Page 1

G A S I F I C A T I O N B O I L E R S

EBW SERIES

HIGH-EFFICIENCY

WOOD-FIRED BOILERS

O P E R A T O R ’ S

MANUAL

C US

1

Page 2

G ASIFICAT I O N B O ILERS

Manufactured by:

ECONOBURN LLC

A Division of Abasco Inc.

2 Central Avenue

Post Office Box 689

Brocton, New York 14716

Telephone: 716-792-2094

Toll Free: 1-866-818-5162

Facsimile: 716-792-2098

For technical assistance call: 716-792-2095

Website: www.econoburn.com

Email: info@econoburn.com

Email: Techassist@econoburn.com

© 2008 EconoburnLLC

All Rights Reserved

Revised 9/12

2

Page 3

TABLE OF CONTENTS

INTRODUCTION 5

BOILER DIAGRAM 7

CONTROLLER PROGRAMMING 8/9

OPERATING INSTRUCTIONS 10

WOOD-BURNING 10

STORAGE OF WOOD 11

INSPECTION & CLEANING 11

THE FLUE DRAFT CONTROL SYSTEM 11

FUEL LOADING 13

BOILER CONTROL 14

FIRING YOUR BOILER 15

COMBUSTION AIR & NEGATIVE PRESSURE 16

CLEANING CREOSOTE BUILD UP 16

GENERAL SAFETY TIPS FOR BOILER OPERATION 17

TIPS FOR MAXIMIZING BOILER EFFICIENCY 17

BOILER OPERATING CHECKLIST 18

MAINTENANCE AND CLEANING 20

BOILER MAINTENANCE 20

CLEANING THE HEAT EXCHANGER 20

ASH DISPOSAL 21

HEAT EXCHANGER MAINTENANCE 21

MAINTENANCE TIPS 22

3

Page 4

CHIMNEY MAINTENANCE 22

TROUBLESHOOTING GUIDE 23

SPECIFICATIONS 24/25

ECONOBURNTM BOILER WARRANTY 26

4

Page 5

G A S I F I C A T I O N B O I L E R S

INTRODUCTION

Congratulations on the purchase of your new ECONOBURNTM Wood-Fired Boiler. Developed in

the northeastern United States, the ECONOBURNTM Wood-Fired Boiler has been designed to allow

you to heat and supply hot water for your home or business, by burning wood, one of North

America’s most plentiful, affordable and environmentally friendly fuels.

Your ECONOBURN

standards for dependability, ease of operation, and operator safety. When properly maintained and

cared-for, the ECONOBURNTM Wood-Fired Boiler will give you years of energy-efficient, rugged

and trouble-free performance.

The ECONOBURNTM Wood-Fired Boiler utilizes gasification burning technology to get an

astonishing eighty-seven percent (87%) energy efficiency out of traditional wood fuel sources, and

will provide you with many, many years of safe and cost effective space and water heating.

To ensure that you have a clear understanding of the operating procedures of your

ECONOBURNTM Wood-Fired Boiler, please take the time to read this manual carefully and

completely, and follow all instructions. If you have any questions regarding the operation of your

Boiler, please contact us by email, through the ECONOBURNTM website at www.econoburn.com or

call our technical support team at 1-716-792-2095. We will be happy to assist you.

IMPORTANT: The ECONOBURNTM Wood-Fired Boiler must be installed by a certified and

properly trained and qualified Heating, Ventilation and Air Conditioning (HVAC) professional. Do

not attempt to install this unit yourself unless you are a certified and properly qualified HVAC

professional. Improper installation could result in fire, personal injury and/or property damage.

TM

Wood-Fired Boiler has been engineered and manufactured to our highest

KEEP THIS MANUAL IN A SAFE PLACE FOR FUTURE REFERENCE

5

Page 6

WARNING

THIS UNIT MUST BE INSTALLED BY A

CERTIFIED AND PROPERLY QUALIFIED

HEATING, VENTILATION AND AIR

CONDITIONING (HVAC) PROFESSIONAL.

DO NOT ATTEMPT TO INSTALL THIS

UNIT YOURSELF UNLESS YOU ARE A

CERTIFIED AND PROPERLY QUALIFIED

HVAC PROFESSIONAL.

IMPROPER INSTALLATION COULD

RESULT IN FIRE, PERSONAL INJURY

AND/OR PROPERTY DAMAGE.

