Ecotherm BISOLID Series, Bisolid 30, Bisolid 18, Bisolid 25 Installation, Operation And Maintenance Manual

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

MANUAL

FOR INSTALLATION, OPERATION AND MAINTENANCE OF PELLET

BOILER OF SERIES BISOLID

Pellet boiler Bisolid 20 July 2017 OM-PBBV02/07/2017/EN

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

CONTENT page.

1. IMPORTANT INFORMATION ABOUT THE PELLET BOILER OPERATION .............................. 3

1.1. SAFETY INSTRUCTIONS ............................................................................................................. 3

2. PELLET BOILER BISOLID DESIGNATION .................................................................................. 5

3. DESCRIPTION OF PELLET BOILER FROM SERIES BISOLID .................................................. 6

3.1. MAIN INFORMATION ON THE PELLET BURNER BISOLID GP XX_B HC> .............................. 7

3.2. MAIN INFORMATION ON THE FUEL HOPPER .......................................................................... 9

4. BISOLID PELLET BOILER’S TECHNICAL DATA....................................................................... 11

5. MOUNTING AND INSTALLATION OF PELLET BOILER BISOLID ............................................ 24

5.1. REQUIREMENTS FOR INSTALLATION OF PELLET BOILER BISOLID .................................. 24

5.2. REQUIREMENTS FOR INSTALLATION OF PELLET BURNER BISOLID GP XX_B HC> TO

BOILER BISOLID .................................................................................................................................. 24

5.3. MOUNTING OF HOT WATER PELLET BOILER BISOLID ........................................................ 25

5.3.1. POSITIONING OF THE BOILER ................................................................................................. 25

5.4. METHODIC FOR INSTALLATION OF BOILER .......................................................................... 26

5.4.1. CONNECTION TO A CHIMNEY.................................................................................................. 26

5.4.2. CONNECTING TO THE HEATING INSTALLATION................................................................... 27

5.4.3. INSTALLATION OF PELLET BURNER FROM SERIES BISOLID GP XX_B HC> .................... 27

5.4.4. MOUNTING THE FIRE-CLAY MADE DIRECTING BRICKS ...................................................... 28

5.4.5. POSITIONING/CHECK OF THE ASH CLEANING SECTION COVER ...................................... 29

5.4.6. MOUNTING OF THE COVER PLATE IN FRONT OF THE FLUE GAS OUTLET ...................... 29

5.4.7. MOUNTING OF THE BOILER’S HORIZONTAL COVERS ......................................................... 31

5.4.8. MOUNTING OF THE COVER OVER THE BOILER’S CONVECTION TRACT .......................... 31

5.4.9. MOUNTING OF THE COVER OVER THE BOILER’S COMBUSTION CHAMBER ................... 32

5.4.10. CONNECTING THE PELLET BURNER TO THE BOILER ............................................. 32

5.4.11. MOUNTING OF THE FUEL TRANSPORT AUGER TO THE BURNER ......................... 33

5.4.12. FILLING UP THE FUEL TRANSPORT AUGER .............................................................. 34

5.4.13. CONNECTING OF THE BOILER TO THE MAIN POWER SUPPLY .............................. 34

5.4.14. EXEMPLAR HYDRAULIC DIAGRAM ............................................................................. 34

6. INITIALIZATION OF THE SYSTEM TO OPERATION ................................................................ 36

6.1. MAIN REQUIREMENTS ABOUT THE USED FUEL ................................................................... 36

6.2. INITIALIZATION TO OPERATION OF THE BOILER BISOLID .................................................. 37

6.2.1. GENERAL CONDITIONS ............................................................................................................ 37

6.2.2. POWERING OF THE PELLET BOILER FROM SERIES BISOLID............................................. 37

6.2.3. SWITCHING OF THE SYSTEM ON ........................................................................................... 38

6.2.4. PARAMETERS FOR BOILER OPERATION ADJUSTMENT ..................................................... 38

6.2.5. PARAMETERS FOR ADJUSTMENT OF PELLET BURNER BISOLID GP XX_B HC> ............. 39

6.2.6. NOMINAL OPERATION MODE OF THE BOILER ...................................................................... 39

6.3. ADJUSTMENT OF THE BOILER HEATING OUTPUT ............................................................... 40

6.4. DECREASING THE BOILER HEATING OUTPUT ..................................................................... 40

6.5. INCREASING THE BOILER HEATING OUTPUT ....................................................................... 40

6.6. ADJUSTMENT OF THE COMBUSTION PROCESS .................................................................. 40

6.7. SWITCHING THE BOILER OPERATION OFF ........................................................................... 41

6.8. EMERGENCY BOILER SHUT DOWN ........................................................................................ 41

6.9. SERVICING AND MAINTENANCE OF THE PELLET BOILER BISOLID .................................. 42

6.10. WARRANTY AND WARRANTY CONDITIONS .......................................................................... 44

6.11. ACTIONS AFTER EXPIRY OF THE BOILER LIFE CYCLE ....................................................... 45

7. TROUBLESHOOTING ................................................................................................................. 46

8. WIRING DIAGRAM OF PELLET BOILER BISOLID IN A SYSTEM WITH PELLET BURNER

BISOLID GP XX_B HC> ........................................................................................................................ 49

Pellet boiler Bisolid OM-PBBV02/07/2017/EN

2

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

1. IMPORTANT INFORMATION ABOUT THE PELLET BOILER OPERATION

Dear Bisolid pellet boiler owners,

We would like to congratulate you for your new pellet boiler. By purchasing this quality

product from the manufacturer you have chosen a system that ensures higher comfort level

and optimized fuel consumption in environmentally protecting and natural resource saving

way. Your pellet boiler is manufactured under strict ISO 9001 standards.

On the next pages we have introduced specific information and important advices about the

system operation, its functions and methods of maintenance. Please pay special attention to

this manual. Good knowledge of this document content will give you the pleasure of longterm and trouble-free operation of the pellet boiler.

1.1. SAFETY INSTRUCTIONS

The hot water pellet boiler from series Bisolid and its accessories correspond to all applicable

directions for safety techniques. Your pellet boiler and all of its accessories operate under

variable electricity 230 VAC. Improper electrical installation or repair may endanger user’s life

from electrical shock. Installation works must be performed only by qualified technicians.

This manual is intended for authorized service specialists only. It is important to know that:

Works on the heating installation should be performed only by technicians who had

acquired such rights by law.

Works on the electrical installation should be performed by qualified electricians only.

Initial operation start up including installation visual checks, adjustments and starting

must be performed by the manufacturer authorized personal.

LEGAL PROVISIONS

While operating with the appliance please observe:

Legal provisions for safety techniques.

Legal provisions for environment protection.

Provisions for proper installation.

Applicable provisions of the European community.

SAFETY INSTRUCTIONS

Danger

Please observe these safety instructions in order to prevent the people from

risks and harms, as well as damage to properties and environment.

Safety instructions explanation:

Please pay attention to the following symbols in this manual:

Pellet boiler Bisolid OM-PBBV02/07/2017/EN

3

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Danger

This symbol warns the user about health risks.

