ECOScience 6300wt, ControlScience 300, 6500wt, 8500wt, 8750wt Installation And User Manual

...

ECOScience ENERGY CENTRE

Installation

and

User Manual

Top Connected System Tank

Control System: CS300

6300wt, 6500wt, 8500wt, 8750wt

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

Congratulations on choosing this ECOScience

product

We are confident that this product will meet all your expectations, both in

terms of climate comfort and energy savings. Choosing one of our

products also shows your commitment and concern for our shared

environment.

Whatever product or package you have chosen, you will be at the

absolute forefront of technology in terms of efficient energy use. If you

have chosen an individual energy centre such as the 6500i, this can

always be used directly to produce hot tap water and radiator heating via

the integrated 4.5 kW electric heaters.

You can add to your energy centre later with a range of add-on modules.

INSTALLATION AND USER MANUAL

The control system manages the add-on modules connected to the

centre using module key updates and at the same time ensures optimum

energy efficiency.

The control system is operated using a user-friendly colour touchscreen.

Managing Director

Mikael Jönsson

Edition: 01; Last updated: 2011-04-12

© ECOScience

i

ECOScience ENERGY CENTRE

INSTALLATION AND USER MANUAL

ii

© ECOScience

Edition: 01; Last updated: 2011-04-12

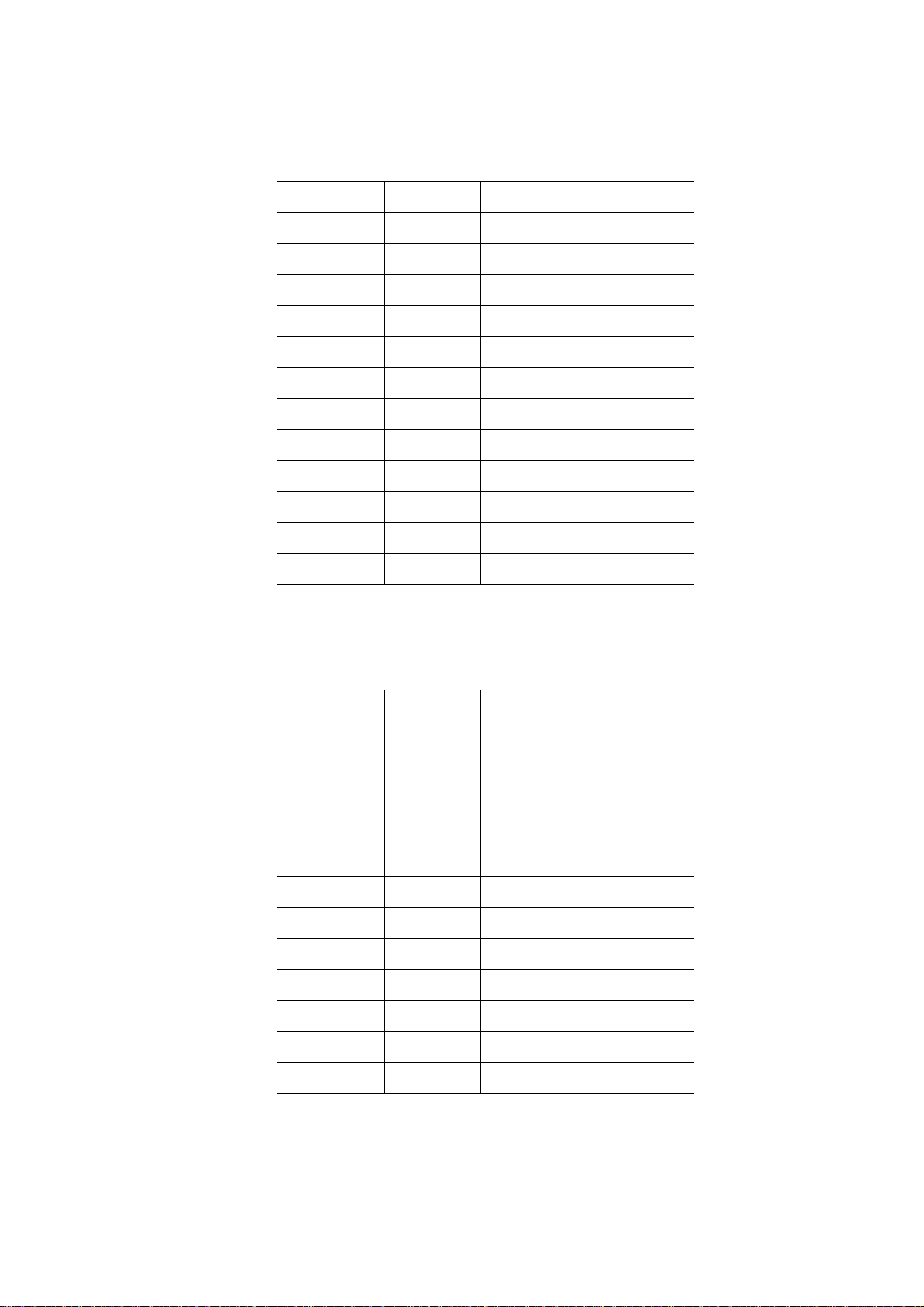

INSTALLATION CERTIFICATE

For warranty cover and to register the product with ECOScience.

PRODUCTS THAT HAVE BEEN INSTALLED:

Name:

Product number:

Date of installation:

THE PRODUCTS HAVE BEEN INSTALLED AT:

Name:

Address:

Postal address:

Telephone:

THE PRODUCTS WERE INSTALLED BY:

Company:

Address:

Postal address:

Telephone:

Installation engineer:

To be sent to:

ECOScience ENERGY CENTRE

TERMS OF WARRANTY

This is an extract from the ECOScience Terms of Warranty. See AA VVS

09 (general terms issued by industry associations) for full terms and

conditions. If the instructions set out in this documentation are not

followed, the obligations that would otherwise be incumbent upon

ECOScience under these terms shall not be binding. Due to the rapid

pace of development in the industry, we reserve the right to amend

specifications and modify parts.

• All products marketed by ECOScience are covered by a 2 year

warranty for design, manufacture and material defects that

commences from the date of installation.

• For the duration of the warranty, the installation engineer

undertakes to rectify any defects that occur, either by repairing and/

or replacing the product.

• If the purchaser wishes to resolve any defects himself, the product

must be examined beforehand by us or by a person we have

appointed. A separate agreement may be entered into regarding

repairs and costs.

INSTALLATION AND USER MANUAL

• In the event of a defect, the installation engineer must be contacted

first.

• A defect means any departure from the normal standard, assessed

by an industry professional. Defects or deficiencies that occur due

to abnormal circumstances, such as mechanical or environmental

circumstances, shall not fall under the scope of the warranty.

• ECOScience shall therefore not be liable if the defect is attributed

to abnormal or varying water quality, such as chalky or aggressive

water, variations in electrical voltage or other electrical interference.

• Nor shall ECOScience be liable for defects if the installation and/or

maintenance instructions have not been followed.

• The product must be examined thoroughly on delivery. Any defects

discovered must be reported before the product is used. All defects

must be reported immediately.

• ECOScience shall not be liable for defects that have not been

reported within 2 years of the date of installation.

• ECOScience shall not be liable for ‘indirect’ damage/loss, including

damage to entities other than the product, for example personal

injury, damage to physical property or losses caused by operational

stoppage etc..

Edition: 01; Last updated: 2011-04-12

© ECOScience

• Nor shall ECOScience be liable for compensation in the event of

any increase in energy consumption caused by a defect in the

product or the installation. For the rest, the provisions set out in AA

VVS 09 apply.

• If the product requires modification or to be serviced by a

professional, consult your installation engineer who will undertake

any necessary adjustments.

• When reporting defects, please state the product production

number, date of installation and details of the installation engineer.

v

ECOScience ENERGY CENTRE

RESPONSIBILITY

The installation engineer is responsible for ensuring that these

instructions are followed and that the environment and the methods

used when the control system is installed, commissioned and operated,

are correct. If these instructions are ignored, costly material damage

and/or serious personal injury may result.

Due to the foregoing, neither the manufacturer nor the supplier of this

product shall be liable for losses, damage or other costs incurred as a

result of incorrect installation and/or commissioning, operation or

maintenance work.

The manufacturer and/or the supplier of this product reserves the right to

amend and/or update, without notice, the composition of the product, its

specifications, technical information and/or the accompanying

installation and operation manual.

If the control system becomes damaged, or deficiencies are discovered

that may put safety and/or operation at risk, the system must be

switched off immediately and the installation engineer called in.

INSTALLATION AND USER MANUAL

vi

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

This user manual forms part of the product documentation in

accordance with the EU’s Pressure Equipment, Electromagnetic

Compatibility and Low Voltage Directives.

This manual is intended for installation engineers and users.

The person responsible must ensure that they have read and

understood the manual and the information in the included

documentation. Particular attention must be paid to the sections on

product and personal safety.

The manual should be kept in an easily remembered and accessible

place and should be consulted even if the slightest doubt exists.

The manufacturer assumes no liability for injury to persons or animals,

damage to property or damage to the product itself that occur as a result

of incompetent handling, are caused by failure to adequately observe

the safety instructions set out in this manual, or by modifying the product

or using unsuitable spare parts.

© 2010

INSTALLATION AND USER MANUAL

Copyright to the manual is held exclusively by

Fueltech Sweden AB

Fridhemsvägen 15

372 25 Ronneby, Sweden

This manual may only be reproduced or provided to a third party with

written consent. This also applies if extracts from the manual are to be

copied or passed on.

Edition: 01; Last updated: 2011-04-12

© ECOScience

vii

ECOScience ENERGY CENTRE

INSTALLATION AND USER MANUAL

viii

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

Contents

1 BASIC INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1 ABOUT THE MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 Explanation of Warnings. . . . . . . . . . . . . . . . . . . . . . .1

1.1.2 Important information . . . . . . . . . . . . . . . . . . . . . . . . .2

1.1.3 Changes and updates. . . . . . . . . . . . . . . . . . . . . . . . .2

1.2 INSTALLATION ENGINEERS . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 ECOSCIENCE Energy Centre. . . . . . . . . . . . . . . . . . . . . . . 3

1.3.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3.2 Manufacturer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.4 PRODUCT MARKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.1 Identification plate. . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.4.2 EC declaration of conformity. . . . . . . . . . . . . . . . . . . .4

2 SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1 GENERAL HAZARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1.1 Space required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1.2 Risks involving spare parts. . . . . . . . . . . . . . . . . . . . .5

INSTALLATION AND USER MANUAL

3 DESCRIPTION OF FUNCTIONS . . . . . . . . . . . . . . . . . . . .6

3.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1.1 System tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.1.2 Energy central unit . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.1.2.1 Tap water circuit . . . . . . . . . . . . . . . . . . . . .7

3.1.2.2 Solar loading circuit . . . . . . . . . . . . . . . . . . .7

3.1.2.3 Heat circuit . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.1.3 Control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4 ASSEMBLY AND INSTALLATION . . . . . . . . . . . . . . . . . .9

4.1 BEFORE USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1.1 Safe disposal of packaging material. . . . . . . . . . . . . .9

4.2 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3 ASSEMBLING THE SUPPORT BASE AND

SYSTEM TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3.1 Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4.4 CONNECTING THE PIPES. . . . . . . . . . . . . . . . . . . . . . . . 12

4.4.1 Please note. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.4.2 Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.4.3 Pipe connections . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.5 ASSEMBLY OF TEMPERATURE SENSORS

AND OVERHEAT PROTECTION . . . . . . . . . . . . . . . . . . . 16

4.5.1 Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.6 ELECTRICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . 17

4.6.1 Please note. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.6.2 Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.7 FILLING THE SYSTEM WITH WATER . . . . . . . . . . . . . . . 18

4.7.1 Please note. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.7.2 Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.7.3 Connections and shut-off valves. . . . . . . . . . . . . . . .20

4.8 EMPTYING THE SYSTEM TANK . . . . . . . . . . . . . . . . . . . 21

4.8.1 Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

Contents 1 / 3

ECOScience ENERGY CENTRE

Contents

5 COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5.1 PREPARATIONS BEFORE STARTING . . . . . . . . . . . . . . 22

5.2 START-UP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.3 NORMAL STOP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6 CONTROL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6.1 START SCREEN (BASIC MODEL) . . . . . . . . . . . . . . . . . . 23

6.2 SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.3 SETUP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3.1 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

6.3.2 Manual operation . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.3.3 Heat-up sequence . . . . . . . . . . . . . . . . . . . . . . . . . .27

6.3.4 Display settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

6.3.5 Calibrating the touchscreen . . . . . . . . . . . . . . . . . . .28

6.3.6 Restore default values . . . . . . . . . . . . . . . . . . . . . . .29

6.3.7 System information. . . . . . . . . . . . . . . . . . . . . . . . . .29

6.3.8 Activating DFU mode . . . . . . . . . . . . . . . . . . . . . . . .29

6.3.9 Calibrating the temperature sensors. . . . . . . . . . . . .30

6.4 DATE/TIME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.5 STATUS TEMP.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.6 STATUS I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.6.1 Explanation of ‘Status I/O’ menu . . . . . . . . . . . . . . .34

6.7 LANGUAGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.8 ALERTS/HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.9 HEATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.10SOLAR CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.11RADIATOR CIRCUIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.11.1 Radiator circuit temperature curve . . . . . . . . . . . . . .39

6.11.2 Scheduled temperature changes in radiator circuit .40

6.11.3 Radiator circuit holiday settings . . . . . . . . . . . . . . . .41

6.12FLOOR HEATING CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . 42

6.12.1 Floor heating circuit temperature curve . . . . . . . . . .43

6.12.2 Scheduled temperature changes in floor

6.12.3 Floor heating circuit holiday settings. . . . . . . . . . . . .45

6.13SOLID FUEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.14BUFFER TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.15HEAT PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.16POOL CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

INSTALLATION AND USER MANUAL

heating circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

7 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

7.1 MAINTENANCE AND FUNCTION CHECKS. . . . . . . . . . . 46

7.1.1 Regular maintenance to be carried out

at least once a year . . . . . . . . . . . . . . . . . . . . . . . . .46

7.2 CLEANING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8 SERVICING AND REPAIRS . . . . . . . . . . . . . . . . . . . . . . .47

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

Contents 2 / 4

ECOScience ENERGY CENTRE

Contents

9 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . .48

9.1 COMMON FAULTS AND SOLUTIONS. . . . . . . . . . . . . . . 48

9.2 TABLE FOR RESISTANCE TEMPERATURE

SENSOR Pt 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.3 ALERTS AND SOLUTIONS. . . . . . . . . . . . . . . . . . . . . . . . 50

9.3.1 Resetting overheat protection for electric heaters . .50

10 TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

10.1TECHNICAL DATA, SYSTEM TANK. . . . . . . . . . . . . . . . . 51

10.2TECHNICAL DATA, ENERGY CENTRAL UNIT . . . . . . . . 51

10.3TECHNICAL DATA, CONTROL SYSTEM. . . . . . . . . . . . . 52

11 APPENDICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

APPENDIX 1 - EC DECLARATION OF CONFORMITY

APPENDIX 2 - FLOW CHART

APPENDIX 3 - WIRING DIAGRAM AND TEMPERATURE

APPENDIX 4 - DEFAULT SETTINGS

APPENDIX 5 - LIST OF COMPONENTS

INSTALLATION AND USER MANUAL

SENSORS

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

Contents 3 / 3

ECOScience ENERGY CENTRE

1 BASIC INFORMATION

1.1 ABOUT THE MANUAL

This manual contains instructions for installation, operation and safety

and is intended for installation engineers and other users of

ECOScience Energy Centre.

