Page 1

Catalog #3562, 3563, 3564, 3565

Rev. 3/06 Page 1 of 16

©2006 Edelbrock Corporation

Brochure #63-0047

PERFORMER MULTI-POINT EFI SYSTEMS

for TBI-Equipped Chevrolet/GMC Trucks & Suburbans

Catalog #s 3562, 3563, 3564, and 3565

INSTALLATION INSTRUCTIONS

STOP!

BEFORE BEGINNING INSTALLATION,

READ THESE IMPORTANT NOTES…

❑ You must purchase a separate Edelbrock Fuel Pump Kit for this installation; single fuel tank

vehicles use Edelbrock #3581, dual-tank vehicles use #3580.

❑ Check the Kit Contents and Suggested Tools lists on page 2 to be sure that you have all

items necessary to finish installation.

❑ Make sure this kit is for your vehicle.

❑ The kits are designed to work with stock engines with stock compression ratios. The

#3564 and #3565 are designed to work with the GM #12371054 502 c.i.d. crate engine.

❑ You must change your computer chip for this kit to function on your vehicle and be

emissions legal. Complete the Chip Information Card and return to Edelbrock. We will send

the computer chip within the continental U.S., free of charge via UPS second day air. Orders

outside of the continental U.S. will be shipped via the best method at the same costs as

continental UPS second day air. If requested, customers may pay for expedited shipping

by providing a current Visa or Master Card.

❑ Your vehicle’s wiring harness and electronics must be in good shape or you may not get

maximum performance and/or may experience problems. The TBI will work with less

adequate connections, but the Performer Multi-Point EFI System is much more sensitive

than a stock TBI.

❑ Read all instructions before beginning installation.

❑ Note that fuel tank or bed of pick-up must be removed.

❑ 1987-1991 vehicles with cruise control MUST use Edelbrock throttle/cruise/kickdown

cable bracket #8031. Order from your Edelbrock dealer before beginning installation.

®

Page 2

MANIFOLD

ASSEMBLY CONTENTS

Catalog #3562, 3563, 3564, 3565

Rev. 3/06 Page 2 of 16

©2006 Edelbrock Corporation

Brochure #63-0047

Qty. Description

❑ 1 Manifold assembly (see detail below)

❑ 1 Installation instructions

❑ 1 EPROM adapter circuit board (#3562 only)

❑ 1 Fuel injector wiring harness

❑ 1 Fuel filter adapter fitting (filter to #6 AN male) with O-ring

❑ 1 Return line adapter fitting

❑ 2 #6 AN straight pushlock fittings

❑ 1 3/8" i.d. pushlock heat resistant fuel line, 10 foot length

❑ 1 #6 AN 45 degree elbow pushlock fitting

❑ 1 #6 AN 90 degree elbow pushlock fitting

❑ 1 Fuel line clamp (floor mounted)

❑ 4 11" tie wrap

❑ 1 Throttle cable bracket

❑ 1 Throttle body block-off plate

❑ 1 Throttle body gasket

❑ 1 EGR gasket

❑ 1 3/8" NPT pipe plug

❑ 1 3/8” I.D. Flatwasher

Qty

. Description

❑ 1 3/8" NPT male to 3/8” NPT female 90 Degree elbow

❑ 1 3/8" NPT to 1/2” hose brass fitting

❑ 1 2 foot length 15/32 i.d vacuum line (power brakes)

❑ 1 6” length 3/8’ fuel line (breather line extension)

❑ 1 1/2" NPT to 3/4" hose barb

❑ 1 36" length 3/4" i.d. heater hose

❑ 1 3" length 5/16" i.d. high pressure fuel line (pump to sending

unit)

❑ 1 2 foot length 5/32" i.d. vacuum line (regulator & EGR)

❑ 1 5-1/8" i.d. air cleaner base gasket

❑ 1 12" length 1/4" i.d. vacuum line (MAP)

❑ 1 1/2” hose clamps

❑ 2 3/4" hose clamp

❑ 1 3/8" hose clamp (fuel injection clamp)

❑ 1 5/16" hose clamp (fuel injection clamp)

❑ 1 1/4" x 1/4" out x 5/32" bottom out vacuum “T” fitting

❑ 1 10-16 x 3/4" TEX screw (self tapping)

❑ 1 Air Cleaner Lid decal

PERFORMER MULTI-POINT EFI

KIT CONTENTS

Qty

. Description

❑ 1 Intake manifold

❑ 1 Driver’s side (left side) fuel rail

❑ 1 Passenger’s side (right side) fuel rail

❑ 4 1/4"-20 x 1.25" Hex head cap screw rail hold down bolts

❑ 1 Fuel pressure regulator

❑ 8 Magnetti Marelli

®

pico injectors

❑ 1 Fuel crossover line (including adapter and schrader valve)

❑ 1 Fuel inlet fitting (3/8" male pipe to #6 AN male, steel)

Qty

. Description

❑ 1 Fuel regulator nut and Viton O-ring

❑ 1 Viton O-ring; fuel regular nut (1/2" o.d. 5/16" i.d.)

❑ 4 1/4" i.d. AN thin flat washers

❑ 1 1/4"-20 x 1/2" hex head cap screw

❑ 1 1/4" i.d. split lock washer

❑ 1 Schrader valve cap

❑ 4 1/4" internal star lock washers

SUGGESTED TOOLS AND MATERIALS FOR INSTALLATION

❑ 3/8" ratchet socket set with extensions

❑ Combination set of open-end wrenches (SAE and metric)

❑ Jackstands, screwdrivers, pliers, crescent wrench, hacksaw,

hammer, brass punch and assorted hand tools

❑ Torx screwdrivers

❑ Tin snips

❑ White grease

❑ Teflon thread sealant or equivalent

❑ Intake gasket set (Edelbrock #7205, GM #10181398, or

equivalent)

❑ Thermostat housing gasket (GM #10105135, Fel-Pro #2201, or

equivalent)

❑ Gasket sealant (Gasgacinch, etc.)

