Page 1

P/N 14000C

ES50LVP / ES90LVP

MODULATING AIR HANDLER

Installation, Operation and Maintenance Manual

Ecosmartair

105 Haist Avenue, Unit 10

Vaughan, ON L4L 5V6

905-857-9755

ecosmartair.com

Page 2

1 | P a g e

Contents

SAFETY INFORMATION .................................................................................................. 3

INTRODUCTION ............................................................................................................ 4

MODES OF OPERATION ................................................................................................. 4

Modulating Mode ................................................................................................................................. 4

Step Modulating Mode ......................................................................................................................... 5

Basic Mode ............................................................................................................................................ 5

SPECIFICATIONS ............................................................................................................ 8

QUICK START-UP PROCEDURES .................................................................................... 10

INSTALLATION ............................................................................................................ 11

Clearances ........................................................................................................................................... 11

Freeze Protection ................................................................................................................................ 11

Rear Piping Connections ..................................................................................................................... 12

Ecosmart Mounting ............................................................................................................................. 12

Plumbing ............................................................................................................................................. 12

Pump ................................................................................................................................................... 13

PIPING DIAGRAMS ...................................................................................................... 15

Tankless Water Heater Piping ............................................................................................................. 15

Combi-Boiler Piping............................................................................................................................. 16

ELECTRICAL................................................................................................................. 17

Electrical Information .......................................................................................................................... 17

Electrical Connections Made to Quick Connects ................................................................................ 17

Thermostat Wiring .............................................................................................................................. 18

Ecosmart ES50LVP/ES90LVP Wiring Diagram ..................................................................................... 19

Miscellaneous Wiring .......................................................................................................................... 20

DIP SWITCH OPTIONS .................................................................................................. 21

Switch Locations ................................................................................................................................. 21

Outdoor Temperature Select .............................................................................................................. 21

Heat CFM (ES90LVP) ........................................................................................................................... 22

Heat CFM (ES50LVP) ........................................................................................................................... 22

Page 3

2 | P a g e

System (ES990LVP and ES50LVP) ........................................................................................................ 22

Cool CFM (ES90LVP) ............................................................................................................................ 23

Cool CFM (ES50LVP) ............................................................................................................................ 23

SEQUENCE OF OPERATION ........................................................................................... 24

Full Modulation ................................................................................................................................... 24

Step Modulation ................................................................................................................................. 24

Basic Modulation Mode ...................................................................................................................... 25

Cooling Mode (Modulation, Step and Basic) ...................................................................................... 25

Dehumidification ................................................................................................................................. 26

............................................................................................................................................................ 26

Fan Mode ............................................................................................................................................ 26

Constant Low Fan Circulation ............................................................................................................. 26

Freeze Protection ................................................................................................................................ 26

Pump Exerciser .................................................................................................................................... 27

SERVICE AND MAINTENANCE ....................................................................................... 27

Filter .................................................................................................................................................... 27

Coils ..................................................................................................................................................... 27

Fan and Motor .................................................................................................................................... 27

Control and Blower Assembly Removal .............................................................................................. 27

TROUBLESHOOTING .................................................................................................... 28

Thermostat call error .......................................................................................................................... 28

External pump does not run ............................................................................................................... 28

External pump is noisy at start-up ...................................................................................................... 28

Water heater temperature and pressure relief valve is weeping ...................................................... 28

Insufficient or no heat ......................................................................................................................... 29

Cold water at hot faucet ..................................................................................................................... 29

Fan runs for cooling but not for heating ............................................................................................. 29

Heating during standby mode ............................................................................................................ 29

WARRANTY ................................................................................................................ 29

All technical information subject to change without notice.

Page 4

3 | P a g e

SAFETY INFORMATION

It is the responsibility of the installer to ensure the installation complies with all national and

local building codes and standards, in addition to the instructions outlined in this manual. All

applicable codes take precedence over any instructions made in this document.

This symbol indicates safety alerts. When you see this symbol on labels or in this

manual, be alert to the potential for personal injury. Understand and pay

particular attention to the signal words DANGER, WARNING, or CAUTION.

DANGER indicates an imminently hazardous situation, which if not avoided, will result

in death or serious injury.

WARNING indicates a potentially hazardous situation, which if not avoided, could

result in death or serious injury.

CAUTION indicates a potentially hazardous situation, which if not avoided, may result

in minor or moderate injury. It is also used to alert against unsafe practices and

hazards involving only property damage.

WARNING - Improper installation may create a condition where the operation of

the product could cause personal injury or property damage. Only a qualified

contractor, installer or service agency should install this product. Improper

installation, adjustment, alteration, service or maintenance can cause injury or

property damage. Refer to this manual for assistance.

CAUTION - This product must be installed in strict compliance with the installation

instructions and any applicable local, state, and national codes including, but not

limited to; building, electrical, and mechanical codes.

WARNING - FIRE OR ELECTRICAL HAZARD. Failure to follow the safety warnings

exactly could result in serious injury, death, or property damage. A fire or electrical

hazard may result causing property damage, personal injury or loss of life.

WARNING - Hot water from a boiler used to satisfy heating requirements can be

heated to temperatures of 180°F. Parts containing water this hot can scald very

quickly. Use extreme caution when servicing or performing maintenance on any

parts containing hot water. To avoid severe burns, allow equipment to cool before

performing maintenance.

Page 5

4 | P a g e

INTRODUCTION

The ecosmart hydronic furnace is designed to maximize performance and comfort in residential

or light commercial applications. The ecosmart can be used with a variety of heat sources such

as boilers and water heaters and can be implemented in combo systems that provide domestic

hot water as well as space heating.

Smart control systems within the ecosmart allow extraction of maximum heat by allowing

condensing high efficiency heat sources to work at their maximum efficiency while providing

ultimate comfort with unmatched performance.

