Page 1

Page1of86Pages

ECON

Operator Panels

Operation manual

Control Solutions Group

'Simple solutions to difficult problems'

Page 2

Page2of86Pages

OP series display

Catalog

Chapter 1 Summary of the

products

................................

..............

4

1-1 Function

................................

................................

................................

...................

41-

2 General specification

................................

................................

................................

51-

3 Product

types

................................

................................

................................

............

61-

4 Each part’s name

................................

................................

................................

......71-4-1 OP320/OP320

-S................................

................................

...........................

71-4-

2 OP320

-A/OP320

-A-S................................

................................

.................

101-

5 Interface definition and connection

diagram

................................

.....................

141-5-

1 OP320

................................

................................

................................

.........

141-5-

2 OP320

-S................................

................................

................................

......151-5-3 OP320

-A................................

................................

................................

.....161-5-4 OP320

-A-S................................

................................

................................

.171-6 Sizes and installing methods

................................

................................

..................

19

Chapter 2 Editor Software OP20

................................

.................

21

2-1 Basic summary of OP20

................................

................................

........................

212-1-

1 About the project and the screen

................................

................................

.212-1-2 The content of screen

................................

................................

..................

212-1-

3 The use flow of OP2

0

................................

................................

.................

222-

2 Edit the user’s screen

................................

................................

.............................

232-2-

1 Create a project

................................

................................

...........................

232-2-2Make a basic screen

................................

................................

....................

252-2-

3 The system parameter of OP20

................................

................................

...262-2-4 Text

................................

................................

................................

.............

262-2-

5 Function key (screen jump)

................................

................................

........282-2-6 Data display window

................................

................................

..................

332-2-

7 Data set window

................................

................................

.........................

372-2-8Status

lamps

................................

................................

................................

392-2-

9 Function key (switch quantity operation)

................................

...................

452-2-10Trend

diagram

................................

................................

............................

462-2-

11 Bar

diagram

................................

................................

..........................

472-2-12diagram

display

................................

................................

.....................

482-2-

13 Dynamic mess

ages

................................

................................

....................

492-2-

14 Alarm list

................................

................................

................................

..522-3 Save a project

................................

................................

................................

.........

542-

4 Download the

screen

................................

................................

..............................

54

Page 3

Page3of86Pages

Chapter 3 Operation methods of OP320

................................

.....

56

3-1 Online communication

................................

................................

...........................

563-

2 Shift the screen

................................

................................

................................

.......563-3 System’s password

................................

................................

................................

.573-4 Modify the data

................................

................................

................................

......

59

3-5 Switch value operating

................................

.........................

59

Chapter 4 New addition function of OP520

................................

................................

....604-1-2 Screen jump function

................................

................................

.............................

624-1-

3 Advanced function

................................

................................

................................

.634-2 Status

status

lamp

................................

................................

................................

......644-3 Application examples of g

lobal function key and button

status

lamp

...............

654-

4 inside clock (optional)

................................

................................

...............................

67

Chapter 5 Application examples of OP520

................................

..

68

5-1

Make a screen

................................

................................

................................

...........

70

Chapter 6 OP320

-

S, OP320

-A................................

......................

71

OP320

-S................................

..............

Error! Bookmark not defined.

93

OP320

-

A/OP320

-A-S................................

................................

........

71

Chapter 7 PLC’s connection method

................................

...........

72

7-1 xinje FC series PLC

................................

................................

...............................

727-

2 Mitsubishi FX series PLC

................................

................................

......................

737-

3 Siemens S7

-

200 series PLC

................................

................................

...................

747-4Omron C series PLC

................................

................................

..............................

767-

5 Koyo S series PLC

................................

................................

................................

.777-6 Schneider NEZAseries PLC

................................

................................

..................

797-

7 DELTADVP series PLC

................................

................................

........................

807-

8 LG Master

-

K series PLC

................................

................................

........................

817-

9 Matsushita FP series PLC

................................

................................

......................

827-

10 FACON FB series PLC

................................

................................

........................

847-

11 Kenyence series PLC

................................

......

Error! Bookmark not defined.

105

Page 4

Page4of86Pages

Chapter 1

Summary of the products

1-1

Function

The

OP series

i

s a mini

human machine interface

The

OP320 display

ha

s the following:

The communication port is

RS232/RS422

Seven keys can be defined

as

function keys, and they can

substitute some

machine

keys on the control

tableLCD display with backlight

STN. It can

display 24 characters × 4 lines, i

The

OP320

-

S display

ha

s the

following

:

The communication port is

RS232/RS422

LCD display with backlight

STN. It can disp

lay 24 characters × 4 lines.

The

OP320

-

A display

has

the follow

ing

:

20 keys can be defined

as

fun

ction keys

(12ofthem can be defined

as

digital keys and

for other use

), and they can

substitute some machine buttons on the control table

C

omm

u

nication

format

, RS232/RS422

LCD display with backlight

STN. It can display 24 characters × 4 lines

.

TheOP320

-A-

S display

ha

s the follow

ing

:

T

he comm

u

nication

format

is

, RS232/RS422

The

OP520 display

ha

s the follow

ing

:42 film

button

s: 10

number

keys, 32 function keys,

in these function keys

16 can be

defined

with the card.

Page 5

Page5of86Pages

There are 16

button

lamps

on th

e panel, which can be used to

status

PLC’s status

The

comm

u

nication

format is

RS232/RS422/RS485

LCD display with backlight

STN.

The

resolution

is 320×240. It can display 40

characters × 15 lines

.

1-2

General specification

1.

Electric

al

specification

Inp

ut voltage

DC20V

~

DC28V

P

ower

consumption

Less than 4W(TYP2.0W)

M

omentary power

-

cut

Less than 20ms

Voltage

endurance

AC1000V

-

10MA

1

minute (between signal

and

earth)Insulation resistance

DC500V

-

about 10M

Ω

(between signal and

earth)2.

E

nvironment

al

condition

s

Amb

ient

operatin

g

temperature

0~50℃,

with

no

condensate

Storage

temperature

-

20~60℃Environment

temperature

20-85%,

with

no

condensate

Vibration

Resistance

10-25Hz

(2G per 30min in X, Y, Z

direction

each

)

Interfere immunity

Voltage noise:1000Vp

-

p, pulse

w

idth

1μs,1

minAmbient a

tmosphere

With

no corrosive air

Protect

con

figuration

Fit the

IP65

Page 6

Page6of86Pages

1-3Product types

Product

s

classification

OP series

OP320

OP320

-SOP320

-AOP320

-A-SOP520

The number of

keys72042

Sizeofthe

screen

3.7”

5.7”

The

background

lamps

LED

CCFL

The

display

color

Monochrome

Communication

port

RS232/

RS422

RS232/

RS485

RS232/

RS422

RS232/

RS485

RS232/RS422/

RS485

Shape and size

163.5W×101.7H×50.4D

172W×94H×30D

284W×194H×50D

Page 7

Page7of86Pages

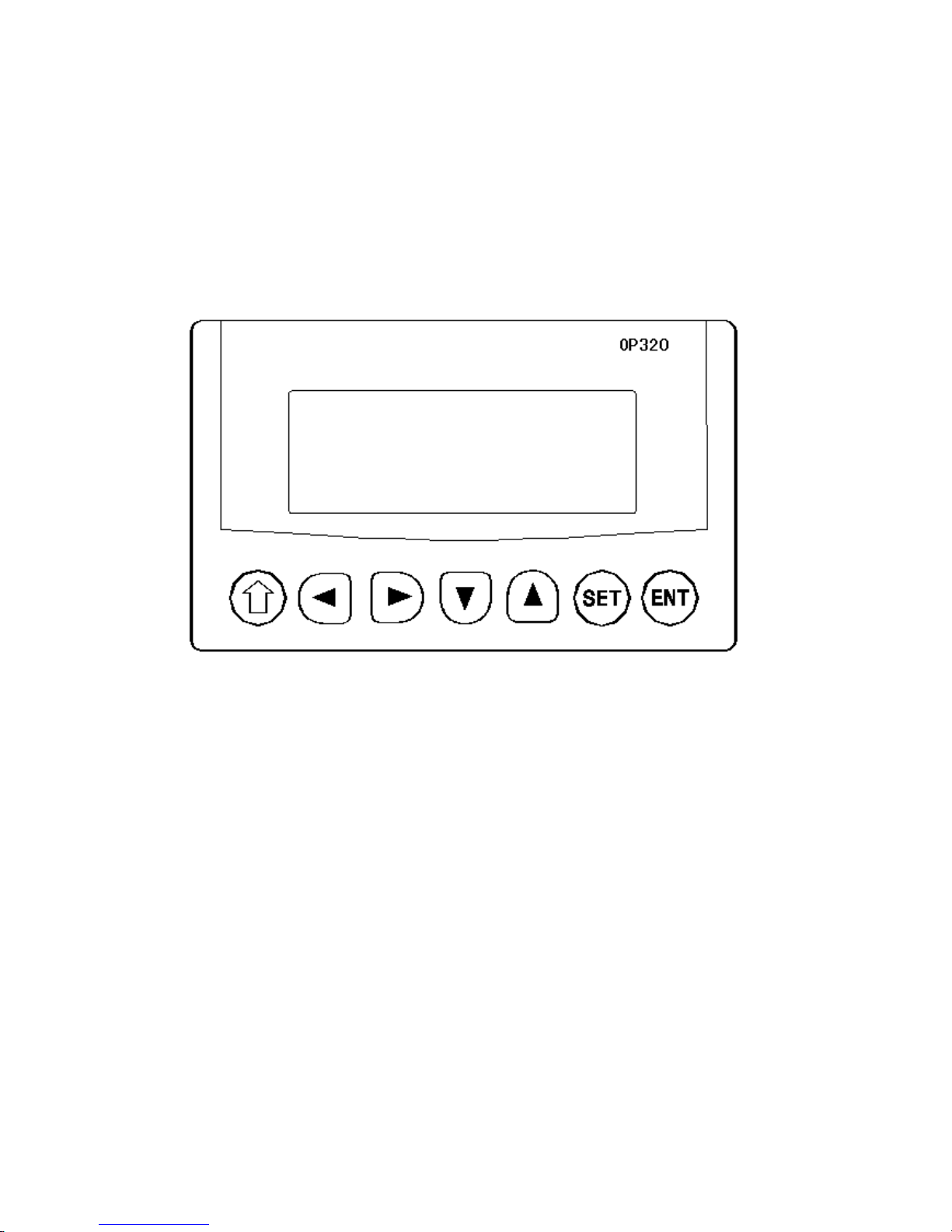

1-4Nam

ing

1-4-1 OP320/OP32

0-S

The

OP320(OP320

-

S),

has the

LCD display window,

and7user

buttons, The seven buttons

can be set to be special function keys,

sc

reen jump

oron-

off set and other function

s

.

Page 8

Page8of86Pages

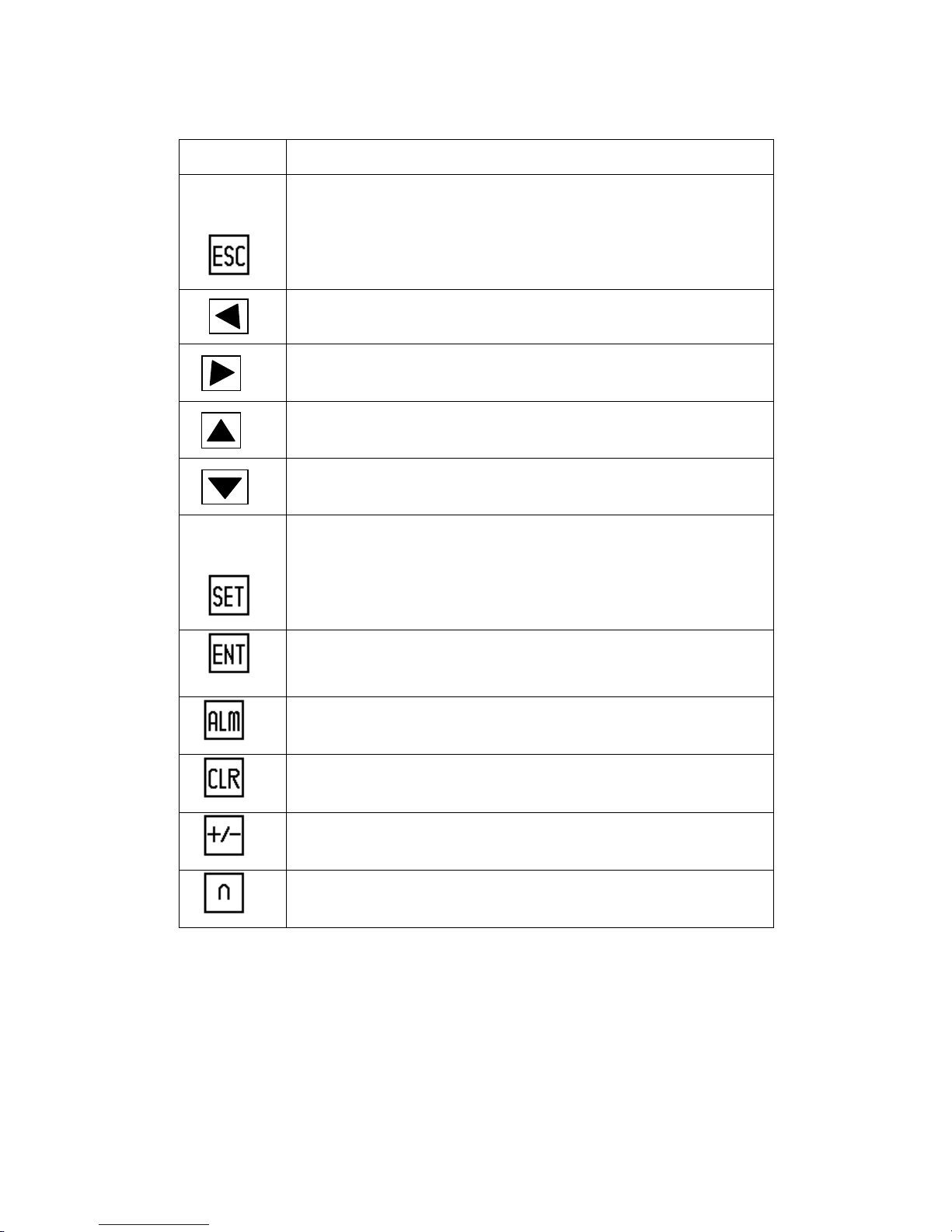

Button

Basic

function

(These keys are not used as func

tion keys)

[ ]

Normally set

s

the main menu or the screen which is used most often to be the

system

’

s initial screen.

