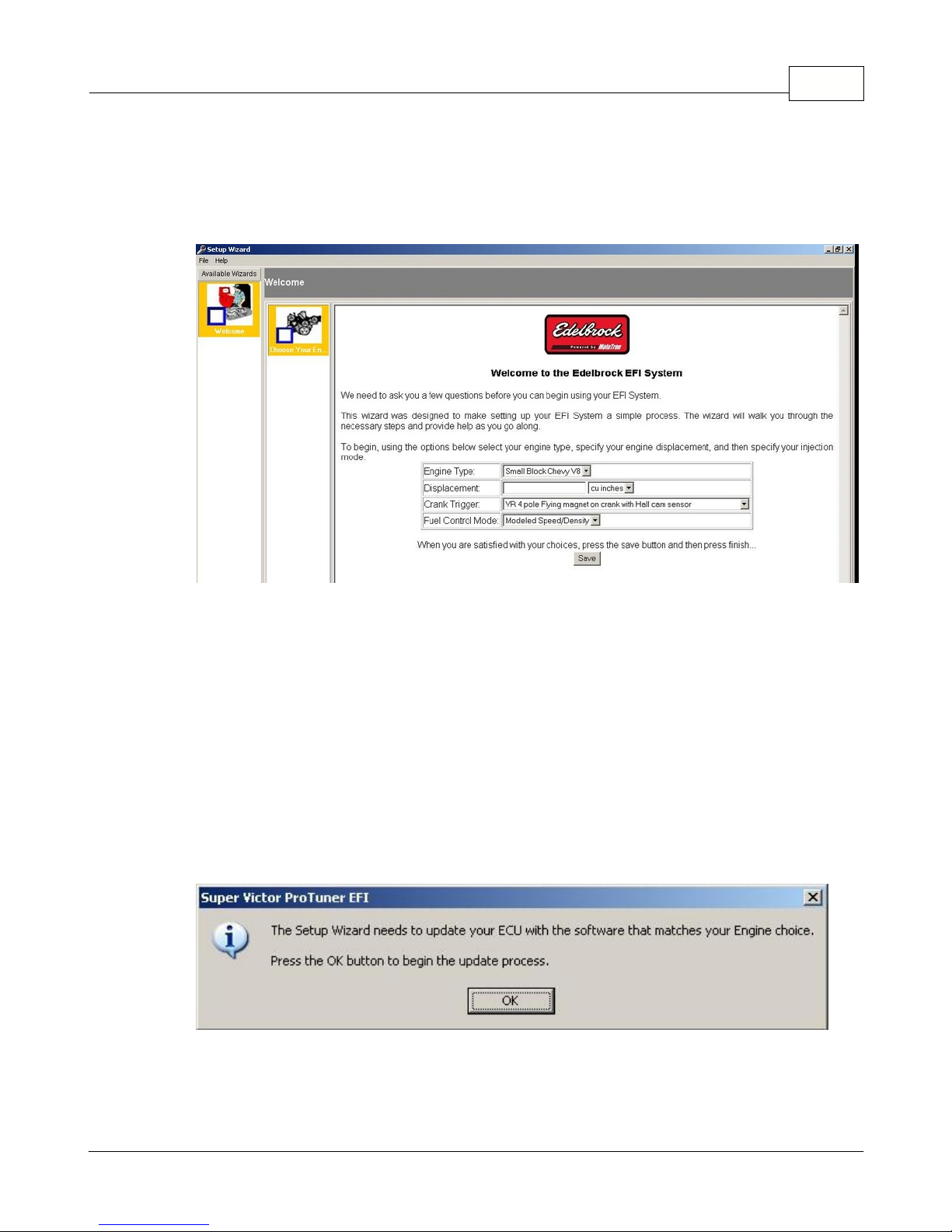

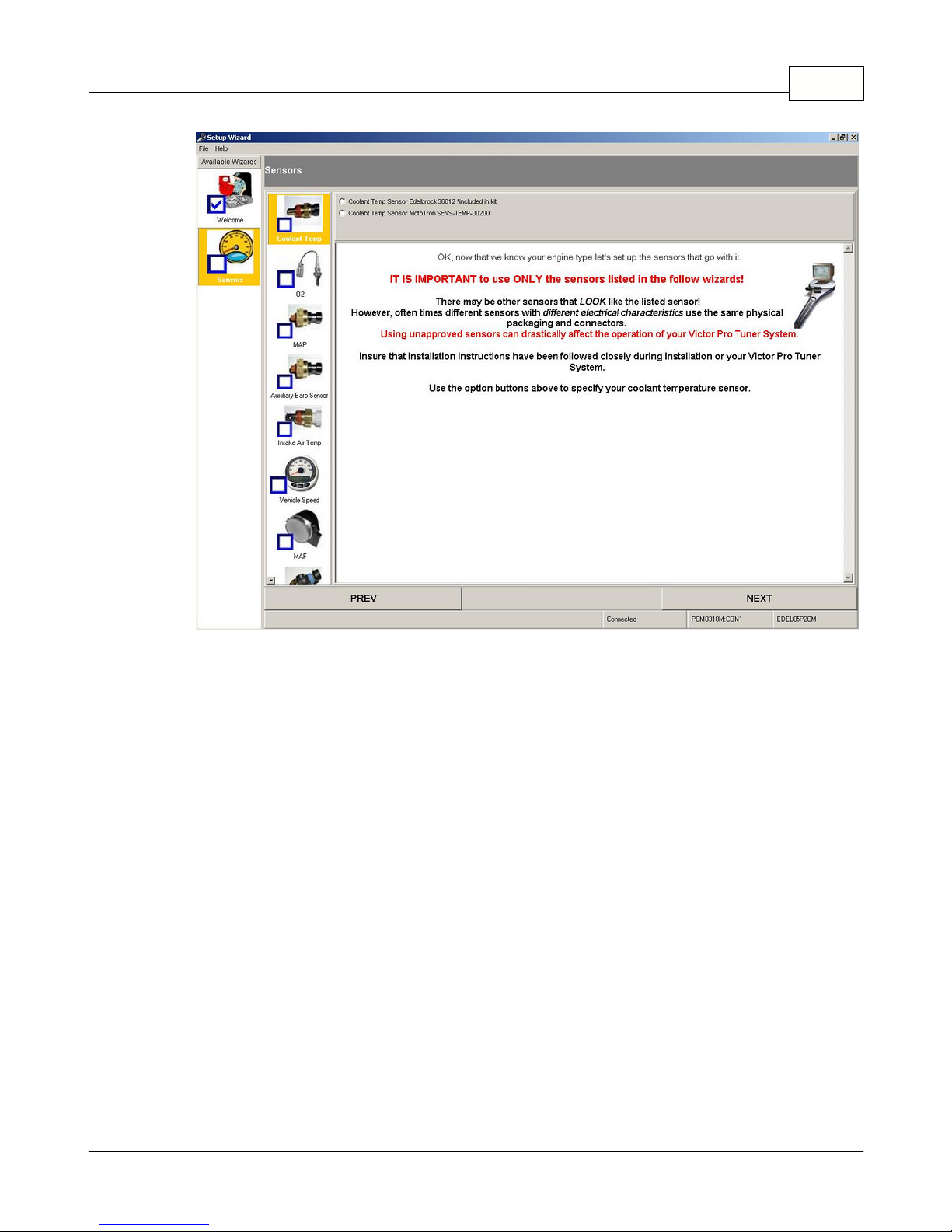

................................................................................................................................... 901 Setup Wizard

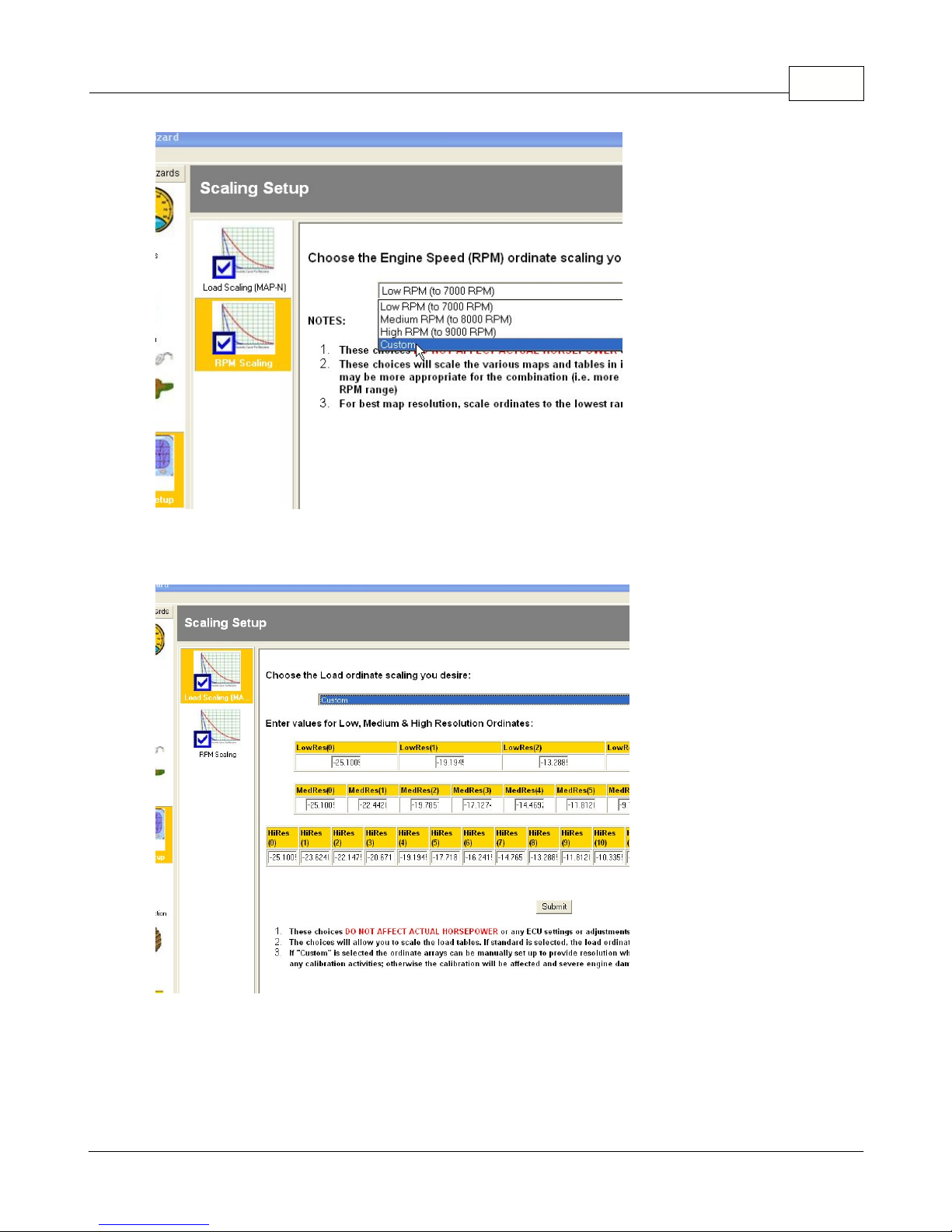

.......................................................................................................................................................... 94Scaling Setup - Custom Load and RPM Axis