6

Page 7

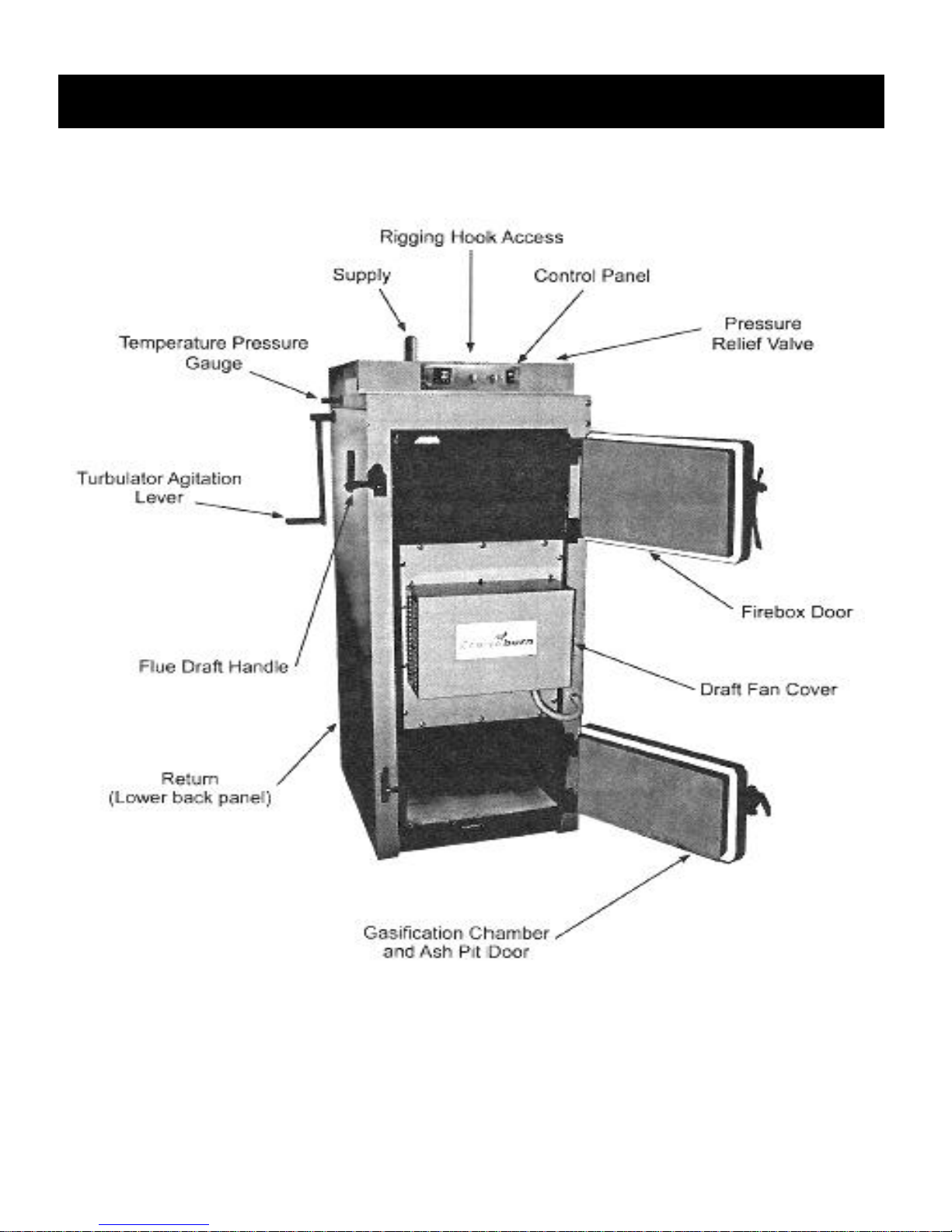

BOILER DIAGRAM

7

Page 8

Ts

0%

Ts-5

Water Temperature (deg F)

40%

100%

Fan

Speed

Ts -10

DFD CONTROL PANEL OPERATION

Normal operating Mode:

To Enter Program mode:

Press Up and Enter together, Actual will flash Pro.

Press Down and Enter together, Actual will change to solid Pro.

Press Up and Down together and Programming mode is entered.

Any incorrect sequence, or no keys for few seconds, will return the display back to water temperature actual and setting for

fan speed.

Menu {hysteresis} (Description)

Notes

Top display

Bottom display/default value (Range, in F)

First Menu (setting Deg F or Deg C)

Sets display between °F and °C

[F]

P-°

F (F or C)

Second Menu {5} (Setting Pump set point)

Above sets: Primary pump is on and Circulator pump is off

8

Page 9

P-P

150 (50 – 200)

Third Menu {20} (Setting Alarm set point)

Above sets: Alarm is on, Buzzer is on, display flashes, Fan is off (no pulse), and Primary is on

P-A

200 (50 – 230)

Fourth Menu {10 + TBD delay} (Setting Stack off point)

Below sets: All outputs are off, On leaves system running.

P-S

100 (On, 50 – 220)

Fifth Menu {N/A} (Setting Delay time)

Delay between high speed fan pulses when water at or above set point in minutes

P-d

15 (1 – 30)

Sixth Menu {N/A} (Setting Pulse time)

On time of high speed fan pulses when water at or above set point in seconds

P-o

15 (1 – 60)

In program mode up and down arrows will adjust the Setting value within the range given in 5 deg steps (except for delay

and pulse menus). Enter proceeds to the next menu. To exit the user enters through all six menus. The program is saved

after the last menu is exited. This allows the user to abort programming by cycling power before program completion.

However programming must be completed to save the program. No key presses for several seconds during programming

will abort the program and the controller will revert to the normal Fan setting mode and use the previously saved

parameters and ignore any new settings.

9

Page 10

OPERATING INSTRUCTIONS

WOOD-BURNING

The ECONOBURNTM Wood-Fired Boiler will burn most solid wood fuels; however, it is recommended

that hardwoods be used for their superior energy content. Burning dry, seasoned wood is also

recommended because a residual moisture content of between 15 and 25% is required for optimal

gasification combustion. The use of dry, seasoned wood will also significantly reduce the

accumulation of creosote in the combustion chamber and heat exchanger.

Use firewood that is that is the appropriate length for your firebox, as referenced in the technical data

sheet. Longer firewood will cause “bridging” which will prevent the wood from falling to the bottom of

the burn chamber and could cause gasification to cease. Do not use excessive amounts of wood that

is cut into tiny pieces. This can generate an intense coal bed that could overheat your Boiler. If you

have small scraps to bum, mix them with regular chunk wood. Do not burn driftwood, wood chips,

manufactured logs, sawdust or pellets.

Do not use chemicals or fluids to start the fire or during operation.

The ECONOBURNTM Wood-Fired Boiler is designed to burn wood, as detailed herein. Do not burn

garbage, gasoline, naphtha, engine oil, plastic or any item with glue or chemicals.

DO NOT BURN DRIFTWOOD, WOOD CHIPS, MANUFACTURED LOGS, SAWDUST OR PELLETS.

DO NOT BURN GARBAGE, GASOLINE, NAPHTHA OR ENGINE OIL.

If you are having problems with heat outputs, check the moisture content of your wood. Firewood

moisture meters are available on the Internet for minimal cost (typically less than $30) and can save

you a lot of time and energy spent trouble-shooting an easy-to-remedy problem. We cannot overstate

the effect that wood moisture content has on the overall performance of your Boiler.

