INSTRUCTION MANUAL

MODEL 441A

FREQUENCY-TO-VOLTAGE

CONVERTER

The information contained in this manual is proprietary. Permission to reproduce all or

part must first be obtained in writing from this company.

Ectron Corporation reserves the right to make specification changes at any time.

LIFE-SUPPORT POLICY: Ectron products are not authorized for use in life-support

devices or systems without the express, written approval of the President of

Ectron Corporation.

Copyright 1996 Ectron Corporation

Ectron Corporation 8159 Engineer Road

All rights reserved San Diego, CA 92111-1907

U.S.A.

Revised September, 2015 858-278-0600

800-732-8159

For units with serial numbers

62230 and above. Fax: 858-278-0372

www.ectron.com

sales@ectron.com

All Ectron instruments are warranted against defects in material and workmanship for one year

from the date of shipment to the original purchaser. Ectron agrees to repair or replace any

assembly or components (except expendable items such as fuses, lamps, batteries, etc.) found to

be defective during this period. Ectron's obligation under this warranty is limited solely to

repairing or replacing, at its option, an instrument that in Ectron's sole opinion proves to be

defective within the scope of the warranty when returned to the factory or to an authorized

service center. Transportation to the factory or service center is to be prepaid by the purchaser.

Shipment should not be made without the prior authorization of Ectron. This warranty does not

apply to products repaired or altered by persons not authorized by Ectron, or not in accordance

with instructions furnished by Ectron. If the instrument is defective as a result of misuse,

improper repair, alteration, neglect, or abnormal conditions of operation repairs will be billed at

Ectron's normal rates. Ectron assumes no liability for secondary charges of consequential

damages as a result of an alleged breach of this warranty; and in any event, Ectron's liability for

breach of warranty under any contract or otherwise shall not exceed the purchase price of the

specific instrument shipped and against which a claim is made. This warranty is in lieu of all

other warranties, expressed or implied; and no representative or person is authorized to represent

or assume for Ectron any liability in connections with the sale of our products other than is set

forth herein.

If a fault develops, notify Ectron or its local representative, giving full details of the difficulty.

Include the model and serial numbers. On receipt of this information, a service date or shipping

instructions will be furnished. If shipment is indicated, forward the instrument, freight prepaid,

to the factory or to the authorized service center indicated in the instructions.

Instruments should be tested upon receipt. If there is any damage, a claim should be filed with

the carrier. A full report of the damage should be obtained by the claim agent, and that report

should be forwarded to Ectron. Ectron will advise the disposition to be made of the equipment

and arrange for repair or replacement. Please include model and serial numbers in all

correspondence.