................................................................................................................................... 962 Screens, Indicators and Tools

.......................................................................................................................................................... 99Dashboard

.......................................................................................................................................................... 101MAPs

.......................................................................................................................................................... 104Details

.......................................................................................................................................................... 105Status Bar

.......................................................................................................................................................... 106About

.......................................................................................................................................................... 107System Information

................................................................................................................................... 1083 Tuning Maps

.......................................................................................................................................................... 116Base Fuel Map

.......................................................................................................................................................... 118Volumetric Efficiency Map

89

Page 3

.......................................................................................................................................................... 121Spark Advance Map

.......................................................................................................................................................... 124Target Air/Fuel Ratio Map

.......................................................................................................................................................... 128Accel / Decel Fuel Settings

.......................................................................................................................................................... 132Closed Loop Compensation (CLC) map

.......................................................................................................................................................... 135ECT Fuel Trim Table

.......................................................................................................................................................... 136A/C Load Compensation

.......................................................................................................................................................... 138IAT Fuel Trim Table

................................................................................................................................... 1394 3D Chart Manipulation

.......................................................................................................................................................... 140EDIT Chart Point

.......................................................................................................................................................... 142ROTATE

.......................................................................................................................................................... 144ZOOM chart

.......................................................................................................................................................... 145MOVE view

.......................................................................................................................................................... 146RESET View

................................................................................................................................... 1475 Logging and Data Viewing

................................................................................................................................... 1516 Initial Start Up and Idle Tuning

................................................................................................................................... 1557 TPS Set Points

................................................................................................................................... 1588 Ignition Sync Offset

................................................................................................................................... 1609 OFFLINE Mode

.......................................................................................................................................................... 164OFFLINE LOAD

.......................................................................................................................................................... 165OFFLINE SAVE AS

.......................................................................................................................................................... 167OFFLINE SAVE

.......................................................................................................................................................... 168OFFLINE SAVE and USE ONLINE

.......................................................................................................................................................... 169View Logger Data

3Contents

Part V

Part VI

Advanced Tuning with the Pro Tuner System

................................................................................................................................... 1721 Warm Up Fine Tuning

................................................................................................................................... 1742 Idle Fine Tuning

................................................................................................................................... 1773 Toggle Closed Loop

................................................................................................................................... 1784 VE Estimator Tool

................................................................................................................................... 1805 Adaptive Fuel "AutoTuning" Capabilities

................................................................................................................................... 1836 Oil Pressure Warning Set Points

................................................................................................................................... 1847 Coolant Fan Output

................................................................................................................................... 1858 Coolant Fan Set Points

................................................................................................................................... 1869 Fault Detection and Troubleshooting

................................................................................................................................... 18910 Reset ECU to last programmed setup

Features Available with Pro option only

................................................................................................................................... 1911 Additional Maps

................................................................................................................................... 2032 Flight Recorder

................................................................................................................................... 2063 Virtual Engine Simulator

................................................................................................................................... 2084 Base Fuel Pressure Set Point

................................................................................................................................... 2105 Adaptive Air "AutoTuning" Capabilities

171

190

Part VII

Appendices

................................................................................................................................... 2151 Engine Controller Pinout Sheets

214

3

Page 4

4

................................................................................................................................... 2182 Frequently Asked Questions (FAQs)

................................................................................................................................... 2193 Trouble Codes/Faults

................................................................................................................................... 2224 Maintenance Procedures

.......................................................................................................................................................... 223TPS Replacement

................................................................................................................................... 2255 Glossary

................................................................................................................................... 2326 Additional Resources/Service

Page 5

1 Introduction

Introduction 5

Visit us at: http://www.edelbrock.com

Edelbrock Pro-Tuner Series Electronic Fuel

Injection (EFI)

"Total Engine Management"

That’s the slogan for Edelbrock’s Pro-Tuner EFI Systems, powered by Mototron Electronic

Control Units (ECU).

Pro-Tuner EFI Systems include everything needed to convert any engine to powerful

electronic fuel injection; with user programmable features and full ignition control as well

as fuel delivery. Two performance levels are available: Victor and Super Victor. Both

versions include an Edelbrock Victor or Super Victor EFI intake manifold, fuel rails,

throttle body, wiring harness, injectors, Pro-Tuner software, sensors, fuel pump

regulator, and Mototron ECU with Power PC, 32-bit micro controller.

Victor Systems include a Mototron ECM for semi-sequential injection, while Super Victor

Systems feature fully sequential operation and individual cylinder adjustment of spark

and fuel for complete optimization, plus a software upgradeable Mototron PCM with

advanced features - and expandability for exciting future options. Through your laptop

computer, all critical aspects of engine tuning are adjustable to suit your application. The

simplified user interface allows a tuner to dial-in the behavior of the state of the art

control strategies running within the ruggedized Engine Control Module (ECM).

The proprietary Mototron ECU is extremely durable. It’s completely sealed making it

waterproof and ideal for not only competition vehicles but for marine as well. Once up

and running, Edelbrock’s Pro-Tuner EFI software offers easy-to-use, yet sophisticated

tuning control with user-friendly pull down menus and screens.

Page 6

6

Available separately, Edelbrock offers a Pro USB key which allows access to enhanced

tuning parameters for more experienced calibrators. A Basic USB key is included

standard.

Before reading this manual and installing your new system, it is important to understand

that your Edelbrock EFI system is more than fuel injection. It is an Engine Management

System. In addition to controlling the fueling of your engine, the system will also be

controlling ignition, idle airflow, monitoring sensor health, and running other optional

actuator outputs.

While every effort is made to simplify the installation and calibration process, the most

important tool is the knowledge and experience of the person tuning the engine. Just as

with carbureted engines; the tuner must know the fueling and ignition limits of the

specific engine he or she is calibrating to avoid engine damage and provide the best

reliability and drivability possible. In addition to reading this manual, there are many

other sources of engine management theory, as well as experienced tuners and

Edelbrock experts available to assist with questions that you have. See the “Additional

Resources” section of this manual for more sources of EFI information. It is highly

recommended that the Tuner educate themselves as much as possible in the area of

electronic engine control and calibration theory and technique.

If you run into problems, you may contact our EFI Technical Hotline at 800-416-8628

from 7:00 am to 5:00 pm PST Monday through Friday. You may also contact us by email

at: EFItech@edelbrock.com

READ THROUGH ENTIRE MANUAL BEFORE BEGINNING

•

SYSTEM INSTALLATION!

THIS CONTROL SYSTEM IS INTENDED FOR OFF-ROAD

•

APPLICATIONS ONLY. THE USER ASSUMES ALL RESPONSIBILITY

FOR THE INSTALLATION AND APPLICATION OF THE SYSTEM AND

MUST COMPLY WITH ALL APPLICABLE RULES AND REGULATIONS

GOVERNING USAGE AND EMISSION REQUIREMENTS.

Page 7

2 Kit Contents

Kit #3670 Contents:

Part No. Description Qty.

