Page 1

©2007 Edelbrock Corporation

Brochure #63-16041 of 6

Catalog #1604, 1606, 1607, 1624, 16041 & 16061

Rev. 3/07 - RS/mc

PERFORMER RPM™ CNC MACHINED CYLINDER HEADS

For 1984 & Later Harley-Davidson

®

Evolution®“Big Twin” Engines

Catalog #1604, 1606, 1607, 1624, 16041 & 16061

INSTALLATION INSTRUCTIONS

PLEASE study these instructions carefully before beginning this installation. Most installations can be accomplished with common tools and

procedures. However, you should be familiar with and comfortable working on your vehicle. If you do not feel comfortable performing this installation,

it is recommended to have the installation completed by a qualified mechanic. If you have any questions, please call our Technical Hotline at:

1-800-416-8628, 7:00 am - 5:00 pm, Pacific Standard Time, Monday through Friday or e-mail us at Edelbrock@Edelbrock.com

. If your question

is motorcycle carburetor-related, please call our Edelbrock Motorcycle Carburetor division at 1-877-888-7504, Ext. 2.

IMPORTANT NOTE: Proper installation is the responsibility of the installer. Improper installation

will void your warranty and may result in poor performance and engine or vehicle damage.

DESCRIPTION: The Edelbrock Performer RPM™ Cylinder Heads are designed to provide increased performance in the idle to 6000+ RPM range, in

1984 and later, 80-inch and larger, Evo Big Twin engines. They feature a CNC-machined, rectangular intake port to provide a noticeable increase in

air flow. The intake port is also raised .125" to help increase the velocity of the incoming air for more power. Edelbrock intake manifolds must

be used with these heads due to the unique port shape (see application chart below). The dual-quench combustion chamber features a

revolutionary new design that promotes a better mix and more efficient combustion. The CNC-machined, “D” shaped exhaust port provides a larger

area for increased flow, and is designed to create a mis-match between the exhaust pipe and the exit to reduce power-robbing exhaust reversion.

Performer RPM™ heads #1604, 1606, 1607, 1624, 16041, & 16061 fit 1984 and later Evolution

®

"Big Twin" engines. Performer RPM™ cylinder heads

are assembled with stainless steel valves (1.940" intake and 1.625" exhaust), ductile iron valve seats and guides, 1.460" O.D. heavy-duty valve

springs, teflon valve stem seals, and machined valve spring retainers and locks. The increased valve sizes require the use of aftermarket or modified

pistons. In 80-inch Evo engines, we recommend using Edelbrock/JE Sportsman Pistons, which match the uniquely shaped combustion chambers of

the Performer RPM cylinder heads. Other engine sizes require modified stock, or other aftermarket pistons.

INTAKE MANIFOLD APPLICATION CHART - Performer™ Cylinder Heads

3-Piece 3-Piece 3-Piece S&S

Cyl. Length

S&S Kit Flange Intake Spigot Intake “G”

Intake

stock (80") -- #1671 #1670 #1669

stock 89" #1671 #1670 #1669

-.050" 93" #1676 #1677 #1683

-.175" 88" #3031 #3030 #3032

+.015" 96" #1671 #1670 #1669

+.075" 98" #1674 #1675 #1684

IMPORTANT NOTES BEFORE BEGINNING INSTALLATION

• It is recommended that the installation of Performer RPM cylinder heads be performed by a qualified engine builder with experience in high

performance or racing modifications to Harley-Davidson®engines.

• If you are using any cam other Edelbrock Performer RPM cam #1740, it is mandatory that valve-to-valve clearance is checked to

determine if these heads are compatible with the camshaft you intend to run. See Page 2.

REPLACEMENT ITEMS

The following replacement items are available separately:

Exhaust Seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .#1643

Intake Seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .#1644

Exhaust Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .#1645

Intake Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .#1646

Exhaust Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .#1647

Intake Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .#1648

Page 2

©2007 Edelbrock Corporation

Brochure #63-16042 of 6

Catalog #1604, 1606, 1607, 1624, 16041 & 16061

Rev. 3/07 - RS/mc

1. Before installing heads on engine, remove valve springs, retainers

and locks from one head. Leave the valve seals on to hold the

valves in position during the clearance check.

2. Use a 6" caliper to measure valve tip height from the valve spring

pocket.

3. Find the cam manufacturer’s "Valve lift at Top Dead Center" specs

and subtract this dimension from the valve tip height you measured

in step 2.

4. Using the calipers to check the new valve tip height, open the valve

by the amount calculated in step 3.

5. Repeat this process for the other valve. Note that intake and

exhaust "Valve lift at Top Dead Center" dimentions are usually

different.