Warning

This symbol warns the user about possible risks and harms to properties and

environment.

Information

This symbol presents text with additional information for the user.

WORKS OR ACTIVITIES FOR SETTING THE APPLIANCE IN PROPER TECHNICAL

WORKING ORDER

Repairs of constructional elements which functions are related to the technical

safety may compromise the safely operation of the installation. Damaged or

faulty elements must be replaced with genuine spare parts provided by the

manufacturer.

After carefully reading of the installation and operation manual, you will

acquire all necessary information about design, controls and safety operation

of the pellet boiler. After unpacking the pellet boiler please check its

completeness and delivered elements. Check whether the pellet boiler size

corresponds to the desired designation.

If any failures or troubles occur the pellet boiler must be led out from operation and removing

of the faults/troubles must be provided by specialized company. For proper functioning, safe

and long-term operation of the pellet boiler, a regular check ups and prophylaxis must be

performed at least once per year. Such technical care guarantees your investment.

Repairs should be performed only with genuine spare parts. In case of faults or troubles

caused by unqualified installation, non-compliance with the requirements or the operation

manual, the manufacturer company is not responsible and does not provide warranty for the

product.

The current manual for operation, installation and maintenance uses notation

of pellet boiler Bisolid includes the model of pellet boilers modification Bisolid

18 (18kW), Bisolid 25 (25kW) и Bisolid 30 (30kW).

Pellet boiler Bisolid OM-PBBV02/07/2017/EN

4

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Bisolid

2. PELLET BOILER BISOLID DESIGNATION

Type designation of boiler series: Bisolid 18

Example

Boiler trade name

Nominal heating output*, kW

* Similar to other models of hot water boilers Bisolid 25 and Bisolid 30.

The pellet boilers from series Bisolid are designated to utilize wood pellets as the boiler has a

steel made construction. These boilers are used for local heating systems and also for

heating of domestic water. The boiler utilizes wood pellets, as described below, as the

generated heat is accumulated by the heat exchanging surfaces of the boiler body and is

transferred to the heat carrier in the heating system.

The hot water pellet boiler from series Bisolid standard delivery kit includes:

Heat exchanger – 1 unit.

Automated pellet burner with manually mechanically cleaning from series Bisolid GP

xx_B hc> – 1kit.

Ash container (tray) – 1pc.

Boiler’s bottom cover panel (between the second and third pass).

Fire-clay made bricks – 2 pcs.

Flap – 1pc.

Door handle – 1pc.

Cleaning kit (scraper – 1pc, hook – 1pc).

Electrical connector for room thermostat – 1pc.

Power supply cable – 1pc.

Nut and washer M10 – 2 pcs.

Manual for installation, operation and maintenance of the boiler – 1pc.

The pellet boiler from series Bisolid is designated to utilize wood pellets with diameter Ø 68mm, from class A1 according to standard EN ISO 17225-2:2014.

Boiler’s advantages:

Compact and simple steel structure that allows dynamic operation, easy installation

and operation - plug & play.

Compact control, interface panel and exported in the back end of the boiler

connectors.

Ability to work with a room thermostat (weekly programmable).

Meets the most stringent European requirements and standards (EN 303-5:2012).

High efficiency and low emissions.

Ability to providing domestic hot water (DHW).

Minimum operating costs.

The boilers are available in two versions for left or right side burner adjustment.

18

Pellet boiler Bisolid OM-PBBV02/07/2017/EN

5

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

3. DESCRIPTION OF PELLET BOILER FROM SERIES BISOLID

The steel made hot water pellet boiler from series Bisolid is designated for heating of local

installations with natural or forced water circulation performed with or without circulations

pump. The heat exchanger unit is module of the system designated for automatic utilization

of pellets and for heating of the circulations water. The cleaning of the ash from the burning

process can be performed manually through the combustion chamber’s lower front door, by

taking out the ash-tray and gathering its content in proper for the purpose containers. The

combustion process organization and the heat exchanging with the boiler body internal

surfaces ensures high efficiency. The operation of the system: hot water pellet boiler from

series Bisolid and automated pellet burner with manually cleaning from series Bisolid GP

xx_B hc> depend on the chimney draught. The chimney draught depends on the chimney

condition and on the flue gas temperature.

The hot water boiler’s Bisolid heat exchanger construction complies with the resistance

requirements for such type of appliances: EN 303-5:2012 - "Heating boilers. Part 5: Heating

boilers for solid fuels, manually and automatically stoked, nominal heat output of up to 500

kW. Terminology, requirements, testing and marking.