22-3601 Firewall Bulkhead Plate Kit 1

38-1515 Bulkhead Plates 2

68-0410 Self-Tapping Screws 4

72-1516 Grommet 1 3/4" O.D. 1

24-0301 Ignition Amplifier Kit 1

Introduction 7

Visit us at: http://www.edelbrock.com

68-0410 Self-Tapping Screws 3

37-3517 Victor Pro-Tuner Kit 1

37-0004 RS485 Comms Cable 1

37-0006 USB Software Key (Basic Key) 1

37-0007 Controller ECM (48 Pin) 1

72-1517 ECM Rubber Grommet 3

82-0111 ECM Mounting Washers 3

82-3519 ECM Mounting Bushing 3

38-1600 Mounting Bracket for 48 pin PCM 1

68-4005 1/4-20 x 7/8" PCM Socket Head Screw 3

37-3545 Main Engine Harness w/ 2-Power Relays 1

N/A Padded J-Clamps 4

37-3546 Distributor Harness 1

37-3547 Fuel Pump Harness 1

63-3670 Instruction Sheet - Quick Start Guide 1

63-3615 Instruction Sheet - Distributor 1

63-0507 CD-ROM 1

37-3518 MAT Sensor GM (AC Delco #12160244) 1

72-9952 MAT Sensor Grommet 1

37-1520 Serial to USB Converter 1

63-91147Serial to USB Converter Instructions 1

Page 8

8

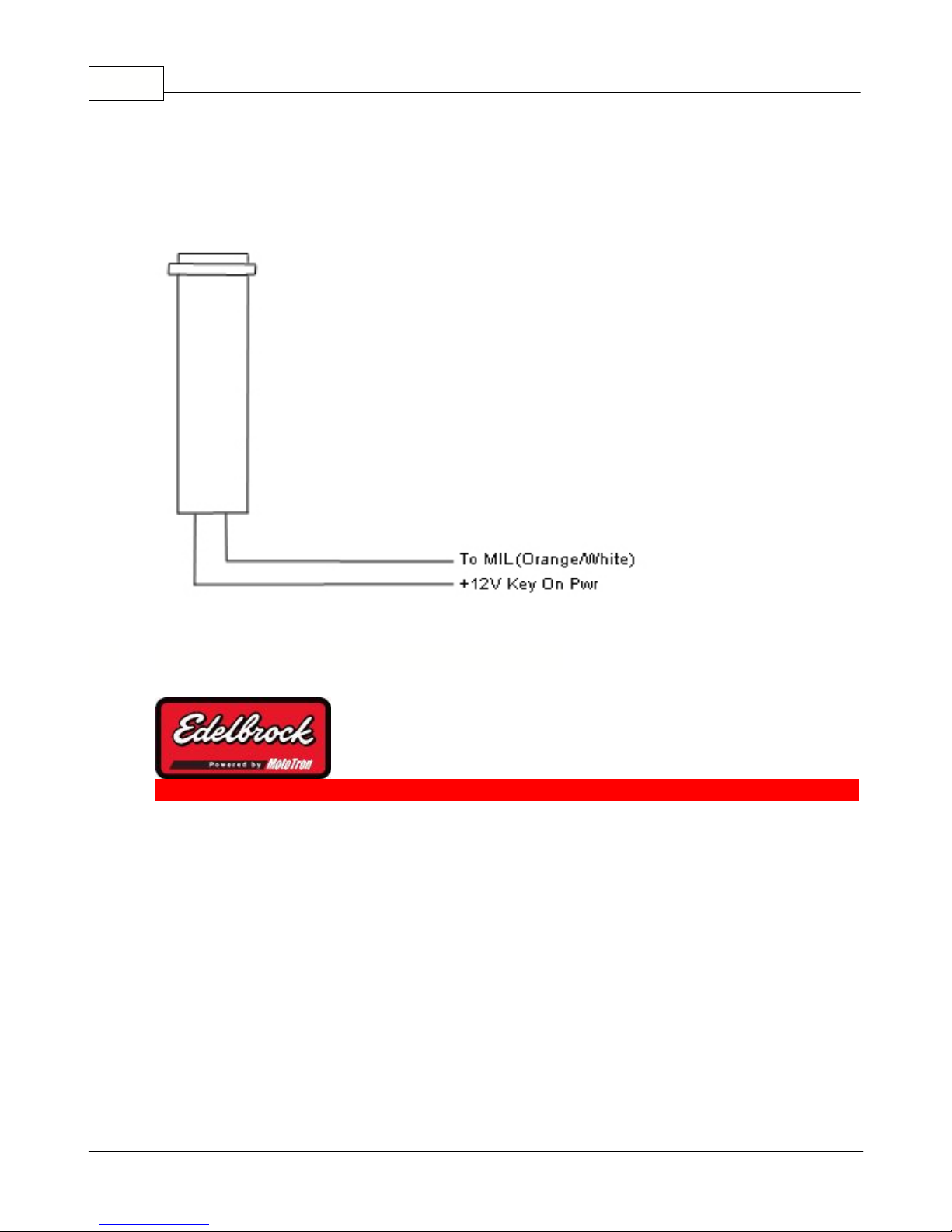

37-3548 Malfunction Indicator Light w/ Clip 1

37-7119 1 Bar Map Sensor (Remove Orange Rubber) 1

38-3601 Gen III Map Sensor Bracket 1

37-3528 60 lb/hr High Impedance Injectors 8

67-1570 Injector O-ring Lube 1

37-3529 MSD Distributor w/ Cam Sync MSD PN 23451 1

37-3543 Temperature Sensor 1

37-3542 Oxygen Sensor Switching 1

52-9710 Oxygen Sensor Bung 1

Page 9

Kit Contents 9

Kit #3690 Contents:

Part No. Description Qty.

22-3601Firewall Bulkhead Plate Kit 1

38-1515 Bulkhead Plates 2

68-0410 Self-Tapping Screws 4

72-1516 Grommet 1 3/4" O.D. 1

24-0301Ignition Amplifier Kit 1

68-0410 Self-Tapping Screws 3

37-3523Victor Pro-Tuner Kit 1

37-0004 RS485 Comms Cable 1

37-3524 USB Software Key (Pro Key) 1

37-0005 Controller PCM (80 Pin) 1

72-1517 PCM Rubber Grommet 3

82-0111 PCM Mounting Washers 3

82-3519 PCM Mounting Bushing 3

38-1601 Mounting Bracket for 80 pin PCM 1

68-4005 1/4-20 x 7/8" PCM Socket Head Screw 3

37-3550Main Engine Harness w/ 2-Power Relays 1

N/A Padded J-Clamps 4

37-3546 Distributor Harness 1

37-3547 Fuel Pump Harness 1

63-3670 Instruction Sheet - Quick Start Guide 1

63-3615 Instruction Sheet - Distributor 1

63-0507 CD-ROM 1

37-3518 MAT Sensor GM (AC Delco #12160244) 1

72-9952 MAT Sensor Grommet 1

37-1520 Serial to USB Converter 1

63-91147Serial to USB Converter Instructions 1

37-3548 Malfunction Indicator Light w/ Clip 1

37-7119 1 Bar Map Sensor (Remove Orange Rubber) 1

38-3601 Gen III Map Sensor Bracket 1

37-3528 60 lb/hr High Impedance Injectors 8

67-1570 Injector O-ring Lube 1

37-3529 MSD Distributor w/ Cam Sync MSD PN 23451 1

37-3543 Temperature Sensor 1

37-3542 Oxygen Sensor Switching 1

52-9710 Oxygen Sensor Bung 1

Page 10

10

3 Installation and Setup

Installation and Setup

In this section, you will have access to information on how to physically install the

system in your vehicle, install the sensors and ECU, and begin the setup process to get

your vehicle on the road!

BEFORE BEGINNING!

Visit us at: http://www.edelbrock.com

A clean and trouble free installation of the Pro-Tuner System is greatly enhanced by

taking the time to organize and plan your installation before beginning. Perform the

following:

· Unpack and inventory the system to ensure that you have all the parts, sensors, and

wiring that are listed on the packing list

· Lay the harness and wiring out on a table or the floor to help visualize the placement of

the sensors, connectors and components

· Take your battery to a local auto parts store and have them test it for proper voltage

and current carrying capacity.

· Be sure your engine is in good mechanical condition. Fouled spark plugs, vacuum

leaks, etc. will prevent you from properly tuning your engine!

3.1 Engine Management Concepts

Visit us at: http://www.edelbrock.com

Engine Management Concepts

In this section, we will discuss the general operation of the Engine Management system,

including strategies, controls and methods used to enable the engine to be efficient,

Page 11

Installation and Setup 11

clean, and reliable.

IMPORTANT!

TO AVOID SERIOUS OR FATAL INJURY, NEVER ATTEMPT

TO WORK WITH THE CALIBRATION LAPTOP COMPUTER

WHILE DRIVING VEHICLE.

NEVER PERFORM CALIBRATION ACTIVITIES ON PUBLIC

STREETS OR HIGHWAYS! DISTRACTION AND/OR

INADVERTENT CALIBRATION CHANGES COULD RESULT

IN SERIOUS ACCIDENTS.

Calibration Introduction

Calibration of an EFI system, presents many challenges and opportunities. The

opportunities are to improve the throttle response, drivability, start ability, fuel economy,

reliability, and reduce emissions of almost any engine. The challenge centers around

optimizing a myriad of variables for every operating condition of the engine to achieve

the desired results. While certain parameters can be “learned” by the engine control

computer through various strategies and algorithms; it ultimately becomes the

responsibility of the calibrator or tuner to decide what the ECM should learn, and to make

critical decisions about how the particular engine he/she is calibrating will behave under

various conditions. Just as it takes time and effort to become a proficient carburetion

calibrator; so it will take as much or more time and practice to become a good EFI

calibrator. Do not become discouraged or intimidated. Start with the basics of fuel and

spark control, then gradually work up to cold starting, transient calibration, idle control,

individual cylinder control, and advanced functions and setups. Always remember to start

with conservative values for spark, fuel, etc. to avoid damaging the engine. (Minimal

spark advance with fueling on the rich side of optimum)

Most tuners agree there is great personal satisfaction when an engine with their own

“optimized” calibration is running well. This calibration guide assumes the reader to be

familiar with general engine tuning and concepts, and experienced in the requirements

and limits of the engine being calibrated. Since each engine and application differ; this

manual does not attempt to dictate detailed tuning specifications (such as dictating "X

degrees of spark advance at 5% load and 800 rpm”) rather; its purpose is to familiarize

the calibrator with the interface software, techniques for tuning various strategies, and

provide background information on how they are used. The user assumes all

responsibility for the application and use of the information and Edelbrock system

software & hardware.

While this guide should prove helpful; it is significantly condensed and simplified to allow

the calibrator to quickly reference specific sections. Depending on your specific system

Page 12

12

and the method of interfacing to the engine; some of the strategies described in this

guide may not be visible or may be pre-calibrated for you. Systems also vary as to their

configuration: mass airflow, speed density or speed-throttle, oxygen sensors, ECU, and

so on – slightly altering the calibration process. Descriptions of the functions are usually

available next to the item or in the header of the map to aid the calibrator. The “HELP”

menu in the calibration software also contains much useful information; as well as the

documentation for your system, and can be selected at any time during software usage.

Always use the documentation for your exact system as the primary reference for system

setup and questions.

Ideally, calibration is performed with the vehicle on a chassis dyno where all loads and

speeds may be calibrated under controlled conditions. In cases where dynamometer

running is not possible, the tuner should enlist the help of another to drive the vehicle

while the tuner makes adjustments with the laptop between runs or make table

adjustments based on recorded logger data. Vehicle calibration should ONLY be done

on a closed road-course or drag strip with helmets and all other proper safety

gear in place. Be aware also that some adjustments may be necessary even

after an engine is dyno tuned. Different engine dynos will load the engine

differently and they do not always accurately simulate vehicle conditions. This

is especially true for transient operation (throttle snaps, etc.).

3.1.1 Strategies and Methods

Strategies and Methods

Control System Concepts

The Engine Management System functions by receiving inputs from various sensors,

making calculations and operational decisions, and sending appropriate instructions to

outputs that control devices and actuators. In order to do this, the Engine Control Module

(ECM) converts the analog inputs to digital signals and processes them within the 32 bit

microprocessor. Outputs are conditioned as required for the assigned purpose.

Visit us at: http://www.edelbrock.com

Your Edelbrock system is capable of three different fuel/timing control strategies.

Modeled speed density uses sensor inputs along with a volumetric efficiency (VE) table

Page 13

Installation and Setup 13

to estimate the airflow through the engine. The air fuel target table is used in

conjunction with this calculated airflow to control the injector pulsewidth. The MAP-N

strategy uses a base fuel map that varies as a function of engine speed and manifold

pressure. The desired base injector pulsewidth is displayed in the table. The Alpha-N

strategy uses a base fuel map that varies with engine speed and throttle position. The

desired base injector pulsewidth is displayed in the table. The Alpha-N strategy works

very well for engines with very large camshafts that exhibit very low idle vacuum. The

table below summarizes the advantages and disadvantages to each control strategy.