GENERAL

PROCEDURE FOR SERVICE

DAMAGE IN TRANSIT

®

Table of Contents

PAGE

Warranty Inside Front Cover

Section I, Description

General 1-1

Features 1-1

About this Manual 1-3

Abbreviations 1-4

Section II, Specifications

General 2-1

Input 2-1

Output 2-2

Frequency-to-voltage Conversion 2-3

Calibration 2-4

Alignment 2-4

Front Panel 2-4

Retention of Settings 2-4

Input Power 2-4

Environment 2-5

Dimensions 2-5

Compatibility 2-5

Section III, Operation

General 3-1

Connections 3-1

Operational-state Diagram 3-1

Limits vs Settings 3-4

View Angle 3-4

Controlling the Model 441A 3-4

Operate Screen 3-6

Frequency-set Screen 3-6

Voltage-set Screen 3-7

Input-signal Screens 3-7

Pulses/Revolution Screen 3-7

Input-sensitivity Screen 3-8

Input-B/W (Filter) Screen 3-9

Output-filter Screen 3-9

i

Table of Contents Model 441A

PAGE

Cal Screen 3-10

Secondary Screens 3-10

Ten-volt Alignment 3-11

Reset 3-12

Enclosures 3-13

Model E408-1 3-13

Model E408-6 3-13

Model R408-14 3-14

Section IV, Applications

General 4-1

Input-signal Conditioner 4-1

Input Signal, Grounding, and Shielding 4-1

Emi Protection 4-2

Frequency-to-analog Conversion 4-2

Output Analog Filter and Output Stage 4-2

Frequency and Voltage Set Points 4-2

Noise 4-3

Uncertainty and Resolution 4-5

Filtering 4-8

Input Bandwidth Filter 4-8

Output Filter 4-9

Digital Filter 4-9

Selectable Input Sensitivity 4-12

Response Time 4-12

Update Rate 4-12

Latency 4-13

Front-panel Indication 4-13

Calibration 4-13

Vehicle Applications 4-14

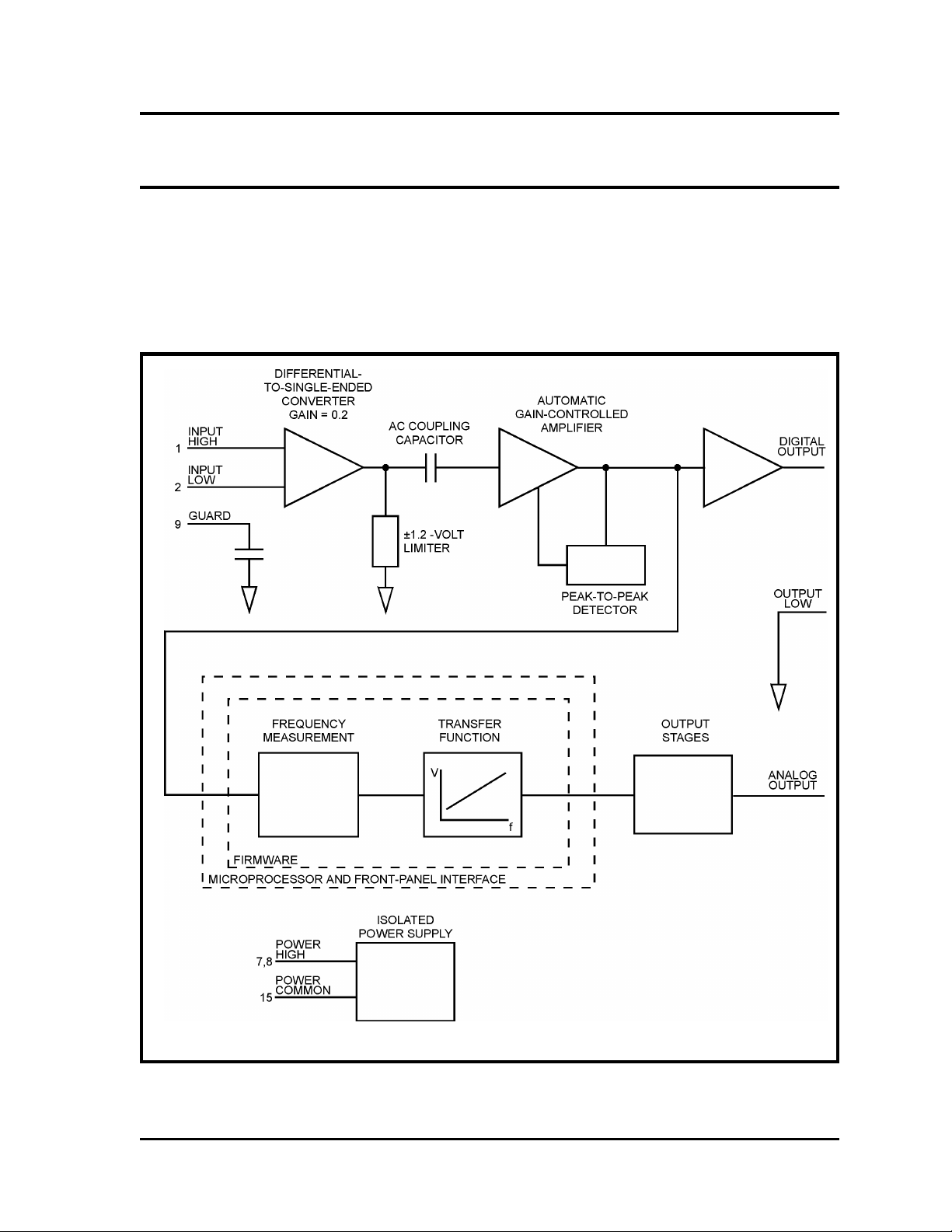

Section V, Theory of Operation

General 5-1

Signal Conditioning (Hardware) 5-2

Frequency Measurement (Firmware) 5-2

Transfer Function (Firmware) 5-2

Output Stages (Hardware) 5-2

Power Supplies (Hardware) 5-3

ii

Model 441A Table of Contents

PAGE

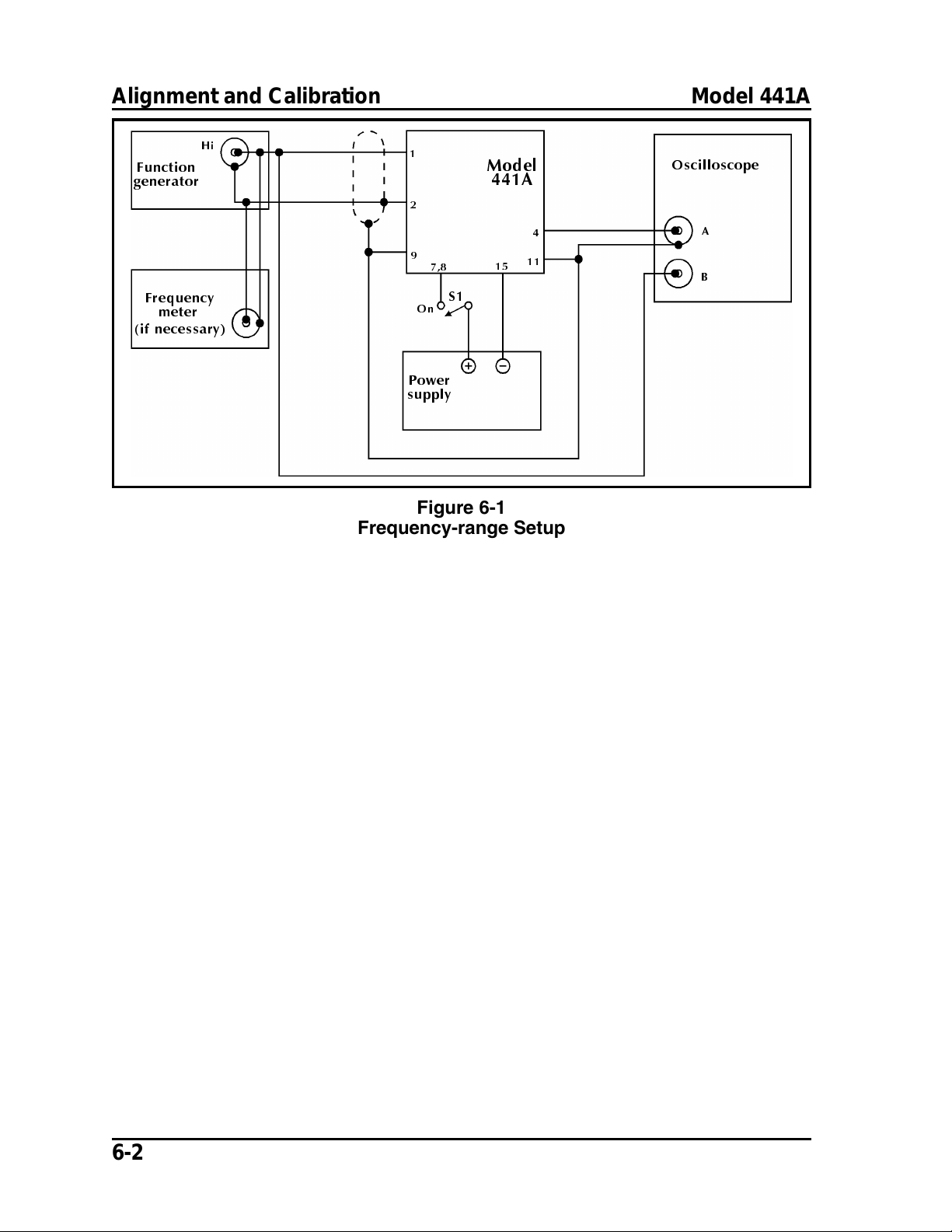

Section VI, Calibration

Equipment Required 6-1

Pre-calibration 6-1

Alignment 6-4

Post-calibration 6-5

Optional Calibration Tests 6-5

Ectron Model 441A Calibration Test Report 6-7

Section VII, Parts Lists

Names of Manufacturers 7-1

Model E408-6 Enclosure 7-2

Model R408-14 Enclosure 7-3

Figures

Model 441A 1-1

Figure 3-1, Operational-state Diagram 3-2

Figure 3-2, View-angle Screens 3-4

Figure 3-3, Operate Screen 3-6

Figure 3-4, Frequency-set Screen 3-6

Figure 3-5, Voltage-set Screen 3-7

Figure 3-6, Pulses/Revolution Screen 3-8

Figure 3-7, Input-sensitivity Screen 3-8

Figure 3-8, Input-bandwidth Screen 3-9

Figure 3-9, Output-filter Screen 3-9

Figure 3-10, CAL Screen 3-10

Figure 3-11, Adjust 10 V Screen 3-11

Figure 3-12, Alignment-required Screen 3-11

Figure 3-13, Memory-error Screen 3-12

Figure 3-14, Reset Screen 3-12

Figure 4-1, Maximum Uncertainty for

Various Frequencies 4-4

Figure 4-2, Worst-case Resolution for

Various Frequencies 4-5

Figure 4-3, Maximum of Uncertainty and

Resolution for Various Frequencies 4-6

Figure 4-4, Maximum Output Noise

with a 10 mV Sine-wave Input 4-7

Figure 4-5, Maximum Output Noise

with a 1 V Sine-wave Input 4-8

Figure 4-6, Effects of the Digital

(Periodic-error) Filter 4-10

iii

Table of Contents Model 441A

PAGE

Figure 4-7, Filtering Scheme for ABS Testing 4-11

Figure 4-8, Filter Circuit for ABS Testing 4-12

Figure 4-9, Strip-chart Recording of ABS Action 4-13

Figure 5-1, Model 441A Block Diagram 5-1

Figure 6-1, Frequency-range Setup 6-2

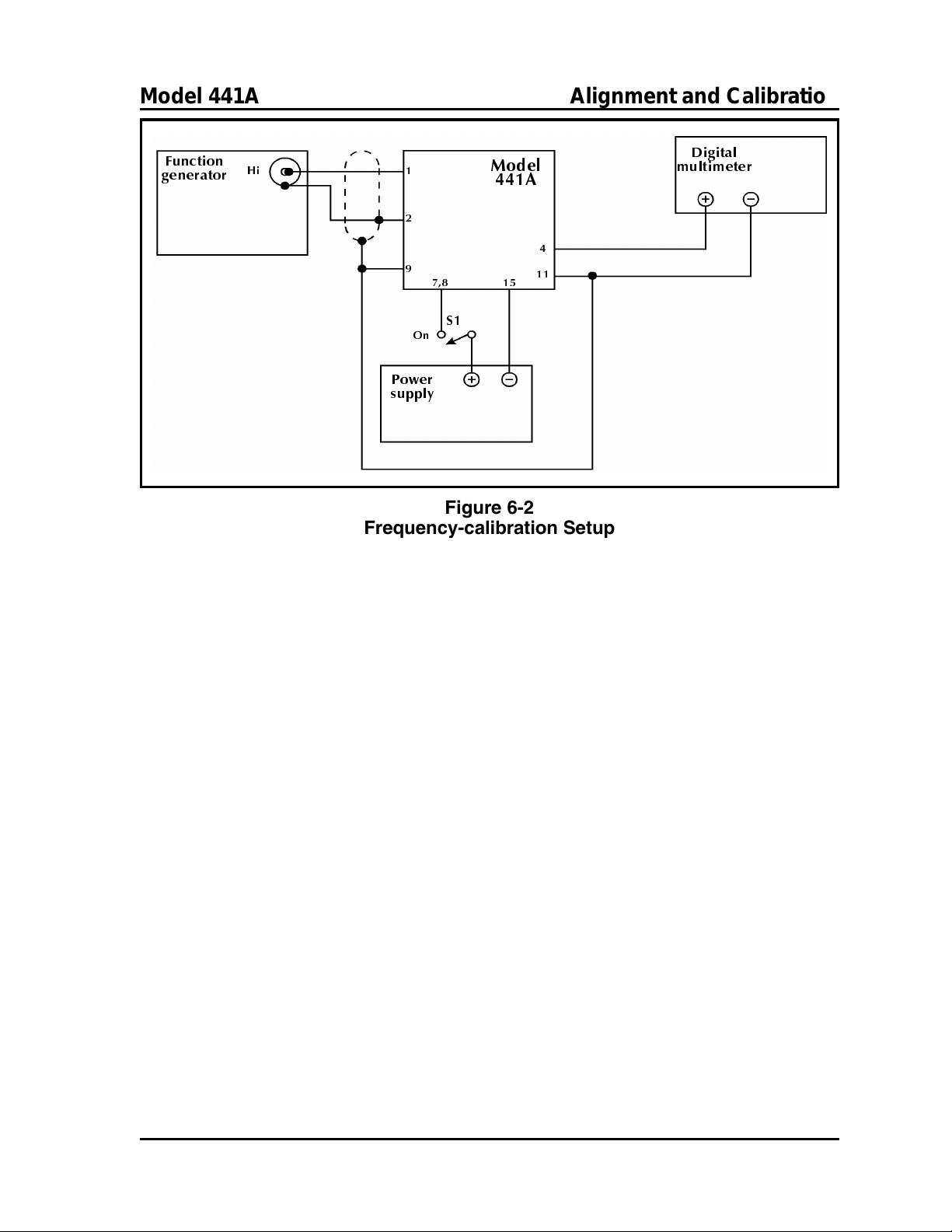

Figure 6-2, Frequency-calibration Setup 6-3

Figure 6-3, Alignment 6-4

Figure 6-4, Optional Tests 6-5

Tables

Table 1-1, Abbreviations in This Manual 1-4

Table 2-1, Input Bandwidth and

Sensitivity Settings 2-1

Table 2-2, Front-panel Screens 2-6

Table 3-1, Connector-pin Assignments 3-1

Table 3-2, Default Settings and Limits 3-3

Table 4-1, Input Frequency vs

Output Voltage (Example) 4-3

Table 4-2, Response Time Versus Output Filter Setting 4-9

Table 6-1, Input Sensitivity 6-6

Table 7-1, List of Manufacturers 7-1

Schematics and Drawings

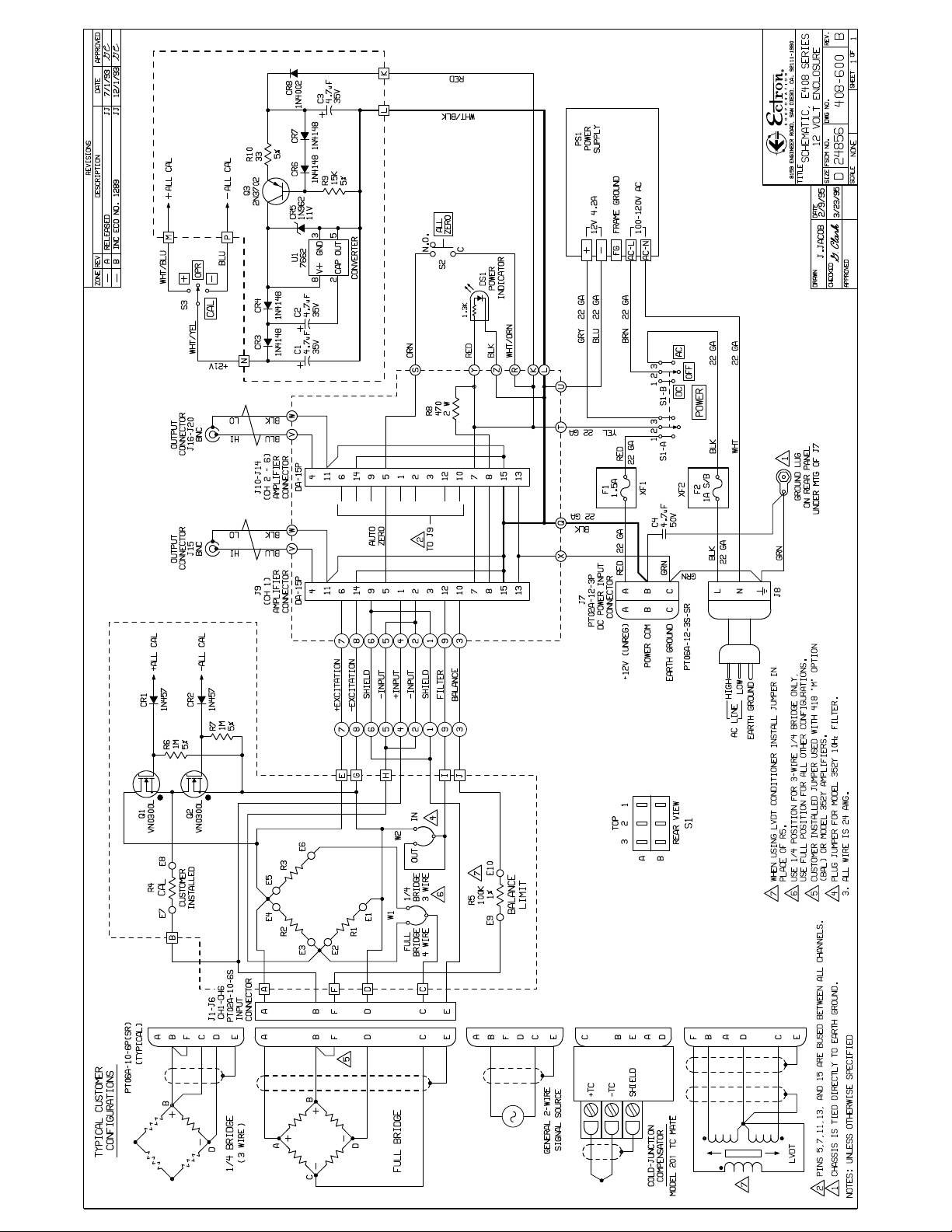

Model E408-6Y (Internal 12 V dc Power Supply) 408-600

Model E408-6X (Internal 28 V dc Power Supply) 408-601

Model R408-14Y (Internal 12 V dc Power Supply 408-605

Model R408-14X (Internal 28 V dc Power Supply 408-606

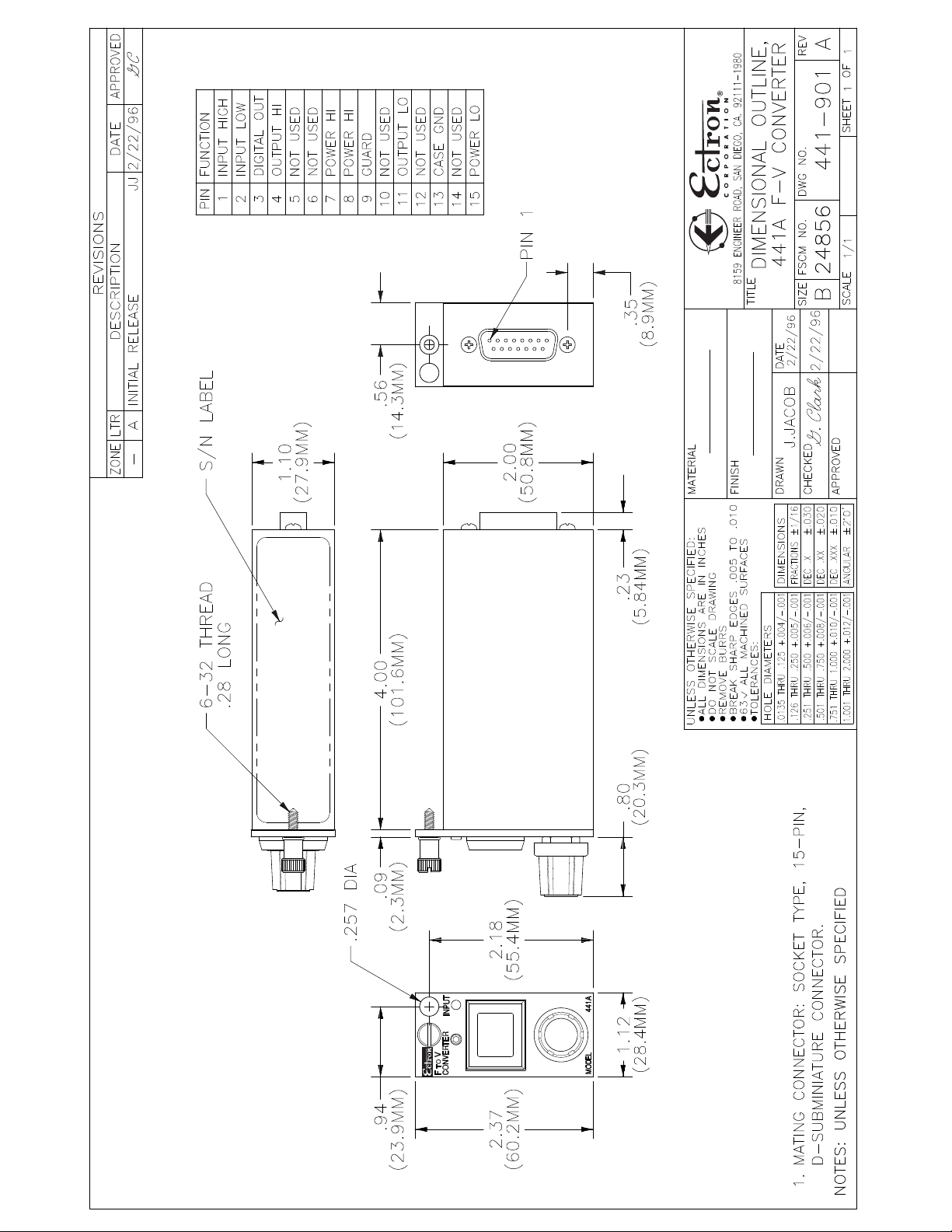

Model 441A Outline Dimensions 441-901

Model E408-1 Outline Dimensions 408-900

iv

Description

GENERAL

The Model 441A produces an analog voltage that precisely represents the frequency of an applied

input signal. Adjustable “input frequency to output voltage” set

points allow the user to quickly

bracket the frequency of interest.

A unique crystal-controlled microcontroller design provides fast response, high conversion accuracy,

and low output noise that is independent of frequency. In the operate mode, the front-panel display

shows the input frequency with up

to five-digit resolution. All operating parameters are set using the

display and only one other frontpanel control. It’s that easy. The

input-signal conditioner automatically provides stable operation for

a wide range of pulse-, square-, and

sine-wave signals from under

10 mV to 100 V.

Section I

FEATURES

Reliable “state of

the art” design

Simplicity

Model 441A

Frequency-to-voltage Converter

The Model 441A combines the same rugged construction used in the Ectron 400 Series product line for the

last 30 years with the latest electronic and surface-mount

technology to produce a true breakthrough in frequencyto-voltage conversion.

Designed in are rapid response to any change in frequency, low output noise that is independent of input

frequency, and input-signal conditioning that automatically provides correct operation for a great variety of

input signals, both in wave shape and amplitude.

Gone is the clutter of switches, knobs, pots, etc. associated with other frequency-to-voltage converters. All

1-1

Description Model 441A

has been replaced with two easy-to-use controls that

allow complete control: the display and the encoder.

Display

Encoder

Wide range of applications With an input-frequency range of 1 Hz to 50 kHz and

Power The Model 441A operates from any dc power from

Model 441AL versus

Model 441A

The backlit digital display has the dual function of display and screen selection. Nine easy-to-use setup

screens, four less frequently used screens, as well as

the operate screen are accessible to the user at the touch

of the display.

