ECO RANGE

Cooker

Oil Condensing Boiler model

For use in Great Britain and Eire (GB & IE)

Instructions for Use, Installation and

Servicing

This appliance must be installed in accordance with the regulations in force and only used in

an adequately ventilated space. Please read these instructions before installation and use and

retain for future reference.

1. Introduction

Thank you for choosing to purchase the condensed oil, balanced flue, Eco Range cooker.

Each cooker is manufactured and assembled by hand in our factory. This appliance is

designed to be capable of operating for long periods of time. With correct installation and

use your Eco Range cooker will provide many years of satisfactory service and cooking

enjoyment.

The appliance consists of two hotplates, a top oven and a bottom oven or warming

compartment. The left sided hotplate is designed for more rapid heating suitable for frying

and boiling, whereas the right sided hotplate is more suitable for slower cooking and

simmering. Hotplate covers are provided to prevent heat losses when not cooking. The two

top ovens operate to provide a consistent temperature controlled environment for all your

cooking and baking needs. The bottom oven operates at lower temperatures and is suitable

for slow cooking or merely as a warming compartment, depending on the control setting.

These instructions detail how to get the most from your cooker, as well as fundamental

information on how the cooker shall be installed, maintained and used in a safe and practical

manner. It is important that some time is taken to read these instructions carefully

before installation and use of the appliance.

In order for the warranty to remain valid it is imperative that the appliance be installed in

compliance with all relevant national and regional regulations.

A competent heating and plumbing engineer must design and approve the proposed system.

The warranty of your Eco Range Cooker applies to products sold in the UK and Eire

only. For products sold outside of these areas please contact the manufacturer for

details warranty authorisation.

2. Safety Instructions

Safety First:

This is a heating appliance; therefore it can become very hot when in service.

Young children and pets should be kept a safe distance from the cooker.

Ceiling mounted clothes dryers are strongly unadvised as they can present a fire hazard, this

also includes leaving towels on the handrail of the cooker.

Pans, especially chip pans, should not be left unattended on the Eco Range cooker.

Read and understand this booklet before installing and operating this appliance.

This appliance must be installed in accordance with the rules in force and used only in a

well ventilated space.

The appliance must only be installed and serviced by a suitably qualified and registered

technician.

The appliance shall not be altered in any way and only approved spare parts shall be

used. Failure to do so will invalidate any warranty or guarantee.

This appliance is very heavy and every care should be taken when trying to manoeuvre

it. Do not attempt to move or lift the appliance by the door handles, this could cause

damage to the doors and handles. It must be sited on a solid, level floor constructed in

accordance with any Building Regulations which may apply to the site.

It is important for the correct operation of this appliance that the installation space and

clearances around the appliance are in line with the specifications detailed in these

instructions.

Sufficient space should be available to allow the doors to be fully opened in excess of

120° from the closed position.

Ventilation openings on the side rear and front of the appliance should never be blocked

or restricted. see ventilation requirements

This appliance is capable of being operational at all times. Parts of the appliance will

become very hot, and remain hot for long periods. Only adults should operate this

appliance and only in accordance with the user instructions. Care should be taken when

using the cooker and the use of oven gloves is recommended when applicable. Children

should be supervised at all times if in the vicinity of the cooker.

In the interest of hygiene and safety the cooker should be kept clean at all times.

The cooker is designed for cooking foods only and must not be used for any other

purpose.

Always allow to cool before cleaning and carrying out maintenance work.

Do not use unstable or unsuitable saucepans and position handles away from the edge of

the hot plate. Thick, flat based saucepans are recommended for best results.

Do not place combustible materials onto the hot plate surfaces even when the cooker is

off.

Your Eco Range Cooker should be serviced at least once every twelve months. It is

impossible to service your cooker while it is hot, therefore DO NOT use your appliance

12 hours before a service is required.

Important:

The installer is responsible to ensure that all persons involved in the installation be provided

with the correct health and safety clothing when handling materials which are known to

cause potential harm.

Ceramic materials: Facemask and gloves must be worn, Contact with eyes, skin and

throat must also be avoided.

Fuels: Wear gloves – avoid ignition sources – Waste fuel should be disposed of

correctly, not via domestic waste water courses.

Fire cement: Wear gloves – wash hands.

Safety Notices and Regulations

The Building Regulations – Part J England and Wales – Part F section III Scotland –

Part L Northern Ireland – Part J Ireland.

BS5440 Parts 1 and 2 Installation of Flues and Ventilation.

D.M.2. Installation of Timber Framed Buildings.

Safety Document 635 The Electricity at Works Regulations.

BS7671 Requirements for Electrical Regulations.

REC Rules regarding PME Earthing (where applicable)

Warning:

Correct earthing must be provided for this appliance.

If in doubt seek advice from a qualified electrical engineer. Prior to carrying out any

work on the appliance switch off at the mains and remove the fuses from the fused spur

outlet and from the user control panel. Replace when works are complete. Always ensure

appliance is ‘electrically dead’ prior to working on the electrics.

