Page 1

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

EHS-580

EtherCAT Hybrid Servo Drive

© 2017 shenzhen ECON Technology Co.,Ltd. Version 2.0

Add:2F,BuildingB,Jintai,Industrial,Park,HangchengAvenue,GushuVillage,XixiangStreet,Bao'anArea,ShenzhenCity,

GuangdongProvince,China

Tel: +86 136 2096 1024

E-mail:enquiry@hybridservo.com

technical01@hybridservo.com

All rights reserved

[Please read this manual carefully before use to avoid damage the drive]

Page 2

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

Contents

Part 1: EHS-580 .......................................................................................................................................................... 5

Hardware Manual ........................................................................................................................................................ 5

1 Descriptions .............................................................................................................................................................. 5

2 Features .................................................................................................................................................................... 5

3 Applications .............................................................................................................................................................. 5

4 Specifications ............................................................................................................................................................ 6

4.1 Electrical Specifications ................................................................................................................................ 6

4.2 Operating Environment ................................................................................................................................. 6

5 Mechanical Specifications ........................................................................................................................................ 6

6 Connectors and Pin Assignment ............................................................................................................................... 7

6.1 Control signals connector .............................................................................................................................. 7

6.2 Encoder Feedback and hall signal Connector ............................................................................................... 8

6.3 Power and Motor ........................................................................................................................................... 8

6.4 EtherCAT Communication Port ..................................................................................................................... 9

7 DIP Switch Settings ................................................................................................................................................ 10

7.1 E-CAT ID Table ........................................................................................................................................... 10

8 Hybrid servo Motors ................................................................................................................................................ 11

8.1 Nema24 and Nema34motor .......................................................................................................................... 11

8.2 Nema34motor ............................................................................................................................................... 11

9 Wiring Diagrams .................................................................................................................................................... 12

9.1 Interface ....................................................................................................................................................... 12

9.2 Diagram ....................................................................................................................................................... 13

10 Protection Indications ........................................................................................................................................... 13

11 Frequently Asked Questions .................................................................................................................................. 13

Problem Symptoms and Possible Causes........................................................................................................... 14

12 Warranty ............................................................................................................................................................... 14

Exclusions .......................................................................................................................................................... 15

Obtaining Warranty Service .............................................................................................................................. 15

Warranty Limitations ......................................................................................................................................... 15

Part 2 : EHS-580 EtherCAT Communication Protocol Specification ....................................................................... 16

1. Introduction ....................................................................................................................................................... 16

2. Operation mode ................................................................................................................................................. 16

2.1 Profile position mode(PP) ........................................................................................................................... 16

2.1.1 Related objects .................................................................................................................................. 17

2.1.2 Control word and Status word .......................................................................................................... 17

2.1.3 Typical motion mode of bit 5 at PP mode ......................................................................................... 17

2.1.4 The bit 8,10.12-15 of status word ..................................................................................................... 18

2.2 Profile velocity mode (PV ) .......................................................................................................................... 19

2.3 Cyclic synchronous position mode mode(CSP) ........................................................................................... 19

2.3.1 Related objects .................................................................................................................................. 19

2.4 Homing mode (HM) ..................................................................................................................................... 20

3. Input and output ................................................................................................................................................. 22

Page 3

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

3.1 Input configuration ................................................................................................................................ 22

3.2 Output configuration ............................................................................................................................. 23

3.3 Related node ID ..................................................................................................................................... 24

3.4 Motor rotation direction setting ............................................................................................................. 24

3.5 Pulse/Revolution setting ........................................................................................................................ 24

4. Parameters ......................................................................................................................................................... 25

4.1 Parameter saving ................................................................................................................................... 25

4.2 Parameter reset ...................................................................................................................................... 25

4.3 Parameters list ....................................................................................................................................... 25

5. Basic Information Of EtherCAT ........................................................................................................................ 29

5.1 EtherCAT Data Frame Structure ................................................................................................................. 29

5.2 Synchronous Mode ....................................................................................................................................... 29

5.2.1 Random running mode ...................................................................................................................... 29

5.2.2 Distributed clock synchronization mode ........................................................................................... 29

5.2.3 EtherCAT state machine ................................................................................................................... 30

5.3 COE ............................................................................................................................................................. 30

5.3.1 Service data object (SDO) ................................................................................................................ 31

5.3.2 SDO protocol and message format ................................................................................................... 31

5.3.3 Suspend SDO transmission ............................................................................................................... 32

5.4 processing data object ................................................................................................................................. 34

5.4.1 PDO mapping ................................................................................................................................... 34

5.4.2 PDO dynamical mapping.................................................................................................................. 35

5.4.3 The difference of PDO and SDO ....................................................................................................... 35

Contact us: ................................................................................................................................................................. 36

Page 4

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

EtherCAT :

EtherCAT (Ethernet for Control Automation Technology) is open network communication using

real-time Ethernet between masters and slaves developed by Beckhoff Automation GmbH, Germany.

This User Manual of EHS-580 Included:

Part 1:EHS-580 hardware manual

This part for hardware, function description, parameter configuration, etc.

Part 2 :EHS-580 EtherCAT communication protocol specification

This part for EtherCAT communication protocol.

Notice!

Read this manual carefully before any assembling and using. Incorrect handling of products in this manual can

result in injury and damage to persons and machinery. Strictly adhere to the technical information regarding

installation requirements.

This manual is not for use or disclosure outside of ECON technology except under permission. All rights are

reserved. No part of this manual shall be reproduced, stored in retrieval form, or transmitted by any means,

electronic, mechanical, photocopying, recording, or otherwise without approval from ECON technology. While

every precaution has been taken in the preparation of the book, ECON technology assumes no responsibility for

errors or omissions. Neither is any liability assumed for damages resulting from the use of the information

contained herein.

This document is proprietary information of ECON technology that is furnished for customer use ONLY.

Information in this document is subject to change without notice and does not represent a commitment on the part

of ECON technology. Therefore, information contained in this manual may be updated from time-to-time due to

product improvements, etc., and may not conform in every respect to former issues.

Page 5

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

Part 1:EHS-580

Hardware Manual

1 Descriptions

EHS-580 is Econ technology's new EtherCAT hybrid servo driver, which adopt the latest floating-point 64-bit

MCU digital processing technology, the advanced vector control technology drive the motor with low heating ,low

noise and extra smoothly. The user can set any ID address within 1-255 and any current value under the rated

current, it can be matched with different of size motors(from Nema17--Nema24) to applied for variable

applications. the drive can auto-tuning for matching the motor when power up, which can automatically generate

optimal operating parameters for different motors to maximize the performance of the motor

2 Features

New floating point 64bit MCU technology

Serial Port And Auto Tune Function

3 channels opto-coupler isolation OC output

Advanced vector control technology

High torque at starting and low speed

5 channels opto-coupler isolation input,2 of them are high speed opto-coupler isolation input

Communication Frequency up to 100MHz

DIPs can set 127 IPs or automatic allocate IP

Current setting range 0.5-8A

Smooth movement and extra low noise

The supported encoder can be 500ppr—5000ppr.

3 Applications

For a variety of small and medium-sized automation equipment and instruments, such as: AGV, speed pass door,

engraving machine, marking machine, cutting machine, laser Phototypesetting, router machine, plotter, CNC

machine tools, automatic assembly equipment. The users can get special effect from small noise, high speed

equipment application.

Page 6

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

Description

EHS-580

Min

Typical

Max

Unit

Output Current(peak)

0.5 - 8.0 A Input Voltage(DC)