Simple, independent heat/cool and system parameters can easily be set by the installer to

adjust for a wide variety of installations. Various parameters are automatically monitored and

fan and pump speeds vary simultaneously. The ecosmart has a built-in variable speed pump

controller that can vary the speed of a standard single speed AC pump.

MODES OF OPERATION

Three modes of operation are available:

1. Full modulation – full control of fan and pump (requires outdoor temperature sensor).

2. Step modulation – timed fan and pump sequencing.

3. Single stage – standard furnace emulation.

Modulating Mode

(ecosmart outdoor sensor installed)

Water temperature is set at the heat generator by referring to the heat generator performance

data. It is best to maintain constant water temperature at the heat generator.

If the heat generator comes with an optional outdoor temperature sensor do not

install it as it will conflict with the ecosmart control.

Page 6

5 | P a g e

The fan operates at the speed selected on the HEAT CFM switch during the setup. Fan and

pump speed automatically reduce as outdoor temperature rises. Fan CFM may reduce by up to

30% from the HEAT CFM switch setting depending on outdoor temperature.

If the heat generator includes a built-in pump, and it is directly connected to the ecosmart, the

ecosmart will vary the pump automatically. If the system is configured for primary/secondary

pumping and the heat generator includes a pump, the secondary pump can be controlled by

the ecosmart.

Step Modulating Mode

(ecosmart outdoor sensor not installed)

Water temperature is set at the heat generator by referring to the heat generator performance data.

Fan operates at 50% of the HEAT CFM setting for 5 minutes then increases to 75% for a further 5

minutes, then increases to 100% until the thermostat is satisfied. If the pump is controlled by the

ecosmart, its speed will be adjusted accordingly as the ecosmart goes through its stages. If the pump is

controlled by the heat source, it will function according to the heat source control strategy.

Basic Mode

(ecosmart outdoor sensor not installed)

Water temperature is set at the heat generator by referring to the heat generator performance

data. Fan operates at 100% of selected HEAT CFM and pump operates at maximum speed until

the thermostat is satisfied.

