Page 1

Instruction Manual

MP40w

Protecting your VorTech

Protect the pump from water

The VorTech’s motor housing and

driver are NOT WATERPROOF. Any

water allowed into these components

can damage them enough to require

replacement. This kind of damage is

NOT covered in the VorTech’s warranty.

Protect these components from splashes

of any kind.

Maintenance

Wear of the drive shaft

The VorTech pump features a wear

component in the form of the drive shaft.

This part is designed with a special

engineering grade plastic which extends

the part’s lifetime. The plastic drive

shaft can be expected to last for years,

depending on the speed, frequency, and

alignment of the pump.

The wet magnet and drive shaft should

be observed periodically to monitor

wear. If the magnet begins to how signs

of rapid oxidation in the form of bubbles

on the magnet surface, they may need

to be replaced. Replacements can be

purchased directly from EcoTech Marine.

Cleaning your VorTech

The VorTech may need thorough cleaning

of the components periodically to

keep it running optimally. This can be

accomplished by disassembling the wet

half of the pump and gently brushing

the components with a soft brush under

running water. Soaking these par ts in

a mild acid solution such as vinegar

may be necessary if there is an extreme

amount of calcium buildup. Do not use

strong acids as this may damage the

components.

Troubleshooting

Break-in

The VorTech pump is engineered to adapt

to its aqueous environment. During the first

week of use, your pump may run noisier or

stall. The noise should quiet dramatically over

night and any stall conditions can safely be

reset by manually cycling the power to your

pump.

Driver Error Codes

Over Temperature Condition

In the event of a motor overheating, the

pump will automatically shut down for a

period to allow for cooling. Once the motor

has cooled, the driver will automatically

restart and resume normal operation. You

may experience an overheating error from a

misalignment.

Stall Condition

In the event of a motor stall, the pump may

have stopped for a few possible reasons. You

should first check that there is not something

blocking the propeller from spinning. Next,

check to make sure the magnets are not

rubbing on either the pin spacer or the frame

cover.

Miscellaneous Error

This error could be attributed to a

communication error between pumps or an

unidentified error in the wave driver.

FCC Warnings:

Operation is subject to the following two

conditions: (1) this device may not cause

interference, and (2) this device must accept

any interference including interference that

may cause undesired operation of the device.

Changes or modifications not expressly

approved by EcoTech Marine could void

the user’s authority to operate the VorTech

Wireless Wave Driver.

Customer Support

service@ecotechmarine.com

(610) 954-8480

OR visit our forum at www.ReefCentral.com

Sales inquiries please contact:

sales@ecotechmarine.com

(800) 785-0338

ErrorCodes:

Stall

Condition

OverTemp

Condition

MiscError

Normal Oxidized

Page 2

To remove the nozzle from the wet-frame, remove the entire

wet-half of the pump from the aquarium and place it on a nonmetallic surface. Gently but firmly press down on the nozzle

with your palm and twist counter clockwise. The nozzle should

become free of the wet-frame. It may then be cleaned of any

obstructions

Specifications and Operating Parameters

Flow: 200-3,000 gallons/hour, Power: 12-23 watts,

Maximum Motor Temp: 50-60 degrees C

Aquarium Wall Thickness: 3/16” to 3/4”

Your VorTech propeller pump

Before you start

Preparation

Once you have chosen the location where you wish to install your VorTech pump, clean •

away any algae, calcified or otherwise, using a razor blade.

Notes on placement

The VorTech creates over 3,000 gallons per hour of low velocity flow within your aquarium.

Take care to place the VorTech in a suitable location where corals are not directly in the

line of flow. Place the pump sufficiently high enough above a fine sand bed so that sand is

not blown around by the output or undertow created by the VorTech.

