Page 1

INSTALLATION INSTRUCTIONS

2001 Ford Mustang

nd jack up, applying pressure to the lower control arm for

oving the upper mount, the axle does not drop. Remove the upper nut

e order of removal. The rear axle must be supported to load car in order to

tighten the upper stud bushings. Using a 17 mm socket or wrench, tighten until a bulge in the bushing is

FOR 1987-

§ Please read these instructions entirely before beginning. Proper installation is a must to realize the

maximum performance improvements.

IMPORTANT NOTES:

§ Upon initial inspection, some new shocks may have a small amount of oil in the area of the seal. This is a

normal occurrence following manufacture and does not indicate a problem with your shocks.

§ Any tim e you are working under a vehicle, be sure to use the proper jack stands and tire chocks to prevent

any shifting or slipping of the car. Never use a jack only to support the vehicle while changing shocks.

§ Inspect shock brackets or mounting points before installation to make sure they are not broken or bent.

§ Do not attempt to disassemble these shocks. Return damaged shocks to Edelbrock for any necessary

service or repairs.

Catalog #3381 & #3481

Not for use on IRS

INSTALLATION

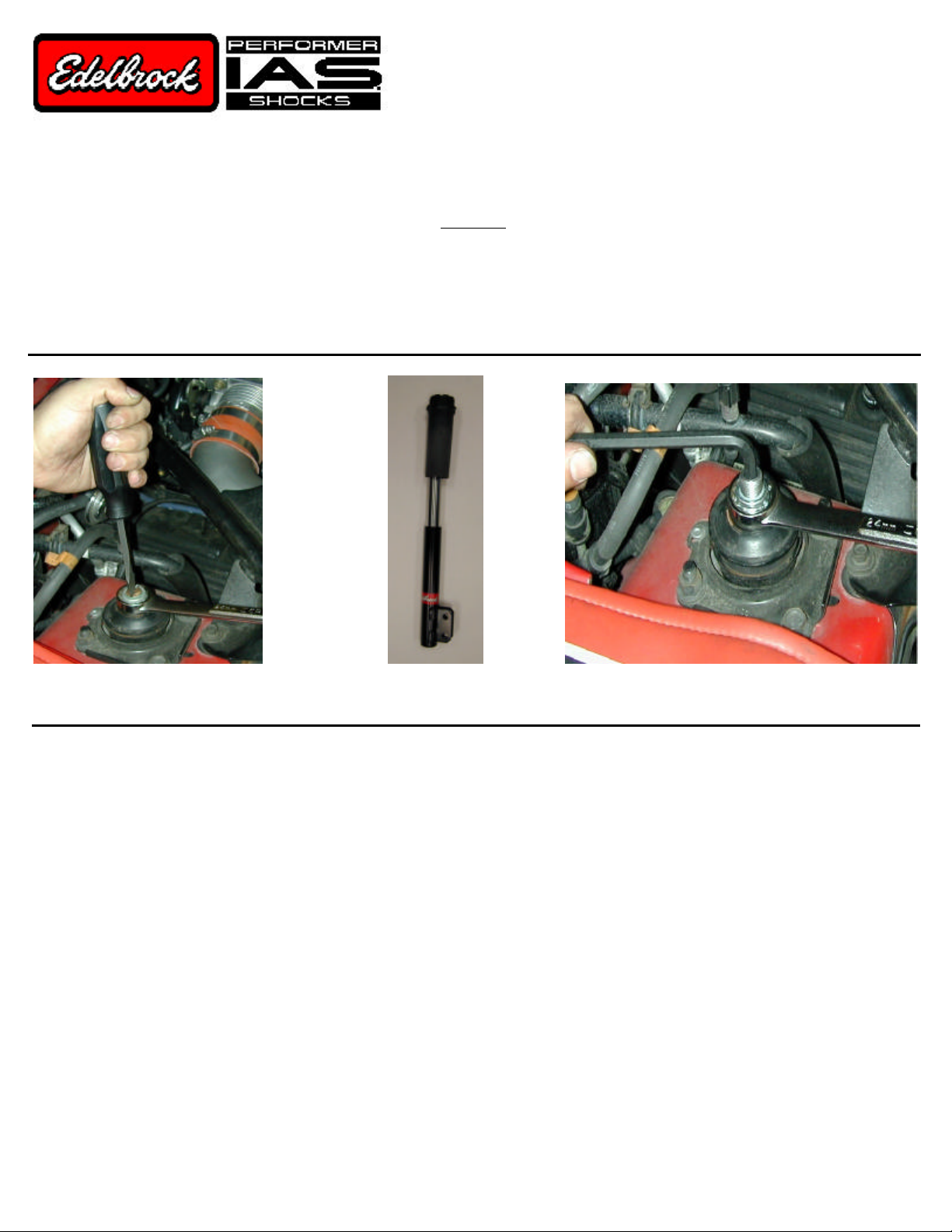

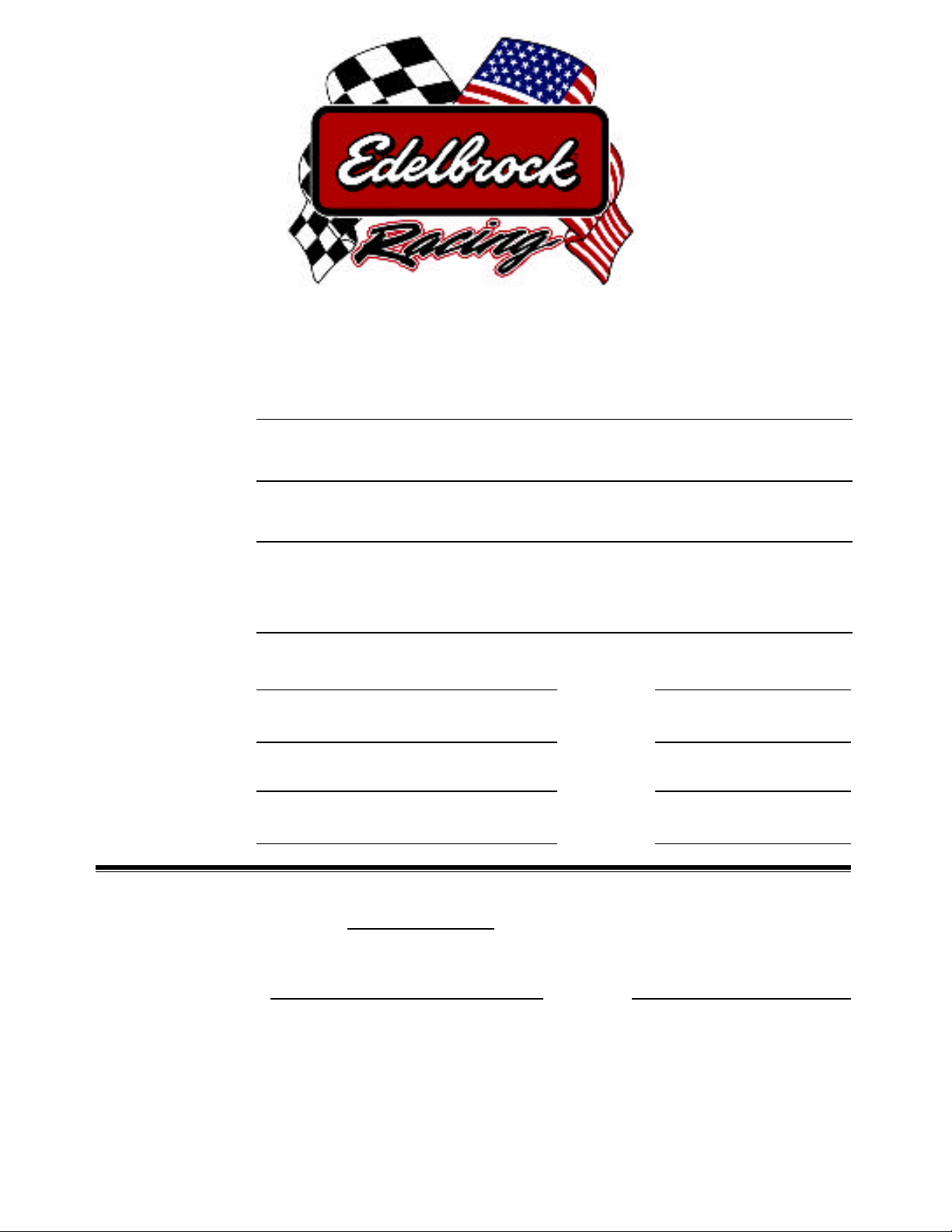

Fig. 1 Fig. 2 Fig. 3

Step 1 Support your Mustang with jack stands or on a lift at proper jacking locations.

Step 2 Remove the front wheels; removal of rear wheels is not necessary, but may make it easer to install.

Step 3 Place floor jack under front lower control arm a

support when removing the strut.

Step 4 Loosen the lower strut nuts. Move A.B.S. line and bracket out of the way, but do not remove the bolts.

Step 5 Loosen the front upper strut stud nut. The strut stud has a screwdriver slot to hold from turning, use a

24mm wrench on nut and screwdriver in slot to loosen and remove nut (fig. 1).