With just this one additional control, the user can completely and easily configure the Model 441A to precisely

what the situation requires. The encoder also has a dual

purpose: character selection and change.

an output-voltage range of −10 V to +10 V, the user

can employ the Model 441A to study a wide variety of

frequency-producing equipment. This is in keeping with

Ectron’s intent to provide instruments with wide application for the serious user.

10.5 V to 32 V. This simplifies test-configuration setup

for the user and may even reduce the cost if fewer power

sources are required.

The Model 441AL incorporates a fixed-gain logic-level

input detector instead of the input automatic gain control

(AGC) of the Model 441A. The Model 441AL is designed to operate with fixed-level input signals with relatively sharp rise and fall times. The input can be set to

accommodate levels of 0 V to 5 V, 0 V to 25 V, and

0 V to 100 V.

The fixed gain of the Model 441AL input stage reduces

the delay in responding to an abruptly starting input

signal unlike the AGC circuit, which has a hard time

responding quickly to an input signal that starts suddenly. AGC timing is a compromise between fast response and noise immunity. As a result the AGC may

not keep up with a rapidly rising input amplitude: the

Model 441A may not respond to this signal for several

hundred milliseconds. A similar situation exists for a

rapidly falling input amplitude. These delays are reduced

to one millisecond plus one period of the input signal

in the Model 441AL since no AGC stage is present.

Enclosures Because the Model 441A uses the same connector as

all other 400 Series products, it can be used in all Ectron

enclosures designed for this product line — even intermixed with Model 428 and 352 conditioner-amplifiers

and Model 451 LVDT-signal conditioner. The Model

441A uses the same input and output pins as do these

1-2

Model 441A Description

other products, so the user who has existing hardware

in place can remove an amplifier-conditioner and plug

in the frequency-to-voltage converter and start using it

immediately.

ABOUT THIS MANUAL

The following sections are in this manual:

Specifications This is a complete technical description of the

Model 441A and the performance that is guaranteed.

While the performance specifications are the best in frequency-to-voltage conversion, they are conservative.

The user may find that a particular unit will perform

well beyond specification.

Operation Here the user will find complete instructions to use the

Model 441A. Pictures of all the screens and an

operational-state diagram enhance the discussion. Also

discussed are the various enclosures available for the

Model 441A and other 352 and 400 Series units.

Applications Because the Model 441A is designed as a universal fre-

quency-to-voltage converter, it would be impossible to

address every possible use for this product. Rather, this

section is written to help the user get the most from the

data resulting from using the Model 441A. Concerns

about cabling, shielding, common-mode voltage, etc. are

addressed.

Theory of operation Because the Model 441A is an encapsulated unit, repair

in the field is strongly discouraged. Therefore, a detailed

circuit analysis is foregone in this manual. However,

theory at the block-diagram level as well as a discussion

of internal software is presented to further aid the user

in operating the frequency-to-voltage converter for best

performance.

Calibration Step-by-step instructions are given to test the Model

441A against its specifications. A brief overview of each

test is given to give the technician further insight into

each test performed.

Drawings Schematic diagrams of several enclosures are included

to aid the user in instrumentation configuration.

Warranty The warranty for this product is on the inside of the

front cover.

1-3

Description Model 441A

ABBREVIATIONS

Table 1-1 lists the abbreviations used throughout the manual.

Table 1-1

Abbreviations in This Manual

Symbol Meaning Typical use

ac Alternating current 120 V ac

A Ampere Power current = 150 mA

C Centigrade

50°C

dc Direct current 10.5 V dc to 32 V dc

°

f

co

f

in

F Farad

f

U

f

L

g Gravitational force, gram

Hz Hertz (cycles per second) f

k

M

m

Degree

50°C

Filter cutoff frequency fco = 100 Hz

Input frequency fin can be 1 Hz to 50 kHz

Input Impedance = … 300 pF

Upper-frequency set point

Lower-frequency set point See f

Volts-per-hertz resolution =

U

Shock resistance = 20 g

Weight = 270 g

can be 1 Hz to 50 kHz

in

Kilo (1 × 10

3

Mega (1 × 10

Milli (1 × 10

−

)

6

)

3

), meter

Maximum frequency = 50 kHz

Noise-measurement

bandwidth = …1 MHz

Width = 28.4 mm

…

V

V

−

U

L

f

f

−

U

L

Ω

Ohm

Output impedance = 1

oz Ounce Weight = 9 oz, nominal

−

p

Peak, pico (1 × 10

12

)

Input sensitivity ≥ 10 mV p

Input Impedance = … 300 pF

p-p Peak to peak 20 V p-p output capability

s Second

Update rate = 1 ms

V Volt or voltage 10 mV to 100 V input

V

U

V

L

″

Upper-voltage set point See f

Lower-voltage set point See f

Inch

Length = 4

U

U

″

1-4

Ω …

…

…

Section II

Specifications

GENERAL

All specifications apply over the temperature range of 0°C to 50°C unless otherwise specified,

and they are the maximum deviation allowed from ideal unless otherwise noted. Table 1-1

lists the various symbols and their respective meanings that are used throughout this manual.

INPUT

Configuration

Impedance

Frequency range

Sensitivity and bandwidth

Differential with a common-mode-voltage rating of up

to 100 V dc or peak ac.

200 kΩ in parallel with 300 pF nominal.

1 Hz to 50 kHz.

Three steps of input sensitivity and three steps of input-bandwidth control are provided to optimize input

signal-to-noise ratio.

Table 2-1

Input Bandwidth and Sensitivity Settings

Screen MIN MID MAX

Input B/W 10 Hz 500 Hz Wideband

Input Sensitivity 200 mV peak 25 mV peak 10 mV peak

All settings are nominal.

Periodic-error filtering

A periodic-error filter can be activated for input signals

that are less than 1 kHz. By entering the pulses per

revolution (cycle), the user can eliminate erroneous variations of periodicity. Two to 999 pulses can be accommodated.

Square- and sine-wave

amplitude range

Pulse amplitude range

Response to rapid

change in amplitude

10 mV to 100 V peak.

40 mV to 100 V peak (2.5% to 97.5% duty cycle, 5 µs

minimum pulse width).

The Model 441A will recover and provide the proper

output within 0.2 s + 1⁄

amplitude of the input signal, where fin is the frequency

of the input signal.

following a 10:1 change in

f

in

2-1

Specifications Model 441A

OUTPUT

Voltage

(V)

Uncertainty

(V

UNC

The linear range of the analog output is from −10 V to

+10 V with up to 10 mA current. The output limits are

approximately ±10.5 V. Output voltage for a given frequency is determined by voltage and frequency set

points using the following:

VU − V

V =

where f

L

fU − f

× ( fin − fL ) + VL ,

L

is the input frequency and VU and VL and f

in

U

and fL are the upper and lower voltage and frequency

settings of the instrument, respectively.

)

For frequencies less than 1 kHz,

2

V

= 0.00122 +

UNC

f

in

1.5 × 106 − f

in

×

VU − V

fU − f

L

,

L

where fin is the input frequency and VU and VL and f

U

and fL are the upper and lower voltage and frequency

settings of the instrument, respectively.

For frequencies of 1 kHz and above,

2

V

= 0.00122 +

UNC

in

(1.5 × 106)F

f

where fin is the input frequency, F is

×

VU − V

fU − f

f

in

⁄

L

,

L

rounded up

1000

to the nearest integer, and VU and VL and fU and fL are

the upper and lower voltage and frequency settings of

the instrument, respectively.

Uncertainty

Scaling

Resolution

2-2

V

Hz

(Hz)

(R)

The uncertainty of the output in terms of frequency is

fU − f

Hz = V

where V

×

UNC

is the uncertainty in volts, and VU and V

UNC

VU − V

L

,

L

and fU and fL are the upper and lower voltage and frequency settings of the instrument, respectively.

VU − V

V

Hz

=

fU − f

L

,

L

where VU and VL and fU and fL are the upper and lower

voltage and frequency settings of the instrument, respectively.

For input frequencies below 1 kHz, the resolution at

the output is:

L

Model 441A Specifications

2

R = 0.00122 V or

f

in

1.5 × 106 − f

whichever is greater, where fin is the input frequency,

VU and VL are the voltage settings, and fU and fL are

the frequency settings.

For input frequencies at or above 1 kHz, resolution in

volts at the output is:

2

f

0.00122 V or

in

(1.5×106)F

×

whichever is greater, where fin is the input frequency,

f

in

⁄

F is

rounded up to the nearest integer, VU and

1000

VL are the voltage settings, and fU and fL are the fre-

quency settings.

Impedance Less than 1 Ω at dc.

Noise Less than or equal to 10 mV p-p independent of input

frequency measured with a bandwidth of 0.1 Hz to

1 MHz. For slower rise-time signals such as sine waves,

output noise depends on input-signal noise and amplitude since accurate timing is hampered by noise.

VU − V

×

fU − f

in

VU − VL

f

− f

U

L

L

,

L

,

Response time Response to an abrupt frequency change is

0.005 s +

1

⁄

, where fin is the frequency of the input,

f

in

with the filter set to wideband. For other filter frequencies, add 5⁄

Update rate 0.001 s or 1⁄

, where fco is the filter cutoff frequency.

f

co

, where fin is the frequency of the input,

f

in

whichever is a longer period of time.

Latency The output will start to respond to a change in input

frequency within 1 ms of each falling edge of the input

signal for input frequencies above 1 kHz and within

1 ms + 1⁄

, where fin is the frequency of the input, for

f

in

frequencies below 1 kHz.

Filter Selectable filter frequencies of 1 Hz, 10 Hz, and 100 Hz

plus wideband (approximately 1.5 kHz). The filter has

a two-pole Bessel characteristic.

FREQUENCY-TO-VOLTAGE CONVERSION

General Following the input-conditioner-agc circuit, a microcon-

troller converts the input frequency to an equivalent analog signal. The output is then scaled to a 14-bit DAC

based on the user-specified frequency and voltage set

points.

Frequency set points

(upper and lower)

These set points determine the input frequency at which

the upper- and lower-voltage set points are reached. The

2-3

Specifications Model 441A

frequency set points can be any two frequencies between

0 Hz and 50 kHz with a resolution of 1 Hz, and they

can be within 10 Hz of each other.

Voltage set points

(upper and lower)

These set points determine the output voltages corresponding to the upper- and lower-frequency set points,

respectively. The voltage set points can be any two voltages from −10 V to +10 V with a resolution of 0.1 V,

and they can be within 0.1 V of each other (the uppervoltage set point always being more positive than the

lower voltage set point).

CALIBRATION

When in the calibration mode, an internally generated calibration signal can be set to any

frequency between 1 Hz and 50 kHz in 1 Hz increments. When enabled, the analog output

assumes a value according to the frequency and voltage set points. The calibration signal

can be toggled on and off when in the CAL mode of operation.

ALIGNMENT

Alignment of the Model 441A is performed using the two alignment modes of −10 V and

+10 V. This feature allows field alignment and calibration of the instrument using only a

voltmeter.

FRONT PANEL

Controls The display/push button allows the operator to sequence

through the various setup screens. The round switch,

encoder, has both push-button and rotary action: the

push-button action moves the cursor to the digit to be

changed while the rotary action is used to change the

selected digit. All operating parameters are set using

these controls and are shown on the display.

Input LED The LED on the front panel indicates that a valid input

frequency signal is present and that the output represents

the input frequency.

Display The front-panel back-lit LCD display shows the input

frequency when in the operate mode. Five digits of resolution are indicated — even at lower frequencies. If the

input frequency is unstable the less-significant digits will

vary. Table 2-2 lists all possible screens and their functions.

RETENTION OF SETTINGS

All settings of the Model 441A are retained in nonvolatile memory.

INPUT POWER

Range 10.5 V dc to 32 V dc, unregulated.

Over-voltage protection Up to +60 V for 15 s; +32 V and −50 V, continuously.

2-4

Model 441A Specifications

Current (nominal) 150 mA.

Protection Protected against polarity reversal.

ENVIRONMENT

Emi/rfi Internal rfi filters are provided on all connector leads.

Operating temperature 0°C to +50°C.

Storage temperature −40°C to +80°C.

Altitude No limit with adequate heat dissipation.

Static-acceleration

200 m

resistance

Shock resistance

Vibration resistance

200 m

100 m

DIMENSIONS (SEE DRAWING 441-900)

Height (panel) 60.2 mm (2.37″).

Height (case) 50.8 mm (2.00″).

Width 28.4 mm (1.12″).

2

⁄

(approximately 20 g) in any plane.

s

2

⁄

(approximately 20 g) for 11 ms in any plane.

s

2

⁄

(approximately 10 g) in any plane.

s

Depth 101.6 mm (4.00″).

Weight 255 g (9 oz) nominal.

COMPATIBILITY

The Model 441A will operate in all standard Ectron enclosures designed for Models 352

and 428 conditioner-amplifiers and the Model 451 LVDT-signal conditioner. Current enclosure

products are Models E408-1, E408-6Y, and R408-14Y.

2-5

Specifications Model 441A

Table 2-2

Front-panel Screens

Screen

Operate

f

and fL set points Select fU and fL between 0 Hz and 50 kHz.

U

V

and VL set points

U

Pulses/revolution

Input sensitivity

Input bandwidth

Output filter

Calibration

Viewing angle Set screen for best visibility.

Function

Default screen; input frequency (f

revolution are displayed.

Select V

Select pulses per revolution for input signal less than 1

kHz to eliminate periodic error. This function can be

turned OFF and ON.

Select input-voltage sensitivity of MIN (200 mV peak),

MID (25 mV p), MAX (10 mV p).

Select input bandwidth of MIN (10 Hz),

MID (500 Hz), MAX (WB).

Select output-filter frequency of 1 Hz, 10 Hz, 100 Hz, or

WB.

Select calibration frequency between 1 Hz and 50 kHz

and turn calibration ON or OFF.

and VL between −10 V and +10 V.

U

) and pulses per

in

Alignment, −10 V

Alignment, +10 V

Memory error Appears only when there is a memory error.