Read the manual carefully and make sure it is always on hand.

Failure to follow the instructions may cause serious personal injury or

damage to the product.

• Take note of all the information contained in the boxes marked

Danger! Warning! Caution! and Please note!

• Remember that any type of electrical equipment may be live.

• Servicing and maintenance: Servicing and maintenance must only

be carried out by qualified service engineers.

INSTALLATION AND USER MANUAL

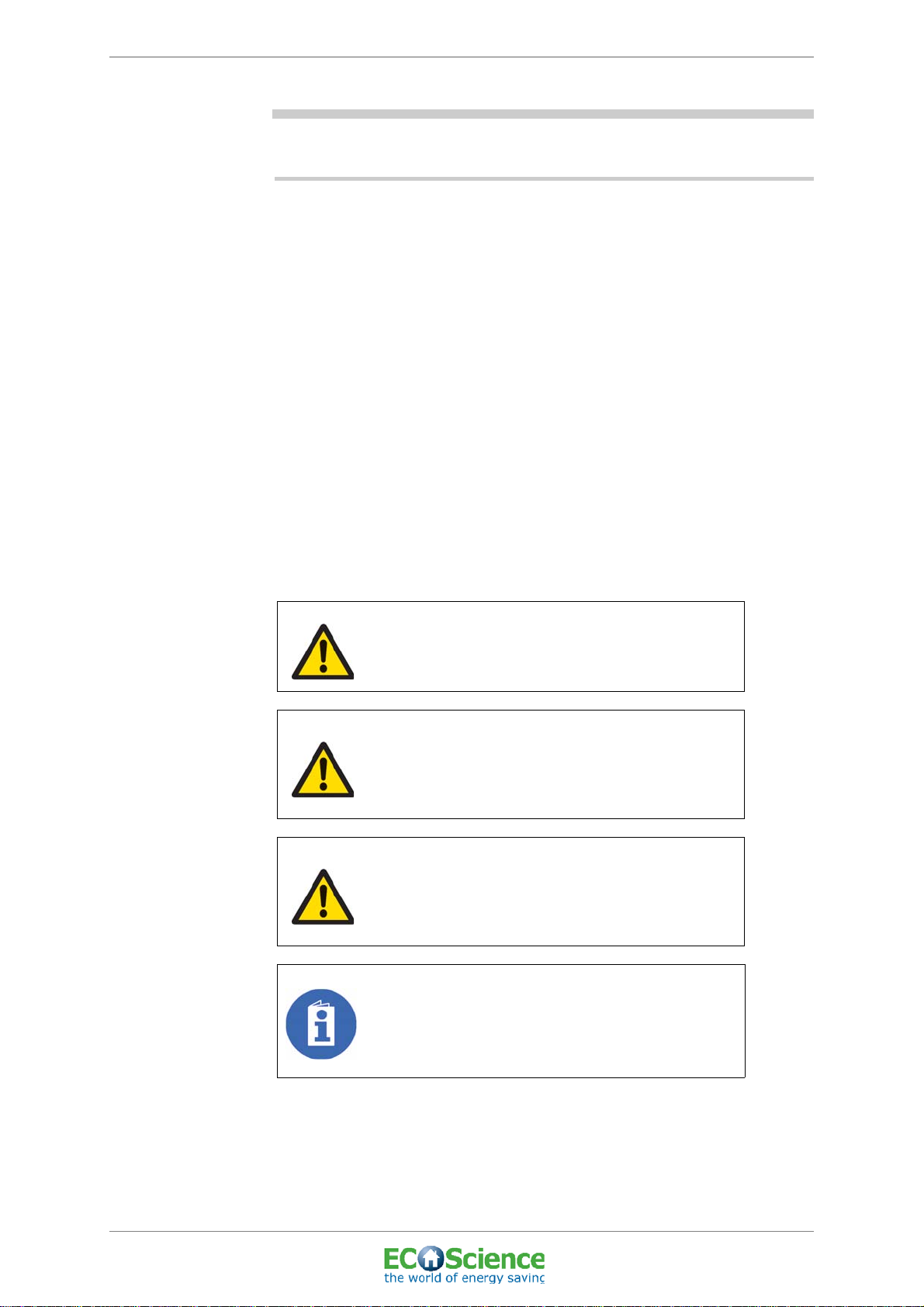

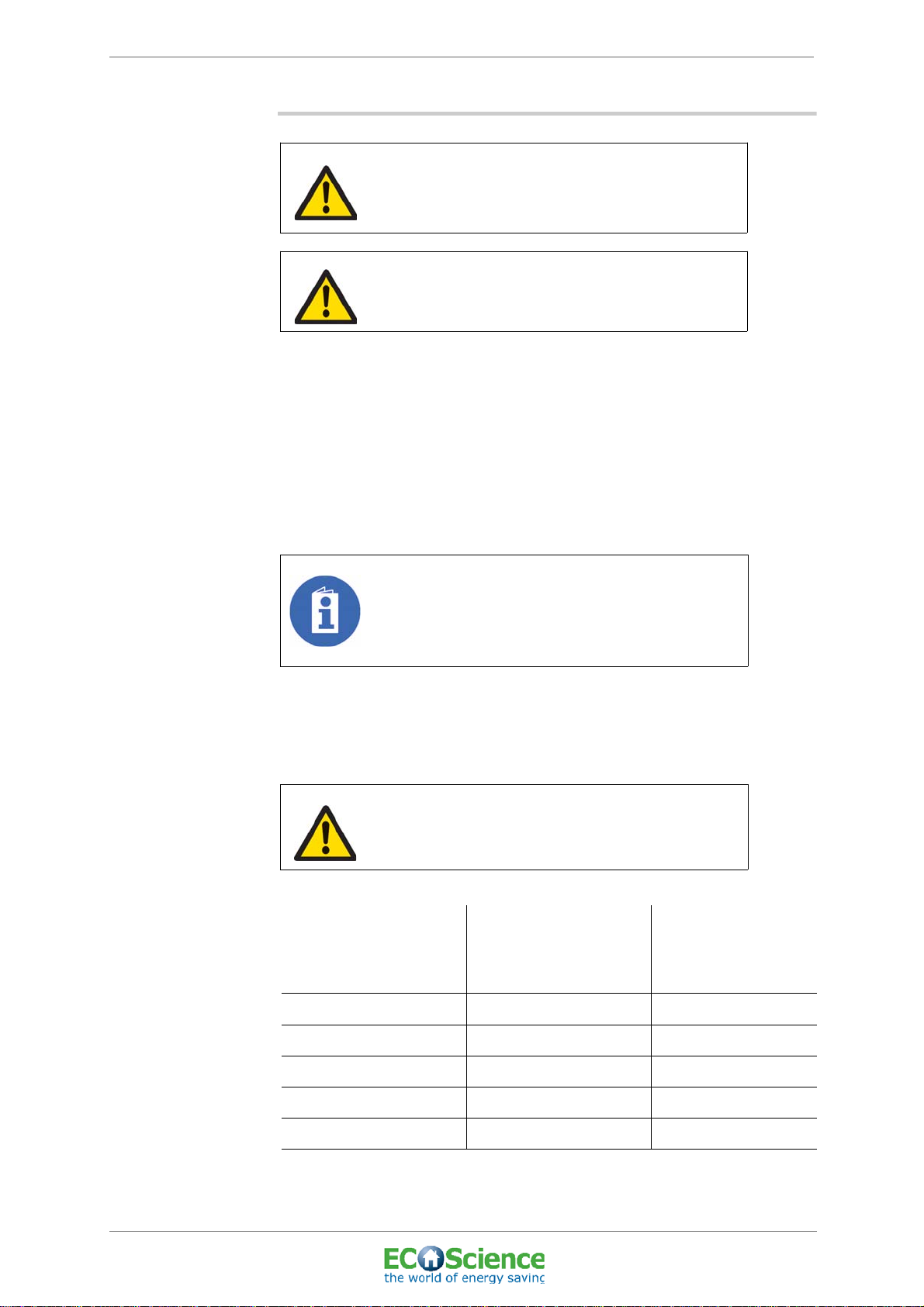

1.1.1 Explanation of Warnings

In this manual, boxes headed Danger!, Warning!, Caution! and Please

note! mean the following:

DANGER!

Ignoring this information could endanger life!

WARNING!

Ignoring this information may result in personal injury

or put life at risk!

CAUTION!

Ignoring this information may result in minor personal

injury or may damage the device!

PLEASE NOTE!

Information requiring particular attention!

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

1

ECOScience ENERGY CENTRE

1.1.2 Important information

The following requirements are mandatory:

The manual and other useful documents must be kept for the entire

service life of the equipment.

This manual and other useful documents shall be regarded as part of the

equipment.

If the owner changes, the manual must be passed to the new owner or

user of the equipment.

The information in the manual must be updated if the product owner

makes additions to this equipment or other modifications.

In the event of conversion or redesign, a new risk analysis is required.

Any type of change must be approved by the product owner.

1.1.3 Changes and updates

If updates are implemented for the control system, the installation

engineer is responsible for ensuring that the manual is also updated, i.e.

that new instructions are added to the manual, replacing the old ones,

which are removed and discarded.

INSTALLATION AND USER MANUAL

The latest version of the installation and user manual for ECOScience

Energy Centre, and any updates/new instructions for the control system

are available to download from our website (http://www.ecoscience.se/

downloads.html).

1.2 INSTALLATION ENGINEERS

ECOScience Energy Centre must only be installed by certified

installation engineers who have the necessary theoretical and practical

training.

After installation, the installation engineer must:

• Fill in the table with the programmed values.

• Walk through the system with the end user.

• Fill in the warranty card and installation certificate.

• Perform final inspection (including checks of all filters and system

pressure).

2

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

1.3 ECOSCIENCE ENERGY CENTRE

PLEASE NOTE: RECYCLABLE!

In the development of ECOScience products and the

choice of materials used, much attention has been paid

to environmental considerations. If the entire product or

replacement parts are to be disposed of, these can be

sorted into waste types and recycled. The ECOScience

system tank is therefore fully recyclable.

1.3.1 Description

ECOScience is an Energy Centre designed for domestic use, which

provides a complete solution for heating and hot water.

PLEASE NOTE!

INSTALLATION AND USER MANUAL

The system tank in the ECOScience Energy

Centre should not be kept outdoors as sunlight

may cause it to discolour

1.3.2 Manufacturer

Fueltech Sweden AB

Fridhemsvägen 15

372 25 Ronneby, Sweden

Website: www.ecoscience.se

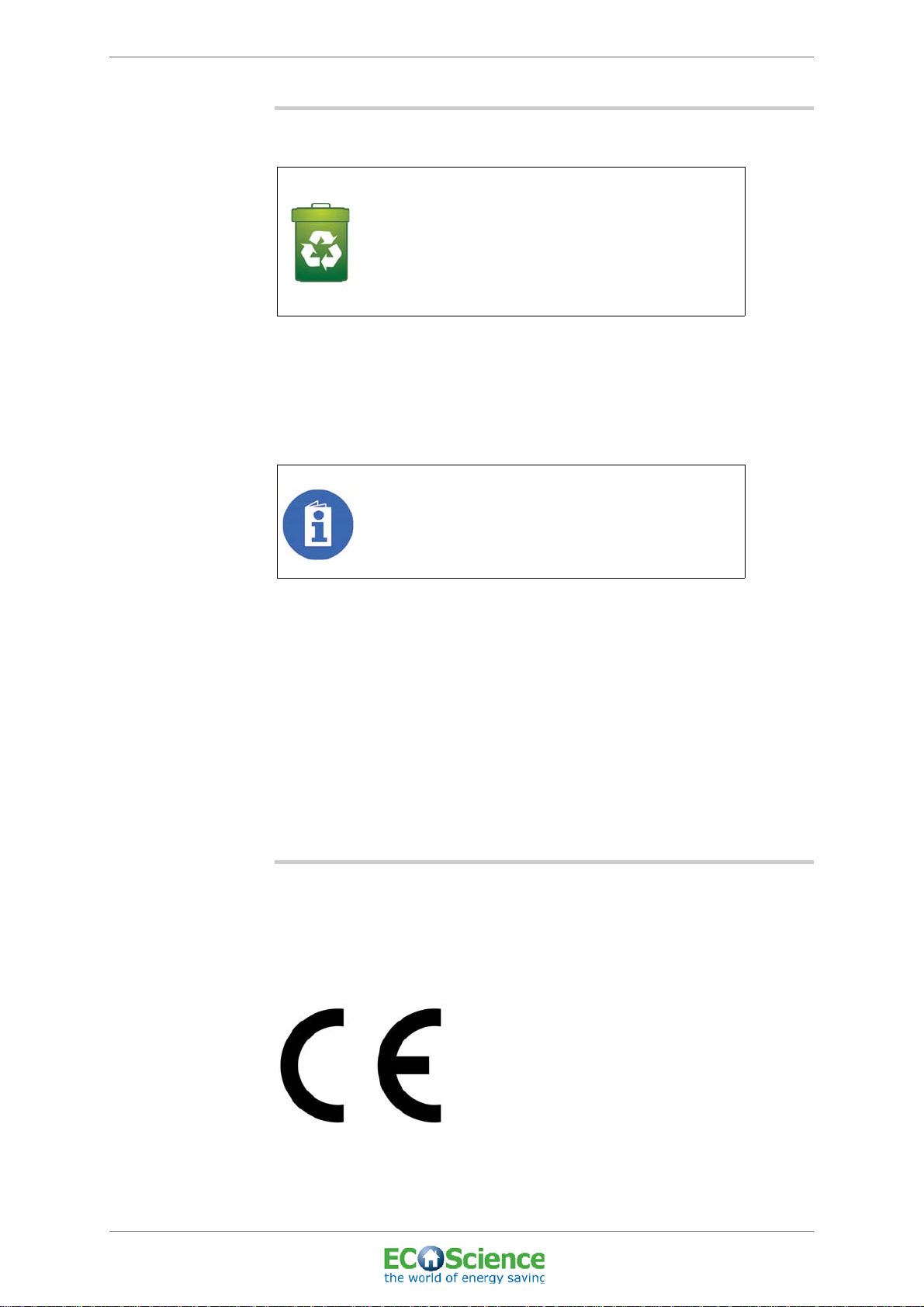

1.4 PRODUCT MARKING

ECOScience carries the CE mark (according to ‘Figure 1. CE mark’),

which means it is designed, manufactured and described in keeping with

EU requirements, for more information see ‘APPENDIX 1 - EC

DECLARATION OF CONFORMITY’.