[ ]

When modifying the register

’

s data, shift the modified data bit to the left

.

[ ]

When modifying the register

’

s data, shi

ft the modified data bit to the right

.

[ ]

Previous page button or i

fin the status of data setting

,

the modified data bit plus

1.[ ]

Next page button or i

fin the status of data setting

,

the modified data bit plus

-1.

[SET ]

Press this key to start modifying

a

register

’

s value

.

[ENT]

E

xit

changing

a

register

s value.

Page 9

Page9of86Pages

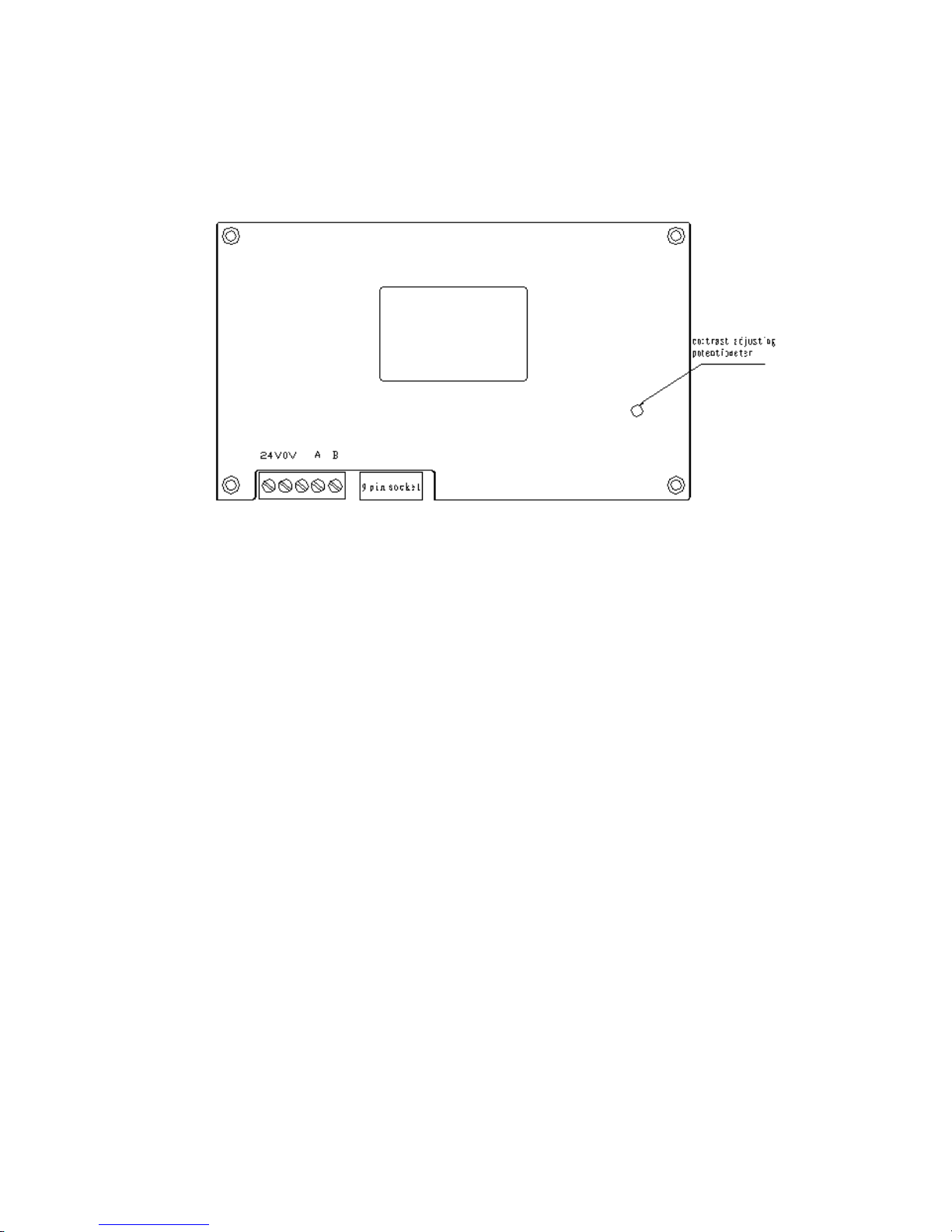

At

the back of OP320

(OP320

-

S), there

are

power

terminal

s

, communication

socket

and

contrast adjusting potentiometer.

OP320 display has back

light

auto turn

off if there

isnooperat

ion

for three minutes.

Page 10

Page10of86Pages

1-4-2 OP320

-

A/OP320

-A-

S

On the face of OP320

-

A (OP320

-A-

S), there is not only LCD display but also

20

button

s

for

user

special function.

R

efertoOP520

for detail button definition.

SET

ENT

ALM

ESC

CLR

+/ -

0

321654987

Page 11

Page11of86

Pages

Table of key

s’

basic f

unction:

Key

Basic

function

Escape to t

he system

’

s initial screen is appointed by the user when

designing the screen

It can also be used as a function key.

It is used as a function key.

It is used as a function key.

It is used as a function k

ey.

It is used as a function key.

Press this key to start modifying

a

register

’

s value

.

Write the modified data to the register and then continue to modify the next

data.Alarm list key

(When the key is not set as a function key)

.

When mod

ifying the register

’

s data

,

clear the

value

areaWhen modifying the register

’

s data

,

it

setsthe data positive or negative

bit.

Number key (0

-

9),in the status of number be

ing

set,the modified number

bit change

s

to the correspond key value

.

Page 12

Page12of86Pages

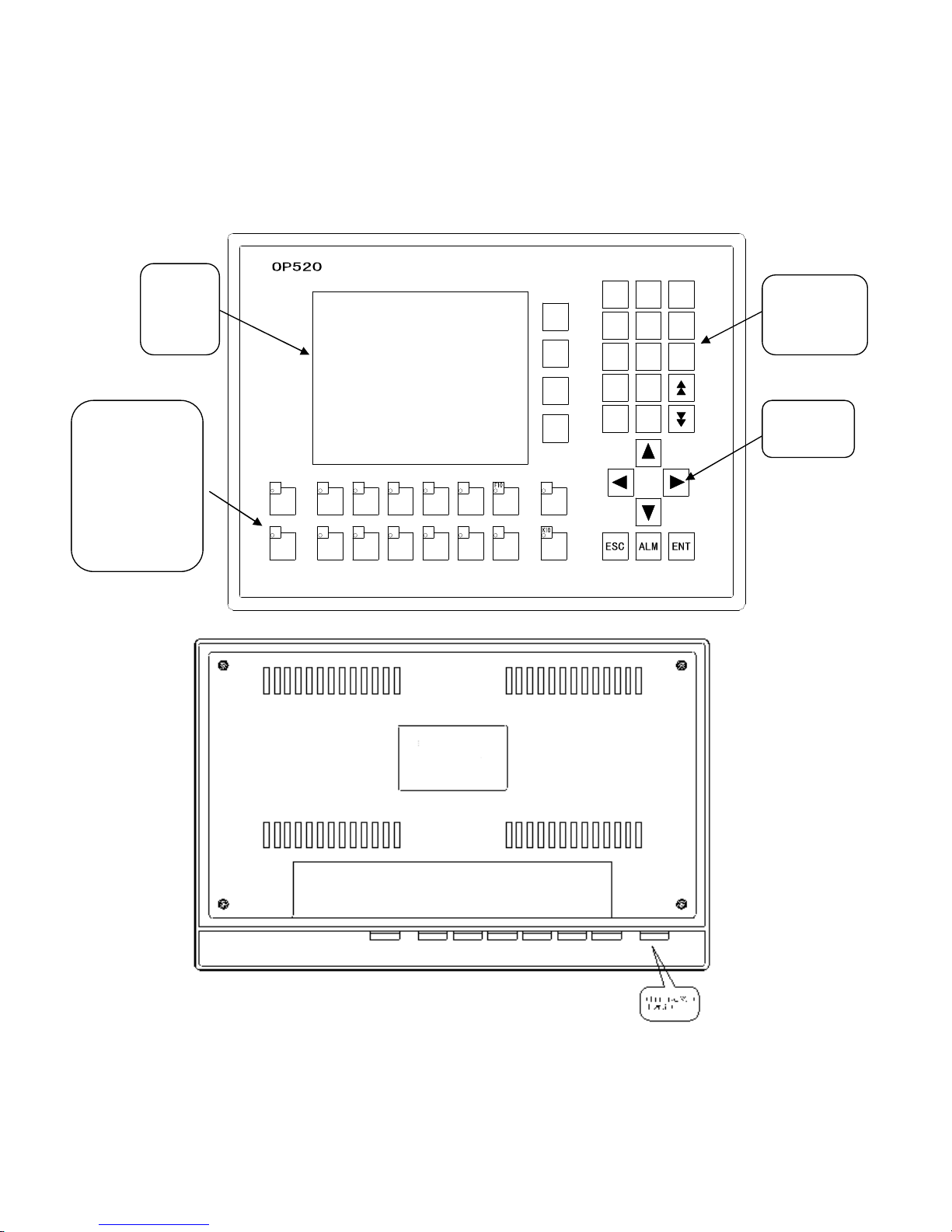

1-4-2

OP520

On the front of

OP520, there are not only LCD display window, but also 42 film

buttons

.

K3K1K5K4K6K8K7K9F6F5F7F8F9

SET

K2

F4F3F2

01CLR3+/ -

2F174685

9

LCD

display

area

Free define

multi

-

function

keys which can

extract and

insert card

(

16

in total

)

Number

keyboard

Direction

ke

y

Page 13

Page13of86Pages

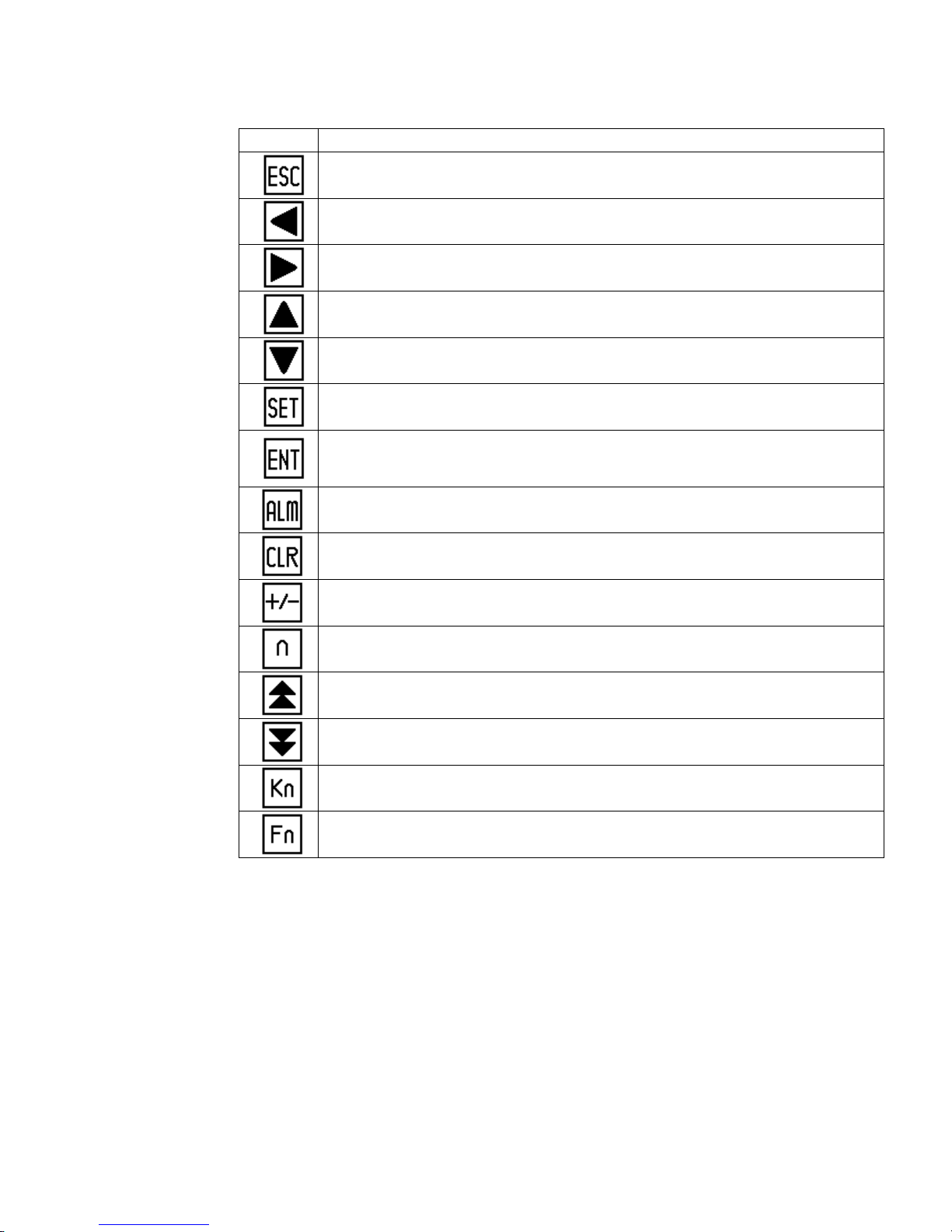

Button

’

s basic function table

Button

Basic function

Escape to t

he system

’

s initial screen is appointed by the use

r when designing the screen

It can also be used as a function key.