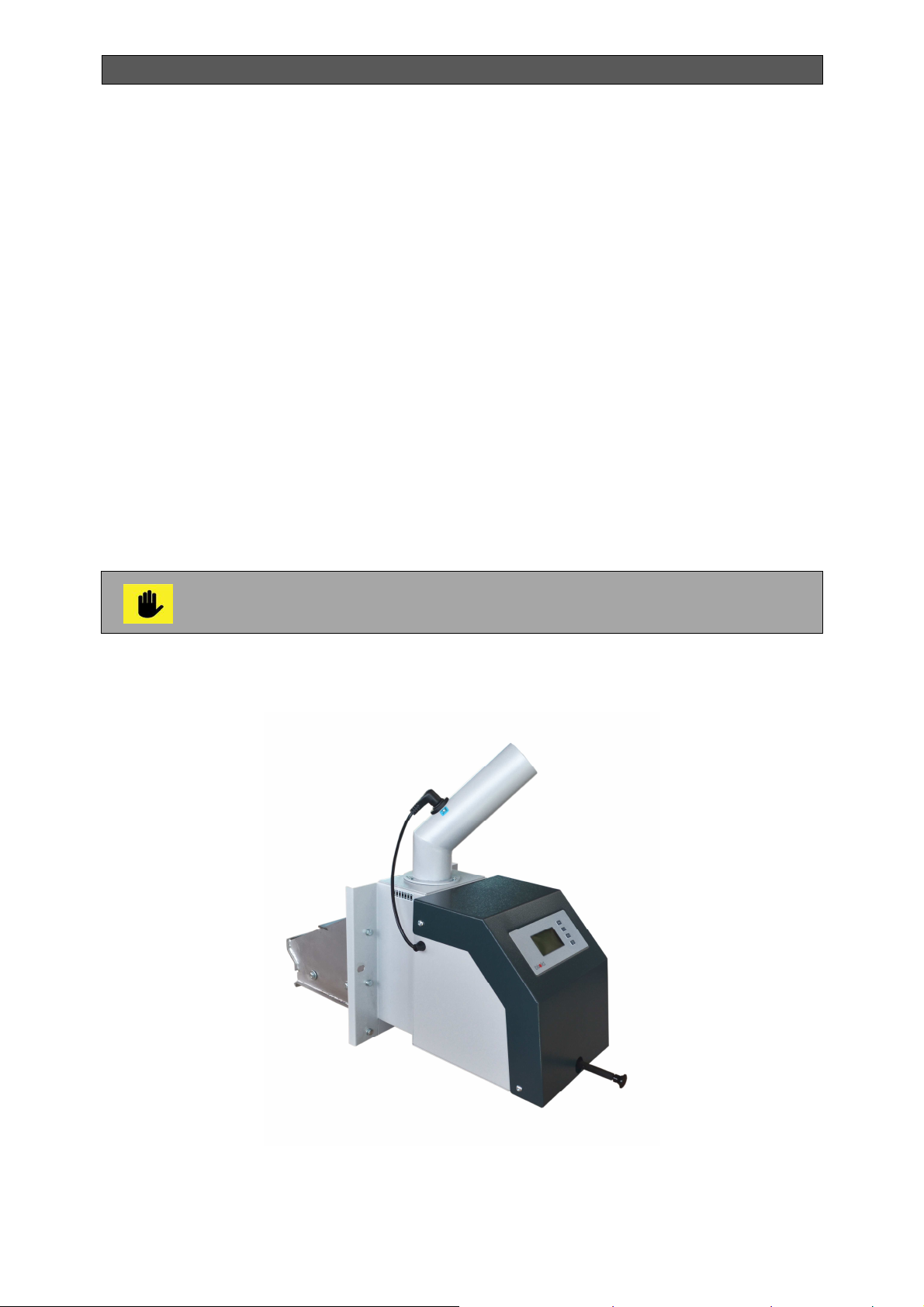

Figure 3.1. External view of steel made hot water pellet boiler from series Bisolid.

The boiler consists of the following components/modules:

The main module of the hot water boiler is the boiler body (heat exchanger), as the

automated burner from series Bisolid GP xx_B hc> is mounted on its side. The heat

exchanger is offered in two versions: so called “left” and “right” mounting. The

automated pellet burner with manually mechanically cleaning can be mounted only on

the left or only on the right side of the boiler body.

The heat exchanger unit construction is made of steel plates. The combustion

chamber is designed in the front lower part of the heat exchanger, as the ash

container is below it. The heat exchanger is with compact size related to the achieved

heating output, because it has three pass design, which provides optimal heat

exchanging and high efficiency.

Pellet boiler Bisolid OM-PBBV02/07/2017/EN

6

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Fire clay made components mounted in the combustion chamber, which ensure

optimal burning process and complete fuel combustion.

The ash-tray is positioned at the bottom of the combustion chamber. The ash

residues are gathered in it providing easy cleaning.

The water inlet and outlet muffs are positioned at the boiler’s back side and are inner

threaded with size G1½”, as through them the appliance can be connected to the

heating system.

The flue outlet (with external diameter Φ149 mm) is positioned centrally in the top

rear side of the boiler and serves for extraction of the flue gasses to the chimney.

The steel made heat exchanger, its cover and doors are isolated with mineral wool,

which limits the heating losses to the local environment.

Manometer, positioned on the boiler body’s front panel, indicates the circulations

water pressure in the heat exchanger.

External decoration side cover panels made of steel plates and painted with high

quality color coating materials.

3.1. MAIN INFORMATION ON THE PELLET BURNER BISOLID GP XX_B HC>

The pellet burner with manually cleaning from series Bisolid GP xx_B hc> is mounted

horizontally and laterally ("left" or "right" installation) of the hot water boiler from series Bisolid

and it is a separate (standalone) module.

The kit of the pellet burner with manually cleaning from series Bisolid GP xx_B includes:

Main module – 1pc.

Fuel transport auger – 1 pc.

Flexible pipe – 1 pc. with brackets – 2 pcs.

Manual for installation, maintenance and operation of pellet burner from series Bisolid

GP xx_B hc> – 1 pc.

The main module of automated pellet burner with manually cleaning from series Bisolid GP

xx_B hc> consists of the following components:

Combustion chamber, that provides conditions for optimal burning process and is

made of high quality fire-proof steel.

Fire-grate of the combustion chamber, that can be easily removed and provides

availability for easy cleaning of the ash.

Air distribution tract, that provides equal firing air distribution and cooling of the

burner’s components.

Electrical heating element, used for initial fuel firing and positioned under the

combustion chamber’s fire-grate.

Fresh (firing) air fan, equipped with sensor for determining the rotation velocity and

providing availability for adjustment.

Photo-sensor for monitoring of the burning process, positioned sideways for easier

cleaning.

Emergency temperature sensor for prevention of the so called “back fire” in the

pellets inlet pipe.

Control module, for monitoring and controlling of the burner operation.

Fuel transport auger connector, used for powering the auger.

Interface panel, equipped with display and keyboard for easy adjustment.

Linkages handle for manually mechanical cleaning of the grate in the combustion

chamber of the burner.

The pellet burner kit includes electrical powered external auger used for transportation of the

fuel from the hopper to the burner. The auger consists of compact size motor-gear equipped

Pellet boiler Bisolid OM-PBBV02/07/2017/EN

7

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

with integrated overheating protection, pipe in which the fuel is transported to the flexible

pipe drop zone.

The flexible pipe made of special transparent thermo-resistant inflammable material (it melts

but does not separate toxic substances) that connects the auger and the burner’s main

module.

The main advantages of the pellet burner from series Bisolid GP xx_B hc> are:

The pellet burner’s are fully automated – ignition, flame control, combustion chamber

blowing. It is also equipped with intuitive LCD display for easy operation.

Automatic adjustment of fresh air and fuel feed rates according to the selected

operating temperature, which feature provides high efficiency of the appliance at

minimum fuel consumption.

Automatic modulation of the burning process decreasing the number of stops and

ignitions, respectively fuel and electricity consumption.

Manually mechanical cleaning of the fire-grate, through leverage without opening the

boiler and without interruption of the operation.

Circulations pump control according to heat carrier (water) temperature.

Quiet operation and low electric power consumption.

Protection from back-fire and from heat carrier (water) freezing.

Circulations pump protection against blocking.

Possibility for control of extractor (flue gas) fan.

Possibility for operation with room thermostat and week programmer.

The actual and detailed information on the construction and technical data of

the pellet burner with manually cleaning from series Bisolid GP xx_B hc> is

given in its manual for operation.