Modeled Speed Density MAP-N Alpha-N

Advantages

Disadvantages

· If properly setup, does

not require tuning of

temperature based trim

tables

· Direct measurement of

engine load (assuming

the VE table is accurately

defined)

· Can adjust for changes in

engine tuning

requirements if used with

optional mass airflow

sensor

· If properly setup, will be

more consistent as

operating conditions

change

· Requires an accurate

volumetric efficiency

table

· Fuel control units more

difficult to understand

· Mass airflow sensor (if

used) difficult to retrofit

onto older engines

· Relatively quick and easy to

tune

· Base fuel map in units of

injector pulsewidth

· Very common tuning method

used in many available

aftermarket EFI systems.

· Works well and easy to tune

for boosted applications

· Easy to modify calibration if

larger injectors installed

· Does not work well with

large overlap camshafts due

to low idle vacuum

· Requires temperature based

trim tables

· Indirect measurement of

load

· Calibration could be

inconsistent if trim tables are

not properly tuned

· Works well for large overlap

camshafts Not affected by low

idle vacuum signal

· Relatively quick and easy to

tune

· Base fuel map in units of

injector pulsewidth

· Easy to modify calibration if

larger injectors installed

· Idle mixture affected by

closed throttle TPS voltage

drift

· Requires temperature based

trim tables

· Indirect measurement of load

· Does not work well with idle

air control motors.

· Calibration could be

inconsistent if trim tables are

not properly tuned

The engine management system requires sensor data to maintain efficient operation

under various conditions, and to provide feedback to the ECM regarding the current

operating conditions. The sensors needed for basic operation include: ECT (Engine

Coolant Temperature), IAT (Intake Air Temperature) or (Charge Air Temperature), TPS

(Throttle Position Sensor), CTS (Crankshaft Trigger Sensor), MAP (Manifold Absolute

Pressure) sensor, and O2 (oxygen sensor). Other sensors can be added for additional

control information or data acquisition; however, the sensors listed are the minimum

ones required for basic engine control with this system.

When calibrating an engine, the basic goals are to optimize torque and minimize

fuel consumption at every speed and load point. However, there are limits to how

far one can go with this in actual application. In practice, you will be constrained by other

factors and may be limited to values that insure running quality and reliability. This is

called the “calibration window” for that condition. We will discuss cal windows later on.

As you proceed, It is very important to understand that engines will attempt to run in

Page 14

14

many conditions in which they should not be exposed – such as detonation or excessive

temperatures. It is your job as a calibrator to balance all of the factors for your specific

combination and program the best target values into the ECM that you can while keeping

the engine in a safe operating window. There is a desired order in which an engine

control system should be calibrated. A general order of activities is listed below:

1. Verify correct system installation and insure the method of wire and hose

routing will prevent any chance of wear, fraying, or proximity to high

temperatures. Insure software and communication to the ECM is

functioning properly.

2. Perform preliminary calibration activities: load proper sensor and engine

configuration calibrations and limits, set crank trigger offset (& cam offset if

available), scale sensors and map ordinates. It is preferable if the tuner starts with

a known calibration for a similar combination whenever possible; as it greatly

speeds the setup and calibration process.

3. Calibrate under steady state conditions for every engine speed and throttle

position (load) - while optimizing fuel, ignition timing, and airflow – and

completing the various maps at each point.

4. Optimize starting, warm-up, and idle calibrations for various temperatures and

conditions. (Cold starts, hot restart, etc.)

5. Calibrate transient fueling (acceleration and deceleration) parameters if needed to

optimize fuel during non-steady state conditions.

Fundamental Steady-State Engine Calibration Goals

1. Minimize BSFC at part-throttle operating conditions.

2. Maximize Torque at WOT.

3. Stay within emissions constraints.

5. Stay within EGT limits

6. Minimize drastic or erratic map value changes between cells

The important thing to remember is to balance all of the factors to create the best

compromise between them.

For example: as a calibrator, you may be personally focused on running quality. You may

find that running quality continues to improve as you advance the spark at a particular

operating point. Even though running quality may actually improve as spark is advanced

into the knock region – one should not cross those limits in pursuit of optimizing one

variable, because doing so could cause engine damage.

The best calibration attempts to keep each variable in the middle of the window for every

operating point. While this may not always be possible due to operating conditions or

engine hardware and design; every effort should be made to keep away from the edges

of the window. For example, let’s say you calibrated your engine on the lean side of the

wide open throttle air/fuel window to reduce fuel consumption during the race. While it

may be OK for that specific combination at that time, you would have to ask yourself,

1.Is the calibration robust enough if my crew chief advances the cam 2 degrees?

2.Will the engine be OK if fuel quality varies?

3.Will the engine detonate if lugged in gear?

For these reasons and others, it is desirable to stay in the center of the variable’s window

Page 15

whenever practical.

Further calibration tips are contained within this manual and associated with the Pro

Tuner function or map that they correspond to.

3.2 Vehicle Installation

Installing the Victor System in the

Vehicle

Installation and Setup 15

Visit us at: http://www.edelbrock.com

Installing the Victor system in a vehicle is a straight-forward procedure that is not

difficult; particularly if you have experience replacing intake manifolds and basic

automotive electrical knowledge. During this stage, it is helpful to consult a factory

service manual (if available) as well as your system documentation.

Since specific procedures may vary with application, a factory manual should be used to

identify and assist in installation in those instances. Some items that may be unique

depending on the applications are:

1.Firing order

2.Location of #1 cylinder

3.Proper idle vacuum, RPM and ignition timing

4.Ignition advance curve

For proper system function and warranty coverage, it is very important that all

installation instructions be followed during installation and operation. If you do not

understand a procedure, contact the Edelbrock hotline. If you do not have the necessary

skill or tools to perform any of the operations, consult a professional dealer/installer for

assistance.

CHEVROLET V8

System Components:

System ECU (ECM/PCM)

•

Software

•

Ignition Module

•

Wiring harness w/Fuel pump and Main Power relays

•

Fuel Pump harness

•

Ignition Harness

•

MSD/Edelbrock HEI distributor

•

Page 16

16

Intake Manifold - Fuel Rail Assembly

•

Edelbrock High Flow 60 pph Fuel Injectors

•

Four barrel Throttle Body w/integrated TPS sensor & Idle Air Control valve

•

Heated Oxygen sensor w/mounting bung

•

1 bar Manifold Absolute Pressure (MAP) sensor

•

Intake Air Temperature (IAT) sensor

•

Engine Coolant Temperature (ECT) sensor

•

Firewall bulkhead grommet/cover plate assembly

•

Additional Hardware and Parts needed:

Intake Gaskets / other engine gaskets as required

•

Edelbrock/GM/or equivalent

•

5/16” steel tubing (approximate equal length to fuel pickup in tank)

•

Edelbrock Gasgacinch #9300

•

Loctite 598 OEM High Temperature Silicone gasket (O2 sensor compatible)

•

Radiator Coolant - Teflon paste thread sealant

•

Manifold bolt kit

•

Factory service manual & wiring diagrams

•

Preliminary Checklist:

CAREFULLY STUDY AND UNDERSTAND ALL INSTRUCTIONS.

•

Examine the system components and packaging for shipping damage. (If

•

damaged, contact your dealer immediately)

Check all threaded manifold holes.

•

Check all internal manifold passages with a light and wire, making sure they are

•

clean and unobstructed.

Check automatic transmission shift points before removal of the stock system, and

•

adjust linkage after Edelbrock manifold installation for same shift points if needed.

Determining Hood Clearance

1. CHECK HOOD CLEARANCE BEFORE REMOVING STOCK MANIFOLD.

2. Use modeling clay or putty to make five small cones 2-3” high.

3. Position cones on air cleaner at front, rear, each side, and on center stud.

4. Close hood fully and reopen.

5. The heights of the cones indicate the amount of clearance between the hood and

the air cleaner. Record the measurements.

Page 17

Installation and Setup 17

AFTER MEASUREMENT:

COMPARING HEIGHT OF STOCK INTAKE ASSEMBLY AND VICTOR PRO TUNER

ASSEMBLY.

1. Remove air cleaner from stock assembly.

2. Lay a straightedge across top of carburetor flange front to rear.

3. Measure from bottom of straightedge to manifold/block sealing surface of manifold

at front and rear of engine. Record measurements (A & B).

4. Add “A” and “B” and divide by 2 to get average height.

5. Measure your Victor assembly using the same method.

6. Compare the measurements. If the Victor dimensions are taller, subtract the

difference from the current hood clearance to determine the new hood clearance.

Page 18

18

*CAUTION: You must maintain a minimum of ½” clearance between air cleaner

and hood due to engine torque movement. If you have insufficient clearance, a

low profile air cleaner may solve the problem.

EMISSION CONTROLS:

The Edelbrock Victor and Super Victor Engine Management Systems will not accept stock

emission control systems. Check local laws for requirements before installing this system.

Not legal on pollution controlled applications.

FUEL REQUIREMENTS:

Because the Victor and Super Victor systems use an oxygen sensor, you must use

unleaded fuel only to avoid damaging the sensor. If you use leaded fuel in your

application, do not install the O2 sensor and configure the system for no O2 sensors

through the setup Wizard. Fueling will then be managed open loop.

The driver's side sensor is always the primary sensor. Always plug into the

driver side only when using a single sensor. If using dual sensors, the system

will use the leanest bank's sensor to provide closed loop feedback.

AUTOMATIC TRANSMISSION CHECK:

For best performance, economy, and emissions, the shift points must be checked before

and after the manifold change.

*NOTE: This check should only be performed on the drag strip or test track.

With the shifter in drive, accelerate to wide open throttle from a standing start. Hold in

this position, noting speedometer reading when the transmission makes the 1-2 shift.

Run the test again after the manifold change. The shift point should be the same. If the

shift point is not the same – adjustment is necessary. We recommend use of the

Edelbrock Throttle, Cruise control, & Transmission Kick-down Mounting Bracket #8031 or

#8032 with Vortec heads. The Turbo 350 and Turbo 200 feature a window to

accommodate user adjustment of shift points at WOT (Wide Open Throttle).

Page 19

Installation and Setup 19

The 200R4 and 700R4 transmissions require precise adjustments. We

recommend that you consult a reputable transmission shop for final adjustment

once the Victor system has been installed.

INCORRECT SHIFT POINTS CAN RESULT IN TRANSMISSION DAMAGE!