Alignment required Appears only when alignment is required.

Reset

Reset (momentary) Appears for one second after a reset.

Alignment between internal analog

and digital components.

Allow user to reset all parameters

to the default settings.

2-6

Section III

Operation

GENERAL

In this section, connections to the Model 441A and the use of its controls are discussed.

The name frequency-to-voltage converter is somewhat misleading in that the real value of

this instrument lies not in its ability to measure frequency—instruments dedicated to that

task do it better—and produce a corresponding voltage output—some frequency-measuring

instruments do this, too—but in its ability to rapidly respond to changes in frequency and

faithfully to produce a corresponding voltage. A more suitable name for the product then

could be “a change in frequency producing a corresponding change in voltage” converter.

This is awkward, so we shorten it.

CONNECTIONS

The Model 441A uses a “D” subminiature fifteen-pin connector for all input and output

connections. Table 3-1 summarizes these connections. These pin assignments are the same

as for Ectron Models 352 and 428 conditioner-amplifiers. Therefore, unless special features

have been incorporated that would preclude using the Model 441A, enclosures designed for

these amplifiers are compatible with the Model 441A including Models E408 and R408.

The Model 441A accepts power from 10.5 V dc to 32 V dc, so enclosures designed for

either 12 V dc or 28 V dc can be used.

Table 3-1

Connector-pin Assignments

Pin Function Pin Function Pin Function

1 Input high 6 --- 11 Output low

2 Input low 7*

3 Digital output high 8* 13 Case ground

4 Analog output high 9 Input guard 14 ---

5 --- 10 --- 15 Power low

* Pins 7 and 8 are internally connected.

Power high

12 ---

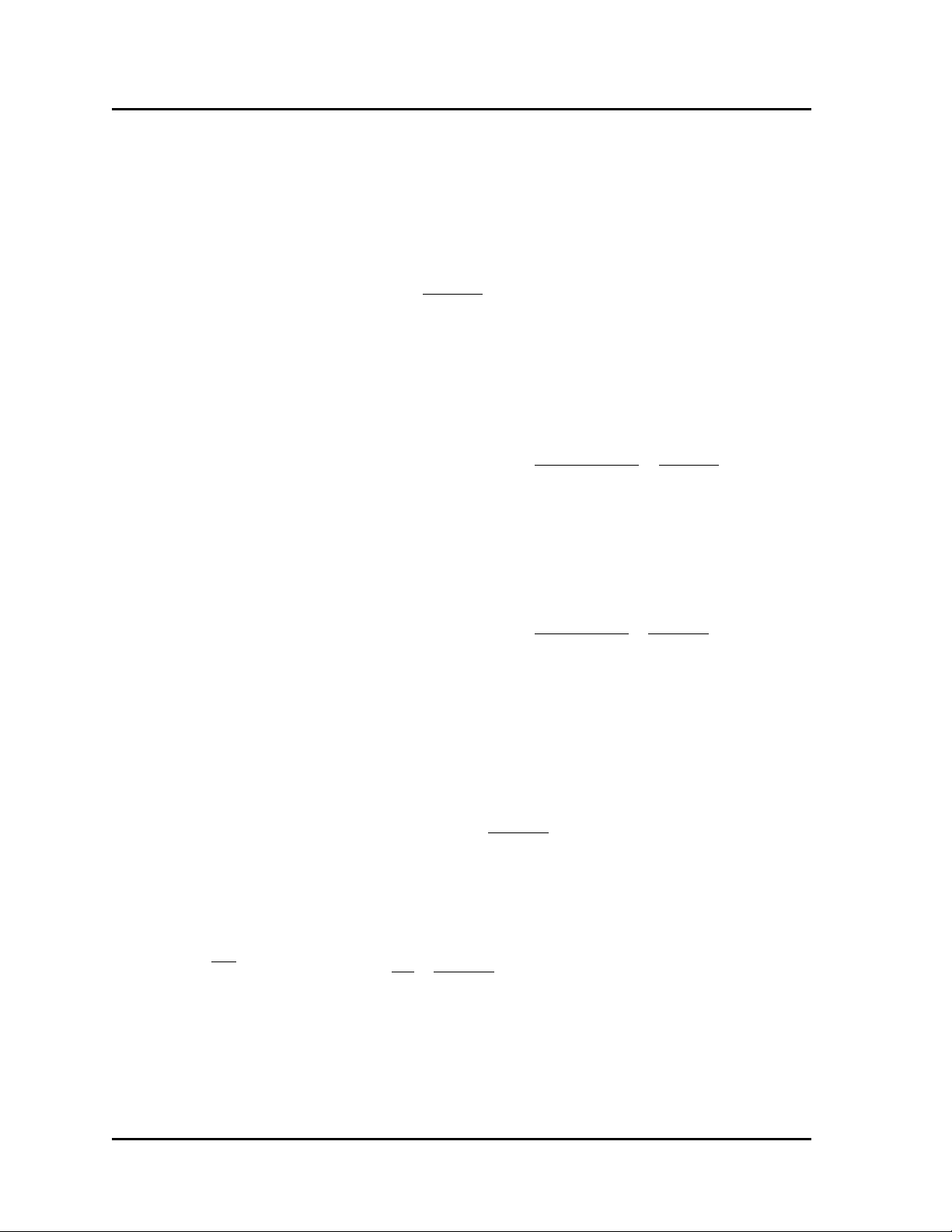

OPERATIONAL-STATE DIAGRAM

Figure 3-1 is the operational-state diagram for the Model 441A. Starting at the top of the

diagram all possible screens and operator choices at these screens are depicted. Additionally,

it shows decisions made by the unit during normal operation. These decisions are diagnostic

in nature; and if an error (such as a memory error) occurs, the user will be notified on the

screen of the event.

3-1

Operation Model 441A

3-2

Figure 3-1

Operational-state Diagram

Model 441A Operation

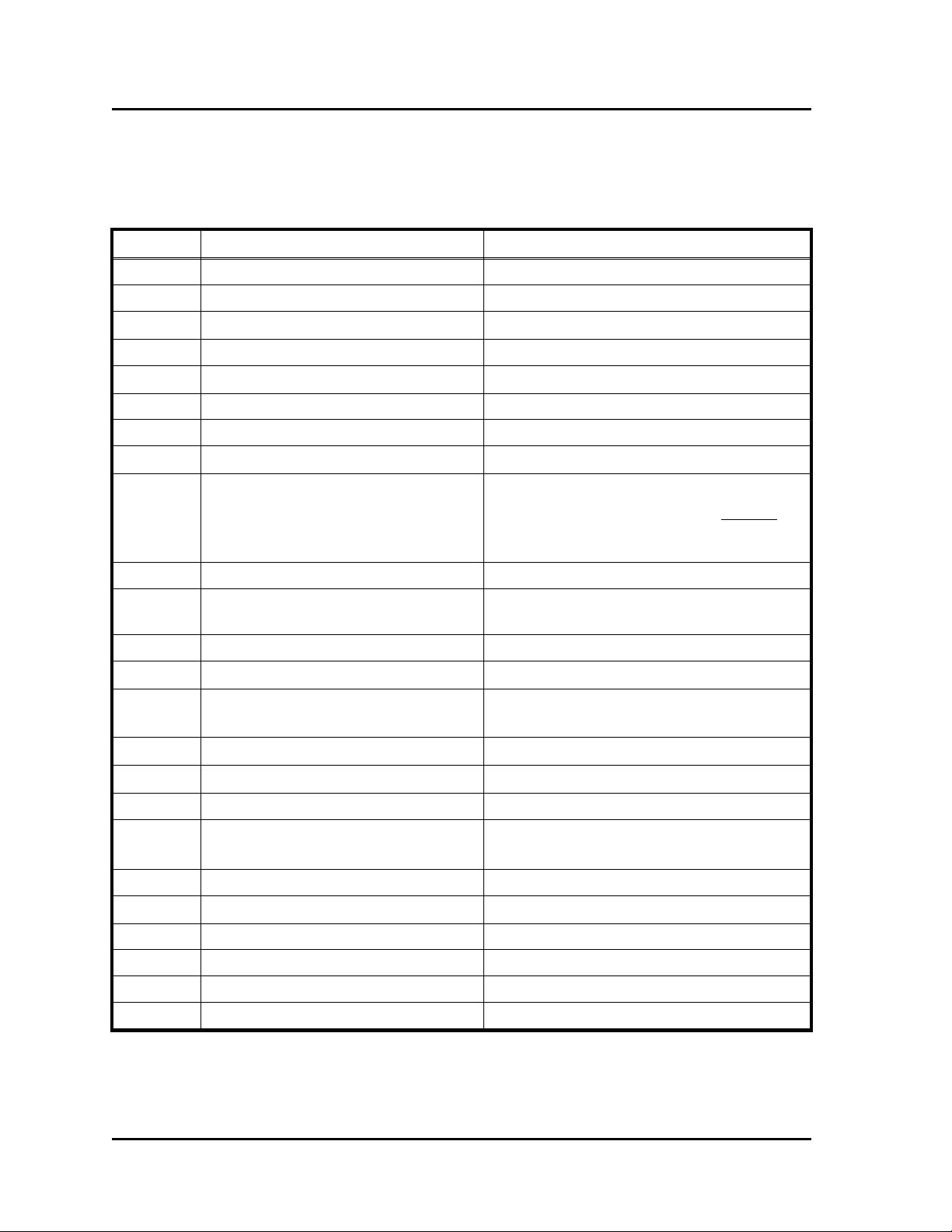

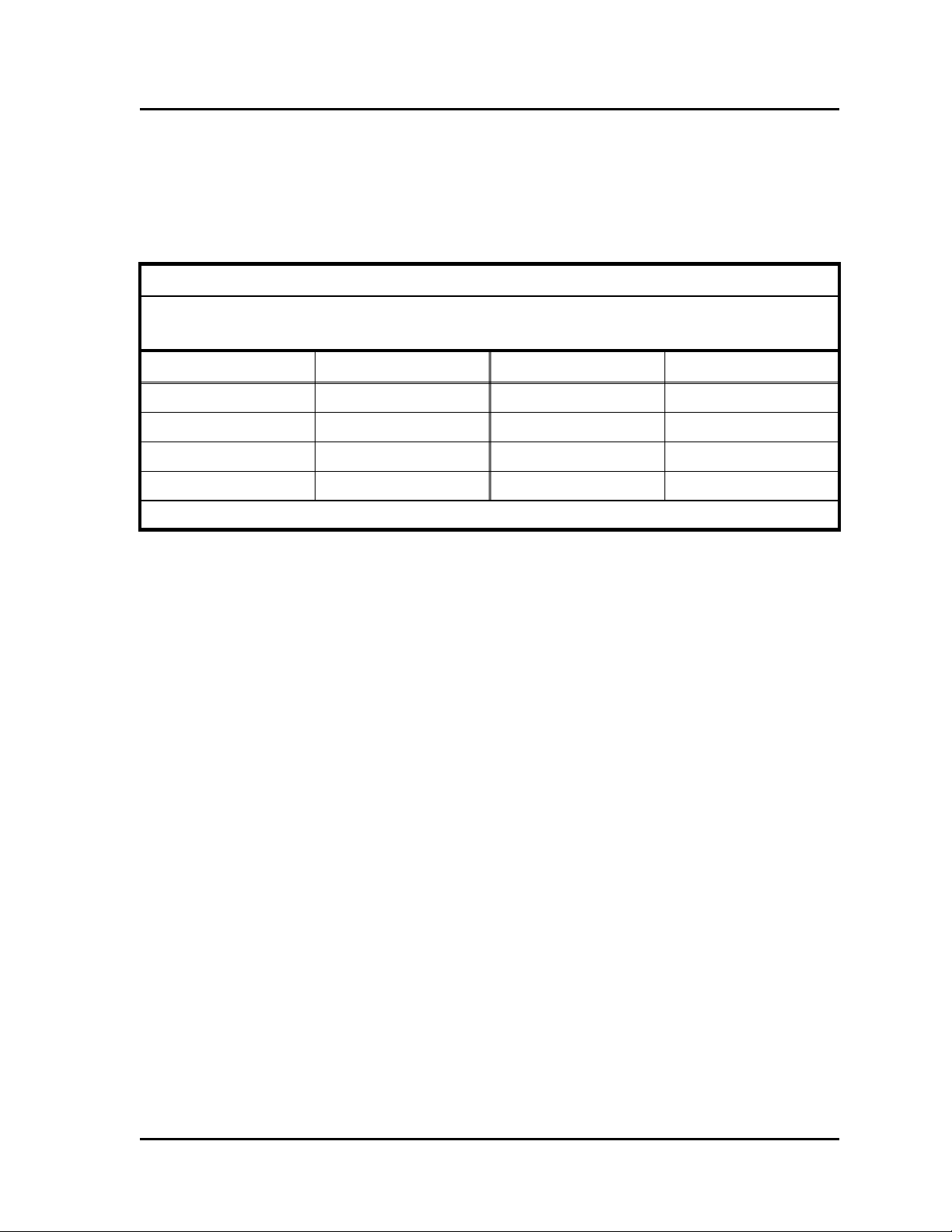

Table 3-2

Default Settings and Limits

Function Parameter Default Setting Screen Limits

10 Hz to 50000 Hz

Upper set point 50000 Hz

Frequency

Lower set point 0 Hz

Upper set point +10.0 V

Voltage

Lower set point 0 V

and 10 Hz higher

than the lower-

frequency set point

0 Hz to 49990 Hz

and 10 Hz lower

than the upper-

frequency set point

−9.9 V to +10 V

and 0.1 V higher

than the lower-

voltage set point

−10 V to +9.9 V

and 0.1 V lower

than the upper-

voltage set point

Pulses/revolution

Input sensitivity Voltage MAX MIN, MID, MAX

Input filter Frequency MAX MIN, MID, MAX

Output filter Frequency WB (wideband)

CAL

Alignment

View angle Contrast Midrange Black & blank

Reset

ON/OFF OFF ON, OFF

Pulses 001 001-999

1 Hz, 10 Hz, 100 Hz

plus WB

ON/OFF OFF ON, OFF

Frequency 25,000 Hz 0 Hz to 50,000 Hz

−10 V +000 ±750 counts

+10 V +000 ±750 counts

Default

settings

NO YES, NO

3-3

Operation Model 441A

LIMITS VS SETTINGS

In setting the controls so that a certain frequency corresponds to a certain voltage and another

higher frequency corresponds to a higher (more positive) voltage, the user should always

remember that these set points do not set the limits of operation. Rather they determine the

volts-per-hertz scaling of the output. The limits are fixed at 0 Hz to 63 kHz and −11 V to

11 V. Table 3-2 lists the default settings and limits for the Model 441A. Except for voltage

+

alignment, these are the settings of a new unit, and they are the settings (including voltage

alignment) when a RESET is performed. New units are aligned when shipped.