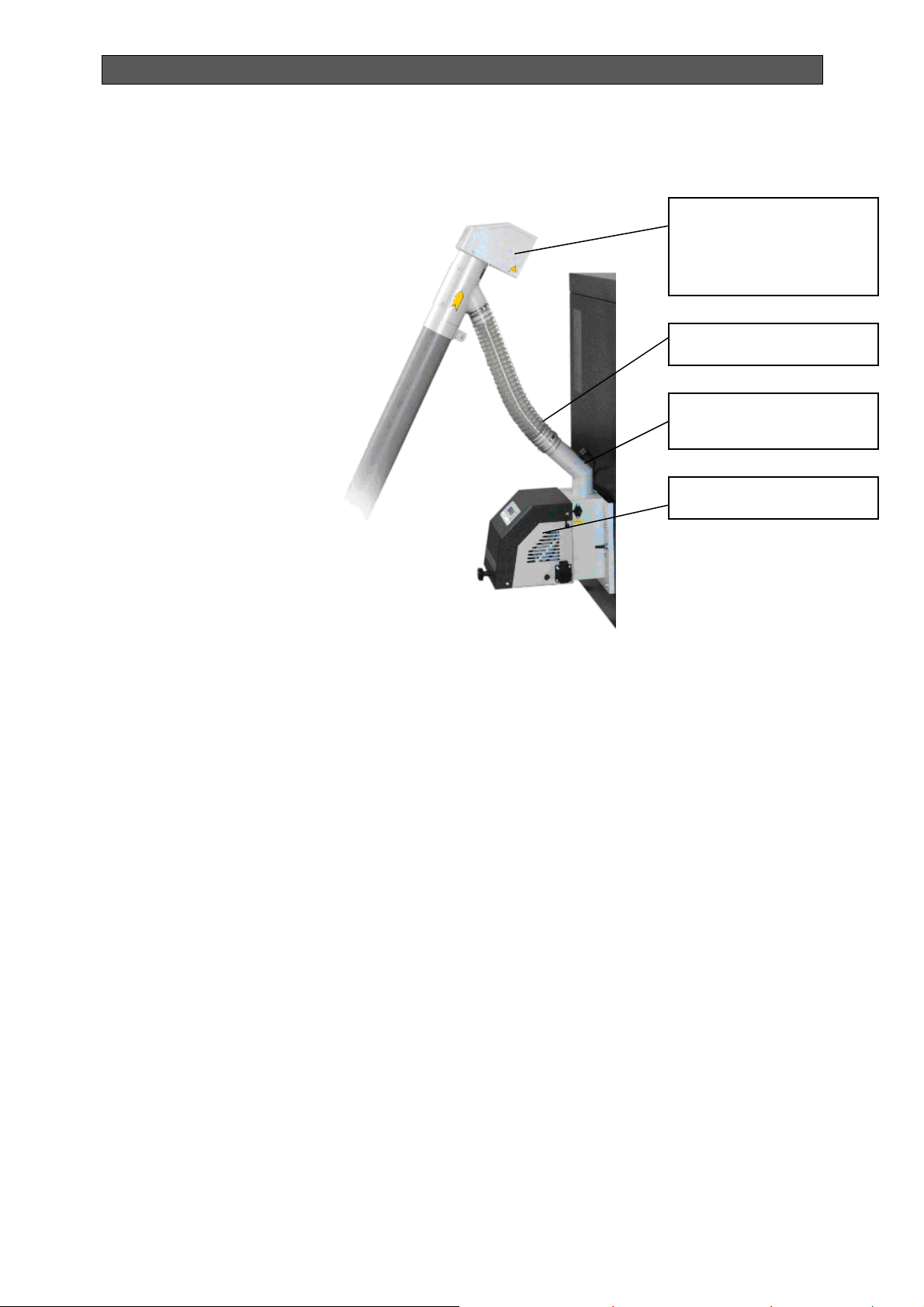

Figure 3.2. External view of automated pellet burner with manually cleaning from series

Bisolid GP xx_B hc>.

Pellet boiler Bisolid OM-PBBV02/07/2017/EN

8

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Figure 3.3. Arrangement of the main modules of the pellet burner

(side view).

External auger for fuel

transport from hopper to

the main burner’s

module

Flexible pipe

Pipe for pellets feeding

Main module

3.2. MAIN INFORMATION ON THE FUEL HOPPER

The pellet hopper is the “reservoir” of the pellet kit that provides conditions for compact

storing of the fuel, needed for long-term operation of the system and optimal conditions for

operation of the burner’s transport auger. In case the hopper is build/constructed at the

customer’s site then its construction must provide free (gravity) fuel flow to the auger’s intake

zone, easy refueling, cleaning and enough capacity for longer operation of the system.

The manufacture company produces sectional (assembled) pellets hoppers, made of

galvanized steel plates, with capacity: 250, 450 и 650 kg.

Pellet boiler Bisolid OM-PBBV02/07/2017/EN

9

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Figure 3.4. Sectional (assembled) sheet metal pellets hopper with 250kg capacity.

Figure 3.5. Sheet metal pellets hopper with capacity of 300 l.

Pellet boiler Bisolid OM-PBBV02/07/2017/EN

10

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

4. BISOLID PELLET BOILER’S TECHNICAL DATA

The technical heating data for hot water pellet boiler from series Bisolid are presented in