15

24/36/48

50

VDC

Control Signal Input Current

6

10

16

mA

Control Signal Interface

Electricity

4.5 5 28

Vdc

OC output Pull-Up voltage

5 - 24

Vdc

Ether-CAT communication

frequency

-

100

-

MHz

Insulation Resistance

100

MΩ

Cooling

Natural Cooling or Forced cooling

Environment

Condition

Far away from other heating device,Avoid dust, oil fog

and corrosive gases, heavy humidity and strong vibration

occasion, forbid flammable gases and conductive dust

Temperature

-10℃~ +50℃

Humidity

40 ~ 90%RH

Vibration

5.9m/s2MAX

Storage Environment

-20℃~60℃

Altitude

Less than 1000m

Weight

about 0.2KG

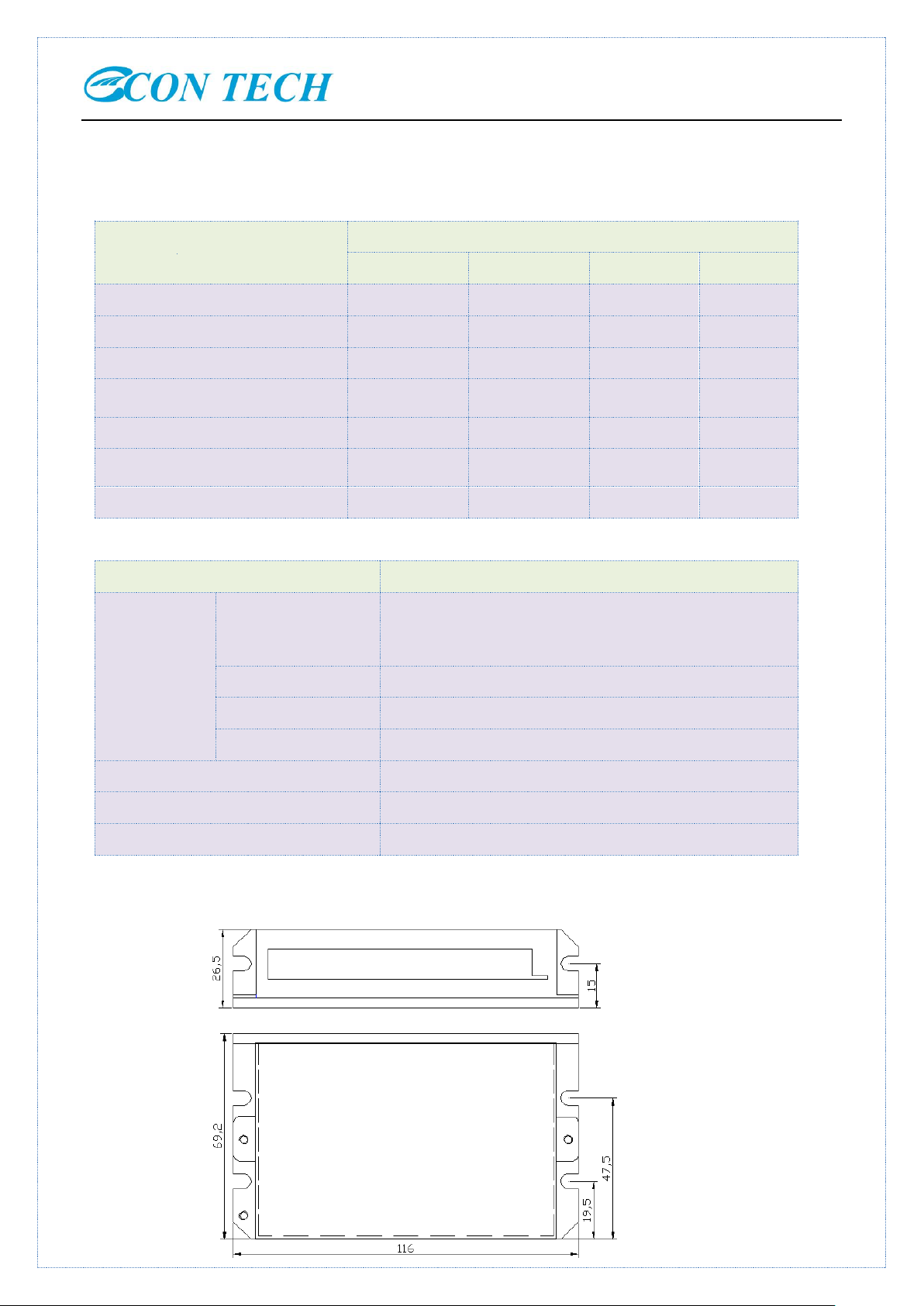

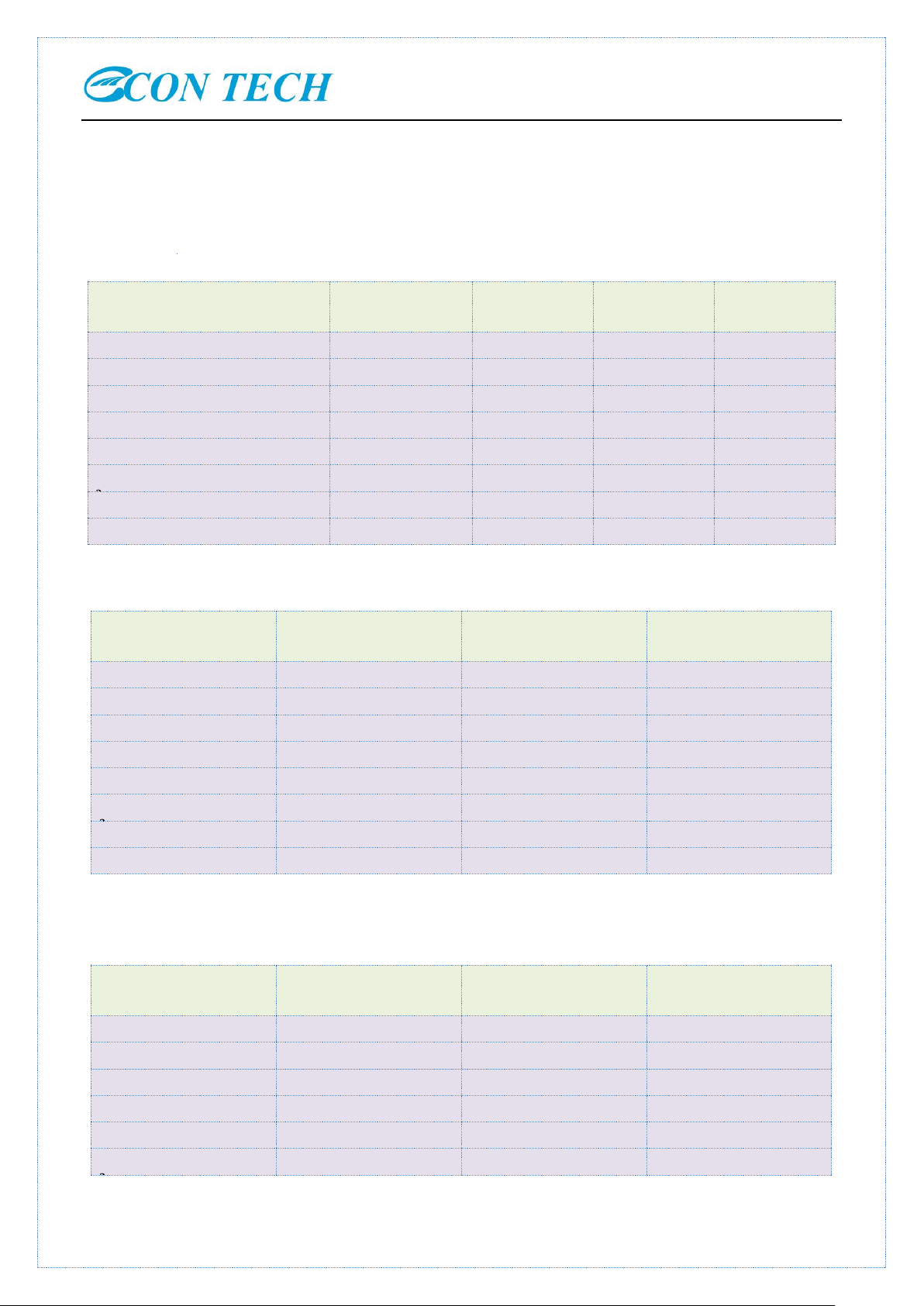

4 Specifications

4.1 Electrical Specifications

4.2 Operating Environment

5 Mechanical Specifications

Page 7

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

Pin Function

Details

pl+

INEFFECTIVE

pl-

dr+

dr-

in+

Low speed signal:in1,in2,in3 common positive input,5-28VDC

in1

Low speed in1 negative input

in2

Low speed in2 negative input

in3

Low speed in3 negative input

ot-

Common negative OC emitter output,ot1,ot2,ot3 emitter OC output common terminal

]I/O signal

Encoder

Motor

Power input

※Recommend side installation, better cooling effect, when design installation dimension, consider the terminal

size and wiring!