6. With both intake and exhaust valves open to the correct

specifications, use a .060" feeler gage to check clearance between

the valve heads. If less than .060" clearance exists, you run the risk

of valves hitting during engine operation, voiding any warranty on

these cylinder heads. If there is less than .060" clearance, select

another cam for your engine.

CHECKING VALVE-TO-VALVE CLEARANCE

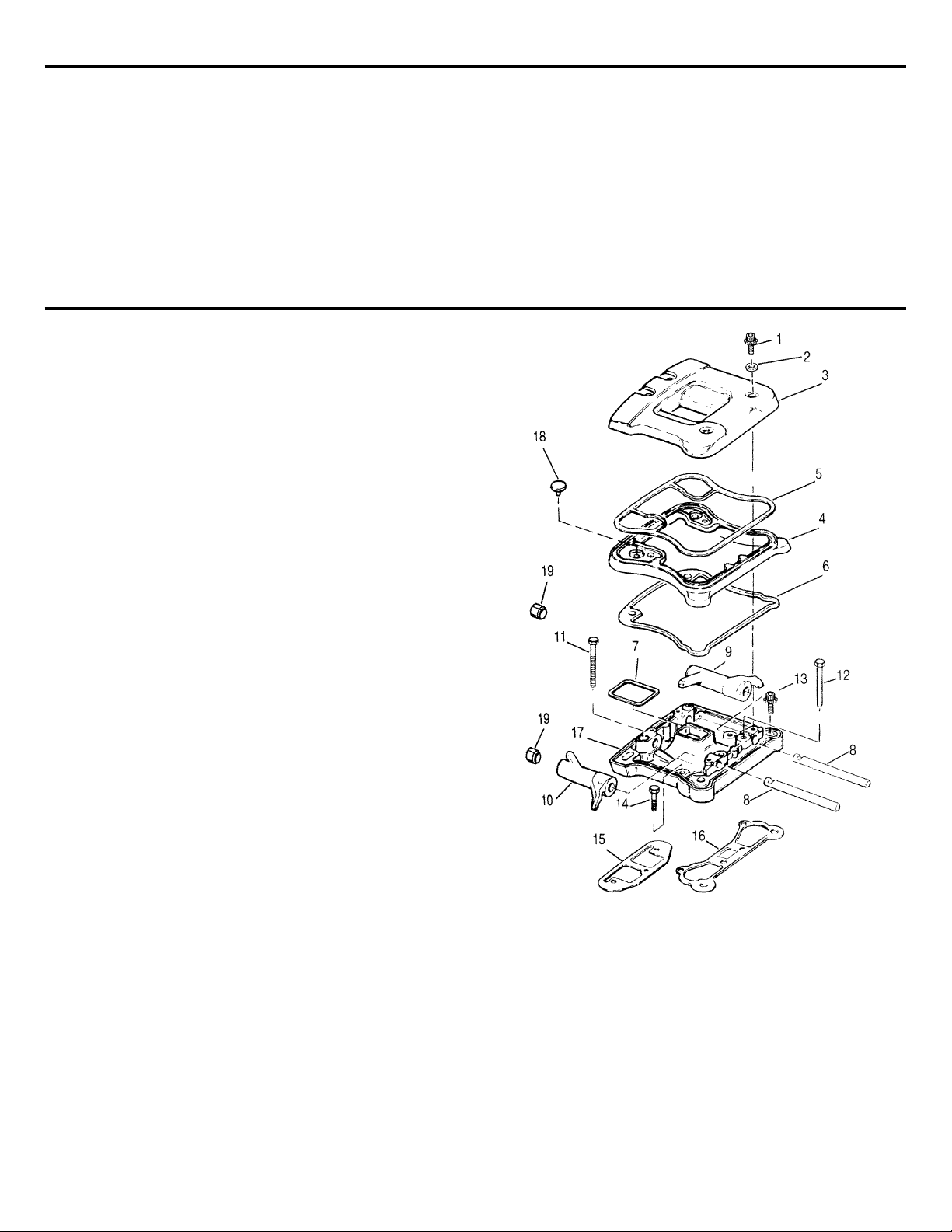

1. Bolt (4)

2. Seal (4)

3. Upper rocker arm cover

4. Middle rocker arm cover

5. Gasket

6. Gasket

7. Gasket

8. Rocker arm shaft (2)

9. Rocker arm

10. Rocker arm

DISASSEMBLY

11. Bolt and washer (2)

12. Bolt and washer (2)

13. Bolt and washer (3)

14. Bolt and washer (3)

15. Gasket

16. Gasket

17. Lower rocker arm cover

18. Umbrella valve

19. Rocker arm bushing (4)

WARNING

To avoid accidental start-up of vehicle and possible personal

injury, disconnect the battery cables (negative cable first) before

performing any of the following procedures.