3. Technical Specification

Appliance type - Cooker and Space heater

Cooker Burner System - Eco Flame Minor

Fuel - 28-35 sec Kerosene

Country of Designation I.E & U.K

Mains supply - 230 Vac @ 50HZ from a dedicated fused spur.

Fuse rating - 3A

I.P Protection - 20

Load (Running) - 130W (Nominal)

Oil Pump working pressure - 115 psi/ 8 bar (Nominal)

Flue - Balance only.

Appliance total energy input - 42KW (Cooker & boiler)

Installation requirements - Must be installed in accordance with good practise

and as laid down by all relevant codes of practise

by suitably qualified installers.

NB: See Installation Instructions within this manual

Balanced flue only - No further ventilation required.

4. Appliance Details

Overall Size - Height (to hob) 910mm

Width (standard models) 1000mm

Depth (to towel rail) 730mm

Hotplates – 340mm diameter x 2

Ovens - Height 270mm

Depth 500mm

Width 345mm

Your cooker is fitted with a thermostatic control device. This operating system provides the

exact heat requirements selected (by the user) for cooking and reduces the overall oil

consumption. The user selects the desired cooking temperature and when the cooker

approaches the selected operating temperature the thermostatic control operates to turn off

the burner flame to maintain a steady temperature. The control knob on the device is marked

which relates to a particular temperature setting of the top oven.

4.1 Using your hotplates

Your appliance has two hotplates, with a joint hotplate in the middle, protected with two

insulated lids which should remain in a closed position when not using the hotplate. The lids

can be raised independently if only using one hot plate. The hot plate temperature is

dependent on the setting of oven temperature. The higher the temperature in the ovens, the

hotter the hotplate will become.

The design of the hot plates is such that the left hand side will become the hottest, making

this suitable for deep fat frying, shallow frying and boiling.

The surfaces of the hotplates are ground flat and it is therefore recommended that all

utensils used have a solid, flat base to come in complete contact with the hot plate for

efficient results.

4.2 Using your Ovens

Your appliance has 2 ovens. The thermostatic dial in the top oven door provides an

indication to the top oven temperatures. This thermometer reading will reduce quite

dramatically when the door is opened and only recover slowly when the door is closed. This

occurrence does not mean that the oven temperature has reduced. The bottom oven is

warmed by the underside of the oven above. Depending on the control device setting and

operational time, this oven will generally operate some 85 – 90°C below the top ovens. It

may be used for small food cooking, biscuits, cakes etc but it is best used as a warming

compartment.

4.3 Overheat thermostat

The cooker is protected by an overheat thermostat designed to shut down the burner if a

fault occurs leading to excessive oven temperatures. The overheat thermostat is located

below the control device, inside the lower left compartment. To reset, unscrew the

protective cap and press the button.

NOTE: If overheat reset occurs more than once contact your service technician.

4.4 Cleaning your cooker

CAUTION: Cleaning of the Eco Range Cooker should only be carried out when the

appliance has cooled down.

The Eco Range cooker should be wiped over daily with a damp soapy cloth. The enamel

should then be dried and polished with a soft dry cloth to avoid streaking. Any spillages

should be wiped up immediately to prevent hardening of deposits which would make

removal difficult at a later stage.

The hot plates can be kept clean by using a light suede wire brush and gently scrubbing the

plates, taking care not to damage the surrounding enamel. Spillages inside the ovens can

become carbonised at high temperatures, therefore the ovens should be cleaned at regular

intervals with a stiff brush. The surfaces of the oven are natural, therefore to prevent

oxidation dry all surfaces after cleaning.

4.5 Routine servicing / maintenance

All oil appliances require regular servicing by a qualified technician. It is recommended that

your cooker is serviced at least once a year. This will ensure your cooker remains fully

functional and in a safe condition.

5.0 Delivery and Transport

Your Eco Range Cooker is an extremely heavy and solid appliance. When attempting to

move or transport your cooker please take into consideration these points:

External – In Vehicle – Ensure unit is securely held by ropes and handled carefully by

qualified personnel.

Internal

Remove all objects from your path, including rugs and breakables.

It is often easiest to unhinge a door in the case that it is too narrow, it also stops damage

being applied to the cooker, the property and injuring people.

The plinth on the cooker is strong and sturdy enough to withhold the unit being moved on

rollers, by removing the oven doors you can also create useful handholds.

IMPORTANT:

The top plate is unable to manage the weight of the cooker so should never be moved

or lifted in this way.

Damage can be caused to the cooker and to persons by using inadequate objects to

lever or move the object.

Difficult terrain, including steps, should not be attempted without adequate

manpower and proper precautions.

The supplier of your new ECO Range Cooker can provide you with an authorised engineer

to attend site, strip the appliance and rebuild in the correct location.

The warranty will become invalid if you strip and rebuild the cooker yourself.

5.1 Site Considerations

1. Sufficient space for appliance, so that access for service and maintenance purposes

can be easily attained.

2. Provision of a satisfactory flue/chimney/cowl.

3. A sold non-combustible hearth capable of supporting the appliance.

4. Adjacent to the cooker then should be no combustible walls or surfaces.

5. The cooker must stand against an outside wall so that there is a supply of unrestricted

air to the burner.