For maximum efficiency when operating without thermal storage, keep an adequate coal bed

established in the upper chamber while adding only a few pieces of wood at a time to maintain the

desired Boiler temperature. This works well when you're at home and can reduce the overall amount

of wood that is used.

If you wait until the fire has burned to coals before refilling the upper firebox, you will have less chance

of smoke rollback into the Boiler room than if a partial load of wood is still burning inside.

Keep the firebox door tightly closed and check the door seal condition regularly. The 10.3-ounce tube

of high-temperature silicone provided with the Boiler should be used to maintain the integrity the seals

of the pressurized chambers. When applying silicon, use a caulking gun. Squeeze the silicone into the

track (i.e., the indentation on the door seal). A 3/16-inch diameter bead will work best, or approximately

half the diameter of a pencil.

10

Page 11

STORAGE OF WOOD

Do not store wood within installation clearances or within the space required for charging or ash

removal.

INSPECTION & CLEANING

During daily wood fuel loading, stoking of the wood in the upper chamber (also referred to as the

“firebox chamber”) should cause most ash to fall through the nozzle to the bottom chamber (also

referred to as the “lower combustion chamber”). Any dead ash that has not fallen through the nozzle

should be removed from the upper chamber. Ash acts as an insulator and will retard performance.

Check the bottom chamber weekly for ash buildup until experience shows how often cleaning is

necessary. Be aware that hotter fires yield greater boiler performance, higher efficiency, and

reduced maintenance. It is recommended that horizontal flue runs be inspected mid-season for

any accumulated ash that may have been entrained in the combustion stream and settled-out in

the flue runs.

THE FLUE DRAFT CONTROL SYSTEM

The ECONOBURNTM Wood-Fired Boiler has been designed so that the firebox door latch remains

locked, preventing the firebox door from opening unless the flue draft handle (see Figure 1) is first

pushed inward as far as it will go toward the rear of the unit. This opens the bypass damper. Opening

this bypass damper depressurizes the upper burn chamber and forces the smoke and flue gasses

directly up the chimney, thereby preventing a surge of smoke and/or flames toward the operator when

the firebox door is opened.

The forced draft fan must be stopped (via the toggle switch on the blower box; see Figure 10) and the

rear damper fully opened for at least one minute before opening the firebox door to refuel.

DO NOT RUN THE BOILER WITH THE FLUE DAMPER IN THE OPEN POSITION.

Running with the damper in the open position will damage the water jacket.

WARNING

NEVER OPEN EITHER DOOR ON THE UNIT (EITHER THE UPPER FIREBOX DOOR OR THE

LOWER COMBUSTION CHAMBER DOOR) WHEN THE BOILER IS IN OPERATION WITHOUT (1)

OPENING THE REAR DAMPER BY PUSHING THE FLUE DRAFT HANDLE ALL THE WAY

TOWARD THE BACK OF THE UNIT, (2) TURNING THE FORCED DRAFT FAN OFF, AND (3)

WAITING A MINIMUM OF ONE MINUTE.