Page 7

6 | P a g e

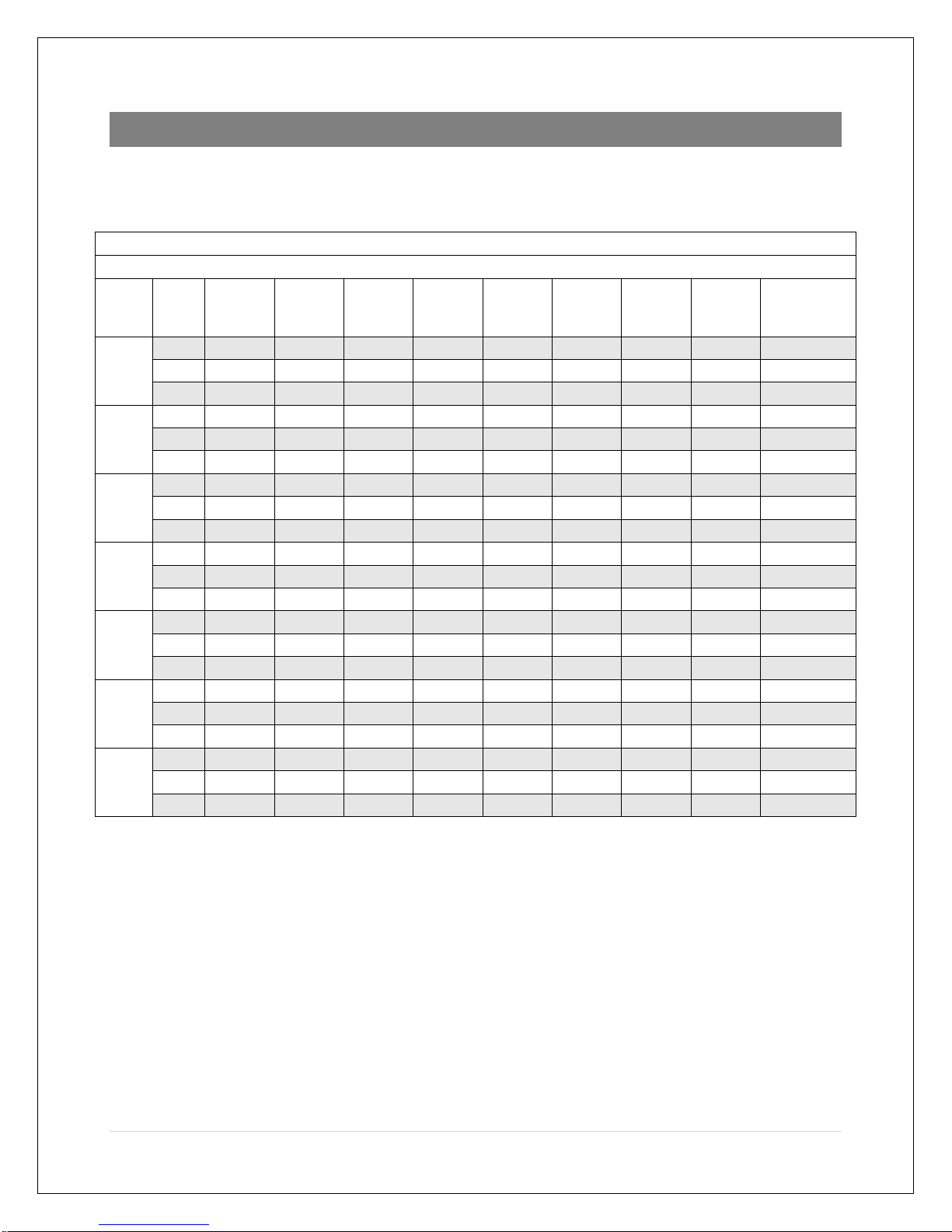

PERFORMANCE RATINGS

ES50LVP

Performance Data - Hot Water Capacities (BTUH) @ 70°F Entering Air Temperature

Entering Water Temperature

CFM

GPM

110°F

120°F

130°F

140°F

150°F

160°F

170°F

180°F

Water PD

feet WC

@140°F

300

3

10,700

13,400

16,100

18,810

21,520

24,240

26,960

29,680

2.32

4

10,970

13,730

16,500

19,270

22,050

24,820

27,600

30,380

3.87

5

11,140

13,940

16,740

19,550

22,360

25,180

27,990

30,810

5.77

400

3

13,260

16,610

19,980

23,350

26,730

30,110

33,500

36,890

2.32

4

13,730

17,190

20,670

24,150

27,640

31,130

34,620

38,120

3.87

5

14,020

17,550

21,090

24,640

28,190

31,740

35,300

38,860

5.77

500

3

15,470

19,390

23,330

27,280

31,240

35,210

39,180

43,160

2.32

4

16,160

20,250

24,360

28,470

32,590

36,710

40,840

44,970

3.87

5

16,600

20,790

24,990

29,200

33,420

37,640

41,870

46,100

5.77

600

3

17,390

21,820

26,260

30,720

35,180

39,660

44,150

48,640

2.32

4

18,330

22,980

27,640

32,320

37,000

41,700

46,400

51,100

3.87

5

18,920

23,710

28,510

33,320

38,150

42,970

47,810

52,650

5.77

700

3

19,090

23,950

28,840

33,740

38,660

43,590

48,530

53,470

2.32

4

20,270

25,420

30,590

35,770

40,970

46,180

51,390

56,610

3.87

5

21,030

26,360

31,710

37,070

42,440

47,820

53,210

58,610

5.77

800

3

20,580

25,840

31,120

36,420

41,730

47,070

52,410

57,760

2.32

4

22,020

27,620

33,250

38,890

44,550

50,220

55,900

61,590

3.87

5

22,950

28,770

34,620

40,480

46,360

52,250

58,150

64,050

5.77

900

3

21,910

27,510

33,150

38,800

44,480

50,170

55,870

61,590

2.32

4

23,600

29,610

35,650

41,720

47,800

53,890

60,000

66,110

3.87

5

24,710

30,990

37,290

43,620

49,960

56,310

62,680

69,050

5.77

Page 8

7 | P a g e

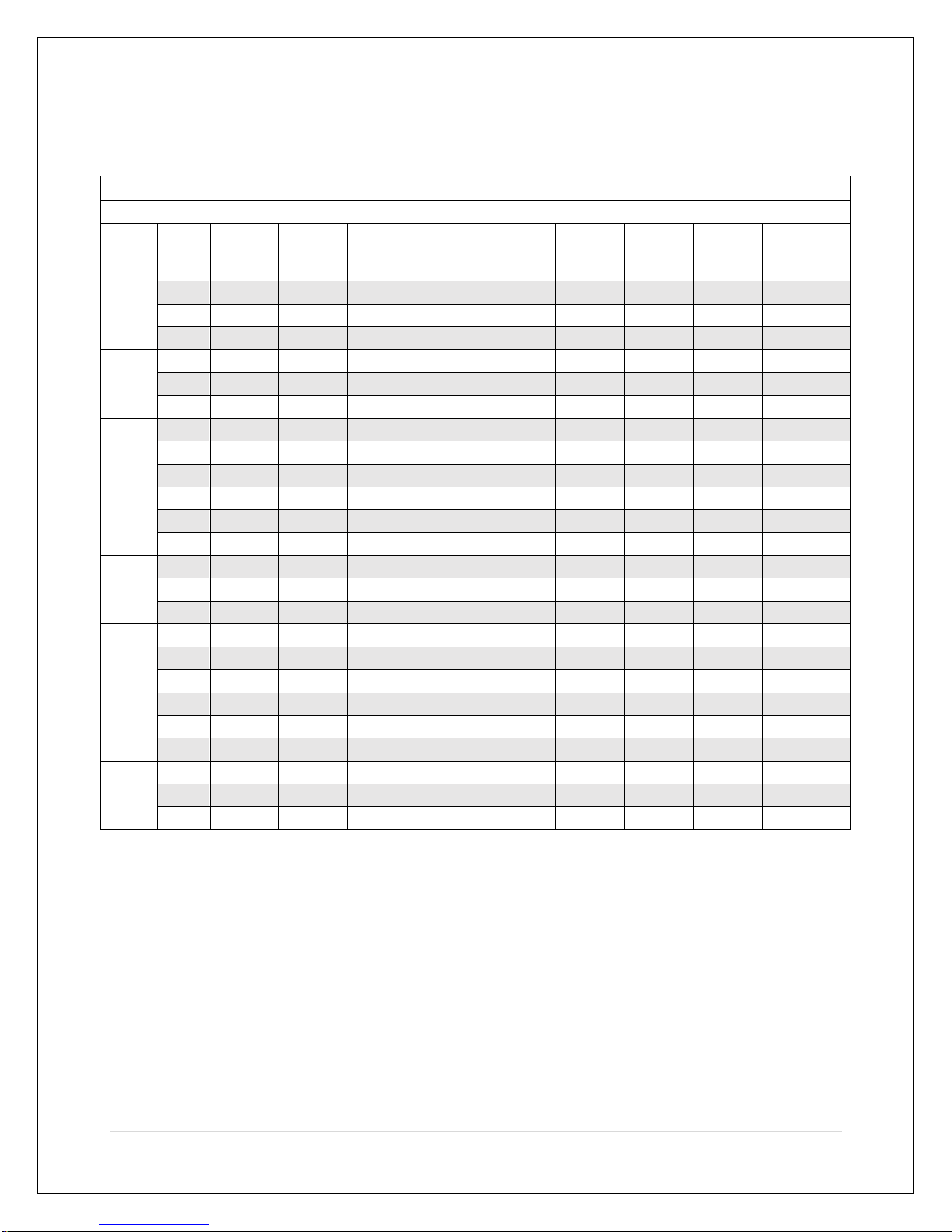

ES90LVP

Performance Data - Hot Water Capacities (BTUH) @ 70°F Entering Air Temperature

Entering Water Temperature

CFM

GPM

110°F

120°F

130°F

140°F

150°F

160°F

170°F

180°F

Water PD

feet WC

@140°F

600

3

18,930

23,720

28,530

33,350

38,180

43,020

47,860

52,710

1.96

4

19,890

24,920

29,960

35,010

40,070

45,140

50,210

55,280

3.26

5

20,500

25,670

30,850

36,040

41,240

46,440

51,650

56,860

4.84

700

3

20,890

26,190

31,510

36,840

42,180

47,540

52,900

58,260

1.96

4

22,140

27,740

33,360

38,990

44,640

50,290

55,940

61,600

3.26

5

22,930

28,720

34,520

40,340

46,170

52,000

57,840

63,690

4.84

800

3

22,630

28,380

34,150

39,940

45,750

51,560

57,380

63,210

1.96

4

24,170

30,300

36,450

42,610

48,790

54,970

61,160

67,360

3.26

5

25,160

31,520

37,910

44,300

50,710

57,130

63,550

69,980

4.84

900

3

24,180

30,340

36,520

42,720

48,930