When modifying the register

’

s data, shift the modified data bit to the left

.

When modifying the register

’

s data, shift the modified data bit to the right

.The default value is the

current screen

’

s ID minus 1)

If setting

data,the modified data bit plus 1

T

he default value is the current screen

’

s ID plus 1)

If setting

data,the modified data bit minus 1

.

Press this key to start modifying

a

register

’

s value

.

Write the modified

data to the register and then continue to modify the next data

register

.

Alarm list key

,

after setting alarm list function

,

press this button to fast switch to the

alarm list screen

。

(When the key is not set as a function key)

When modifying the registe

r’s data

,

clear the

selected

area

When modifying the register

’

s data

,

it will

set the data positive or negative

Number key (0

-9).

Go to the previous data set register.

Go to the next data set register

Canbeusedasaglobal function key or no

rmal function key

Canbeusedasaglobal function key or normal function key

Page 14

Page14of86Pages

There are three communication

formats

for PORT2: RS232, RS422,

or

RS485. Connect

the

OP520

with any

series of PLC with the communication cabl

e, and you can

also

download using

the

same

communication

between

the

OP520

or the

PLC.

1-5 I

nterface definition and

connection

diagram

1-5-1 OP320

S

erial

pin

out for the

OP320

.

Pin ID

definition

1

TD+2RXD

3

TXD

45GND

6TD-78RD-9RD+OP-SYS-CAB connectin

g

diagram

Page 15

Page15of86Pages

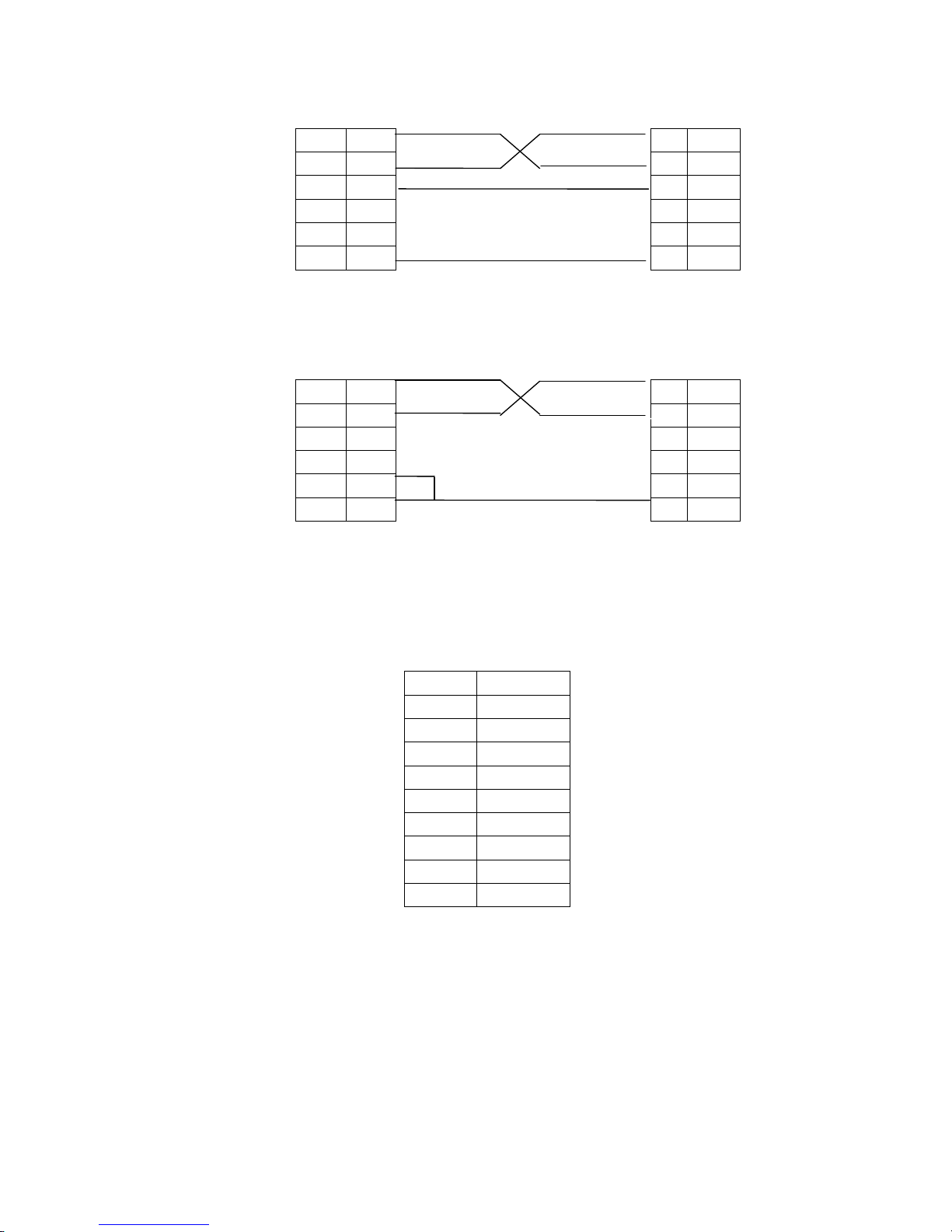

OP side

(

9PIN

plug)RXD22

RXD

TXD33

TXD77

CTS

GND55

GND

OP-SYS-CAB connectin

g

diagram

:

(

V4.0

):

OP side

(

9PIN

plug)computer side

(

9PIN

plug)RXD22

RXD

TXD33

TXD7CTS4GND55

GND

1-5-2 OP320

-

S

S

erial

port

pin’sdefinition ID

number

for the

OP320

-

S.

Pin ID

Definition

1

TD+2RXD3T

XD45

GND6TD-78B9A

Page 16

Page16of86Pages

OP-SYS-CAB connectin

g

diagram

:

OP side

(

9PIN

plug)

computer side

(

9PIN

plug)RXD22

RXD

TXD33

TXD77

CTS

GND55

GND

OP-SYS-CAB connectin

g

diagram

:

(

V4.0

):

OP side

(

9PIN

plug)computer side

(

9PIN

plug

)

RXD22

RXD

TXD33

TXD7CTS4GND55

GND

1-5-3 OP320

-

A

S

erial

port

pin’s definition ID

number of

the

OP320

-

A.

Pin ID

Definition

1

TD+2RXD3TXD45GND6TD-78RD-9

RD+

Page 17

Page17of86Pages

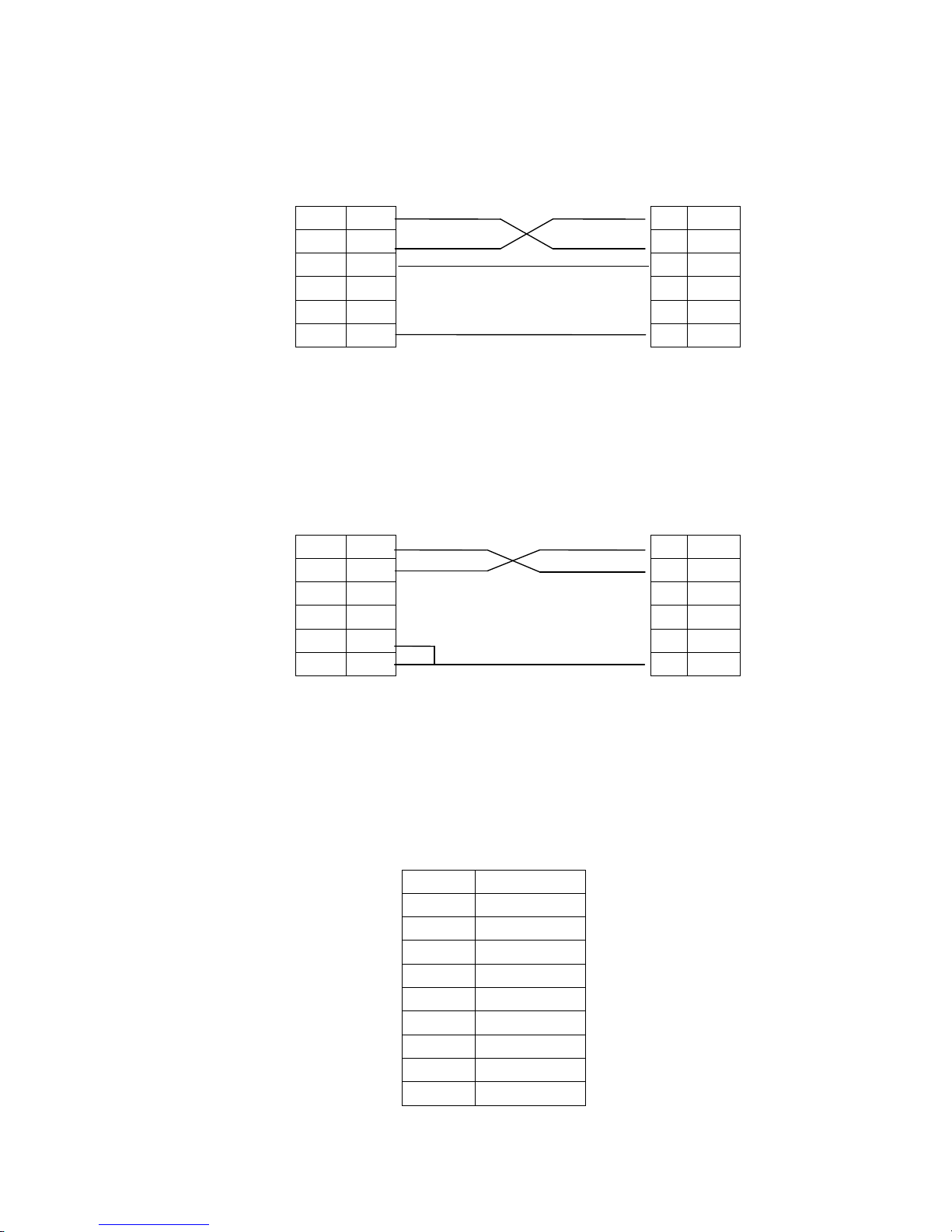

OP-SYS-CAB connectin

g

diagram

:

OP side

(

9PIN

plug)computer(9PIN

plug

)

OP-SYS-CAB connectin

g

diagram

:

(

V4.0

):

OP side

(

9PIN

plug)computer(9PIN

plug)RXD22

RXD

TXD33

TXD7CTS4GND55

GND

1-5-4 OP

320-A-S

S

erial pin’s definition ID

number of

OP320

-

A.