Figure 1. CE mark

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

3

ECOScience ENERGY CENTRE

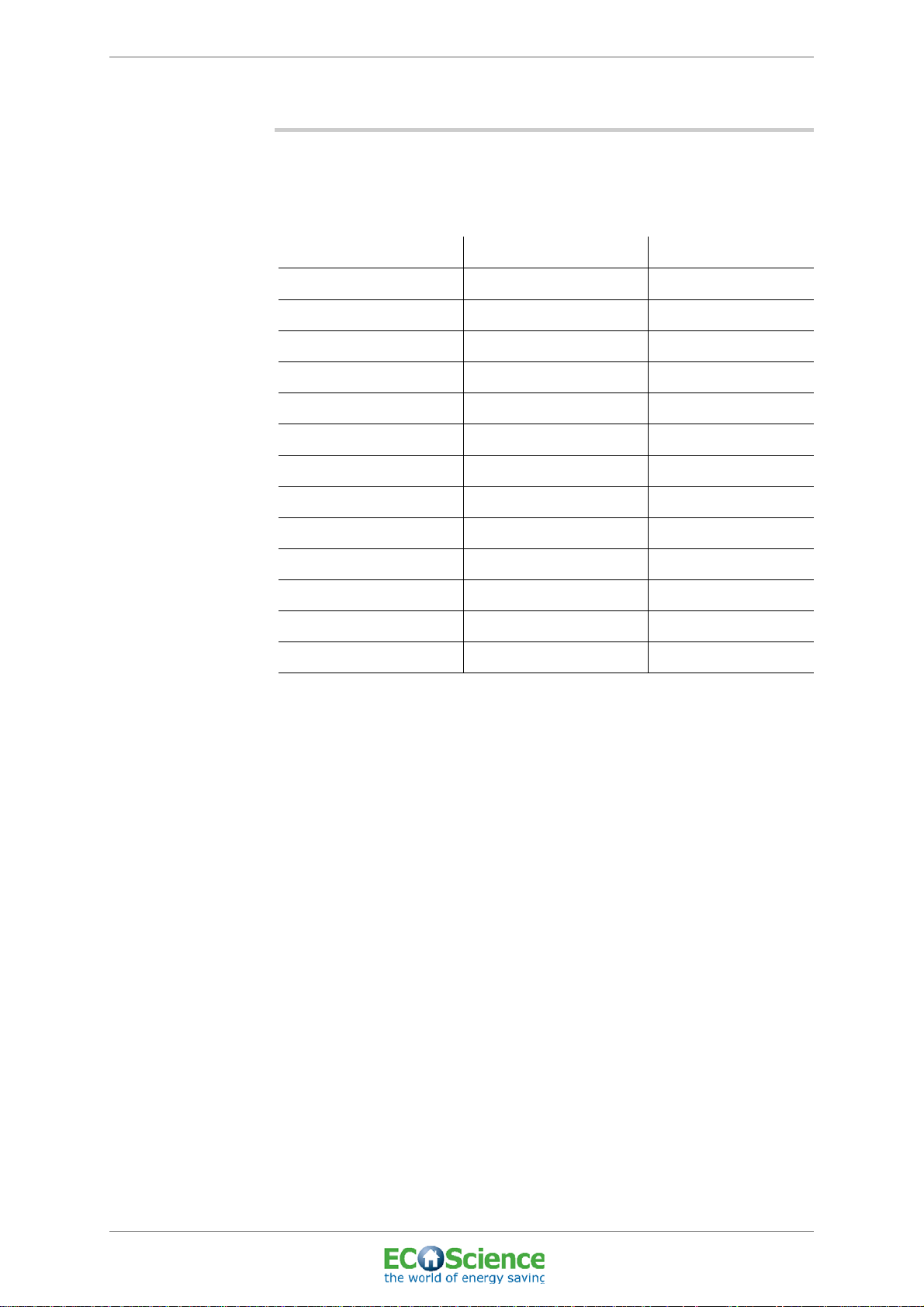

Manufacturer Fueltech Sweden AB

Model 6500i

Product number E65000100x

Volume/Water 520 litre

PED 97/23 Article 3.3

Voltage 400V 3N~ 50Hz

Output 9 kW

Frequency 50 Hz

Operating pressure

1.5/0.9 Max/min bar

Design temp. 85ºC

P mark SC0607-10

Certifying body SP SITAC

Inspection body SP

Date assembled xx-xx-20xx

AO number 20xx-xxx

Individual number E65000100x

1.4.1 Identification plate

INSTALLATION AND USER MANUAL

Figure 2. Identification plate

1.4.2 EC declaration of conformity

See ‘APPENDIX 1 - EC DECLARATION OF CONFORMITY’.

4

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

2 SAFETY INSTRUCTIONS

2.1 GENERAL HAZARDS

INSTALLATION AND USER MANUAL

DANGER: HIGH CENTRE OF GRAVITY!

This product has a high centre of gravity and

precautionary measures must be taken.

DANGER: WEAK FOUNDATION!

Make sure that the location intended to house the

product will bear its weight (for more information see

‘ASSEMBLING THE SUPPORT BASE AND

SYSTEM TANK’ on page 11).

DANGER: RISK OF ELECTRIC SHOCK!

Always switch off the power before any work on the

energy centre starts.

DANGER: RISK OF INJURY!

Never put safety at risk by removing covers that are

screwed in place or by disabling the safety

equipment.

2.1.1 Space required

For information on the space required see ‘ASSEMBLING THE

SUPPORT BASE AND SYSTEM TANK’ on page 11.

2.1.2 Risks involving spare parts

Only use original spare parts from the product supplier.

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

5

ECOScience ENERGY CENTRE

3 DESCRIPTION OF FUNCTIONS

INSTALLATION AND USER MANUAL

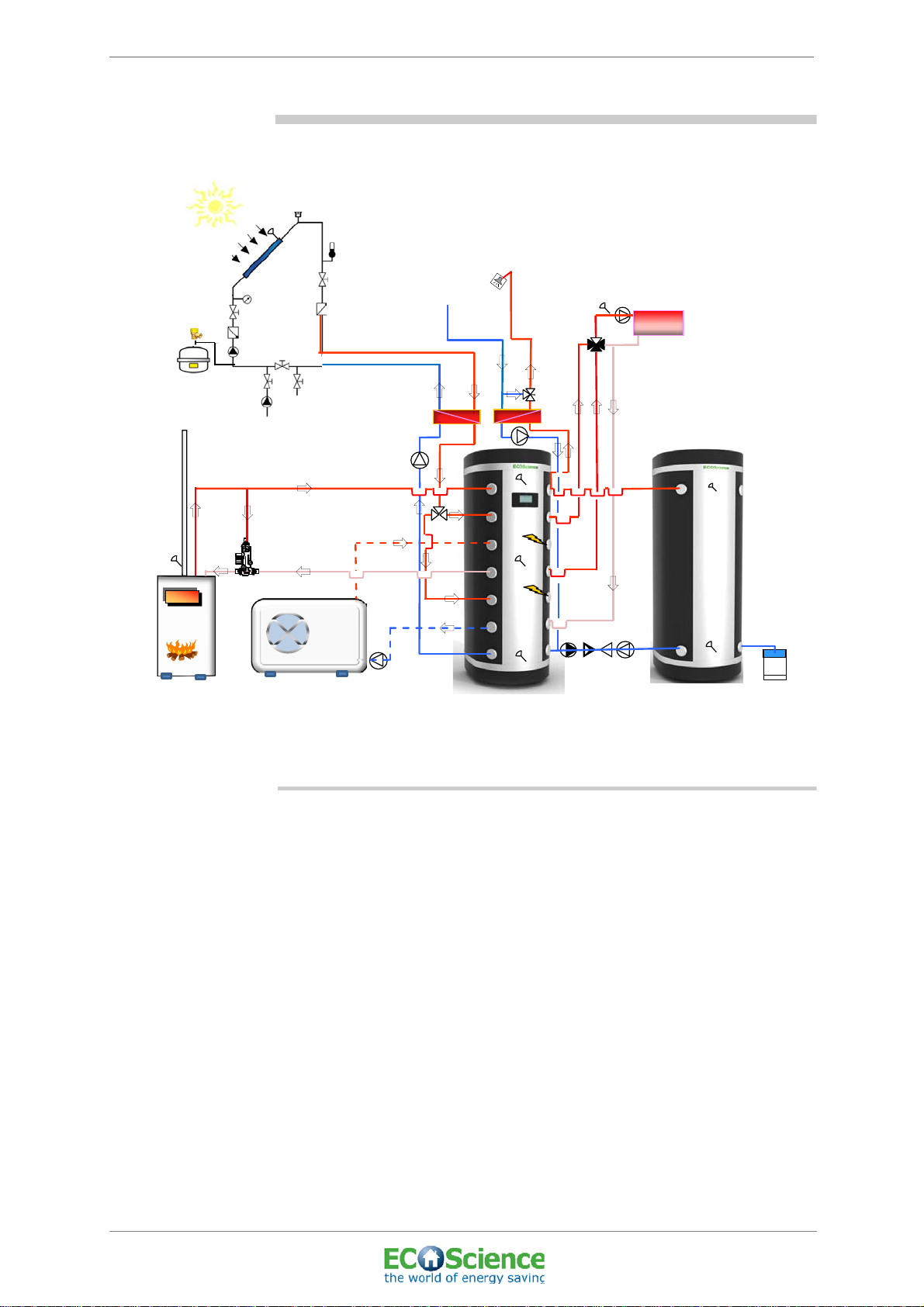

Figure 3. Schematic view of the system integration (with front connected piping)

3.1 GENERAL

The ECOScience Energy Centre is designed for domestic use and

provides a complete solution for heating and hot water.

The ECOScience Energy Centre enables you to harness and store

energy efficiently from many sources (e.g. solar energy, heat pump (air

or ground-sourced)/CHP/fuel cell or solid fuel/oil/gas/district heating).

The energy is then used to produce hot tap water and heat for radiators

or underfloor heating. It can also be used to heat a swimming pool.

The ECOScience Energy Centre comprises a system tank, an energy

central unit and a control system as standard. You can also choose

certain add-on modules e.g. solar heating system, solid fuel (waterjacketed pellet/wood stove, pellet/wood boiler), buffer tank, heat pump

and pool heating.

6

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

3.1.1 System tank

The system tank is a water-filled tank that can be connected to external

energy sources. The heat energy for producing hot water can therefore

come from several different energy sources depending on the add-on

modules you have chosen. The standard system tank also has 2 built in

electric heaters (4.5 kW each) that can provide hot tap water and heating

separately (top heater and bottom heater). You can choose how much

power (1.5 kW, 3 kW or 4.5 kW) you want the electric heaters to

contribute using the control system.

There are three temperature sensors in the system tank, positioned at

the top, in the middle and at the bottom of the tank. The water at the top

of the tank is used for hot tap water, the water in the middle supplies the

radiators and the water at the bottom is used for underfloor heating or air

ventilation heating and for pool heating.

3.1.2 Energy central unit

The energy central unit, which can be integrated into the top of the

system tank, free-standing or wall-mounted, comprises a tap water

circuit, a solar load circuit and a heat circuit.

INSTALLATION AND USER MANUAL

The energy central unit features a safety valve that opens if the pressure

in the system exceeds 1.5 bar.

3.1.2.1 Tap water circuit

The tap water circuit manages the distribution of hot tap water for the

house’s existing pipe system and is equipped with a heat exchanger.

This allows tap water to be heated quickly and means that no water is left

standing in the system, thus eliminating any risk of Legionella growth.

The tap water circuit features a mixing valve to prevent scalding.

3.1.2.2 Solar loading circuit

The solar load circuit features a heat exchanger, a circulation pump and

a bivalent valve to distribute the hot water to the right level in the system

tank.

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

7

ECOScience ENERGY CENTRE

3.1.2.3 Heat circuit

The heat circuit manages the distribution of hot water to the radiators or

underfloor heating. If you only have radiators or underfloor heating, the

control system coordinates the distribution of heat using a shunt valve

and a circulation pump, in conjunction with indoor and outdoor sensors.

The shunt valve mixes the hot supply water from the system tank with

the colder water from the return pipe so that the right temperature is

achieved for the water that feeds the radiators or underfloor heating. The

shunt valve is controlled using sensors that measure the outdoor

temperature, the indoor temperature and the supply pipe temperature.

If you have both radiators and underfloor heating, the control system can

only control the radiators. An external control unit is therefore required

for controlling underfloor heating. For further information contact your

Service Representative.

3.1.3 Control system

The control system ensures that at any given time, the most efficient

energy source is prioritised in order to produce the energy needed to

heat the water in the system tank.

INSTALLATION AND USER MANUAL

The control system is operated using a colour touchscreen located on

the front of the system tank.

General settings are already programmed in the control system when it

is delivered (see ‘ APPENDIX 4 - DEFAULT SETTINGS’), although each

installation will require customer-specific settings to optimise the

system. The installation engineer will do this during initial setup.

8

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

4 ASSEMBLY AND INSTALLATION

4.1 BEFORE USE

Check that the packaging is intact and the product is not damaged

before using it. Check that none of the parts specified on the delivery

note are missing.

4.1.1 Safe disposal of packaging material

Sort the packaging by material according to local regulations.

PLEASE NOTE: PACKAGING CAN BE

RECYCLED!

In the development of ECOScience products and the

choice of materials used, much attention has been paid

to environmental considerations. Packaging can be

sorted into waste types for disposal and recycled.

ECOScience packaging material is therefore fully

recyclable.

INSTALLATION AND USER MANUAL

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

9

ECOScience ENERGY CENTRE

4.2 GENERAL

PLEASE NOTE: EQUIPMENT!

ECOScience recommends the use of vacuum bleeding

and top-up devices (Flamco ENA or equivalent for

example) when setting up the product and system.

This will ensure that the system water is correct,

creating the right conditions for optimum energy

exchange.

If bleeding and top-up equipment is not used,

ECOScience shall not be liable under warranty.

PLEASE NOTE: INSTALLATION!

For flow chart see ‘APPENDIX 2 - FLOW CHART’.

INSTALLATION AND USER MANUAL

PLEASE NOTE: INSTALLATION!

Installation must be carried out in accordance with the

national standards and laws for heating and hot water

installations.

DANGER: RISK OF ELECTRIC SHOCK!

Always switch off the power before starting any work

on the energy centre. Electrical installations must

always be performed by a qualified electrician.

CAUTION: RISK OF MALFUNCTION!

Air bleeds from the system during initial setup.

10

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

4.3 ASSEMBLING THE SUPPORT BASE AND SYSTEM TANK

4.3.1 Instructions

1. Ensure that the space intended to house the product is large

enough and that the floor is capable of bearing its weight. A clear

height of approximately 300 mm above the system tank is

recommended in order to facilitate the installation and adjustments.

For dimensions see ‘10 TECHNICAL DATA’ on page 51.

PLEASE NOTE: SPACE FOR

INSTALLATION!

There must be a floor drain where the system tank and

buffer tank are housed.

2. Remove the product from the packaging and carefully check that no

damage has occurred during transport/handling.

3. Lift out the support base and check that all 6 adjustable feet (1 of

which is spare) have been included.

4. Attach the feet to the support base.

5. Place the support base where the tank is to be installed.

6. Check that the support base sits flat using a spirit level as shown in

according to ‘Figure 4. Spirit level check’.

INSTALLATION AND USER MANUAL

Figure 4. Spirit level check

7. Lift the product off the pallet and place it over the support base.

8. Check that the support base is positioned directly under the tank.

9. Check that the product is not obstructed by any surrounding

equipment/structures.

10. Check again that the product sits flat using a spirit level, adjust the

feet if necessary.

CAUTION: RISK OF INSTABILITY!

Check that the product sits flat after it has been filled

to ensure its stability.

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

11

ECOScience ENERGY CENTRE

4.4 CONNECTING THE PIPES

4.4.1 Please note

• All existing or new systems must be flushed clean before any pipe

fittings are connected permanently.

• The system tank must be connected to a closed expansion vessel.

A manometer that indicates the system pressure must be mounted

in the connection to the expansion vessel (see ‘ APPENDIX 2 FLOW CHART’). (The manometer and expansion vessel are

provided by the installation engineer.)