55,160

61,400

67,640

1.96

4

26,030

32,630

39,260

45,910

52,570

59,250

65,930

72,610

3.26

5

27,220

34,110

41,030

47,960

54,900

61,860

68,820

75,790

4.84

1,000

3

25,580

32,100

38,640

45,210

51,790

58,400

65,000

71,620

1.96

4

27,720

34,770

41,840

48,930

56,040

63,160

70,290

77,430

3.26

5

29,120

36,510

43,910

51,340

58,780

66,240

73,700

81,170

4.84

1,100

3

26,830

33,680

40,550

47,450

54,370

61,310

68,260

75,210

1.96

4

29,270

36,720

44,200

51,700

59,210

66,750

74,290

81,840

3.26

5

30,880

38,720

46,590

54,480

62,380

70,310

78,240

86,170

4.84

1200

3

27,970

35,110

42,280

49,480

56,710

63,950

71,200

78,460

1.96

4

30,700

38,520

46,370

54,240

62,140

70,050

77,980

85,910

3.26

5

32,520

40,790

49,080

57,400

65,730

74,090

82,450

90,830

4.84

1,300

3

28,990

36,400

43,850

51,320

58,820

66,340

73,860

81,400

1.96

4

32,020

40,170

48,370

56,590

64,840

73,100

81,380

89,670

3.26

5

34,050

42,710

51,400

60,120

68,860

77,620

86,380

95,170

4.84

Page 9

8 | P a g e

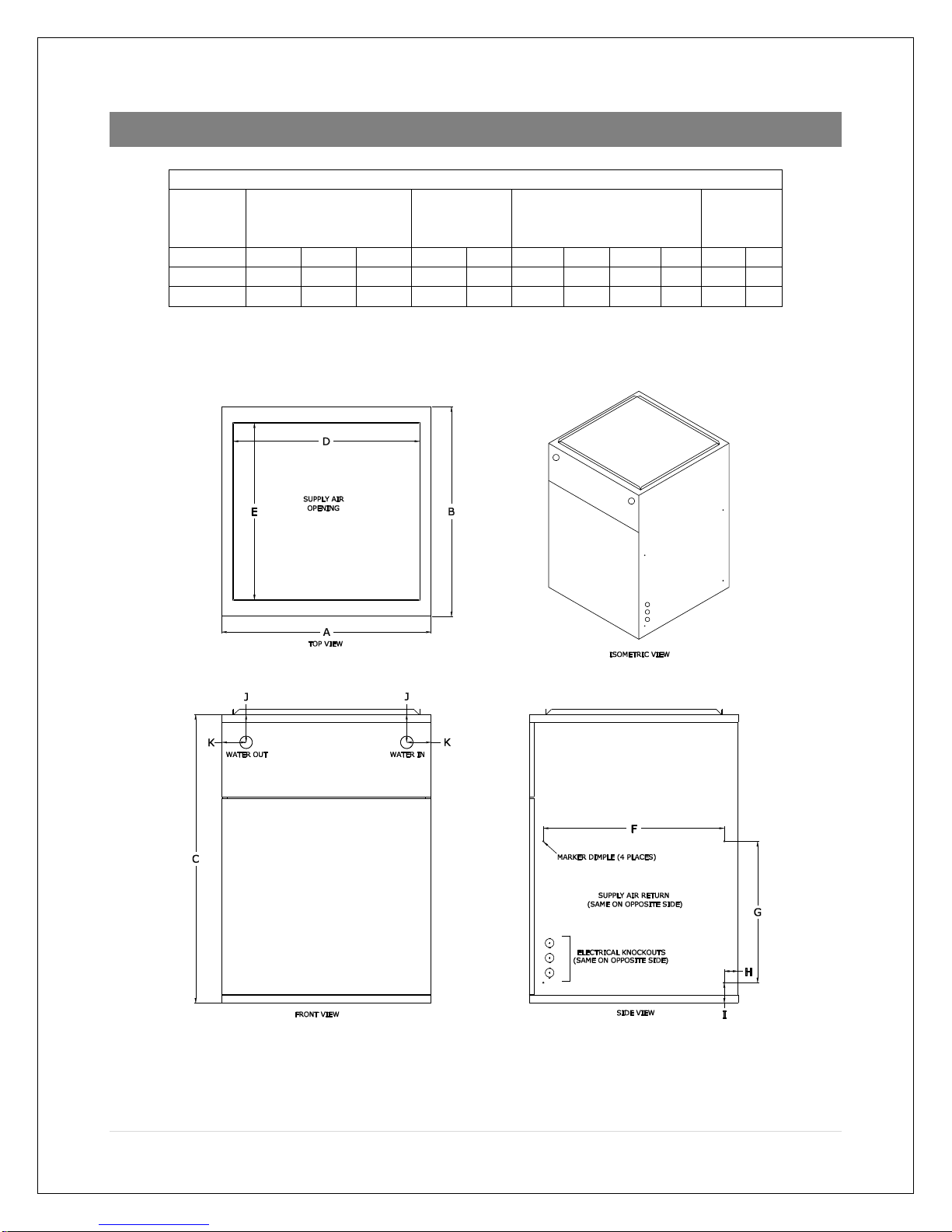

SPECIFICATIONS

PHYSICAL DATA - INCHES

Model

Overall Dimensions

W x D x H

Supply

Opening

W x D

Side Return

Piping

Location

A B C D E F G H I J K ES50LVP

14.0

21.0

29.0

11.8

17.8

18.3

14.3

1.4

2.0

2.8

2.4

ES90LVP

21.0

21.0

29.0

18.8

17.8

18.3

14.3

1.4

2.0

2.8

2.4

Page 10

9 | P a g e

MODEL

ES50LVP

ES90LVP

DX Cooling Capacity (tons)

1 to 2

1.5 to 3.5

Power (Volts/Phase/Hz)

120/1/60

120/1/60

Cabinet Size W x D x H (in)

14 x 21 x 29

21 x 21 x 29

Supply Air Opening W x D (in)

11.8 X 17.8

18.8 x 17.8

Side Return Air Opening (in)

18.3 X 14.3

18.3 X 14.3

Recommended Filter Size (in)

16 x 20

16 x 20

Shipping Weight (lb)

85

95

Shipping Dimensions W x D x H (in)

15 x 24 x 30.5

22 x 24 x 30.5

ES50LVP ECM blower performance (CFM/amps)

SWITCH

SETTING

0.1” WC

0.2” WC

0.3” WC

0.4” WC

0.5” WC

300 CFM

298

0.36

315

0.55

338

0.70

342

0.91

348

1.1

400 CFM

352

0.45

384

0.66

392

0.85

408

1.04

411

1.22

500 CFM

478

0.7

491

0.92

497

0.95

511

1.34

519

1.56

600 CFM

615

1.13

624

1.35

630

1.61

643

1.86

655

2.13

700 CFM

681

1.47

698

1.74

726

2.02

733

2.32

736

2.56

800 CFM

800

2.01

798

2.31

806

2.58

831

2.95

849

3.26

900 CFM

905

2.70

908

2.99

916

3.31

927

3.65

937

3.9

Page 11

10 | P a g e

ES90LVP ECM blower performance (CFM/amps)

SWITCH

SETTING

0.1” WC

0.2” WC

0.3” WC

0.4” WC

0.5” WC

600 CFM

603

0.82

607

1.02

610

1.25

618

1.49

620

1.7

700 CFM

681

1.04

688

1.26

699

1.47

702

1.76

708

1.99

800 CFM

756

1.22

782

1.58

800

1.92

823

2.28

844

2.58

900 CFM

874

1.7

894

2.08

918

2.44

927

2.82

940

3.11

1000 CFM

1000

2.31

1022

2.76