11

Page 12

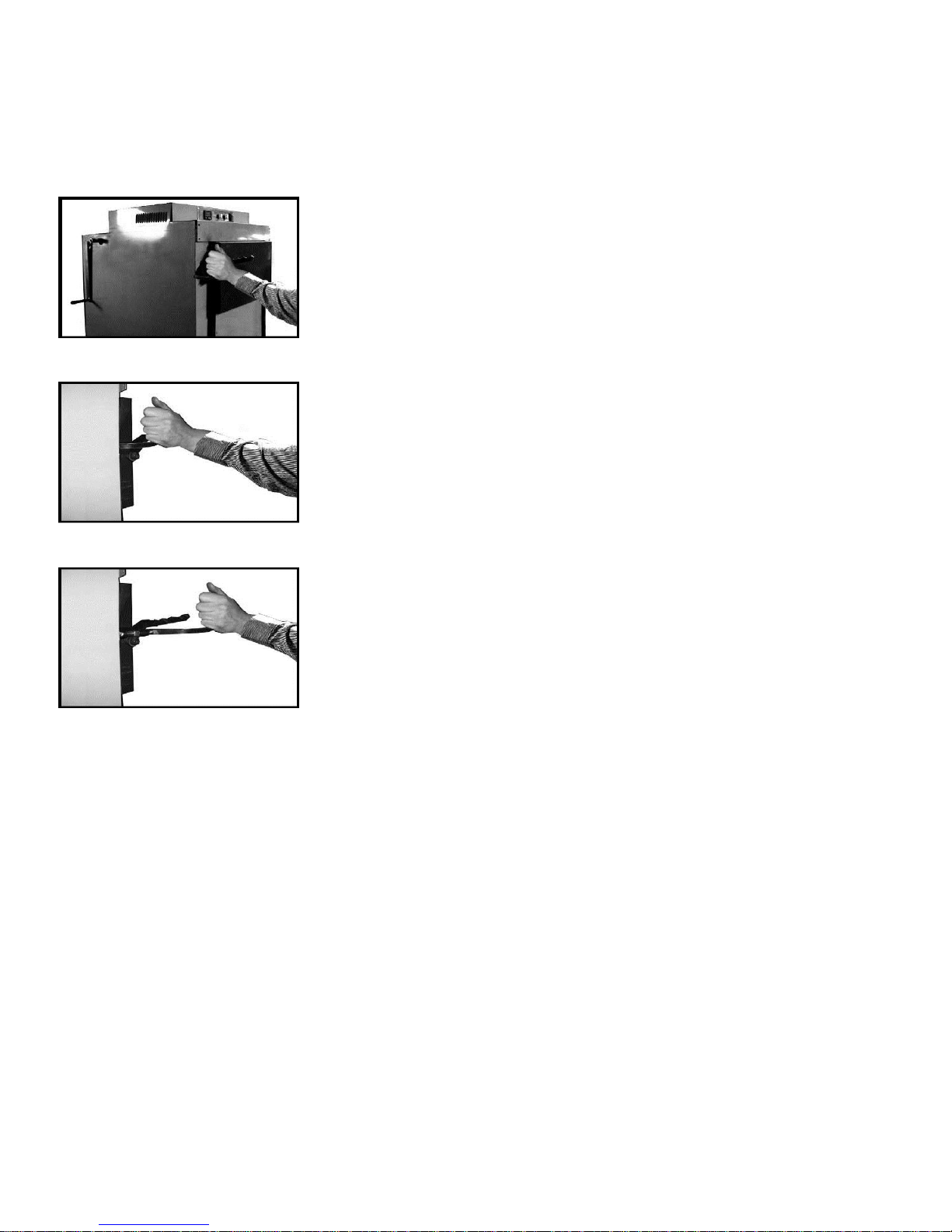

Figure A

FUEL LOADING

1. Open the Boiler’s bypass damper by pushing the flue

draft handle as far to the rear of the unit as it will go.

(See Figure A.)

2. Turn off the forced draft fan at the blower cover.

(Toggle switch.)

3. Wait a minimum of one minute.

4. SLOWLY open the firebox door. (See Figure B)

5. Load fuel into the firebox. Although your

ECONOBURNTM Wood-Fired Boiler is very ruggedly

built, do not throw wood into the firebox haphazardly

as you may chip the gasification nozzle.

6. Close the firebox door.

7. Close the bypass damper by pulling the flue draft

handle all the way forward. This will engage the

mechanical safety lock. (See Figure C.)

8. Turn the forced draft fan on once again at the blower

cover. (Toggle switch.)

Figure B

Figure C

To load your ECONOBURNTM Wood-Fired Boiler with fuel (wood), ALWAYS use the following

procedure:

WARNING

THE FORCED DRAFT FAN MUST BE STOPPED AND THE FLUE BYPASS DAMPER FULLY

OPENED FOR AT LEAST ONE MINUTE BEFORE OPENING THE FIREBOX DOOR TO REFUEL.

THIS IS NECESSARY TO ENSURE THAT SMOKE AND FLAMES FROM THE FIRE WILL NOT EXIT

THE FIREBOX DOOR AND HARM THE OPERATOR.

NEVER OPEN EITHER DOOR ON THE UNIT (THE UPPER FIREBOX DOOR OR THE LOWER

COMBUSTION CHAMBER DOOR) WHEN THE BOILER IS IN OPERATION WITHOUT FIRST

OPENING THE FLUE DAMPER HANDLE AND WAITING A MINIMUM OF ONE MINUTE.

12

Page 13

BOILER CONTROL

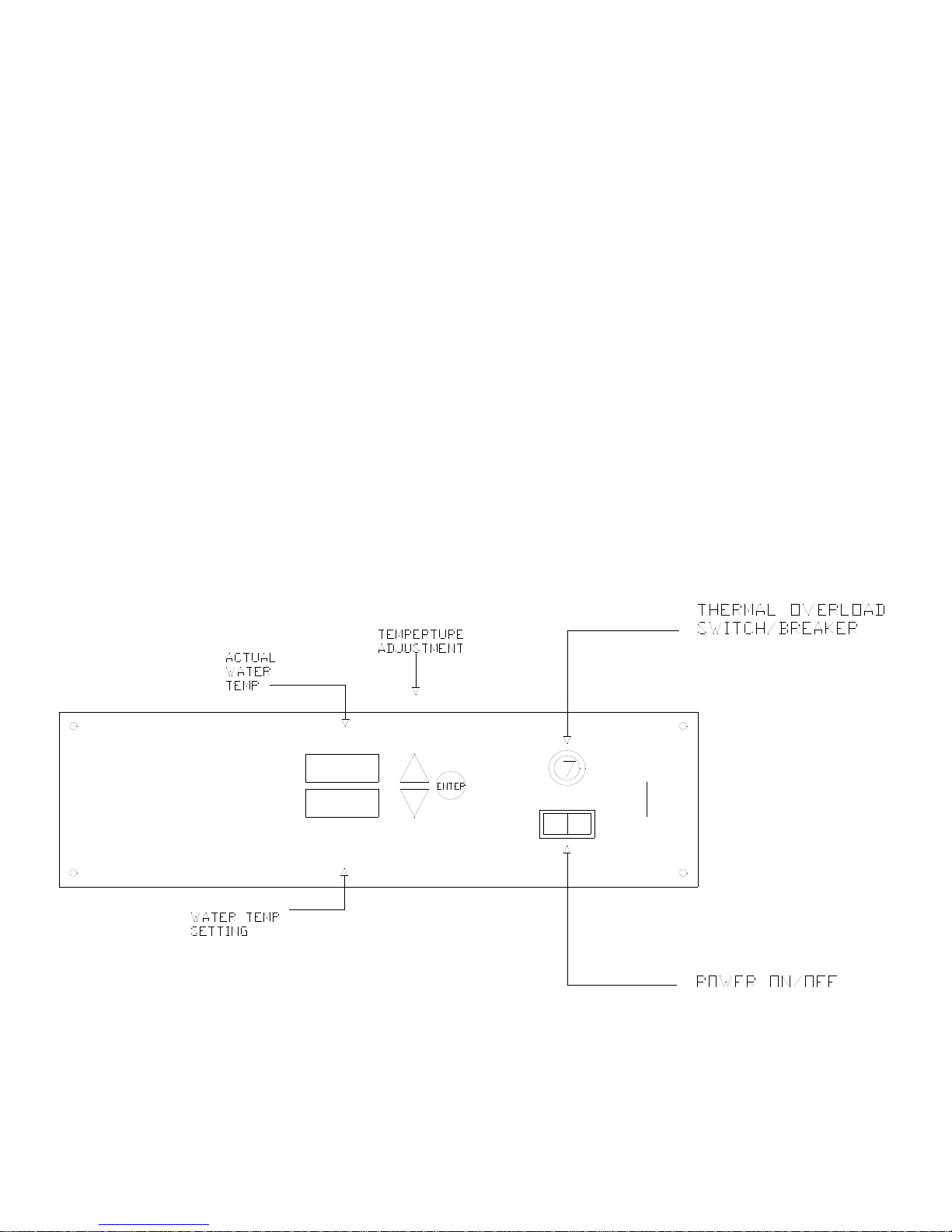

FIGURE 10 – CONTROL PANEL

The Control Panel (see Figure10 below) includes an LED display which is set at the temperature

desired for the temperature of the water of the Boiler. An immersed temperature sensor is installed

at the top of the Boiler to monitor the water temperature. The factory default temperature is set at

160 degrees Fahrenheit.