• The system pressure must not fall below 0.9 bar.

• ECOScience recommends stainless steel or PEX pipes. If these are

not available, copper pipes should be used.

INSTALLATION AND USER MANUAL

CAUTION! CUTTING PIPES!

In order to avoid any metal filings that may clog filters

and connections and lead to corrosion in the system,

pipes must only be cut with pipe cutters. Circular

cutting saws or hacksaws must not be used.

• All connection fittings to the system are ¾”.

4.4.2 Instructions

1. Connect pipes as shown in the pipe connection diagrams.

2. Fit an existing or new circulation pump to the radiator circuit supply

pipe (see ‘ APPENDIX 2 - FLOW CHART’ and see ‘ APPENDIX 3 WIRING DIAGRAM AND TEMPERATURE SENSORS’).

3. Connect a hose between the safety valve and floor drain (”4.4.3

Pipe connections” No. 7).

12

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

7

17

8

4

15

18

5

14

16

1

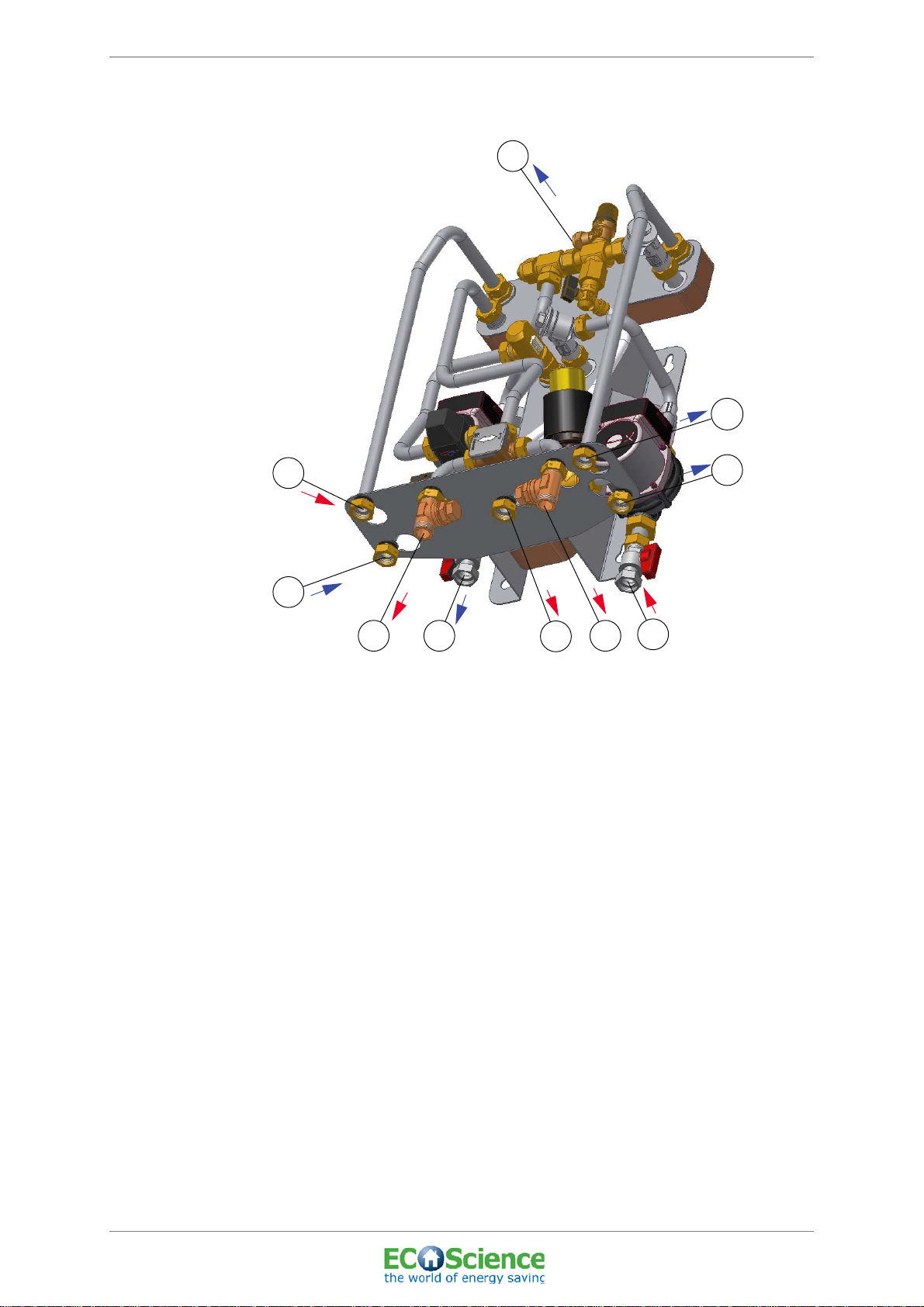

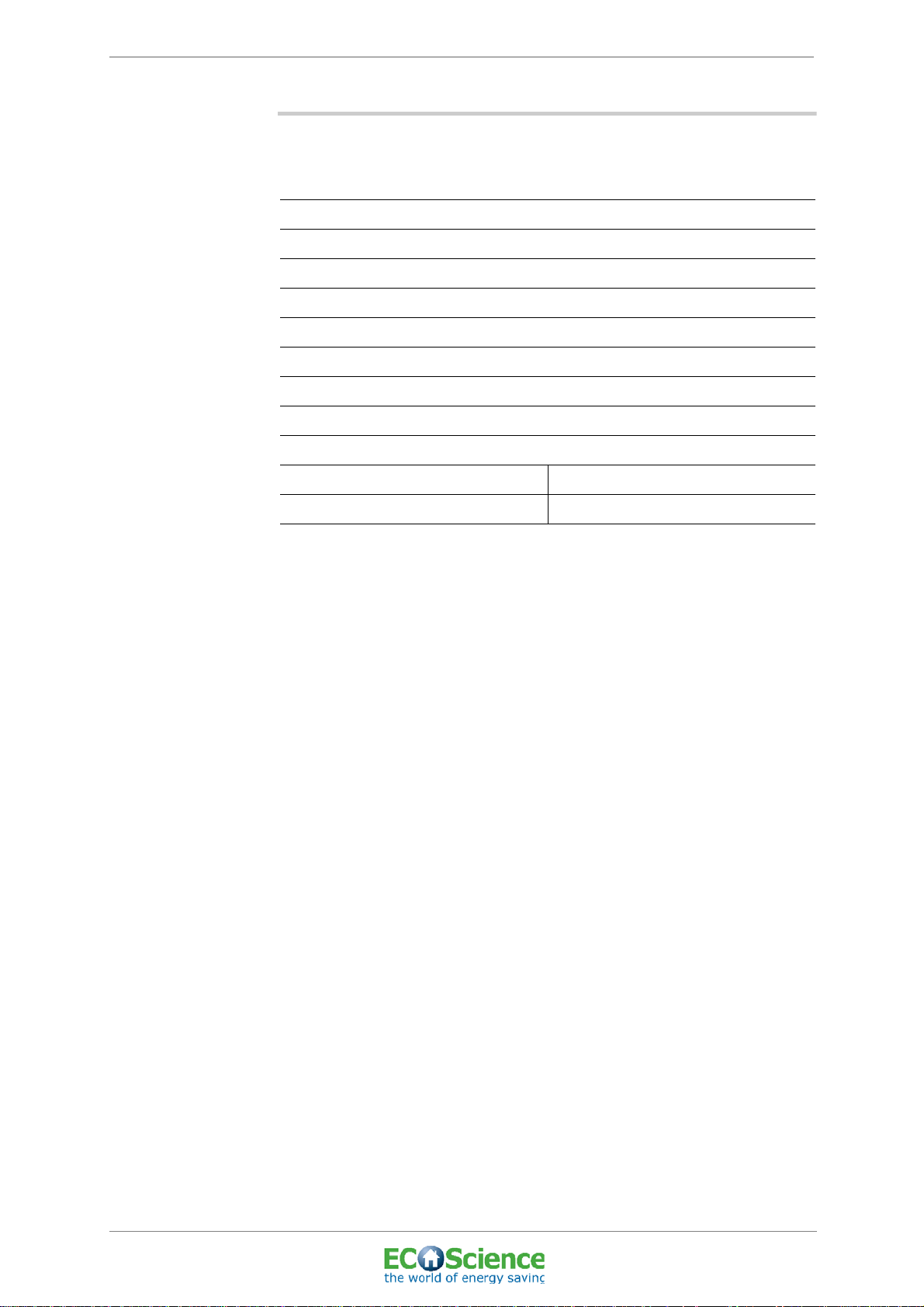

4.4.3 Pipe connections

INSTALLATION AND USER MANUAL

Figure 5. Energy Central Unit pipe connections

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

13

ECOScience ENERGY CENTRE

13

19

23

12

*

**

9

6

9

10

18

17

14

15

19 9

11

6

13

16

12

B

22

6

21

20

A

C

VIEW FROM ABOVE

A: Bleeder valve

B: Reserve

C: Temperature sensors,

overheat protection

Connected when delivered

Please note! Connections 6 and 9

are top or front connections.

See ‘Figure 8. List of pipe connections’ on page 15.Pipe connections

for heat circuit:

INSTALLATION AND USER MANUAL

Figure 6. Pipe connections for top connected heat circuit

* Connected when delivered.

See ‘Figure 8. List of pipe connections’ on page 15.

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

Figure 7. Pipe connections for top connected system tank

See ‘Figure 8. List of pipe connections’ on page 15.

14

ECOScience ENERGY CENTRE

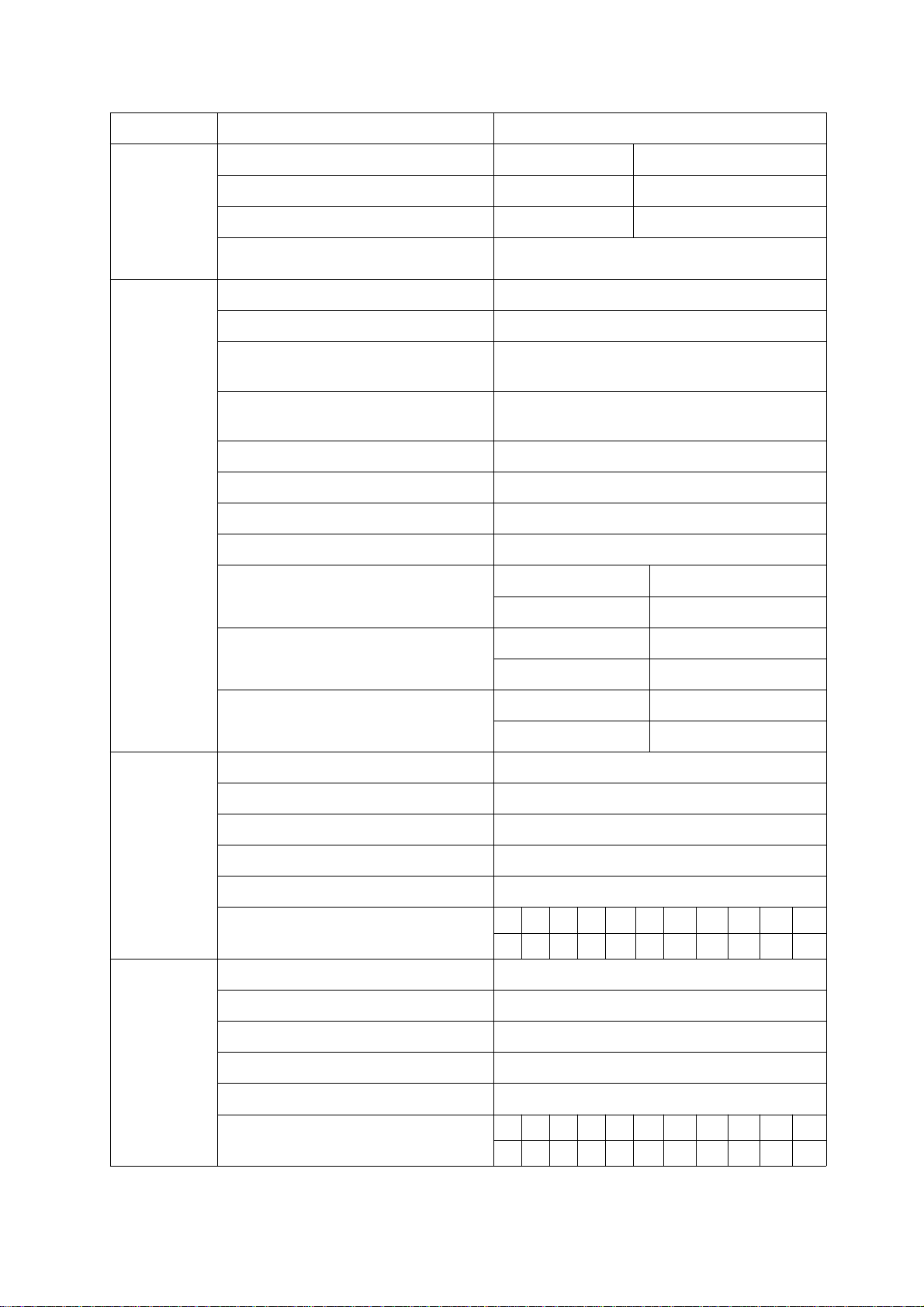

No Connection

1 Return solar circuit I (to collector)

2 Supply to radiator circuit

3 Return from radiator circuit

4 Incoming cold tap water

5 Outgoing hot tap water

INSTALLATION AND USER MANUAL

6

7 Overflow pipe / Safety valve connection

8 Supply solar circuit I (from collector)

9 (i, wt) Buffer tank loading and unloading

9 (wf)

10 Return to heat pump / Return from pool

11

12 Supply to bivalent shunt high temp

13 Supply to bivalent shunt low temp

14 Supply > 61°C solar circuit II (from solar heat exchanger)

15 Supply < 61°C solar circuit II (from solar heat exchanger)

16 Supply from solid fuel / Supply to tap water heat exchanger

17 Return from tap water heat exchanger

18 Return solar circuit II (to solar heat exchanger)

Return to solid fuel without solar / Supply and return pump group

buffer tank / Expansion vessel

Supply to tap water heat exchanger / Buffer tank Loading and

unloading

Supply from heat pump low temp. / Return to solid fuel with solar /

Supply to pool

19 Return from bivalent shunt

20 Top electric heater

21 Bottom electric heater

22 Drain connection

23 (wf) Supply from heat pump high temp. / Return to solid fuel with solar

Figure 8. List of pipe connections

PLEASE NOTE: In order to facilitate installation, the connections at

equal level on the system tank are optional. This means that pipe

connections 16 and 9 , for example, may be switched.

Supply = from energy source, hot water

Return = to energy source, cold water

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

15

ECOScience ENERGY CENTRE

12 5 4

3

4.5 ASSEMBLY OF TEMPERATURE SENSORS AND

OVERHEAT PROTECTION

INSTALLATION AND USER MANUAL

Figure 9. Tubes for temperature sensors and overheat protection see ‘Figure 7.

Pipe connections for top connected system tank’ on page 14 No. C

1. Tube for the temperature sensor at the top of the system tank.

system.

2. Tube for the overheat protection for the top electric heater in the

system tank.

3. Tube for the temperature sensor in the middle of the system tank.

4. Tube for the overheat protection for the bottom electric heater in the

system tank.