Enhance Cooling method

A:The driver's reliable operating temperature is usually within 60 ℃, the motor operating temperature is within

80 ℃;

B: It is recommended to use the automatic half-flow mode, the current will be automatically reduced by half when

the motor stops, so as to reduce the heating of the motor and the drive;

C: When installing the driver, please use the vertical side installation, so that the cooling teeth form a strong air

convection; when necessary, install a fan where is close to the drive, forced cooling to ensure that the drive is in a

reliable working temperature range

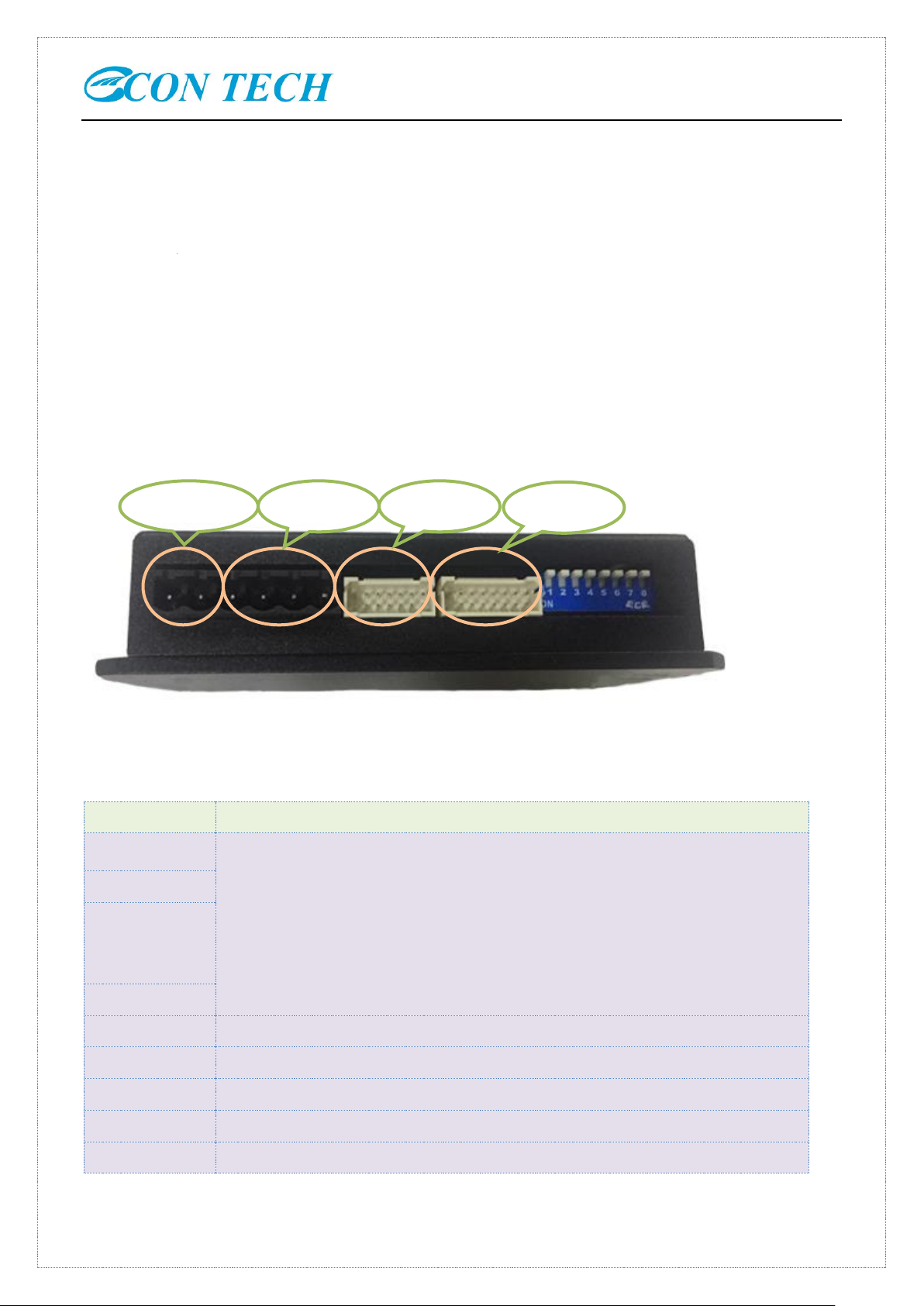

6 Connectors and Pin Assignment

The EHS-580 has four connectors, connector for i/o connections, connector for Encoder Feedback and hall signal,

connector for power and motor connection, and the CAT Communication Port

6.1 Control signals connector

Page 8

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

ot1

ot1emitter output,the Max pull-up voltage 24Vdc,the pull-up resistance 2KΩ,the Max

output current 100mA

ot2

ot2 emitter output,the Max pull-up voltage 24Vdc,the pull-up resistance 2KΩ,the Max

output current 100mA

ot3

ot3 emitter output,the Max pull-up voltage 24Vdc,the pull-up resistance 2KΩ,the Max

output current 100mA

gnd

5V-

RS232-TX

RS232-RX

5V

5V+,current 50mA

Pin Function

Details

ea+

Encoder channel A input

ea-

eb+

Encoder channel B input

eb-

ez+

Encoder channel Z input(if there is Z signal in encoder ,no connection needed )

ez-

eu+

Hall U channel U input, special for dc brushless servo, open loop/hybrid servo no

connection needed

eu-

ev+

Hall V channel U input, special for dc brushless servo, open loop/hybrid servo no

connection needed

ev-

ew+

Hall W channel U input, special for dc brushless servo, open loop/hybrid servo no

connection needed

ew-

5V

Provide 5V+ dc power to motor encoder and Hall components, current 100mA

gnd

5V-

Pin

Definition

I/O

Description

1

A+ O Motor Phase A+

2

A- O Motor Phase A- (U for dc brushless servo motor)

3

B+ O Motor Phase B+ (V for dc brushless servo motor)

4

B- O Motor Phase B- (W for dc brushless servo motor)

5

+VDC

I

15-50VDC,36VDC is recommended, leaving rooms for voltage fluctuation

6.2 Encoder Feedback and hall signal Connector

6.3 Power and Motor

Page 9

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

6

GND

GND

and back-EMF.

PIN

Signal

Function Description

1

TX+

Ether CAT data sending positive port

EtherCAT IN(ECAT IN)

2

TX-

Ether CAT data sending negative port

3

RX+

Ether CAT data receiving positive port

4

NC

No connected

5

NC

No connected

ECAT IN

ECAT OUT

Power supply voltage between the provisions of the normal work, EHS-580 driver is best to use non-regulated DC

power supply,can also use the transformer step-down + bridge rectifier + capacitor filter. However, take care that

the peak value of the rectified voltage ripple does not exceed its maximum specified voltage. It is recommended

that users use DC voltage lower than the maximum voltage to supply power and avoid the fluctuation of power grid

beyond the working range of driver voltage.

If you are using a regulated switching power supply, be aware that the output current range of the switching power

supply needs to be maximized.

Please note!

A:When wiring, pay attention to the positive and negative poles of the power supply.

B:Better use non-regulated power supply;

C:When use a non-regulated power supply, the power supply current output capacity should be greater than 60% of

the drive setting current;

D:The use of regulated switching power supply, the output current of the power supply should be greater than or

equal to the working current of the driver;

E:To reduce costs, two or three drives can share a power supply, but should ensure that the power supply is large

enough.