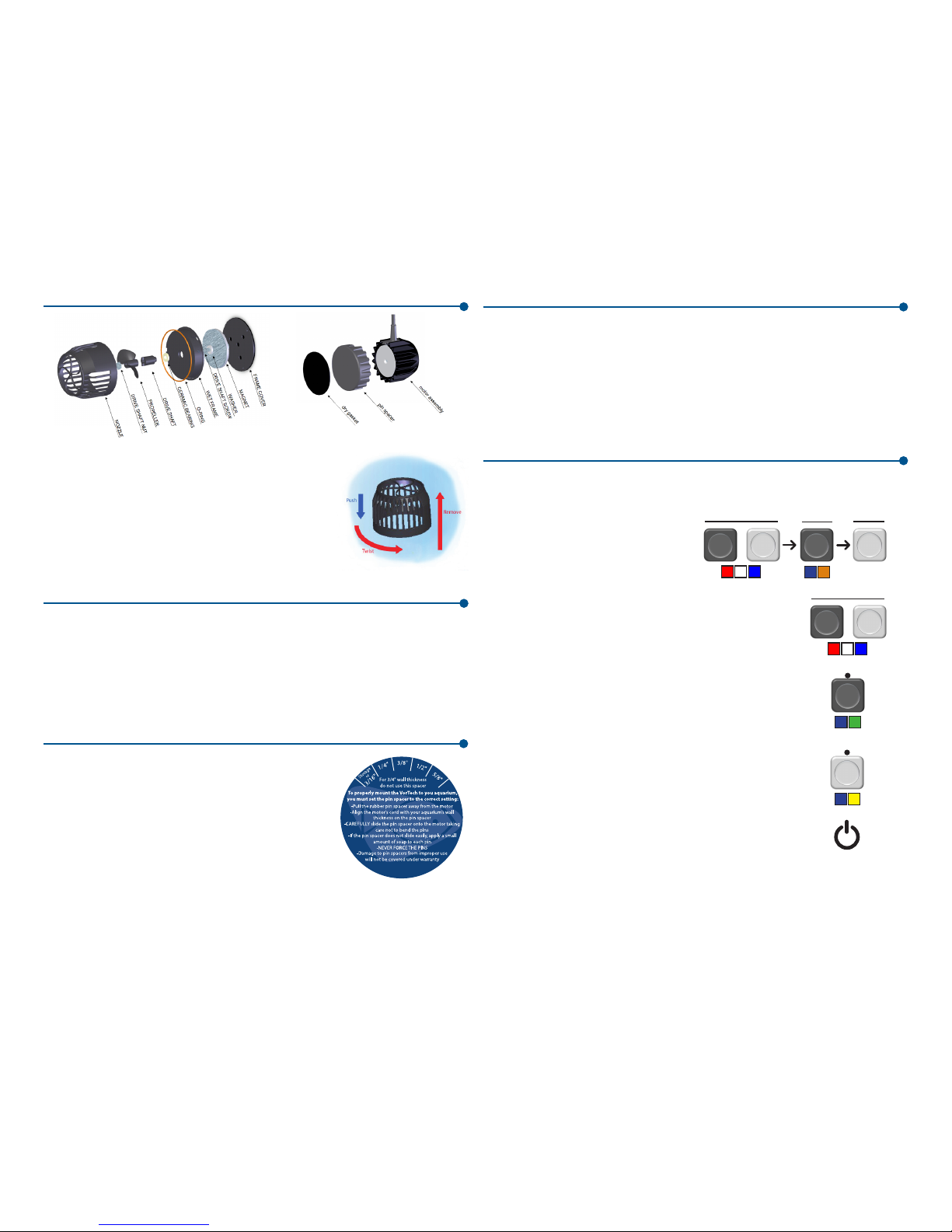

Adjust the pin spacer

The VorTech pump is designed to operate with a constant

gap between both halves of the device. The pin spacer is

used to ensure the proper spacing for various aquarium wall

thicknesses.

Make sure to measure your aquarium’s glass thickness us-•

ing a ruler or contact the aquarium manufacturer in order

to determine the exact thickness.

To adjust for the proper aquarium thickness, pull the pin •

spacer from the motor housing. Then align the VorTech’s

power cord emerging from the motor with your aquarium’s wall thickness to achieve the proper offset from your

aquarium.

Note: 5/8” and 3/4” thick aquariums do not use the pin spacer at all.

IMPORTANT: When adjusting the pin spacer, be sure not to bend the pins as they are

inserted into the holes within the heat sink as this may permanently damage your

VorTech. Bent pins WILL NOT be covered under warranty.

Sync Mode

When a slave pump is entered into sync mode, it will replicate exactly what the master

pump is doing. This function can be used with a master pump that is currently in any

general mode of operation.

Anti-Sync Mode

When a slave pump is entered into Anti-Sync Mode, it will inversely replicate the master

pump. For example, when the master pump is at high speed, the slave pump will be at low

speed. This function can be used with a master pump that is currently in lagoon, reefcrest, or pulse modes. In constant speed mode, the anti-sync pumps will operate at the

same speed as the master pump.

Slave Modes

Step 1: Clear Driver Memory

The internal memory of each unit must be

cleared before setting up a group.

Programming Multiple Pumps

A pump group consists of one master pump and at least one slave pump. There can only

be one master pump per group which can include an unlimited number of slave pumps. It

is possible to have up to eight groups in one area each with a unique master pump.

Step 2: Enter Configuration Mode

All pumps in a group must then be set into configuration mode

before the assignment of slave or master status. This configuration

must be performed with the drivers in close proximity to ensure

proper assignment. The drivers will blink red, white and blue in this

mode.

Step 3: Assign the Master

Set the master pump by pressing the mode button. The LED will

then blink blue and green.

+

Step 4: Assign the Slaves

Set all the slave pumps by pressing the set button on each driver.

The LED will then blink blue and yellow.

Step 5: Cycle the Power

Pull the power cord from the driver box to reset each pump. They

will restart in their respective slave or master modes. Alternatively,

hold mode on any one pump to rest them all.

Cycle

Power

Step 6: Program Subsequent Groups

Now that the first group is programmed, repeat steps 1-5 on then next group of pumps if

so desired.