Step 6 Remove the lower bolts. The strut can now be removed.

Step 7 Remove the dust shield and reinstall on the new strut (fig. 2).

Step 8 Reinstall by reversing removal procedure. Do not tighten the lower nuts at this time.

A - Torque the upper post nut to 56-92 ft. lbs. Use Allen wrench to hold strut from turning (fig. 3).

B - Place jack or jack stand under wheel studs and apply pressure to load spindle and strut, torque the

nuts to 141-199 ft lbs. (Fig. 4).

Step 9 Removal of rear shock, remove the inside trunk liners to gain access to the upper shock nut (fig. 5).

Step 10 Support the rear axle, so when rem

using a 15 mm socket or wrench.

Step 11 Remove the lower bolts using a 15 mm on the bolt hex and 18 mm on the nut. Shock can now be removed.

Step 12 Install the rear shocks in revers

noticeable. Do not over tighten. Screw jam nut against nut.

Step 13 Torque lower nuts to 57-75 ft. lbs. (fig. 6). Reinstall wheels and torque to 85-105 ft. lbs.

Page 2

Fig. 4 Fig. 5 Fig. 6

Parts List

Qty. Description 3381 Qty. Description 3481

1 Front strut P/N 3381 1 Rear shock P/N 3481

1 1 top stud retaining nut per strut 1 Bushing parts pack per shock

1 1 top polyurethane bushing

Enjoy the improved ride and handling from your new Edelbrock IAS shocks.

Edelbrock Corporation

2700 California Street

Torrance, California 90503

Office (310) 781-2222

Fax (310) 320-1187

Toll-Free Tech Line (800) 416-8628

Tech E-mail: edelbrock@edelbrock. com

PN 84-8154

2001 Edelbrock Corporation

Rev. 2/01

Page 3

INSTALLATION INSTRUCTION

PROOFING FORM

Date:

From:

To:

Part No./

PN 3381/3481 – Shocks for 1994-2001 Ford

Description:

Reviewed by:

Reviewed by:

Reviewed by:

Approved by:

No. of copies to be printed:

Received by:

F0505D

2/20/01

Gary Nelson

Jack Mayberry

Mustang

Date

Date

Date

Date

Date

Loading...

Loading...