ENGINE CLEANING:

Always perform the installation with a clean engine and engine compartment. Use utmost

care in the cleanliness of ALL parts during the process.

EXHAUST MANIFOLD HEAT RISER:

If your vehicle is equipped with an exhaust manifold heat riser (typically located on the

passenger side of the vehicle under the exhaust manifold), remove the valve for proper

operation.

HEADERS:

For best performance, headers are recommended. Consult Edelbrock or your exhaust

supplier for recommendations on header, pipe, and muffler specifications for your

combination.

INSTALLING THE EFI INTAKE MANIFOLD:

The procedure for installing your new EFI manifold is nearly identical to installing a

carbureted manifold. Always install new gaskets per manufacturer recommendation and

follow the Edelbrock torque specifications for your particular manifold.

PRE-INSTALLATION

Before installing the induction system, take the following steps to ensure successful

installation and performance:

1. Check all components thoroughly for damage when unpacking.

2. Make sure all throttle linkages open entirely and close freely.

3. Make sure all fuel inlet and vacuum ports are free from packing material.

4. Check the installation kit for proper parts.

REMOVING THE STOCK CARBURETOR AND MANIFOLD

1. Disconnect battery.

2. For ease of installation, keep all parts in order.

CAUTION: Do not remove manifold if engine is hot.

3. Drain radiator coolant (radiator drain plug is typically located on lower right facing

engine).

4. Remove gas cap to relieve pressure. Disconnect fuel line and plug. Replace gas

cap.

5. Disconnect all linkage from carburetor such as throttle, throttle springs,

transmission, cruise control and automatic choke.

6. Tag and remove coil wires and sensor wires.

7. Remove previously marked vacuum lines.

8. Remove radiator hose, thermostat housing and thermostat, if mounted on

manifold.

9. Remove all brackets from the manifold.

10.Loosen or remove valve cover bolts for manifold removal and replacement. It may

be necessary to replace valve cover gaskets if broken, to prevent oil leakage.

Page 20

20

PORT SURFACE CLEANING

1. When cleaning old gaskets from head surfaces, lay rags in the lifter valley and stuff

paper into the ports, to prevent pieces of the old gasket from falling into ports and

combustion chambers or valley.

2. When clean, remove paper, making sure that all particles fall on the rags in the

lifter valley.

3. Remove rags, and wipe surfaces clean with rags soaked in lacquer thinner in order

to remove oil or grease.

NOTE: This procedure is necessary to ensure proper sealing.

INSTALLING FITTINGS, PIPE PLUGS, AND STUDS

Do not over-tighten or cross-thread fittings, pipe plugs, studs, or bolts in your aluminum

manifold. Damage to threads or a cracked mounting boss may result unless caution is

used when installing accessories. Use Teflon sealant on all pipe threads.

GASKET SURFACE PREPARATION

CAUTION: Replace all gaskets as recommended. Do not use race-type nonembossed gaskets for street applications. Due to material deterioration under

street driving conditions, internal vacuum and oil leaks may occur. We

recommend Fel-Pro Printoseal gaskets or equivalent. Do not use Fel-Pro Perma

torque Blue gaskets, which are designed for use on stock cast iron intake

manifolds only.

1. Check gaskets on head surface and manifold to make sure they are correct.

Embossed side faces up. NOTE: In some cases, there may be a different right and

left side gasket. Make sure both are placed correctly.

2. Coat head surface and both sides of gaskets with Edelbrock Gasgacinch #9300.

3. Apply Loctite 598 OEM High Temperature Silicone Gasket around water passages

on head surface.

4. Gaskets and surface will become tacky to the touch within a few minutes. Carefully

place gaskets on head surface, aligning ports and bolt holes.

5. Edelbrock recommends the use of Loctite 598 OEM High Temperature Silicone

Gasket instead of end seal gaskets. Apply a 1/4-inch thick bead of sealant across

each end seal surface, overlapping the intake gasket at the four corners.

NOTE: Use the ONLY recommended O2 SENSOR SAFE sealer . Others may

damage the O2 sensor. This method eliminates end seal slippage and

deterioration. For ease of installation, we recommend using an Edelbrock

Manifold Bolt and Washer Kit.

6. Apply Edelbrock Gasgacinch #9300 or equivalent to port surface of the manifold

and to the head surfaces to ensure a good seal.

7. Apply RTV gasket sealer around water passages on the manifold.

8. Surfaces will become tacky to the touch within a few minutes.

INDUCTION SYSTEM INSTALLATION

1. Carefully position manifold and air valve on engine, centering bolt holes with the

bolt holes in the head.

2. Apply thread sealer or Teflon tape to bolt threads where exposed to water or oil.

3. Hand tighten all bolts.

4. Torque all manifold bolts to Edelbrock specifications.

Page 21

Installation and Setup 21

5. Re-connect throttle linkage and springs, transmission, cruise control, and fuel

lines. Check all linkage for smooth throttle operation from idle to Wide Open

Throttle (WOT).

Note: Do not install with a throttle rod, use a cable actuated throttle.

Throttle rods can transfer engine movement to the throttle and possible

lead to binding.

6. Re-tighten the valve cover bolts.

Page 22

22

3.2.1 Fuel System Installation

Visit us at: http://www.edelbrock.com

Fuel System

FUEL SYSTEM BASICS

Because your Edelbrock Pro Tuner system controls fuel delivery very differently than a

carburetor, some conversions to your fuel system may be necessary. Victor/Super Victor

Pro-Tuner electronic fuel injection requires high and constant fuel volume and fuel

pressure. For this reason, a good primary fuel line is critical. A 3/8-inch (minimum)

HIGH PRESSURE fuel line must be used as the primary fuel line.

The fuel that bypasses the injectors must be returned to the fuel tank via a return fuel

line. If your vehicle is already equipped with a fuel pump bypass line, this line can be

used as the return fuel line. If not, the original primary line may be used as the return

line or a new return line plumbed with 5/16” ID steel or high pressure line.

Many late-model cars are equipped with an additional fuel line which runs to a charcoal

canister mounted on the driver side of the vehicle. This line MUST be re-installed after

the fuel system conversion and MUST NOT be used as the return fuel line.

FUEL SYSTEM PLUMBING

Edelbrock recommends parallel plumbing for performance applications. Parallel plumbing

is accomplished by teeing the feed hose from the pump into both fuel rails and

connecting the two outlets to the fuel pressure regulator. See Fig. 2 below. This gives

twice the capacity of series configuration plumbing. It also reduces the fuel velocity in

the fuel rail when compared to series plumbing. If the fuel velocity is too high it may

cause flow disturbance in the fuel rails. A parallel configuration is recommended to

achieve the best cylinder to cylinder distribution.

Page 23

Installation and Setup 23

Figure 2

FUEL PUMP AND FILTER

The Victor/Super Victor Pro-Tuner system uses a single Edelbrock high-pressure electric

fuel pump which is capable of pumping 50 or more psi (depending upon the pump). The

pump relay will prime the system on key-up and shut down the pump if it does not

receive an engine-run signal from the ECU, as in the case of a stall. This safety

precaution is necessary when using a high-pressure fuel system. It is very important that

the fuel flow capacity of the EFI pump exceed your peak demand by 20-25% to avoid

engine damage due to loss of pressure. Electrical connectors should face the front of

vehicle when mounting. Consult your Edelbrock representative for assistance in pump

selection. A high pressure/high volume EFI fuel filter should be mounted between the

engine compartment and the fuel pump. A high quality inlet filter should also be

installed to protect the fuel pump from contamination. See Fig. 2. Consult your

Edelbrock representative for assistance in filter selection. Use the mounting instructions

for the pump and filters that you are using.

RECOMMENDED FUEL PUMP AND REGULATOR KITS

Page 24

24

Up to 600 HP

Edelbrock P/N 35943 - Kit includes fuel pump #3594 and regulator #1728

Up to 800 HP

Edelbrock P/N 17903 - Kit includes fuel pump #1790 and regulator #1729

Up to 1500 HP

Edelbrock P/N 17943 - Kit includes fuel pump #1794 and regulator #1729

FUEL PRESSURE REGULATOR

Fuel pressure is as important as fuel volume, particularly in fuel injection. The Victor/

Super Victor Pro-Tuner system requires that the fuel pressure regulator maintains a

constant pressure at the injectors. It is recommended that Manifold Absolute Pressure

references the regulator diaphragm to maintain constant pressure across all 8 injectors,

regardless of fluctuating manifold pressure (vacuum) level. The fuel that is not injected is

returned to the fuel tank via the return fuel line. Recommended pressure settings vary

with application. Consult your Edelbrock representative for pressure recommendations. A

typical regulator installation is shown in Figure 3.

FUEL LINE SIZES

A high pressure EFI system does not need the same size lines as a low pressure

carbureted engine. A 3/8" diameter (-6 AN) is adequate for engines to at least 750 HP.

A 1/2" diameter line should be used on engines over 750 HP.

RETURN FUEL LINE

There are three options for installing a bypass return line.

1. Use the 5/16 rubber fuel line provided with the system as the fuel return line.

Figure 3

Page 25

Installation and Setup 25

2. Use the vehicle’s existing primary line as the fuel return line with modification to

the pick up as described below.

3. Use the vehicle’s existing return line (if so equipped) as the fuel return line. This

option applies only to vehicles previously equipped with fuel injection. If the

vehicle is not already equipped with a return line, some fuel tank modifications are

required for routing the return line through the sending unit plate back into the

tank. The first two methods listed below require some welding and should be done

by a professional radiator or fuel system repair shop.

RUBBER RETURN LINE METHOD

Drill a 5/16-inch hole in the sending unit plate adjacent to where the main line enters the

tank. This will be the hole for your return line. Insert a short length of 5/16-inch hard

line (available at most radiator shops) into the hole and weld it to the sending unit plate.

The hard line should extend through the hole 1 to 2 inches on each side of the plate.

Connect a length (at least 4 inches) of 5/16-inch rubber return line hose to the hard line

that will extend into the tank. Connect the rubber line to the fuel pickup line using tie

wraps.

BULKHEAD FITTING METHOD

Drill a 9/16-inch hole in the sending unit plate adjacent to where the main line enters the

tank. This will be the hole for your return line. Insert a #6 AN bulkhead fitting (available

at most radiator shops) into the hole, the narrow end of the fitting on the inside of the

plate. Apply a rubber washer or RTV sealant and fasten the fitting to the plate with the

Figure 4

Page 26

26

nut. Connect a length (at least 4 inches) of flexible return line (rubber or braided hose)

to the fitting end. Connect the return line to the fuel pickup line using tie wraps.