Figure 3-2

View Angle

Normal and extreme

view angles

VIEW ANGLE

Although this screen is actually considered a secondary screen, accessed by pressing and

holding the display for more than one second, it is discussed first because the possibility

exists that if the instrument is in an extreme-temperature environment, the screen will not

be visible when the unit is energized. It may be black or it may be blank. If this occurs,

press and hold the display for more than one second, and then rotate (counterclockwise if

too dark, and clockwise if too light) the encoder (round knob) until the words VIEW ANGLE

are visible.

At this point, the user can either wait approximately twenty seconds (or press the display

twice or press and hold the display for more than one second) to return to the operate screen.

CONTROLLING THE MODEL 441A

The controls on the front panel consist of a display, which has the additional function of

screen selection, and the encoder, which has the dual function of character selection and

control. Using these two controls is all that is necessary to fully operate the Model 441A.

Display As stated above, the display has the dual function of

display and screen selection. There are two ways to

select a screen. One is to press and release. This selects

3-4

Model 441A Operation

the screens that the user would typically access while

operating the Model 441A. The other is to press and

hold the display for more than one second. This evokes

a set of secondary screens to set parameters less

frequently changed.

Encoder The round encoder has the dual function of character

selection and control. Once a screen has been selected,

a blinking cursor will appear that will cover one or

more characters. The cursor always first appears on the

top left-most character. Pressing the encoder moves the

cursor across the screen and down through all the

changeable characters and back to the top left. If the

user inadvertently steps past the character to be changed,

simply continue pressing the encoder until the cursor is

where he or she wants it to be.

Once the character to change has been selected, rotate

the encoder either clockwise or counterclockwise until

the character is correct. When changing numbers, rotating the encoder can change digits to either side of

the digit being changed. For example, if the user is

changing one of the voltage set points, and the cursor

is on the tenths digit, then changing it from 9 to 0 will

increment the ones digit. The user should remember

that the Model 441A screen values will not violate the

limits shown in Table 3-2. If he or she is rotating the

encoder and the character under the cursor is not changing as expected, the most likely cause is that the

Model 441A is being asked to exceed a limit.

The encoder has two additional functions when the user

wants to reset the default parameters. When at the screen

to align +10 V, pressing and holding the encoder for

more than one second evokes the RESET screen, which

gives the user the opportunity to perform a reset. If the

user then chooses Yes and presses the encoder, a reset

is performed.

Once a character has been changed, and the operate

screen restored, the nonvolatile memory is updated with

the new information. However, if power is interrupted

between the time of character change and return to the

OPERATE screen, memory is not updated.

3-5

Operation Model 441A

The following paragraphs discuss all the screens of the Model 441A. How to get to each

screen from the operate screen, how to set each screen, and how to return to the operate

screen are presented.

Figure 3-3

Operate

Input frequency of 123.45 Hz

and PR set to 96

OPERATE SCREEN

When the Model 441A is energized this screen is normally displayed. When the green light

is on, the number on the screen is the frequency of the input signal. It can be any frequency

from 1 Hz to 63 kHz. Below 1 Hz, zeroes are displayed; above 63 kHz, dashes are displayed.

Full floating-point presentation is employed. Also displayed is PR (pulses per revolution)

and the current setting of the pulses-per-revolution (digital periodic-error) filter.

Figure 3-4

Frequency Set

Upper-frequency set point

of 16,475 Hz and a lower-

frequency set point

of 9832 Hz

FREQUENCY-SET SCREEN

Function To set the upper- and lower-frequency set points.

From the OPERATE screen Press the display once.

To the OPERATE screen Press the display seven times or wait approximately

twenty seconds.

Defaults 50000 Hz and 00000 Hz.

Discussion The upper-frequency set point can be any frequency

from 10 Hz to 50 kHz while the lower-frequency set

point can be any frequency from 0 Hz to 49,990 Hz.

Operation There are ten possible characters to set on this screen.

When the screen is first displayed, the blinking cursor

is on the 10,000’s digit of the upper-frequency set point.

Press (and release) the encoder until the cursor is at the

digit to be changed. Then, rotate the encoder until that

3-6

Model 441A Operation

digit is set. Continue until all the digits are set. Remember that the two frequencies can never be closer to each

other than 10 Hz.

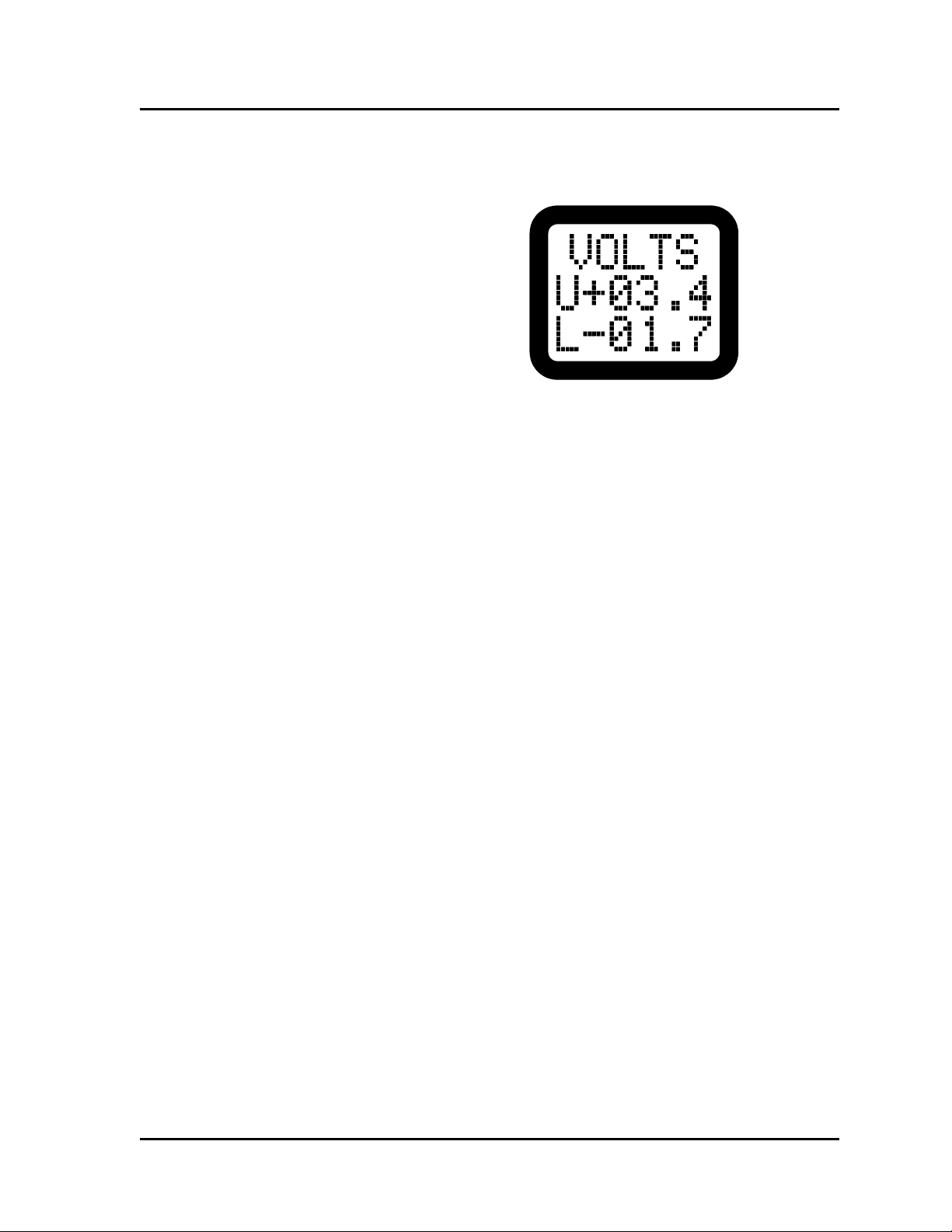

Figure 3-5

Voltage Set

Upper-voltage set point of

+3.4 V and a lower-voltage

set point −1.7 V

VOLTAGE-SET SCREEN

Function To set the upper- and lower-voltage set points.

From the OPERATE screen Press the display twice.

To the OPERATE screen Press the display six times or wait approximately twenty

seconds.

Defaults +10.0 V and +00.0 V.

Discussion The upper-voltage set point can be any voltage from

9.9 V to +10.0 V while the lower-voltage set point

−

can be any voltage from −10 V to +9.9 V.

Operation There are four possible characters to set on this screen.

When the screen is first displayed, the blinking cursor

is on the 1’s digit of the upper-voltage set point. Press

(and release) the encoder until the cursor is at the digit

to be changed. Then, rotate the encoder until that digit

is set. Continue until all the digits are set. Remember

that the two voltages cannot be closer to each other

than 0.1 V.

INPUT-SIGNAL SCREENS

There are three screens to filter and condition the input signal to enhance the performance

of the Model 441A. The first, PULSES/REVolution, eliminates input-signal error due to

periodic, repetitive variations or errors. The next two screens, INPUT SENSitivity and

INPUT B/W, work in conjunction with each other to provide the user nine combinations

of input conditioning for the input signal. See the Applications section for further discussion.

Pulses/Revolution Screen

Function To set the number of pulses of the input signal that

occur during one revolution (or cycle).

From the OPERATE screen Press the display three times.

3-7

Operation Model 441A

Figure 3-6

Pulses/Rev

P/R set ON and number of

pulses set to 96

To the OPERATE screen Press the display five times or wait approximately twenty

seconds.

Default OFF, 001.

Discussion The pulses/revolution filter can be set ON or OFF, and

the number of pulses can be set from 1 to 999. Note

that even though the PULSES/REV has been turned

ON, this function ceases to operate when the input signal

is outside the range of 1 Hz to 1 kHz (i. e. the time

between two consecutive input pulses is less than 1 ms

or greater than 1 s). It will reactivate automatically if

and when the input signal returns to within that range.

Once this digital filter has been turned ON or internally

reactivated, one revolution must occur before the output

of the Model 441A is averaged.

Operation Pressing the encoder moves the cursor from one char-

acter to the next, (ON or OFF is the first choice). Then

rotate the encoder for the number of pulses per cycle.

Figure 3-7

Input Sensitivity

Input sensitivity

set to MAX

Input-sensitivity Screen

Function To set the input-voltage sensitivity.

From the OPERATE screen Press the display four times.

To the OPERATE screen Press the display four times or wait approximately

twenty seconds.

Default MAX.

3-8

Model 441A Operation

Discussion The input sensitivity can be set to MIN, MID, or MAX.

Operation Since there is only one character to change on this

screen, the encoder push-button action has no function.

Simply rotate the encoder to select the desired sensitivity.

Figure 3-8

Input bandwidth

Input bandwidth

set to MID (midrange)

Input-B/W (Filter) Screen

Function To select the input filter.

From the OPERATE screen Press the display five times.

To the OPERATE screen Press the display three times or wait approximately

twenty seconds.

Default MAX.

Discussion The input bandwidth can be set to MIN, MID, or MAX.

Operation Since there is only one character to change on this

screen, the encoder push-button action has no function.

Simply rotate the encoder to select the desired filter.

Figure 3-9

Output filter

Output filter

cutoff frequency

of 100 Hz

OUTPUT-FILTER SCREEN

Function To set the output filter.

From the OPERATE screen Press the display six times.

To the OPERATE screen Press the display twice or wait approximately twenty

seconds.

Default WB (wideband).

3-9

Operation Model 441A

Discussion The filter can be set to 1 Hz, 10 Hz, 100 Hz, or WB,

which is approximately 1.5 kHz.

Operation Since there is only one character to change on this

screen, the encoder push-button action has no function.

Simply rotate the encoder to select the desired filter.

Figure 3-10

CAL screen

CAL “on”

and CAL frequency

set to 12.5 kHz

CAL SCREEN

Function To set the calibration frequency.

From the operate screen Press the display seven times.

To the operate screen Press the display once or wait approximately twenty

seconds.

Defaults OFF, 25000 Hz.

Discussion The calibration frequency is used in conjunction with

the upper and lower set points of frequency and voltage.

It simulates the frequency and puts out the corresponding

voltage when ON. For example, if the user has frequency

set points of 1 kHz and 2 kHz and voltage set points

of 1 V and 2 V, he or she may want to set a CAL

frequency of either the upper or lower frequency set

points or perhaps the midpoint, 1.5 kHz. This is not to

say that the cal frequency must be within the frequency

set points.

Operation First, set the CAL function to ON or OFF by rotating

the encoder, select the digit or digits to be set using the

push-button function of the encoder, and then set them

with the rotary function.

SECONDARY SCREENS

Access to these screens, VIEW ANGLE and ±10 V ALIGNMENT is by pressing and holding

the display while at any of the primary displays. The sequence is VIEW ANGLE, –10 V ALIGN-

MENT, and +10 V ALIGNMENT. Adjustment of VIEW ANGLE is discussed on Page 3-4.

3-10

Model 441A Operation

Figure 3-11

Adjust +10 V

screen used

to align the out-

put with internal

software

Ten-volt Alignment

Function The alignment screens allow the operator to align the

output of the Model 441A with its internal software using a voltmeter.