Pin ID

Definition

1

TD+2RXD3TXD45GND6TD-78B9A

RXD22

RXD

TXD33

TXD77CTS

GND55

GND

Page 18

Page18of86Pages

OP-SYS-CAB connectin

g

diagram

:

OP side

(

9PIN

plug)computer(9PIN

plug

)

OP-SYS-CAB connectin

g

diagram

:

(

V4.0

):

OP side

(

9PIN

plug)computer(9PIN

plug)RXD22

RXD

TXD33

TXD7CTS4GND55

GND

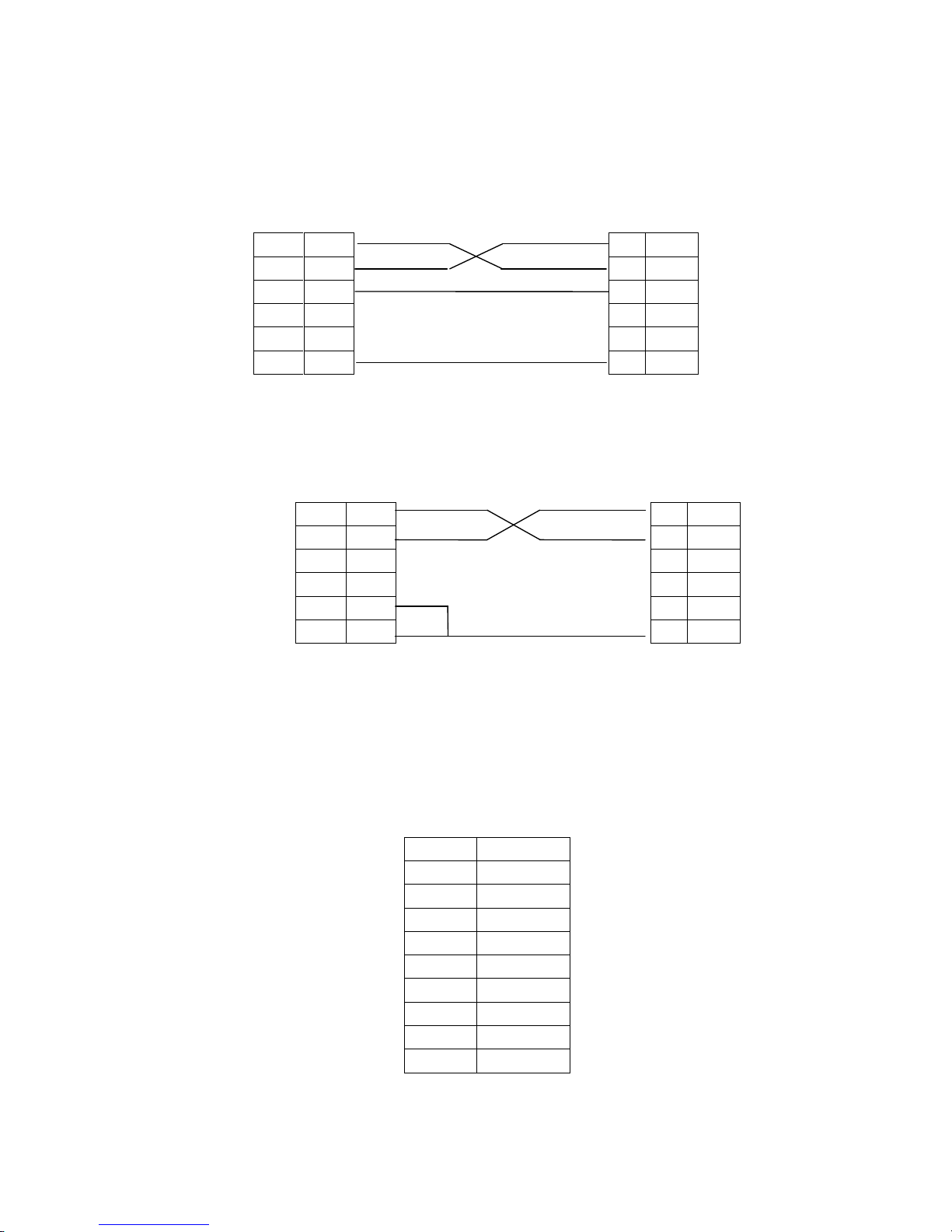

1-5-5 OP520

Serial port pin

’

s de

finition ID number of

the

OP520.

PORT1 (download port):

Pin’s ID

Definition

1NC2

RXD

3TXD4NC5GND

6NC7

RTC8NC9NC

RXD22

RXD

TXD33

TXD77

CTS

GND55

GND

Page 19

Page19of86Pages

PORT2 (communication port):

OP-SYS-CAB connecting

diagram

:

DP210

(

9PIN

female

)

Computer

(

9PIN

female

)

RXD

22RXD

TXD

33TXD

RTS77

CTS

GND

55GND

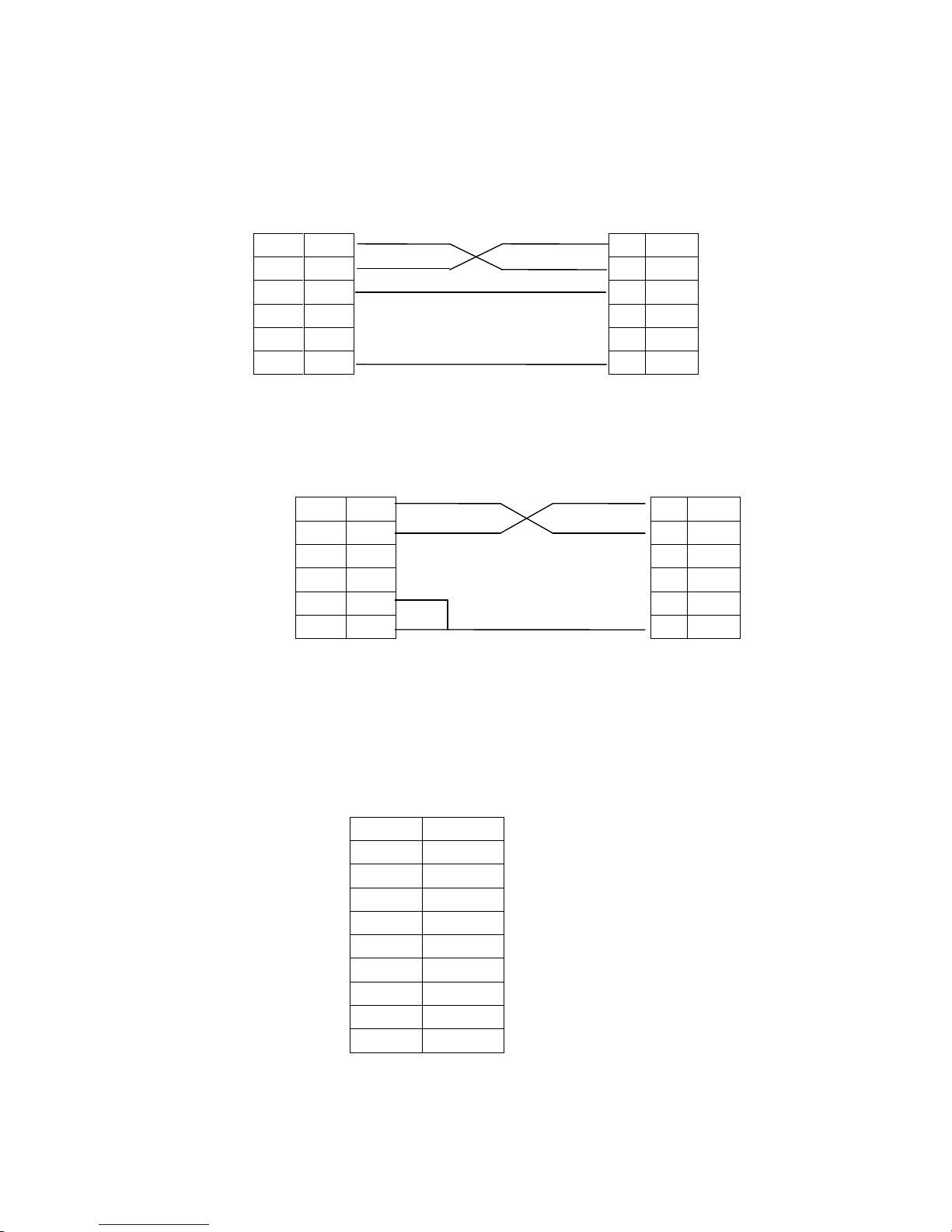

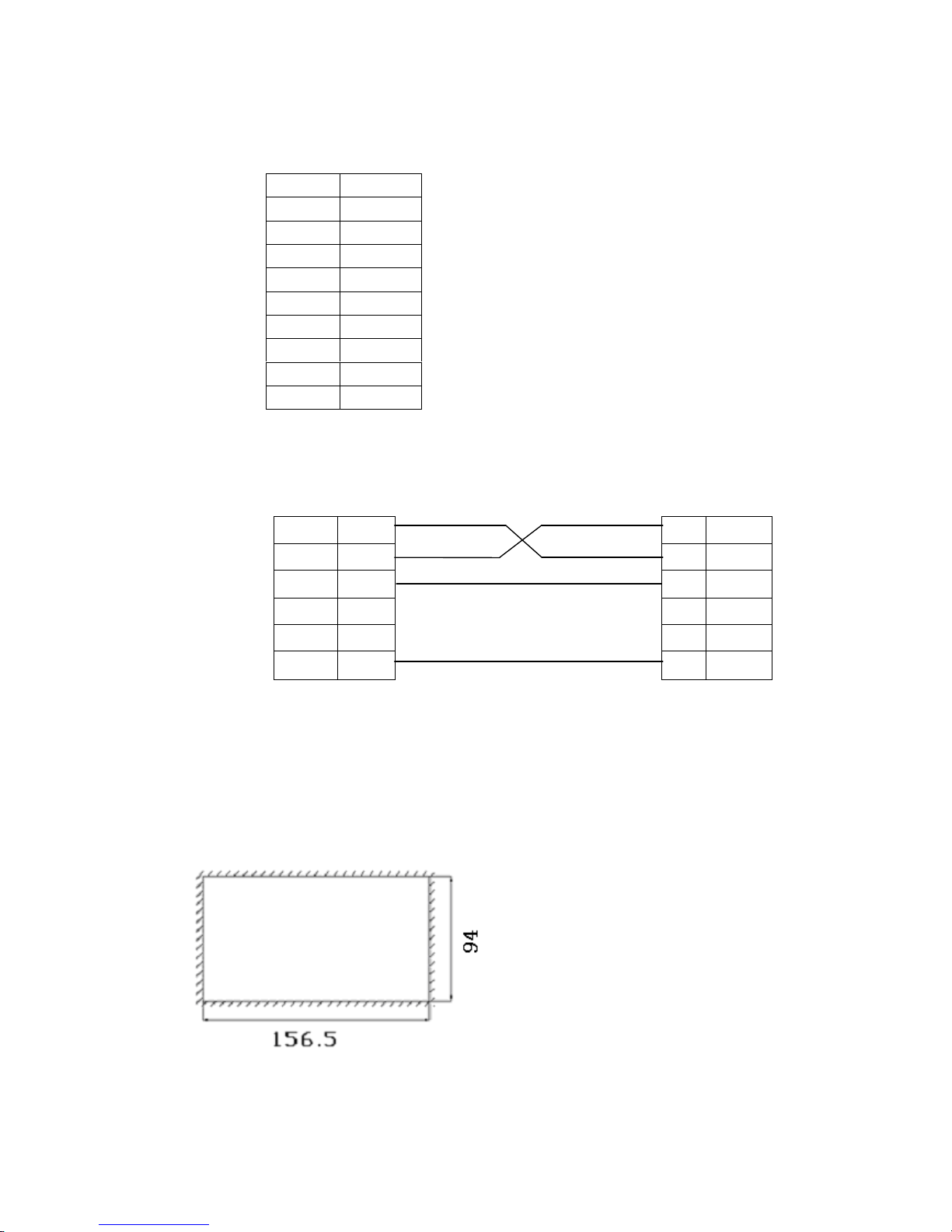

1-6Installing

methods

OP320

(OP320

-S)The product

’

s actual size

is

: 155.5×92.7×

50.4 (

in mm

)

The

cutout

sizeis:

156.5

×

94 (in mm)

Pin’s ID

Definition

1

TD+2RXD

3

TXD

4

Empty

5

GND

6TD-

7空8RD-9RD+

Page 20

Page20of86Pages

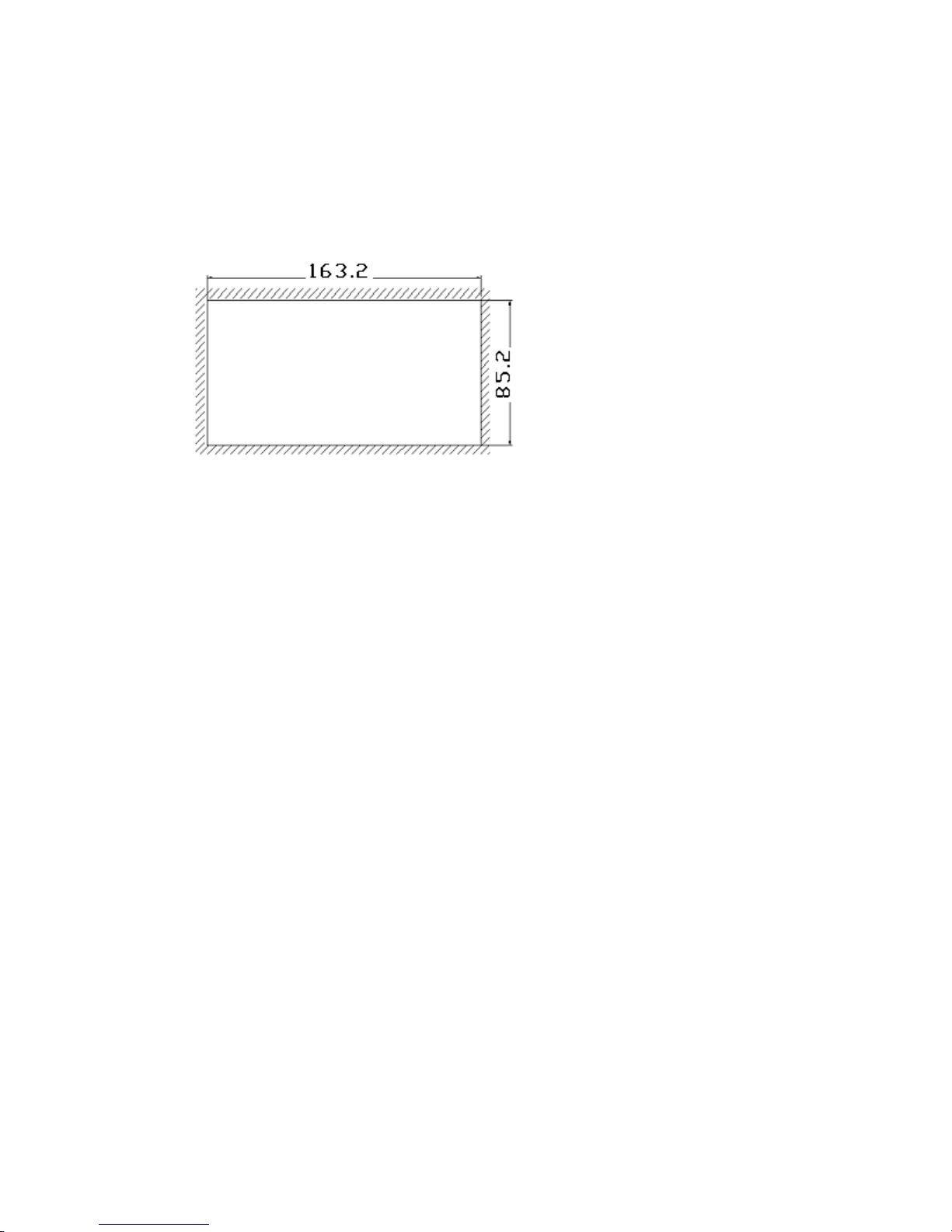

OP320

–A(OP320

-A-S)The product

’

s actual size

is

: 1

62.2×84.2×30(in mm

)