NOTE: THIS METHOD REQUIRES NO WELDING OF THE FUEL SYSTEM.

NOTE: Whichever method you use to install the return fuel line, be careful to keep

the end of the line away from the fuel pickup, as shown. Otherwise, aerated return

fuel can be drawn into the pickup.

HARD RETURN LINE METHOD

Drill a 5/16-inch hole in the sending unit plate adjacent to where the main line, enters

the tank. This will be the hole for your return line. Insert a length of 5/16-inch hard line

(available at most radiator shops) into the hole and weld it to the sending unit plate. The

hard line should extend through the hole 1 to 2 inches on the outside of the plate. On the

inside of the plate, the hard line should follow the contours of the fuel pickup line. Bend

the end of the return line away from the sock on the end of the fuel pickup line.

Figure 5

Page 27

Installation and Setup 27

Figure 6

Solder or weld the return hard line to the fuel pickup line.

Page 28

28

Figure 7 - Completed return line installation

FUEL SYSTEM INSTALLATION

1. Disconnect the vehicle battery.

2. Drain the fuel tank.

3. Remove all lines from the tank and carburetor.

4. Remove the fuel tank if sender plate is inaccessible. While fuel tank is removed

from vehicle, it is recommended that it be professionally cleaned in order to

remove any rust or dirt that may have accumulated inside which could damage the

injectors.

5. Remove the sending unit from the fuel tank. Refer to RETURN FUEL LINE METHODS

above for installing the bypass fuel return line.

6. Install the high pressure fuel line next to the original line, which may now serve as

the return line. Use large radius bends. Avoid exhaust components, sharp edges,

and possible wear points. Mount the lines firmly and high in the underbody to

insure that they will not be exposed to ground clearance obstacles or road debris

hazards that could catch or damage the line.

7. If you do not use the original fuel as the return line, route the return line directly

alongside the provided primary fuel line.

8. Mount the fuel pump between the tank and the fuel filter as low and as close to the

fuel tank as possible. The pump is directional. Electrical connectors should face the

front of vehicle. The fuel pump needs to be at or below the level of fuel in the tank.

Page 29

Installation and Setup 29

9. Mount the fuel filter between the fuel pump and the engine.

10.Re-install the modified sending unit plate to the clean fuel tank.

11.Reinstall the fuel tank.

12.Attach the primary line and return line to the sending unit plate on the tank.

13.Re-attach all other fuel lines at the tank (vapor purge lines, etc., if so equipped).

14.Secure the primary and return fuel lines with the provided tie-wraps, or with Adel

clamps if available.

15.Re-attach all fuel lines to the induction system once it has been installed.

NOTE: REMOVE FUEL SENDING UNIT FROM TANK BEFORE MODIFYING. ALL

WELDING AND SOLDERING OF THE FUEL SYSTEM MUST BE PERFORMED BY

A PROFESSIONAL RADIATOR OR FUEL SYSTEM REPAIR SHOP.

INJECTOR INSTALLATION

DO NOT INSTALL FITTINGS WITH RAIL INSTALLED. TORQUE APPLIED TO

THE ASSEMBLY COULD DAMAGE PARTS AND CAUSE FUEL LEAKS!

1. Fasten fuel rail stands (if applicable) to manifold per Edelbrock instructions;

making sure the stands are parallel with the injector bosses in the manifold.

2. Lightly grease the injector O-rings at the top and bottom of injector per Figure 5.

using supplied o-ring lube.

Figure 8

3. Install the top of each injector into the fuel rail; carefully inserting the injector to

avoid pinching or damaging the sealing O-ring. Orient the injector so that the

connector is facing outward. (The outside of the rail has the Edelbrock logo on the

side).

4. Carefully insert the rail w/injectors into the manifold, insuring that each injector

enters the manifold straight and lower O-rings do not get pinched or damaged.

5. Align mounting holes in rail with the rail mounts.

6. Install with hardware provided.

7. Remember to attach the coated injector harness clips to each rail mount, orienting

so the clip is above the mounting hole.

Page 30

30

NOTE: If O-rings are damaged even slightly, they MUST be replaced before

pressurizing system!

Injectors should not bind in the ports. You should be able to rotate

them slightly.

A typical rail installation is illustrated in Figure 9.

3.2.2 ECU and Main Harness Installation

ECU and Main Harness

Figure 9

Visit us at: http://www.edelbrock.com

Page 31

Installation and Setup 31

Installing the Main harness and ECU

To install the system harness, you should first layout the harness in your vehicle to

determine the best layout and routing for your application. Of primary concern, is the

mounting location of the Engine Control Module (ECM/PCM), relays, interface connectors,

and system fusing.

You may choose to mount the ECM inside the passenger compartment similar to OEM

practice. However, the ruggedized ECM also gives you the option of mounting it under

hood. Layout the harness with the appropriate injector connectors corresponding with the

injectors on the engine. Within the available length of the harness, determine potential

mounting locations for the ECM and relays.

Improper installation may cause system

failure and void your warranty.

To mount the ECM and relays correctly, the following rules should be followed:

1. Keep ECM, components, and wiring as far away from heat and exhaust parts as

possible. You may need to install heat shields over certain areas in the engine

compartment to prevent excessive heat from reaching the electrical components.

2. Mount the ECM and relays using only the grommets, bushing's, and washers

provided. Use the Edelbrock ECU mounting bracket shown below for proper

mounting and flexible orientation. These parts are specially engineered to insure

proper isolation of the ECM. Locate the fuse pack so that it can be accessed

conveniently. The fuse pack is shown in Figure 10 below:

Page 32

32

Figure 10

3. Insure that the ECM case does not touch or rub against anything,

particularly metal or wiring. The case MUST be isolated from grounds and

voltage sources.

4. Do not mount hardware in such a manner as to cause stress on the harness. Do

not pull, stretch, or kink wires and connectors. Minimize effect of engine torque

movement on short sections of harness. Improper installation can cause

intermittent wire or connector failure or total loss of connection.

5. Route harnessing to avoid sharp edges, heat, and wear points. Clamp harnessing

with approved clamps and clips. - Do ALL installation work with the vehicle battery

disconnected.

6. A typical PCM under-hood mounting installation is shown in Figure 11.

Page 33

Installation and Setup 33

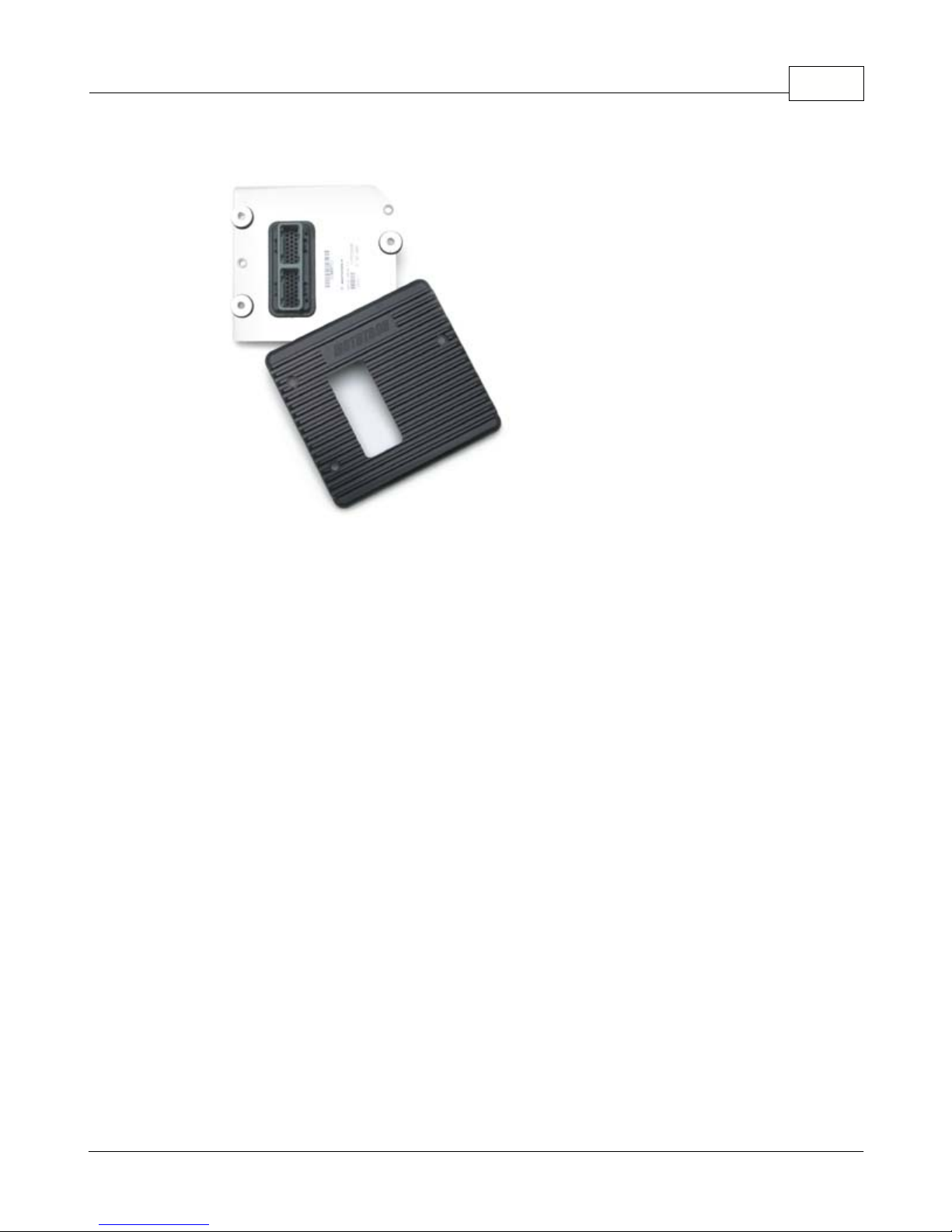

Figure 11 - 80 pin Super Victor PCM

The ECM (48 pin) or PCM (80 pin) controllers mount using specially designed bushing's

and isolation grommets.

When installing the mounts, first install the rubber grommets into the 3 mounting holes.

Insert the bushing from the BACKSIDE of the grommet. Finally, mount to the desired

surface using the provided retaining washer on the top side of the grommet and a 6mm

X 1.0 or ¼-20 screw. Figure 12 below shows the 48 pin ECM with mount installed without

the top retaining washer yet added.

