Page 1

INSTALLATION INSTRUCTIONS

Super Victor Race Manifold for 8.7” Deck Blocks

For Ford Windsor Engines

Please study these instructions carefully before installing your new intake manifold. If you have any questions or problems,

please call our Technical Hotline at: 1-800-416-8628, 7:00 am – 5:00 pm, Pacific Standard Time, Monday through

Friday or e-mail us at edelbrock@edelbrock.com .

DESCRIPTION: The Edelbrock Super Victor 2934 racing intake manifold is designed for ultra-high output 8.7” (302cid)

deck-height Windsor racing engines. Its runners have been enlarged substantially as compared to standard manifolds

designed for 8.2” deck height engines. It is compatible with stroker applications up to 380 C.I. The manifold has provisions

for late model water neck and throttle brackets. This manifold is neither intended nor legal for street use.

MANIFOLD FEATURES:

• Single plane design

• Standard Square bore carburetor pad

• Drilled and tapped throttle bracket bosses

• Rear cooling water bosses (not drilled)

• Nitrous bosses

MANIFOLD SPECIFICATIONS:

• The carburetor pad is 3-¾” tall measuring from the plenum floor.

• Runner average cross sectional area is 2.85 sq. in.

• Operating range is 4500 to 8500 rpm (could vary depending on engine size, bore and stroke combination).

• Manifold height A= 6.35” (end seal-carb pad).

POWER OPTIONS: Although this manifold will work with ported factory cast iron heads, we highly recommend the use of

either our #7716 Victor Jr. or our #7721 Victor cylinder heads. These heads offer higher airflow levels with minimum

preparation required. See our catalog for details. To order a catalog, call (800) FUN-TEAM.

CARBURETOR RECOMMENDATIONS: This manifold is designed to use square bore carburetors only. The use of

Dominator style carburetors requires an adapter plate.

GASKET RECOMMENDATIONS: Fel-Pro P/N 1262 or equivalent has a port opening 2.10” tall by 1.28” wide (2.66 sq. in.

opening area). P/N 1262-R is 2.25” tall by 1.40” wide (3.12” sq. in. opening area) or equivalent.

INSTALLATION INSTRUCTIONS

Catalog #2934

1. Fully clean all traces of old gasket material and sealant from all of sealing surfaces. Apply Edelbrock Gasgacinch to both

the head intake flange and back of gasket. Let dry and install gasket to head.

2. Do not use cork or rubber end seals. Use RTV silicone sealer instead. Apply a ¼” high bead across each block end seal

surface, overlapping the intake gasket at the four corners. This method will eliminate end seal slippage and

deterioration.

3. For ease of installation and a cleaner look, we recommend using Edelbrock Manifold Bolt and Washer Kit #8524.

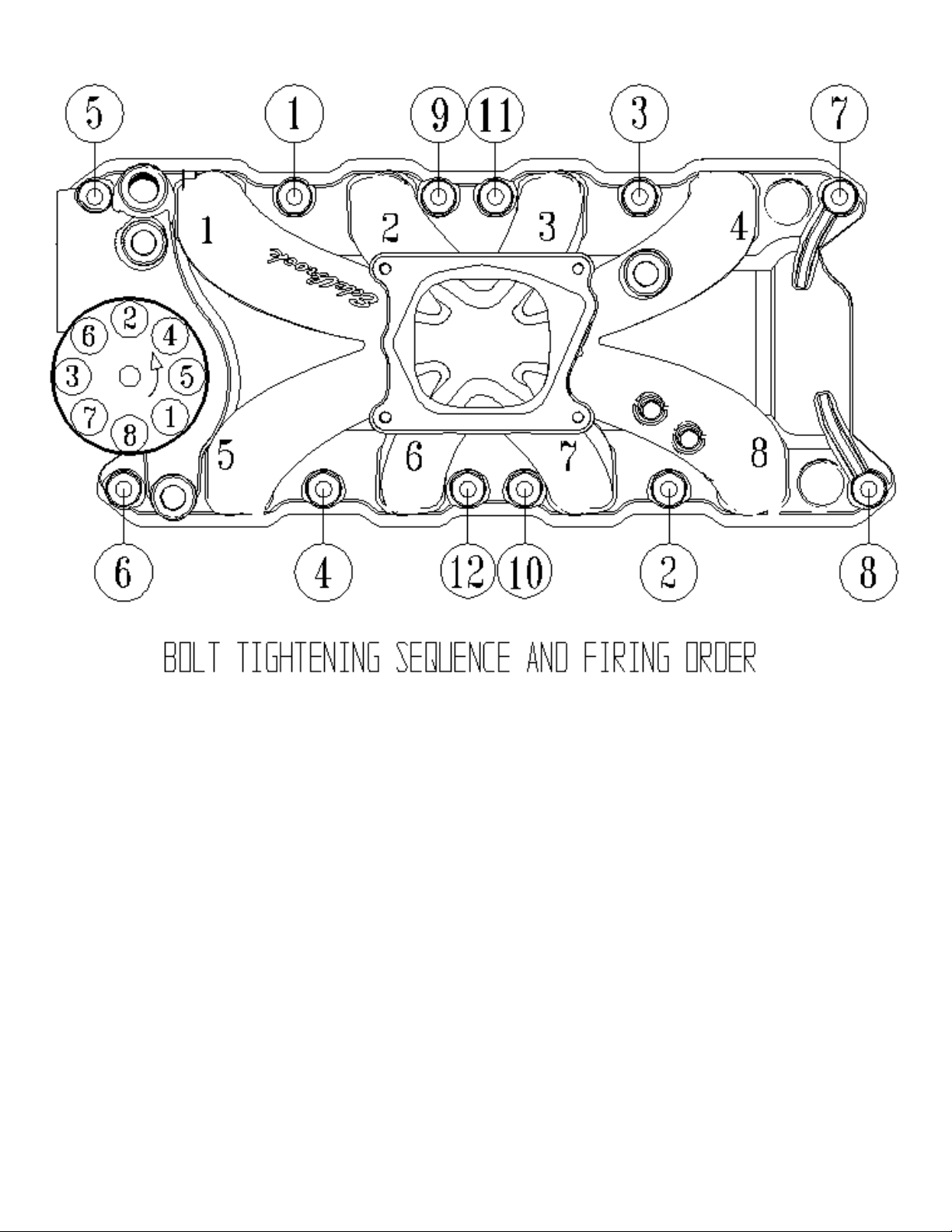

Manifold Torque: See figure 1. On early model factory heads there is no support underneath manifold boltholes circled 5,

6, 7, and 8. These bolts need to be hand tightened with a short box end wrench being very careful not to damage the

manifold. Torque all other bolts in the sequence to 15-18 ft-lbs.

PREP AND TUNING FOR POWER:

Optimum cylinder head port opening size should be as close as possible to the size of the gasket being used. Port-match the

manifold exits .020” per side smaller than either the gasket being used or the cylinder head port opening, whichever is

smaller.

FIRING ORDERS: Standard 302 – 1-5-4-2-6-3-7-8

Certain 302’s and 351’s use – 1-3-7-2-6-5-4-8.

©2001 Edelbrock Corporation Rev. 11/01

Brochure No. 63-0049

Page 2

Figure 1 – Bolt tightening sequence.

PLEASE complete and mail your warranty card. Be sure to write the model number of his product in the

“Part #________” space.

THANK YOU.

Edelbrock Corporation ••2700 California Street ••Torrance, California 90503

©2001 Edelbrock Corporation Rev. 11/01

Brochure No. 63-0049

Loading...

Loading...