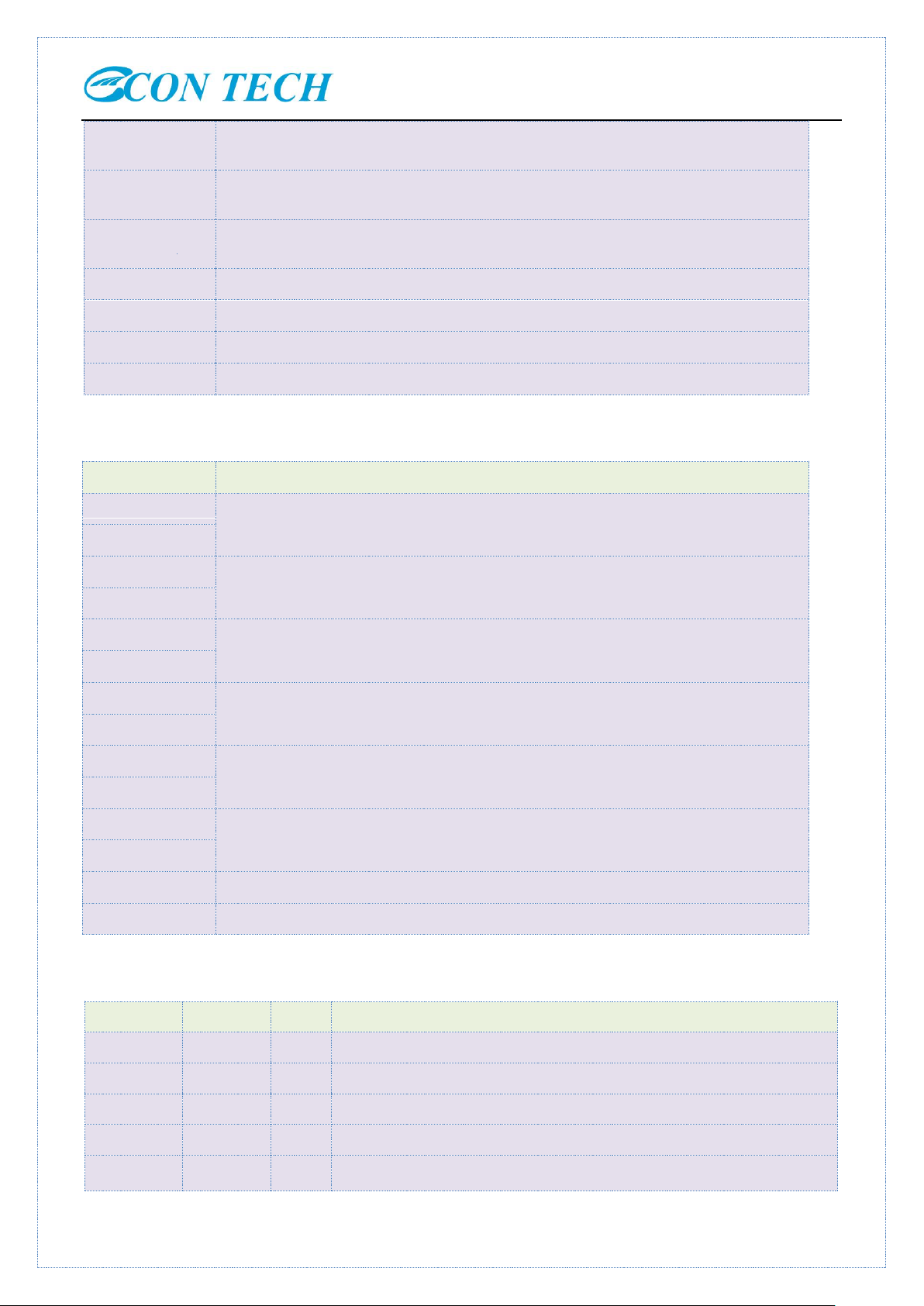

6.4 EtherCAT Communication Port

Two RJ45 terminals

Page 10

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

6

RX-

Ether CAT data receiving negative port

7

NC

Disconnect

8

NC

Disconnect

9

TX+

Ether CAT data sending positive

EtherCAT OUT(ECAT

OUT)

10

TX-

Ether CAT data sending negative

11

RX+

Ether CAT data receiving positive

12

NC

No connected

13

NC

No connected

14

RX-

Ether CAT data receiving negative

15

NC

No connected

168

NC

No connected

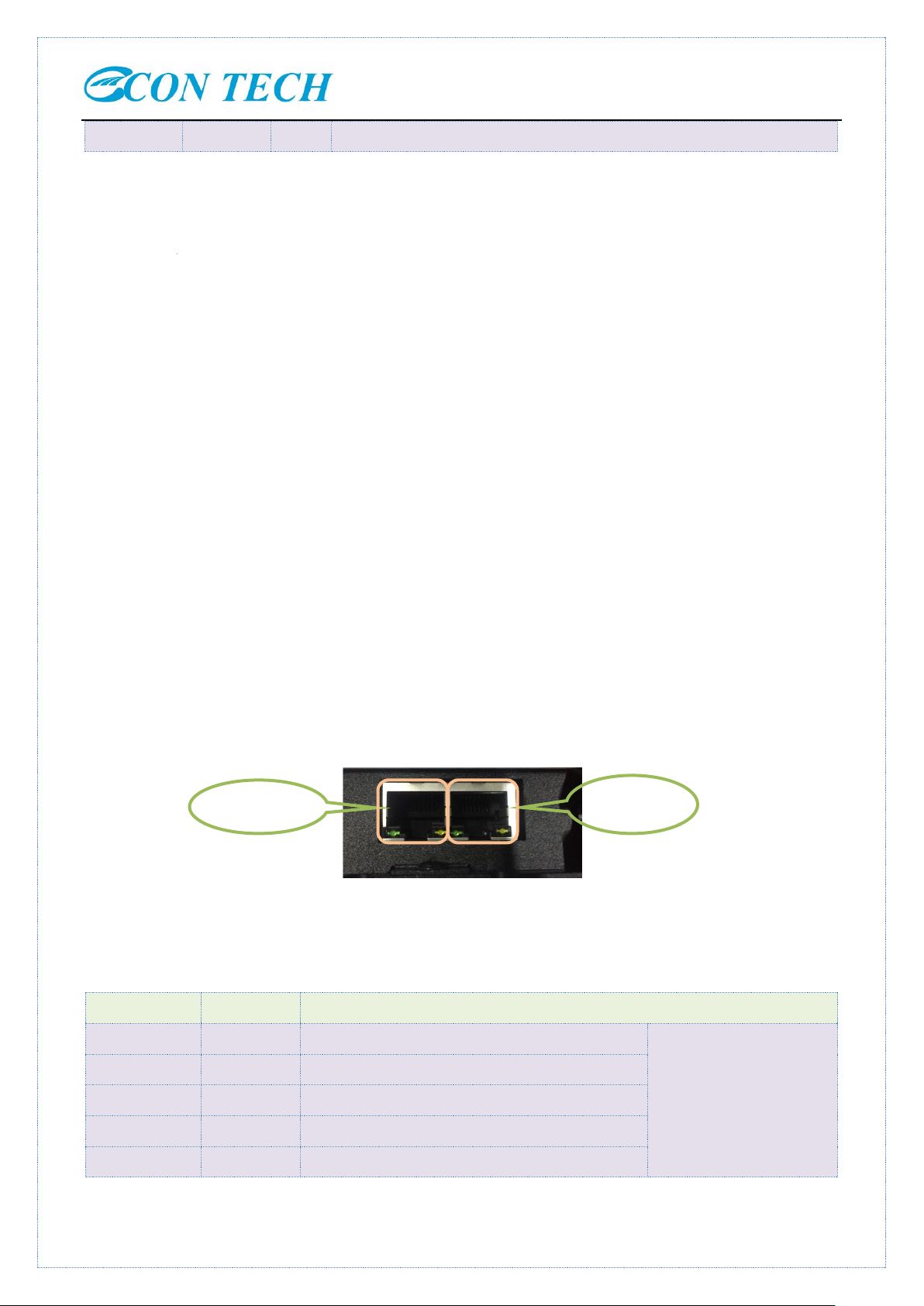

SW1

SW2

SW3

SW4

SW5

SW6

SW7

SW8

Filter Sel

SW6

SW7

Nema11

on

on

Nema17

off

on

Nema23/nema24

on

off

Nema34

off

off

Motor selection

Direction

Filter time setting

Open/closed loop Working mode

Self- test

DIP switch

Note: The cable connecting EHS-580 to PC must be a dedicated cable. Please check before use to avoid damage.

7 DIP Switch Settings

7.1 Motor selection

Page 11

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

TC42-03

TC42-04

TC42-06

TC42-08

Step Angle (Degree)

1.8

1.8

1.8

1.8

Holding Torque (N.m)

0.3

0.4

0.6

0.8

Phase Current (A)

2.3

1.68

2.3

2.3

Phase Resistance (Ohm)

0.94

1.65

1.3

1.7

Phase Inductance (mH)

1.8

2.8

2.5

4.6

Inertia (g.cm2)

57

73

86

102

Weight (Kg)

0.24

0.37

0.45

0.5

Encoder (lines / Rev.)

1000

1000

1000

1000

TC57-11

TC57-24(BK)

TC57-28

Step Angle (Degree)

1.8

1.8

1.8

Holding Torque (N.m)

1.1

2.4

2.8

Phase Current (A)

6.0

5.6

5.6

Phase Resistance (Ohm)

0.2

0.4

0.5

Phase Inductance (mH)

0.52

1.5

2.0

Inertia (g.cm2)

300

480

550

Weight (Kg)

0.7

1.1

1.8

Encoder (lines / Rev.)

1000

1000

1000

TC60-15

TC60-30

TC60-40

Step Angle (Degree)

1.8

1.8

1.8

Holding Torque (N.m)

1.5

3.0

4.0

Phase Current (A)

6.0

6.0

5.6

Phase Resistance (Ohm)

0.3

0.6

0.5

Phase Inductance (mH)

1.1

1.8

2.1

Inertia (g.cm2)

400

840

840

8 Hybrid servo Motors

EHS-580 can work with the following ECON technology’s hybrid servo motors:

8.1 Nema17

8.1 Nema23

BK:the motor supports brake

8.3 Nema24 motor

Page 12

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

Weight (Kg)

0.8

1.4

1.6

Encoder (lines / Rev.)

1000

1000

1000

TC86-45

TC86-85

TC86-120

Step Angle (Degree)

1.8

1.8

1.8

Holding Torque (N.m)

4.5

8.5

12

Phase Current (A)

6.0

6.0

6.0

Phase Resistance (Ohm)

0.325

0.5

0.73

Phase Inductance (mH)

3.0

6.0

8.68

Inertia (g.cm2)

1400

2700

4000

Weight (Kg)

2.3

3.8

5.3

Encoder (lines / Rev.)

1000

1000

1000

8.4 Nema34 hybrid servo motor

Note: All motors can make brake

9 Wiring Diagrams

9.1 Interface

Page 13

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

Flashes Times

Red LED flash wave

Fault Description

1

over-current or phase short-circuit fault

2

over-voltage fault

3

under-voltage fault

7

over-error alarm

9

phase fault or current collecting fault

9.2 Diagram

10 Protection Indications

The green indicator turns on when power-up. When drive protection is activated, the red LED blinks periodicity to

indicate the error type.