❑ RTV Silicone sealant; O2 sensor-safe

❑ Wire stripper & crimper

❑ Heat gun or lighter

Page 3

Catalog #3562, 3563, 3564, 3565

Rev. 3/06 Page 3 of 16

©2006 Edelbrock Corporation

Brochure #63-0047

IMPORTANT INSTRUCTIONS

For ordering your FREE Edelbrock computer chip.

You must use

an Edelbrock chip with the Performer Multi-Point EFI conversion

You must change the computer chip in your stock computer (ECU) for proper functioning and maximum performance with the

Edelbrock Performer Multi-Point EFI for 7.4L or 8.2L Chevy/GMC engines.

To receive your ECU chip, please complete the attached postage-paid card and send to Edelbrock. After receiving your card,

Edelbrock will send the computer chip within the continental U.S., free of charge via UPS second day air. Orders

outside of the continental U.S. will be shipped via the best method at the same costs as continental UPS second

day air. If requested, customers may pay for expedited shipping by providing a current Visa or Master Card.

When filling out your information card, please print c

learly.

The information below will help you to locate your ECM Service Number and Broadcast Code:

SERVICE NUMBER

BROADCAST CODE

Typical ECM Label

SERV. NO. 16144288 AWHF

86AWHF K112731181

16155501 AWHF

1. The ECM is accessible in pick-ups by removing the glove box liner. This requires removing four (4) small hex head screws

and pulling out the liner. The ECM sits vertically in a plastic cradle on the far right side of the dash with the connectors

facing to the rear.

2. The Broadcast Code is stamped on a white paper label, located on the top of the ECM. Typical codes for the 5.7L run

from AKSM to BDXX, increasing alphabetically with later release dates.

There is a plastic decal on the bottom of the glove compartment with a list of the RPO codes for that vehicle.

This is a listing of the “RPO” codes and what they stand for:

CODE VEHICLE EMISSIONS

NA1 Under 8600 GVW

NA4 Over 8600 GVW

NA5 Federal

NB2 California

NB8 New York/California

NM8 Special Fuel Compatible

CODE TRANSMISSION

MD8 4L60 Auto

M30 4L68E Auto

MT1 4L80E Auto

MG5 Manual w/ Deep Low

MY2 Manual 5-Speed

M20 Manual 4-Speed

CODE

ENGINE

L03 5.0L TBI V8

L05 5.7L TBI V8

L19 7.4L TBI V8

CODE REAR AXLE

GU2 2.73:1

GU3/GW9 2.93:1

GU4 3.08:1

GU6 3.42:1

GT4 3.73:1

GT5 4.10:1

HC4 4.56:1

®

86AWHFK112731181

Page 4

Catalog #3562, 3563, 3564, 3565

Rev. 3/06 Page 4 of 16

©2006 Edelbrock Corporation

Brochure #63-0047

®

INSTALLATION INSTRUCTIONS

for Performer Multi-Point EFI System

for 7.4L TBI-Equipped Chevrolet/GMC Vehicles

Catalog #3562 and #3564 for 1987-1990 Model Years

Catalog #3563 and #3565 for 1991-1995 Model Years

• APPLICATION INFORMATION: Performer Multi-Point EFI Systems are designed for 1987-1990 (#3562 and #3564) and

1991-1995 (#3563 and #3565) 7.4L Chevy/GMCs originally equipped with Throttle Body Injection. These complete

systems utilize the stock computer and throttle body unit for a simple and effective conversion to multi-point fuel injection.

Fuel is injected directly into each port in the head for ideal fuel distribution and efficiency.

• TECHNICAL SUMMARY: In 1987, Chevrolet introduced their Throttle Body Injection (TBI) systems. Produced from 1987

to 1995 on all pick-up trucks and Suburbans, this TBI system was essentially an intermediate step between a carburetor

and true port (multi-point) fuel injection. In these TBI systems, two injectors are positioned above the throttle blades of a

two-barrel throttle body and fuel is injected into the manifold, much like a carbureted system. This arrangement suffers

from distribution problems because the fuel spray from the injectors does not stay in suspension with the incoming air,

resulting in uneven distribution. Our Performer Multi-Point Systems include an intake manifold designed to deliver an

equal air charge to each cylinder. Each injector delivers exactly the same amount of fuel to each cylinder for an extremely

even air/fuel ratio from cylinder-to-cylinder. This permits us to tune the system for ideal fuel and spark delivery for more

horsepower, torque and improved mileage.

Performer Multi-Point Systems include all parts needed to make the conversion. The stock TBI unit is retained as an air

valve and the factory computer (re-programmed) is also retained to control the injectors in a batch-fire mode. In the

Edelbrock systems, all of the factory sensors are retained and fully functional. The compact size was achieved by using

extruded aluminum fuel rails with new Magnetti Marelli®pico injectors. These are half the size of conventional style

injectors.

• SPECIAL NOTICE: This Edelbrock part has received an Executive Order number (E.O. #) from the California Air Resources

Board (C.A.R.B.) making it legal for street use on pollution-controlled motor vehicles in all 50 states. To assist you with

emissions inspection, we have included a silver fan shroud decal to verify that this part is a legal replacement part on the

vehicle for which it is cataloged. The adhesive-backed decal should be affixed to your fan shroud next to the existing

emission and engine specification decal. Do not cover your original equipment specification decal with the Edelbrock fan

shroud decal. E.O.# decal is shipped with the computer chip .