6. If the cooker is to be placed within an inglenook, allow a minimum of 1.5 meters

height clearance for comfortable operation.

7. Units and other work tops should be given enough space, allow 25mm for kitchen

units and 10mm for worktops, 3mm should be given for granite and composite stone.

8. The cooker must not be built in, especially the top plate and front plate which must

be removed for maintenance.

6.0 Balanced Flue

A balanced flue allows the cooker to be placed against an outside wall, with either rear or

top outlet concentric flue.

Maximum length of rear flue: 500mm

Maximum length of top outlet flue: 300mm vertical

500mm horizontal

The surrounding area must be taken into consideration, as strong winds may affect flue

performance.

Balanced flue units are supplied with the following components:

1 no. Outer flue pipe 5” (air intake)

1 no. Inner flue pipe 3” (exhaust outlet)

1 no. Flue terminal

1 no. Heatproof silicon

4 no. Stainless steel self-trapping screws

1 no. Oven vent pipe with tee

Instructions for installation:

1. A suitable position for the range must be taken into consideration before attempting

to install or move the appliance. See section 5.1 for site considerations.

2. Mark the positions for the flue and oven vent, it is important to confirm all

measurements by physically measuring the appliance.

3. Push oven vent through hole and manoeuvre cooker into position. After the cooker

has been moved to the correct position, tighten the compression fitting so that there is

a 3/5º drop from appliance to outside termination.

4. Cut the pipes to the correct length.

5. With the supplied tape and silicon make a seal on the inner and outer pipes. Push into

the cooker, whilst making sure no excess sealant has leaked that may block the

cooker spigots. Ensure minimum of 3º drop.

6. With suitable material make a good flue hole.

7. Fit the terminal to the pipes whilst ensuring the inner pipe has adequate clearance

between terminal end and outlet (min. 50 mm). Secure terminal with supplied screws

and heatproof silicon.

8. The oven vent must then be cut to the correct length, solder tee to pipe with outlets

top and bottom. It is vital that there are no bends in the oven vent.

Boiler:

INTRODUCTION

Thank you for choosing our condensing oil boiler, please read the following carefully.

To the installer

This manual must be left with the householder by the installer who will instruct the user on the boiler

operation.

To the user

Please read the user section of this manual to familiarise yourself with the boiler operation