Page 34

34

Figure 12

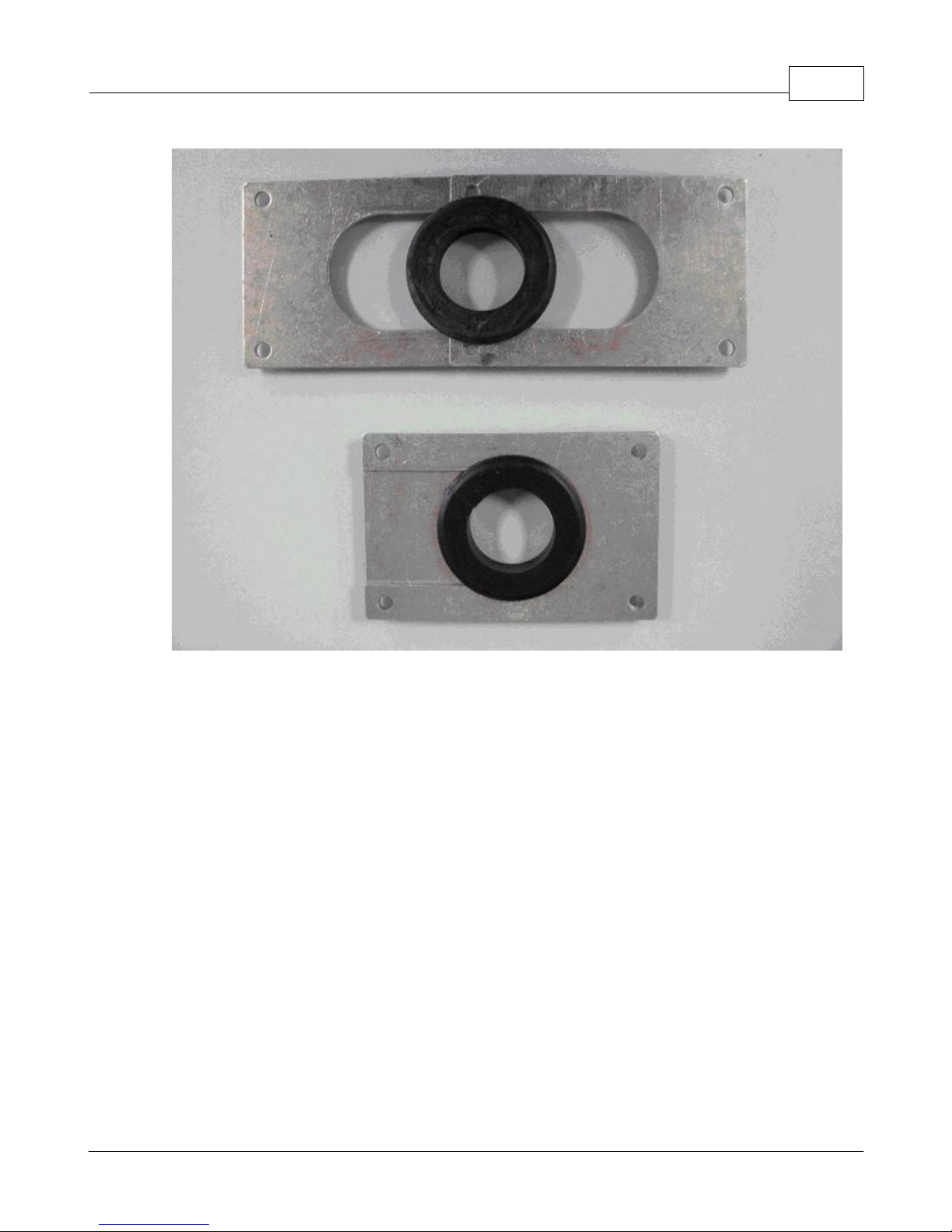

To mount the ECM or PCM inside the vehicle, a hole will have to be made in the firewall

for the harness and connectors to pass through. A firewall bulkhead grommet and cover

plate is included to seal the hole and support the harness where it passes through the

firewall, or you can make your own.

1. To run the harness into the passenger compartment, select the appropriate

location for the harness to pass through for your vehicle – making sure you have

access from the inside of the vehicle and that no components are in the way or can

be damaged during the process.

2. Use the grommet and cover plate assembly as a template. Mark the outline on the

firewall. - Using a hole saw, nibbler, or chassis punch, create a 2” x 2-3/8”

rectangular hole in the firewall – being sure to center the hole in the template

outline. De-burr all edges when finished.

3. Carefully work the harness through the firewall, passing the 32 pin (PCM only)

connector through first, followed by the other connectors. The ECU connector

covers may need to be temporarily removed in some cases to get them through

easily. - Install the firewall plate with the screws provided by slicing the O-ring and

wrapping it around the main harness bundle. Slide each side over the grommet

and harness until the mounting holes line up as in figure 8. Fasten to the firewall.

Use of a silicone sealant between the plate and the firewall is optional. See Figure

13.

Page 35

Installation and Setup 35

Figure 13

Before proceeding further with harness installation, install and mount all sensors and

components.

Page 36

36

3.2.3 Component and Sensor Installation

COMPONENT AND SENSOR OVERVIEW:

The diagram below identifies the location of the major components of the Pro-Tuner

electronics. Not shown below is the air temperature sensor as it is normally mounted in

the air cleaner base.

Page 37

3.2.3.1 Distributor and Ignition

Distributor and Ignition

Installation and Setup 37

Visit us at: http://www.edelbrock.com

The Pro-Tuner Distributor with Cam-Sync is designed for use with our Victor Pro-Tuner

EFI systems for the Small Block and the Big Block Chevrolet. The distributor includes an

adjustable hold down collar (to accommodate various deck heights and custom intake

manifolds), a large distributor cap, and the mechanical advance is locked out. It is

equipped with a steel distributor drive gear. The Pro-Tuner distributor also features a

Magnetic Crank Pickup and uses a Hall-Effect Cam-Sync Pickup with LED indicator for the

Camshaft Sensor. The Cam Sync has a 12” lead and a 3-prong Weatherpak connector.

The crank trigger has an 8” lead and 2-prong Weatherpak connector.

Page 38

38

DISTRIBUTOR KIT CONTENTS

· 1 Pro-Tuner Distributor

· 1 Rotor (MSD #8421) Installed

· 1 Distributor Cap (MSD #8408) Installed

· 1 Wire Retainer

· 2 1.5” Long, Self Tapping Screws

· 1 Distributor Gasket

· 2 O-Rings

· 1 Tube of Assembly Lube

IMPORTANT INSTALLATION NOTES

· DO NOT use a Solid-Core type spark plug wire set, such as copper core, etc. You must

use a suppression type spark plug wire. Failure to use the correct wires will cause

electrical interference with the Engine Control Module.

· When installing the distributor, make sure to disconnect the vehicle’s battery BEFORE

beginning the installation.

· If the drive gear is ever replaced, you must use a MSD #8531 distributor drive gear

due to the .500” diameter drive shaft.

· HALL-EFFECT PICKUP LED OPERATION: The LED is on whenever the magnet is NOT in

front of the pickup. The LED Turns off when the magnet passes over the center of the

pickup (approximately 40°)

· This Distributor has a steel drive gear, check with your camshaft manufacturer for cam

compatibility with this gear.

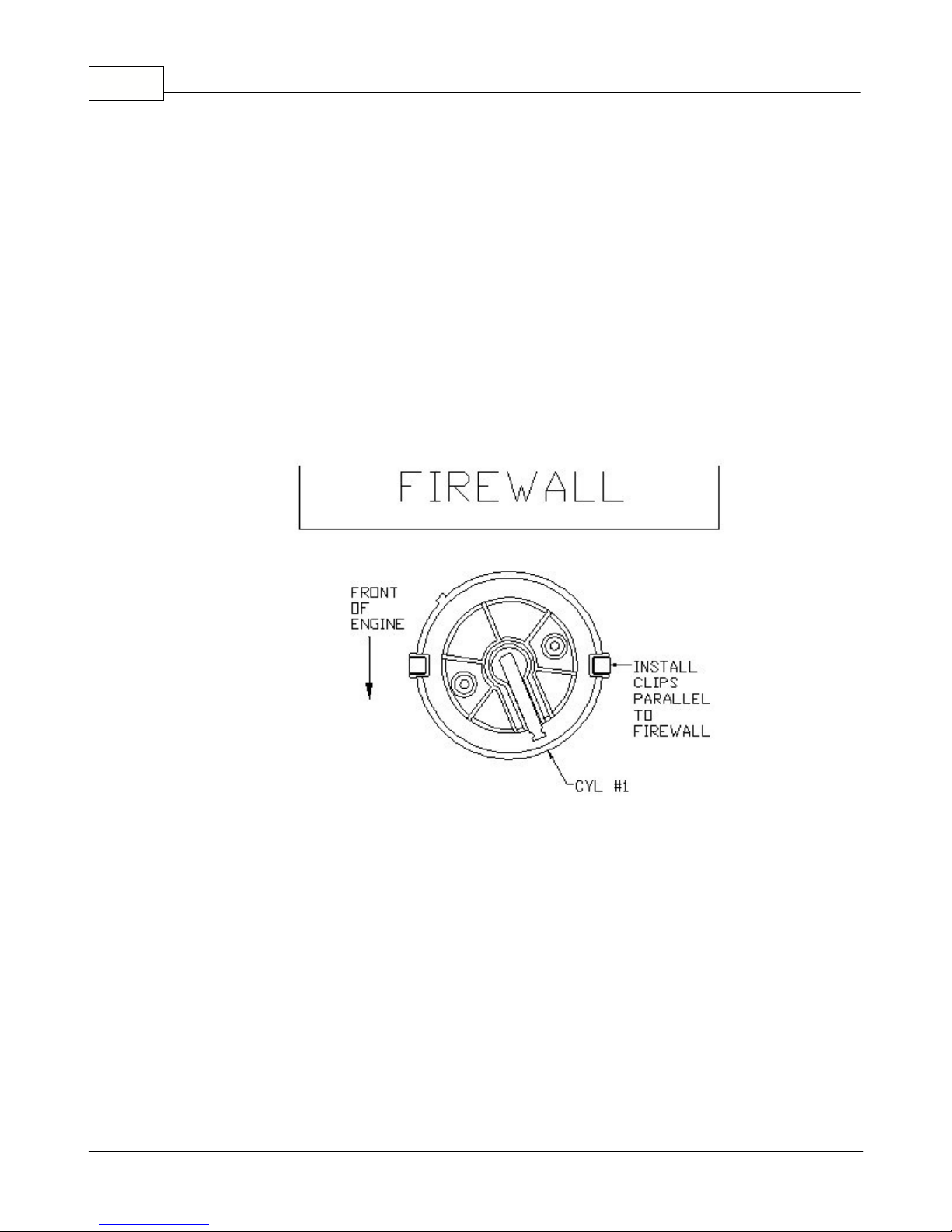

· A white dot is located on the distributor base directly under the #1 cylinder

post. See figure 14 below for proper orientation.