When the temperature of the water is less than the desired set point, the forced draft fan is raised to

maximum RPM, forcing air into the upper combustion chamber and nozzle. This creates the highly

efficient gasification process. The fan remains on as long as the water temperature is below the

desired water temperature.

Packed with the ECONOBURNTM Wood-Fired Boiler is a pump which would be used in the near

boiler circulating loop. (See Diagram C - Plumbing Connections - Page 25) This pump circulates the

water (from a cold-start) in a short loop around and within the Boiler to rapidly heat the water in the

Boiler and more rapidly raise the temperature of the refractory to ensure optimum performance, and

prevent thermal shock. This pump is activated when the Boiler is turned on and shuts off at 150°F, at

which point another pump may send heated water to the distribution system.

13

Page 14

The Controller display is made up of two temperature indicators.

The top numerical indicator is the actual temperature of the water in the Boiler.

The lower numerical indicator displays the desired Boiler water temperature setting. This is controlled

by the increment-decrement buttons on the right side of the display; it will change in 5 degree

increments.

The overheat audible alarm will sound and the control panel display will flash when the unit exceeds

200 degrees Fahrenheit. At the same time a relay will energize for the over temp zone.

The thermo overload/7 amp circuit breaker protects the Control Panel from any electrical shorts or

power surges in excess of 7 amps with any external electrical devices wired through the rear of the

Boiler. This could include the primary or circulating pump, or an overheat valve/pump if installed, and

connected to the electrical box at the rear of the boiler.

In the event of the breaker tripping, the switch will pop outwards. Simply press the switch back into

place to reset the breaker.

WARNING

DO NOT ADD MORE FUEL UNTIL YOU ARE CERTAIN THAT ALL CONTROLS ARE FUNCTIONING

PROPERLY AND NO DAMAGE HAS BEEN DONE TO THE BOILER.

FIRING YOUR BOILER

When first firing the Boiler, use dry kindling and leave the bypass damper open for approximately 15 to

20 minutes. This will allow time to establish the coal bed above the refractory nozzle, which will in turn

yield the most efficient gasification. You will likely find your own routine for firing your Boiler, but this

method works well.

We do not recommend leaving the Boiler off and the bottom door open to get your fire going faster. In

the event that you leave the Boiler and forget to close the door, the fire will grow to the point that the

Boiler overheats and produces steam.

As a starting point, set the temperature controller approximately 10 to 15 degrees below the

temperature you would like your system to operate. Unlike gas or oil fired boilers, when the

ECONOBURNTM Wood-Fired Boiler goes into stand-by mode, its temperature will continue to rise until

the lack of combustion air slows the fire enough to stabilize the water temperature. This setting will

vary from system to system and will be dependent upon the size of your Boiler, the amount of water in

the system, the time of year, and the heat load on the Boiler.

COMBUSTION AIR SUPPLY & NEGATIVE AIR PRESSURE

An adequate flow of air to the Boiler must exist at the location where the Boiler is to be installed in

order to ensure proper combustion and to maintain safe ambient room temperatures. For Boilers

located in a confined space, or in an unconfined space in a building or structure of unusually airtight

construction, outdoor air must be provided.

14

Page 15

Prior to installation of your Boiler, the installer MUST test for negative air pressure at the location

where the ECONOBURNTM Wood-Fired Boiler is to be installed. If needed, outdoor air may be

provided by the creation of two (2) permanent openings which communicate directly or by duct with the

outdoors. Any air openings, if needed, must be constructed at the time of installation by the installation

professional.

WARNING: If the ECONOBURNTM Wood-Fired Boiler does not draw air steadily, the Boiler may

experience smoke roll-out, burn poorly, or back-drafts might occur, whether or not there is combustion

occurring.

NOTE: Outside combustion air supply may be necessary if fans are installed in the same room where

the Boiler is to be installed, or if the house is equipped with a well-sealed vapor barrier and tight-fitting

windows, and/or has any powered devices that exhaust house air. Excessive condensation on

windows in the winter is also an indication that negative air pressure may exist in the structure.

Negative air pressure is also likely to exist where a ventilation system has been installed in the

structure.

CLEANING CREOSOTE BUILD-UP

Creosote is a flammable and corrosive substance that can build up on the walls of your fireplace and

chimney. Creosote is formed when unburned wood particles, fly ash and other volatile gases combine

as they exit the chimney. If there’s a poor draft, these unburned particles and gases can condense

and build up on the walls of your chimney. Over time, these creosote or soot buildups can become a

danger as they can potentially result in a chimney fire.

The failure to clean and remove any existing creosote build-up could result in chimney fire, property

damage and/or personal injury. Your installation contractor should inspect the chimney for creosote

build-up before beginning installation of your Boiler. If creosote exists in the chimney, it MUST be

cleaned by a professional (e.g., chimney sweep) prior to installation of the ECONOBURNTM WoodFired Boiler.