A:Over current or phase Short circuit protection

When a short circuit occurs or the internal drive over-current, the drive RED Led flashes 1 time, and repeat flashing

within 3 seconds. At this point must discharge fault, re-power and reset.

B: Over-voltage protection

When input voltage is higher than 55V, the driver RED Led flashes twice, and flashes repeatedly within 3 seconds.

At this point must discharge fault, re-power and reset.

△ Note! Since the drive does not have the power supply reverse polarity protection function, therefore,

before power on, make sure the positive and negative power supply wiring is correct. Reverse polarity will

lead to burn the fuse in the drive!

11 Frequently Asked Questions

In the event that your drive doesn’t operate properly, the first step is to identify whether the problem is electrical or

Page 14

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

Problem

Possible Reason

Solution

Motor is not rotating

Power supply light is off

check power supply line, keep power supply

normal

motor shaft disabled

Pulse signal weak, increase signal current to

7-16mA

Micro-step too small

select the suitable micro-step

current setting is too small

Select the correct current

drive protected

Reboot

Enable signal too low

Pull up enable signal or disconnect

no action to control signal

Check the power supply input

Wrong motor motion

Motor cable incorrect

connect

Change any two cables of same phase(such as

A+/A- change)

Motor cable has breakage

Check and correct wiring connection

The drive In alarm

motor cable incorrect

connect

Check wiring

over-voltage or

under-voltage

Check power supply

motor or drive damaged

Replace a motor or drive

Position inaccurate

signal is interfered

Exclude interference

Shield ground disconnect or

bad connect

Reliable ground connection

Motor cable has breakage

Check and correct wiring connection

Wrong micro-step

Set correct micro-step

Current small

Increase current

Motor stall when

speed increase

Acceleration time is too

short

Increase acceleration time

Motor torque is too small

Select big torque motor

Voltage is low or current is

small

Suitable increase voltage and current

mechanical in nature. The next step is to isolate the system component that is causing the problem.As part of this

process you may have to disconnect the individual components that make up your system and verify that they

operate independently. It is important to document each step in the troubleshooting process. You may need this

documentation to refer back to at a later date, and these details will greatly assist our Technical Support staff in

determining the problem should you need assistance.

Many of the problems that affect motion control systems can be traced to electrical noise, controller software errors,

or mistake in wiring.

Problem Symptoms and Possible Causes

12 Warranty

Shenzhen ECON Technology Co., Ltd. warrants its products against defects in materials and workmanship for a

Page 15

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

period of 12 months from shipment out of factory. During the warranty period, ECON technology will either, at its

option, repair or replace products which proved to be defective.

Exclusions

The above warranty does not extend to any product damaged by reasons of improper or inadequate handlings by

customer, improper or inadequate customer wirings, unauthorized modification or misuse, or operation beyond the

electrical specifications of the product and/or operation beyond environmental specifications for the product.

Obtaining Warranty Service

To obtain warranty service, a returned material authorization number (RMA) must be obtained from customer

service at e-mail: technical01@hybridservo.com before returning product for service. Customer shall prepay

shipping charges for products returned to ECON technology for warranty service, and ECON technology shall pay

for return of products to customer.

Warranty Limitations

ECON technology makes no other warranty, either expressed or implied, with respect to the product. ECON

technology specifically disclaims the implied warranties of merchantability and fitness for a particular purpose.

Some jurisdictions do not allow limitations on how long and implied warranty lasts, so the above limitation or

exclusion may not apply to you. However, any implied warranty of merchantability or fitness is limited to the

12-month duration of this written warranty.

Page 16

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

Command input type

Variable

Operation mode

BUS command input

Address 6060H=1

PP mode

Address 6060H=3

PV mode

Address 6060H=6

HM mode

Address 6060H=8

CSP mode

Part

2 :EHS-580

EtherCAT Communication Protocol

Specification

1. Introduction

EHS-580 is a new released EtherCAT hybrid servo drive , which support CANopen over EtherCAT (CoE) control

and CiA 402 operating modes ,including Profile Position (PP), Profile Velocity (PV), Homing (HM) and Cyclic

Synchronous Position (CSP). This drive is compatible with many EtherCAT controller/PLC ,such as Beckhoff,

Omron, etc. its excellent performance can meet many applications with extra low noise, low heating and super

smoothness.

2. Operation mode

A: PP mode:profile position mode

B: PV mode:Profile velocity mode

C: HM mode:Homing mode

D: CSP mode:Cyclic synchronous position mode

2.1 Profile position mode(PP)

Profile Position control mode is general point to point operation, to move to target position of Target position

(607Ah) object with receipt of Control word (6040h) input, need to set Profile Position Mode at operation mode

object (6060h). The Operation Mode Display object (606lh) is shown as Profile Position Mode.

Page 17

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

Data write/read

Object

Description

Value

Unit

RXPDO

6060h

Operation Mode

1

-

6040h

Control word

User self-defined

-

607Ah

Target Position

User self-defined

Unit

6081h

Maximum speed

User self-defined

Unit/s

6082h

Start /Stop speed

User self-defined

Unit/S^2

6083h

Profile Acceleration

User self-defined

Unit/S^2

6084h

Profile Deceleration

User self-defined

Unit/S^2

6085h

Emergency stop deceleration, base

on the value of 605Ah

User self-defined

Unit/S^2

605Ah

Enable the deceleration of E-stop(5:

enable; Others: disable)

User self-defined

-

2000h

Revolution per round

User self-defined

pulse

TXPDO

6041h

Status word

Read only

-

6064h

Actually position Feedback

Read only

Unit

606Ch

Actual velocity feedback

Read only

Unit/s

603Fh

Error code

Read only

-

6061h

Operation mode display

Read only

-

Bit

Value

Description

4(new position)

0 —> 1

The motor run with the max speed(6081h) and

Acc(6083h )/Dec(6084h) to latest target position(607Ah)

5((trigger immediately)

0

Trigger the new movement after the current movement is

completed

1

Interrupt the current movement immediately, and start the

new movement

6 (absolutely /relatively)

0

Process target position(607Ah) as the absolutely position

1

Process target position(607Ah) as the relatively position

Bit 5

0

1

2.1.1 Related objects

2.1.2 Control word and Status word

In PP Mode, the bits 4~6 of Control word (6040h)

2.1.3Typical motion mode of bit 5 at PP mode

Page 18

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

Forward movement to updated

target position with Acc/constant

speed

Forward movement to updated

target position with Dec

Backward movement to updated

target position

Bit

Value

Description

8 (abnormal stop)

0

Normal movement

1

Trigger by abnormal stop, motor will stop

10 (position reached)

0

Movement is continue

1

target position reached

12 (new position

response)

0

When current movement is completed or interruptable, can update new target

position

1

When current motion uncompleted/uninterruptable, it can not update new target

position

14(parameters value

for movement are 0)

0

Parameters for movement are effective, and all necessary parameters are not 0

1

One of parameters( max speed-6081h, acceleration-6083h) and deceleration

--6084h)must be 0

15 (Trigger

response)

0

When current movement is not completed or not interruptable,can not update

new target position

1

When current movement is completed or interruptable, can update new target

position

A:Command change time of master

B:Arrived time to the target position(before updated)

C:Arrived time to the target position(after updated)

2.1.4 The bit 8,10.12-15 of status word

A: Bit8 abnormal stop is effective at the triggered status for hardware limit switch, deceleration stop and

emergency stop

B:Bit 12 of Status word (6041h) will clear to 0 when the bit 5 of control word (6040h) is triggered and bit 4 of

Page 19

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

Data write/read

Object

Description

Value

Unit

RXPDO

6060h

Operation Mode

1

-

6040h

Control word

User self-defined

-

60FFh

Target Position

User self-defined

Unit

6083+00h

Profile Acceleration

User self-defined

Unit/S^2

6084+00h

Profile Deceleration

User self-defined

Unit/S^2

TXPDO

6041h

Status word

Read only

-

6064h

Actually position Feedback

Read only

Unit

606Ch

Actual velocity feedback

Read only

Unit/s

Bit

Value

Description

8(quickly stop)

0

Quickly stop is disabled

1

Quickly stop is enabled

10(speed reached)

0

The current speed has not reach to target speed

1

The current speed reach to target speed

12 (speed is 0)

0

Speed is not 0 , the movement is not completed

1

Speed is 0 or the speed is ready to be 0 with Dec

Data write/read

Object

Description

Value

Unit

6060h

Operation Mode

1

-

(6040h) is invalid triggered (for example 6040h = 0x2F/4F), it can be interrupted

C: The logic of bit 5 and bit 12 is always reverse in PP mode.

