Page 1

Installation & Operation Manual Proven Quality since 1892

ECON ELECTRIC

Fig. 7907, type ELA80 - 3000

ACTUATOR

Compact quarter turn actuator

Mechanical position indicator

High output torque

Multi mounting base

Manual override

Installation and operation Manual for actuator type:

ELA80, 100, 150, 200, 300, 500, 600, 800, 1200, 2000, 2700 & 3000o, Republic

ECON actuator Fig 7907, type ELA80 – 3000 www.eriks.com

Rev.13 – January 7, 2019

:

Page 2

Installation & Operation Manual Proven Quality since 1892

Contents

1. INTRODUCTION 3

1.1 Purpose 3

1.2 Safety notices 3

2. PRODUCT IDENTIFICATION 4

2.1 Product

2.1.1 Marking 4

2.1.2 Applied Standards 5

2.1.3 Certification 5

2.2 Initial Inspection 5

2.3 Storage 5

3. GENERAL INFORMATION AND FEATURES 6

3.1 General Information 6

3.1.1

3.1.2

3.1.3 ELA-Series Options 7

3.1.4 Duty Cycle 7

3.1.5 Space Heater 7

3.1.6 Hand Wheel and Declutching 7

3.1.7 Lubrication 8

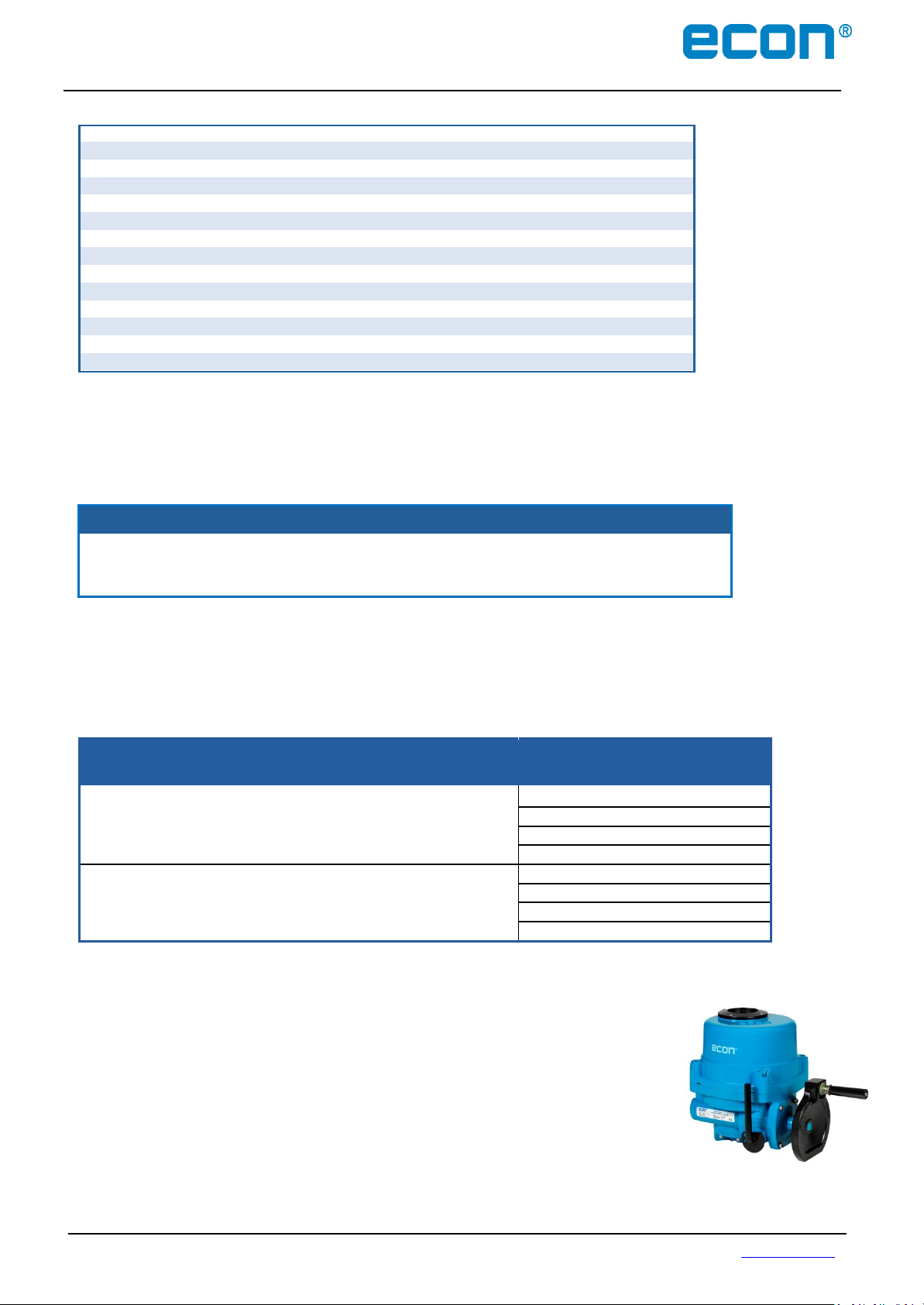

3.2 External Parts for Standard Models 8

3.2.1 ELA80-1200 8

3.2.2 ELA2000 - 3000 (Actuator + Gear Box) 8

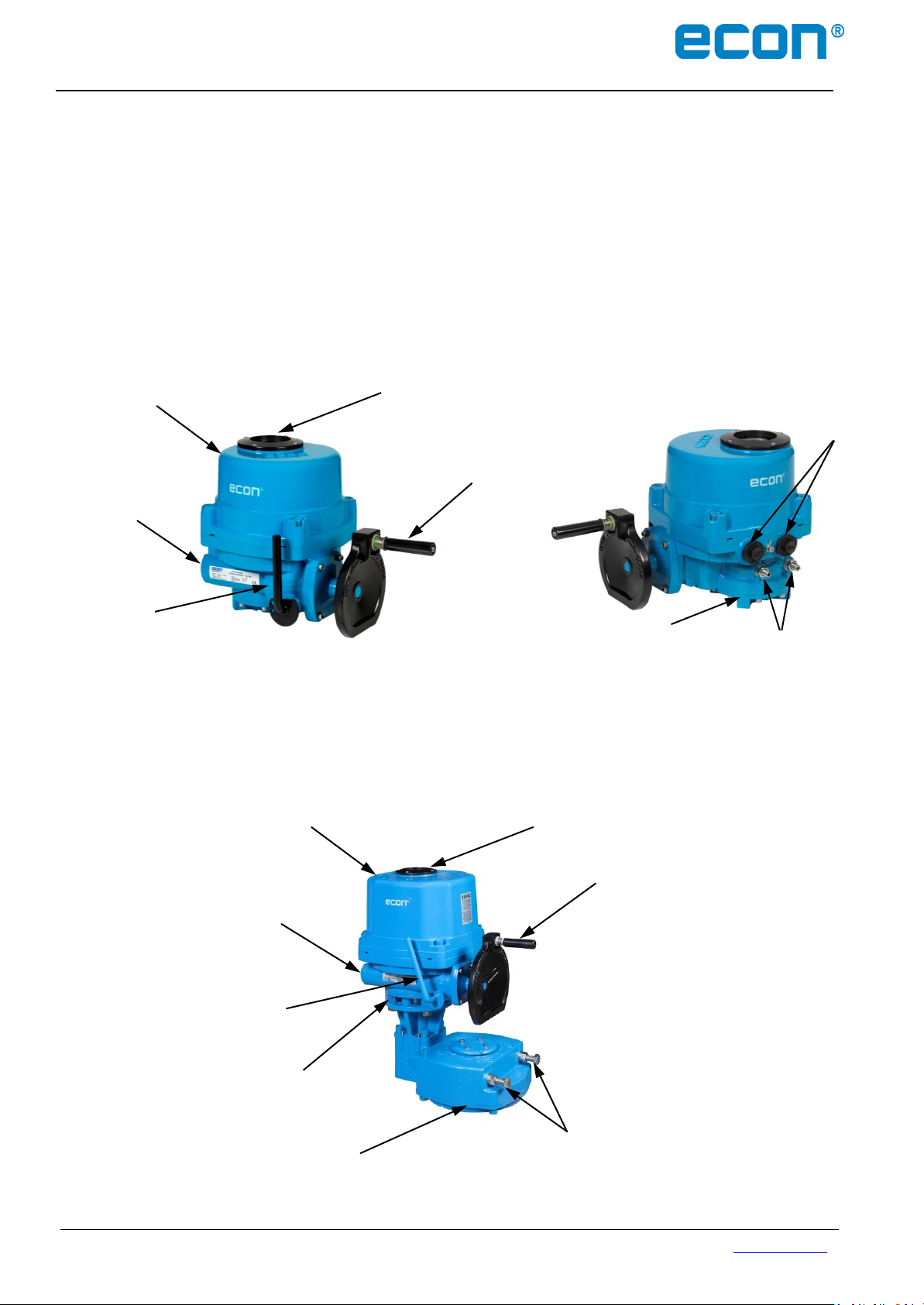

3.3 Internal Parts for Standard

3.3.1 ELA80-3000 9

Standard Technical Data 6

ELA Actuator Versions and Additional Technical Data 6

4. INSTALLATION 10

4.1 Pre-installation 10

4.1.1 Use in General Service 10

4.1.2 Use in Potentially Explosive Atmosphere 10

4.2 Actuator Mounting 10

4.2.1

4.2.2

4.3

4.4

4.5

4.6