The

cutout s

izeis:

163.2

×

85.2 (in mm)

OP

520 The product

’

s actual size

is:284×194×50(inmm)

The

cutout

sizeis:

269.2

×

156.4 (in mm)

Page 21

Page21of86Pages

Chapter 2

OP20

Software

2-1 Basic s

ummary

of

the

OP20

OP20 develop

s

software for character display

for the

OP series application screen. It runs

on

WINDOWS 98/2000

/XP

system.

2-1-1

Project sc

reens

The project

’

s basic element is

the

screens.

2-1-2

Screen content

You can place Characters, lamp

s

, switch

es

, data display set window

s,and next screen

keysand other element in each screen.

You can a

lso

set the

alarm list monitor

ing

.

Page 22

Page22of86Pages

2-1-3

The us

e

flow

of OP20

The basic use flow

foranOP20

program

:

Set up the software.

Run the program.

Create or open

a

project

Create or open a screen

Edit the screen.

Save the

project

Transfer the screen.

Run

Page 23

Page23of86Pages

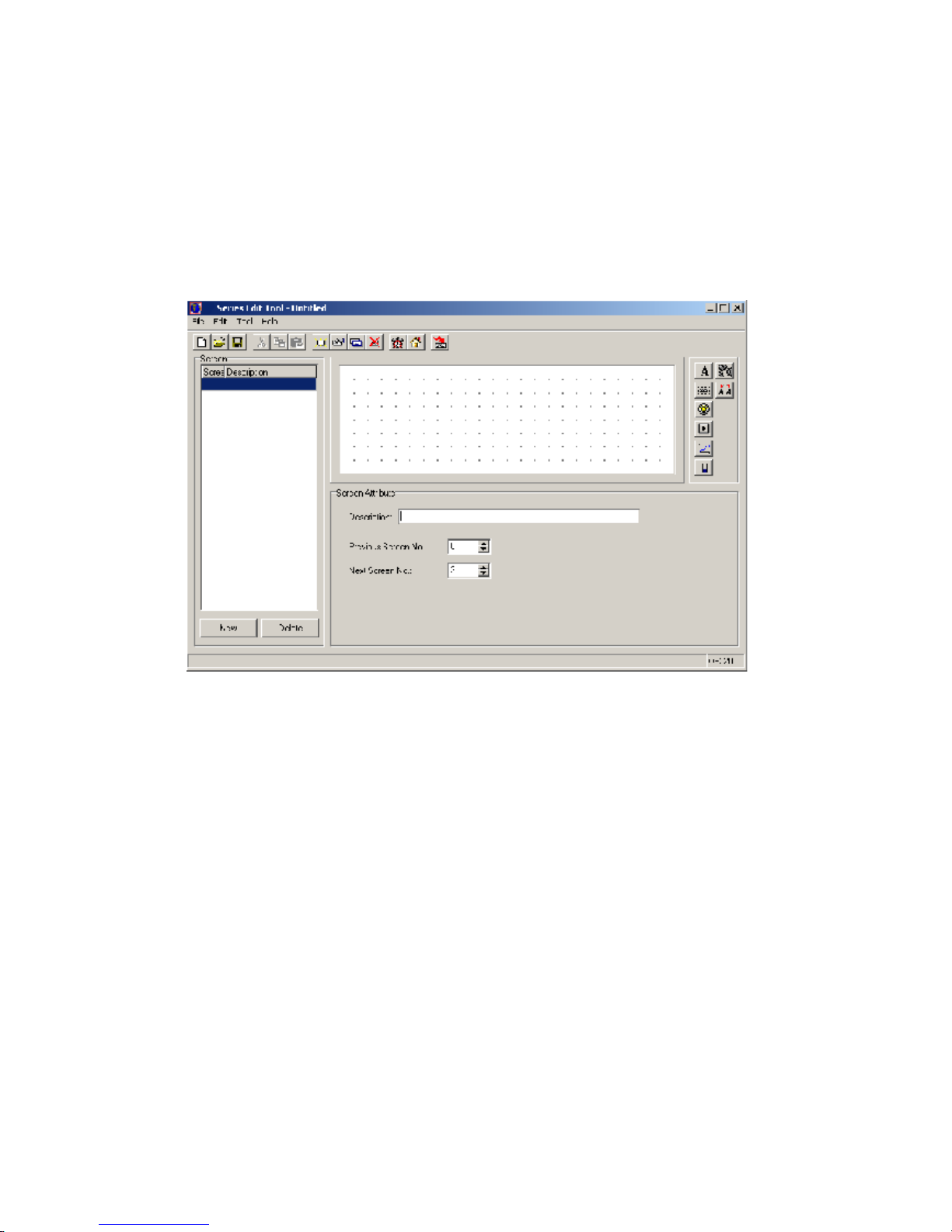

2-2Editing

the user’s screen

2-2-1Create a proje

c

t

After run

ning

the OP20 Software,

There will be a screen editor in the center of the

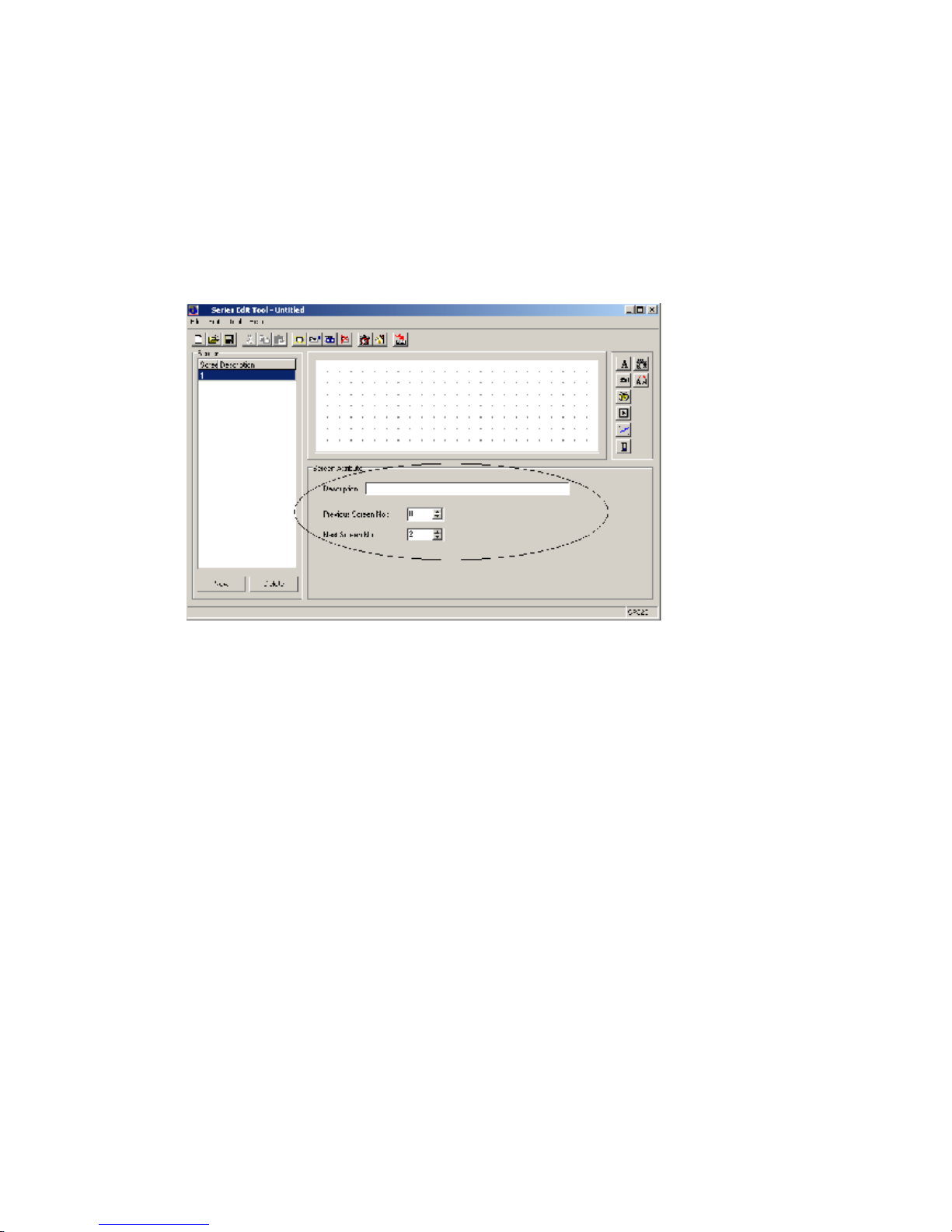

computer

’

s display.

Screen

Display all the screen’s serial number

in

the project.

Description

D

escript

ion of the screen fun

ction

“New”

key

Create a new screen.

“Delete”

key

Delete the current screen.

Page 24

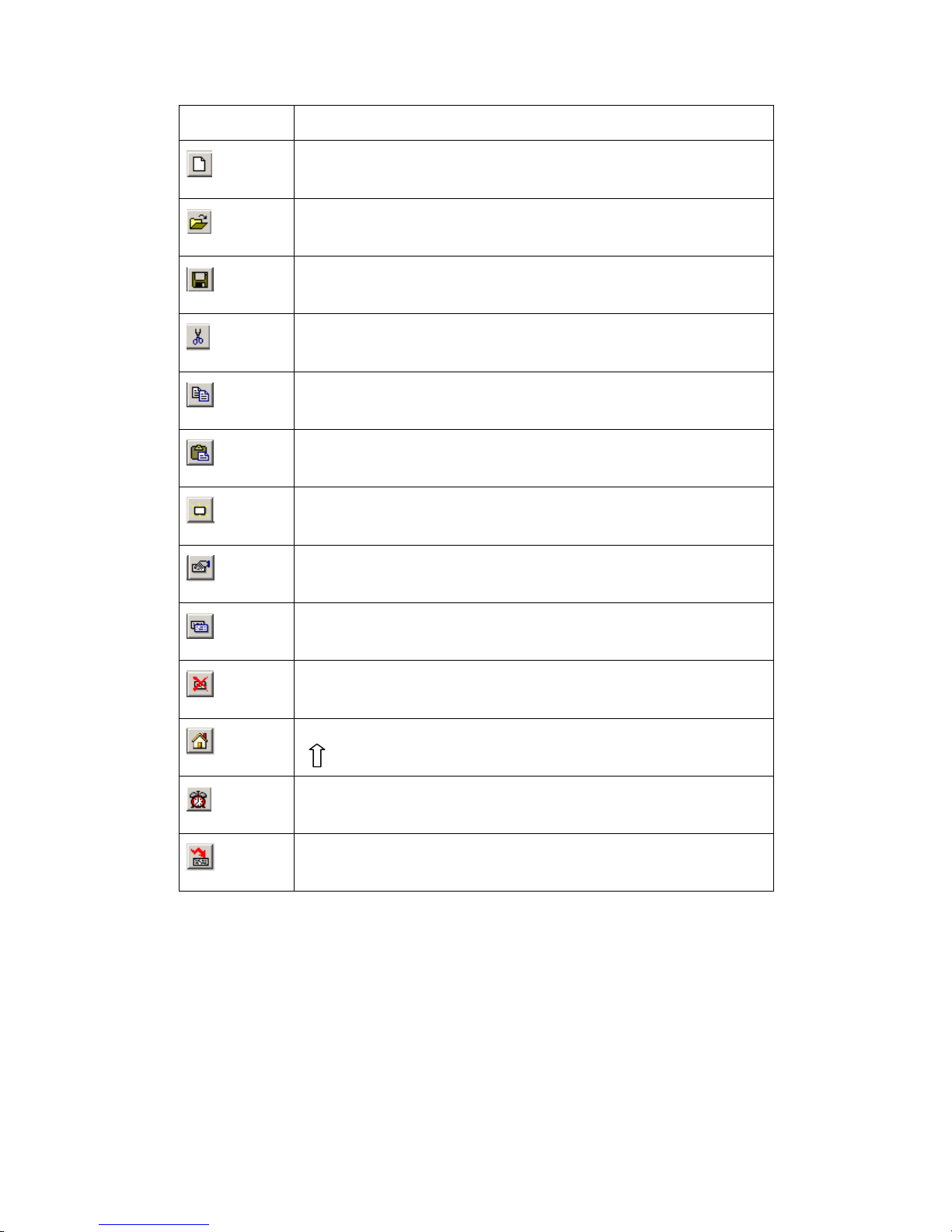

Page24of86Pages

Key

Description

Create a new project

.