If you have any questions, please call our...

EFI Technical Hotline at: (800) 416-8628, Option 3

8:00 am - 5:00 pm, Monday-Friday (Pacific Standard Time)

Page 5

Catalog #3562, 3563, 3564, 3565

Rev. 3/06 Page 5 of 16

©2006 Edelbrock Corporation

Brochure #63-0047

INSTALLATION PROCEDURE

1. Disconnect negative battery cable.

2. Drain coolant.

3. Remove air cleaner assembly.

4. Label all lines, wires, and connections with masking tape

before disassembly to aid in re-assembly. Disconnect all

throttle cables and accessories, disconnect all vacuum lines to

throttle body. Disconnect both fuel lines at rear of throttle body.

Be careful of line pressure. Remove 3 throttle body mounting

bolts and remove throttle body.

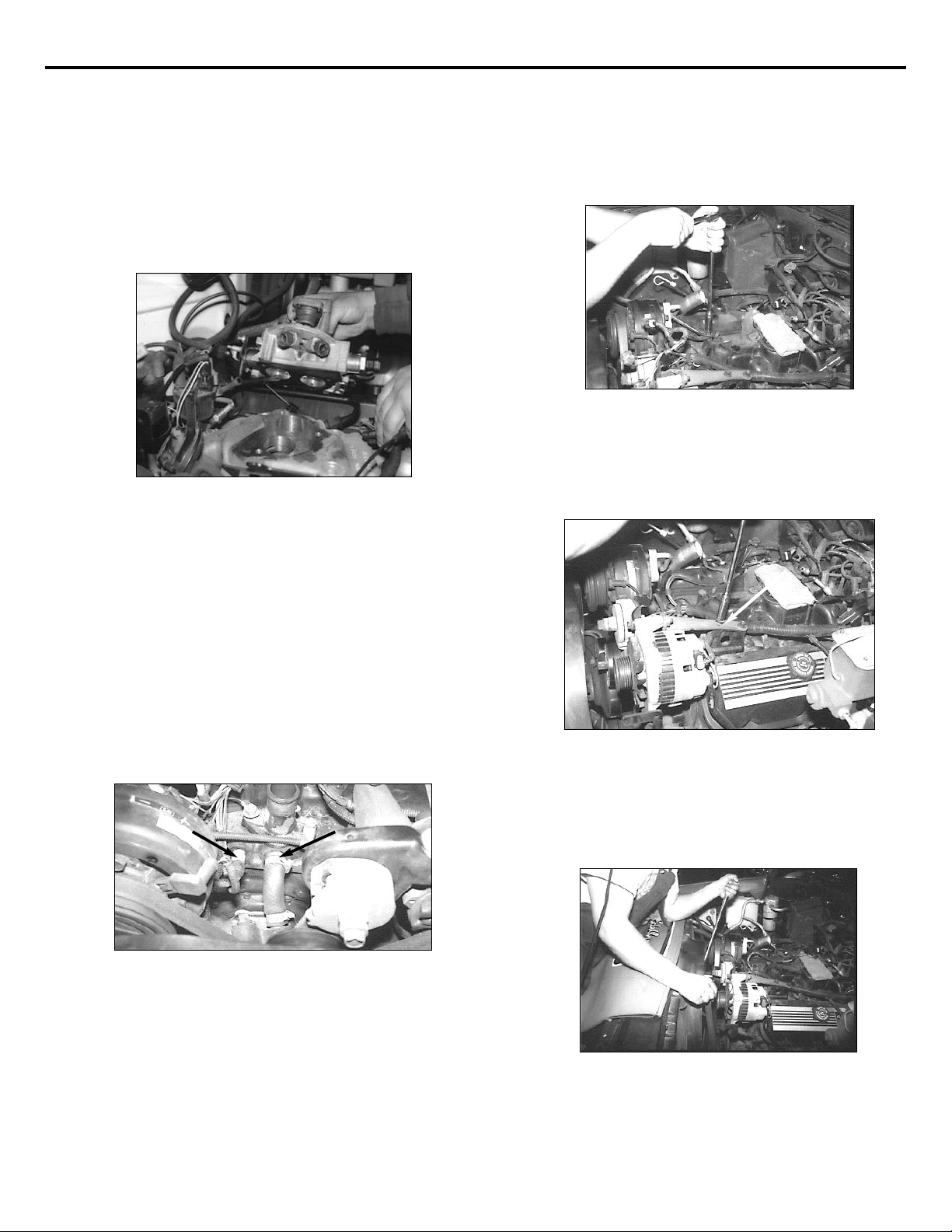

Remove top alternator mounting bolt and the bolt holding the

belt tension assembly. Remove two bolts that hold bracket to left

front support base, which is mounted to the two left front

manifold bolts. Remove bracket assembly. NOTE: On later

vehicles, this procedure may not be required.

9. Alternator has a support bracket running from the two left front

intake manifold bolts to the rear of the fan belt tension assembly

and the upper alternator bolt (this will be re-used during

assembly). Release the belt tension using a ratchet and socket,

then remove the fan belt.

8. The electronic vacuum regulator valve is mounted on the third

bolt from the front, on the right side of the manifold. When you

remove the bracket, there will be two support brackets running

from different locations on the backside of the A/C compressor,

both meeting the manifold at one spot. Remove bolts and

brackets. (Brackets will be re-used).

6. Disconnect vacuum fitting for power brake booster from intake

manifold.

7. Remove heater hose connection from the manifold (most will be

located at the right rear of the manifold).