4.7 Setting Potentiometer (Optional

4.8

4.8.1 Standard Features 14

4.8.2

4.9 PCU-A Proportional Control Unit Alternating Current (Optional) 16

4.10

4.10.1 LED Signal Indication 18

4.10.2

4.11

4.12 Rechargeable Battery Pack – RBP (Optional) 25

4.12.1 General 25

4.12.2 Features 26

4.12.3 Specifications 26

4.12.4 PCB Layout 27

4.12.5 Operations 29

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 1

Actuator Mounting Base Details (ISO 5211) 11

Actuator Drive Bushing 11

Limit Switch Setting 12

Torque Switch Setting 13

Counter-Clockwise to Close Setting 13

Mechanical Travel Stop Adjustment 13

Current Position Transmitter – CPT (Optional) 14

Calibration of Zero and Span – CPT 15

PCU-D

Setting PCU Functions 18

AC/DC Multi-Board

Identification 4

Models 9

) 14

Proportional Control Unit Direct Current (Optional)

17

(Optional) 23

Page 3

Installation & Operation Manual Proven Quality since 1892

5. Fieldbus communication protocols (Optional) 30

5.1 ProfiBus Controler 30

5.1.1 Specification 30

5.2 ModBus Controler 30

5.2.1 Specification 31

6. OPERATION 32

6.1 Electrical Connections and Preliminary Test 32

7. MAINTENANCE 33

7.1 Maintenance 33

7.2 Tools 33

8. TROUBLE SHOOTING 34

9. INSTALLATION AND MAINTENANCE TIPS 35

APPENDIX I : Wiring Diagram 36

APPENDIX II : Grounding 55

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 2

Page 4

Installation & Operation Manual Proven Quality since 1892

1 INTRODUCTION

1.1 Purpose

The purpose of this manual is to introduce and explain the installation, operation and maintenance of

ELA-series electric actuators.

1.2 Safety Notices

This manual contains safety notices and precautions the user must take to reduce the risk of personal

injury and damage to the equipment. The user(s) must read these instructions before the installation,

operation or maintenance of the ELA-series electric actuators.

DANGER: Refers to personal safety and alerts the user for danger and/or injury.

Hazardous or unsafe practice may result in severe injury or death.

WARNING: Refers to personal safety. Alerts the user for potential danger.

Not following warning notices could result in personal injury or death.

CAUTION: Directs the user’s attention to general precautions that,

if not

followed, could result in personal injury and/or equipment

damage.

Note: Information in this manual is critical to the user’s understanding of the actuator’s installation

and operation.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 3

Page 5

Installation & Operation Manual Proven Quality since 1892

2 PRODUCT IDENTIFICATION

2.1 Product Identification

The actuator name plate is located on the opposite side of the conduit entry. The name plate

contains the following:

2.1.1 Marking

A) General

ECON logo (trade mark)

Electrical power supply

Model

Type

Rated current

Torque

Only applicable for North-American markets

Operation time (seconds)

Serial No.