Open a saved project

.

Save a project

that

is editing currently

Cut the characters

in

the tex

t

box.Copy the characters

in

the textbox

.

Paste the characters

in

the textbox

.

Creat

e

a new screen,

Display the

normal

ty

content

ofthe

current screen.

Copy a screen to be another

one

Delete the current screen.

P

ointtothe system’

s

initial screen,

when

the display is working, click the

[ ]

button

to

return

back

to thi

s screen

.

Log in the

alarm list information,

each piece of

alarm information

correspond

s

withan

internal

relay.

Via RS232 port of

the

computer, download the completed project file to

OP320 display.

Page 25

Page25of86Pages

PLC typ

e

Select

the

PLC’s type

so w

hen

the

OP20

is

download

ed

the screen,

will

transfer the

appoint PLC

’

s communication protocol along with the screen data to the display.

2-2-2

Make a basic

screen

The following we will take Mitsubishi FX series PLC as the examp

le to describe:

First, enter the edit status of the system

’

s initial screen (If default it will be the No.1 screen).

In the bottom of the screen is the current screen

’

s (No.1 screen)

normal

ty

.

Page 26

Page26of86Pages

2-2-3The system parameter

s

of OP20

Click

button, or click “tool”

”set OP20” command

The ma

in

control screen

After

powering up

, the first screen OP320 displays

the main menu

.

Password

All the screens

in

a project use

the

same password, when the

encrypt

normal

ty of “data

set

window

”,

“fun

ction key” is va

lid,only when

the system’

s

password

hasbeen

opened

.

P

ower conservation

protection

The default value of the backlight hold time is 3 minutes. When

its

set it to be 0, the

backlight will light

stay on

.

Sampl

e

analog

quantity

data

OP320 ca

n connect with a 8

-

channel

analog

value

sample

module or a

n8-

channel

temperature sampl

e

module via

the

RS485 communication port.

The register

’

s head address which

the

analog quantity

is

auto store

d

is assigned by this

parameter.

2-2-4Text

B

efore ed

iting

the screen

,

describe the 8 elements

’

function in the right of the screen edit

window.

PartsFunction

Input

texts.

D

ata monitor window or data set

window

(The

address

isaPLC data register)

Page 27

Page27of86Pages

Indicat

ion

lamp, display

s

theon-

off

status of

internal

relay.

Function key,

all

the seven keys in the bottom of OP320 can be defined

as

function key

s.Create a real time trend

.

Bar is

used to display

analog quantities

parameter intuitively, such as

fl

ux

,

press

ure

,

liquid level

,

etc. Its

height,

w

idth

and direction can be appointed

randomly.

Insert

a bitmap file, it can display

the machine

’sdiagram

, make the

opera

tor easy to understand. It can also display the

mark

and

badge

of

the

factory

,

improve the product

image.

Dynamic

text

, display the

current

status of

the

machine

with

dynamic

text.Make the operator

easy

to operate,

improve the

produce

efficiency. Dynamic

text

is your

ideal

cho

ice.C

lick the

button, there

will be a rectangle dashed frame in the screen

Page 28

Page28of86Pages

Coordinate

The X value

status

s

this text’s

horizontal

position

The Y value

status

s

this te

xt’s

vertical

position

The coordinate origin point is

in

the

left

top

of the screen.

Special

Double

:

Display the characters multiply in horizontal and vertical.

Inverse

:

The color of the message and

the

background displays

inversely

.Message

. Theconte

nt

of this column

can be cut, copied or pasted.

E

.g.Display the text

“mainmenu”

in

inverse

. Input “ma

in

menu” in the set

column, and

select

the“inverse

”

in the

“

special

”

frame.

2-2-5Function ke

y

(screen

jump

)

C

lick

button, there

will be

a

dashed

rectangle frame

that

moves with

the

mouse.

Click

the left button

of

the

mouse to confirm the position of the function key.

Then there will be a

hand

diagram

and the function key

to be set in the window.

Page 29

Page29of86Pages

Key

In the pul

l down menu of

“

key”,

select

the appropriate key f

ro

m seven keys.

Hand

In order that the operator can operate

it

correctly and quickly, add a hand

diagram

in front of

the

button

.

Encrypt

This function key is

only valid

when the system’

s

password

has been

opened.

Set coil

The function key

’

s action

will

switch

the value

setting.

Screen jump

This function key’s action

will set the

screen jump.

Coil

No.:

Address of the PLCs coil.

Force

ON

Set the appointed

internal

relay to

be ON

.Force

OFF

Set the appointe

d

internal

relay to

be OFF

.Reverse

Set the appointed

internal

relay to be the reverse logic.

Momentary

ON

When the key been pressed down, set the appointed

internal

relay to be ON; when the key

popsup, set the appointed

internal

relay to be OFF.

Page 30

Page30of86Pages

Select a key i

n the pull

-

down menu of

“

key”, there are seven keys

Page 31

Page31of86Pages

After set

ting

the function key,

place text

“

set parameter

”

to the right of the button

diagram

to prompt the operator. Click

“<”key to enter parameter.

You can set the NO.20 screen to be the state set screen.

Page 32

Page32of86Pages

In the main menu screen, add an alarm screen jump key.

Y

ou can jump to the alarm list

screen, refer to the alarm information.

For the alarm information, you can refer to 2

-2-

14

Page 33

Page33of86Pages

2-2-6

Data display

window

Setting

methods of parameter display window

s

and parameter set window

s

in detail. Also,

how to set the password.

E.g. T

he NO.10 screen can monitor and set three

groups

of

parameters, with the production

of Class A

, Class B, Class C.

The

row

in the left is

the

current value

, the row

in the right is

the

target value. The current value can

only

be used to monitor the data, the target value can

not only monitor but al

so modify the data. The

relationship between the three groups of

parameters and PLC data register is

as

follow

s:The correspond address of

the

current value

The correspond address of

the

target value

The production of

Class

A

D100

D110

The production of

Class

B

D101

D111

The production of

Class

C

D102

D112

Click the [new] button,

there will be a dialog box of the screen

’

s ID No. and screen

description setting:

Screen

No.

The new screen’s

ID

number

Description

Describe

the new scr

een’s

normal

ty

.

Page 34

Page34of86Pages

Set the screen

No.

to be 10, enter the

screen description

“

set

parameter”.

Click

[OK] button to confirm. After that, there

will be

the content of screen

attribute

in

the

right

bottom of the screen. Set

the“Previous Scr

een No.

”

to be 0, set the

“

Next screen No.

”

to be 20. Then in the normal display status (not in the status of data setting), click

“∧”

key

to directly enter the main menu screen, click

“∨”

key to directly enter the state setting

screen

At

the

normal

position,

place

text “the current value”, “the target value” , “the production of

Class A”, “the production of Class B”, “the production of Class C”.

Page 35

Page35of86Pages

C

lick the

button, there

will be

a rectangle

dashed

frame mov

es

with

the

mouse, move

it to

normal

position

,

then click on the left button

of

mouse to confirm it.

Display

“

12345

”

these five numbers inside the dashed frame, that means that this element is

a register display window or regis

ter set window whose length is five bits.

Register

No.

PLC register

’sNo.R

egister number

Sequential display or set the number of registers, the minimum is 1, the maximum is 2.

Set

This

parthas the function of set

ting a value to the register.

E

ncrypt

Only when the system

’

s password

has

been opened can you modify the data, the password

value is set by the tool menu.

Digits

Display

or set the

data’s

max

digit

.Decimal

The number of

decimal places

.

Page 36

Page36of86Pages

Decimal

system

Display the data

in

the register in de

cimal

format

Signed

Select this

normal

ty only when

the

display data in decimal format,

if the highest bit of the

register is 1, then

display

the data in

negative

. e.g. FFFEH

equals

–

2.HEX/BCD

Display the data in

HEX.

In this example, set by the following

contents:

R

egister’

s address

=

D100; the number of

the

register = 1;

the digits of data

=4; the

number

of

decimal fraction

= 0; display in decimal system;

don

t display

negative data

.

Set the cu

r

rent values display window of Class B an

d Class C. The addresses of

the

registers

are D101 and D102

respectively

,

the

other

normal

ties are the same as

before

.

Page 37

Page37of86Pages

2-2-7Data set window

Click

button, there

will be a rectangle dashed frame which moves with the mouse in

the scree

n..Click on the left key of mouse to confirm.

In the register

column,

select

“set”,

the monitor function, the

element

also has

a

set function.

Page 38

Page38of86Pages

After

the frame

“

Set”been

selected

, add

another

two

option

s

: “

Encrypt

” and “upp

er/lower

limit

ation”.Encrypt

:All parameters can be protected by

a

password

. The method

s

of setting and

modifying

the password

isasfollow

s:Pick

“tool”

“set OP20” command,

there will be a

dialog box

:

set

OP series

:

Input

the

passwor

d or modify the

original

password, e.g. input password “5678”, then press

“OK”

button

, the password is confirmed.

Page 39

Page39of86Pages

U

pper/lower limit: can

be

set

. T

his will

limitaninput too large or too small. E.g. set the

upper limit to be 9000, the lower limi

t to be 0. Only when

0<

the

set value<9000

can the set

value be written into

the

PLC.

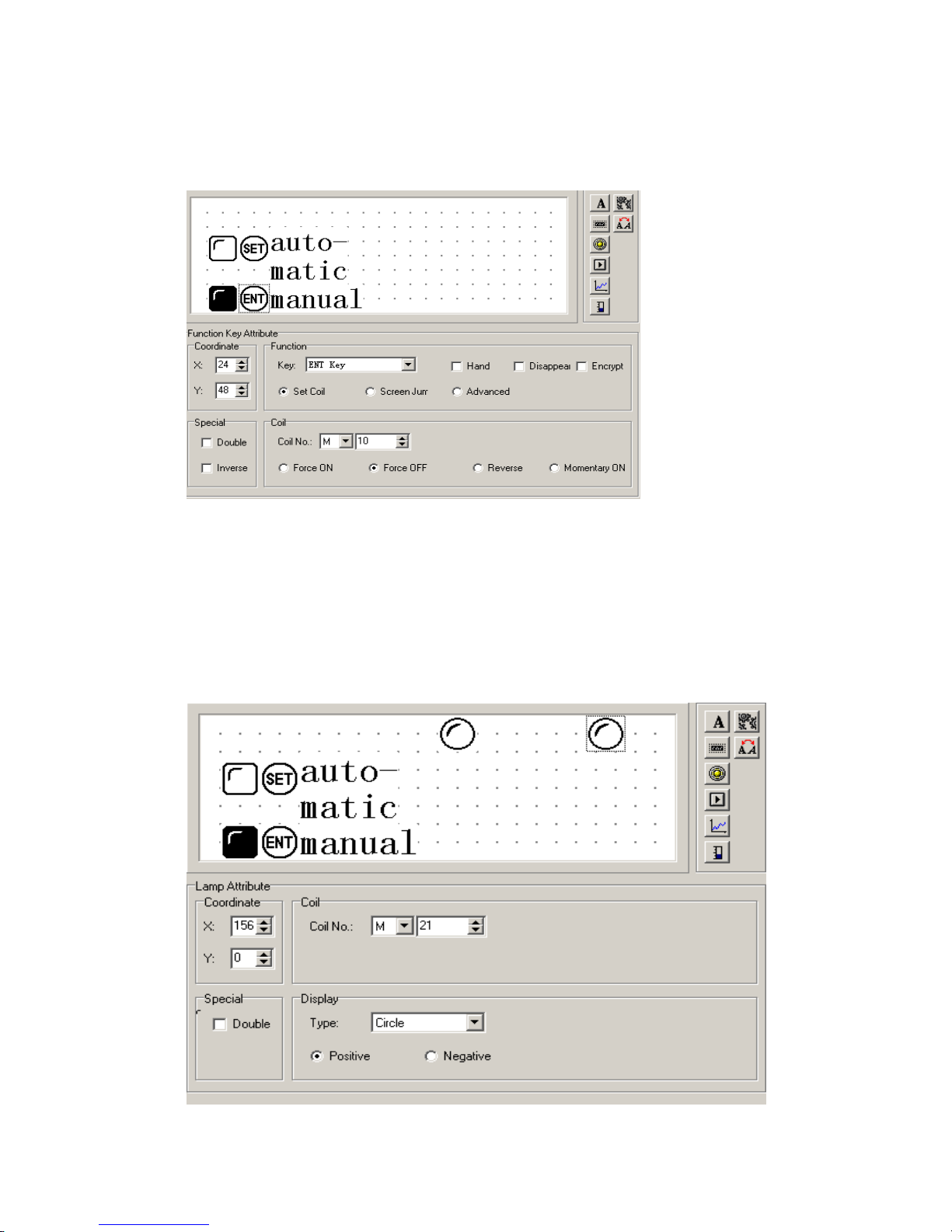

2-2-8Indicat

ion

lamp

s

H

ow to make a mode set screen. At the same time set

the

indicat

or

lamps and function keys

in detail.