5. Remove top radiator hose, remove thermostat housing and

thermostat. NOTE: Ground wires may be located on thermostat

mounting bolt. It is important to note the location of all ground

wires so they can be put back exactly as they were.

It is a good idea to replace your old thermostat at this time. For

proper ECM operation it must be the correct temperature, usually

195°F (check manufacturer's specifications). Remove the water

pump bypass hose located under the thermostat on front of the

manifold. Looking at the front of the engine, directly to the left of

the water pump bypass is the coolant temperature-sending unit.

Disconnect the electric connection, remove the sending unit and

set aside. It is better to remove sensor at this time to avoid

damage upon manifold removal. The sensor will be re-used in

the new manifold.

Coolant

Sensor

Water Pump

Bypass

Alternator

Bracket

Page 6

Catalog #3562, 3563, 3564, 3565

Rev. 3/06 Page 6 of 16

©2006 Edelbrock Corporation

Brochure #63-0047

10. DISTRIBUTOR REMOVAL

Remove plug wires from top of distributor cap. Make note of

location of each wire. Remove distributor cap. Before removal of

distributor, note the location of the distributor body and the

ignition rotor by marking distributor body with a felt tip marker.

Loosen distributor clamp and remove distributor. Be careful not

to turn engine over after distributor has been removed.

With the distributor removed, remove the ignition coil and throttle

bracket. NOTE: On early applications, you will not re-use your

throttle bracket. You will use the Edelbrock throttle bracket

supplied in kit. Remove remaining manifold bolts and brackets,

noting the location of studded bolts so you can replace them in

the same location. The MAP sensor bracket assembly is

mounted on the right rear manifold bolts. It will mount in the

same location on new manifold. If you remove any ground wires,

note their location as well.

11. MANIFOLD REMOVAL

Using a flat blade screwdriver or a small pry bar, wedge tool

under front end seal of the intake manifold and pry to break seal.

Remove intake manifold, being careful not to spill too much

coolant into engine. If any coolant is spilled, use paper towels to

absorb quickly. Clean out any debris that may have fallen in

engine valley upon removal of manifold. Place rags over valley

and place rags or paper towels into all exposed ports on cylinder

heads to keep out debris.

12. FUEL LINE REMOVAL

Remove two existing fuel lines hanging over the rear, near center

of the engine block. On most late models (1992-1995), the fuel

lines are routed down the left side of the truck, coming down the

bellhousing and running over to the frame where they connect to

the fuel filter. The return line will have a coupler-type fitting

where it connects. Remove these lines; they will not be used

with the new kit. Be careful of any remaining fuel in lines. Then,

there will be a mounting clamp holding lines to the upper left

transmission mounting bolt. Remove fuel line support bracket,

along with line.

NOTE FOR 1987-1991 MODELS:

The fuel lines may run down the right side of the bellhousing.

Both of the connection fittings will be between the transmission

and the frame. Disconnect both lines, being careful of remaining

fuel in lines. The mounting clamp holding both lines is usually

bolted to the rear of the cylinder head. Remove mounting bolt or

nut and the fuel lines. These lines will not be used in new

system. Remove the two fuel lines from the junction point back

to the fuel filter for the inlet line, and to the return junction block,

located just above fuel filter. These two lines will not be used in

the new system.

Page 7

Catalog #3562, 3563, 3564, 3565

Rev. 3/06 Page 7 of 16

©2006 Edelbrock Corporation

Brochure #63-0047

13. INTAKE PREPARATIONS

With fuel lines out of the way, scrape remaining intake gaskets

off of cylinder heads and scrape both end seals clean. With

surfaces clean, install intake gaskets to cylinder heads. Use GM

gaskets #10181398. Apply gasket sealant to gaskets on surface

facing heads only. Glue gaskets in place.

While gaskets set-up, place the new manifold next to the old

manifold. You will need to swap certain parts like the distributor

hold down clamp and bolt, EGR valve and on some models, a

vacuum fitting located at the right rear of throttle body pad.

When re-installing the EGR valve on the new manifold, notice that

it is relocated up near the thermostat area. The EGR mounting

pad is drilled for the different EGR valves used from year to year.

We provide a gasket that will accommodate all EGR valves.

Determine which EGR bolt holes are to be used and install your

old studs and EGR valve onto manifold.

For models equipped with a power brake vacuum booster, you

will need to install the 1/2" NPT-to-1/2" barbed 90-degree

fitting. This will be used later in the installation for your vacuum

supply relocation. This fitting goes on the rear of the throttle

body pad.

NOTE: If any of the holes in the manifold are not used, plug them

with the pipe plugs supplied and always use Teflon sealant or

equivalent when installing fittings and plugs (does not apply to

unused EGR pad holes).

NOTE: On early models (1987-1990), the cruise control vacuum

diaphragm bracket is mounted directly on the intake manifold.

For these models, it is necessary to relocate this assembly. Using

GM part #14056623, mount this bracket to the left rear cylinder

head. Install your diaphragm assembly to this bracket.

NOTE: It is easier to install this bracket before manifold is

installed on engine.

14. MANIFOLD INSTALLATION

Before installing the manifold, make sure all ports and the valley

of the engine are clean. Apply a 1/8" bead of 02 sensor safe

silicone around the four water ports on the engine. Apply a 1/4"

bead of silicone on the two end seal areas of the engine block.

Install the intake

manifold onto the

engine, be careful to

set it down as

straight as possible.

Do not set down and

slide into place.

Install your stock

intake manifold

bolts in the same

locations that they were removed from. The bolts with studs

need to be in certain holes for the brackets.

If your vehicle has the cast iron base for the bracket which came

off the rear of the alternator and idler pulley, you will need to

install it at this time.