WARNING

THE CHIMNEY MUST BE CLEANED AND FREE OF ALL CREOSOTE PRIOR TO INSTALLATION

AND OPERATION OF THE ECONOBURNTM WOOF-FIRED BOILER. THE FAILURE TO CLEAN

AND REMOVE ANY EXISTING CREOSOTE BUILD-UP COULD RESULT IN CHIMNEY FIRE,

PROPERTY DAMAGE AND/OR PERSONAL INJURY.

15

Page 16

BUILDING A NONCOMBUSTIBLE BASE AND/OR AN ELEVATED BASE

If the Boiler installation site has a combustible floor, a noncombustible floor MUST be constructed by a

professional contractor, as described in detail in the Installation Manual enclosed herewith.

For basement installation, if the existing floor is not level or if water might accumulate on the floor

around the Boiler, an elevated noncombustible base (such as a concrete pad) must be constructed for

your Boiler.

GENERAL SAFETY TIPS FOR BOILER OPERATION

Never refuel the boiler during a power failure. If a prolonged power failure occurs do not fire the unit

until the power supply resumes and stabilizes.

Never attempt to operate the boiler with natural draft by opening the flue gate.

During a power failure, do not refuel the Boiler, if refueled during a power failure it is possible for the

boiler to overheat causing damage to piping, and to the Boiler. Do not open the doors or damper. This

will stop the amount of oxygen to enter the burn chambers. It is recommended to let the gravity loop

handle the excess Btu’s or install a battery back-up to allow the pumps to circulate and dissipate the

excess heat.

TIPS FOR MAXIMIZING BOILER EFFICIENCY

Proper sizing and installation of your boiler by a qualified heating professional.

Burn clean hardwoods with a moisture content in the 15-25% range.

Ashes should be removed twice per week from the upper and lower chambers.

Add the proper amount of wood for the heat output required from the boiler. Short, hot, burns

yield the highest efficiency.

The integration of thermal storage will yield the highest efficiency and gain the most energy

from the wood.

It is advisable to install an auxiliary power supply to power the boiler during a power failure.

A gravity flow piping circuit should be installed.

BOILER OPERATING CHECKLIST

Keep area around your ECONOBURNTM Wood-Fired Boiler clean and clear of combustibles.

Use only wood. DO NOT burn any other combustible material, or liquid.

16

Page 17

Remove ashes as directed.

Watch for soot in flue pipe - clean regularly.

Be aware of danger due to over firing unit.

This unit is NOT suitable for automatic stoking.

Load the firebox chamber carefully.

Always observe the following minimum clearances to combustible materials:

Front 48”

Right side 18”

Left side and rear 24”

Flue pipe 18”

Floor must be non-combustible.

Maintain seals on firing door in good condition.

Establish a routine for storage of fuel, care of the appliance, and firing techniques.

DO NOT OPERATE WITH FUEL LOADING OR ASH REMOVAL DOORS OPEN. DO NOT STORE

FUEL OR OTHER COMBUSTIBLE MATERIAL WITHIN MARKED INSTALLATION CLEARANCES.

INSPECT AND CLEAN FLUES AND CHIMNEYS REGULARLY.

CAUTION - HOT SURFACES - KEEP CHILDREN AWAY! DO NOT TOUCH DURING OPERATION!

KEEP THE DOORS CLOSED AND MAINTAIN SEALS IN GOOD CONDITION.

OFF-SEASON MAINTENANCE BY A QUALIFIED PROFESIONAL..

CLEANING OF THE HEAT EXCHANGER, FLUE PIPE, CHIMNEY AND DRAFT INDUCER, IF

USED, IS ESPECIALLY IMPORTANT AT THE END OF THE HEATING SEASON TO MINIMIZE

CORROSION DURING THE SUMMER MONTHS CAUSED BY ACCUMULATED ASH.

INSTALLER INSTRUCTIONS TO THE BOILER OWNER

1. Keep area around unit clean.

2. Use SOLID wood only. Hardwood is preferred.

17

Page 18

3. Load carefully. Plan wood load based on BTU requirement. Maintain intense burns for

maximum efficiency.

4. Remove ash regularly as directed.

5. Watch for soot build up in Flue pipe, and Heat Exchanger.

6. Realize the danger of extreme overheating due to over firing.

7. Danger of flue fire if poor maintenance produces creosote buildup.

8. Operation of unit during power failure, (i.e. manual operation of zone valves and flow check

valves).

9. When shutting down for extended periods, clean unit thoroughly.

10. BEFORE RELOADING THE BOILER WITH WOOD, DRAFT CONTROL FAN MUST BE

STOPPED, AND FLUE DAMPER FULLY OPENED FOR AT LEAST ONE MINUTE BEFORE

OPENING THE LOADING DOOR TO REFUEL.

This is necessary to ensure that smoke and flames from the fire will not exit the loading door and harm

the operator.

18

Page 19

Figure 11

Figure 12

MAINTENANCE AND CLEANING

The ECONOBURNTM Wood-Fired Boiler must be cleaned regularly to maintain top efficiency. A good

practice is to establish a routine for the storage of fuel, care of the appliance, and firing techniques.

BOILER MAINTENANCE

Turbulator assembly should be exercised every day of boiler usage when the unit is hot.

Ashes should be removed as needed. Recommend weekly.

Clean heat exchangers annually with a 2 inch bore brush or similar device.

Inspect refractory and nozzles every month to check condition.

Grease door hinges annually.

CLEANING THE HEAT EXCHANGER

Every day of boiler use, the turbulator assembly should be exercised. To perform this

maintenance, grasp the turbulator agitation lever on the upper left side of the Boiler (see Figures

11 & 12) and firmly raise and lower it several times. The turbulator arm will only move a short

distance (from the 6 o’clock to the 3 o’clock position) back and forth, and should be left as shown

in Figure 12, below.

When the turbulator agitation lever is moved back and forth, it clears the heat exchanger tubes of

any buildup of soot and ash that might have collected from the normal functioning of the Boiler

combustion.

19

Page 20

ALWAYS FOLLOW THIS PROCEDURE TO CLEAN THE

HEAT EXCHANGER.