2.2 Profile velocity mode(PV )

Profile velocity mode is a relatively simple operating mode via execution related command sending by EtherCAT

master

2.2.1Controlword and Status word

In PV Mode, bits 4~6of Control word (6040h) are not effective, the movement will be active by setting some

movement parameters, including target velocity (60FFh), acceleration/deceleration (6083h/6084h).

2.3Cyclic synchronous position mode(CSP)

Cyclic Synchronous Position mode (CSP Mode) assigns target position to EHS-580hybrid servo drives by Master's

profile creation function through cyclic communication. Drives internally execute position/velocity control with

receipt of target position in each cycle.

The supported synchronizing cycles are: 250us, 500us, 750us, 1000us, 2000us and 4000us.

2.3.1 Related objects

Page 20

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

RXPDO

6040h

Control word

User self-defined

-

607Ah

Target Position

User self-defined

Unit

60B0h

Maximum speed

User self-defined

Unit/s

2000h

Revolution per round

User self-defined

pulse

TXPDO

6041h

Status word

Read only

-

6064h

Actually position Feedback

Read only

Unit

606Ch

Actual velocity feedback

Read only

Unit/s

603Fh

Error code

Read only

-

6061h

Operation mode display

Read only

-

Data write/read

Object

Description

Value

Unit

RXPDO

6060h

Operation Mode

1

-

6040h

Control word

User self-defined

-

607Ah

Target Position

User self-defined

Unit

6081h

Maximum speed

User self-defined

Unit/s

6082h

Start /Stop speed

User self-defined

Unit/S^2

6083h

Profile Acceleration

User self-defined

Unit/S^2

6084h

Profile Deceleration

User self-defined

Unit/S^2

6085h

Emergency stop deceleration, base

on the value of 605Ah

User self-defined

Unit/S^2

605Ah

Enable the deceleration of E-stop(5:

enable; Others: disable)

User self-defined

-

2000h

Revolution per round

User self-defined

pulse

TXPDO

6041h

Status word

Read only

-

6064h

Actually position Feedback

Read only

Unit

606Ch

Actual velocity feedback

Read only

Unit/s

603Fh

Error code

Read only

-

6061h

Operation mode display

Read only

-

2.4 Homing mode(HM)

Homing mode is the way of detecting the home point with command of Control word (6040h). 6060h is address for

homing Mode enable/disable. And will execute the command once Mode of operation display (6061h) indicates

Homing Mode.

2.4.1 Related objects

2.4.2 The bits 4~6 of Control word (6040h)

Page 21

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

Bit

Value

Description

4(new position)

0 —> 1

The motor run with the max speed(6081h) and

Acc(6083h )/Dec(6084h) to latest target position(607Ah)

5((trigger immediately)

0

Trigger the new movement after the current movement is

completed

1

Interrupt the current movement immediately, and start the

new movement

6 (absolutely /relatively)

0

Process target position(607Ah) as the absolutely position

1

Process target position(607Ah) as the relatively position

Bit

Value

Description

8 (abnormal stop)

0

Normal movement

1

Trigger by abnormal stop, motor will stop

10 (position reached)

0

Movement is continue

1

target position reached

12 (new position

response)

0

When current movement is completed or interruptable, can update new target

position

1

When current motion uncompleted/uninterruptable, it can not update new target

position

14(parameters value

for movement are 0)

0

Parameters for movement are effective, and all necessary parameters are not 0

1

One of parameters( max speed-6081h, acceleration-6083h) and deceleration

--6084h)must be 0

15 (Trigger

response)

0

When current movement is not completed or not interruptable,can not update

new target position

1

When current movement is completed or interruptable, can update new target

position

2.4.3 The bit 8,10.12-15 of status word

A: Bit8 abnormal stop is effective at the triggered status for hardware limit switch, deceleration stop and

emergency stop

B:Bit 12 of Status word (6041h) will clear to 0 when the bit 5 of control word (6040h) is triggered and bit 4 of

(6040h) is invalid triggered (for example 6040h = 0x2F/4F), it can be interrupted

C: The logic of bit 5 and bit 12 is always reverse in PP mode.

Page 22

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

Address

Definition

Default

value

Range

Description

2152+01

Input 1

R/W/S

1

0—32768

1:homing

2:limit4:limit+

2152+02

Input 2

R/W/S

2

0—32768

1:homing

2:limit4:limit+

2152+03

Input 3

R/W/S

4

0—32768

1:homing

2:limit4:limit+

2152+04

Input 4

R/W/S

8

0—32768

1:homing

2:limit4:limit+

2152+05

Input 5

R/W/S

0

0—32768

1:homing

2:limit4:limit+

2153+01

Filter time for Input1

R/W/S

20

1—60000

Unit:50us

2153+02

Filter time for Input2

R/W/S

20

1—60000

Unit:50us

2153+03

Filter time for Input3

R/W/S

20

1—60000

Unit:50us

2153+04

Filter time for Input4

R/W/S

20

1—60000

Unit:50us

2153+05

Filter time for Input5

R/W/S

20

1—60000

Unit:50us

Input connector

Output connector

3. Input and output

3.1 Input configuration

The IN1~IN3 are single end input ports(The power supply from host Controller/PLC/motion Control card should

be 12-24VDC, current ≥ 100mA), pl+,pl-,dr+,dr- are high speed differential pulse input ports.

Page 23

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

2154+00

Logic configuration for

inputs

R/W/S 0 0/1

0:Positive logic

1:negative logic

bit0: input1 polarity setting

bit1: input2 polarity setting

bit2: input3 polarity setting

bit3: input4 polarity setting

bit4: input5 polarity setting

2155+00

Level configuration for

inputs

R 0

0/1

0:Low level

1:High level

bit0: input1 polarity setting

bit1: input2 polarity setting

bit2: input3 polarity setting

bit3: input4 polarity setting

bit4: input5 polarity setting

Address

Definition

Description

60FD+00

Input status

R

bit0:limit-

bit1:limit+

bit2:homing

Address

Definition

Default value

Range

Description

2005+01

Output1

R/W/S 1 1—4

bit0:Alarm output

bit1:Ready output

Bit2: Pend output

2005+02

Output 2

R/W/S 1 1—4

bit0:Alarm output

bit1:Ready output

Bit2: Pend output

IO Status display

3.2 Output configuration

A:The power supply for outputs is 12-24VDC, and if power supply is wrong wiring, it is a risk to burnt the drive

B: It is OC output with the maximum capacity of 50mA/25V, it is recommended to connect a resistor to power

supply(1K Ohm for 12VDC ,2K Ohm for 24VDC)

C:If the output is a relay, it is recommended to connect a freewheel diode with inverse parallel connection to relay

for protection the drive

Page 24

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

2008+00

Output level

R/W/S 0 0/1

0:Low level

1:High level

bit0 :out1

bit1: out2

Address

Definition

Default value

Range

Description

2150+00

Slave address

R/W/S

1

1—65535

Slave address

2151+00

Salve address

resource

R/W/S 0

0~2

0:From DIP switch,when the DIP setting

is 0, it is from EEPROM.

1:From 2150h

Address

Definition

Default value

Range

Description

2051+00

Motor rotation

direction

R/W/S 0 0/1

0:no change for motor rotation direction

1:reversed motor rotation direction

Address

Definition

Default value

Range

Description

2001+00

Pulse/Revolution

R/W/S

50000

200—51200

Pulse for per revolution

3.3 Related node ID

The master can scan the node address automatically ,and it also can be set by manual

3.3.1 DIP switch setting

When the 2151h value is 0,the user can set the slave address by DIP switch(it is effective only after restarting drive)

3.3.2Reading the ID alias of ESC

The EtherCAT master can configure ID alias to the EEPROM 0004h of ESC, when the 2051h is 0, and the address

setting via DIP switches is 0, the value at address 0004h will be the ID alias of the slave after the power supply

restarted.

3.3.3 Setting the ID alias via object dictionary

If the 2151h is 1,the value of 2150h will be the ID alias after the power supply restarted.

3.4 Motor rotation direction setting

The motor rotation direction can be set by command from master

3.5 Pulse/Revolution setting

Page 25

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

Address

Definition

Default

value

Range

Description

2000+00

Peak current

R/W/S

3200

1 to the max

current

Output current(mA)。

2001+00

Pulse/revolution

R/W/S

50000

200—51200

Pulse for per revolution

(pulse)

2002+00

Stand-by time

R/W/S

500

100—10000

Unit:ms

2005+01

Output1

R/W/S 1 1—4

bit0:Alarm output

bit1:Ready output

Bit2: Pend output

2005+02

Output 2

R/W/S 1 1—4

bit0:Alarm output

bit1:Ready output

Bit2: Pend output

2008+00

Output level

R/W/S 0 0/1

0:Low level

1:High level

bit0 :out1

2009+00

Pulse filter time

enable/disable

R/W/S 0 0/1

0:Disable

1:Enable

2010+02

Filter time

R/W/S

1000

50—25600

Unit:us

4. Parameters

4.1 Parameter saving

The master save the parameters to EEPROM via 0x1010-04 written. When the drive detect the value of

0x1010-04 from master is 0x65766173, the drive will save parameters to EEPROM.