Note: Some grinding on the bracket ears and on the rear of the

bracket, where it makes the bend, may be required. It is

important to make sure the bracket sets onto the manifold

squarely to avoid damage to the bracket and manifold.

New EGR

Location

Stock EGR

Location

Cast Iron Bracket

Page 8

Catalog #3562, 3563, 3564, 3565

Rev. 3/06 Page 8 of 16

©2006 Edelbrock Corporation

Brochure #63-0047

Tighten the manifold bolts following the tightening sequence

shown below. Torque to 25 ft. lbs. Install the distributor in the

engine. Using your marks as a reference, snug down distributor

clamp.

NOTE: Final timing will be adjusted after engine start-up. Install

cap and re-install plug wires in the correct location using your

marks as a reference. Install ignition coil.

NOTE: We provide four bases for the two different coil styles. On

early models (1987-1990), you will use the two coil bosses

towards the rear of the manifold. For the later model style coils,

you will use the two bosses towards the front of the manifold.

Install coil wires and electrical connections on coil and

distributor. Re-install your MAP sensor bracket, which mounts on

right rear second and third studded manifold bolts. Install the

EGR vacuum regulator valve on the third bolt from the front on

the right side.

If your vehicle has the bracket for the alternator and idler belt

tension pulley, you need to install it at this time. Re-install

tensioner and bracket assembly. Re-install serpentine belt.

Make sure tensioner bolt and bracket bolts are tight!

15. THERMOSTAT AND HOSES

If your vehicle came with the 44mm O-ring style thermostat, you

will need to purchase a standard size thermostat and gasket.

You will re-use your original housing. Thermostat operation and

engine coolant temperature are very important for proper ECM

operation. Check service information for suggested temperature

(usually 195 degrees). Install thermostat and housing. Re-install

ground wire to one of the thermostat housing mounting bolts (if

originally equipped).

Install radiator hose and water pump bypass hose. Re-install the

coolant temperature sending unit (located to the right of the

water pump bypass hose). Check coolant sensor wire

connection and make sure all hose clamps are tight.

Page 9

Catalog #3562, 3563, 3564, 3565

Rev. 3/06 Page 9 of 16

©2006 Edelbrock Corporation

Brochure #63-0047

16. HEATER HOSE SUPPLY LINE

For all years, the heater core supply will come from the right front

water port on intake manifold. You will need to install the 1/2"

NPT-to-3/4" hose fitting into manifold using Teflon sealant on

threads. Remove your existing heater supply hose at its junction

point, usually at the heater core. Using the 3/4" heater hose and

two clamps supplied, route the hose from the intake manifold to

the heater core supply entrance. Some cutting of the hose may

be required. Secure hose on both ends with hose clamps.

17. INJECTORS AND RAILS

NOTE: Fuel injectors and fuel rails are assembled on

manifold and ready to run unless you had to remove them

for manifold installation. If they were removed, use the

following procedure for re-installation. If not, skip this

procedure and move on to the next step.

Using non-silicone based spray lubricant or white grease,

lubricate injector O-rings (top and bottom) before sliding them

into fuel rails. Push injectors into rails, making sure that the

electrical connectors on injector bodies face up. Now push fuel

rails and injectors into manifold. Use caution not to damage

O-rings upon installation. Place fuel rail with pressure

regulator on passenger's side with regulator toward rear of

engine. Place other rail on driver's side of manifold. Push down

with enough force to seat lubricated O-rings in manifold, making

sure not to cut O-rings. Once injectors are seated and before

replacing the 1/4-20 x 1.25 bolts, make sure the injectors rotate

in their bores easily. Once installed, secure rails with 1/4" bolts

and flat washers supplied in kit. Torque to 8 ft./lbs.

18. FUEL LINE CONNECTION

From the kit contents, locate the length of 3/8" high pressure fuel

hose, one 45° #6 Pushlock fitting, one 90° Pushlock fitting, and

two straight #6 Pushlock fittings.

PUSHLOCK FITTING-TO-HOSE INSTALLATION

Use this procedure for installing each one of the Pushlock

Fittings onto hose ends:

Clamp Pushlock fitting in vise, being careful not to crush fitting.

Lubricate inside of hose end and Pushlock fitting barb with a

small amount of lubricant (oil, spray lube, or white grease). Push

the hose over the barb until it stops against the fitting collar. No

clamping is necessary.

Before making the fuel lines, you must install the fuel filter

adapter fitting and the return line adapter fitting. The fuel filter

adapter fitting is a male #6-to-16mm threaded male with an Oring on the end of the fitting. Install into fuel filter and tighten

securely. The return adapter fitting is the female 14mm-to-#6

fitting. This will attach to the return fuel line. NOTE: Be careful

not to damage the O-rings on the fittings or the existing fuel

lines.

Install both fittings as shown in photo.

Return Line Adapter

Fitting (14mm)

Fuel Filter Adapter

Fitting (16mm)

Page 10

Catalog #3562, 3563, 3564, 3565

Rev. 3/06 Page 10 of 16

©2006 Edelbrock Corporation

Brochure #63-0047

19. FUEL RETURN LINE INSTALLATION

Install the 90° #6 pushlock fitting into the 10-foot length of hose

using the pushlock fitting installation procedures described

previously. Tape off the open end of fuel line to prevent debris

from entering. Route the open end (taped) of hose down the

bellhousing towards the fuel filter and return line area.

NOTE: This may be left or right side, depending on year and

model.

Connect the #6 90° fitting to the fuel pressure regulator fitting on

fuel injection assembly (passenger's side fuel rail). Be sure that

the hose is routed safely with no sharp bends down the

bellhousing to the frame where the connection will be made.