From the OPERATE screen Press and hold the display for more than one second

and then press the display once for negative 10 V alignment and twice for positive 10 V alignment.

To the OPERATE screen From the negative 10 V alignment screen, press the dis-

play twice; from the positive 10 V screen, once.

Default +000.

Operation When at the negative 10 V alignment screen, connect

a DMM to the output of the Model 441A and then using

the encoder, adjust the output for −10 V ±0.005 V. Next

press the display once to go to positive 10 V alignment

screen and adjust the encoder for +10 V ±0.005 V. The

three-digit number on each display is a reference number

for the convenience of the user. The user may want to

note the readings once the alignment is made. Then if

an alignment is required in the future and a voltmeter

is unavailable, the user can simply reset the numbers

to those noted above with confidence that the unit is

properly aligned.

There are four additional secondary screens: MEMORY ERROR, RESET, ALIGNMENT

REQUIRED, and a temporary screen seen only after a reset is made.

Figure 3-12

The ALIGNMENT

REQUIRED screen will

appear so long as ±10 V

alignment is necessary.

The displayed digits

are for factory use.

3-11

Operation Model 441A

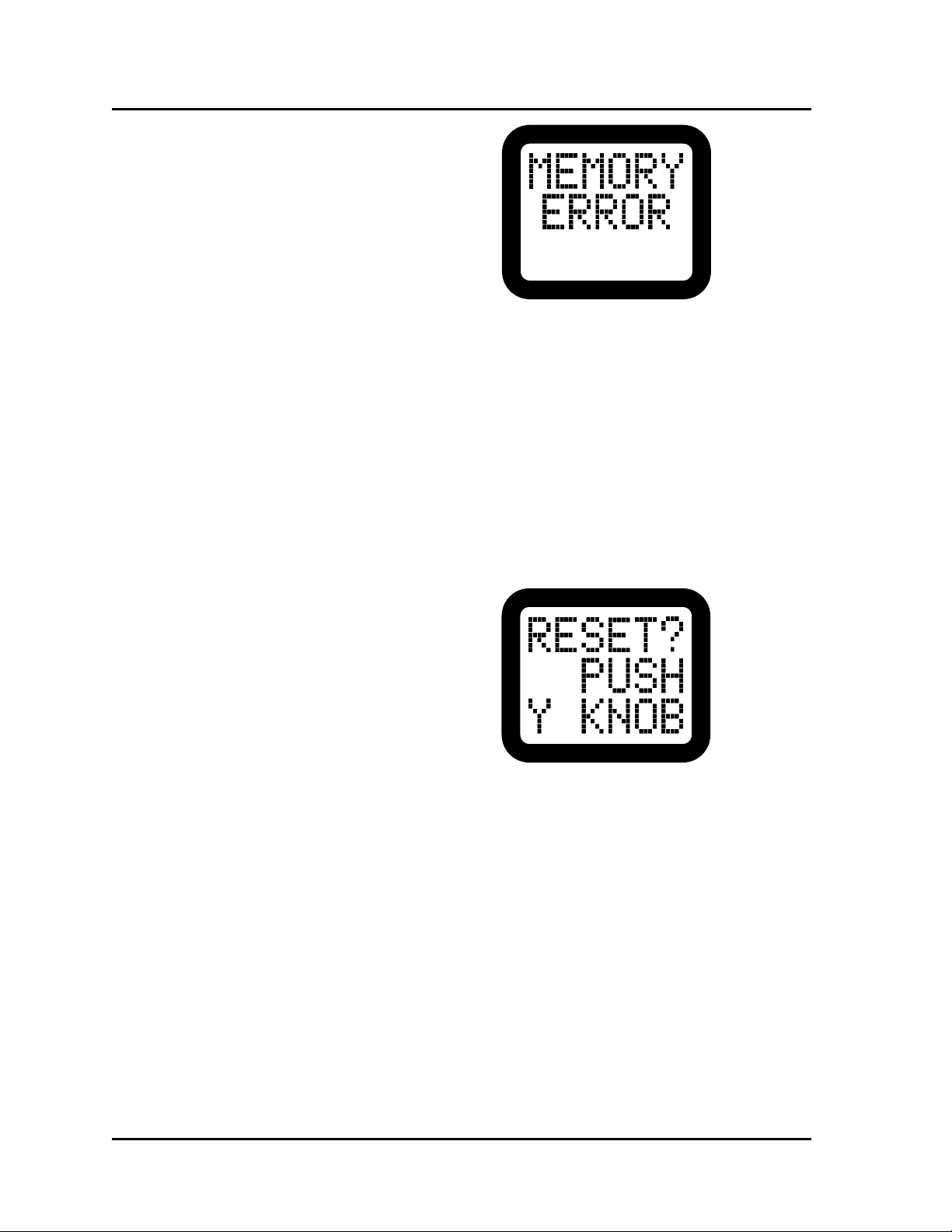

Figure 3-13

The MEMORY-ERROR

screen will appear

if an error in nonvolatile

memory occurs.

MEMORY ERROR is inaccessible by the user and will normally never be seen. As is

shown in Figure 3-1, each time the Model 441A is energized, nonvolatile memory is tested.

Normally, it will pass the test and will immediately display the OPERATE screen. However,

should a memory error occur, the MEMORY ERROR screen will be displayed. To advance

past this screen, press the display or press or turn the encoder. The Model 441A will then

restore the default settings (Table 3-2) and go to the ALIGNMENT REQUIRED screen.

Again the operator can press the display or press or turn the encoder, and the unit will

advance to the OPERATE screen. Until the two 10 V alignments are performed, the unit

will stop at the ALIGNMENT REQUIRED screen each time power is applied.

If the user chooses, the default settings can be restored by going to the RESET screen and

selecting Y (yes) PUSH KNOB.

Figure 3-14

Use the RESET

screen to restore

the default parameters.

Reset

Function To restore the default settings.

From the OPERATE screen Press and hold the display until VIEW ANGLE is dis-

played, press the display twice more (plus 10 V alignment), and then press and hold the encoder for one

second or more.

To return to the OPERATE

screen (without having

performed a reset)

To return to the OPERATE

screen (having performed

a reset)

Press the display when the screen displays N (no) PUSH

DISPlay or wait 20 seconds.

Press the encoder when the screen displays Y (yes)

PUSH KNOB. As shown in the operational-state dia-

gram, the operate screen is displayed only after a momentary RESET screen and the alignment-required

3-12

Model 441A Operation

screen has been cleared by pressing the display or pressing or turning the encoder.

Operation Rotate the encoder to select Y (yes) PUSH KNOB or

N (no) PUSH DISPlay.

Discussion Only when the user has selected Y PUSH KNOB and

has pressed the encoder will a reset be performed. Then

the unit will display the ALIGNMENT REQUIRED

screen, and the user can proceed as previously described.

ENCLOSURES

Model E408-1

The Model E408-1 is a single-unit mount designed to mount directly to a bulkhead or to a

DIN rail (Option D). It can be mounted on three of its six sides with screws (10-32 machine

screws are recommended) in any aspect. The installed unit can be right-side up or down

within the mount as well. A right-angle hooded DAM-15S connector is provided for cabling.

The hooded shell can be mounted right-side up or down, too, depending on where the user

would like the cabling to exit. Drawing 408-900 shows all unit dimensions as well as mounting

dimensions.

Model E408-6

The Model E408-6 enclosure is a six-channel bench-top unit, which will hold Models 352,

428, 441A, 441AL, and 451 in any combination. Being small, lightweight, and powered

either by ac or dc, the enclosure is well suited for use in the field as well as the laboratory.

Features

Inside the top cover, which is held on by four captive

•

screws, are terminals for each channel for bridge completion, CAL, and bridge balance (for Model 352).

Channel-input and dc-power connectors are PT series,

•

and output connectors are BNC. An ac power cord and

mating connectors for all but the BNC’s are provided.

Front-panel controls include power on-off (for ac and

•

externally applied dc); ALL ZERO for Model 428

equipped with autozero (Option O); and CAL with positions of +, −, and OPR (operate), which is functional

when a CAL resistor and any bridge configuration are

installed or connected. Calibration is input shunt calibration by means of electronically switching a customerinstalled CAL resistor in parallel with selected arms of

the bridge to produce either a plus or a minus calibration.

Also included are provisions for bridge balance for units

•

so equipped and output frequency-response control for

Model 352 amplifier-conditioners.

As with all Ectron enclosures, the Model E408-6 does

•

not degrade any plug-in specifications.

3-13

Operation Model 441A

Model E408-6Y has an internal 12 V dc power supply,

•

and the E408-6X has a power supply of 28 V dc.

When setting up the Model E408-6 for operation, refer

•

to either Drawing 408-600 (for 12 V dc systems) or

408-601 (28 V dc systems) at the rear of this manual

for settings of plug jumper W1 (W2 is not active when

using the Model 441A in this enclosure). Also depicted

are typical input configurations the customer may want

to use.

Model R408-14

The Model R408-14 enclosure is a 14-channel 3-

1

-inch-high,19-inch-wide rack-mount unit

⁄

2

that holds Models 352, 428, 441A, 441AL, and 451 in any combination. It also is powered

by either dc or ac and comes in both 12 V dc (Option Y) and 28 V dc (Option X) versions.

Features

Beneath the top cover are terminals for each channel

•

for bridge completion, CAL, and bridge balance (for

Model 352).

Channel-input and dc-power connectors are PT series,

•

and output connectors are BNC. An ac power cord and

mating connectors for all but the BNC’s are provided.

Front-panel controls include power on-off (for ac and

•

externally applied dc); ALL ZERO for Model 428

equipped with autozero (Option O); and CAL with positions of +, −, and OPR (operate), which is functional

when a CAL resistor and any bridge configuration are

installed or connected. Calibration is input shunt calibration by means of electronically switching a customerinstalled CAL resistor in parallel with selected arms of

the bridge to produce either a plus or a minus calibration.

Also included are provisions for bridge balance for units

•

so equipped and output frequency-response control for

Model 352 amplifier-conditioners.

3-14

As with all Ectron enclosures, the Model R408-14 does

•

not degrade the specifications of any plug-in.

Model R408-14Y has an internal 12 V dc power supply,

•

and the R408-14X has a power supply of 28 V dc.

When setting up the Model R408-14 for operation, refer

•

to either Drawing 408-605 (for 12 V dc systems) or

408-606 (28 V dc systems) at the rear of this manual

for settings of plug jumper W1 (W2 is not active when

using the Model 441A in this enclosure). Also depicted

are typical input configurations the customer may want

to use.

Section IV

Applications

GENERAL

To best understand how to apply the Model 441A, it is important to know some characteristics

of its design. This information is available in Section V, Theory of Operation, where some

of the features of the design as they apply to application of this product are covered.

INPUT-SIGNAL CONDITIONER

The job of the input-conditioner section of this instrument is to accommodate input signals

with a variety of waveforms, frequencies from 1 Hz to 50 kHz plus harmonics, and amplitudes

from 10 mV peak to 100 V peak. This must be accomplished such that the frequency integrity

of the input signal is carefully maintained, even while short-term frequency and amplitude

variations occur. Furthermore, the input must be adaptable to many signal sources and grounding conditions.

To minimize ground-loop problems the input was made differential and isolated from case

and power ground. Although signal levels are several-orders-of-magnitude greater than those

of transducer amplifiers, noise effects are still very important if accuracy and response are

required. This is because noise on the input signal causes unavoidable jitter in the conversion

process. (Filtering reduces this jitter but at a sacrifice of response time.)

Three controls are provided to improve conversion stability. These are a three-step inputsensitivity control, a three-step input-bandwidth control, and a digital periodic filter that

eliminates cyclic variations in the input signal.

An automatic-gain-control (AGC) circuit converts the input-frequency waveform to a waveform of relatively constant amplitude. Since zero crossings determine the action of the frequency-to-voltage converter, these must be carefully preserved in the signal conditioner.

Then a squaring circuit increases the rise and fall times of the waveform.

Since a sine wave does not have an abrupt wave front, frequency conversion for these signals

is not so accurate as for square or pulse waveforms. Thus, a low-amplitude sine-wave signal

will be more susceptible to noise and will generally show more noise on the output analog

signal as well as the frequency read-out on the display.

Square and pulse waveforms will give the most noise-free operation. The duty cycle of pulse

signals should be greater than about 5%. Minimum acceptable pulse width is approximately

5 µs. Although there is no minimum for rise or fall time, little is gained below about 0.6 µs.

INPUT SIGNAL, GROUNDING, AND SHIELDING

Four independent grounds exist within the Model 441A. As a result, flexibility exists in

adapting this unit to a variety of input signal sources. The available ground systems are:

• Input (two input leads and shield).

• Output (output high and low).

• Dc power (plus and common).

• Case.

4-1

Applications Model 441A

Proper use of these grounds will result in lower noise and more accurate data. (See the

paragraphs under uncertainty, resolution, and noise in this section.) However, incorrect grounding will increase noise and degrade data accuracy. Some grounding recommendations follow:

Input In any signal system, use only one ground point. This

applies to the input and output signal systems. The signal

input can be “floated off” ground to 100 V dc or peak

ac and grounded anywhere that suits the application.

The input-shield pin (Pin 9) should be tied to the signal-source common. Shielding and use of twisted-pair

leads are recommended if the input amplitude is below

100 mV or the electrical environment is poor.

Output The high- and low-output leads can and usually should

be grounded at the load device. Depending on the load

device, connecting this common to earth ground or dcpower-supply ground can minimize noise.

Power The negative of the dc power source should be connected

to earth or power-line ground. In Ectron enclosures, this

is accomplished by proper use of the third-wire-ground

pin on the power cord.

Case Case ground (Pin 5) should be connected to earth or

power ground. This is done in Ectron enclosures.

EMI PROTECTION

All connections to the converter go through emi-rfi filters to minimize the effects of rf noise.

The filter frequency coverage starts with about −3 dB of attenuation at 1 MHz, increasing

to −66 dB at 200 MHz and beyond. Emi-rfi filtering is particularly important in vehicle

testing, especially involving an engine where wideband emissions are generally high.