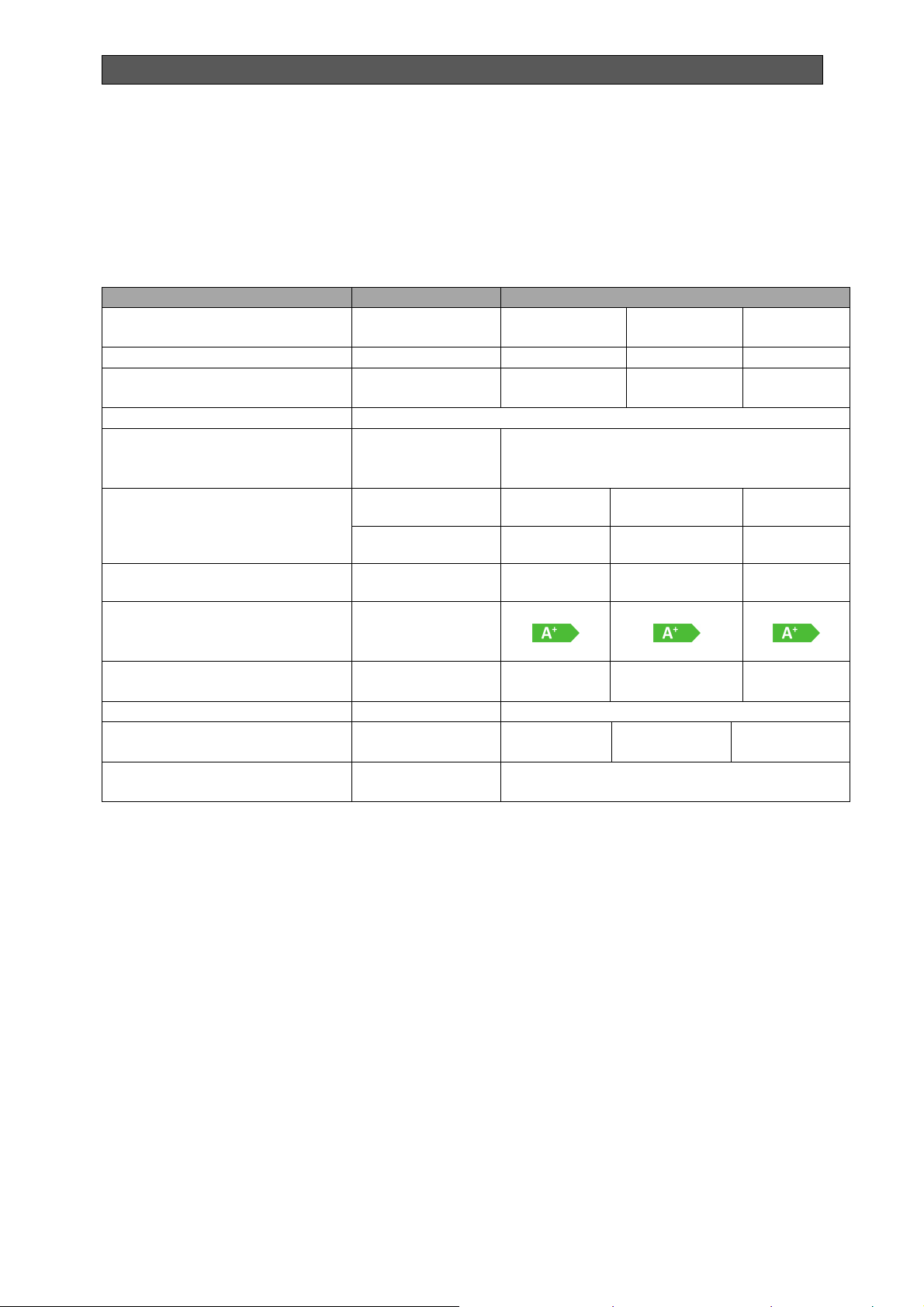

Table 4.1.

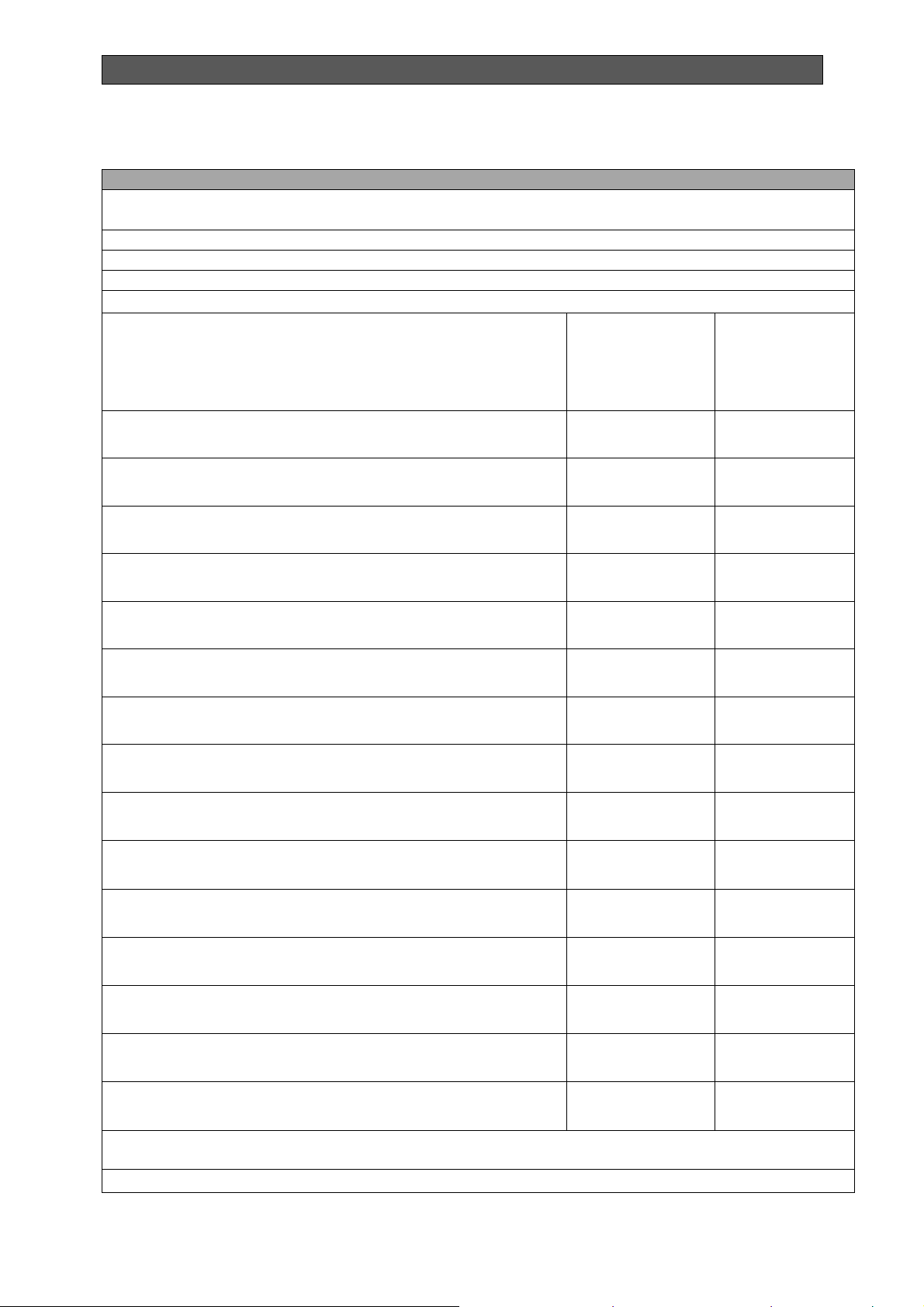

Table 4.1. Technical heating data for hot water pellet boiler from series Bisolid.

PARAMETER DIMENSION VALUE

Pellet boiler model

Nominal heat output kW 18 25 30

Heating output adjustment

range

Used fuel Wood pellets

Suitable wood pellets class

according to standard

EN ISO 17225-2:2014

-

kW 7.5 - 18 7.5 – 25 9 - 30

- A1

Bisolid 18

Bisolid 25 Bisolid 30

Required air quantity to

achieve effective burning

process

Flue gas mass flow rate g/s 9.4 15.6 19.8

Energy efficiency class

according to regulation

(ЕU) 2015/1187

Efficiency at nominal operation

mode

Excess air ratio coefficient

Flue gas temperature at

nominal operation mode

Residues from the burning

process

The technical data for hot water pellet boiler from series Bisolid are presented in Table 4.2.