Determine the length needed, adding in a little extra to allow

mounting fuel line clamp to the floor of vehicle. Mark the line,

remove from vehicle and cut to length.

NOTE: Carefully flush out all debris after cutting lines!

Install #6 straight pushlock into hose. Tape end of return line

again, then re-install on vehicle. Tighten both fittings securely.

20. FUEL INLET LINE INSTALLATION

Install the 45° #6 pushlock fitting into the remaining length of

hose and tape other end to prevent debris from entering. Route

open end (taped) of hose down bellhousing and thread 45° fitting

onto rear of fuel rail. From under vehicle, determine length

needed to reach the fuel filter adapter fitting. Be sure to add a

little extra to allow mounting a fuel line clamp to the floor of

vehicle. Remove line from vehicle and cut to length. Install #6

straight pushlock into hose. Tape end of return line again, then

re-install on vehicle. Tighten both fittings securely.

From Regulator on

Passenger Side Fuel Rail

To Rear of Driver’s

Side Fuel Rail

With the lines routed so they are not kinked, use the fuel line

clamp kit supplied to mount to the floor. IMPORTANT NOTE:

Using two zip ties, fasten the fuel lines to wire harness running

down transmission (and possibly one up top) to ensure that they

are not touching firewall or any other sharp areas.

21. THROTTLE BRACKET

On all vehicles with a vacuum actuated cruise control (1987-

1991), you will need to install the throttle bracket supplied.

Install this bracket on the studded intake manifold bolts on the

left side of the manifold (third and fourth bolts from the rear).

Later vehicles use the stock bracket. Install bracket and connect

throttle cable to your new or existing bracket.

22. INJECTOR HARNESS

Lay out the injector harness (supplied in kit) on the engine,

looping it around the backside of the throttle body pad. The “tee”

with pink line connectors coming out of the bottom should end

up by the right rear of the throttle body pad, just in front of the

fuel regulator. Push 8 connectors onto injectors until they snap

on easily. The old TBI injector harness has two plugs which go to

your old injector assembly. Just below the old plugs is a black

grommet. Lay the old injector harness over the new harness and

determine the length of the old wire harness needed to splice

into the new harness. NOTE: Usually the cut will be above the

black grommet of the old wire loom.

Page 11

Catalog #3562, 3563, 3564, 3565

Rev. 3/06 Page 11 of 16

©2006 Edelbrock Corporation

Brochure #63-0047

Pull rubber grommet off of wires. Force silicone (oxygen sensorsafe) through these four holes, filling them with silicone.

Install the grommet on air valve in groove to prevent dirt from

entering the system.

23. ELECTRICAL CONNECTION

Separate four wires cut previously out of the factory loom. These

will be used to mate with the corresponding butt connectors;

green to green, blue to blue, and the two pink wires go to either

connector (on some vehicles pink to pink and pink to white). Use

stripping tool to strip end of the wires back 1/4".

After sticking stripped end into connector, crimp connector onto

wire using a crimping tool. Tug on wire slightly after crimping to

make sure you have a good connection.

After crimping all four connectors, take heat gun or cigarette

lighter (be careful not to burn wires) to heat the ends of the

connectors. They will shrink down around the wires and ensure

a tight connection. After cooling, slide all wires into black sleeve

coming off of the wire loom.

24. VACUUM HOSE

Remove the factory molded vacuum line which ran from the MAP

sensor to the rear of the throttle body. Locate the 1/4" x 12"

vacuum hose, the 1/4" x 1/4" x 5/32" vacuum tee and the 24"

of 5/32" vacuum hose from kit. Put one end of the 5/32" hose

on the vacuum nipple of the fuel regulator and loop it around the

coil area (be careful not to kink the hose). The other end should

end up in the area around the rear of the throttle body. Install the

1/4" vacuum hose from the MAP sensor to the rear of the throttle

body. This is easier with the throttle body off (estimate length if

throttle body is not yet installed). Insert plastic vacuum tee into

the section of 1/4" vacuum hose where the 5/32" vacuum hose

from the fuel regulator will easily intersect. Cut the hose and

insert the tee and connect all three hoses. For vehicles with

vacuum actuated EGR valve, you will need to remove the hard

preformed vacuum hose from the EGR vacuum regulating valve.

Install the remaining 5/32" vacuum hose from the EGR valve to

the regulating valve (cut hose as needed).

25. POWER BRAKE BOOSTER CONNECTION

Vehicles equipped with vacuum booster need to use the vacuum

port found at the right rear corner of the throttle body pad (if not

used, plug with pipe plug supplied). From kit contents, locate the

2 ft. x 15/16" vacuum hose, two clamps, 90° brass fitting, and

3/8" NPT to 1/2" hose fitting. Install 90° fitting in vacuum port

using teflon sealant, then install 3/8" to 1/2" hose fitting into 90°

fitting, aiming the hose end of fitting towards vacuum brake

booster. Remove original 90° plastic fitting from booster supply

line and install in end of vacuum brake hose supplied. Clamp

fitting to hose. Route hose to vacuum supply port (90° fitting just

Page 12

Catalog #3562, 3563, 3564, 3565

Rev. 3/06 Page 12 of 16

©2006 Edelbrock Corporation

Brochure #63-0047

installed in manifold). Route hose and cut as necessary to

prevent interference with linkage. Tighten both clamps and

secure with tie wrap as shown.