FREQUENCY-TO-ANALOG CONVERSION

The digital section receives the conditioned and shaped input-frequency signal. First, frequency-to-digital conversion takes place followed by digital-to-analog conversion. Both of

these digital-domain processes are governed by the user-selected frequency and voltage set

points.

OUTPUT ANALOG FILTER AND OUTPUT STAGE

To smooth the resulting analog signal, four user-selectable filter frequencies are available:

1 Hz, 10 Hz, and 100 Hz having second-order Bessel characteristics and a wideband (WB)

one-pole filter at approximately 1500 Hz. The analog output stage can drive loads at up to

±10 V at 10 mA. A short circuit on the output for an indefinite period will not harm the

instrument.

FREQUENCY AND VOLTAGE SET POINTS

The frequency set points determine the input frequency at which the upper- and lower-voltage

set points are reached. The frequency set points can be any frequency between 0 Hz and

50 kHz with a resolution of 1 Hz. The two frequency set points can be within 10 Hz.

4-2

Model 441A Applications

Similarly, the voltage set points determine the output voltages corresponding to the upperand lower-frequency set points, respectively. The voltage set points can be any voltage from

−10 V to +10 V with a resolution of 0.1 V. The two voltage set points can be within 0.1 V.

Table 4-1 illustrates converter operation with hypothetical frequency and voltage set points.

Table 4-1

Input Frequency vs Output Voltage (Example)

Frequency set points Voltage set points

(

)

Upper

Lower

f

2000 Hz

U

(

)

f

L

1000 Hz

Upper

Lower

Input Frequency Output Voltage Input Frequency Output Voltage

(

)

V

+

5 V

U

V

(

0

)

V

L

1000 0 3500

1500

2000

3000

2.5 900

+

5 500

+

10 0

+

10.5*

+

0.5

−

2.5

−

5

−

* The output limits at approximately ±11 V.

Should the application require it, the output can be set to provide a bipolar output (e.g., for

a certain frequency range the output can be set to go from −5.000 V to +5.000 V). Similarly,

the output voltage could be set to be all negative. Note that the higher frequency will always

produce the more positive output voltage.

Because the minimum difference between the upper- and lower-frequency settings is 10 Hz,

and the minimum difference between the upper- and lower-voltage settings is 0.1 V, it is

possible to set fU at 1000 Hz and fL at 990 Hz, VU to 1.0 V and VL = 0.9 V, thus giving a

frequency-to-voltage sensitivity of 100 Hz/V. Exactly the same results would be obtained if

the settings were fU = 1500 Hz, fL = 900 Hz, VU = 6 V, and VL = 0 V. The following section

shows that extreme settings can result in poor resolution and noise.

NOISE

In addition to frequency jitter of the input signal, noise at the output of the Model 441A

will be a combination of input signal noise, waveform character, signal amplitude, and instrument settings. For square and pulse waveforms, output noise should be well under the

10 mV p-p specification assuming sharp rise times and good pulse-to-pulse frequency and

phase stability. Ideally, rise times should be under 5 µs to utilize the extraordinary conversion

accuracy, resolution, and stability of this instrument. A further source of noise can be grounding problems of input and output signal circuits.

Despite the fact that the amplifier’s input is differential, input-to-output cross talk can exist

external to the amplifier. Good wiring practices should be followed to minimize this effect

(see Page 4-1, INPUT SIGNAL GROUNDING AND SHIELDING).

An additional source of input-to-output crosstalk is an inadequate case ground. All pins of

the connector incorporate emf-rfi filters. The capacitors associated with these filters connect

to case ground (Pin 5 on the DA connector). Consequently, if no case ground exists, signals

from one pin will be coupled to other pins by these capacitors. For example, if a sharp-rise

4-3

Applications Model 441A

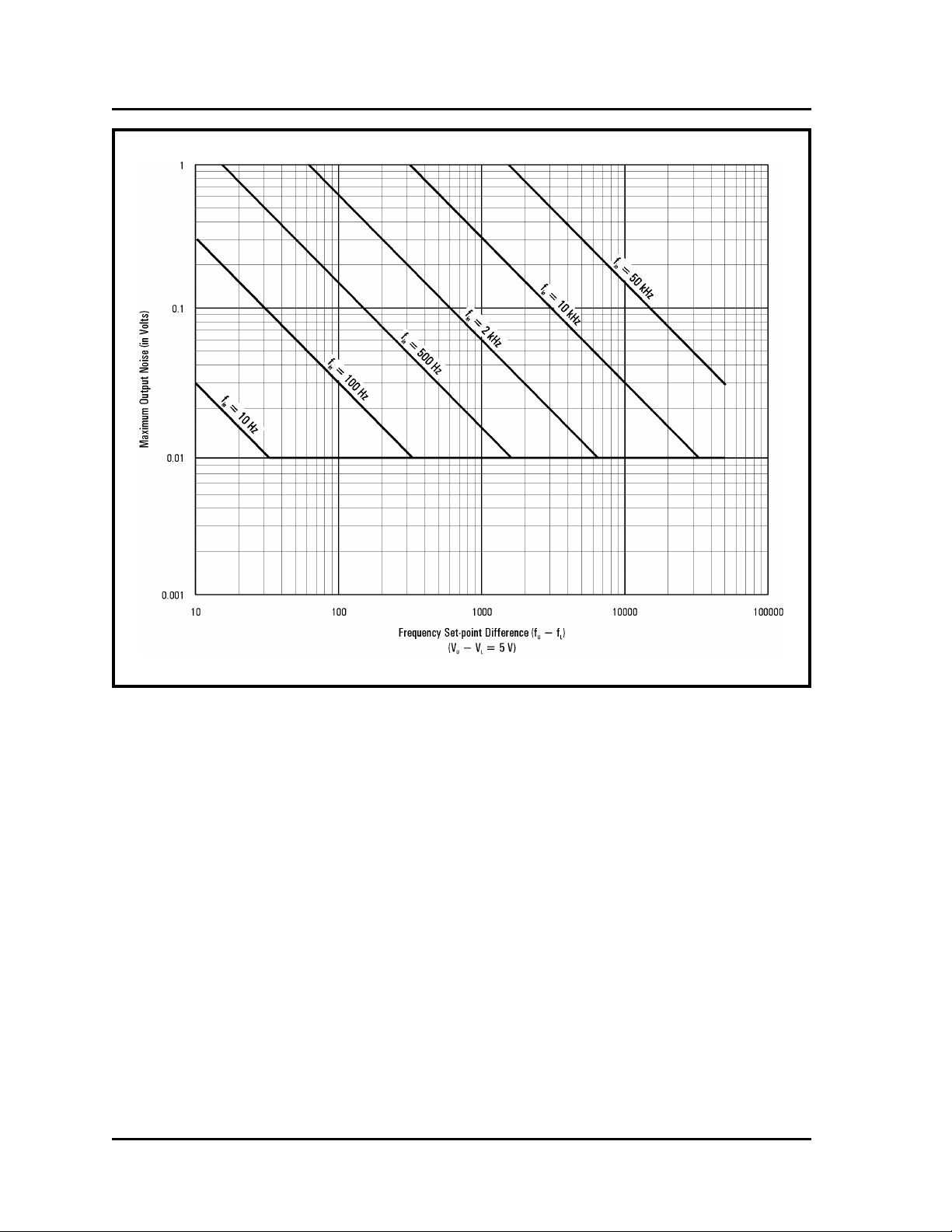

Figure 4-1

Maximum Uncertainty for Various Frequencies

square-wave signal exists on the signal input pins, pulses will be seen on the analog output

signal unless a good case ground exists. Ectron enclosures provide such a ground assuming

input power, either ac or dc, includes a good ground. Note that neither the input nor output

filters of the Model 441A will have much effect on these feed-through pulses.

For any frequency-to-voltage converter with fast response, sine-wave signals are the most

difficult from which to produce a low-noise output. This is because the slightest noise will

cause jitter in the “wave to wave” timing.

If a 10 mV p-p sine wave has even 100 µV of amplitude noise, then timing errors can cause

the frequency conversion to produce volts of output noise when the frequency input is high

and the frequency set-points difference is small. Figures 4-4 and 4-5 indicate expected output

noise for “clean” sine-wave signals of 10 mV p-p and 1 V p-p, respectively.

To reduce the output noise under difficult input signal conditions, the operator should use

as much filtering as possible and should set a wide frequency-set-points difference. Another

possibility is to reverse the input leads to the unit. This may improve the waveform at the

transition point of the converter and produce less output noise.

4-4

Model 441A Applications

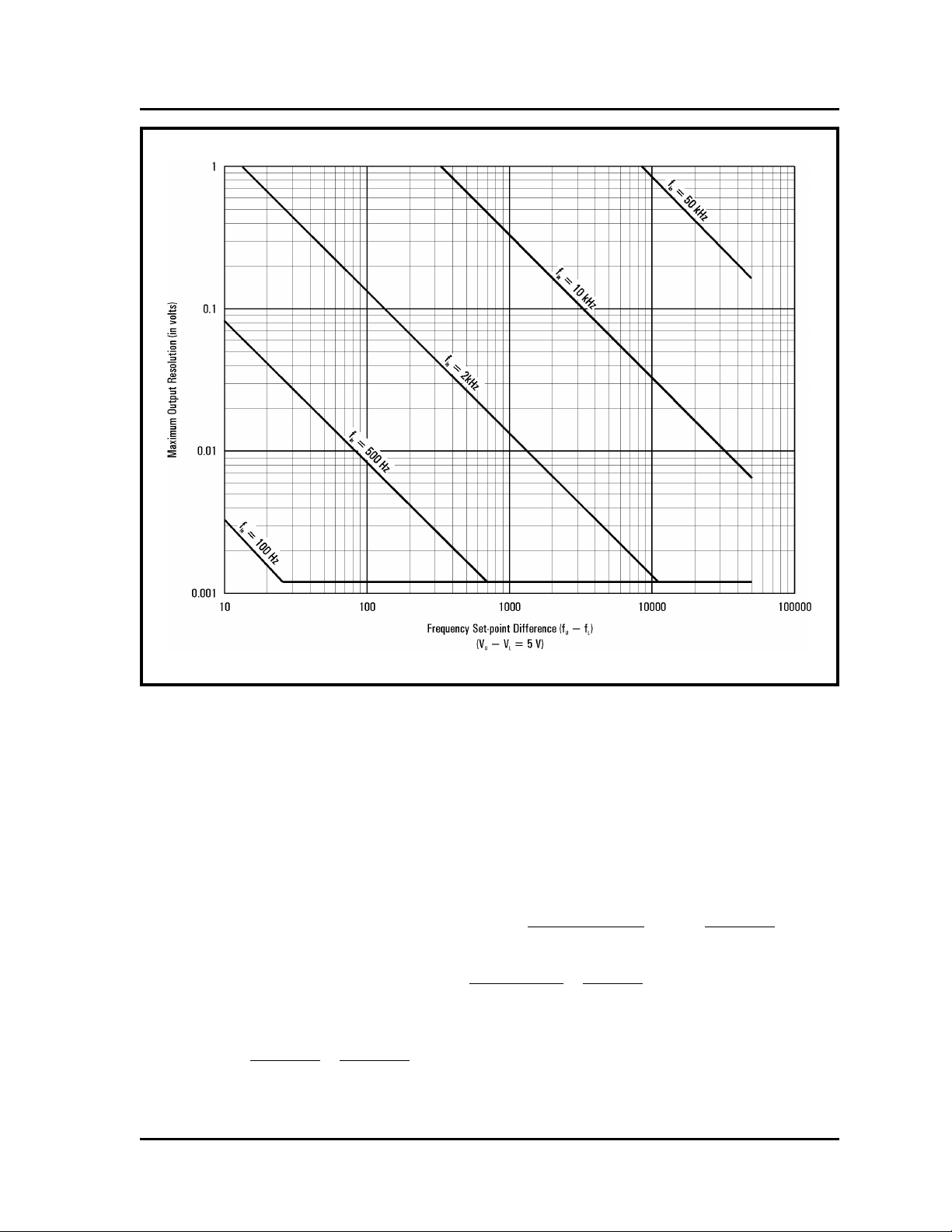

Figure 4-2

Worst-case Resolution for Various Frequencies

If the input waveform is sawtooth, then output noise will be best if the slow-rise portion of

the waveform is positive going, and the abrupt fall is negative going. This is true since the

internal conversion circuit of the Model 441A uses the fall time for triggering. However, if

the waveform is the reverse, slow fall and abrupt rise, simply reverse the frequency-input

leads. Since the input is differential, this reversal will not cause noise or ground-loop problems.

UNCERTAINTY AND RESOLUTION

10

×

6

)f

10

6

) −

VU − V

fU − f

in

f

L

Output analog uncertainty is within ± 0.00122 +

quencies less than 1 kHz, and ± 0.00122 +

(

1.5

× 106)F

f

in

(1.5 ×

2

(1.5 ×

and above. Output resolution for input frequencies of 1 kHz or below is the greater of

2

0.0012 V or

f

in

1.5 × 10

×

6

VU − VL

f

U

− f

, resolution for frequencies above 1 kHz is 0.0012 V

L

V

− VL

− f

in

in

L

for frequencies of 1 kHz

U

×

fU − f

for fre-

L

4-5

Applications Model 441A

Figure 4-3

Maximum of Uncertainty and Resolution for Various Frequencies

(Figures 4-1 and 4-2 Combined)

2

or

f

in

1500F

×

V

fU − f

U

− V

L

, and output analog noise is less than 10 mV p-p independent of

L

input frequency measured in a bandwidth of 0.1 Hz to 1 MHz assuming a clean, fast, zero-

1

crossing signal.

The preferred signal is a square wave or a pulse with fast fall times (the

internal detector operates on the negative-going portion of the waveform.) For slow-rise-time

signals including sine waves, output noise depends on input-signal amplitude and noise,

since accurate timing determination is hampered by noise.