1. Remove seat.

2. Remove instrument cover (FX/Softail and Dyna Glide models).

3. Drain fuel tank. Disconnect fuel line and plug end of fuel line with

5/16" bolt. For split tanks use a 1/4" bolt and rubber cap to plug

fuel line and opening. Disconnect any wires from tank. Remove fuel

tank.

WARNING

Gasoline is flammable and fumes are explosive. To

avoid possible personal injury, drain gasoline in well

ventilated area away from fire or flame. Drain

gasoline into approved gasoline container only.

NOTE: FX/Softail Models

An access hole has been provided through the frame to

remove the left rear rocker box bolt. A rolled up paper tube

should be inserted through the hole in the frame and around

the bolt head during removal, to prevent accidentally

dropping the bolt into the frame opening.

4. Remove upper cylinder head stabilizer from frame and cylinder head

bracket. Do not loosen stabilizer jam nuts.

5. On FXR model remove ignition switch.

6. Remove spark plugs.

7. On FLT models remove lower attaching bolts from right side

footboard.

8. Remove exhaust system.

9. Remove air cleaner cover, filter element and back plate.

10. Remove fuel and V.O.E.S. (Vacuum Operated Electric Switch) hoses

from carburetor.

11. Remove carburetor.

12. Remove intake manifold flange screws and remove intake manifold.

13. Support engine with small jack and piece of wood, then remove

large center bolt from front engine mount. On some bikes, it may be

necessary to remove ignition module first.

14. Remove bolt from outer end of front stabilizer.

15. Remove both front engine mount bolts and remove front engine

mounting plate with stabilizers.

16. Use the jack to raise and lower engine as needed for clearance.

Figure 1 - Rocker Arm Cover Assembly.

Page 3

©2007 Edelbrock Corporation

Brochure #63-16043 of 6

Catalog #1604, 1606, 1607, 1624, 16041 & 16061

Rev. 3/07 - RS/mc

REMOVE ROCKER ARM COVERS

1. Remove bolts (1) and seals (2)

(See Figure 1)

. Use a shortened

3/16" allen wrench.

2. Remove top (3) and middle (4) sections of rocker box. Remove

gaskets (5, 6, and 7) and discard.

3. Rotate the engine so both valves are closed on the head being

removed.

4. Remove the rocker arm retaining bolts (11) and washers nearest the

rocker arm shafts at the push rod end.

NOTE: Remove lower rocker boxes as an assembly then

disassemble if necessary.