Tie Wrap

Brake Vacuum

Hose From Booster

to Supply Port

26. THROTTLE BODY CONVERSION

Remove the fuel inlet and return fittings at rear of the original

throttle body assembly. Next remove three torx screws retaining

the fuel injector/regulator assembly to the main body. Remove

this assembly while leaving the factory gasket in place. Using

the factory torx screws, install the injector block off plate

supplied in kit. The throttle body is now ready to be installed

using the new base gasket supplied in kit. Once installed, make

sure all vacuum and electrical connections are secure. Make

throttle connections.

Install the converted throttle body assembly and the new throttle

body base gasket (supplied) onto the manifold. Install and

tighten three mounting bolts. Make all electrical connections.

Connect the throttle cable and cruise cable assembly. Make

vacuum connections at the rear of the throttle body as well as all

of the connections in front. Double check all ground connections

and electrical connections.

27. ACCESS FUEL TANK

For the TBI multipoint conversion, it is necessary to install a highpressure fuel pump (#3581 for single tank vehicles, sold

separately). IMPORTANT NOTE: On trucks with dual tank setups, it will be necessary to install Edelbrock Dual Fuel Tank

Conversion Kit #3580, available from your Edelbrock dealer, or

call Edelbrock directly for sales or dealer assistance: 800-416-

8628, Option 3. Dual tank vehicles do not require removal of

the tanks or pick-up bed, as the new fuel pump kit #3580

mounts on the vehicle frame. See installation instructions

supplied in kit.

Stock TBI Injector Modified TBI Injector

Dual Tanks Require Kit #3580

(Bed does not

need to be removed for

dual tank pump installation)

To install pump #3581 on single tank vehicles, you must gain

access to the top of your fuel tank. If you have a Suburban, you

will need to drain the fuel tank and drop from the rear of the

vehicle. If you have a truck, we recommend removing the bed to

reach the fuel tank. On truck beds, you will usually find eight

mounting bolts, two ground wires, a couple of weather pack

electrical connectors (near license plate area), and you will need to

disconnect your fuel fill neck from the bed.

Ground

Connections

With all bed bolts and wires disconnected, four people can lift off

the bed. This takes about 20-30 minutes, which is much faster

than draining and removing tank. With bed removed, you will see

top of fuel tank. Take a brush or compressed air and clean the top

of fuel sending unit area so no debris enters in fuel when removing

this assembly. Disconnect two fuel lines, two hoses, and an

electrical connection with a ground wire. There is a center fuel

pump sending unit assembly lock ring holding assembly into tank.

Page 13

Catalog #3562, 3563, 3564, 3565

Rev. 3/06 Page 13 of 16

©2006 Edelbrock Corporation

Brochure #63-0047

Fuel

Tank

Disconnect two fuel lines, two hoses, and an electrical connection

with a ground wire. There is a center fuel pump sending unit

assembly lock ring holding assembly into tank. Using a hammer

and brass punch, gently strike open edge of lock ring in a counter

clockwise direction. Keep hitting until lock ring rotates enough to

release. Again blow or brush top area clean and carefully remove

the entire assembly. Be careful on removal! Take your time!

28. FUEL PUMP ASSEMBLY

With fuel pump assembly on bench, loosen and slide up the

lower plastic clamp on top of fuel pump. Now disconnect

electrical connection. On the bottom of the fuel pump, there is a

fuel strainer sock; remove the bottom strainer sock after marking

it so you can re-assemble in the original orientation.

ALTERNATE PROCEDURE: LOWERING FUEL TANK

Suburbans (or trucks that you cannot remove the bed), require removal of the fuel tank(s). The fuel tank must be lowered from beneath the

vehicle. First drain the fuel, then disconnect the ground wire and the weather pack electrical connector. Then disconnect gas fill hose and vent

hose. Let the tank drop enough to gain access to the fuel lines, then disconnect fuel lines and remove tank from vehicle. Most tanks have two

mounting straps which must be removed.

Ground

Connection

Gas Fill Hose

Connection

Gas tank

mounting straps

Note: There is a kit supplied with the 3501 and 3502 that

provides you with new fuel line and clamps. Install the 3" length

of fuel hose onto the 3/8" steel tubing where the old fuel pump

junction hose was previously. Use the 3/8" hose clamp to secure

hose to steel tubing.

Note: You may want to replace the fuel sock at this time with a

new factory replacement. Use a small flat blade screwdriver to

gently pry around strainer and it will pop off. Carefully slide the

factory fuel pump out of the assembly. Install the new fuel pump

supplied in the kit into this assembly.

Page 14

Catalog #3562, 3563, 3564, 3565

Rev. 3/06 Page 14 of 16

©2006 Edelbrock Corporation

Brochure #63-0047

Note: The fuel line will be a very tight fit over the 3/8" tubing.

It may be necessary to lube the tubing with some spray lubricant

to ease hose installation. Slip the 5/16" clamp over the rubber

hose, then insert fuel pump barb into hose and secure with 5/16"

clamp. Be sure there is adequate clearance between the metal

clamp and the electrical connections on the pump. Some

shortening of the rubber hose may be necessary for proper

alignment of the pump with the pump hanger.

NOTE: DO NOT RE-USE THE ORIGINAL

IN-TANK FUEL HOSE OR CLAMPS.

New Hose

5/16”

5/16”

Clamp

3/8”

Clamp

Use the new rubber base gasket for fuel pump. If the big O-ring

in fuel tank is OK (not torn), you may reuse it. If necessary,

replace with original equipment O-ring from a GM dealer. Make

sure to grease large O-ring with white grease or equivalent.

Making sure clamp is tight and electrical connector is connected,

install strainer sock into same position (it will just push on with

your thumb).

