Page 1

©2003 Edelbrock Corporation

Rev. 3/03

Page 1 of 2

Catalog #2886

Brochure #63-0177

Victor 383 Chrysler Intake Manifold

For Chrysler 361, 383, and 400 c.i.d. engines

Catalog #2886

INSTALLATION INSTRUCTIONS

Please study these instructions carefully before installing your new intake manifold. If you have any questions or

problems, please call our Technical Hotline at: 1-800-416-8628, 7:00 am - 5:00 pm, Pacific Standard Time, Monday

through Friday or e-mail us at edelbrock@edelbrock.com

. Please fill out and mail your warranty card.

DESCRIPTION: The Edelbrock Victor 383 manifold has been designed for 361, 383, and 400 c.i.d., as well as stroker

engines based on big-block Chrysler B engines. It is not compatible with 1962-64 Max Wedge cylinder heads. This

manifold is recommended for high performance, race vehicles only. The Victor 383 manifold provides good throttle

response and increases performance above the 5000 rpm range. It also provides horsepower and torque increases within

the listed rpm range, when used with any mix of aftermarket equipment available for vehicles operating within that range.

MANIFOLD FEATURES:

•

Single plane design

• Carburetor pad designed for spread bore or square bore carburetors (dual bolt pattern)

• Nitrous bosses

MANIFOLD SPECIFICATIONS:

•

Hood clearance similar to that of a Performer RPM

• Runner average cross-sectional area is 3.25 sq. in.

• Operating range is 3500 to 7500 rpm (could vary depending on engine size, bore and stroke combination).

•

Manifold height 6.13" (end seal-carb pad is flat)

POWER OPTIONS: Although this manifold will work with ported factory cast iron heads, we highly recommend the use

of either our # 60929 RPM heads or our #60189 RPM cylinder heads. These heads offer higher airflow levels with

minimum preparation required. See our catalog for details. To order a catalog, call (800) FUN-TEAM.

CARBURETOR RECOMMENDATIONS: This manifold is designed to use square bore and can be modified for spread bore

carburetors. The use of an adapter may ease the conversion to thermo-quad carburetors. The use of Dominator style

carburetors requires an adapter plate.

GASKET RECOMMENDATIONS: Fel-Pro P/N 1215 or equivalent has a port opening 2.27" tall by 1.23" wide (2.76 sq. in.

opening area). With custom gaskets trimming is needed if larger area is desired.

1. Fully clean all traces of old gasket material and sealant

from all of sealing surfaces. Wipe surfaces with rags

and lacquer thinner.

2. Apply Edelbrock Gasgacinch sealant #9300 or

equivalent to intake paper gasket and head. Allow a

few minutes to become tacky and attach gasket to

cylinder head.

3. Apply a small amount of Silicone sealant to paper

gasket intake side, next apply a small amount of

silicone to block side of the valley pan front and rear.

Install pan and secure with factory hardware.

4. Apply Edelbrock Gasgacinch sealant #9300 or

equivalent to intake paper gasket and valley pan. Allow

a few minutes to become tacky and attach gasket to

valley pan.

5. Apply a small amount of Silicone sealant to paper

gasket intake side, next rest intake on gaskets and

align boltholes. Manifold Torque sequence listed below.

6. For ease of installation and a cleaner look, we

recommend using Edelbrock Manifold Bolt and Washer

Kit #8594.