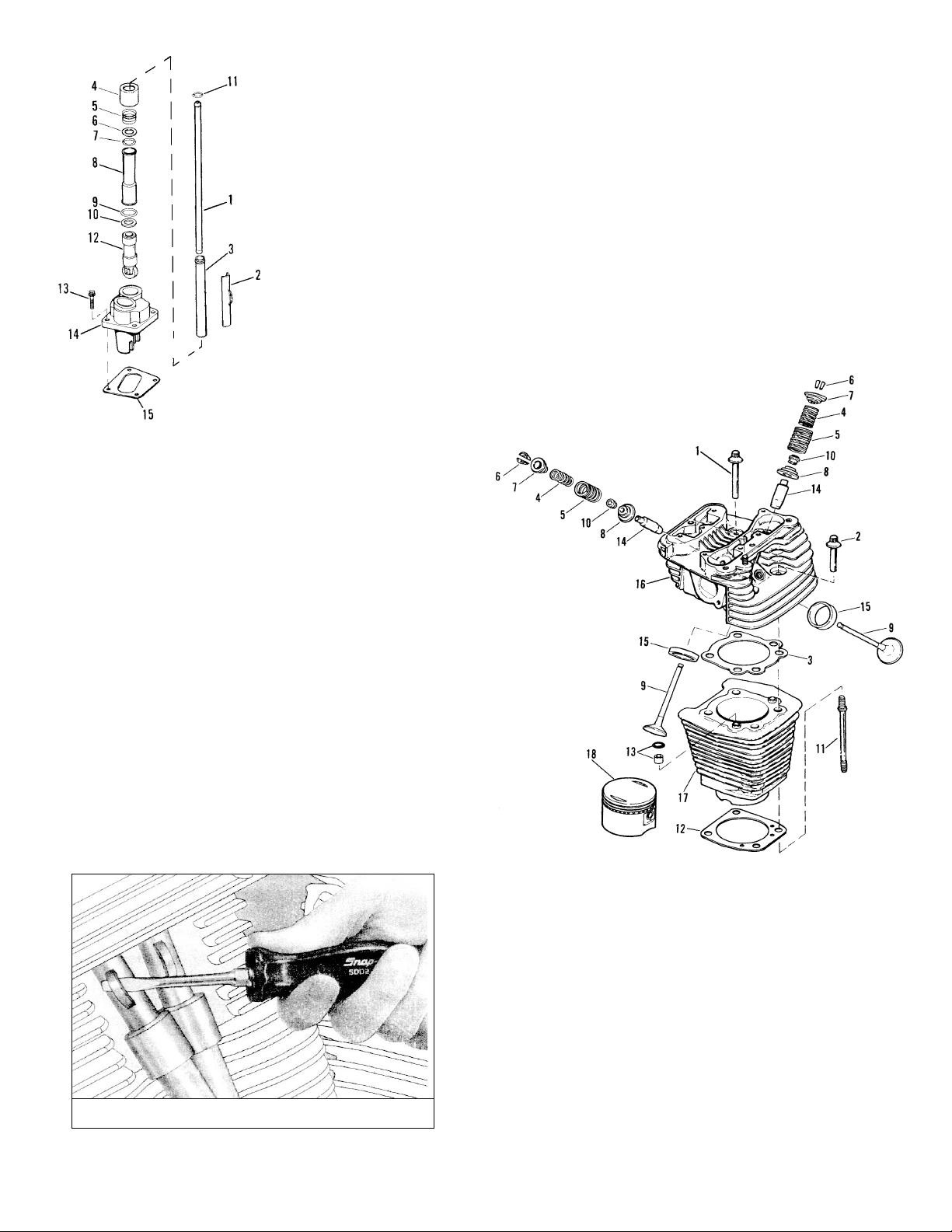

5. Remove the push rods (1) and mark their location and orientation,

top and bottom

(See Figure 2)

.

6. Remove spring cap retainers (2) on push rod covers and remove

push rod covers and associated parts (3 through 11)

(See Figures

2 & 3)

.

CAUTION

All valve train components must be reinstalled in their

original positions. Remove Spring Cap Retainers.

1. Push rod (2)

2. Spring cap retainer (2)

3. Upper push rod cover (2)

4. Spring cap (2)

5. Spring (2)

6. Spacer (2)

7. O-ring (2)

8. Lower push rod cover (2)

9. O-ring (2)

10. Spacer (2)

11. O-ring (2)

12. Tappet (2)

13. Bolt (4)

14. Lifter guide (2)

d15. Gasket (2)

Figure 2 - Pushrod and Cover Assembly

Figure 3 - Removing Spring Cap Retainers

7. Remove the remaining fasteners (12, 13 and 14) holding the lower

rocker arm cover (17) to the cylinder head

(See Figure 1)

.

8. Remove the lower rocker cover and gaskets (15 and 16).

9.

See Figure 4

. Loosen each head bolt (1, 2) 1/8 turn following the

cross pattern sequence shown in

Figure 9

CAUTION

Loosen head bolts gradually, in a cross pattern, to

prevent distorting the head, cylinder and crankcase

studs.

10. Continue loosening in 1/8 turn increments until bolts are loose.

11. Remove bolts.

12. Remove cylinder head and head gasket.

13. Repeat steps 1 through 14 for the other head.

NOTE: It may be necessary to raise or lower engine in frame

for clearance. Use small jack under engine.