NOTE: The subsequent pump groups must be programmed near the original group. For

example, if running two different groups in separate areas of your house, the second

group must be programmed near the first group to ensure proper communication.

Pump

Resets

+

hold

hold

hold

hold

tap

tap

Page 3

Your VorTech Wireless Wave Driver

General Operational Modes

Constant Speed Mode

When a pump is in constant speed mode, the dial is used to set the operational speed. If

this pump is a master, the associated slave pumps will replicate the master.

Reef-Crest Random Mode

When a pump is in Reef-Crest Random Mode, the dial is used to set the maximum

operational speed, and the driver will automatically randomize the pumps output to

simulate a high energy reef-crest environment. If this pump is a master pump, the

associated slave pumps will replicate the master in sync or anti-sync modes.

Lagoonal Random Mode

When a pump is in Lagoonal Random Mode, the dial is used to set the maximum

operational speed, and the driver will automatically randomize the pumps output to

simulate a low energy lagoonal reef environment. If this pump is a master, the associated

slave pumps will replicate the master in sync or anti-sync modes.

Pulse Mode

When a pump is first entered into Pulse Mode, you must set the maximum pump speed

by adjusting the dial. When the desired speed is achieved, press the Set button to lock

this speed. The LED will now begin to blink. This blinking LED represents the pulsing

frequency. Now adjust the dial to make the pump pulse faster or slower.

Feed Mode

To enter Feed Mode, press and hold the mode button for three seconds. The LED will

now blink white indicating that the pumps are in feed mode. Regardless of your system’s

master/slave pump configuration, all pumps will enter feed mode when that mode is

selected on any one pump. The pumps will spin very slowly for ten minutes and then

resume their prior operating conditions.

Battery Backup Mode

When a battery backup accessory is added to the VorTech pump the pump will

automatically switch to Battery Backup mode during a power outage. The pumps will run

at the minimum speed to maximize their run time during this critical period.

The wireless wave driver has seven different modes of

operation, and can be assigned to a master or a slave

pump configuration. If you assign a pump to be a

master, it will communicate wirelessly with the slave

pumps.

There are two buttons and one dial on your driver.

Use the mode button to switch between the different

modes of operation. The dial and set button will be

used to adjust the speeds and frequencies of the

different modes.

The VorTech utilizes very powerful magnets and can cause severe personal injury.•

NEVER connect the two halves of this device without a proper spacer in-between.•

NEVER place either half of this device near magnetically attractive surfaces or sensitive •

electronics.

The motor and driver can become HOT. Be cautious around these surfaces.•

Never run the pump dry as the heat buildup may cause damage to your components.•

Warnings

Attach the VorTech

Attach the motor assembly

Apply the rubber gasket at the chosen location for the VorTech •

pump, on the outside of your aquarium.

Apply the cord mounting tab approximately 2” above this loca-•

tion. Make sure the glass is clean and free of any grease or

dirt prior to applying this tab.

Place the VorTech motor, with or without the pin spacer at-•

tached, upon the black gasket, and secure the cord to the

mounting tab using one of the provided wire-ties.

The cord must be positioned pointing upwards so that if the •

VorTech were to fall off the aquarium, it does not swing and

damage your aquarium. When operating, make sure the gasket

is properly recessed within the pin spacer.

Attach the propeller housing

Apply the wet gasket/cover to the rear of the propeller housing. •

Place this into the aquarium, making sure to allow ALL air to •

escape from the propeller housing.

Carefully connect both halves of the pump together and visually •

align both halves of the pump.

Align the VorTech

Turn the speed up to the maximum speed by using the •

speed control knob on the driver.

Plug the power supply into the driver. If vibration or •

noise is detected, carefully adjust the propeller housing by moving it VERY slightly left, right, up or down,

until the noise/vibration is eliminated or minimized as

much as possible.

After alignment has been ensured, turn the speed •

control knob to achieve the desired flow rate within

your aquarium.

IMPORTANT: If the VorTech is not properly aligned, a strong vibration will be heard. If the

alignment is not corrected, this can cause increased electrical consumption, excessive wear

on the components, excessive heat and excessive noise.

Protect the Pump From falling

Due to the nature of the magnetically coupled design, it is possible for the VorTech to

become dislodged from the aquarium glass and fall to the ground. The cord should be

positioned vertically above the pump with the mounting tab directly above the motor to

ensure that the motor does not move in the event of a decoupling of the magnets.

The provided cord-mounting tab MUST be used to prevent damage to the motor or the •

surrounding environment.

The motor will shut down automatically if either half of the pump is removed.•

SlavePumpModes:

Sync AntiͲSync

Mode

Set

Constant

Speed

Lagoon

Random

ReefͲCrest

Random

Pulse

speed

SinglePumpModeorMasterModes:

OperationalModes

Holdtoenter

andexit

FeedMode:

Pulse

frequency

Battery

Backup

Blinking

White

Loading...

Loading...