5. Tube for the temperature sensor at the bottom of the system tank.

4.5.1 Instructions

1. When replacing a temperature sensor or an overheat protection a

few drops of oil should be poured into the tube before the installing

of the temperature sensor or the overheat protection.

16

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

4.6 ELECTRICAL INSTALLATION

4.6.1 Please note

• All installations and reconnections in the connection box must be

carried out by a qualified electrician.

• All wiring must be implemented in accordance with the applicable

rules.

• The equipment must be permanently connected to the correct

safety devices.

• High voltage power lines and low voltage cables must always be

kept separate to prevent interference problems (also outside the

product).

• The installation engineer is responsible for incoming switches.

4.6.2 Instructions

INSTALLATION AND USER MANUAL

1. Connect the incoming three-phase cable to an approved safety

switch.

PLEASE NOTE: WIRING DIAGRAM!

For wiring diagram see ‘APPENDIX 3 - WIRING

DIAGRAM AND TEMPERATURE SENSORS’ on

page 53.

DANGER: RISK OF ELECTRIC SHOCK!

Check that the switch is disconnected during wiring

(i.e. no current is running through the system).

PLEASE NOTE: CONNECTION

INFORMATION!

For connection information

see ‘10.3 TECHNICAL DATA, CONTROL SYSTEM’ on

page 52.

PLEASE NOTE: FOR SEPARATE

CIRCUITS!

If separate circuits are used for heating (via external

heat exchangers), the cable of the existing circulation

pump must be connected in parallel to the secondary

pump via an IP-rated box.

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

17

ECOScience ENERGY CENTRE

4.7 FILLING THE SYSTEM WITH WATER

4.7.1 Please note

• All side systems must be flushed clean and be free of any

contamination. (Please note! Side systems must be flushed before

being connected to the system tank. If this has not been done, these

connections must be removed.)

INSTALLATION AND USER MANUAL

CAUTION: RISK OF MALFUNCTION!

The side system containing glycol or another

chemical mixture must be connected via the external

heat exchanger.

CAUTION: RISK OF MALFUNCTION!

If additional water is needed, the air bleeding process

must be performed again.

• The pH value of the water used in the system should be between

should be between 7 and 8.5, the ideal value being 8.

PLEASE NOTE: WATER QUALITY!

ECOScience recommends that a water sample be

taken to ensure the quality of the water. The

recommended pH value is between 7 and 8.5, 8 being

the ideal value.

4.7.2 Instructions

1. Always check the initial pressure in the expansion vessel using an

air pressure gauge before the system is filled.

CAUTION!

If the pressure in the expansion vessel is too low, it

must not be filled with regular air. Follow the

manufacturer’s instructions.

Height (m)

(between expansion

vessel and uppermost

point of system)

Initial pressure (bar)

in expansion vessel

(before filling)

System pressure (bar)

18

0-7 0.9 1.1

81.01.2

91.11.3

10 1.2 1.3

11 1. 3 1.3

• To ensure tap water is produced as intended, the system pressure

must never fall below 0.9 bar.

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

PLEASE NOTE: SYSTEM PRESSURE!

The system pressure must never fall below 0.9 bar.

2. Check that the shut-off valves are open (”4.7.3 Connections and

shut-off valves” (No. 1 and 3)).

PLEASE NOTE: EQUIPMENT!

ECOScience recommends the use of vacuum

bleeding and top-up equipment (Flamco ENA or

equivalent for example) when the product and

system are being filled.

This will ensure that the system water is correct,

creating the right conditions for optimum energy

exchange.

If bleeding and top-up equipment is not used,

ECOScience shall not be liable under warranty.

INSTALLATION AND USER MANUAL

3. Make sure that the valve for bleeding air out of the system is open.

4. Connect the tap water via the tap water connection (No. 4) and fill

with water until water comes out of the bleeding valve.

5. Close the bleeding valve and continue to fill with water until the

desired system pressure is reached (min: 0.9 bar, max: 1.3 bar).

6. Check there are no leaks.

7. Close the shut-off valves (Nos. 1 and 3).

8. Remove hose (No. 2).

The system is now ready for commissioning (see ‘5 COMMISSIONING’)

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

19

ECOScience ENERGY CENTRE

1

3

2

4

4.7.3 Connections and shut-off valves

INSTALLATION AND USER MANUAL

Figure 10. Filling the water system

1. Shut-off valve

2. Hose

3. Shut-off valve

4. Tap water connection

20

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

4.8 EMPTYING THE SYSTEM TANK

4.8.1 Instructions

PLEASE NOTE: EMPTYING!

A hose connection is supplied for emptying the system

tank.

• Check that no current is running through the system.

• Remove the protection cover (, No. 22). see ‘Figure 7. Pipe

connections for top connected system tank’ on page 14

INSTALLATION AND USER MANUAL

DANGER: RISK OF ELECTRIC SHOCK!

Ensure no current is running through the system by

turning the main switch to OFF before emptying the

system tank.

• Open the drain valve by screwing the stopper off.

• Connect a hose to the hose connection supplied and ensure that

the other end of the hose is connected to a floor drain.

WARNING: RISK OF SCALDING!

Make sure than nothing comes into contact with the

water being emptied from the system tank – risk of

scalding.

• Fasten the hose connection to the drain valve. Note that the water

starts to be drawn off as soon as the connection is fastened on.

• Open the valve for bleeding air out of the system at the top of the

system tank , No. A) see ‘Figure 7. Pipe connections for top

connected system tank’ on page 14

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

21

ECOScience ENERGY CENTRE

5 COMMISSIONING

Before operation, make sure you have read and understood section ”2

SAFETY INSTRUCTIONS” onwards.

RESPONSIBILITIES OF THE

INSTALLATION ENGINEER!

The installation engineer is responsible for walking

through the system with the end user.

5.1 PREPARATIONS BEFORE STARTING

Check that:

• The product is earthed.

• All parts are installed correctly and flushed clean.

INSTALLATION AND USER MANUAL

• There are no leaks in the system.

• All sensors are mounted and connected properly. The installation

engineer is responsible for ensuring that all sensors included with

delivery are installed in accordance with the flow chart. Outdoor

sensors must be positioned to be north-facing wherever possible.

Indoor sensors must be positioned 1.60 m above the floor, in the

centre of the house wherever possible and must not be exposed to

direct sunlight or located near a heat source.

5.2 START-UP

1. Turn on the main switch so that the display window lights up.

2. If necessary: Adjust the settings in the control system to optimise

the system.

3. Activate the heat-up sequence (see ‘6.3.3 Heat-up sequence’).

5.3 NORMAL STOP

1. Ensure no current is running through the system by turning the main

switch to OFF.

22

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

6 CONTROL SYSTEM

6.1 START SCREEN (BASIC MODEL)

INSTALLATION AND USER MANUAL

PLEASE NOTE!

The ECOScience control system is pre-programmed in

the factory so that the product can be started directly to

provide heat and hot water. To restore these factory

settings press ‘Restore default values’ in the Setup

screen.

Figure 11. Basic start menu

• Press ‘System’ to continue.

PLEASE NOTE: ADD-ON MODULES!

This is the start screen for the basic system. Other

symbols will be displayed if add-on modules have been

installed.

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

23

ECOScience ENERGY CENTRE

see 6.9

see 6.11

see 6.12

see 6.10

see 6.3

see 6.4

see 6.5

see 6.6

see 6.7

see 6.8

6.2 SYSTEM

All submenus for the system can be accessed from this menu. The

submenus for general settings are displayed on the left. The submenus

for setting the different modules are displayed on the right (the grey

buttons indicate add-ons that have not been chosen).

PLEASE NOTE: ADD-ON MODULES!

Grey text indicates an add-on module, requiring a

module key. To access extra add-ons please contact

your Service Representative.

INSTALLATION AND USER MANUAL

Figure 12. System menu

• Press the required button to continue.

• To return to the previous menu, press ‘Back’.

24

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

see 6.3.1

see 6.3.2

see 6.3.4

see 6.3.5

see 6.3.3

see 6.3.6

see 6.3.7

see 6.3.8

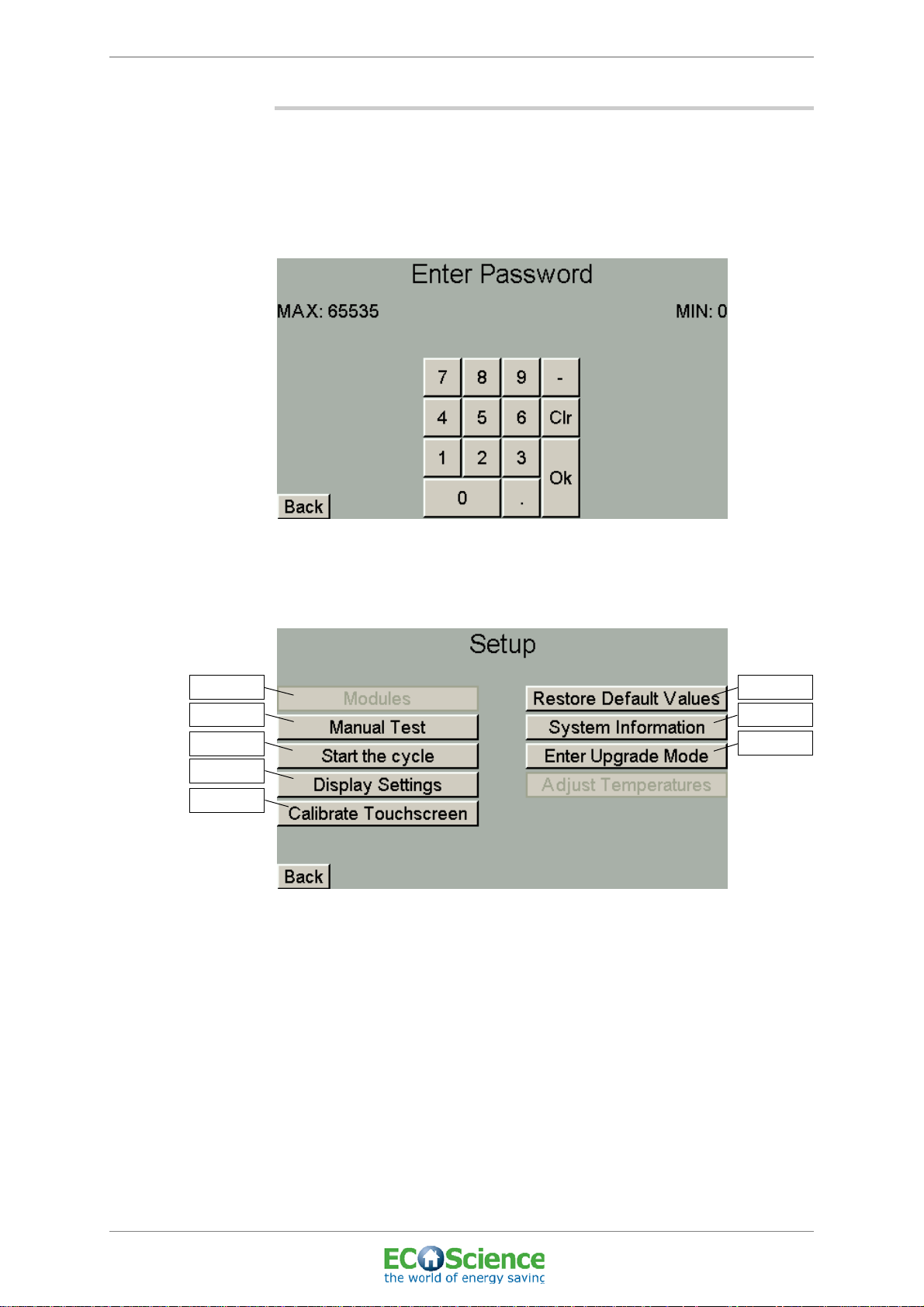

6.3 SETUP

To access the Setup menu, you must first enter a password in the code

menu.

The installation engineer also uses this menu to enter a code (known as

a ‘module key’) if add-on modules are chosen.

INSTALLATION AND USER MANUAL

Figure 13. Setup code menu

• Press the grey password box and enter the code 55. Then press OK

to continue.

Figure 14. Setup menu

• Press the required button to continue.

• To return to the previous menu, press ‘Back’.

Edition: 01; Last updated: 2011-04-12

6.3.1 Modules

This menu is used by the installation engineer if add-on modules have

been chosen. A code is required to access this menu. Contact your

installation engineer for more information.

Top connected system tank, CS300

© ECOScience

25

ECOScience ENERGY CENTRE

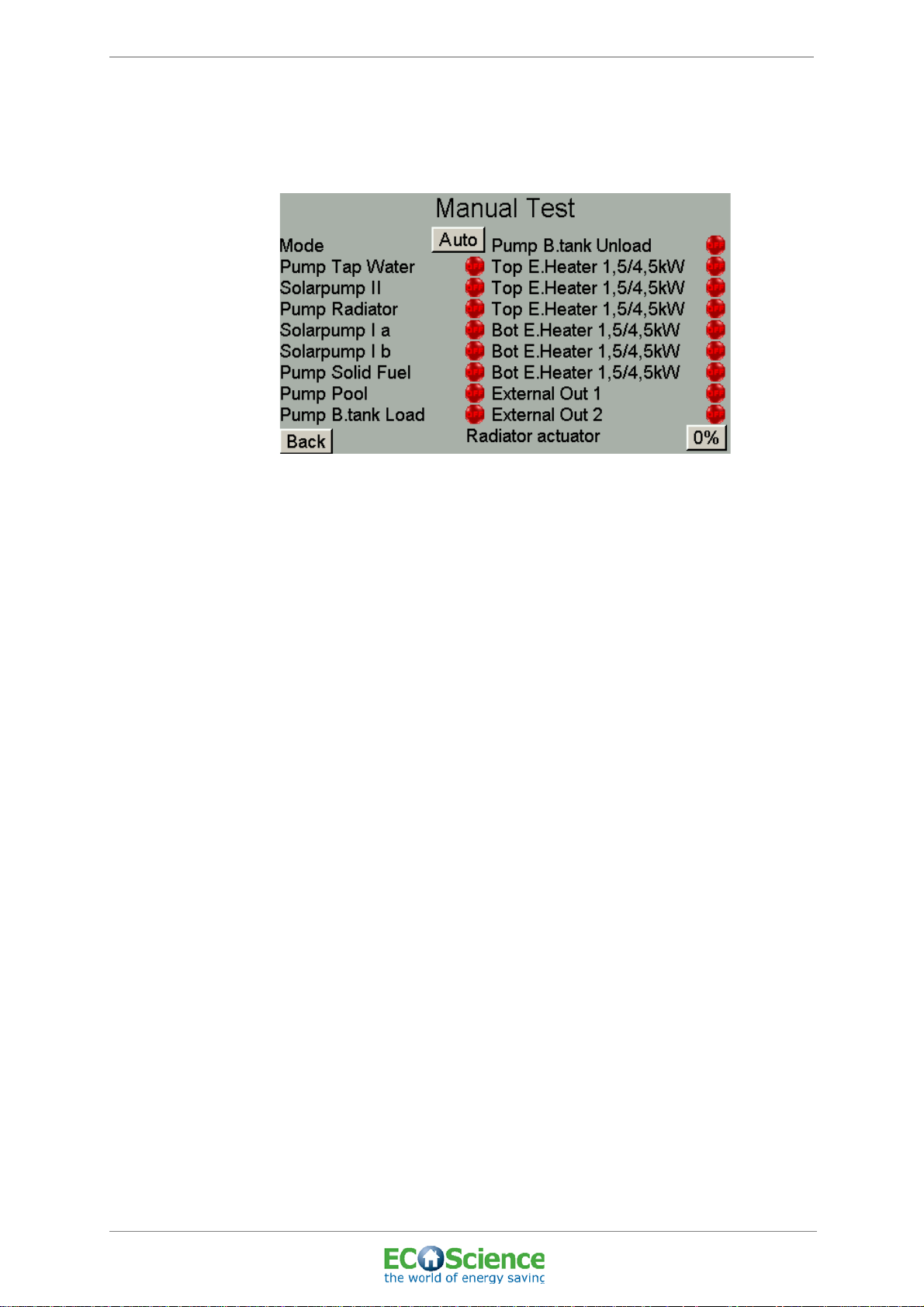

6.3.2 Manual operation

Here you can switch between automatic and manual operation of the

system.