Install complete assembly back in the fuel tank. Make sure you

do not bend anything while reinstalling. Lock assembly back in

place by rotating lock ring clockwise until it hits its stops. Now

tighten fuel connections and hose clamps. Make electronic

connection and ground connection. Re-install fuel tank

(Suburbans, etc.). Do not re-install bed on pick-up trucks at

this time. Before installing bed, see Fuel Pressure Test

Section on page 15.

29. HOT RESTART FUEL MODULE

You must remove the Hot Restart Fuel Module before starting

your 1987-1989, over 8600 lbs. GVW HD vehicle. The Hot Restart

module is located on the Break Pedal Bracket between the

firewall, and the back of the gauge cluster. Its dimensions are

approximately 1-3/8” x 2-1/8” x 3-1/4”. There are three wires in

the harness for the Hot Restart Fuel Module; a pink wire with a

black stripe, a black wire with a white stripe, and a tan wire with

a white stripe.

CAUTION: iF THE HOT RESTART FUEL MODULE IS NOT

REMOVED, IT WILL OVERLOAD AND BURN ON START UP,

CAUSING SMOKE AND POSSIBLE FIRE HAZARD!

30. NEW COMPUTER CHIP INSTALLATION

IMPOR

TANT NOTE: COMPUTER CHIP MUST BE

ORDERED BEFORE BEGINNING INSTALLATION.

Open glove box and remove four screws mounting the inner tray.

Remove glove box tray.

On the ECM, you will find the service number and the broadcast

code. Both are needed in order to make a new calibration chip

for your particular vehicle. This should be done well before

installation to allow enough time for the new chip to arrive. Use

the chip order card enclosed with these instructions.

After removing two screws and cover from ECM, remove old chip

by pressing down on the two outside retaining clips.

Page 15

Catalog #3562, 3563, 3564, 3565

Rev. 3/06 Page 15 of 16

©2006 Edelbrock Corporation

Brochure #63-0047

This installation uses a piggyback chip adapter. Push your new

computer chip into the adapter, then install these two parts into

ECM. There is an alignment lug so that they only fit one way. Be

careful not to bend any pins. Put plate back on and re-install

ECM in the vehicle. NOTE: Early models do not require the

adapter; the chip simply replaces the stock chip.

31. INITIAL START UP

Re-connect battery negative cable. Double check connections

and fill radiator with a 50/50 mix (or manufacturer’s

recommendation) of anti-freeze and water. Turn key to the “On”

position. You will hear the fuel pump run for a few seconds and

stop as it fills the fuel system with fuel. There will be air trapped

in system. At this time, inspect all fuel connections for leaks. If

there are no leaks and everything looks good, crank it over. It

might not start right away. If not, stop and cycle key so fuel pump

runs (this will allow air trapped in system to evacuate). Try to

start again. Once running, check for fuel leaks again, then water

leaks.

32. SET IGNITION TIMING

If there are no leaks, set ignition timing following manufacturer's

procedures and specifications. You must disconnect the ignition

interrupter wire before you set the timing. This is a single tan

wire with a black stripe and a black plastic connector. On late

style vehicles, it is usually found under the dash on the

passenger's side, between the blower motor and the duct work

(next to the courtesy light). On earlier vehicles, it is usually found

on the passenger's side firewall, behind a plastic cover which is

secured with two screws. If you are not certain of the location of

this wire, consult factory service manual. Re-connect wire after

timing is set. If you have a truck, re-install bed after checking for

leaks around sending unit assembly.

NOTE: You may notice a slight surge in the idle in “

Park”

or

“

Neutral”.

This is normal and will smooth out when the

transmission is shifted into any drive gear.

Retaining

Clips

Page 16

Catalog #3562, 3563, 3564, 3565

Rev. 3/06 Page 16 of 16

©2006 Edelbrock Corporation

Brochure #63-0047

Edelbrock Corporation • 2700 California St. • Torrance, CA 90503

EFI Tech-Line: (800) 416-8628, Option 3 • E-Mail: EFITech@Edelbrock.com

BASIC TROUBLESHOOTING

1. Engine Combinations

a. If you assemble a combination of parts other than stock or the Edelbrock MPFI package called out in our catalog, your vehicle may not

perform properly.

b. Stroker motors are not supported.

c. All engine assemblies must maintain stock compression ratios.

d. A 190- to 195-degree thermostat should be used for optimum mileage, performance and emissions. Thermostats temperatures below

185 degrees should be avoided.

2. Engine Assemblies

a. Heavy duty L19-454, 1987-1990 P/N 88890529

b. Heavy duty L19-454, 1991-1995 P/N 88890530

c. GM P/N 12371054 Retrofit 8.2L (502) Long Block (3564, 3565 MPFI)

3. Fuel Pressure

Fuel pressure must be checked with a fuel pressure gauge only. Do not use a tire pressure gauge.

Test:

a. Turn key to “On” position, but do not start the engine

.

b. Fuel pressure should read 42-45 psi depending on your altitude . The higher the altitude the lower the pressure.

c. The system’s fuel pressure should not drop more than 10 psi in 5 minutes, and should maintain residual pressure even after sitting for

24 hours. If pressure drops more than 10 psi, check fuel pump hose and clamps in fuel tank. If the original hose and clamp were used,

replace them with the supplied hose and clamps per the instruction. If fuel pressure still drops off too quickly, contact Edelbrock.

d. With engine running, check fuel pressure. The idle fuel pressure should be between 34-38 psi depending on idle vacuum.

4. Engine Runs On Only One Bank

a. Check injector wiring for correct connections, green to green, blue to blue or red to red (some cases white to red).

b. Check that your original MemCal (blue capped chip) is installed on the supplied green piggyback adapter and chip alignment in the green

piggyback adapter.

See “New Computer Chip Installation” section and diagram on page 15.

®

Loading...

Loading...