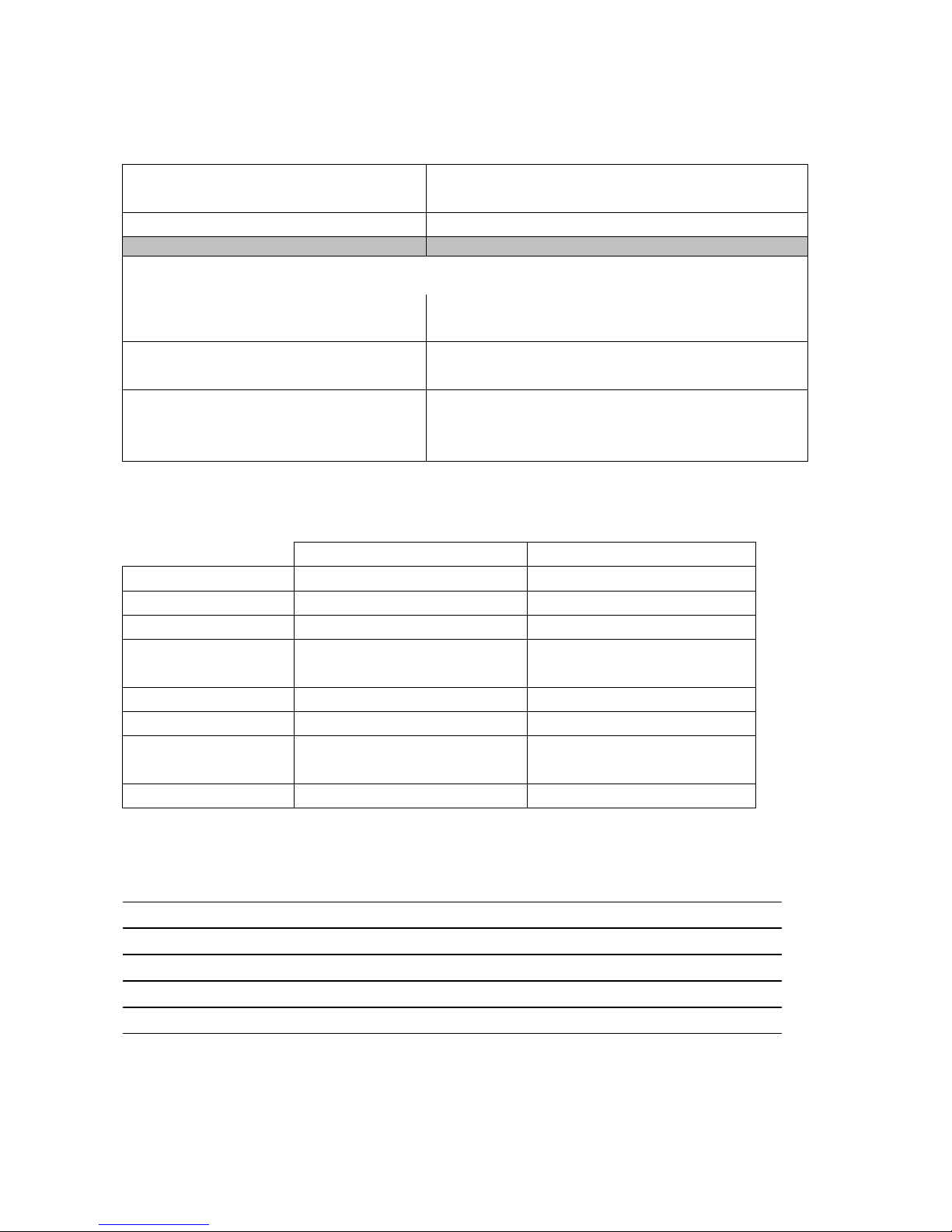

WARRANTY

WARRANTY FOR YOUR BOILER MUST MEET THE FOLLOWING

CONDITIONS OR YOUR WARRANTY MAY BE INVALID

Warranty on the Heat Exchanger: 5 Years (Excludes labour)

Warranty on Burner and Controls: 2 Years

CONDITIONS OF WARRANTY:

1. Boiler MUST BE installed by an OFTEC registered engineer, if not permission will be required by

building control.

2. Boiler MUST BE commissioned after installation by an OFTEC registered engineer.

3. Boiler MUST BE serviced every 12 months after installation by an OFTEC registered engineer.

4. Installer MUST COMPLETE an Installation/Commission Form, which will be found along with your

manual and this, must then be returned to the address on the warranty form. Failure to return this form

may invalidate your warranty.

WHAT IS A CONDENSING BOILER AND HOW DOES IT WORK?

On all standard boilers the flue gases that go up the chimney have quite a high temperature (200°C / 260°C)

and are made up of a few different types of gases. A condensing boiler is designed so that these flue gases

pass through a stainless steel heat exchanger connected to the boiler. These flue gases transfer heat to the

water contained in the secondary heat exchanger.

This results in (a) increasing the temperature of the water returning to the main boiler

(b) Converting some of the flue gases into condensate

(c) Lowers the exit flue gas temperatures considerably (Less than 85°C)

This all results in increased efficiency in the boiler and therefore a saving on oil.

IMPORTANT CHANGES TO BOILER MANAGEMENT:

Annual Service –This is very important in order to keep the flue ways clean and ensure the boiler is

correctly set.

Quarterly Check – empty and clean the condensing trap (Fig.4)

Always ensure that the condensate is flowing freely through the outlet into the drain. This can get dirty and

block flow or it can freeze in extreme conditions.

Plume – a condensing boiler, which produces a white plume from the flue into the air. This is caused by the

low flue gas temperatures mixing with the colder air outside.

Best performance:

Radiator Heating System - Flow Temperature 70°C - Return Temperature 50°C

Underfloor Heating System - Flow Temperature 50°C - Return Temperature 40°C

Note: return temperature should never be less than 40°C

BOILER OPERATION

The Boiler Control Thermostat responds to the temperature of the water within the boiler and switches power

to the burner when heat is required.

The burner has an independent control system which regulates the firing and (shut-off) of the burner.

Automatic firing of the burner will occur when the water temperature within the boiler falls below the

control thermostat set point which will continue to run until the water temperature rises to the temperature set

on the boiler control thermostat.

SWITCHING THE BOILER ON

- Check there is water in the system.

- Check radiator valves are on.

- Turn on oil supply.

- Switch electrical supply to the boiler on (including time clock) and then set the boiler control thermostat

to recommend setting.

BOILER CONTROLS

BOILER CONTROL THERMOSTAT

The temperature of the water within the boiler is controlled and maintained by the Boiler Control

Thermostat located on the boiler control panel.

TEMPERATURE SETTINGS:

The Boiler Control Thermostat has a range of 50°C to 80°C. The recommended setting for the boiler control

thermostat is:

WINTER Heating and hot water supply 80°C

SUMMER Domestic hot water supply 65°C

It is not recommended to operate the boiler with a thermostat setting of less than 60°C as this will precipitate

corrosion, thus reducing the life of the boiler.

HIGH LIMIT STAT

The high limit lockout will occur when the water within the boiler is or has overheated e.g. reached a

temperature above that set on the high limit thermostat.

TO RESET THE BOILER

When the boiler has had time to cool, unscrew black cap and press button on the control panel to reset.

LOCKOUT INDICATOR: RED

The lock out indicator will illuminate when the burner has failed to fire, e.g. No fuel or an electrical fault.

Wait for two minutes then press the manual reset button (coloured red – Fig 1) on the control box to reset.