Figure 15. Menu 1 ‘Manual operation’

INSTALLATION AND USER MANUAL

• To run the system manually, press ‘Auto’ so that the mode changes

to ‘Man’. (If the system is being operated manually, this is also

indicated on the start screen by ‘Manual operation’ flashing on the

screen.)

• To start or stop each function, press the lamp symbol (green=start,

red=stop).

• External Out 1 and External Out 2 control any external heat sources

that have been connected to the system (e.g. air-sourced heat

pump, pellet stove etc.).

• To specify how far the actuator must open, i.e. the amount of water

from the system tank that is to be distributed to the radiators/

underfloor heating, press the grey box marked ‘Radiator actuator’

and enter how far the actuator should open (enter value from 0 to

100%).

• To return to automatic operation, press ‘Man’ so that the mode

changes to ‘Auto’.

• To return to the previous menu, press ‘Back’.

26

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

6.3.3 Heat-up sequence

When the system has been filled with water during installation and

servicing, the water should be heated up to a certain temperature for a

certain duration so as to ensure as little air in the system as possible.

During the heat-up sequence, air bleeds from the system via the bleeder

valve.

INSTALLATION AND USER MANUAL

Figure 16. ‘Start Sequence’ menu

• Set the desired duration by entering the number of hours that the

heat-up sequence should last (recommended duration: 2 hours).

• Specify the target temperature for the water by entering the desired

temp. in tank/tanks (recommended temp.: 80°C).

• To activate the heat-up sequence, press the lamp symbol so that it

turns green.

• To return to the previous menu, press ‘Back’.

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

27

ECOScience ENERGY CENTRE

6.3.4 Display settings

Here you can program different settings for the display.

Figure 17. ‘Display settings’ menu

• Press the box for ‘Time before returned to startscreen’ and enter the

desired value.

INSTALLATION AND USER MANUAL

• Press the box for ‘Time before backlight is turned off’ and enter the

desired value.

6.3.5 Calibrating the touchscreen

• Press the cross in the top left-hand corner.

• Press the cross in the bottom right-hand corner.

• The new settings are now stored.

28

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

6.3.6 Restore default values

Here you can restore the system to its default values.

Figure 18. ‘Restore Default Values’ menu

• Press ‘Yes’ to restore default values.

• Press ‘No’ to retain your own settings.

INSTALLATION AND USER MANUAL

PLEASE NOTE: DEFAULT VALUES!

See ‘APPENDIX 4 - DEFAULT SETTINGS’ for more

information.

6.3.7 System information

Information about the system is shown here.

Figure 19. ‘System Information’ menu

• To return to the previous menu, press ‘Back’.

6.3.8 Activating DFU mode

Activate DFU mode during upgrades.

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

29

ECOScience ENERGY CENTRE

6.3.9 Calibrating the temperature sensors

The temperature sensors can be calibrated here against the actual

temperature. The installation engineer will measure the temperatures for

checking purposes during installation. In the event of any deviations, the

sensor in question should be adjusted (i.e. calibrated).

INSTALLATION AND USER MANUAL

Figure 20. Menu 1 'Temperature adjustments control circuit board'

Figure 21. Menu 2 'Temperature adjustments control circuit board'

30

Figure 22. Menu 1 'Temperature adjustments I/O circuit board'

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

Figure 23. Menu 2 'Temperature adjustments I/O circuit board'

• "To calibrate the sensor in question press '-' or '+' until the actual

temperature is shown.

INSTALLATION AND USER MANUAL

• "To go to the next menu, press 'Next'.

• "To return to the previous menu, press 'Back'.

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

31

ECOScience ENERGY CENTRE

6.4 DATE/TIME

The date and time are set here.

Figure 24. ‘Date/Time’ menu

INSTALLATION AND USER MANUAL

• Press the required box and enter the correct date and time.

• To return to the previous menu, press ‘Back’.

6.5 STATUS TEMP.

The current values indicated by the integrated temperature sensors are

shown here.

32

Figure 25. ‘Status Temp.’ menu

• Press ‘Next’ to see more values.

• To return to the previous menu, press ‘Back’.

• N/A may indicate the sensor is broken or is not connected, i.e. the

module is missing.

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

6.6 STATUS I/O

The status of the system’s various units is shown here. The light symbols

indicate which units are active at the moment (green = active) (”6.6.1

Explanation of ‘Status I/O’ menu”).

INSTALLATION AND USER MANUAL

Figure 26. Menu 1 ‘Status I/O’

• Press ‘Next’ to see more units.

• To return to the previous menu, press ‘Back’.

Figure 27. Menu 2 ‘Status I/O’

• To return to the previous menu, press ‘Back’.

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

33

ECOScience ENERGY CENTRE

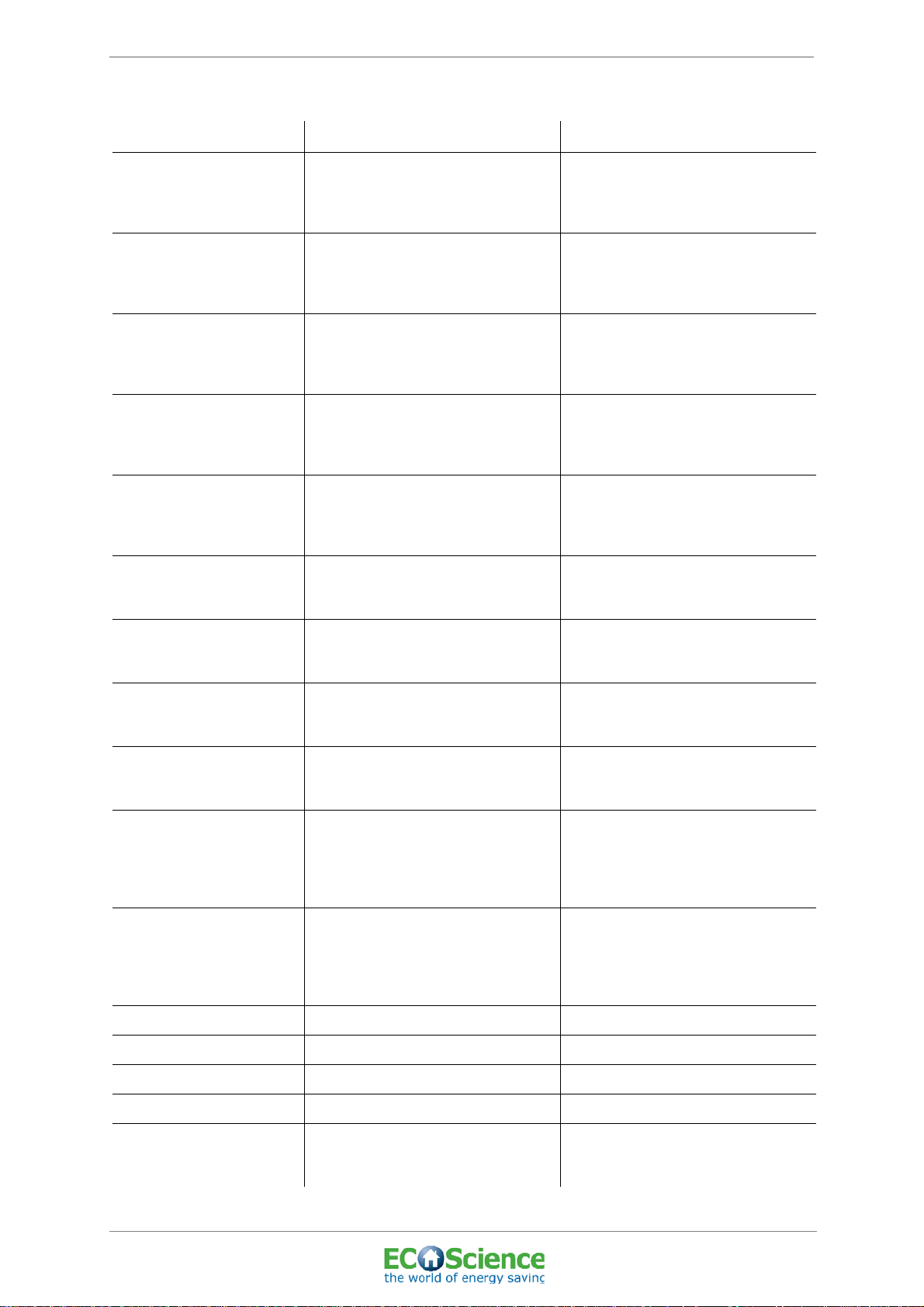

6.6.1 Explanation of ‘Status I/O’ menu

INSTALLATION AND USER MANUAL

Pump Tap Water (tap water circuit)

Solar pump II -

Pump Radiator (heat circuit)

Solar pump I a 1 (single solar circuit)

Solar pump I b 2 (double solar circuit)

Pump Solid Fuel -

Lamp indicator Green ON

The circulation pump between the

system tank and the heat exchanger

for hot tap water (so-called secondary

side) is operating.

The circulation pump between the

system tank and the heat exchanger

for the solar circuit (so-called

secondary side) is operating.

The circulation pump between the

system tank and the radiators/

underfloor heating (i.e. heating in the

house) is operating.

The circulation pump between the

solar panels and the heat exchanger

for the solar load circuit (so-called

primary side) is operating.

The circulation pump between the

solar panels and the heat exchanger

for the solar load circuit (so-called

primary side) is operating.

The circulation pump between the

solid fuel source and the system tank

is operating.

Lamp indicator Red OFF

The circulation pump is not operating

(for example when no hot water is

being drawn).

The circulation pump is not operating

(see ‘Installation and user manual,

solar heating system’ for information)

The circulation pump is not operating

(for example when no extra heating is

needed in the house).

The circulation pump is not operating

(see ‘Installation and user manual,

solar heating system’ for information)

The circulation pump is not operating

(see ‘Installation and user manual,

solar heating system’ for information)

The circulation pump is not operating

(see ‘Installation and user manual,

solid fuel’ for information)

The circulation pump between the pool

Pump Pool -

Pump B.tank Load -

Pump B.tank Unload -

Top Electric Heater

1.5/4.5kW

Bottom. Electric Heater

1.5/4.5kW

External Out 1 - External heat source has started. External heat source has stopped.

External Out 2 - External heat source has started. External heat source has stopped.

External In 1 - Option to connect external control unit. External control unit is off.

exchanger and the system tank is

operating.

The circulation pump between the

system tank and the buffer tank is

operating.

The circulation pump between the

buffer tank and the system tank is

operating.

The electric heater at the top of the

system tank is on and producing

1.5 kW. Each lamp on means that the

electric heater is producing 1.5 kW

(2 lamps = 3 kW, 3 lamps = 4.5 kW).

The electric heater at the bottom of the

system tank is on and producing

1.5 kW. Each lamp on means that the

electric heater is producing 1.5 kW

(2 lamps = 3 kW, 3 lamps = 4.5 kW).

The circulation pump is not operating

(see ‘Installation and user manual,

pool’ for information)

The circulation pump is not operating

(see ‘Installation and user manual,

buffer tank’ for information)

The circulation pump is not operating

(see ‘Installation and user manual,

buffer tank’ for information)

The electric heater is not on.

The electric heater is not on.

External In 2 - Option to connect external control unit. External control unit is off.

Tap water flows and the switch starts

Flow Switch

the circulation pump for tap water heat

exchanger.

No tap water flows.

Top connected system tank, CS300

34

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

INSTALLATION AND USER MANUAL

Lamp indicator Green ON

Phase L1 Incoming phase is OK, normal.

Phase L2 Incoming phase is OK, normal.

Bottom overheat

protection Ok

To p ov erheat protection

Ok

Radiator Actuator

overheat protection for the bottom

electric heater in the system tank has

not been triggered.

overheat protection for the top electric

heater in the system tank has not been

triggered.

Indicates how far the actuator is to open, determining the amount of water from

the system tank that is to be distributed to the radiators/underfloor heating.

Lamp indicator Red OFF

Phase missing (see ‘9.1 COMMON

FAULTS AND SOLUTIONS’)

Phase missing (see ‘9.1 COMMON

FAULTS AND SOLUTIONS’)

overheat protection for the bottom

electric heater in the system tank has

been triggered.

(see ‘9.3.1 Resetting overheat

protection for electric heaters’)

overheat protection for the top electric

heater in the system tank has been

triggered.

(see ‘9.3.1 Resetting overheat

protection for electric heaters’)

6.7 LANGUAGE

The language to be used in the display is selected here.

Figure 28. ‘Language’ menu

• Press the required flag to change the language.

• To return to the previous menu, press ‘Back’.

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

35

ECOScience ENERGY CENTRE

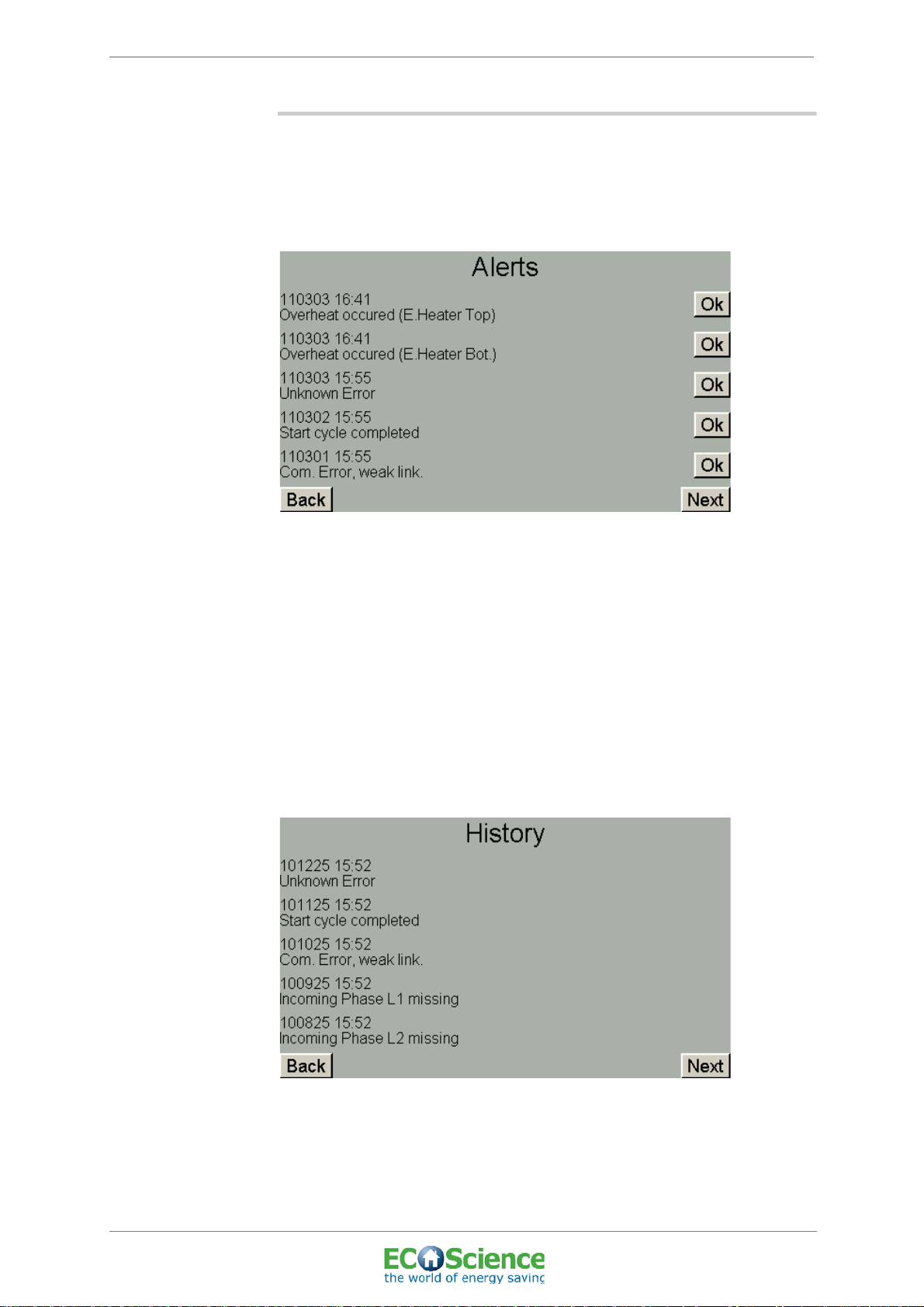

6.8 ALERTS/HISTORY

The various alerts that the system has generated but that have not yet

been acknowledged are shown here, together with the date and time the

alert was triggered. For more information see ‘9.3 ALERTS AND

SOLUTIONS’).