Options

B) Additional Markings for Ex-version Actuators

Flame Proof versions

Dust Ignition Proof versions

ECON logo (trade mark)

CE ATEX and IECEx mark

Model

Motor specification

Ambient temperature

Production date

Serial number

Manufacturer’s address

Warning

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 4

Page 6

Installation & Operation Manual Proven Quality since 1892

2.1.2 Applied Standards

IEC60079–0:2011 (Ed.6 +ISO1), EN60079-0 :2012 +A11

IEC60079-1 :2014 (Ed.7), EN60079-1:2014

IEC60079-31 :2013 9ED.2), EN60079-31:2014

2.1.3 Certification

Series ELA80 ~ ELA3000

IECEx:

Ex db IIB T4 Gb, Ta -20°C to +60°C

Ex tb IIIC T135°C Db

ATEX

II 2 G Ex db IIB T4 Gb, Ta -20°C to +60°C

II 2 D Ex tb IIIC T135°C Db

Notes :

Sealing devices must be used and shall be fitted directly at the enclosure wall when using

conduit.

Cable glands shall be suitable for the environment and shall be certified as flameproof if used in

Zone 1 application.

Cable glands and conduit to be installed for minimum 6 full threads and the thread length must

be 8mm minimal.

The temperature of the cable entry is maximum 100℃. A heat resistance cable is recommended.

Ex db and/or Ex tb certified cable glands suitable for 100℃ must be used.

Minimal requirements concerning the material and the allowance of LCU fasteners:

o Fasteners with yield strength ≥ 210MPa (stainless steel)

o Bolts type: M5x0.8, M6x1, M8x1.25, M10x1.5, M12x1.75 (Tolerance Fit 6g).

Cable connection: Refers to the Appendix I - (Wiring Diagram)

For cable entries or conduit entries that are not used, user or installer shall close them with

certified blanking elements (stopping plugs) in order to maintain flameproof or dust ignition proof

properties of the enclosure.

Always ground the enclosure in accordance with local electric codes. The most effective

enclosure grounding method is a direct connection to earth ground with minimal impedance.

Methods for grounding the enclosure include:

o Internal ground connection: The internal ground is located in the terminal block #1. Refer

to the enclosed wiring diagram.

o External ground connection: The ground lug is located on the centre of cable entries. For

more information, refer to the Appendix II – (Grounding).

Stainless steel name plates for the flame proof and dust ignition proof versions shall be

permanently attached by rivets.

2.2 Initial Inspection

Upon on the receipt of the actuator, the user should inspect the condition of the product and

ensure that the product specification stated on the name plate matches with the order sheet.

Remove the packing wrap or wooden box carefully. Inspect the product for any physical

damage that may have occurred during shipment.

Check the product specification of the received product. If a wrong product has been

supplied, please immediately report this to the distributing company.

2.3 Storage

Actuators must be stored in a clean, cool and dry area. The unit should be stored with the cover

installed and the conduit openings sealed. Storage must be off the floor, covered with a sealed

dust protector.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 5

Page 7

Enclosure Rated Weatherproof IP67, NEMA 4, 4X & 6

Enclosure High grade aluminium alloy, corrosion coated

Power Supply 115 / 230VAC ±5% 1Ph, 380 / 440 VAC 3Ph 50/60Hz

acc. To IEC 60034-1 24VAC and 24VDC

Duty Type See table in paragraph 3.1.2

Motor Squirrel caged induction motor

Limit Switches 2 x open/close SPDT, 250V AC 16A rating

Auxiliary Limit Switches 2 x open/close SPDT, 250V AC 16A rating (except for ELA80 and ELA100 Ex-versions)

Torque Switches Open/close SPDT, 250VAC 16A Rating (except for ELA80 and ELA100)

Stall Protection Built–in thermal protection

Travel Angle 90 degree +/- 10%

Indicator Continuous position indicator

Manual Override Declutchable manual override

Self-Locking By means of worm gear

Mechanical Travel Stops 2 x external adjustable mechanical travel stops

Space Heater See table in paragraph 3.1.5

Conduit Entries 2x M25 or 2x NPT 3/4 (for “Ex db" versions)