1034

3.14

1045

3.53

1060

3.89

1100 CFM

1120

3.07

1133

3.5

1145

3.93

1153

4.38

1170

4.8

1200 CFM

1195

3.56

1205

4.07

1211

4.5

1223

4.9

1228

5.38

1300 CFM

1282

4.32

1286

4.74

1295

5.2

1305

5.73

1312

6.17

QUICK START-UP PROCEDURES

Refer to the superseding installation instructions before following the start-up procedures.

1. Fill the system with water. Do not start the system.

2. Purge all air from the system. Isolation and purge valves are strongly recommended.

3. Purge all air from the space heating loop by closing the isolation valve on the return leg

of the loop and open the drain to purge air. Open the return leg isolation valve and

then close the drain valve.

4. Start the hot water generating equipment per the manufacturer’s recommendations.

Set the design water temperature to deliver the necessary amount of BTUs to the air

handler.

Page 12

11 | P a g e

5. Once all air has been purged, turn on the power to the ecosmart and set the room

thermostat to heat and set the temperature high enough to initiate a call for heat. This

will energize the air handler an in turn the fan and pump.

6. Once the heat source is supplying hot water, check supply and return pipes for a

temperature difference to make sure there is flow. There should be a noticeable

difference in temperature between supply and return lines. Use caution when supply

water temperature is above 120 F / 49 C.

INSTALLATION

The installer must comply with all local and national code requirements pertaining to the

installation of this equipment.

Clearances

The ecosmart is approved for up-flow, down-flow, and horizontal configurations. Clearances do

not change with orientation. This hydronic furnace is for indoor installation only.

Clearance from

Combustibles (in)

Recommended Service

Clearance (in)

Top

0

0

Bottom 0 0

Front 0 24

Back

0

0

Sides 0 0

Freeze Protection

It is not recommended to install the ecosmart in an unheated space.

Should the ecosmart be installed in an area where the ambient temperature may fall below

freezing, ethylene or propylene glycol should be added into the hydronic heating system to

protect against damage, which would not be covered under warranty. Make sure the glycol is

compatible with all system components and is permitted by local and national codes.

Page 13

12 | P a g e

Rear Piping Connections

The heating coil may be reversed to allow rear piping:

• Remove upper door

• Disconnect supply air sensor from extension cable

• Slide out heating coil

• Re-mount supply air sensor and grommet to opposite end of heating coil

• Remove rear knock-outs

• Slide in heating coil

• Use plastic plugs (provided) to close up holes on upper door

Ecosmart Mounting

The ecosmart can be installed in up flow, down flow and left or right horizontal applications.