Note! During the EEPROM written operation , please don’t cut off power supply of drive , otherwise cause the

wrong data written

4.2 Parameter reset

The master reset the parameters to default value via 0x1010-04 written. When the drive detect the value of

0x1010-04 from master is 0x64616f6c,all parameter will be reset to default value .

4.3 Parameters list

4.3.1 General parameter list

Page 26

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

2013+00

Current loop KP,KI

auto tuning

enable/disable

R/W/S 1 0/1

Auto tuning the Current loop

KP,KI when power up

0:disable 1:enable

2015+00

Current Kp

R/W/S

1000

200—

32767

When the 2013+00 is 1(enable),

this parameter read only

2016+00

Current Ki

R/W/S

200

0—32767

When the 2016+00 is 1(enable),

this parameter read only

2017+00

Current Kc

R/W/S

100

80—300

Read only

2020+00

Motor resistor

R/W/S

1000

1—20000

Unit:mOhms

2021+00

Motor inductance

R/W/S

1

1—6000

Unit:uH

2024+00

Open/closed mode

R/W/S 2 0~2

1:open loop mode

2:closed loop mode

2025+00

Control mode

R/W/S 5 0—10

0:DIP switch

1:Lead2:PM

3:FOC

4:self- test

5:CL

2026+00

Current for shaft

locking

R/W/S

50

0—100

Unit:%,Effective at open loop

mode only

2029+00

Encoder resolution

R/W/S

1000

200—60000

p/r

2030+00

Position following

error

R/W/S

1000

1—60000

pulse

2039+00

Pulse amount H

R 0 0~65535

The received pulse amount H

(16bit)

2040+00

Pulse amount L

R/W 0 0~65535

The received pulse amount16bit

write:write1to clear counter

2041+00

Encoder feedback

amount H

R 0 0~65535

The received encoder feedback

pulse amount H(16bit)

2042+00

Encoder feedback

amount H

R 0 0~65535

The received encoder feedback

pulse amount L(16bit)

write:write 1 to clear counter

2051+00

Motor rotation

direction

R/W/S 0 0/1

0:no change for the rotation

direction

1:reversed rotation direction

2053+00

Pend output

R/W/S 0 0~1

0:low level

1:high level

Page 27

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

2056+00

Fault detecting

selection

R/W/S

0xc3

0—0xffff

2057+00

Fault clear

enable/disable

R/W/S 0 0/1

0:Disable

1:Enable

2058+00

Current soft-start time

for shaft enable

R/W/S

1

0—10000

For reducing the vibration when

power up or motor shaft enable

Unit:50us

2083+00

Shaft right left wiggle

when power up

enable/disable

R/W/S 0 0/1

0:Disable

1:Enable

2137+00

Position loop KP

R/W/S

120

0~150

-

2138+00

Position loop KI

R/W/S

50

0~150

-

2139+00

Position loop KVFF

R/W/S

70

0~150

-

2140+00

Speed loop KP

R/W/S

60

0~150

-

2150+00

Slave ID

R/W/S

1

1—65535

Slave address

2151+00

Slave ID resource

R/W/S

0

0~2

0:from DIP switch , when DIP

switch is 0,it is from EEPROM.

1:from2150h

2152+01

Input 1

R/W/S

1

0—32768

1:homing

2:limit4:limit+

2152+02

Input 2

R/W/S

2

0—32768

1:homing

2:limit-

2152+03

Input 3

R/W/S

4

0—32768

1:homing

2:limit-

2152+04

Input 4

R/W/S

8

0—32768

1:homing

2:limit-

2152+05

Input 5

R/W/S

0

0—32768

1:homing

2:limit-

2153+01

Filter time for Input1

R/W/S

20

1—60000

Unit:50us

2153+02

Filter time for Input2

R/W/S

20

1—60000

Unit:50us

2153+03

Filter time for Input3

R/W/S

20

1—60000

Unit:50us

2153+04

Filter time for Input4

R/W/S

20

1—60000

Unit:50us

2153+05

Filter time for Input5

R/W/S

20

1—60000

Unit:50us

Page 28

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

2154+00

Logic configuration for

inputs

R/W/S

0

0/1

0:Positive logic

1:negative logic

bit0:input1 polarity

setting

bit1: input2 polarity

2155+00

Level configuration for

inputs

R 0

0/1

0:Low level

1:High level

bit0: input1 polarity

setting

bit1: input2 polarity

setting

bit2: input3 polarity

setting

bit3: input4 polarity

setting

bit4: input5 polarity

setting

2093+00

Record for fault clear

R/W

Address

Definition

Description

6040+00

Control word

R/W

Control word

6041+00

Status word

R

Status word

6060+00

Operation mode

RW

1—PP mode

3—PV mode

6—HM mode

8-CSP mode

6061+00

Mode display R Display the operation mode

6062+00

Command position

R

Display the motor command position

6064+00

Actual position

R

Display the motor actual position

606B+00

Command speed

R

Display motor command speed

606C+00

Actual speed

R/W

Display the motor actual speed Unit:RPM

607A+00

Target position

R/W

The target position at PP mode,if the control word setting for

movement start, it will be changed to valid command position

607C+00

Homing offset

R/W

Homing offset

6081+00

Trapezoidal speed-

R/W

The max trapezoidal speed at PP mode

4.3.2 Operation mode control parameter list

Page 29

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

6082+00

Start-stop speed

R/W

The start and stop speed at PP mode

6083+00

Trapezoidal Acc

R/W

Trapezoidal Acc

6084+00

Trapezoidal Dec

R/W

Trapezoidal Dec

6085+00

Dec for E-stop

R/W

Dec for E-stop,it is enabled or disabled depend on the value of

6098+00

Homing research mode

R/W

Homing research mode

6099+01

Homing research speed

R/W

Speed for researching limit switch

6099+02

Homing research speed

R/W

Speed for researching homing

609A+00

Homing research Acc

R/W

Acc of Homing research

60F4+00

Position following error R Position following error

60FD+00

Input status

R

bit0:limit-,bit1:limit+,bit2:homing

60FF+00

Target speed

R/W

The max speed at PV mode

Frame structure

Definition

Target address

MAC address of Receiver

Source address

MAC address of Sender

EtherCAT frame header: data length

EtherCAT the total length of all sub messages in the data field

EtherCAT frame header type

1: communication with slave stations; others are reserved

FCS

The Frame check

5. Basic Information Of EtherCAT

5.1EtherCATData Frame Structure

EtherCAT transmit the data with the network data frame; the fixed frame type is 0x88A4. It includes two bytes of

EtherCAT frame header and 44~1498 bytes of EtherCAT data. The EtherCAT data field consists of one or some

EtherCAT sub messages, each message is corresponding to a storage area of the slave station.

5.2 Synchronous Mode

5.2.1 Random running mode

At this mode, the drive adopt asynchronous mode to process the processing data from master, it is suitable for

asynchronous operation mode only, such as HM mode, PP mode.

5.2.2 Distributed clock synchronization mode

After the master sending the processing data , the slave station receive and read the processing data immediately, at

Page 30

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

Communicationfunction

In it

Communication between master and slave stations

Pre-Operation

Mail communication is effective, and no processing data communication, means SDO

function is effective

Safe-Operation

Mail communication and processing data objects sending are effective, means SDO and

TX PDO are effective

Operation

Mail communication, processing data receiving and are is effective, means SDO, RX PDO

and TXPDO are effective

the same time ,it wait the Synchronous signal to trigger the processing data and effect to drive

The processing data must reach drive earlier than SYNC0 T1,and the drive must compete all Analysis of data and

related control algorithm. after receiving SYNC0,drive send the control command immediately. This mode is very

good for data Synchronization

5.2.3 EtherCAT state machine

EtherCAT state machine, commonly called as "communication state machine.it mainly manage the communication

between master and slave .this communication function includes the communication for mail and processing data.

EtherCAT state machine transmission blow chart

The transmission of the EtherCAT state machine features:

A:From initialization to operation, it must follow the sequence(low--high)strictly: you must switch from low to

high ,such as initialization→pre-operation→Safe-operation→operation

B:From high to low transmission, it can be skipped .

C:The master is the sender for all state transmission, the slave must response all request from master

D:If the request from master is failed ,the slave will feedback error to master

5.3 COE

COE is similar as CANopen DS301,but basic on CANopen DS301 , the COE has some changes and extension, the

main difference as below chart

Page 31

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

Items

COE

DS301

Fieldbus

EtherCAT

CAN

Message structure

Standard Ethernet

CAN 2.0Astandard

SDO data collection

SM mailbox data area

CAN message

PDO data collection

SM processing data area

CAN message

The length for Each PDO mapping

Maximum 32 bytes

Maximum 8bytes

Communication state machine

0x120/0x130 register

NMT (network management tool)

Identification of communication

Synchronization management

COB-ID (object dictionary identification

5.3.1 Service data object (SDO)

EHS-580 hybrid servo drive supports SDO function, the EtherCAT master can write/read the object dictionary of

drive ,and configure ,monitor, control the drive by SDO.