E

.g.

The function of N

o.20 screen is to select the machine

’

s work mode. Manual/automatic

:

In the manual mode,

and to

control

the

machine

.

The status of the

internal

relay

The

content of

action

M10 = 1

Automatic mode

M10 = 0

Manual mode

M20 = 1

M

otor

run

forward

M21 = 1

Motor

run back

M20 = 0 , M21 = 0

M

otor stop

Page 40

Page40of86Pages

Click the [new] button,

and

popupa dialog box of

“

New Screen

”

. Set the screen

’

s No. to be

20,

and type

“

set mode

”

in the description.

Click [

OK]button to confirm.

Then there will be the screen

’snorm

altydisplay

.

Page 41

Page41of86Pages

Click

button to place the

status

lamp, there

will be a rectangle dashed frame

that

moves with the mouse.

C

lick the left key of the mouse to confirm.

CoilNo.

The define ID No. of the

interna

l

relayofthe PLC.

T

ype

The shape of the

status

lamp,

either

square

or

circle.

Positive

When the relay is ON, the

status

lamp display

insolid

Negative

When the

internal

relay is ON, the indicator lamp display

in

vacant

Page 42

Page42of86Pages

S

et the coil’

s

No.tobeM10, select the

square

lamp;positive logic. Then in the window

there will be

a vacant

square

status

lamp.

Click the

button to lay the function key, there

will be

a rectangle d

ashed

frame

which

moveswith

the

mouse, t

hen move it to the

normal

position and click on the left key of

mouse to confirm it.

Page 43

Page43of86Pages

In the function column, select the “SET” button to

be

the

auto mode setting button. S

et the

coil’s defin

ition

No.tobe

M10, and

set

the

action

mod

e tobeON..

Place text

“

automatic

”

to the right of the button., it means that this button

’

s function is

select automatic mode.

Page 44

Page44of86Pages

Set the manual button and the manual status lamp

with

the same method. The ad

dress of the

lampisstill M10.

Select

the display

normal

ty negative logic. The butto

n

is “ENT” button,

the button

’

s function is

to

set M10 relay OFF.

Set two circle lamps, positive logic. Each one

’

s address is M20 and M21,

to

monitor

the

motor

’

s work

ing

states. When the lamp in the left lights, it means the motor is

running

forward

, when the lamp in the right lights, it means the motor is

running

back.

Page 45

Page45of86Pages

2-2-9Function key (switch

quantity operation

)

C

lick

button to place the function key, select “>” button,

the

correspond address is

M20, its function is

momentary

set

M20 relay to

be

ON, and

keep

the hand

diagram

. It

status

s that when

you

click on the “>” button, M20

of PLC

is set to

be

ON, an

d the

motor

begins to

run forward

.

(PLC program, us

esM20 to trigger Y0); when

you

releas

e

the “>”

button

,

M21

of PLC

goes back

to

the

OFF

state,

, and the motor

will

stop

running.

Page 46

Page46of86Pages

2-2-10Single

line

Trend

Inthe

proce

ss

industry

,

the value of

some parameters

change

slowly.

The operator want

stoknow

these parameters

’

change process in a certain time. The

trend

diagram

is the best way

to display these values.

Click the

b

utton, there

will be a rectangle dashed frame moving with the mouse.

Move to the

desired

position and click the mouse

’

s left key to confirm.

Register

No.

The

address correspond

s

with the

trend

diagram

.Full

value

When the

trend

diagra

m

displays in 100% scale, the value

correspond

s

with the

register

Z

ero value

When the

trend

diagram

displays in 0% scale, the value

correspond

s

with

the register

S

ampled

ata (the number of the dot

s)The number of all

the

sampled dot

s

from left to right.

The larger th

e

number, the

more

detailed

the

trend

has.Sample

cycle

The inter

v

al time of every two sampl

ed

dots.

Range

This value

sets

the length and the w

id

th of the

trend

diagram

.

Note:

One

trend

diagram

element can only display one line.

Page 47

Page47of86Pages

2-2-11Bargraph

.

Click the

button, there

will be a rectangle dashed frame

that

moves with the mouse.

Move to the

normal

position and click the left key of the mouse to confirm.

Register

No.

The

register

’saddress correspond

swith the

bar graph

.Full

value

When the bar

graph

displays in 100% scale, the valu

e

correspond

s

with

the register.

Z

ero value

When the bar

graph

displays in 0% scale, the value corresponds with the register.

Direct

The display direction of the bar, it can b

e up, down or be left, right.

Range

This value

d

ictates

the length and the w

id

th of the bar.

Page 48

Page48of86Pages

This bar monitor

s

the value in D300. When the bar displays in

the full

scale, it

status

s that

the value in D100 is 100;

w

hen the bar displays i

n 50% scale, it

status

s that the value in

D300 is 50.

2-2-12Diagram

display

Insert a bitmap

file

, which can

display the machine

’spicture

and make

s it easy for

the

operator to understand. Also it can display the factory

’slogo

, badge

.

Click the

button, there

will be a search dialog box in the screen.

Select the bitmap

file

which

you

intend to display, then double

-

click it or click on the open

button, there

will be a rectangle dashed frame

that

moves with the mouse. Move

it

to the

no

rmal

position and click the mouse

’

s left key to confirm.

Page 49

Page49of86Pages

Note: it can display

a

bitmap

with

192×64 pixel

s at most.

The

extra

part w

ill

be removed

automatically.

2-2-13

Dynamic messages

You can d

isplay the current machine

’

s status via words

which

makes

the operator

s job

eas

ier,and

will improve the monitor

ing

efficiency. The dynamic message is your

best

choice.

Click the

button, there

will be a rectangle dashed frame

that

moves with the mouse.

Move to the

normal

position and click th

e mouse

’

s left key to confirm.

Page 50

Page50of86Pages

In the screen

’

s edit area, there are some initial words

“

dynamic message

”

and the following

normal

ties in the dialog box.

Register

No.

The register

’

s No. of

the

PLC

.Decimal

Value format.

HEX/BCD

Display the data in hex

system

.Display

Textedit

area

. Write the text

that need

stobe displayed.

Value

Data in the PLC register.

Content

Now, begin to edit the

content

. First, select the line

to

be edited, then click the left key of

mouse, “

D

ynamic

Message

”

.

Page 51

Page51of86Pages

E.g. Input

“

No.1 motor

runs forward

”

in the first line, input

“

No.1 motor

runs in reverse

”inthe second line, input

“

No.1 motor stop

s”in the third line.

The dynamic message responds

to

data in D200. If data in D200 hasn

’

t been set, then the

text fr

ame has no display, if data in D200 is 0, then display

“

No.1 motor clockwise

”.If data in D200 is 1,then display

“

No.1 motor

…………

”.If

data

in D200 is 2, the

n display

“

No.1 motor stops running

”

.

Page 52

Page52of86Pages

2-2-14Alarm list

Each project of

the

OP320 can set a group of alarm list information. A piece of alarm

information corresponds with a

internal

relay. The definition No. is sequential. The

internal

relay’s initial address can be set by the user accordin

g to the actual program. When any of

the

internal

relay turns to ON from OFF, that means that when there is an alarm,

the

OP320

will auto

matically

popupthe alarm display screen, then display

s

the alarm information in

the first line. When another

internal

relay be ON, display a new alarm information in the

second line.

Click the

button,

there will pop

up

t an

alarm list dialog box:

Page 53

Page53of86Pages

Input other information

in

the same way.

After all the

alarm information

been

input

, change the coi

l’s

No.tobe

M100

(example), i.e.

it

status

s that M100 to M106

i

ndividually

correspond

s

with the 7 alarm

s.

The operator can

immediately

reacttosolve

the

problem.

If

you

want to return b

ack to the

monitor screen,

just

click [ ] button.

Page 54

Page54of86Pages

2-3Save

a

project

After

finish the

screen edit

ing, you can save

the

project file, and

download

the screen

project to

the

OP20

.

Press

button,

in

the

screen

there will be a dial

og box for you to save the project.

Select the correct path and file name to save it, and the file’

s

extend name

will auto

matically

be

defined to be

.dp2 .

Input the file

name

, select the

right

path, then press “save” button to save it.

2-4 D

ownload

ing

t

he screen

Connect the computer

’

s 9 pin RS232 port and the 9 pin port of OP320 with the

download cable. Make sure that OP320

is

power

ed.Click the

button to begin

download

ing

the data

.

Note:

In the process of downloading the screen

’sdata,

make sure that

the

OP320

does

not

lose

power

After finish

ing

transferring the screen, there will be a dialog box,

that says

all the screens

have been transferred.

Page 55

Page55of86Pages

Turn off the display’s power. Pull out the

screen

’

s transfer cable

OP-SYS-CAB0, c

onnect

the

OP320 and PLC with the PLC communication cable.

T

here will be

“

communicating

”inthe right bottom of the display, that means OP320 is communicating with PLC.

Page 56

Page56of86Pages

Chapter 3

OP320

O

perat

ion

method

s

3-1Online communication

Note:

N

o m

atterifthe PLC is running or program

ming

,

the

OP320

will

operate

normally.

3-2

Shift

the screen

O

P320

will first

display the NO.1 screen. (

B

ecause the system’

s

initial screen is

No.1screen

.)The No.1 screen is a menu screen

.

Now, data in the left column displays the three classes

each, corresponding with

the

PLC’s

address: D100,D101,

and

D102.

Page 57

Page57of86Pages

3-3System’

s

password

B

efore modify

ing

the data, you should

first

open the system’

s

password.

Press

the

password

select

key,and type the password.

Click the

button to enter the password screen, the screen display

sthe

following:

Select 1, execute the operation of opening password; select 2,

to close the password

. Click

on the button, return

ing

back to

the

monitor status.

Page 58

Page58of86Pages

Select 1, the screen display

s:Click the “

∧

” button or “

∨

”button to

input

the password’

s

value,

and

click the “ENT”

button to confirm.

If the password value is correct, the screen displays:

If the password value

isinerror, the screen displays:

Select 2 , c

lose the password, the screen displays:

Page 59

Page59of86Pages

3-4Modify

ing

the data

value

If the password has been

entered

, click the

“ENT” button.

The p

roduction set value of class

A will

high light

, which means

you can

set class A

’

s production

value.

C

lick the “

∧

” button

and “

∨

” button to modify the value, click on the “<” and “>” to set the

digit’s position

, the

data range

i

s 0 to 9.

3-5Switch value

After the set value, click the

“ ” button to return back to the

system

’sinitial screen

(the

NO.1 screen.)

.

Click the

“>” button to enter

status set

screen

.

Page 60

Page60of86Pages

Chapter 4 New addition

al

function

softhe

OP520

4-1 Set

ting

general function key

When editing the project screen of

the

OP520, press

the

key, there will be a dialog box

for you

to set the general function key.

The dialog box displays 20 function keys (K1~K10,F1~F10), If the function key is not set,

it means that this key can only be used as the normal function key. Only when the display

’sscreen show

s

this function key can it

be effective to operate this key. After setting the global

function key, the display will display any screen

.

4-1-1 Set

ting a

coil’s function

In the

“

set the global function key

”

dialog box.

Select

“

set coil

”

for K1, the dialog box will

display coil set o

ption:

Page 61

Page61of86Pages

★

Force ON

When the key is pressed down, set the

coil

ON.★Force OFF

When the key is pressed down, set the

coil

OFF.

★

Reverse

When the key is pressed down, set the

coil

in reverse.

★

Momentary ON

When the key is pressed down, set the

coil

ON, w

hen the key pops up, the

coil

will be

set OFF.

Set encryption

Select

encryption multi

-

select frame. Then the function key will have the function of

the

password protection. Press this button, there will be a password check screen.

Page 62

Page62of86Pages

4-1-2 Screen jump function

In the

“

Set General Function Key

”

dialog box, set function key K1 to make it have the

function of screen jump. The dialog box will display screen jump

select

:★Screen

T

he screen will jump to one which

has the

number in the number

select frame as the

screen No.

★

Password

T

he screen will jump to the password check screen.

★

Alarm list

T

he screen will jump to the alarm list screen

★

Date/time

T

he screen will jump to the Time/Date screen.

Page 63

Page63of86Pages

Set the encryption

Select

the

encryption check box, then the key will have the function of

the

password

protection.

4-1-3 Advanced function

s

In the dialog box

“

Set Global Function Key

”,select

the advanced function

s

for K1.The

dialog box will display advanced function option:

★

RUN

The

PLC will

go into run mode

.★STOP

The

PLC will

go into stop mode

.

After

you

finish setting the global function key, press [OK] button, then the set global

function key will be

saved.

Page 64

Page64of86Pages

4-2 Status lamp

s

There are 16 button

status

lamps in the left

bottom of OP520, they can display the register

’sdata, it will reflect the machine

’

s work status.