SWITCHING THE BOILER OFF

The boiler can be switched off at anytime using one of the following:

- Turn the boiler control thermostat to the OFF position

- Switch the mains (electrical supply) to OFF

- Set the control system to OFF (e.g. Time Clock)

PLEASE NOTE: For longer periods of shutdown e.g. while away on holiday, switch OFF the mains

(electrical supply) and turn OFF the OIL supply.

If shutdown occurs during cold weather ensure boiler is protected against frost damage.

BURNER LOCKOUT

The burner has an independent control system (Burner Control Box); this includes a flame detector

(Photocell), which senses the presence of a flame. In the event of a flame failure, the burner control box

activates a second re-ignition sequence. Should the photocell not detect a flame presence within 15 seconds

the burner goes to LOCKOUT and shuts down.

Continued LOCKOUTS are a result of a fault in the operation of the boiler and can be attributed to

following examples:

- An interruption of the fuel supply.

- Electrical Supply Fault e.g. Extreme low voltage.

- Failure of a burner component.

- A fault within the heating system.

- Burner combustion not being correct.

The Burner Reset button on the Control Box illuminates to indicate that a lockout has occurred.

In the event of the Burner locking out, do not attempt to restart the Burner by pressing the Reset Button on

the Burner Control Box for at least 2 minutes. A Bi-metallic timer within the Control Box has a minimum

cooling time of 45 seconds thus the 2 minute interval will ensure that this Bi-metallic timer has cooled and is

therefore in a position where it may be reset.

RESTARTING AFTER LOCKOUT

When lockout has occurred, inspect for any obvious causes e.g. oil leaks. Also check the fuel line from the

tank to the boiler and that any oil shut off valve has not been inadvertently closed.

RESTART

- Check there is adequate oil in the storage tank.

- Check oil supply valves are open

- Switch on heating system (e.g. Time Clock)

- Press the Burner Reset Button on the burner Control Box, which will be illuminated. The Burner Reset

Button (illuminated)(Fig 1) will go out and the burner will commence the ignition start sequence. After

15 seconds the Burner should fire normally.

PLEASE NOTE: Should the Burner not start, the lockout indicator, on the Control Box/Burner Reset

Button will illuminate again.

- Wait at least 3 minutes and press the Burner Reset Button again.

Failure to start a second time indicates a fault requiring attention.

In the event of a second failure to start:

- Switch off electrical supply

- Call service engineer.

REGULATIONS

The installation of oil-fired boilers should comply with the following standards and codes of practice:

- BS5449 Forced circulation hot water heating systems for domestic use.

- BS5410-Part 1 Oil installations up to 45kw

- BS7593 Water treatment of hot water central heating systems

- BS7671 Electrical Regulations

- Building Regulations Part 1L and J 2002 England and Wales, Part F Scottish Regulations and

Technical Booklet L Northern Ireland.

- OFTEC Codes of Practice Published or Recommended.

After installing, the system needs to be flushed with a cleanser like Fernox Heavy Duty Restore, for fastacting removal of lime scale, black sludge (magnetite) and other deposits from the boiler and the central

heating system. Then add a Fernox protector to give long-term protection of the central heating system

against internal corrosion lime scale formation.

WATER CONNECTIONS

Only two connections for the heating and hot water system on a standard condensing boiler:

1. Flow from top of boiler (Fig.2) and return to top of stainless steel heat exchanger (Fig.2).

2. The PVC pipe (fig 3) is 21.5mm Ǿ and should continue from the condensate trap in side the boiler

casing, which should be plumbed to an external source ensuring one of the following options:

- Internal waste drainage system - Soil/vent stack

- External Drainage system - External condensate absorption point

NOTE: condensate pipe work must fall at least 50mm per metre towards the outlet ensuring all joints are

leak proof.

WARNING: the condensate trap must be filled with water prior to starting the boiler to stop flue gases

escaping

BOILER LOCATION

Sound levels should be discussed with the householder, as some people may be sensitive to low noise levels

in a small room, as is may appear more annoying than in larger rooms. Please Note installation should take

into account of flue position (see diagram).

RECOMMENDED FLUE POSITION

OIL SUPPLY

A flexible oil pipe is supplied to connect the burner to the incoming oil supply pipe.

IMPORTANT NOTES:

- If sitting oil tank above burner height, use single supply pipe only.

- If sitting oil tank below burner height, use twin pipe supply or Tiger loop.

- Please refer to Burner Manual for conversion to oil pump for two pipe system.

ELECTRICAL ENTRY

The electrical supply to the boiler must be wired using a double pole-isolating switch 230v/50hz, fused 5

amps. The mains supply must be connected with the boiler dual stat, the supply will then continue down to

the burner control box. The burner is supplied with a three wire cable plug which allows disconnection for

maintenance.

General Data

Electrical Supply. 240w-50hz

Oil Supply Connection ¼” BSP

Fuel: 28 Second

High Limit Stat: Manual Reset

Maximum Control Thermostat Setting 85°C

Maximum Operating Pressure:

3 Bar – 45psi – 28m Static head room 92ft

Draught Limit

Min 12.5 Nm2 – 0.05” WG

Max 33.0 Nm2 – 0.12” WG

Note: 28 sec fuel must only be used on ECO Range Cookers & boilers

SERVICING INSTRUCTIONS

A competent service engineer OFTEC registered should be appointed on an annual basis.