kg/h 27 – 30 45 – 50 57 - 64

m3/h 24 – 27 39 – 44 50 - 56

-

℅ 92.4 91.5 91.0

λ 1.5 – 1.7

ºC 160 170 180

Ash

The quantity depends on the fuel’s ash

content

Pellet boiler Bisolid OM-PBBV02/07/2017/EN

11

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

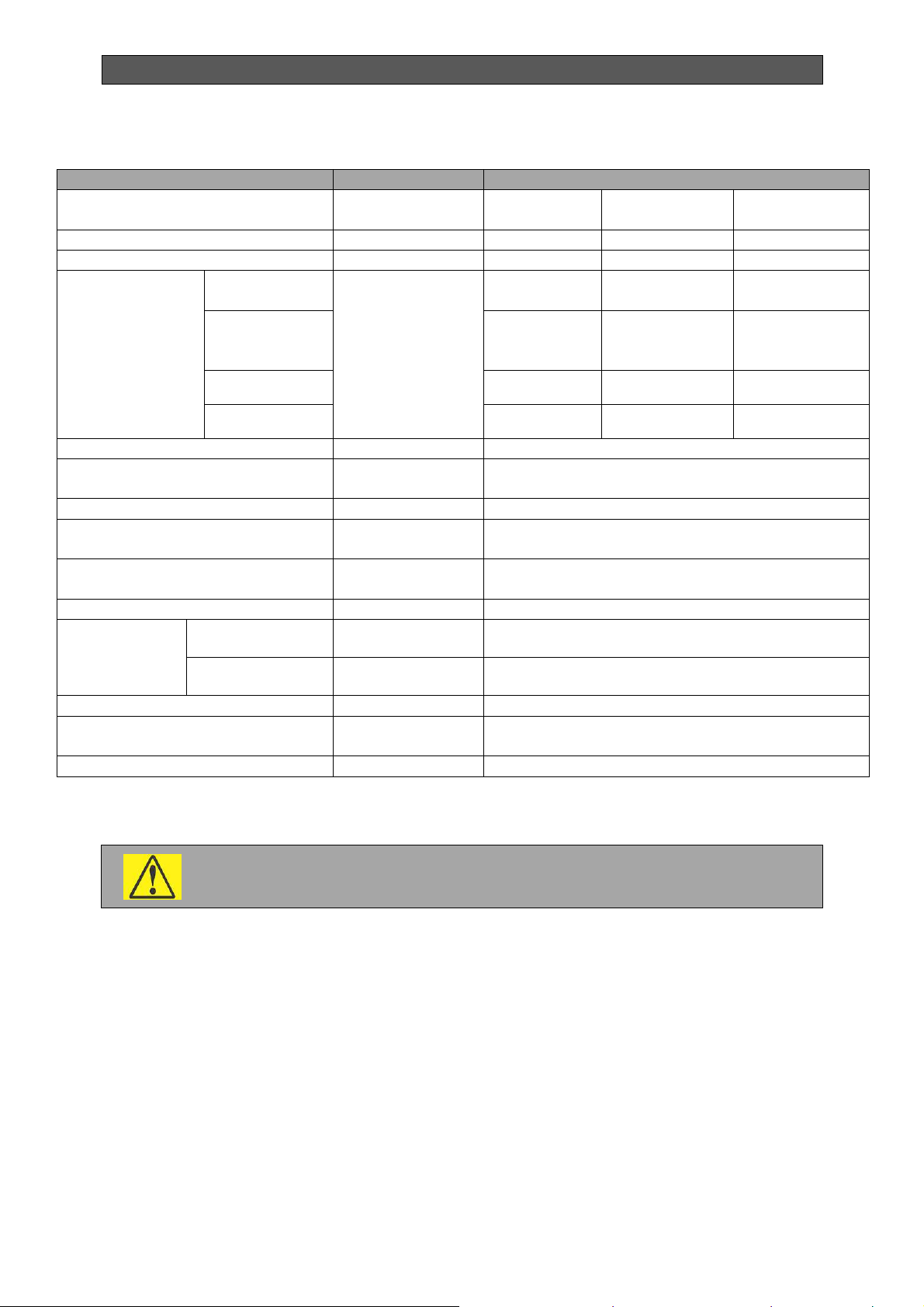

-

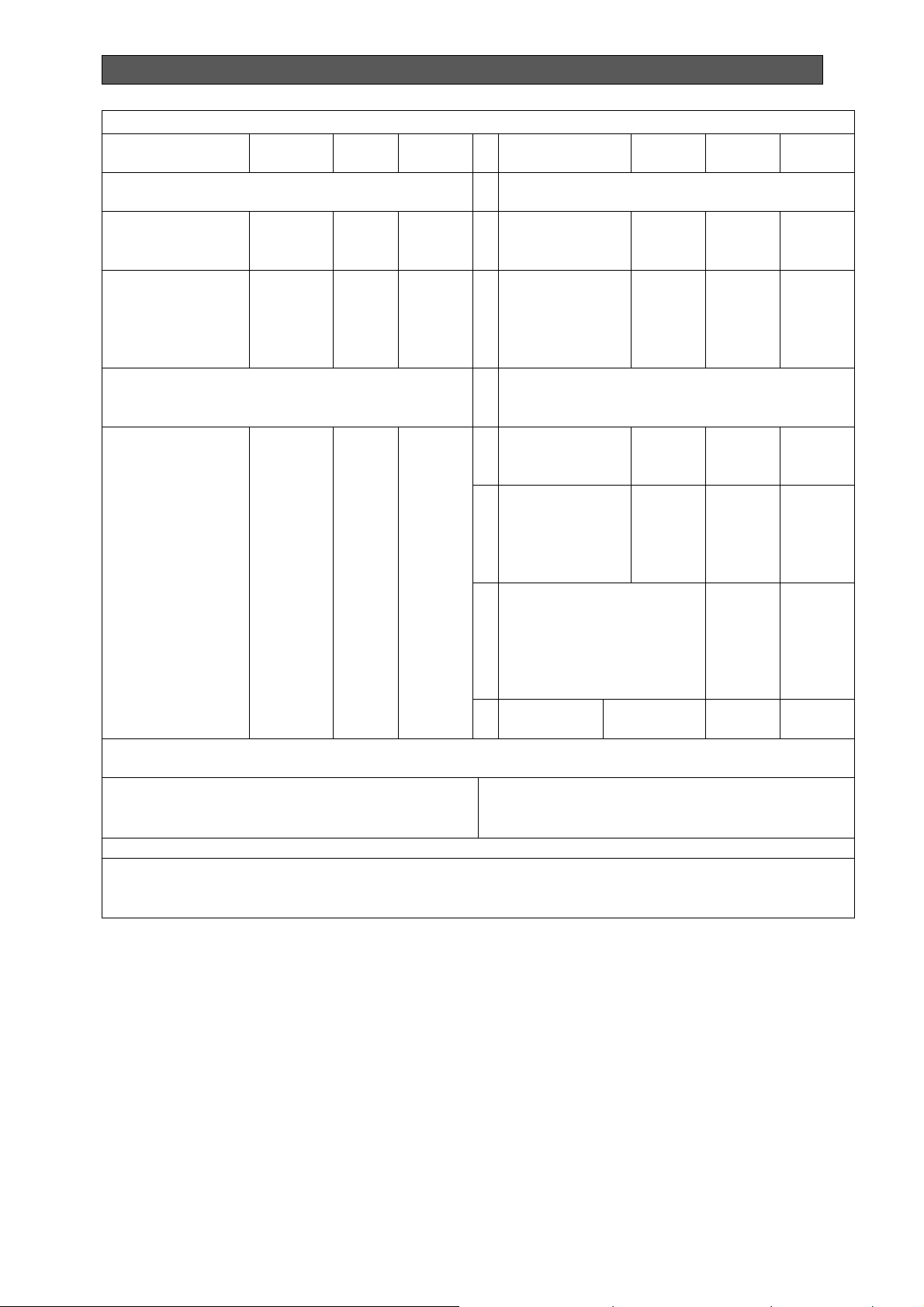

Table 4.2. Technical data for hot water pellet boiler from series Bisolid.