1. Head bolt, long (2)

2. Head bolt, short (2)

3. Cylinder head gasket

4. Inner valve spring (2)

5. Outer valve spring (2)

6. Valve keeper (4)

7. Upper collar (2)

8. Lower collar (2)

9. Valve (1) intake, (1) exhaust

10. Valve stem seal (2)

11. Cylinder stud (4)

12. Cylinder base gasket

13. O-ring and insert (2)

14. Valve guide (2)

15. Valve seat (2)

16. Cylinder head (2)

17. Cylinder (2)

18. Piston

Figure 4 - Cylinder Head and Cylinder

Page 4

©2007 Edelbrock Corporation

Brochure #63-16044 of 6

Catalog #1604, 1606, 1607, 1624, 16041 & 16061

Rev. 3/07 - RS/mc

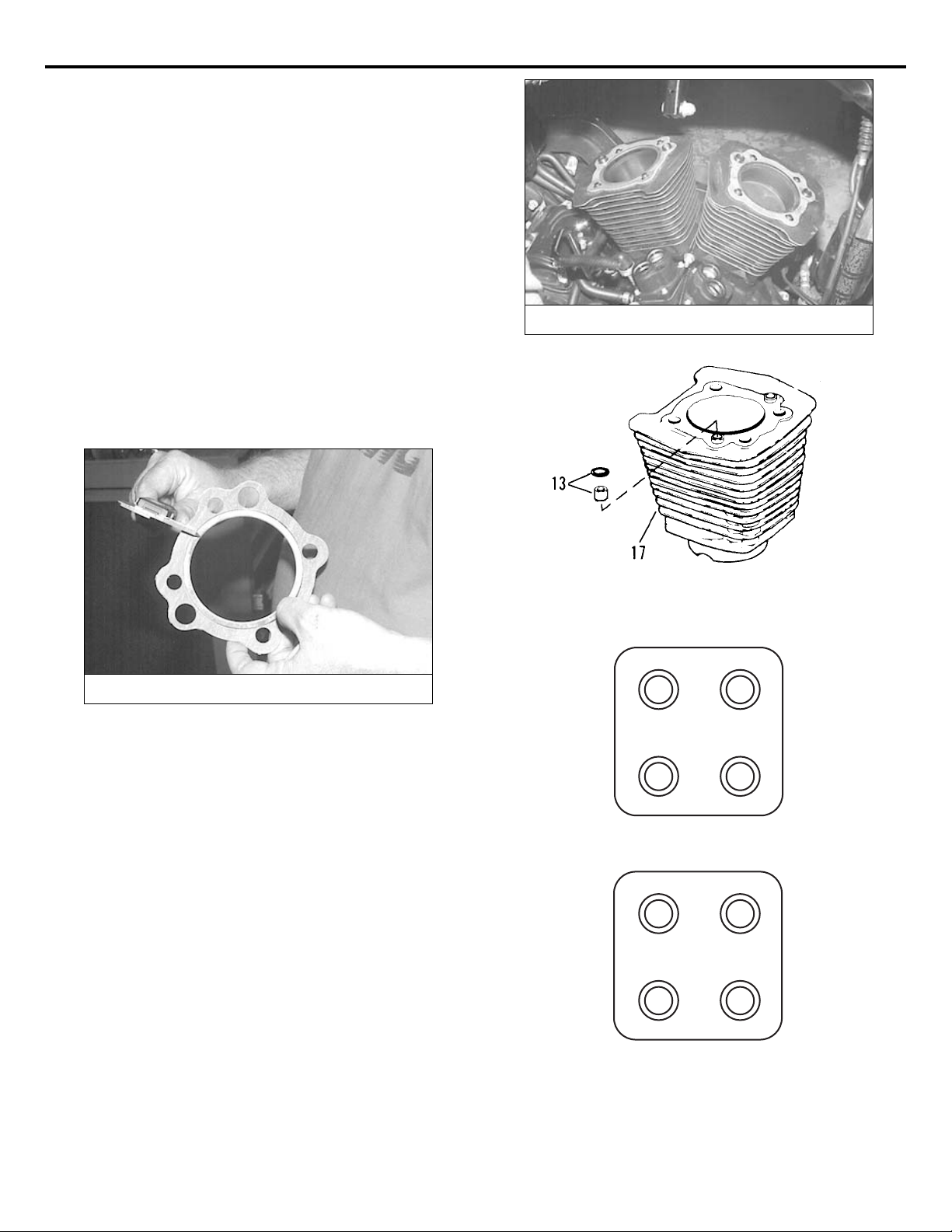

CYLINDER HEAD INSTALLATION

CAUTION

Install new O-rings over the cylinder dowels before

installing the head gasket. Install the O-rings first to

ensure alignment of the head gasket and prevent

gasket leaks.

CAUTION

Use only original equipment specification head bolts

and other hardware. All original hardware is

hardened grade 8 material, which is required for

proper performance of these parts.

1. Be sure the gasket surfaces and stud holes are clean and dry

(See

Figure 6)

. Place new O-rings (13) on the cylinders and position the

head gaskets on the inserts (13)

(See Figure 7)

.

2. Dip the head bolt threads and bottom face of bolt head in oil; then

wipe off any excess. Install the head bolts (1 and 2, Figure 4) finger

tight.

HEAD GASKETS

You must use the correct head gaskets to achieve a 9.5:1

compression ratio for best power. Thicker gaskets will lower

compression and power, and thinner gaskets will raise compression

higher than advisable for use with today's unleaded pump gasoline.

1. Use Edelbrock gasket set #1640 for 1984-91 or #1641 for

1992 and later engines. This set includes the proper thickness

head gaskets (.045") and the special intake manifold gaskets

required for these cylinder heads.