1. Remove back and top jacket panels of the Boiler.

2. Cut insulation to expose top clean out.

3. Remove 1/4” steel top cover plate and rear flue plate.

4. Disconnect the turbulator rod by removing the nut and

bolt which affixes it to the turbulator shaft.

5. Remove the turbulator arms by grasping the turbulator

connecting rod and lifting them out of the heat exchanger.

6. Using a steel brush, remove any soot and ash buildup from

the heat exchanger tubes and vacuum any ash

accumulated on the top of the heat exchanger.

7. Remove ash from the lower combustion chamber.

8. Replace 1/4” steel top cover plate and rear flue plate

making sure all connections are tight, sealed with a high

temperature silicone.

ASH DISPOSAL

Figure 13

Figure 14

Before removing ashes, cease refueling and allow the fire to die down. Before opening the lower

combustion chamber door, ensure the fire in the boiler is completely extinguished.

Ashes should be placed in a metal container with a tight fitting lid. The closed container of ashes

should be placed on a non-combustible floor or on the ground, well away from all combustible

materials, pending final disposal. If the ashes are disposed of by burial in soil or otherwise locally

dispersed, they should be retained in the closed container until all cinders have thoroughly cooled.

WARNING

ASHES USUALLY CONTAIN LIVE DORMANT COALS, WHICH MAY BURN FOR MANY HOURS

AFTER A RECOGNIZABLE FLAME HAS DISAP¬PEARED. USE EXTREME CAUTION WHEN

HANDLING AND DISPOSING ASHES.

HEAT EXCHANGER MAINTENANCE

The boiler Heat Exchanger must be thoroughly cleaned at least once a year. This consists of cleaning the Heat Exchanger tubes of accumulated soot and ash with a wire brush (Figs. 13 & 14)

MAINTENANCE TIPS

20

Page 21

Make sure your chimney stays clean. Your ECONOBURNTM Wood-Fired Boiler will not produce the

creosote levels that other conventional woodstoves and boilers create, but if you're not using thermal

storage it's likely that some creosote will form. It's always better to be safe and inspect your chimney

once a year.

Keep an eye on your pressure gauge. If you see a drop in pressure over time, it could mean that there

is a leak in your system somewhere. Low water levels can prevent circulation and damage your

equipment.

Be sure to cycle your turbulator arm once every day, and only when the boiler is hot. This will keep

your boiler operating at peak efficiency. If the handle is stuck or difficult to move, DO NOT FORCE IT.

This could sheer the bolts off of the mechanism inside. Wait until the boiler has been in the gasification

mode for a while before attempting to move the lever, and gently work the turbulators free. If you are

consistently experiencing sticky turbulators, you are probably burning wood with a higher moisture

content than is recommended, or you need to work the turbulator arm more often.

Burning potatoes in the lower chamber can help free up sticky turbulators. Just place 2 or 3 decent

sized potatoes on the refractory below the gasification nozzle in the bottom chamber and operate the

boiler normally. In a few hours, depending how much your boiler gasifies, your sticky turbulators

should free up. Your best bet is to burn them over night.

Keep the ashes cleaned out of the combustion chamber, especially from in front of the heat exchanger

port at the rear of the chamber. We recommend that ashes be removed from this area around twice

per week in order to keep the efficiency of your Econoburn at maximum.

If ashes accumulate in the upper firebox, rake them through the gasification nozzle and into the lower

combustion chamber. A thick pile of ashes on top of the refractory in the base of the firebox will

insulate the coal bed from the refractory and reduce the gasification efficiency, or prevent gasification

altogether. We recommend letting your boiler burn down to just hot coals at least a few times per

month to facilitate this type of upper chamber cleaning.

For indoor installations, maintenance of the upper chamber door seal is imperative. Even a slight leak

in this gasket will be immediately noticeable by a creosote smell which some find objectionable in their

home. The best way we have found to prevent this is to brush the door gasket with mineral oil once per

week. The mineral oil keeps the gasket swollen and pliable so that it seals completely each time the

door is closed. Caution: mineral oil is flammable use discretion when applying.

CHIMNEY MAINTENANCE

Inspect monthly during heating season. For extra safety, have your chimney inspected by an

accredited professional yearly, prior to the heating season.

21

Page 22

PROBLEM

CAUSE

SUGGESTED REMEDY

Boiler doesn’t reach desired

temperature.

Wood too moist.

Use properly seasoned wood.

Nozzle plugged.

Clean firebox.

Chimney plugged.

Clean chimney.

Smoke escaping while

loading wood.

Intense wind or down draft.

Consider installing a

chimney cap.

Inadequate chimney length.

Add proper chimney length.

Negative building pressure.

Ensure adequate air for

combustion.

Improper draft.

Install barometric damper.

Smoke escaping from

closed boiler doors.

Leak in door gasket.

Adjust door hinges

per instructions.

Rope seal worn.

Replace rope or service call.

Fan not functioning.

Thermal protection engages.

Investigate reason for boiler

overheating.

No power to unit.

Check fuse, breaker

and wiring.

Fan damaged.

Call service department.

Fan blocked.

Inspect and clean unit.

Fan making excessive noise.

Bearings damaged.

Call service department.

Fan blades dirty.

Inspect and clean unit.

Debris in fan cover.

Inspect and clean unit

Control settings and

indicators off.

Not determined.

Call dealer or service

department.

