Eddie Motorsports MS100-03S User Manual

MS100-03S Power Steering Banjo Fitting Instructions

The enclosed banjo compression fitting is designed for use with Teflon lined braided stainless

steel hose with .030” wall thickness . Care must be taken when mounting the fitting onto the line

to insure that it is installed correctly. Please read the instructions thoroughly before attempting

to assemble the hose and fitting.

Determining pressure line length: With the pulley system installed and the banjo compression

fitting screwed into the power steering pump , loosely route the hose to the steering box or rack

& pinion unit to determine the length. Be sure to avoid any moving parts or sharp bends. Mark

the hose for the cut length.

Cutting braided stainless hose: Place the compression nut from the banjo fitting over the hose

before you cut it to length!

Unscrew the compression nut from the tube on the banjo fitting and set aside the brass ferrule

that is enclosed. Place the nut over your hose with the threaded side facing the end of the hose.

When cutting braided stainless hose it is easier to do so with a chop saw or cut off wheel (as thin

a wheel as you can find). Wrap the hose with tape at the cutting point. This will help to prevent

most of the fraying that often occurs when cutting braided stainless hose.

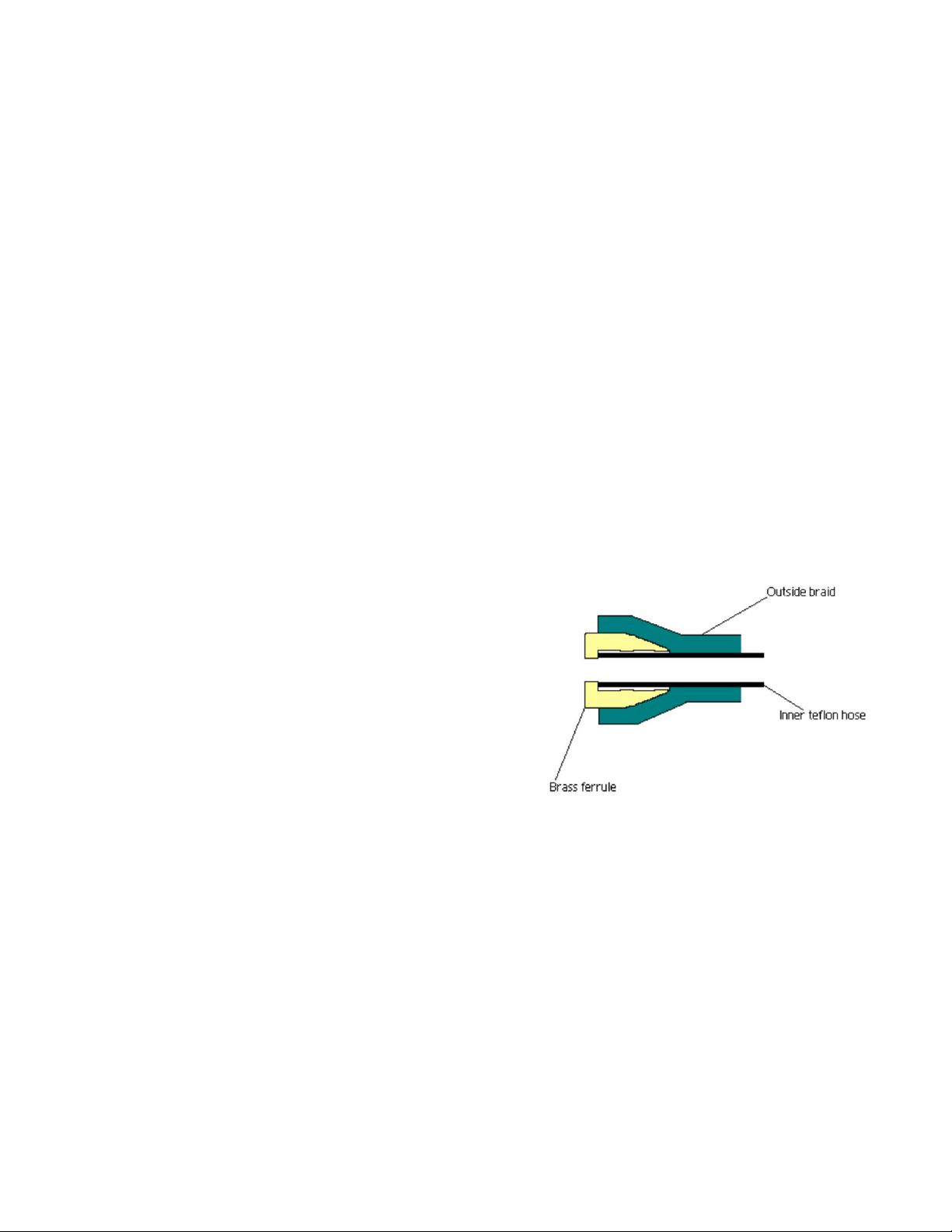

Banjo compression fitting installation: Remove any tape that was left on the end of the hose

from cutting. Place the tapered end of the brass

ferrule onto the end of the hose (as shown). It is

important to make sure that the Teflon hose is

completely pushed up inside the brass ferrule until it

stops at the back edge of ferrule (as shown below).

Use transmission or hydraulic fluid to lubricate the

tube end of the banjo fitting. Insert the tube through

the ferrule and into the Teflon line making sure that

you don’t pinch or tear the inner Teflon hose. Tighten the nut to approximately to 15ft/lbs.

Loading...

Loading...