Install the ecosmart with the door in place to make sure the cabinet remains square. Flip the

unit for down flow applications so that the top of the unit is now the bottom. No modification is

required for any configuration.

The ecosmart can be suspended from floor joists, rafters or concrete using rods, pipe, angle

supports or straps. Units must be hung level to ensure quiet operation.

CAUTION - Use any of the existing screw holes in the cabinet when using straps. If

the existing screw is too short for securing a mounting strap, a longer screw should

be used provided care is taken not to damage any internal components. Product

warranty does not cover any damage or claims resulting from damage from longer

screws or from the unit being improperly suspended.

The cabinet is designed so that the return air can be located on either side of the cabinet, or

from the bottom of the cabinet. Position a filter rack so that the filter is readily accessible. A

filter and filter rack are not included. Sides are marked for a standard 16 x 20 in filter rack.

WARNING - Special care should be taken in the vicinity of the coil to avoid

puncture. Screw into opening flange instead of top of cabinet when fastening the

supply air duct.

Plumbing

Install a sediment faucet or ball valve for use as a drain/purge valve. The drain valve must be

located downstream of the pump and check valve, and upstream of the isolation valve (if

Page 14

13 | P a g e

isolation valve is present). With this arrangement, any air trapped in the system can easily be

flushed out following the instructions in the Start-up & Troubleshooting sections.

Isolation valves are recommended ease of servicing.

When the space heating loop connections are made to the domestic water connections:

• The heating loop connections should be positioned horizontally in a vertical section of

the domestic water line for both inlet and outlet. Refer to the piping schematic for

details.

• Connect the heating loop to the domestic water connections as close to the water

heater as possible

Avoid sections of pipe in the heating loop that can trap air where possible. It is usually

impossible to install a system without having at least one part of the system or heating coil able

to trap air. This will not be a problem if the connection to the domestic water lines is made

properly, and purge valves and air eliminator devices are installed.

• Following the flushing procedures in the Start-up section will ensure that there is no air

in the system after initial set-up.

Follow recommendations supplied by the manufacturer of the heating source being used.

ecosmart includes a flow switch connection where a flow switch can be connected to allow for

domestic water priority. Note: the correct type of flow switch is a normally open (NO) device.

The flow switch closes when domestic water is flowing.

Check Valve

A check valve may be required for your system to meet local codes and to work effectively. A

check valve:

• Protects against back-flow of water to avoid short circuiting around the water heater

during domestic use

• Protects against thermal siphoning

• Is required in all potable water systems

Pump

A pump is not included inside the ecosmart. Whether you are using an external pump or an

internal built-in pump, it should be sized for the system. Pumps supplied with the heat

generating units can be used as the sole pump provided it meets the needs of the system. This

Page 15

14 | P a g e

is especially the case in retrofit applications where a much larger pump may have previously

been used in the system.

The ecosmart includes a built-in variable speed pump controller that can control a standard

single speed pump up to 250 watts. Operational modes are as follows:

• When set up in modulating mode, the pump will operate as a continuously variable

speed pump

• When set up in step-modulating mode, the pump will operate as a multi-speed pump.

• When set up in basic mode, the pump will operate as a single-speed pump

• The ecosmart controller has a built-in pump timer that exercises the pump for 1 minute

every 24 hours to prevent the possibility of ‘sticking’ due to sediment and local codes

Water Heater or Boiler Setup

Follow the manufacturer’s installation and start-up instructions of the water heater or boiler.

Make sure the equipment is turned off during installation and service. Make certain the

equipment has been refilled and all air is purged from the system before turning on the heater.

WARNING - When the system requires water temperatures higher than 120F,

a mixing valve shall be installed to reduce domestic hot water temperature to

safeguard against scalding.

Combo Systems

The ecosmart is ideal for use in combo systems which provide space heating and domestic hot

water from a single heat source. Any properly sized gas, propane or oil fired water heater or

boiler will work in a combo system. Make sure any water heater being used is approved for

combo applications.

Page 16

15 | P a g e

PIPING DIAGRAMS

Tankless Water Heater Piping

Page 17

16 | P a g e

Combi-Boiler Piping

Page 18

17 | P a g e

ELECTRICAL

• WARNING - Make sure the installation meets all national and local

electrical codes.

Electrical Information

The ecosmart wiring diagram is located on the cover of the electrical box behind the lower front

panel. Ratings data is located on the lower front panel.

• The ecosmart operates on 120VAC 60Hz single phase line voltage

• All control circuits are standard 24VAC

• ecosmart must be grounded via the green wire within the control box

Electrical Connections Made to Quick Connects

• Stranded or solid wire may be used

• Male tab size on control board: 0.250 in x 0.032 in

• Correct female disconnects to mate with male tabs:

o Wire range: 22-18 AWG (Red) Panduit # DNF18-250 or equivalent

Wire range: 16-14 AWG (Blue) Panduit # DNF14-250 or equivalent

• Use a quality ratchet crimping tool to ensure reliable connections

Page 19

18 | P a g e

Thermostat Wiring

Any standard heat/cool thermostat is compatible with the ecosmart.

Wire thermostat to lower right tabs as marked. The ecosmart supports optional 2-stage cooling

if required.

Page 20

19 | P a g e

Ecosmart ES50LVP/ES90LVP Wiring Diagram

Page 21

20 | P a g e

Miscellaneous Wiring

Miscellaneous wiring to the upper right tabs of control board as marked:

• FLOW – When using a water heater and domestic water priority is required, connect a

normally open (NO) flow switch. If there is a call for DHW, fan and pump will shut down

after 1 minute. If flow switch is active longer than 30 minutes, fan and pump will resume

normal operation.