2. You may use standard Harley-Davidson

®

head gaskets, if desired.

They vary in thickness, so it is advisable to measure your gasket

before use

(See Figure 5)

. Recommended thickness is .045".

CAUTION

If you use copper head gaskets, be aware that they

must be properly annealed prior to installation. Even

if gaskets were annealed when new, copper can reharden during storage. Failure to anneal before

installation may lead to head gasket failure.

INSTALLATION PROCEDURE

Figure 5 - Measuring Cylinder Head Gasket

Figure 7 - Cylinder O-Rings and Inserts

Figure 6 - Cleaning Gasket Surfaces

Figure 8 - Cylinder Head Bolt Torque Sequence

1

Front cylinder

2

2

Rear cylinder

1

3

4

4

3

Page 5

©2007 Edelbrock Corporation

Brochure #63-16045 of 6

Catalog #1604, 1606, 1607, 1624, 16041 & 16061

Rev. 3/07 - RS/mc

PUSH ROD INSTALLATION

1. Rotate the engine so that both lifters of the cylinder being serviced

are on the base circle (lowest position) of the camshaft.

NOTE: When using an aftermarket performance camshaft,

such as Performer RPM, which is dyno matched and

recommended for use with Performer RPM Cylyinder Heads,

you must use an adjustable pushrod kit such as Edelbrock

#1737. Refer to the instructions provided with your pushrod

kit for the proper valve adjustment procedure. Complete this

adjustment procedure BEFORE performing the final pushrod

installation.

2. Refer to

Figure 1

. Install push rod covers and associated parts,

using new O-rings. Install push rods.

NOTE: Be sure to use new O-rings on push rod tubes to

prevent leaks. Also check carefully to be certain old O-rings

were removed from push rod tubes and lifter bores.

3. Install gaskets (15 and 16). Place lower rocker box assemblies (17;

with rocker arms and shafts) in position.

NOTE: Rocker arm shafts are notched to accept the rocker

arm retaining bolts. Align the notches with the bolt holes

before installing the bolts (See Figure 10).

3. Cylinder Head bolt torque sequence

(See Figure 8)

:

The procedure for tightening the head bolts is extremely critical; not

only to prevent gasket leaks, but to prevent stud failure and heads

and cylinders distortion.

CAUTION

Be sure you thoroughly clean and lubricate the

cylinder head bolts before tightening to the correct

torque. Friction because of dirt or grime will cause

the torque wrench readings to be incorrect. Clean

and lubricate the threads with engine oil and screw

the bolts onto the crankcase studs by hand to be sure

there is no friction.

A. Cylinder Head Torque Sequence for 1984-85 Models

CAUTION

Use only original equipment head bolts and studs

for your year vehicle to ensure proper torque and

head gasket life.

1.

See Figure 8

. With a torque wrench, start at the

cylinder head bolt numbered "1" and tighten to 7-9

ft./lbs. Then tighten "2", "3", and "4" in order to 7-9

ft./lbs.

2. Following the torque sequence, tighten each bolt to

15-17 ft./lbs.

3. Following the torque sequence, tighten each bolt to

24-26 ft./lbs.

CAUTION

The cylinder head bolts are not

to be checked

for tightness after final torquing at reassembly

is completed. Retightening the bolts to

specified torque at regular intervals will place

undue stress on bolts and bolt anchoring

threads.

B. Cylinder Head Torque Sequence for 1986-95 Models

CAUTION

Use only original equipment head bolts and studs

for your year vehicle to ensure proper torque and

head gasket life.

1.

See Figure 8

. With a torque wrench, start at the

cylinder head bolt numbered "1" and tighten to 7-9

ft./lbs. Then tighten "2", "3", and "4" in order to 7-9

ft./lbs.

2. Following the torque sequence, tighten each bolt to

12-14 ft./lbs.

3.