Remove inspection door, burner and baffle assembly

Brush down the inside of the heat exchanger and vacuum out debris

Clean baffle assembly

Pull out inserts from stainless steel heat exchanger and clean before replacing.

Ensure stainless steel heat exchanger is thoroughly cleaned.

Empty and clean condensing trap (Fig.4)

Inspect and clean burner assembly, and replace with new nozzle (see burner manual)

Renew any insulation e.g. inspection door or inside base of heat exchanger

Reassemble baffles and replace inspection door.

Replace paper oil filters

Test oil pressure and test combustion.

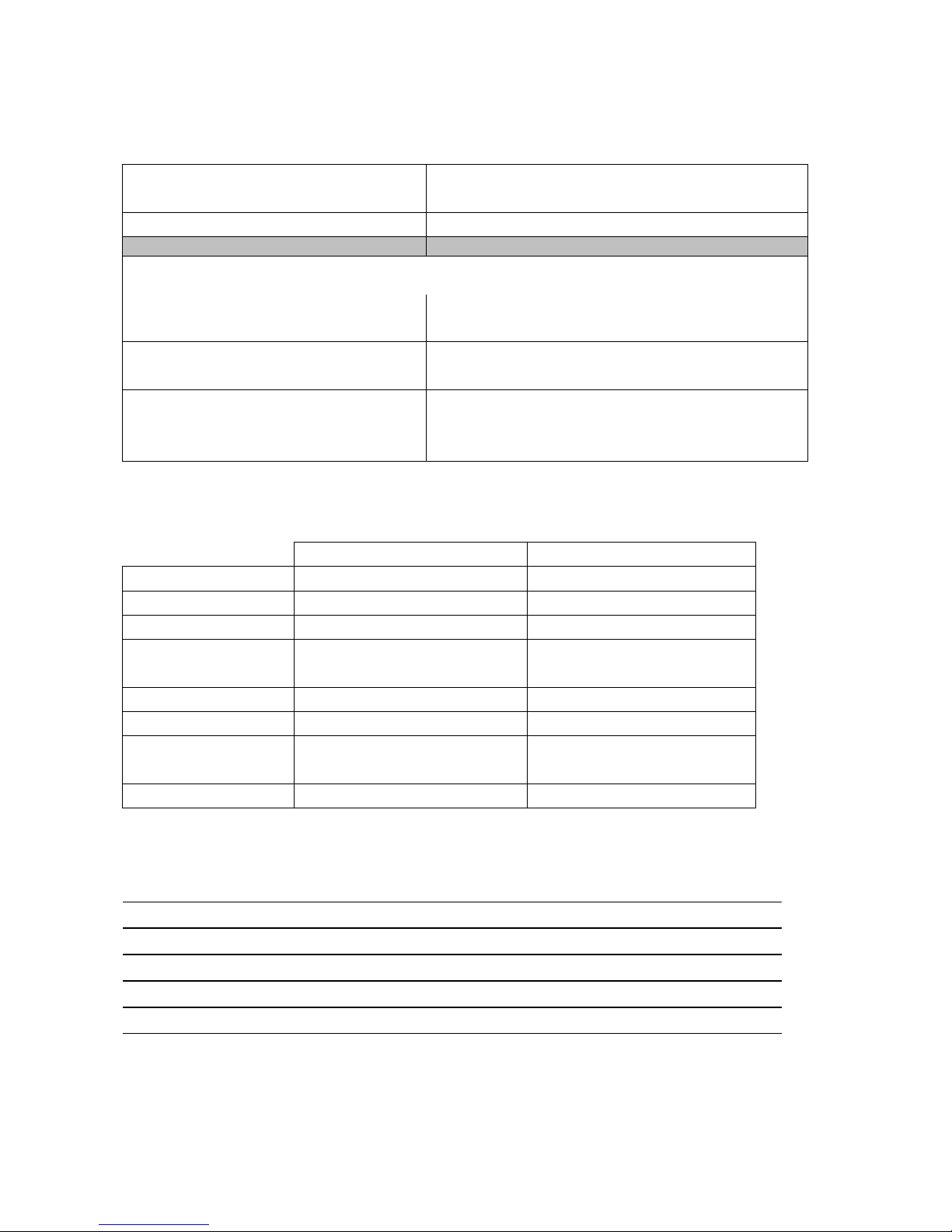

BOILER SIZE

NO. OF INSERTS FROM L/H SIDE OF CONDENSER

REMAINING TUBES WITHOUT INSERTS

15/21 KW

10

6

1 SET OF BAFFLES

15/21 KW

BURNER SETTINGS

BOILER MODEL

15/21

MAXIMUM OUTPUT

Btu/hr

72000

Kw/hr

21

FACTORY SETTING

Btu/hr

63000

Kw/hr

18.5

NOZZLE SIZE

0.55 80 deg H

OIL PRESSURE

Bar

8

BURNER AIR

SETTING

7

SMOKE 0

CO2

%

11.5

FLUE GAS

TEMPERATURE

°C

80

WATER

INLET/RETURN

mm

22

WATER

OUTLET/FLOW

mm

22

CONDENSATE FLOW

mm

22 pvc rigid pipe

2MAX OPERATING

PRESS

Bar

2.5

BOILER EFFICIENCY*

SEDBUK A RATING

%

98 % 93.5

Electrical Power

230/240 V 50 Hz

Fuse

5 amp

SERVICE REQUIREMENTS

The boilers are serviced through an access panel at the front. A service access space of at least

700mm should be made available at the front of the boiler.