TROUBLESHOOTING GUIDE

22

Page 23

Boller Model

EBW-150 EBW-200 EBW-

EBW-500 EBW-

Design Application

Indoor

Indoor

Indoor

200,000

Indoor

300,000

Indoor

Outdoor Outdoor

BTU Output

100,000

150,000

500,000

150,000

200,000

Boiler Dimensions

Depth

A

477 119.4cm

47"/ 119.4cm

477 119.4cm

I • II

507 127cm 63"/ 160cm

54.257137.8cm

54.257137.8cm

Width

B

267 66cm

267 66cm

307 76.2cm

367 91.4cm

41"/ 104.1cm

48.4" / 122.9cm

48.47 122.9cm

Height

C

63.757161.9cm

63.75"/161.9cm

64.25"/163.2cm

707 177.8cm

767 193cm

80"/ 203.2cm

80.5"/ 204.5cm

Weight Empty

1,670Lbs/708 kg

1,670 Lbs/708kg

1,980 Lbs/898 kg

2,515 Lbs/1,141kg

3,405 Lbs/1,544 kg

-1,800 Lbs/ 816 kg

-2,100 Lbs/953 kg

Firebox Dimensions

Depth

23"/ 58.4cm

237 58.4cm

23"/ 58.4cm

26"/ 66cm

32"/ 81.3cm

237 58.4cm

23"/ 58.4cm

Width

167 38.1cm

16"/ 38.1cm

21"/ 53.3cm

24"/ 61cm

27"/ 68.6cm

16"/ 40.6cm

21"/ 53.3cm

Height

287 71.1cm

287 71.1cm

297 73.7cm

32"/ 83.8cm

39"/ 99. 1cm

28"/ 71.1cm

297 73.7cm

Maximum Log length

21"/ 53.3cm

217 53.3cm

217 53.3cm

24"/ 83.8cm

33"/ 83.8cm

217 53.3cm

21"/ 53.3cm

Firebox Door Height

J

12"/ 30.5cm

12"/ 30.5cm

12"/ 30.5cm

12"/ 30.5cm

12"/ 30.5cm

12"/ 30.5cm

12"/ 30.5cm

Firebox Door Length

H

15.75"/ 38.1cm

15.75"/ 38.1cm

20.57 52.1cm

23.57 59.7cm

27.5"/ 69.9cm

15.75"/ 40cm

20.57 52.1cm

I Piping Data

Water Volume

37 Gal / 140 L

37 Gal / 140 L

42 Gal / 159 L

79 Gal / 299 L

95 Gal / 360 L

37 Gal / 140 L

42 Gal / 159 L

Supply Pipe (female connection)

D

2"

2"

2"

2.5"

4"

2"

2"

Return Pipe (female connection)

E

2"

2"

2"

2.5"

4"

2"

2"

Min Boiler Loop Size

1-W

1-W

1-W

2"

3"

1-1/4"

1-I/2"

Fill / D rain Valve Size

1-1/4"

1-1/4"

1-I/2"

1-1/2"

1-V2"

1-1/4"

1-1/2"

- -

[ Flue Dimensions

Flue Outlet Diameter

F

8"

8"

8"

8"

12"

8"

8"

Height to Center of Flue

G

50.75"

50.75"

51.25"

57"

61.5"

50.75"

51.25"

Operating Data

Max Operating Temperature

210°F/ 99 °C

Max Operating Pressure

30 PSI / 207 kPa

Output Temperature (raw

170°F - 200°F / 77°C - 9 3°C

Specified Fuel

Wood (recommended moisture content: 15-22%)

Minimum Draft Required

-0.02 to -0.06 inch WC/ -0.005 kPa to -0.015 kPa

SPECIFICATIONS

ECONOBURNTM Specifications (subject to change without notice):

Specifications

23

Page 24

Flue Gas Temperature

280°F - 400°F / 138°C - 204°C

E l e c t r i c a l D a t a

Boiler Power Requirement

110 volt, 15 amp

175

Electrical Consumption (watts)

100

175

175 175

200

175

Aquastat Overheat Setting

220°F/ 104°C

Electrical Consumption

< 5 amps

24

Page 25

ECONOBURNTM BOILER WARRANTY

WARRANTY PERIOD

The warranty period for the main boiler is 25 years against defects in workmanship. Any purchased

components will carry such warranty as covered by the particular vendor.

CONDITIONS OF WARRANTY

Your ECONOBURNTM boiler must be installed by a qualified, and licensed Plumbing and Heating

professional. Any other method of installation will void this warranty.

User must have, and retain written proof of, an annual boiler inspection performed by a qualified

boiler inspector.

WARRANTY

This warranty covers normal consumer use. It does not cover damages incurred in shipment or that

result from alteration, accident, misuse, abuse, neglect or commercial use.

We warrant each ECONOBURNTM boiler to be free from defects in material and workmanship under

normal use and service; our obligation under this warranty being limited to making good, at our factory,

any part or parts which shall as defined below, after installation by the original purchaser, be returned

to us with transportation charges prepaid and which our examination shall disclose to our satisfaction

to have been defective, this warranty being expressly in lieu of all other warranties express or implied,

including the implied warranties of fitness and merchantability, and of all other obligations or liabilities

on our part, and we neither assume nor authorize any other person to assume for us any other liability

in connection with the sale of our boiler.

This warranty shall not apply to any ECONOBURNTM boiler which has been repaired or altered

outside of our factory or in any way so as, in our judgment, to affect stability or reliability, nor which

has been subject to misuse, negligence or accident, nor to any boiler made by us which shall not

have been operated in accordance with our printed instructions or beyond the factory rated capacity.

Econoburn shall not in any event be liable for any consequences, damages, secondary charges,

expenses of erecting or disconnecting, losses or damages resulting from alleged defects to the

apparatus. We make no warranty whatsoever with respect to pressure regulators, piping, or other

equipment or accessories which are warranted by their respective manufacturers.

This warranty shall not apply to any ECONOBURNTM boilers, or any parts of them, which have been

repaired or altered, without company’s written consent, outside company’s factory or altered in any

way so as, in the judgment of company, to affect adversely the stability or reliability of the machine, or

which have been subject to misuse, negligence, or accident, or have not been operated in accordance

with company’s printed instructions or have been operated under conditions more severe than, or

otherwise exceeding, those set forth in the specifications for such machine.

25

Loading...

Loading...