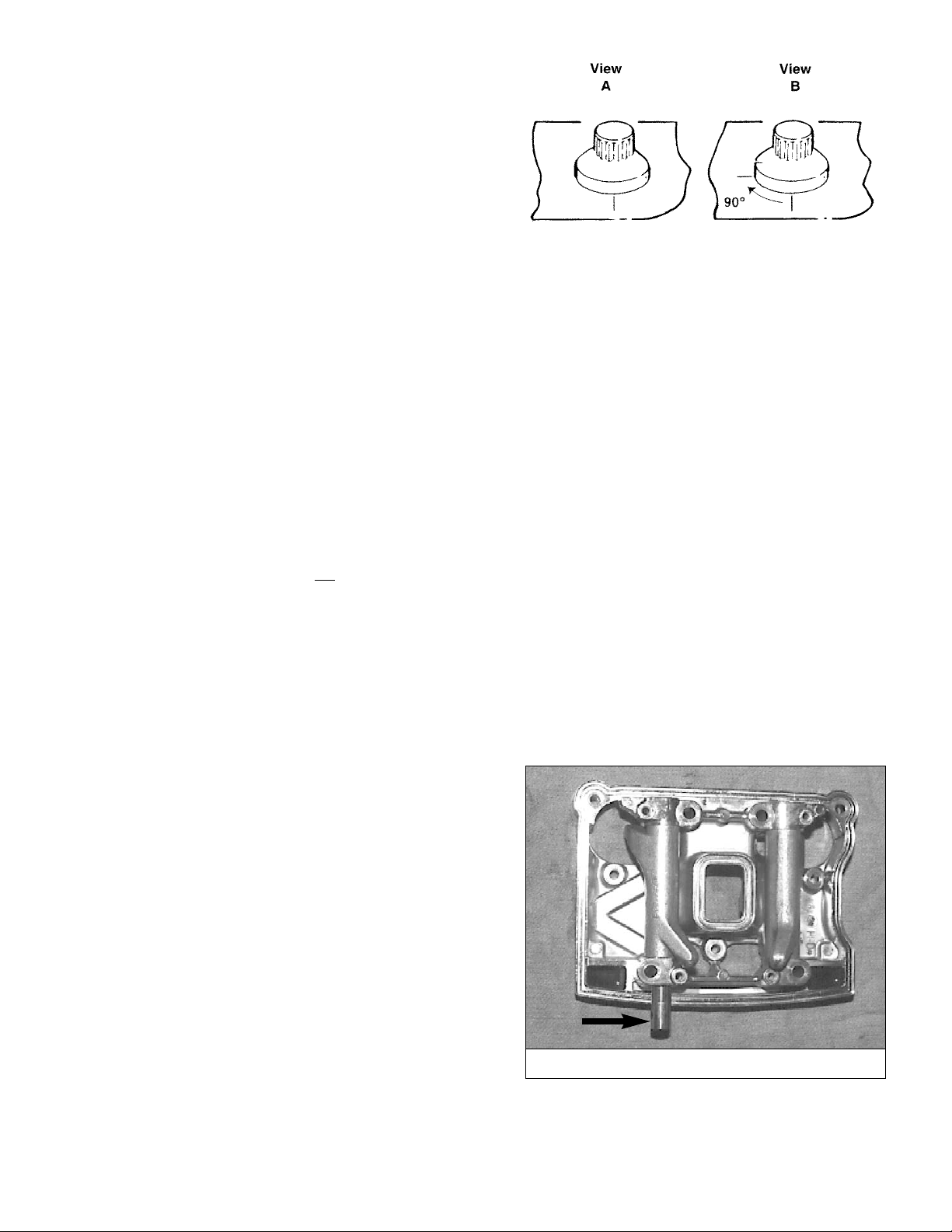

See Figure 9

. Mark a line on the cylinder head and

a corresponding line on the head of the cylinder head

bolt as shown in View A. Following the same

sequence 1, 2, 3, then 4, turn each bolt, one at a time

one quarter turn (90°) using the marks as a guide.

When marks are all positioned, as in View B, the

procedure is completed.