THE HEARTH

The temperature of the surface below the boiler is less than 85°C. If the floor under the boiler is of

combustible material, then protection such as steel should be fitted between the boiler and the floor.

Consideration should be given to the weight of the filled boiler; the floor must provide adequate

support. Please consult the building regulation for safe floor loadings.

CONTROL PANEL

The boiler control panel is factory fitted prior to despatch. The phials of the Control and High Limit

Thermostat are inserted into the pockets situated on the left hand side of the boiler heat exchanger.

ELECTRICAL ENTRY

The electrical supply to the boiler must be 230v/50hz, fused at 5 amps. Connection of the appliance and any

system controls, to the mains supply, must be a common isolator and must be fused at 5A maximum.

This must be fixed wired to a double pole-isolating switch that has a maximum contact separation of 2mm in

both poles. The isolator should be clearly marked showing its purpose, and preferably positioned close to the

boiler.

COMMISSIONING & SERVICING INSTRUCTIONS

A competent service engineer OFTEC registered should be appointed on an annual basis.

Isolate Power to the boiler

De-pressurise heating system and check expansion vessel pre-charge is the same as the cold fill

pressure, of the heating system. Expansion vessel pre-charge must not exceed 1.5 bar.

Remove inspection door, burner and baffle assembly

Brush down the inside of the heat exchanger and vacuum out debris

Clean baffle assembly

Pull out inserts from stainless steel heat exchanger and clean before replacing.

Ensure stainless steel heat exchanger is thoroughly cleaned.

Empty and clean condensing trap

Inspect and clean burner assembly, and replace with new nozzle (see burner manual)

Renew any insulation e.g. inspection door or inside base of heat exchanger

Reassemble baffles and replace inspection door.

Replace paper oil filters

Turn electrical supply to the boiler to ON.

Set central heating controls so they are calling for heat.

Set burner pump pressure.

Allow time for the boiler to reach normal operating temperature.

Check the smoke reading.

Measure the Co2

Measure net flue gas temperature.

Check domestic hot water flow and hot temperature is acceptable to the householder.

PLEASE NOTE: Reducing the air supply into

the burner air inlet shutter, decrease the flue

gas temperature and increases the Co2

Condensing Trap

BOILER WILL NOT START

Check if mains electricity supply is reaching boiler control panel, making sure control thermostat is turned

on and time clock is calling for heat. Mains indicator green should be illuminated. If green light is not

illuminated and fuse has been checked then heating system charge may be low, check black needle on

pressure, located inside boiler cabinet (top right hand side) is reading 1 bar or more. If not depressurised,

refer to fault diagnosis.

Warranty Registration

Guarantee

Your cooker now has a one year parts and labour guarantee and a further four year parts guarantee.

It is the responsibility of the installer to ensure that the cooker is properly commissioned. This must

be by a qualified technician. It is essential that the commissioning procedures detailed in this

manual are carried out by a qualified engineer, using recognised test equipment and that the relevant

section of the latest edition of BS 5410, Part 1 is read and fully adhered to. The following warranty

registration page should be completed by the installer, signed by the customer and returned to Eco

Range Cookers. The installer should re-check the cooker and ensure everything is completely

satisfactory before demonstrating the operation of the cooker to the householder.

WARNING: Failure to return the Warranty Registration will render the guarantee null and void.

This complete manual must be left with the householder.

WARRANTY REGISTRATION

Appliance Model Serial Number

Date of Commissioning:

CUSTOMER DETAILS

Customer Name: (in BLOCK CAPITALS)

Address:

Town:

County:

Postcode:

Customer Signature

COMMISSIONING TECHNICIANS DETAILS

Technician’s Name: (in BLOCK CAPITALS)

Technician’s Competent Persons

OFTEC Registration Number

Address:

Town:

County:

Postcode:

Technician's Signature

Cooker

Boiler

Burner pressure psi

CO2%

CO ppm

CO/CO2

FGT

Electrical Safety

Before leaving Eco Range Cookers this unit was: Checked By:

Date:

Please return this completed page to:

Eco Range cookers

60 Wincheap

Canterbury

Kent

CT1 3RS

SERVICE RECORD

Appliance Model Serial

Number

Date of Service:

ENGINEER DETAILS

Engineer's Name: (in BLOCK

CAPITALS)

Engineers Registration

Number

Engineer's Signature

Date

COMBUSTION ANALYSIS

Cooker

Boiler

Pump pressure

CO2 %

CO ppm

Flue Gas

Temperature

CO/CO2

Efficiency %

Engineer's

Comments:

Jet Changed

Yes

Yes

PARTS REPLACED:

Jets should be changed annually.