INSTALLATION INSTRUCTIONS

®

Page 2

©2003 Edelbrock Corporation

Rev. 3/03

Page 2 of 2

Catalog #2886

Brochure #63-0177

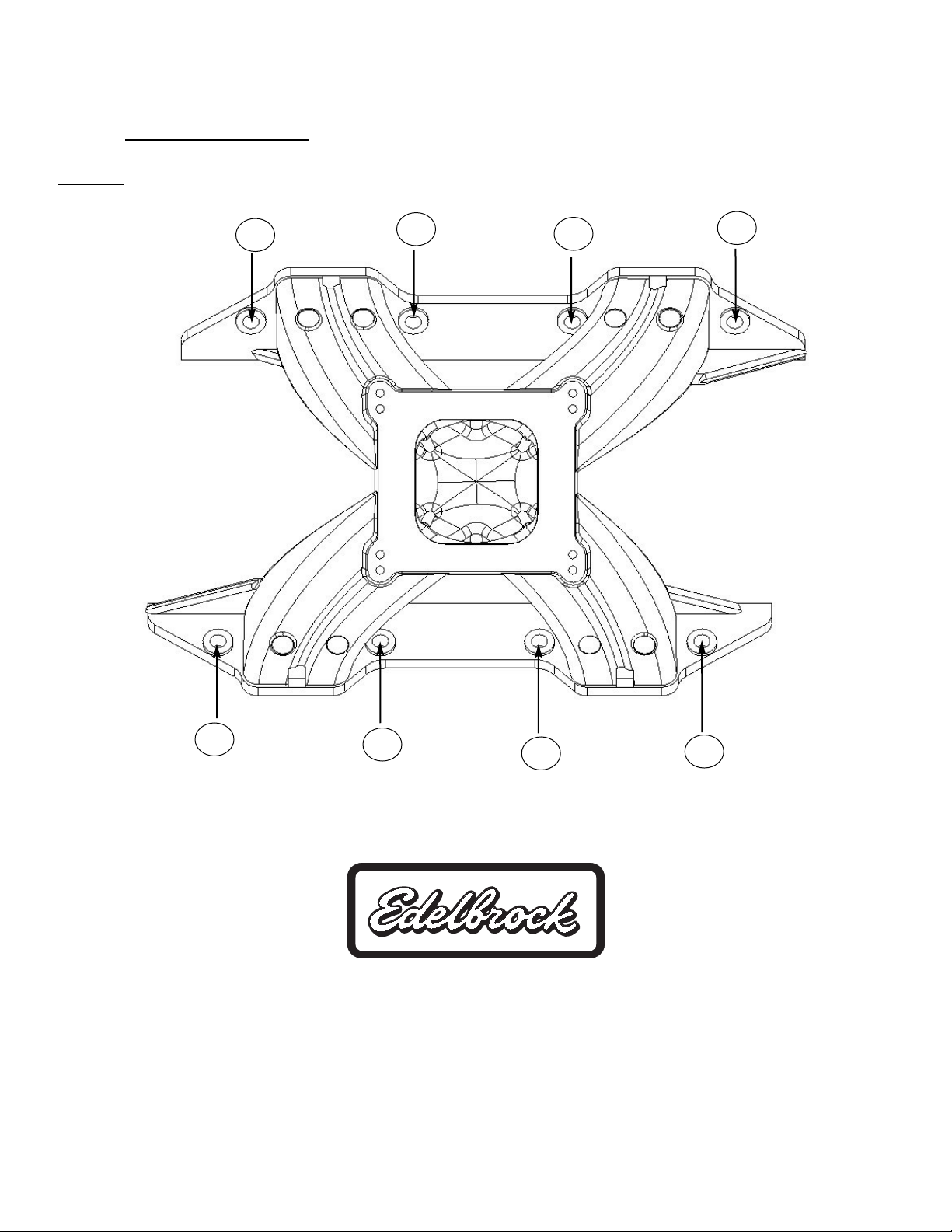

MANIFOLD TORQUE: Torque all bolts in the sequence to 25 ft-lbs. See figure 1.

PREP AND TUNING FOR POWER:

Optimum cylinder head port opening size should be as close as possible to the size of the gasket being used. Port-match

the manifold exits .020" per side smaller than either the gasket being used or the cylinder head port opening, whichever

is smaller

.

Edelbrock Corporation

2700 California Street

Torrance, CA 90503

Toll-Free Tech Line: 1-800-416-8628

Office: 310-781-2222

Tech Fax: 310-972-2730

Tech E-Mail: edelbrock@edelbrock.com

6

4

2

8

7

3

1

5

Fig. 1

®

Loading...

Loading...