Press the key, open the system setting

.

Select

the display function for the status lamp. The 16

button

status

lamps

are each

controlle

d by Bit0

-Bit10 of D0 register.

Bit7

Bit8

Bit5

Bit4

Bit3

Bit2

Bit1

Bit0K1F5F6F7F8F9

F10K2K3K4K5K6K7K8K9

K10

Bit15

Bit14

Bit13

Bit12

Bit11

Bit10

Bit9

Bit8

E.g. If you want to light [K1]

status

lamp, then Bit7=1, D0=H0080.

If you want to

light [K3]

status

lamp, then Bit3=1,D0=H8000

.

Page 65

Page65of86Pages

4-3 Application examples of global function key

s

and button

status

lamp

s

In t

he following

example

, we will start/stop the motor with the global function key. A

nd

use

the panel

status

lamp to

monitor the

ON/O

FF status.

Create a new project, in the display

s

selected

dialog box,

select

OP520.

Select

Mitsubishi in

the PLC

select

ion

dialog box

and

press

the

key.Set [K1] to make it the general function key, its function is set M0 momentary ON.

Set [K3]

to make it the general function key, its function is set M1 momentary ON.

Set the correspond address for the

status

lamp, single click

the《Toolbar

》

menu:

Page 66

Page66of86Pages

Single click

《

Set OP Series

》

Select

《

Light Panel Status LED

》

check box, the correspond

ing

word address of the 16

status

lamps is D0.

Program the

Plc

with

the following action:

If M0=1 Then SET Y0 RST Y1 D0=H0080

If M1=1 Then RST Y0 SE

T Y1 D0=H8000

Page 67

Page67of86Pages

4-4 in

ternal

clock (optional)

To s

et the clock, click

the

button, or click

“

Tool”->“

Set OP Series

”

command, there

will be a OP20 system parameter setting dialog box:

Select

“

Use Data/Time Module

”,and

set the control register

’

s No.

if

you use. E.g. D46,

then the clock

’

s data will be placed into three groups of registers which start with D46. D46

will store of year and month, D47 will store date and hour, D48 will store minute and

second.

After finish setting the clock, set a bu

tton with which we can enter the clock

display

screen:

.

Page 68

Page68of86Pages

Chapter 5 Application examples of

the

OP520

5-1 Examples

In the

following

example

we will take our company

’sE

C series PLC to make a project.

Page 69

Page69of86Pages

Page 70

Page70of86Pages

5-1

Make a screen

Open

the

OP20 screen set tool

and

create a new project,

selected

dialog box from the program.

Select

OP520 and click OK.

There will pop

up

a PLC

select

ion

dialog box. In the pull down menu,

select

econ E

C series

and click OK. Then you can start screen

edit.

Now f

irst, edit the main screen, here No.1 screen has

defaulted

(the program

default

s

it),

select

No.1 screen to be the main screen. In the screen

description

text, fill in the main

screen.

To i

nsert a

diagram

: Press

the

button,

Select

the LOG

O

diagram

that has been

made and insert it in, place the

diagram

to the

normal

position in the screen.

Page 71

Page71of86Pages

Chapter

6

OP320

-

S, OP320

-AOP320

-

A/OP320

-A-

S

OP320

-

A/OP320

-A-

S is a

cut down

version

of OP520, you can refer

to

OP520

for

its use,

but there is no

global set function key

s

, you can refer

to

OP320

for

its us

e

and refer

to

OP520

for its number keys

’

.

Page 72

Page72of86Pages

Chapter

7

PLC’

s

connection method

7-1

Econ

E

C series

PLC

OP series can communicate with

econEC series

PLC

, the

communication

port is the

PLC’

s

program port.

Item

Content

OP320

communication port

9 pin

communication port

PLC

communication port

Program port

The default communication

parameter

9600 bps, 8 bit, 1 stop, ODD

ID1Communication distance

(the

farthest)

15 m

Communication

format

RS232

The type of the cable

OP-FC-CAB0

The corresponding addresses of the

switch value

M0-M383

The corresponding addresses of the

digital value

W0-W2047, FW0

-

FW191, TW0

-

TW127,

CW0

-

CW127, WX0

-

WX13, WY0

-

WY13,

WM0

-

WM23

Page 73

Page73of86Pages

The connect

ion

diagra

m

of OP

-FC-

CAB0

2 RXD

5 TXD

OPside3 TXD

4 RXD

PLCsid

e(9PIN

)

(

8PIN

)

5 GND

8 GND

Note: it is

normal

for all OP series

models

7-2

Mitsubishi

FX series PLC

OP series can communicate with all FX series of Mitsubishi

at present

. The

communication

port is PLC program port or FX2N

-

422BD module of

theFX2N series PLC.

Item

Content

OP320

communication

port

9 pin

communication

port

PLC

communication

port

Program port or FX2N

-

422BD

The default communication

parameter

9600bps, 7bit, 1 stop, Even

ID0C

ommunication

distance

( the

farthest)

70 m

Comm

unication

format

RS422

The type of cable

OP-FX-CAB0

FX0S

FX0N

FX2N

The corresponding addresses of

the switch value

M000

-

M511

M000

-

M511

M000

-

M511

The corresponding addresses of

the digital value

D00-D31

D000

-

D255

D000

-

D511

Page 74

Page74of86Pages

The connect

ion

diagram

o

f OP-FX-CAB0

1 TD+

2RD-

6 TD

-1RD+OPside8 RD

-4TD-PLCsid

e(9PIN

)

9 RD+

7

TD+(8PIN

)

5 GND

3

GND

Note: it is

normal

for OP320, OP320

-

A, OP520.

7-3

Siemens

S7-200 series PLC

OP series can communicate with

the

program port

or extension port of S7

-

200 series PLC

via PPI protocol.

Item

Content

OP320

communication

port

RS485 communication port

PLC

communication

port

Programming port or expansion port

The default communication

parameter

9600 bps, 8 bit, 1 stop, Even

ID2C

ommunication distance

(the

farthest)

100 m (twisted

-

pair)

Communication

format

RS485

The type of the cable

OP-S7-CAB0

The corresponding addresses of the

switch value

M000

-

M317

The corresponding addresses of the

digital value

VW000

-

VW4096

Page 75

Page75of86

Pages

The con

nection

diagram

of OP

-S7-

CAB0

1OPside93 A

PLCside9

plug68 B(9PIN

)

8

Note: it is

normal

for OP320

-

S, OP320

-A-

S, OP520.

Page 76

Page76of86Pages

7-4

Omron

C series PLC

CPM1A, CQM1

-

CPU11 has only one communication port.

In orde

r to communicate with

the

OP320, it needs the communication cable CIF01

-

CAB produced by our company to

transfer the program port

’

s signal to RS232 signal.

ItemContent

OP320

communication

port

9 pin communication

terminal

PLC

communication

port

Program

port or expansion port

The default communication

parameter

9600 bps, 87bit, 2 stop, Even

ID0Communication distance (the

farthest)

15 m

Communication

format

RS232

The type of the cable

OP-CQM

-

CAB0 or CIF01

-

CAB0

The corresponding addresses of

the

switch value

IR20000

-

22715

The corresponding addresses of

the digital value

DM0000

-

DM1024

The connecti

ondiagram

of OP

-

CQM

-

CAB0

2 RXD

2 TXD

OP

side

3 TXD

3 RXD

PLC

side(9PIN

plug)(

9PIN)5 GND

9 GND

Note: it is

normal

f

or all OP series

models

.

Page 77

Page77of86Pages

7-5 Koyo

S series PLC

When OP series communic

ates

with SZ

-

4, OP320 can con

nect

with not only Port1 but also

Port2.

Item

Content

OP320

communication

port

9 pin communication port

PLC

communication

port

Program port or ex

te

nsion

port

The default communication

parameter

9600 bps, 8 bit, 1 stop, ODD

ID1Communication distance (the

farthest)

15 m

Communication

format

RS232

The type of the cable

OP-SZ-CAB0 corresponds with SZ, SH, SH series

OP-SG-CAB0 corresponds with SU, SG se

ries

The corresponding addresses of

the switch value

M000

-

M377

The corresponding addresses of

the digital value

R2000

-

R3777

The connecti

ondiagram

of OP

-SZ-

CAB0

1 GND

2 RXD

2OPside

3 TXD

3 RXD

PLCside(

9PIN

plug)4 TXD

(

6PIN)5

5 GND

6 GND

Page 78

Page78of86Pages

The connecti

ondiagram

of OP

-SU-

CAB0

1

2 RXD

2 TXD

OPside3 TXD

3 RXD

PLCside(

9PIN

plug)4 RTS

(

25PIN

)

5 CTS

5 GND

7 GND

Note: it is

normal

for all OP series

models

.

Page 79

Page79of86Pages

7-6 Schne

iderNEZA series PLC

The

OP series can communicate with the NEZA series PLC via MODBUS protocol.

Item

Content

OP320

communication

port

RS485 communication port

PLC

communication

port

Program port

The default communication

parameter

9600 bps, 8 bit, 1 stop,

Even

ID1Communication distance (the

farthest)

100 m

Communication

format

RS485

The type of the cable

OP-NEZA

-

CAB0

The corresponding addresses of

the switch value

%M000

-

%M127

The corresponding addresses of

the digital value

%MW000

-

%MW511

Page 80

Page80of86Pages

Th

e connecti

ondiagram

of OP

-

NEZA

-

CAB0

1OPside91 A

PLC

side

(9pin

plug)6

2 B(9

PIN)857

Note: it is

normal

for OP320

-

S, OP320

-A-

S, OP520.

7-7

DELTA

DVP series PLC

OP series can communicate with DVP series PLC,

the

communication

port is PLC program

port.

Item

Content

OP320

communication

port

9 pin communication port

PLC

communication

port

Program port

The default communication

parameter

9600 bps, 8 bit, 1 stop, Even

ID1Communication distance (the

farthes

t)

15 m

Communication

format

RS232

The type of the cable

OP-DVP-CAB0

The corresponding addresses of

the switch value

M0-M999

The corresponding addresses of

the digital value

D0-D599

Page 81

Page81of86Pages

The connecti

ondiagram

of OP

-

DVP-CAB0

2 RXD

5 TXD

OPside3 TXD

4 RXD

PLCside(

9PIN)(

8PIN)5 GND

8 GND

Note: it is

normal

for all OP series

models

.

7-8LGMaster

-

K series PLC

The

OP series can communicate with

LG

Master

-

K series PLC, the communication port is

port 2.

Item

Content

OP32

0

communication

port

9 pin communication port

PLC

communication

port

Port2

The default communication

parameter

9600 bps, 8 bit, 1 stop, Even

ID1Protocol

Modbus Slave ( RTU ( HEX ) )

Communication distance (the

farthest)

15 m

Communication

format

R

S232

The type of the cable

OP-LG-CAB0

The corresponding addresses of

the switch value

M000

-

M191F

The corresponding addresses of

the digital value

D0000

-

D4500

Page 82

Page82of86Pages

The connecti

ondiagram

of OP

-LG-

CAB0

2 RXD

7 TXD

OPside3 TXD

4 RXD

PLCside(

9PIN)(

9PIN)5 GND

5 GND

Note: it is

normal

for all OP series product.

7-9 Matsushita

FP series PLC

The

OP320 can communicate with Matsushita

FP series PLC

, the communication

port is

PLC program port or ex

te

nsion port.

ItemContent

OP320 communication port

9 pin communication port

PLC communication port

Program port or ex

te

nsion port

The default communication

parameter

9600 bps, 8 bit, 1 stop,

ODD

ID1Communication distance (the

farthest)

15 m

Communication

format

RS23

2

The type of the cable

OP-FP1-CAB0

The corresponding addresses of

the switch value

R0000

-

R875F

The corresponding addresses of

the digital value

DT0000

-

DT9999

Page 83

Page83of86Pages

The connecti

ondiagram

of OP

-FP-

CAB0

2 RXD

2 TXD

OPside3 TXD

3 RXD

PLCside(

9PIN)(

9PIN)5 GND

7 GND

458

9

Note: it is

normal

for all OP series

models

Page 84

Page84of86Pages

7-10

FACON

FB series PLC

The

OP320 can communicate with FACON

FB series PLC

, the communication port is PLC

program port or ex

te

nsion port.

Item

Content

OP320 communication port

9 pin communication port

PLC communication port

Program port or ex

te

nsion port

The default communication

parameter

9600 bps, 8 bit, 1 stop, Even

ID

1

Communication distance (the

farthest)

15 m

Commu

nication

format

RS232

The type of the cable

OP-FB-CAB0

The corresponding addresses of

the switch value

M0000

-

M1911

The corresponding addresses of

the digital value

R0000

-

R8071

Page 85

Page85of86Pages

The connecti

ondiagram

of OP

-FB-

CAB0

1 RXD1

2 RXD

2 TXD1

OPside3 TXD

PLCside(

9PIN)(

15PIN

)

5 GND

6 GND

3 RTS1

4 CTS1

Note: it is

normal

for all OP series

models

Page 86

Page86of86Pages

ECON

From

Control Solutions Group

'Simple solutions to difficult problems'

Web

www.controlsolutionsgroup.eu

E-mail

support@controlsolutionsgroup.eu

Please consider the environment before printing this document

Loading...

Loading...