PARAMETER DIMENSION VALUE

Hot water pellet boiler model

Boiler weight kg 192 212 222

Boiler water volume dm³ 44 50 60

Overall

dimensions of

the system:

W х D х H

W1- Length of

boiler body

W – Length

with pellet

burner

D - Depth

-

mm

Bisolid 18

580 580 580

954 954 954

770 770 770

Bisolid 25 Bisolid 30

H -Height

Boiler class - 5

Operation water overpressure in

the boiler

Boiler test overpressure

Recommended operation water

temperature in the boiler

Minimum boiler inlet water

temperature

Chimney draught *

Connection

pipes

Power supply voltage - L1, N, PE, 50Hz; 230VАС;

Electrical consumption (with

ignition)

System electrical protection

* If the chimney draught operation parameters are lower than the above presented values it

is necessary to install flue gas extraction fan.

The technical parameters of hot water solid fuel boilers series Bisolid according to the

delegated Regulation (EU) 2015/1187 are presented in Table 4.3.

Inlet/outlet water

Flue outlet

The selection, installation and connection to the flue gas extraction fan have to

be made by the technically trained and qualified person.

bar 2.5

bar 4

ºC 80

ºC 60

Pa 12-15*

G 1½”

mm 149

W

885 965 1044

+1100

<100

IP20

Pellet boiler Bisolid OM-PBBV02/07/2017/EN

12

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

no

no

no

no

no

no

no

no

no

no

no

no

no

Characteristics when operating with the preferred fuel:

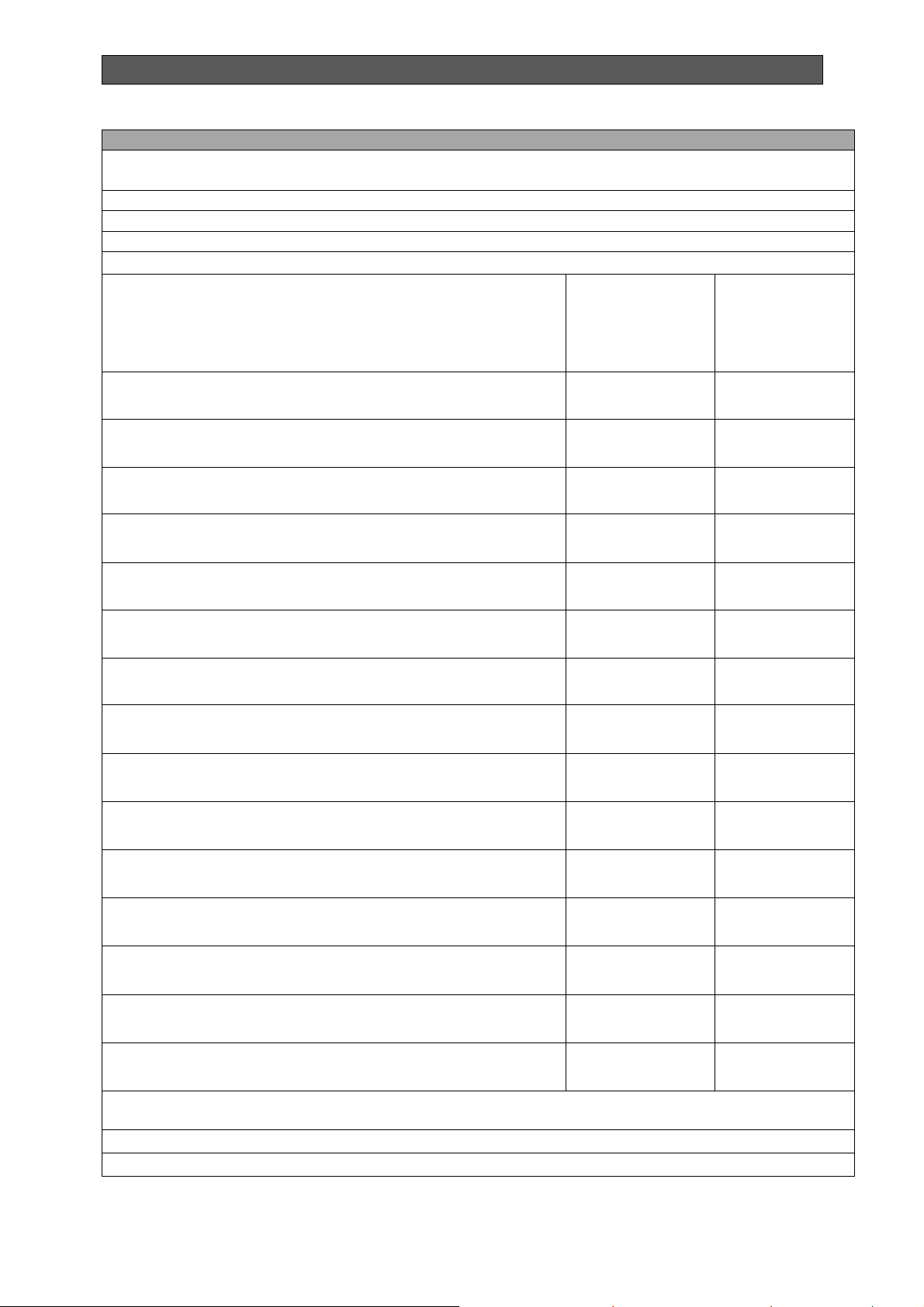

Table 4.3 Technical parameters of hot water solid fuel boilers series Bisolid according to the

delegated Regulation (EU) 2015/1187.

Model identifier: Hot water pellet boiler Bisolid 18.

Stoking mode: Automatic: it is recommended that the boiler be operated with a hot water storag e

tank of a volume of at least 360 litre (**)

Condensing boiler: no

Solid fuel cogeneration boiler: no

Combination boiler: no

Fuel

Log wood, moisture content ≤ 25 % no no

Chipped wood, moisture content 15-35 % no

Chipped wood, moisture content > 35 % no

Compressed wood in the form of pellets or briquettes yes no

Sawdust, moisture content ≤ 50 % no

Other woody biomass no

Non-woody biomass no

Bituminous coal no

Preferred

fuel (only one):

Other suitable

fuel(s):

Brown coal (including briquettes) no

Coke no

Anthracite no

Blended fossil fuel briquettes no

Other fossil fuel no

Blended biomass (30-70 %) and fossil fuel briquettes no

Other blend of biomass and fossil fuel no

Seasonal space heating energy efficiency ƞs [%]: 87

Pellet boiler Bisolid OM-PBBV02/07/2017/EN

13

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Auxiliary electricity consumption