INSTALLATION PROCEDURE

1.Loosen the adjustable slip collar, Install the Distributor into the engine without the

gasket installed, make sure the oil pump shaft is fully engaged, slide the slip the collar

down to sit against the manifold. Tighten the collar and remove the distributor. Tighten

the set screws on the collar and install the gasket.

2.Rotate the crankshaft in the direction of normal rotation until cylinder #1 is coming up

on the compression stroke. Stop turning when the crankshaft is at 22° BTDC.

3.Install the distributor, with gasket and cam gear lubricated, so that the rotor comes to

rest pointing at what will be the #1 terminal on the cap. Position the cap such that #1

is in the Location shown on the drawing below. You may need to remove and reinsert

the distributor a few times to get the alignment correct. Make sure that the distributor

seats down completely and has fully engaged the oil pump drive. You may need to

rotate the oil pump shaft to ensure it is engaged properly.

4.Lift the rotor by hand to make sure that there is adequate end play. Lack of end play

indicates that the rotor shaft is bottomed out on the oil pump shaft. If there is no end

play readjust the Slip Collar as mentioned above.

5.Align Distributor cap clips parallel with the firewall, Hall Effect sensor should be

pointing toward the forward drivers side of the engine. See Figure 14.

6.Tighten Distributor hold down clamp.

Page 39

Figure 14

Installation and Setup 39

INSTALLATION PROCEDURE O-RING SEALS

The Pro-Tuner Distributor features an o-ring groove in the uppermost bottom land of the

housing in order to seal the oil gallery. The o-ring should only be installed if the block

has been modified. See Distributor Specifications for procedure.

CHECKING THE DISTRIBUTOR DRIVE GEAR MESH

It is recommended to check for proper gear mesh between the drive gear on the

camshaft and the drive gear on the distributor. In order to check the mesh, coat the

distributor gear with the supplied assembly lube and install the distributor into the

engine. Rotate the engine several revolutions and remove the distributor. The mesh

pattern in the lube should be even and in the middle of the gear. Adjust the slip collar to

obtain the proper mesh, if necessary.

CHECKING THE OIL PUMP TO DISTRIBUTOR SHAFT OVERLAP

After checking the drive gear mesh. it is very important to have the proper overlap

between the the distributor shaft and the oil pump shaft.

The tongue of the distributor shaft should sit into the oil pump shaft groove by a

minimum of 1/4”. Check this measurement according to the procedure below:

1.Measure the distance between the base of the slip collar and the tip of the distributor

shaft.

2.Using a straight edge, measure the distance from the intake manifold distributor flange

to the top of the oil pump intermediate shaft.

3.Subtract the measurement from Step 1 from the measurement taken in Step 2. This

difference is the overlap. If there is too much, or not enough clearance, a shorter or

longer oil pump drive shaft will be required.

4.Lightly tighten the hold down clamp so that the distributor can still be turned to

determine final setting when checking the timing.

5.Re-attach the distributor cap. Make sure the rotor is still pointing to #1.

6.Install your spark plug and coil wires and connect the distributor to the wiring harness.

Page 40

40

Make sure to install the spark plug wires one at a time and verify they are in the

correct position. A wire retainer is supplied to secure the wires to the cap. Align the

retainer with the mounting bosses, and use the supplied 1.5” self-tapping screws to

secure the retainer.

ROTOR PHASING

Rotor phasing is defined as the alignment between the rotor tip and the distributor cap

terminal when the spark occurs. This position can be very important to your engine’s

performance. If the alignment is incorrect, the spark will jump to the next closest

terminal, or another ground resulting in a misfire and loss of power. In applications with

extreme cylinder pressures, such as with nitrous or forced induction, correct rotor

phasing increases in importance. More voltage is required to ionize the plug gap and if

rotor phasing is off, the spark is more apt to find an easier path to ground rather than

the correct cap terminal. This may result in severe engine damage.

CARE AND MAINTENANCE

Periodically, visually inspect the cap terminals and rotor tip for wear and look for traces

of carbon tracking where spark scatter occurs. Check your spark plug wires for burns or

tears. It is also recommended to periodically test the resistance of the wires. See for an

exploded view of the distributor and its parts.

Figure 15

Page 41

3.2.3.2 Intake Air Temperature Sensor (IAT)

Intake Air Temperature Sensor

Installation and Setup 41

Visit us at: http://www.edelbrock.com

Installing / Replacing the Intake Air Temperature (IAT) sensor

The Intake Air Temperature sensor is a thermistor device which measures air

temperature. This sensor must be installed into the air cleaner base. Drill the air cleaner

base with a 3/4” drill, deburr any sharp edges, install the sensor grommet, then slide the

air temp sensor into the grommet. This sensor is usually placed in the rear of the base

for best appearance.

Page 42

42

3.2.3.3 Engine Coolant Temperature Sensor (ECT)

Engine Coolant Temperature Sensor

(ECT)

Visit us at: http://www.edelbrock.com

Installing / Replacing the Engine Coolant Temperature (ECT)

sensor

The engine coolant temperature sensor is a thermistor device which measures coolant

temperature. It should be screwed into the coolant passage of the intake manifold near

the thermostat housing to measure coolant before it exits the engine on its way to the

radiator. It has 3/8 NPT pipe thread and comes with a thread sealant pre-applied.

Page 43

3.2.3.4 Manifold Absolute Pressure Sensor (MAP)

Manifold Absolute Pressure (MAP)

Installation and Setup 43

Visit us at: http://www.edelbrock.com

Installing / Replacing the Manifold Absolute Pressure (MAP)

sensor

The MAP sensor measures pressure in the intake manifold. (A pressure below

atmospheric is typical in a running engine, and is sometimes called vacuum when the

value is referenced to atmospheric baseline.) The manifold pressure is low (highvacuum) in a light load condition, while in a high load condition – the pressure will rise

(low vacuum). Manifold pressure provides the ECM information that helps the system

determine the load on the engine so the appropriate output changes are calculated and

executed.

The MAP sensor must have an unobstructed signal to the intake manifold plenum: either

at the throttle body below the throttle blades, or in the plenum itself. A small bracket is

supplied to mount the MAP sensor to one of the 4 throttle body hold down bolts/studs. A

Page 44

44

small length of vacuum line (not supplied) should be installed between the MAP sensor

and the vacuum port reference location. Replacement of sensor should be done using the

original mounting hardware.

Note: If the MAP sensor has an orange ribbed sleeve on the reference port,

remove it prior to installation. It is not necessary for proper operation.

Page 45

3.2.3.5 Idle Air Control Valve (IAC)

Idle Air Control Valve

Installing / Replacing the Idle Air Control valve (IAC)

Installation and Setup 45

Visit us at: http://www.edelbrock.com

The Idle Air Control (IAC) valve is controlled by the ECM and tailors airflow to help

maintain a set point speed at idle. The behavior of the valve can be calibrated for your

combination through the laptop Pro Tuner software. The IAC comes installed on your

system throttle body. Replacement of the valve is through removal of the 2 mounting

screws, remove old valve, replace gasket, and install new valve.

Page 46

46

3.2.3.6 Fuel Pressure Sensor (optional)

Fuel Pressure Sensor

Visit us at: http://www.edelbrock.com

Figure 16

Installing / Replacing the optional Fuel Pressure Sensor

An optional fuel pressure sensor may be used with your system to provide additional

information to the ECU and for readout on digital smart gauges and displays over the

CAN network. It is also used by the system for automatic fuel pressure compensation if

the sensor is in the system. The pressure sensor should be mounted in the fuel rail or

crossover line prior to the fuel regulator. In all cases, but especially if the rail is drilled

and tapped for the 1/8” NPT thread: cleanliness is a must to avoid contamination of the

fuel system and potential engine or injector damage. After machining and during

assembly/disassembly – clean the rail assembly and associated lines thoroughly. Make

sure there are no chips, particles, or overhanging burrs that could break loose.

A typical sensor installation is shown in figure 16.

Page 47

3.2.3.7 Oil Pressure Sensor (optional)

Oil Pressure Sensor

Installation and Setup 47

Visit us at: http://www.edelbrock.com

Figure 17

Installing / Replacing the optional Oil Pressure Sensor

An optional Oil pressure sensor may be used with your system to provide additional

information to the ECU and for readout on digital smart gauges and displays over the

CAN network.

The sensor also enables the low pressure warning limit array. This table allows you to set

the minimum oil pressure for your engine over the RPM range. If the pressure drops

below your calibrated value, the MIL (Malfunction Indicator Lamp) will light to alert the

driver of the condition.

The sensor should be installed as close to an engine oil gallery as

possible and away from exhaust heat.

The sensor features a 1/8”NPT thread and can be used in addition to standard oil

pressure sender units. Use every precaution to prevent dirt or debris from entering

lubrication system during installation. A typical sensor installation is shown in figure 17.

Page 48

48

3.2.3.8 Mass Air Flow (MAF) Sensor (optional)

Mass Air Flow (MAF) Sensor

Visit us at: http://www.edelbrock.com

Figure 18

Installing / Replacing the optional Mass Airflow (MAF) Sensor

Your Victor or Super Victor System has the capability to run a GM digital Mass Airflow

sensor (MAF). A MAF sensor will feed the ECM airflow information which is used in the

control calculations and used to auto-calibrate the Volumetric Efficiency map.

The MAF can be used only for the auto-cal OF VE during dyno testing, or it can be run all

of the time; constantly adjusting for changes in airflow due to wear or engine

modifications. The sensor that should be used is a 1999-2002 GM # 25318411 or the

25341604

tuning session, be sure to turn the sensor off by selecting "none" in the MAF section of

the setup wizard. This will prevent Mass Airflow sensor faults during later operation.

In high horsepower applications, your system is capable of running two of these sensors