Figures 4-1 through 4-5 illustrate the variation of uncertainty, resolution, and noise for an

output of 0 V to 5 V (VL to VU). Different input frequencies (fin) are plotted against frequency

set-points differences (f

− fL).

U

Figure 4-1 illustrates the effect on uncertainty of different input frequencies and with different

frequency-set-points difference (f

1

For the four equations,

V

are the upper and lower voltage settings; and

L

f

is the input frequency; F is

in

− fL). Output-voltage set points are assumed to be 0 V

U

f

f

/

, rounded down to the nearest integer;

1000

in

f

and

are the upper and lower frequency settings.

U

L

V

and

U

4-6

Model 441A Applications

Figure 4-4

Maximum Output Noise with a 10 mV Sine-wave Input

and +5 V. Note that for the plot for an input frequency of 10 kHz, uncertainty reaches

0.023 V when (fU − fL) reaches 100 Hz. This could be for an upper-frequency setting of

10,050 Hz and a lower-frequency setting of 9950 Hz. Even for a frequency setting difference

of 10 Hz, uncertainty at 10 kHz only reaches a total of 0.27 V out of a full scale of 0 V

to 5 V.

Figure 4-2 shows that resolution reaches a worst case of 0.015 V for input frequencies of

up to 2,000 Hz and a frequency set-points difference of 1000 Hz or higher. Again, output

voltage set points are 0 V and +5 V. However, as input frequency increases and the frequency

set-points difference decreases, resolution degrades. Fortunately, extreme sets of conditions

should seldom occur.

Figure 4-3 is a combination of Figures 4-1 and 4-2 to illustrate the worst case the user can

expect at extreme settings.

4-7

Applications Model 441A

Figure 4-5

Maximum Output Noise with a 1 V Sine-wave Input

FILTERING

There are three types of selectable filters in the Model 441A: input, output, and periodic-error.

The first two are analog low-pass filters, and the last is a digital filter. These filters have

the following characteristics and application.

Input Bandwidth Filter This filter is used to reduce noise on the input frequency

signal to provide reliable triggering. The screens are

labeled MIN, MID, and MAX bandwidth corresponding

to a single-pole low-pass filter with approximate corner

frequencies of 10 Hz (MIN), 500 Hz (MID), and

150 kHz (MAX). The proper setting for this filter depends on the noise frequencies and their relation to the

desired signal and is usually set by trial and error in

conjunction with the sensitivity control INPUT SEN-

Sitivity. Use the lowest bandwidth setting that provides

reliable triggering. Frequently, best operation is obtained

with the filter frequency set below that of the signal of

4-8

Model 441A Applications

interest. During setup, the lowest and highest signal frequencies should be tested for proper operation.

Output Filter This two-pole active filter is used to reduce noise of

the output analog signal. Corner frequencies are 1 Hz,

10 Hz, 100 Hz, and WB (approximately 1.5 kHz).

Since the lower the filter frequency the slower the response, a compromise must be made between noise and

response. (Response of the digital filter adds to the response of the analog output filter.) Table 4-2 indicates

the response to a step-frequency change for the four

filter frequencies assuming the digital filter is set to a

PULSES/REVolution of 001. In general, the user

should select the lowest filter setting consistent with the

response requirements of the application.

Table 4-2

Response Time Versus Output Filter Setting

Output Filter in Hz

WB (1500) 0.005*

100 0.055*

10 0.5*

15.0*

1

⁄

* add

f

in

where

f

in

Approximate Response Time

in Seconds

is the input frequency

Digital Filter For operational frequencies up to 1 kHz, this unique

filter uses digital averaging of the converted input signal

to eliminate the unwanted effects of a signal whose frequency varies in a periodic manner. For example, the

output frequency of a paddle-wheel flow sensor usually

changes as the wheel rotates because the paddles are

not evenly spaced. If the sensor has eight paddles, its

output will consist of a repeating sequence of eight

pulses. If this signal is fed to a frequency-to-voltage

converter without this filtering, the output analog signal

will have a cyclic component with a period equal to

the period of rotation of the device. However, by using

the digital filter with an eight-pulse running average,

the period variation is averaged out and a much more

stable analog output is obtained.

Figure 4-6 illustrates the function of the digital filter

for a signal from an eight-paddle sensor. At first, the

unfiltered (stair-step) analog output varies about 5 V;

then the speed of rotation is increased so the signal

varies about 5.4 V. Keying in eight pulses per revolution

4-9

Applications Model 441A

Figure 4-6

Effects of the Digital (Periodic-error) Filter

changes the analog output to that shown by the smoothed

trace. Note that the second cycle of eight steps is changed

to a steady 5.0 V level. When the frequency abruptly

changes to the 5.4 V level, the digitally-averaged signal

linearly changes so that in eight steps, the 5.4 V level

is reached. As a result of the digital filter, the variation

(noise) caused by the eight-step cycle is eliminated. During and after the transition to a new level, eight-step

averaging continues.

The stair-step wave form during the frequency change

in Figure 4-6 is a result of the update rate of the unit,

which when period averaging is allowed, is longer than

1 ms. That is, period averaging only works below 1 kHz.

The filtering effect of digital averaging is useful in reducing random noise signals as well as periodic signals.

Response time will be reduced in direct proportion to

the Sample Count setting although response time will

change with input frequency. For example, for an eightcount sample period and an input frequency of 64 Hz

the response time (to reach final value) will be

For a frequency of 6400 Hz the response time will be

1

⁄

s.

800

1

⁄8 s.

4-10

Model 441A Applications

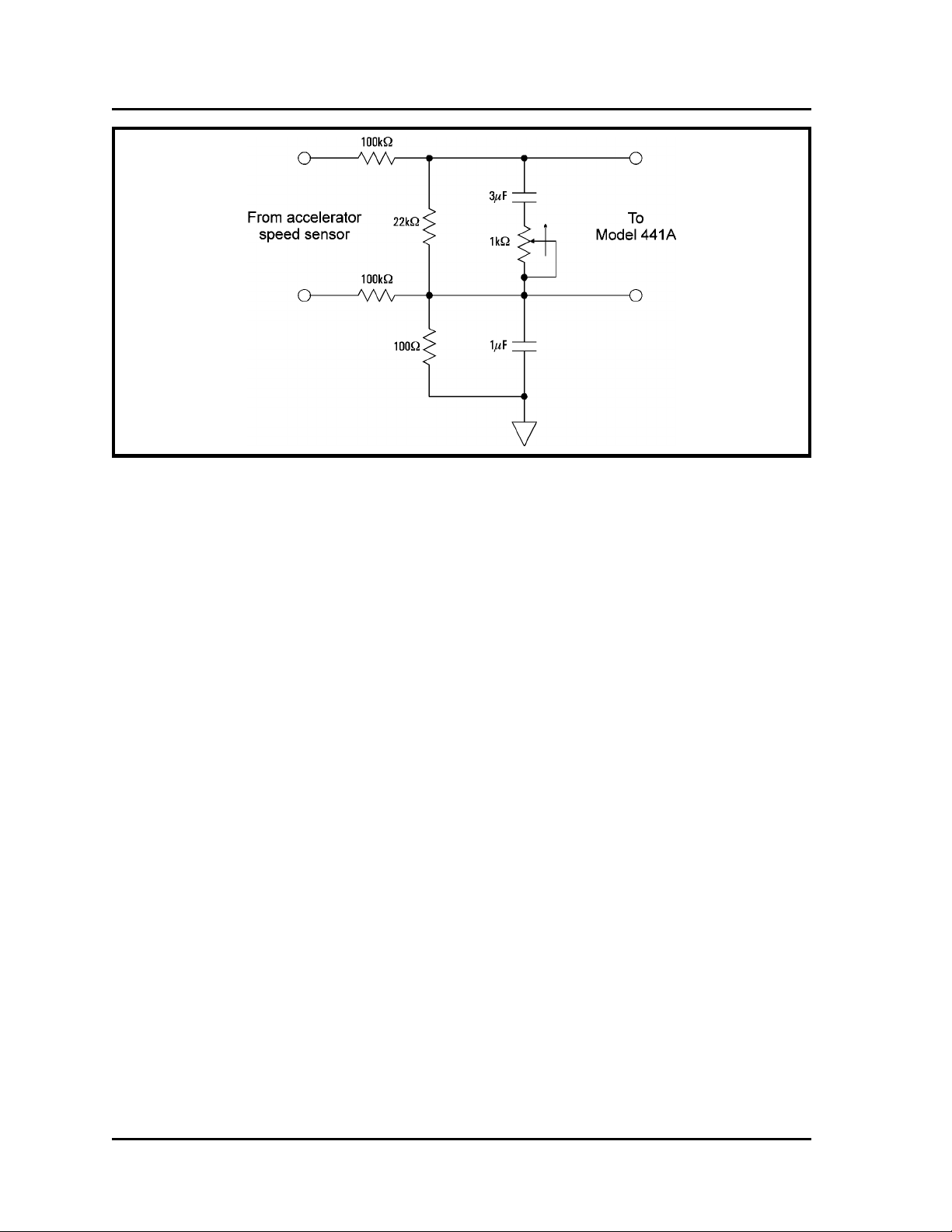

Figure 4-7

Filtering Scheme for ABS Testing

The Model 441A allows the user to set the number of

cycles of the period filter from 001 to 999 (001 being

the same as OFF) by setting the number as the PULSES

/ REVolution. (See Section III for instructions.)

For frequencies exceeding 1 kHz, the periodic filter is

automatically turned off. This means that anytime the

time interval between two pulses is less than 1 ms, the

filter is shut off (even though it has been activated at

the front panel by the user) and will automatically turn

on (provided it is programmed on by the user) if and

when the time interval exceeds 1 ms. Then, as soon as

the required number of pulses (determined by the pulsesper-revolution setting) has been received as input, the

output will again show the elimination of the periodic

error. The user who is operating near 1 kHz should be

mindful of this operation.

Applications for the period filter include flowmeters of

the turbine or propeller type, rotating-cup anemometers,

wheel-speed sensors of the cogged-wheel type (ABS

systems) used on automobiles, rotary optical encoders,

shaft torque detectors, etc. Usually, periodic errors are

caused by irregular spacing of the steps of the rotating

element of the device, but they can also be caused by

lack of concentricity between the rotating element and

the pick-off (run out).

Another application would be a jet turbine engine whose

rpm needs to be known or controlled exactly. A cogged

4-11

Applications Model 441A

Figure 4-8

Filter Circuit for ABS Testing

wheel rides on the engine shaft that has spacing irregularities. This causes a slight variation in the output pulse

spacing and would produce noise in the resulting analog

output of the Model 441A. This noise would prevent

knowing the exact rpm. If the wheel has 40 cogs, using

a PULSES / REVolution setting of 040 would eliminate the noise caused by the spacing irregularities.

Therefore, using digital averaging allows the output to

be as exact as the inherent high accuracy and stability

of the Model 441A.

SELECTABLE INPUT SENSITIVITY

This control adjusts the gain of the input amplifier and is useful when noise is causing

erratic triggering. This can occur when no signal is present or when the signal level is low.

Usually, the optimum setting of this control is made in conjunction with the input filter

setting. Gain decreases by a factor of approximately 6:1 from the MAX setting to the MID

setting. A further decrease of approximately 8:1 occurs between the MID setting and the

MIN setting.

RESPONSE TIME

Response to an abrupt frequency change is 0.005 s + 1⁄

band (f

is the new frequency). Thus, if the input frequency is 10 Hz and suddenly changes

new

to 1000 Hz, the analog output will assume the new value in less than 6 ms. For lower filter

frequencies,

5

(in seconds) must be added.

⁄

f

co

with the output filter set to wide-

f

new

UPDATE RATE

The update rate is 1 ms or 1⁄

, whichever is greater.

f

in

4-12

Model 441A Applications

Figure 4-9

Strip-chart Recording of ABS Action

LATENCY

Latency is the time required for the output to respond to a change in input frequency. Latency

in the Model 441A is within 1 ms of each falling edge of the input signal for input frequencies

above 1 kHz, and within 1 ms +

1

for frequencies below 1 kHz.

⁄

f

in

FRONT-PANEL INDICATION

The display on the front panel indicates the frequency of the incoming signal with a resolution

of five digits and the pulses per revolution setting of the periodic-error filter. Displaying the

input frequency serves several purposes during setup and operation of a test. First, it gives

the operator a “warm and fuzzy” feeling knowing that everything works. It confirms that

the pickup device is working and connections to the converter are correct. If the frequency

is approximately correct, it shows that the signal level is probably acceptable to the converter.

During the test, an operator can monitor the read-out to get a quick look at the frequency

data. The green front-panel LED will extinguish if no signal is present, and the display will

read 0.0000. If the input signal exceeds 50 kHz the read-out will continue to read correctly

until the frequency exceeds 63 kHz. Above this frequency, the read-out will show dashes.

(The analog output also will continue to be correct until it reaches approximately 11 V.)

The setting of periodic filter has also been selected for this screen because an incorrect

setting such as the wrong number of pulses per revolution increases noise as can using it

above 1 kHz.

CALIBRATION

The CALibration mode allows the operator to set a calibration signal from 0 Hz to 50 kHz

in 1 Hz increments. When CAL is enabled, the analog output assumes a voltage value of

the CAL frequency in accordance with the frequency and voltage set points. The calibration

circuit does not test the input-signal-conditioning circuitry and ignores any input signal.

To turn on the calibration signal, go to the CAL screen, adjust the frequency, and set OFF-ON

to ON. At this time, the output will assume the analog value corresponding to the frequency

and voltage set conditions. This output and the CAL screen will remain until it is exited or

the CAL is toggled OFF.

4-13

Applications Model 441A

The CAL mode can be used as a highly accurate linearity check of the equipment that

follows the Model 441A. First, perform the voltage alignment as described in Section III,

and then step the calibration settings over the range of interest, perhaps from zero to full

scale in 10% increments. This test should produce a system linearity check within an

uncertainty of 0.1% of full scale.

VEHICLE APPLICATIONS

Because the modern automobile generates a great variety of sometimes intense noise signals,