Figure 9 - Tightening 1986-1995 Head Bolts

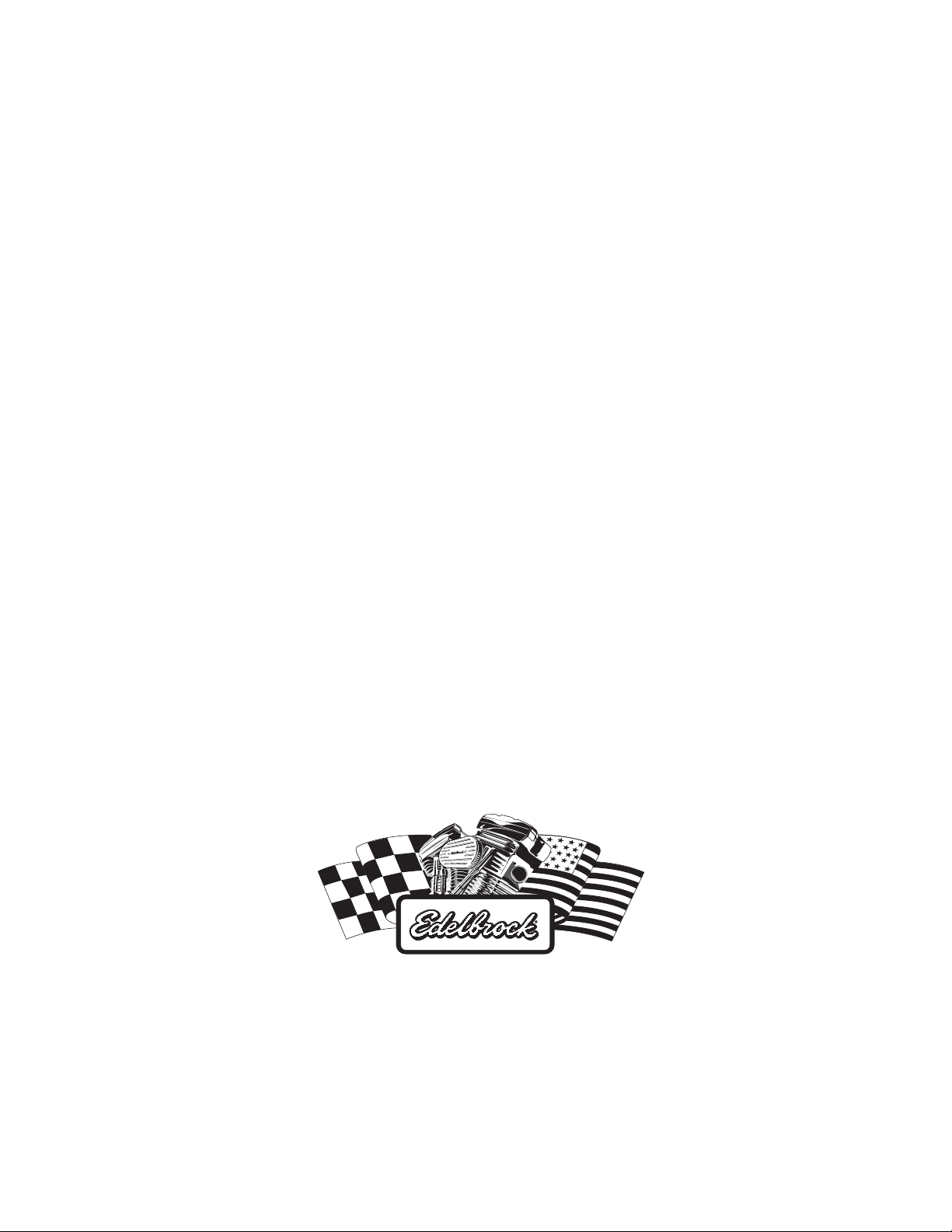

Figure 10 - Rocker Arm Shaft Bolt Notches

Page 6

©2007 Edelbrock Corporation

Brochure #63-16046 of 6

Catalog #1604, 1606, 1607, 1624, 16041 & 16061

Rev. 3/07 - RS/mc

4. Install bolts and washers (11 and 12, 13 and 14). Slowly snug lower

rocker box fasteners in small increment (one at a time) in a cross

pattern. This will bleed the lifters. Check carefully as you go to be

certain push rods are still in their proper position in the rocker arm.

Tighten the 5/16" bolts (11, 12) to 15-18 ft./lbs. and tighten the 1/4"

bolts (13, 14) to 10-13 ft./lbs.

CAUTION

Do not turn engine over until push rods spin freely.

Damage could occur to valves.

4. Install the middle (4) and top (3) rocker arm covers, using new

gaskets and new fiber seals. The fiber seals must be under the steel

washers. Be sure the middle cover section is spaced evenly on all

sides before tightening the cover screws. Tighten the screws to 1013 ft./lbs. following a crisscross pattern. If a torque wrench cannot

be used, tighten securely by hand.

Edelbrock Corporation • 2700 California St. • Torrance, CA 90503

Tech-Line: 1-800-416-8628 • E-Mail: Edelbrock@Edelbrock.com

The words Evolution, Harley and Harley-Davidson are registered trademarks of

Harley-Davidson, Inc., Milwaukee, Wisconsin, USA and are used in this

instruction sheet for reference only.

Edelbrock is a registered trademark of Edelbrock Corp, Torrance, CA, USA.

5. Install the intake manifold according to the instructions provided

with the intake manifold.

6. Install the carburetor, V.O.E.S. and ignition components.

7. Reassemble all components removed during disassembly, connect

battery cables, and re-fuel gasoline tank.

8. To prevent discoloration when the engine reaches operating

temperature, carefully wipe off grease, fingerprints, stains, etc.,

from all chrome and polished surfaces with a lint-free cloth and

alcohol, Windex, etc., before starting engine.

Loading...

Loading...