• BOILER – dry contacts to initiate heat source

• AUX 24V – 24VAC output for humidifier or other accessory. Active when heating is on

• OUTDOOR – included outdoor temperature sensor connects here. If sensor is not

connected, ecosmart assumes coldest temperature is present and will not modulate fan

and pump

Page 22

21 | P a g e

DIP SWITCH OPTIONS

Switch Locations

Four DIP switches are located on the top, mid-section of the control board.

WARNING – to prevent damage, use a small screwdriver to change switch position.

Up is ON as marked on the switch body and are identified with numbers below.

• OUTDOOR TEMP – set the lowest outdoor temperature expected

• HEAT CFM – set 1 of 8 fan CFM rates for heating

• SYSTEM – set various system parameters

• COOL CFM – set 1 of 8 fan CFM rates for cooling

Outdoor Temperature Select

Select lowest possible expected outdoor temperature.

DESIGN TEMP °C

DESIGN TEMP °F

SWITCH 1

SWITCH 2

SWITCH 3

< -18

< 0

OFF

OFF

OFF

-17 to -10

1 – 14

ON

OFF

OFF

-9 to 0

15 – 32

OFF

ON

OFF

1 to 10

33 – 50

ON

ON

OFF

>10

>50

OFF

OFF

ON

NOT USED

X X X

NOT USED

X X X

NOT USED

X X X

Page 23

22 | P a g e

Heat CFM (ES90LVP)

Select required heating CFM.

CFM @ 0.5” WC

SWITCH 1

SWITCH 2

SWITCH 3

600

OFF

OFF

OFF

700

ON

OFF

OFF

800

OFF

ON

OFF

900

ON

ON

OFF

1000

OFF

OFF

ON

1100

ON

OFF

ON

1200

OFF

ON

ON

1300

ON

ON

ON

Heat CFM (ES50LVP)

Select required heating CFM.

CFM @ 0.5” WC

SWITCH 1

SWITCH 2

SWITCH 3

300

OFF

OFF

OFF

400

ON

OFF

OFF

500

OFF

ON

OFF

600

ON

ON

OFF

700

OFF

OFF

ON

800

ON

OFF

ON

900

OFF

ON

ON

System (ES990LVP and ES50LVP)

Select required system parameters.

Mode

SWITCH 1

SWITCH 2

SWITCH 3

SWITCH 4

Full Modulation

OFF

OFF X X

Step Modulation

ON

OFF X X

Single Stage

OFF

ON X X

Test Mode (1)

ON

ON X X

Normal Fan Cooling (2)

X X OFF X Dehumidification Fan Cooling (2)

X X ON X Normal Continuous Fan (3)

X X X

OFF

Low Speed Continuous Fan (3)

X X X

ON

Page 24

23 | P a g e

(1) Test Mode - heat source is brought on, fan runs at HEAT CFM setting and pump runs at full

speed irrespective of thermostat setting. Useful for eliminating air in the system during

installation.

(2) Normal Fan Cooling runs at rate set by COOL CFM switch.

Dehumidification Fan Cooling runs at 85% of COOL CFM rate for 10 min. and then reverts back

to rate set by COOL CFM.

(3) Normal Continuous Fan runs at rate set by HEAT CFM switch.

Low speed Continuous Fan runs at 50% of rate set by HEAT CFM switch.

Cool CFM (ES90LVP)

CFM @ 0.5” WC

SWITCH 1

SWITCH 2

SWITCH 3

600

OFF

OFF

OFF

700

ON

OFF

OFF

800

OFF

ON

OFF

900

ON

ON

OFF

1000

OFF

OFF

ON

1100

ON

OFF

ON

1200

OFF

ON

ON

1300

ON

ON

ON

Cool CFM (ES50LVP)

CFM @ 0.5” WC

SWITCH 1

SWITCH 2

SWITCH 3

300

OFF

OFF

OFF

400

ON

OFF

OFF

500

OFF

ON

OFF

600

ON

ON

OFF

700

OFF

OFF

ON

800

ON

OFF

ON

900

OFF

ON

ON

Page 25

24 | P a g e

SEQUENCE OF OPERATION

Full Modulation

Heating Mode – (ecosmart outdoor sensor installed)

Thermostat calls for heat

• R is connected to W

• Heat generator is turned on

• Auxiliary 24VAC power is turned on

• Pump turns on 100%

• After a 15 second delay to allow for system water to heat up coil, fan ramps up to HEAT

CFM speed

• ecosmart control automatically adjusts fan and pump speeds to meet the outdoor

temperature conditions

Thermostat is satisfied

• R is disconnected from W

• Heat generator is turned off

• Auxiliary 24VAC power is turned off

• Pump turns off and fan speed ramps down to zero, extracting any remaining heat in the

coil

Step Modulation

Heating Mode – (ecosmart outdoor sensor not installed)

Thermostat calls for heat

• R is connected to W

• Heat generator is turned on

• Auxiliary 24VAC power is turned on

• Pump turns on 100%

• After a 15 second delay to allow for system water to heat up coil, fan ramps up to HEAT

CFM speed

• ecosmart goes through three steps:

• 50% of HEAT CFM setting for 5 minutes – pump LO

• 75% of HEAT CFM for 5 minutes – pump MID

• 100% of HEAT CFM until thermostat is satisfied – pump HI

Page 26

25 | P a g e

Thermostat is satisfied

• R is disconnected from W

• Heat generator is turned off

• Auxiliary 24VAC power is turned off

• Pump turns off and fan speed ramps down to zero, extracting any remaining heat in the

coil

Basic Modulation Mode

Heating Mode – (ecosmart outdoor sensor not installed)

Thermostat calls for heat

• R is connected to W

• Heat generator is turned on

• Auxiliary 24VAC power is turned on

• Pump turns on at 100%

• After a 15 second delay to allow for system water to heat up coil, fan ramps up to HEAT