The SDO is the user/server mode, the master is corresponds to the user in the SDO operation, and

The drive is a server, all of transmission/command must be from master to user.

At the CANopen DS301 mode, the SDO protocol can transmit 8 bytes one time in order to match the

data length of CAN packets. at the COE enhancement mode, it expand the payload data only, and don’t change the

protocol header. In this way, the SDO can use the larger mailbox, and improve the efficiency of data transmission.

5.3.2 SDO protocol and message format

Here are two SDO service supported by EHS-580 hybrid servo drive

A:Fast transmission service: it is same as CANopen DS301,use 8 bytes only to transmit 4 bytes of valid data

B:Conventional transmission service: the max bytes of transmission data depend on the capacity of mail box

manager.

SDO download service format as below chart

The details table for transmission requested service data of SDO downloading

Page 32

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

Data area

Bytes

Bit

Definition

Description

Mail header

2

16

Length n

n≥0x0A,COE command and length of SDO data

2

16

Address

Data resource address

1

0~5

Channel

Reserved

6~7

Priority grade

0: lowest priority

1

0~3

Type

3: COE

4~7

Reserved

COE

command

2

0~8

PDO code

0

9~11

Reserved

12~15

Service type

2: SDO request

SDO data

1(control

byte)

0

Quantity mark

0: Not set;

1: Set byte of transmission

1

Transmission

0:conventional/segment

2~3

Byte

transmission

0:conventional/segment transmission invalid;

others: number of byte transmission

4

Completed visit

0: incomplete visit;

1: complete visit

5~7

Command code

0:segment download request

1: download request

2

16

Index

Object dictionary index

1 8 Sub-index

Object dictionary sub-index

4

32

Data

Fast transmission: specified object dictionary data

Conventional transmission: total bytes of object dictionary

n-10

Extended data

Conventional transmission for extended data

Data area

Bytes

Bit

Definition

Description

Mail header

2

16

Length n

n≥0x0A,COE command and length of SDO data

2

16

Address

Data resource address

1

0~5

Channel

Reserved

6~7

Priority grade

0: lowest priority

1

0~3

Type

3: COE

5.3.3SuspendSDO transmission

If it occurs error for data analysis during SDO transmission, the request for suspending SDO transmission can be

sent to master, and receiving the request, SDO transmission is suspended immediately

Suspend SDO transmission chart

Page 33

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

4~7

Reserved

COE

command

2

0~8

PDO code

0

9~11

Reserved

12~15

Service type

2: SDO request

SDO data

1(control

byte)

0

Quantity mark

0

1

Transmission

0:conventional/segment

2~3

Byte

transmission

0

4

Reserved

5~7

Command code

4:Terminate SDO transmission request

2

16

Index

Object dictionary index

1 8 Sub-index

Object dictionary sub-index

4

32

suspend code

Details refer to the suspend code chart

Termination code

Meanings

0x05040000

SDO transmission timeout

0x05040001

Command code is invalid or unknown

0x05040005

Memory overflow

0x06010000

An attempt to manipulate objects that do not support access

0x06010001

An object that attempts to write only properties

0x06010002

An object that attempts to write a read-only property

0x06020000

The object to access does not exist

0x06040041

Object cannot be mapped to PDO

0x06040042

The length of the PDO mapping exceeds the prescribed length

0x06090011

The object sub-index does not exist

0x06090031

The input value exceeds the max value and it’s set to the max value automatically

0x06090032

The input value exceeds the min value and it’s set to the min value automatically

0x08000000

General error

0x08000020

Unsupported transmission/save operation

0x08000021

Invalid save operation

Suspend code chart

Page 34

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

Bit

31~16

15~8

7~1

Content

Index of mapped object

Sub-index of mapped object

Bit length (hexadecimal

form)

Example 6040h

00h

10h (length:16bits)

PDO mapping

object index

PDO object

sub-index

Mapping

content

Mapping content details

Mapping content

definition

Index

Sub-index

Bit length

RXPDO1

(1600h)

01h

60400010h

6040h

00h

10h (16bits)

Control word

02h

607A0020h

607Ah

00h

20h (32bits)

Target position

03h

60B00020h

60B0h

00h

20h (32bits)

Position offset

04h

60B80010h

60B8h

00h

10h (16bits)

Probe function

RXPDO2

(1601h)

01h

60400010h

6040h

00h

10h (16bits)

Control word

02h

607A0020h

607Ah

00h

20h (32bits)

Target position

03h

60810020h

6081h

00h

20h (32bits)

Max. speed

04h

60830020h

6083h

00h

20h (32bits)

Acceleration

05h

60840020h

6084h

00h

20h (32bits)

Deceleration

06h

60600008h

6060h

00h

08h (8bits)

Operation mode

RXPDO3

(1602h)

01h

60400010h

6040h

00h

10h (16bits)

Control word

02h

60FF0020h

60FFh

00h

20h (32bits)

Target speed

03h

60830020h

6083h

00h

20h (32bits)

Acceleration

04h

60840020h

6084h

00h

20h (32bits)

Deceleration

06h

60600008h

6060h

00h

08h (8bits)

Operation mode

5.4 processing data object

PDO generally used for real time data updating :it includes RXPDO and TXPDO.RXPDO is that master send the

data to slave station , and TXPDO is reversed

5.4.1 PDO mapping

The mapping objects can be real time transmission via PDO mapping.

E5-CAT supports 4groups RXPDO and 2 groups TXPDO for data transmission at the same time. Each PDO object

mapping to 8bytes object dictionary(the max length is 32bytes).

The PDO mapping format

The default PDO mapping(same as XML file)

Page 35

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

RXPDO4

(1603h)

01h

60400010h

6040h

00h

10h (16bits)

Control word

02h

60980008h

6098h

00h

08h (8bits)

Homing mode

03h

60990120h

6099h

01h

20h (32bits)

Homing speed (fast)

04h

60990220h

6099h

02h

20h (32bits)

Homing speed(slow)

05h

609A0020h

609Ah

00h

20h (32bits)

Homing

acceleration/

deceleration

06h

607C0020h

607Ch

00h

20h (32bits)

Homing offset

07h

60600008h

6060h

00h

08h (8bits)

Operation mode

TXPDO1

(1A00h)

02h

60410010h

6041h

00h

10h (16bits)

Status word

03h

60610008h

6061h

00h

08h (8bits)

Operation mode

display

04h

60640020h

6064h

00h

20h (32bits)

Actual position

05h

60B90008h

60B9h

00h

10h (16bits)

Probe status

06h

60BA0020h

60BAh

00h

20h (32bits)

Probe 1 rising edge

position

07h

60FD0020h

60FDh

00h

20h (32bits)

Digital input status

TXPDO2

No default mapping

Index

Sub-index

Range

Data type

Access property

RXPDO

Specified

object (1C12h)

00h

0~4

U8*1)

RO

01h

1600h~1603h

U16

RW

02h

U16

RW

03h

U16

RW

04h

U16

RW

TXPDO

Specified

object (1C13h)

00h

0~2

U8

RO

01h

1A00h~1A01h

U16

RW

02h

U16

RW

Contrast terms

PDO

SDO

5.4.2 PDO dynamical mapping

COE use PDO specified object(1C12h/1C13h) to configure PDO mapping object(1600h~1603h/1A00h~1A01h) to

the PDO object synchronization manager (synchronization manager 2/3)

PDO specified object

5.4.3The difference of PDO and SDO

Page 36

SHENZHEN ECON TECHNOLOGY CO.,LTD User Manual For EHS-580 EtherCAT Hybrid Servo Drive

Communication ability

The Maxis 64 bytes

General 4 bytes (fast transmission)

Efficiency

high

low

Priority level

high

low

Real-time performance

Real-time(synchronous mode)

Non-real-time

Transmission initiative

Active transmission

Passive transmission

Object dictionary visit

Indirect visit

Direct visit

Visit PDO mapping object

Visit arbitrary objects

synchronism

synchronization/synchronization

Synchronization

Application

Real-time data transmission

Configure PDO mapping、parameter

setting

Contact us:

Shenzhen ECON Technology Co.,Ltd

Add:2F,BuildingB,Jintai,Industrial,Park,HangchengAvenue,GushuVillage,XixiangStreet,Bao'anArea,

ShenzhenCity,GuangdongProvince,China

Tel: +86 136 2096 1024

Sales: enquiry@hybridservo.com

Technical support: technical01@hybridservo.com

Loading...

Loading...