INSTALLATION AND USER MANUAL

Figure 29. ‘Alerts’ menu

• To acknowledge an alert, press ‘Ok’. Please note that some alert

triggers may require mechanical resetting so as to be

acknowledged, e.g. the overheat protection for the electric heater

(see ‘9.3.1 Resetting overheat protection for electric heaters’ on

page 50).

• To see more alerts press ‘Next’.

• To see the alert history press ‘Next’ again.

This menu shows the alerts previously generated by the system,

together with the date and time they occurred.

36

Figure 30. ‘History’ menu

• To see more alert history press ‘Next’.

• To return to the previous menu, press ‘Back’.

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

6.9 HEATING

This menu can be used to activate the heat sources from which energy

is to be supplied to the system and to specify the temperatures at which

these are to be activated. The temperatures at which the pool is to be

heated are also set here, if you have chosen this add-on, together with

the power that you want the electric heaters to supply to the system. You

can also set the desired maximum temperature for the system tank.

INSTALLATION AND USER MANUAL

Figure 31. ‘Heating, System tank’ menu

• To set the start temperature for the heat source selected, press the

required box under ‘Start’ and enter the temperature at which the

heat source should start to supply heat to the system.

• To set the temperature at which the heat source should stop

producing heat for the system tank, press the required box under

‘Stop’ and enter the desired temperature.

• When the start and stop temperatures have been selected, activate

the heat source by pressing the red lamp symbol. This will turn

green, indicating that the heat source has been activated and will

produce heat for the system when the criteria (start and stop

temperatures) are met.

• To set the power that the electric heaters need to produce for

heating, press the box for the required electric heater and select

1.5kW, 3kW or 4.5kW.

• A tolerance of several degrees can be set to prevent the system

from switching off continuously when the temperature is around the

maximum temperature programmed for the system tank.

• To return to the previous menu, press ‘Back’.

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

37

ECOScience ENERGY CENTRE

6.10 SOLAR CIRCUIT

The ECOScience Energy Centre has been designed to accommodate a

solar heating system. A solar loading circuit comprising a heat

exchanger and bivalent valve that distributes water at the right level in

the system tank is included in the basic model. See ‘ECOScience

Installation and user manual_Solar heating system’ for further details.

6.11 RADIATOR CIRCUIT

Here you can set the desired temperatures and times for the radiator

circuit and the desired indoor temperature. You can also set the pump to

stop when a certain outdoor temperature is reached. Stopping the pump

means that in order to save energy and prevent unnecessary heating,

the circulation pump to the radiators is turned off when the outdoor

temperature reaches a certain level.

INSTALLATION AND USER MANUAL

Figure 32. Menu 1 ‘Radiator Circuit’

• Press the required box and enter the desired value.

• To return to the previous menu, press ‘Back’.

• To go to the next menu, press ‘Next’.

38

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

Figure 33. Menu 2 ‘Radiator Circuit

• Press ‘Temp. Curve’ to access the menu for setting the temperature

curve for the radiator circuit (”6.11.1 Radiator circuit temperature

curve”).

• Press ‘Settings’ to access the menu for temporarily reducing the

temperature for the radiator circuit (”6.11.2 Scheduled temperature

changes in radiator circuit”).

INSTALLATION AND USER MANUAL

• To return to the previous menu, press ‘Back’.

6.11.1 Radiator circuit temperature curve

The temperature curve is shown here. This is based on a curve which is

pre-programmed in the system.

Figure 34. ‘Radiator circuit temperature curve’ menu

• For a parallel shift in the curve upwards or downwards press ‘+1’ or

‘-1’.

• To set your own values for the curve press the grey boxes, enter the

desired value and then press OK.

• To return to the previous menu, press ‘Back’.

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

39

ECOScience ENERGY CENTRE

6.1 1.2 Scheduled temperature changes in radiator circuit

Temporary reductions in temperature in the building (-1°C to -3°C

inclusive) can be programmed and activated in this menu for each day of

the week.

INSTALLATION AND USER MANUAL

Figure 35. ‘Scheduled temperature changes in radiator circuit’ menu

• To set the time that the temperature reduction is to begin, press the

time box (hr:min). Enter the desired time then click OK. Repeat this

procedure for the time when the temperature reduction is to end

and when the temperature is to return to its regular settings.

• To set the reduction in temperature (-1°C to -3°C inclusive) press

the required temperature box and enter the desired value.

• To set the day of the week on which the temperature reduction is to

start or end, press the box for the required day of the week. The box

will then appear crossed.

• To activate the temperature reduction, press the lamp symbol,

which then turns green.

• If a larger reduction in temperature is required or a temperature

reduction for a longer period, press ‘Next’ to access the holiday

reduction settings for radiators.

• To return to the previous menu, press ‘Back’.

• To go to the next menu, press ‘Next’.

40

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

6.11.3 Radiator circuit holiday settings

This menu can be used to program and activate holiday settings for

radiators.

Figure 36. ‘Radiator circuit holiday settings’ menu

• Enter the start date when the reduction in temperature is to start or

the end date when the temperature is to return to its regular

settings.

INSTALLATION AND USER MANUAL

• Enter the desired temperature during holiday.

• To activate the holiday settings, press the lamp symbol, which then

turns green.

• To return to the previous menu, press ‘Back’.

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

41

ECOScience ENERGY CENTRE

6.12 FLOOR HEATING CIRCUIT

Here you can set the temperature and times for underfloor heating and

the desired indoor temperature. You can also set the pump to stop when

a certain outdoor temperature is reached. Stopping the pump means

that the circulation pump for the floor heating is turned off when the

outdoor temperature reaches a certain level in order to save energy and

prevent unnecessary heating.

INSTALLATION AND USER MANUAL

Figure 37. Menu 1 ‘Floor Heating Circuit’

• Press the required box and enter the desired value.

• To return to the previous menu, press ‘Back’.

• To go to the next menu, press ‘Next’.

Figure 38. Menu 2 ‘Floor Heating Circuit’

• Press ‘Temp. curve’ to access the menu for setting the temperature

curve for the floor heating circuit (”6.12.1 Floor heating circuit

temperature curve”).

42

• Press ‘Settings’ to access the menu for temporarily reducing the

temperature for floor heating (”6.12.2 Scheduled temperature

changes in floor heating circuit”).

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

6.12.1 Floor heating circuit temperature curve

The temperature curve is shown here. This is based on a curve which is

pre-programmed in the system.

Figure 39. ‘Floor heating circuit temperature curve’ menu

INSTALLATION AND USER MANUAL

• For a parallel shift in the curve upwards or downwards press ‘+1’ or

‘-1’.

• To set your own values for the curve press the grey boxes, enter the

desired value and then press OK.

• To return to the previous menu, press ‘Back’.

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

43

ECOScience ENERGY CENTRE

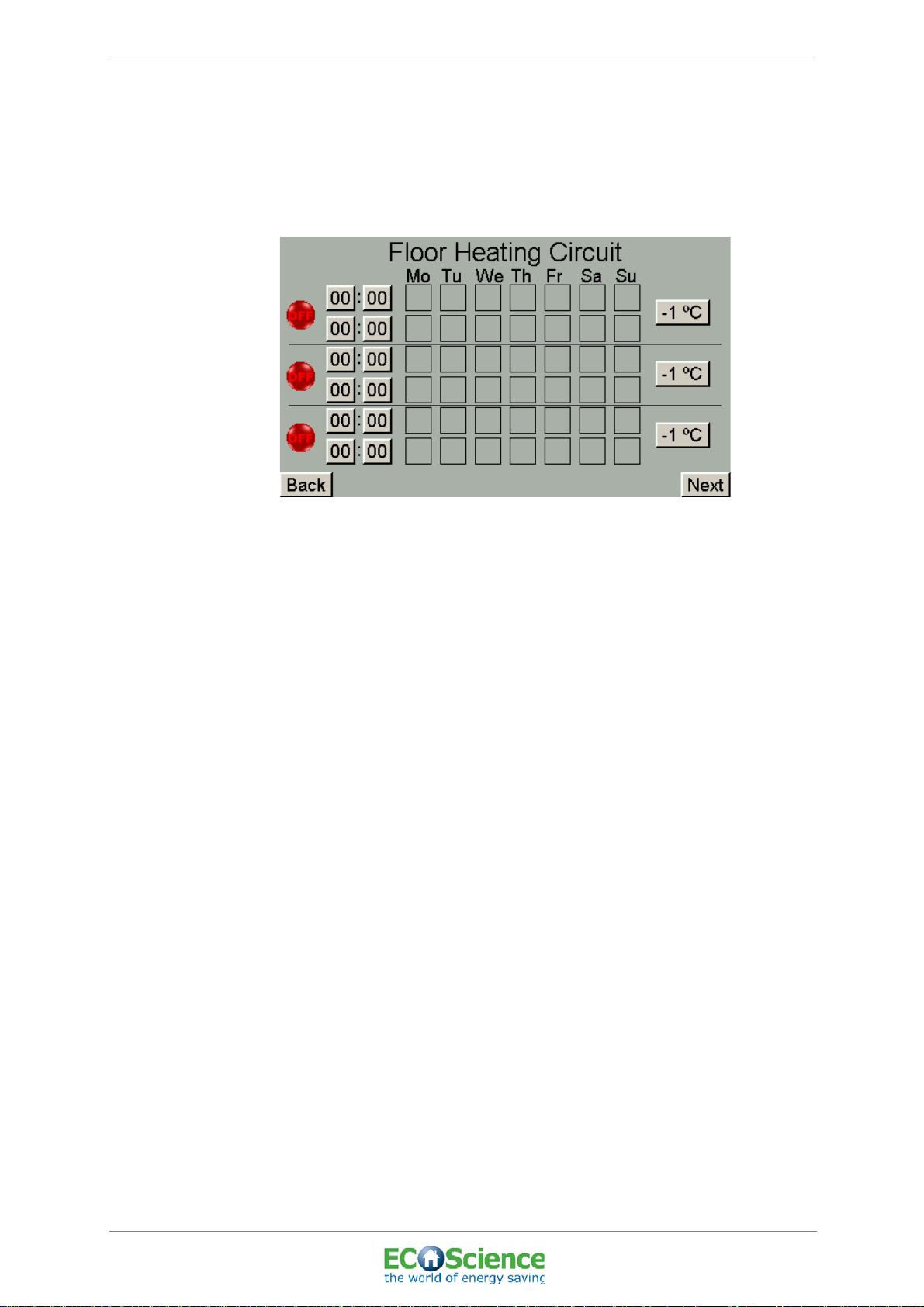

6.12.2 Scheduled temperature changes in floor heating circuit

Temporary reductions in the temperature in the building (-1°C to -3°C

inclusive) can be programmed and started/stopped in this menu for each

day of the week.

INSTALLATION AND USER MANUAL

Figure 40. ‘Scheduled temperature changes in floor heating circuit’ menu

• To set the time that the temperature reduction is to begin, press the

time box (hr:min). Enter the desired time then click OK. Repeat this

procedure for the time that the temperature reduction is to end and

the temperature is to return to its regular settings.

• To set the reduction in temperature (-1°C to -3°C inclusive) press

the required temperature box and enter the desired value.

• To set the day of the week on which the temperature reduction is to

start or end, press the box for the required day of the week. The box

will then appear checked.

• To activate the temperature reduction, press the lamp symbol,

which then turns green.

• If a larger reduction in temperature is required or a temperature

reduction for a longer period, press ‘Next’ to access the holiday

reduction settings for floor heating.

• To return to the previous menu, press ‘Back’.

• To go to the next menu, press ‘Next’.

44

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

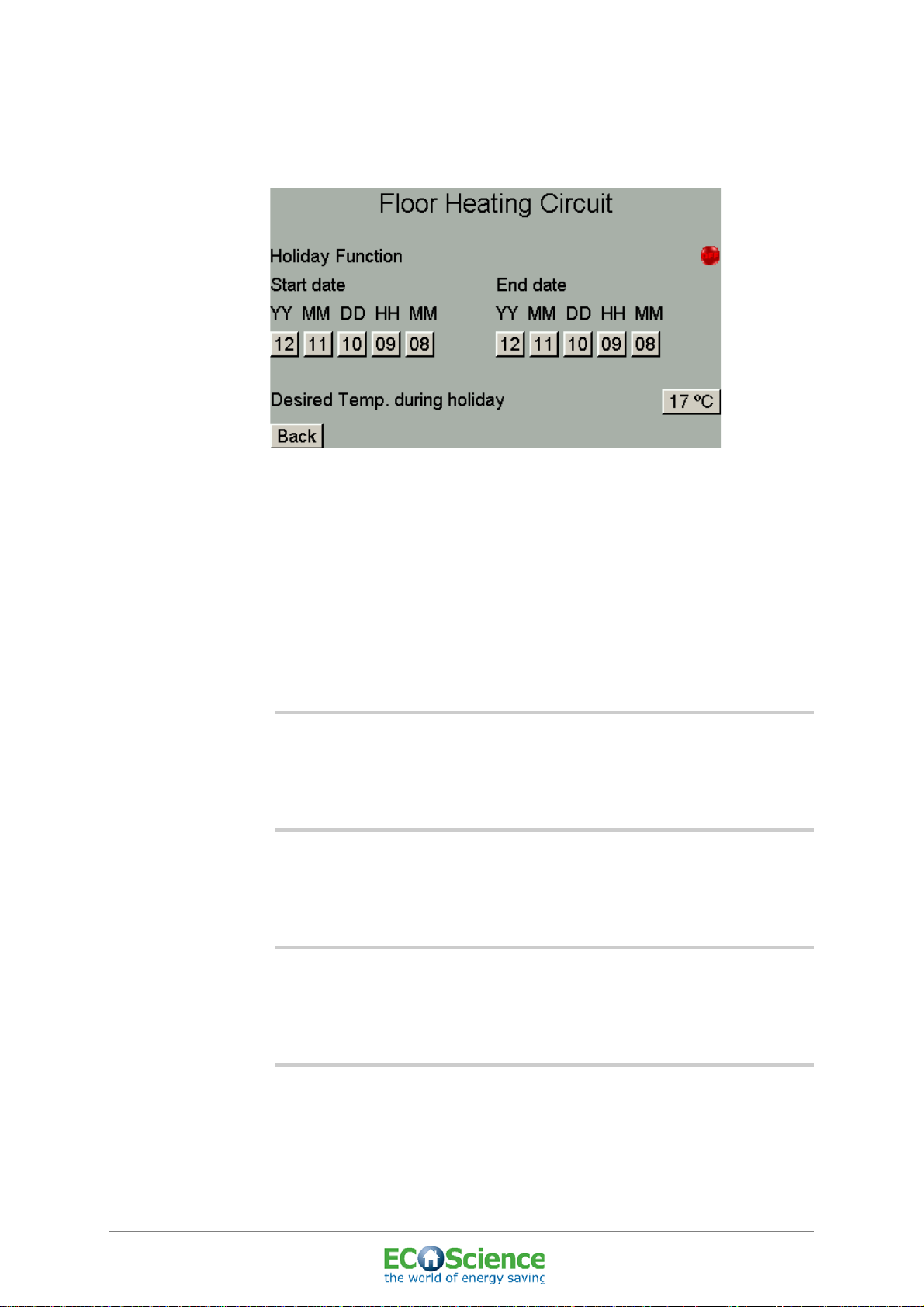

6.12.3 Floor heating circuit holiday settings

This menu can be used to program and activate holiday settings for floor

heating.