SERVICE RECORD

Appliance Model Serial

Number

Date of Service:

ENGINEER DETAILS

Engineer's Name: (in BLOCK

CAPITALS)

Engineers Registration

Number

Engineer's Signature

Date

COMBUSTION ANALYSIS

Cooker

Boiler

Pump pressure

CO2 %

CO ppm

Flue Gas

Temperature

CO/CO2

Efficiency %

Engineer's

Comments:

Jet Changed

Yes

Yes

PARTS REPLACED:

Jets should be changed annually.

SERVICE RECORD

Appliance Model Serial

Number

Date of Service:

ENGINEER DETAILS

Engineer's Name: (in BLOCK

CAPITALS)

Engineers Registration

Number

Engineer's Signature

Date

COMBUSTION ANALYSIS

Cooker

Boiler

Pump pressure

CO2 %

CO ppm

Flue Gas

Temperature

CO/CO2

Efficiency %

Engineer's

Comments:

Jet Changed

Yes

Yes

PARTS REPLACED:

Jets should be changed annually.

SERVICE RECORD

Appliance Model Serial

Number

Date of Service:

ENGINEER DETAILS

Engineer's Name: (in BLOCK

CAPITALS)

Engineers Registration

Number

Engineer's Signature

Date

COMBUSTION ANALYSIS

Cooker

Boiler

Pump pressure

CO2 %

CO ppm

Flue Gas

Temperature

CO/CO2

Efficiency %

Engineer's

Comments:

Jet Changed

Yes

Yes

PARTS REPLACED:

Jets should be changed annually.

SERVICE RECORD

Appliance Model Serial

Number

Date of Service:

ENGINEER DETAILS

Engineer's Name: (in BLOCK

CAPITALS)

Engineers Registration

Number

Engineer's Signature

Date

COMBUSTION ANALYSIS

Cooker

Boiler

Pump pressure

CO2 %

CO ppm

Flue Gas

Temperature

CO/CO2

Efficiency %

Engineer's

Comments:

Jet Changed

Yes

Yes

PARTS REPLACED:

Jets should be changed annually.

SERVICE RECORD

Appliance Model Serial

Number

Date of Service:

ENGINEER DETAILS

Engineer's Name: (in BLOCK

CAPITALS)

Engineers Registration

Number

Engineer's Signature

Date

COMBUSTION ANALYSIS

Cooker

Boiler

Pump pressure

CO2 %

CO ppm

Flue Gas

Temperature

CO/CO2

Efficiency %

Engineer's

Comments:

Jet Changed

Yes

Yes

PARTS REPLACED:

Jets should be changed annually.

SERVICE RECORD

Appliance Model Serial

Number

Date of Service:

ENGINEER DETAILS

Engineer's Name: (in BLOCK

CAPITALS)

Engineers Registration

Number

Engineer's Signature

Date

COMBUSTION ANALYSIS

Cooker

Boiler

Pump pressure

CO2 %

CO ppm

Flue Gas

Temperature

CO/CO2

Efficiency %

Engineer's

Comments:

Jet Changed

Yes

Yes

PARTS REPLACED:

Jets should be changed annually.

SERVICE RECORD

Appliance Model Serial

Number

Date of Service:

ENGINEER DETAILS

Engineer's Name: (in BLOCK

CAPITALS)

Engineers Registration

Number

Engineer's Signature

Date

COMBUSTION ANALYSIS

Cooker

Boiler

Pump pressure

CO2 %

CO ppm

Flue Gas

Temperature

CO/CO2

Efficiency %

Engineer's

Comments:

Jet Changed

Yes

Yes

PARTS REPLACED:

Jets should be changed annually.

SERVICE RECORD

Appliance Model Serial

Number

Date of Service:

ENGINEER DETAILS

Engineer's Name: (in BLOCK

CAPITALS)

Engineers Registration

Number

Engineer's Signature

Date

COMBUSTION ANALYSIS

Cooker

Boiler

Pump pressure

CO2 %

CO ppm

Flue Gas

Temperature

CO/CO2

Efficiency %

Engineer's

Comments:

Jet Changed

Yes

Yes

PARTS REPLACED:

Jets should be changed annually.

This publication or any part of it cannot be copied by any means without the prior written

consent of the authors.

Our products are subject to continuous development and improvement and it is

consequently acknowledged that errors and omissions may occur.

This publication is intended only to assist the reader in the use of our products. Eco Range

Cookers will not accept any liability for any loss or damage whatsoever arising from the use

of any information, error or omission found in this guide.

Maintenance on our products must only be carried out by approved personnel.

Eco Range Cookers

60 Wincheap

Canterbury

Kent

CT1 3RS

info@ecorangecooker.co.uk

www.ecorangecooker.co.uk

Loading...

Loading...