Energy efficiency index EEI: А+

Item Symbol Value Unit Item Symbol Value Unit

Useful heat output Useful efficiecny

At rated heat

Pn (***) 18 kW

output

At [30 %/50%] of

Рр 11 kW

rated heat

output, if

applicable

For solid fuel cogeneration boilers: Electrical

efficiency

At rated heat

output

Ƞ

el,n

-

%

At rated heat

output

At [30 %/50%]

of rated heat

output, if

applicable

At rated heat

output

At [30 %/50%]

of rated heat

output, if

applicable

Of incorporated

secondary emission

abatement equipment,

if applicable

ƞn 92,4 %

ƞp 92,6 %

el

0,156 kW

max

el

0,134 kW

min

- kW

PSB 0,0048 kW

Contact details

In standby

mode

Ekoterm Proekt EAD / ZMM Haskovo AD

6300, Haskovo

67 Saedinenie Blvd.

(*) Tank volume = 45 × Pr × (1 – 2,7/Pr) or 300 litres whichever is higher, with Pr indicated in kW

(**) Tank volume = 20 × Pr with Pr indicated in kW

(***) For the preferred fuel Pn equals Pr

Pellet boiler Bisolid OM-PBBV02/07/2017/EN

14

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

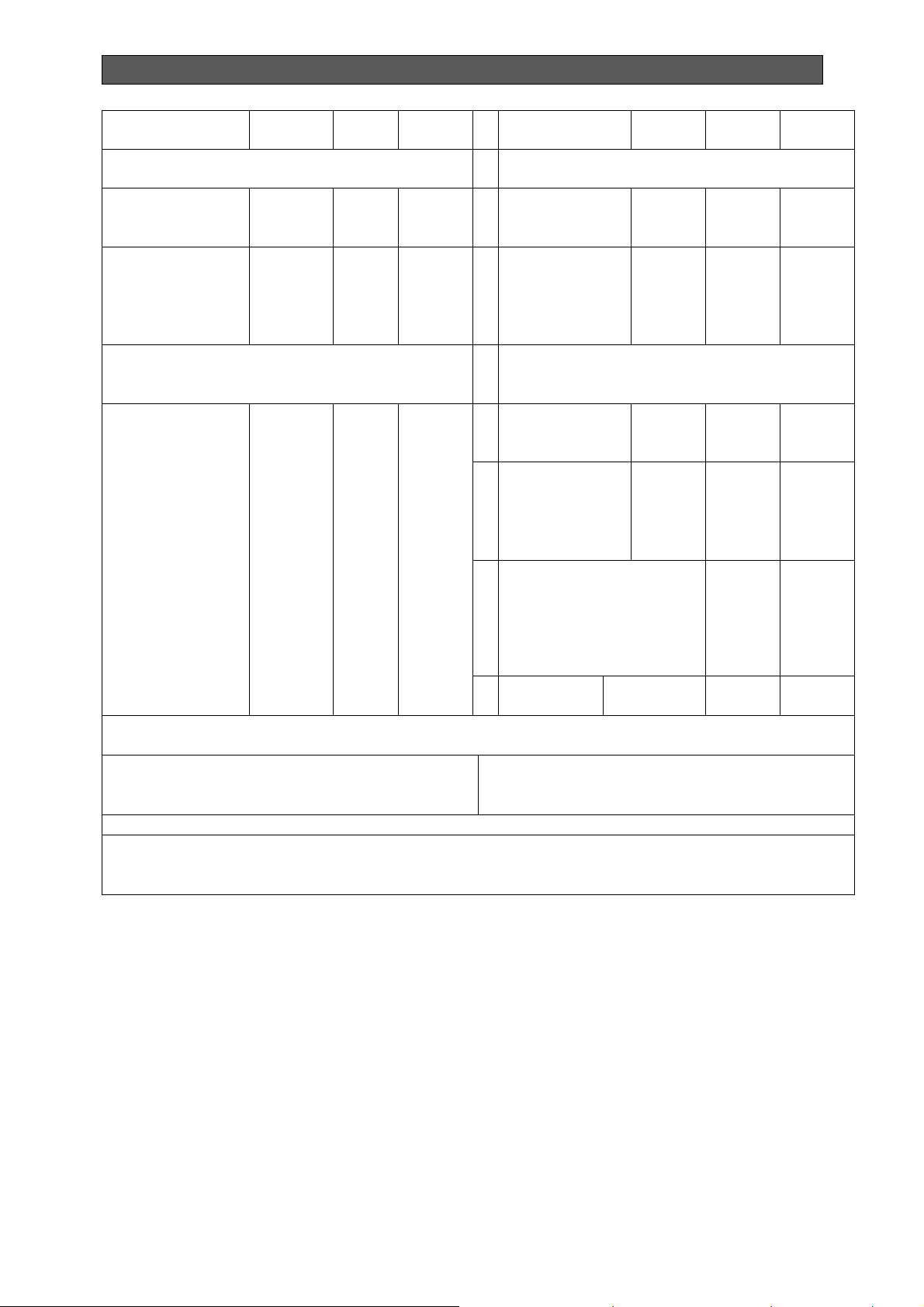

Characteristics when operating with the preferred fuel:

Model identifier: Hot water pellet boiler Bisolid 25.

Stoking mode: Automatic: it is recommended that the boiler be operated with a hot water storag e

tank of a volume of at least 500 litre (**)

Condensing boiler: no

Solid fuel cogeneration boiler: no

Combination boiler: no

Fuel

Log wood, moisture content ≤ 25 % no no

Chipped wood, moisture content 15-35 % no no

Chipped wood, moisture content > 35 % no no

Compressed wood in the form of pellets or briquettes yes no

Sawdust, moisture content ≤ 50 % no no

Other woody biomass no no

Non-woody biomass no no

Bituminous coal no no

Preferred

fuel (only one):

Other suitable

fuel(s):

Brown coal (including briquettes) no no

Coke no no

Anthracite no no

Blended fossil fuel briquettes no no

Other fossil fuel no no

Blended biomass (30-70 %) and fossil fuel briquettes no no

Other blend of biomass and fossil fuel no no

Seasonal space heating energy efficiency ƞs [%]: 89

Energy efficiency index EEI: А+

Pellet boiler Bisolid OM-PBBV02/07/2017/EN

15

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Auxiliary electricity consumption

Item Symbol Value Unit Item Symbol Value Unit

Useful heat output Useful efficiecny

At rated heat

Pn (***) 25 kW

output

At [30 %/50%] of

Рр 18 kW

rated heat

output, if

applicable

For solid fuel cogeneration boilers: Electrical

efficiency

At rated heat

output

Ƞ

el,n

-

%

At rated heat

output

At [30 %/50%]

of rated heat

output, if

applicable

At rated heat

output

At [30 %/50%]

of rated heat

output, if

applicable

Of incorporated

secondary emission

abatement equipment,

if applicable

ƞn 93,9 %

ƞp 94,1 %

el

0,156 kW

max

el

0,134 kW

min

- kW

PSB 0,0048 kW

Contact details

In standby

mode

Ekoterm Proekt EAD / ZMM Haskovo AD

6300, Haskovo

67 Saedinenie Blvd.

(*) Tank volume = 45 × Pr × (1 – 2,7/Pr) or 300 litres whichever is higher, with Pr indicated in kW

(**) Tank volume = 20 × Pr with Pr indicated in kW

(***) For the preferred fuel Pn equals Pr

Pellet boiler Bisolid OM-PBBV02/07/2017/EN

16

Loading...

Loading...