Figure 41. ‘Floor Heating Circuit Holiday Settings’ menu

INSTALLATION AND USER MANUAL

• Enter the start date when the reduction in temperature is to start or

the end date when the temperature is to return to its regular

settings.

• Enter the desired temp. during holiday.

• To activate the holiday settings, press the lamp symbol, which then

turns green.

• To return to the previous menu, press ‘Back’.

6.13 SOLID FUEL

Only when the add-on module is chosen. See ‘ECOScience Installation

and user manual – solid fuel’ for further details.

6.14 BUFFER TANK

Only when the add-on module is chosen. See ‘ECOScience Installation

and user manual - buffer tank’.

6.15 HEAT PUMP

Only when the add-on module is chosen. See ‘ECOScience Installation

and user manual - heat pump’.

6.16 POOL CONTROL

Only when the add-on module is chosen. See ‘ECOScience Installation

and user manual - pool’.

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

45

ECOScience ENERGY CENTRE

7 MAINTENANCE

Before maintenance and cleaning, make sure you have read and

understood section ”2 SAFETY INSTRUCTIONS”.

7.1 MAINTENANCE AND FUNCTION CHECKS

7.1.1 Regular maintenance to be carried out at least once a year

• Check the safety valve by turning it anti-clockwise until it jumps out.

For the location of the safety valve see ‘4.4.3 Pipe connections’

(No. 7).

• Check the pressure in the system by reading the manometer

located in the connection to the expansion vessel.

INSTALLATION AND USER MANUAL

PLEASE NOTE: SYSTEM PRESSURE!

The system pressure must never fall below 0.9 bar.

7.2 CLEANING

Wipe the product regularly using a rag, warm water and a mild detergent.

CAUTION: RISK OF SURFACE DAMAGE!

Never use corrosive agents or agents that could

scratch the product!

46

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

8 SERVICING AND REPAIRS

Servicing and repairs must be carried out by the installation engineer or

his/her representative. Before servicing and repairs, make sure you

have read and understood section ”2 SAFETY INSTRUCTIONS”.

INSTALLATION AND USER MANUAL

DANGER: RISK OF ELECTRIC SHOCK!

Turn the main switch to OFF before servicing!

The control panel must only be opened by qualified

professionals!

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

47

ECOScience ENERGY CENTRE

INSTALLATION AND USER MANUAL

9 TROUBLESHOOTING

9.1 COMMON F AULTS AND SOLUTIONS

Description of problem Possible cause Solution

Noise from pump or radiators/floor

heating.

Fault in flow switch. This may be due to dirt in the flow

Low pressure in the system tank.

Manometer shows a pressure of

<0.9 bar.

No heat coming out to the radiators/

floor heating.

Phase L1 lamp illuminated in I/O

menu

Phase L2 lamp illuminated in I/O

menu

Often caused by air in the system. Bleed the air out of the system,

switch or if the switch is broken.

Possible leak or air has bled from

the system with no topping up.

Manual operation of shunt has been

activated via the control system or

actuator has been set to manual.

Error in radiator circuit circulation

pump.

Can be caused by air in the system.

Fault with incoming phase (L1). Contact a qualified electrician.

Fault with incoming phase (L2). Contact a qualified electrician.

including the pump.

Clean the flow switch.

Contact Service Representative.

Check that the system is not set

to manual operation (”6.3.2

Manual operation”)

Contact your Service

Representative if the circulation

pump has a fault.

Bleed the air out of the system,

including the pump.

Temperature value on screen shows

N/A.

The control system indicates hot

water being drawn but this is not

happening.

Temp. value on screen shows -40°C. Broken sensor or broken wire. Contact Service Representative

Sensor broken or not connected. Check sensor or contact Service

Representative.

Dirt may have collected in the flow

switch from incoming cold water

(municipal or from own well).

Clean the flow switch.

for change of temp. sensor.

48

Top connected system tank, CS300

© ECOScience

Edition: 01; Last updated: 2011-04-12

ECOScience ENERGY CENTRE

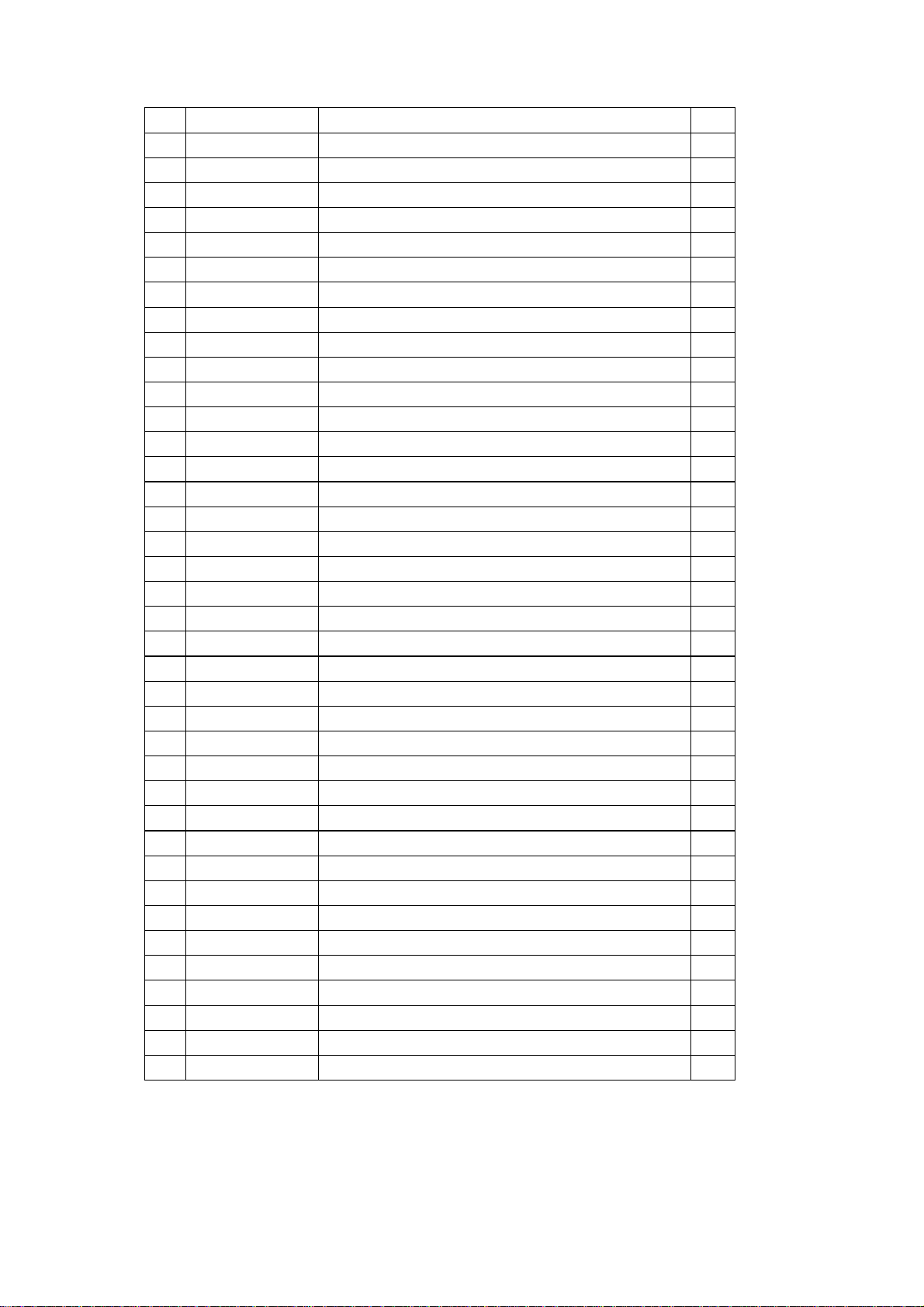

9.2 TABLE FOR RESISTANCE TEMPERATURE SENSOR PT 100

You can check that the temperature sensors are functioning properly by

using the table below and an instrument for measuring resistance.

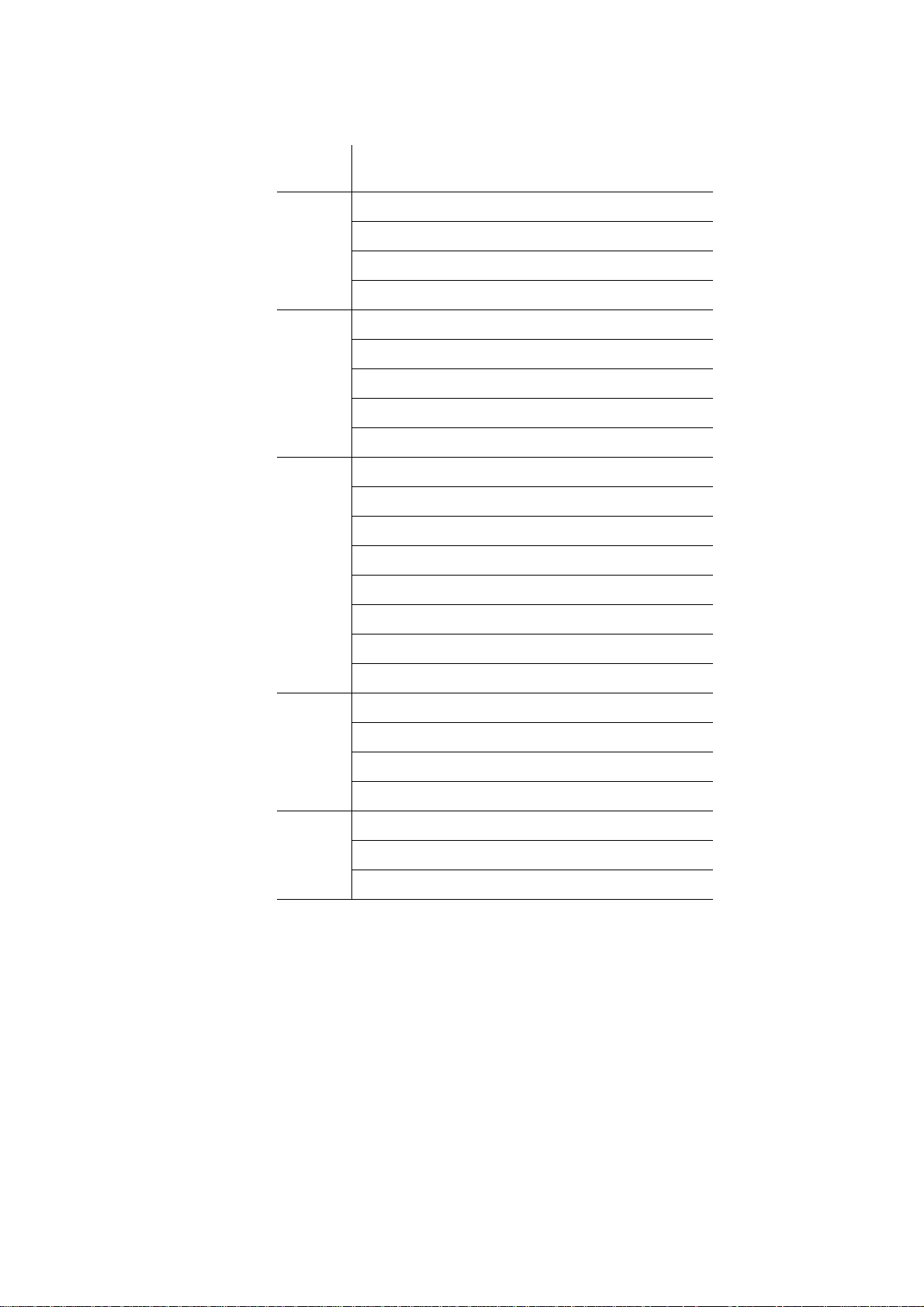

Temp °C Resistance ohm DR/Dt ohm/°C

-20 92.160 0.393

-10 96.086 0.392

0 100.000 0.391

10 103.903 0.390

20 107.794 0.389

30 111.673 0.387

40 115.541 0.386

INSTALLATION AND USER MANUAL

50 119.397 0.385

60 123.242 0.384

70 127.075 0.383

80 130.897 0.382

90 134.707 0.380

100 138.506 0.379

Top connected system tank, CS300

Edition: 01; Last updated: 2011-04-12

© ECOScience

49

ECOScience ENERGY CENTRE

9.3 ALERTS AND SOLUTIONS

The control system has a monitoring function which triggers an alert if

something unexpected occurs. The alert is indicated by a red warning

triangle on the start screen. The triangle simply indicates that an alert

has occurred. To obtain more information on why the system has

generated an alert, go to the ‘Alerts’ menu (”6.8 ALERTS/HISTORY”).

Alert message Meaning and solution

INSTALLATION AND USER MANUAL

Overheat occurred (Electric Heater

Top/Bottom)

Communication Error Error in communication between

Start Seq. completed This is not an alert but notification

Incoming Phase L1/L2 missing Fault with incoming phase, contact

Heating circuit supply temp. not

reached.

Overheat protection for the electric

heater has been triggered (see ‘9.3.1

Resetting overheat protection for

electric heaters’ on page 50).

control circuit board and I/O circuit

board. Check cable.

that the start sequence is complete

(for more information see ‘6.3.3

Heat-up sequence’ on page 27).

qualified electrician.

Set value not reached. Possibly due

to air in the heating system. Check

the heating circuit circulation pump.

9.3.1 Resetting overheat protection for electric heaters

If the system has generated an alert indicating that the overheat

protection has been triggered for the top or bottom electric heater, it

must be reset. Please note that this protection should not normally be

triggered. However, if the protection has been triggered, the procedure

is as follows:

50