CFM speed

Thermostat is satisfied

• R is disconnected from W

• Heat generator is turned off

• Auxiliary 24VAC power is turned off

• Pump turns off and fan speed ramps down to zero, extracting any remaining heat in the

coil

Cooling Mode (Modulation, Step and Basic)

(ecosmart outdoor sensor not installed)

(Assumes a condenser and DX coil is installed within the system)

• R is connected to Y or Y2*

• Condenser turns on

• Fan ramps up to COOL CFM setting

* If thermostat and condenser support 2-stage cooling

Page 27

26 | P a g e

Thermostat is satisfied

• Condenser turns off

• Fan speed ramps down to zero, extracting any remaining cooling from the DX coil

Dehumidification

When in cooling mode, a dehumidification function can be set using system switch 3 as follows:

• OFF - Normal cooling fan runs at rate set by COOL CFM switch

• ON - fan runs at 85% of COOL CFM rate for 10 min. and then reverts back to rate set by

COOL CFM

Fan Mode

• R is connected to G

• If fan is set to “ON” on thermostat, fan runs as follows:

• If SYSTEM switch 4 is OFF, fan runs at selected HEAT CFM rate

• If SYSTEM switch 4 is ON, fan runs at 50% of selected HEAT CFM rate

• If fan is set to “OFF” on thermostat, fan runs at HEAT or COOL CFM settings

Constant Low Fan Circulation

Fan may be run at a low rate using system switch 4 as follows:

• OFF – fan runs at rate set by HEAT CFM switch

• ON – fan runs at 50% of rate set by HEAT CFM switch

Freeze Protection

The ecosmart is equipped with a freeze protection sensor to help prevent any damage to the

hot water coil from a freeze up. In any mode, heating, cooling or standby, when the outlet air

temperature sensor reads a temperature of 40°F or lower the ecosmart will bring on the

circulating fan and energize the pump relay.

Page 28

27 | P a g e

Pump Exerciser

• The circulating pump is exercised for 1 min every 24 hr when the ecosmart is OFF,

COOLING (Y), COOLING2 (Y2) or FAN (G) to prevent the possibility of ‘sticking’ due to

sediment and to meet local codes.

• During the 1 min pump on-time, the fan is turned off and resumes once the pump

exercising is completed

• Pump runs continuously if the outlet air temperature drops below 40F to prevent the

chance of freezing

SERVICE AND MAINTENANCE

NOTE: The ecosmart is not to be used for temporary heat during construction. Use for this

purpose will void equipment warranty.

Filter

Inspect the filter monthly and replace, remove and vacuum or rinse as required. A clogged or

inadequate filter may void product warranty. Replacement filter size is 16 x 20 x 1.

Coils

Air conditioning and heating coils should not require cleaning if the filter maintenance schedule

is adhered to. If a filter is damaged or collapses from plugging, dust may foul the coils. If this

happens, replace the filter and carefully vacuum the coils. The fan may need to be removed to

gain access to the face of the heating coil.

Fan and Motor

Check fan for dust once a year. If dirty, vacuum or wash to remove dust. Keeping the fan blades

clean will reduce noise and improve capacity and efficiency of the heating system.

Control and Blower Assembly Removal

1. Turn off main power.

2. Disconnect power, thermostat and any other miscellaneous wiring from the control

board and remove them from the control casing.

Page 29

28 | P a g e

3. On the bottom side of the upper cover, disconnect the supply air temperature sensor by

sliding out the rubber grommet.

4. Gently pull out the black wire until a white connector is revealed.

5. Unplug the white connector noting that there is a polarizing/locking feature when re-

assembling.

6. Remove (Qty. 2) ¼-20 bolts, lockwashers and flat washers holding the control and

blower assembly to the centre plate.

7. Slide out assembly.

8. Re-assemble in the reverse order.

TROUBLESHOOTING

Thermostat call error

If the ecosmart does not run when the thermostat is calling, jumper R to W for heating, or R to

Y (Y2) to verify if the problem is with the thermostat or ecosmart control. Note that some

thermostats have a delay (typically five minutes) before they will re-start cooling.

External pump does not run

In areas where hard water is present the pump may stick and fail to run. Often, closing the

isolation valve on the return leg and opening the drain port so that water flows through the

pump can free this. If this fails to free the pump, removal for cleaning or replacement is

necessary. The daily pump exerciser will help prevent pump sticking.

External pump is noisy at start-up

If sound has not diminished within 1 minute, air may be present in the system and may need repurging. If the heat source is a water heater, check to make sure branch connections for the

heating loop are horizontal to prevent the collecting of air in the loop.

Water heater temperature and pressure relief valve is weeping

A check valve or back-flow preventer may have been installed in the system. Some form of

pressure relief may be required. Consult water heater manufacturer’s instructions. An

expansion tank may be required.

Page 30

29 | P a g e

Insufficient or no heat

• Check that the heat generator is functioning properly.

• Plugged air filter or coil. Refer to maintenance section for filter care and coil cleaning.

• Air in heating loop - purge system.

• Inlet and outlet connections to ecosmart are backwards - reverse connections.

• Supply water temperature set too low or heat generator is not supplying water at the

specified setting.

• Restrictions on heating loop - remove restrictions, check if valve is stuck, isolation valves

could be too restrictive or left partially closed after purging, or a closed valve.

Cold water at hot faucet

When the heat source is a water heater, the most probable cause is reverse flow through the

heating loop from a stuck check valve - repair or replace valve.

Fan runs for cooling but not for heating

The room thermostat may be connected improperly. Refer to Electrical section or wiring

schematic on ecosmart for proper installation.

Heating during standby mode

Probable cause is thermal siphoning.

WARRANTY

Warranty is 2 years’ parts. Visit ecosmartair.com/warranty.htm for full details.

Loading...

Loading...