2x M20, 2x M25 or 2x NPT 3/4" with M30 adapter (for ”Ex tb” versions )

Lubrication Grease moly EP

Ambient Temperature

-20°C (-4°F) up to +80°C (176°F)

Ex-versions: -20°C (-4°F) up to +60°C (140°F) (CPT and PCU boards excluded)

External Coating D

ry Polyester powder coating

12VDC

24VDC

(24VAC)

2

115VAC

3

1 Phase

230VAC

3

1 Phase

230VAC

3

3 Phase

380VAC

3 Phase

440VAC

3 Phase

460VAC

3 Phase

Nm (in-lb)

s/90°

(50/60Hz)

A A

A

(50/60Hz)

A

(50/60Hz)

A

(50/60Hz)

A

(50/60Hz)

A

(50/60Hz)

A

(50/60Hz)

IEC 60034-1

S4

Number W kg (lbs)

ELA8 0 80 (708) 16/13 6,4 3,70 1 ,0/1,0 0,5/0,5 - 0,3/,04 0,6/0 ,4 -

70%

4

10

107

5

7,5 (16.5)

ELA1 00 1 00 (88 5) 20 /17 9,5 4 ,00 1,0/1,0 0,5/0,5 - 0,3/0,4 0,6/0,4 -

70%

4

10

107

5

7,5 (16.5)

ELA1 50 150 (1,328) 2 5/21 6,20 1,6/1,8 0,8/0,9 0,7/0,5 0,4/0,3 0,4/0,4 0,3/0,2 70% 11 216 16,5 (36.4)

ELA2 00 200 (1,770) 2 5/21 6,50 1,6/1,8 0,8/0,9 0,7/,05 0,4/0,3 0,4/0,4 0,3/0,2 70% 11 216 16,5 (36.4)

ELA3 00 300 (2,655) 3 1/26 3,00 1,4/1,7 0,7/0,9 0,5/0,4 0,4/0,3 0,5/0,3 0,3/0,3 70% 13,5 187 2 2 (48.5)

ELA5 00 500 (4,425) 3 1/26 - 4,3/3,6 1,4/1,3 0,9/0,8 0,6/0,5 0,7/0,5 0,5/0,4 70% 13,5 410 23 (50.7)

ELA6 00 600 (5,310) 3 1/26 - 4,3/3,6 1,4/1,3 0,9/0,8 0,6/0,5 0,7/0,5 0,5/0,4 70% 13,5 410 23 (50.7)

ELA8 00 800 (7,080) 3 7/31 - 3,6/5,0 1,9/2,8 1,5/1,1 0,9/0,7 1,1/0,7 0,8/0,6 70% 16,5 483 29 (63.9)

ELA1 200 1200 (10,620) 37 /31 - 3 ,6/5,0 1,9/2,8 1,5/1,1 0,9/0,7 1,1/0,7 0,8/0,6 70% 16,5 483 29 (63.9)

ELA2 000 2000 (17,701)

37/31

1

- 3,6/5,0 1,9/2,8 1,5/1,1 0,9/0,7 1,1/0,7 0,8/0,6 50% 49,5 483 75 (165.3)

ELA2 700 2700 (23,897)

56/47

1

- 3,6/5,0 1,9/2,8 1,5/1,1 0,9/0,7 1,1/0,7 0,8/0,6 50% 49,5 483 75 (165.3)

ELA3 000 3000 (26,552) 11 2/93 - 3,6/5,0 1,9/2,8 1,5/1,1 0,9/0,7 1,1/0,7 0,8/0,6 50% 49,5 483 75 (165.3)

Maximum

Power

Weight

Fig. 7907

type

Maximum

torque

Operating

time

Duty cycle

according to

Hand wheel

turns

Rated current

Installation & Operation Manual Proven Quality since 1892

3 GENERAL INFORMATION AND FEATURES

3.1 General Information

ECON ELA-series electric actuators are designed for the operation of industrial valves; e.g. butterfly

valves and ball valves.

The actuator has a torque output range from 80 Nm to 3,000 Nm (708 in-lbs to 26,552 in-lbs).

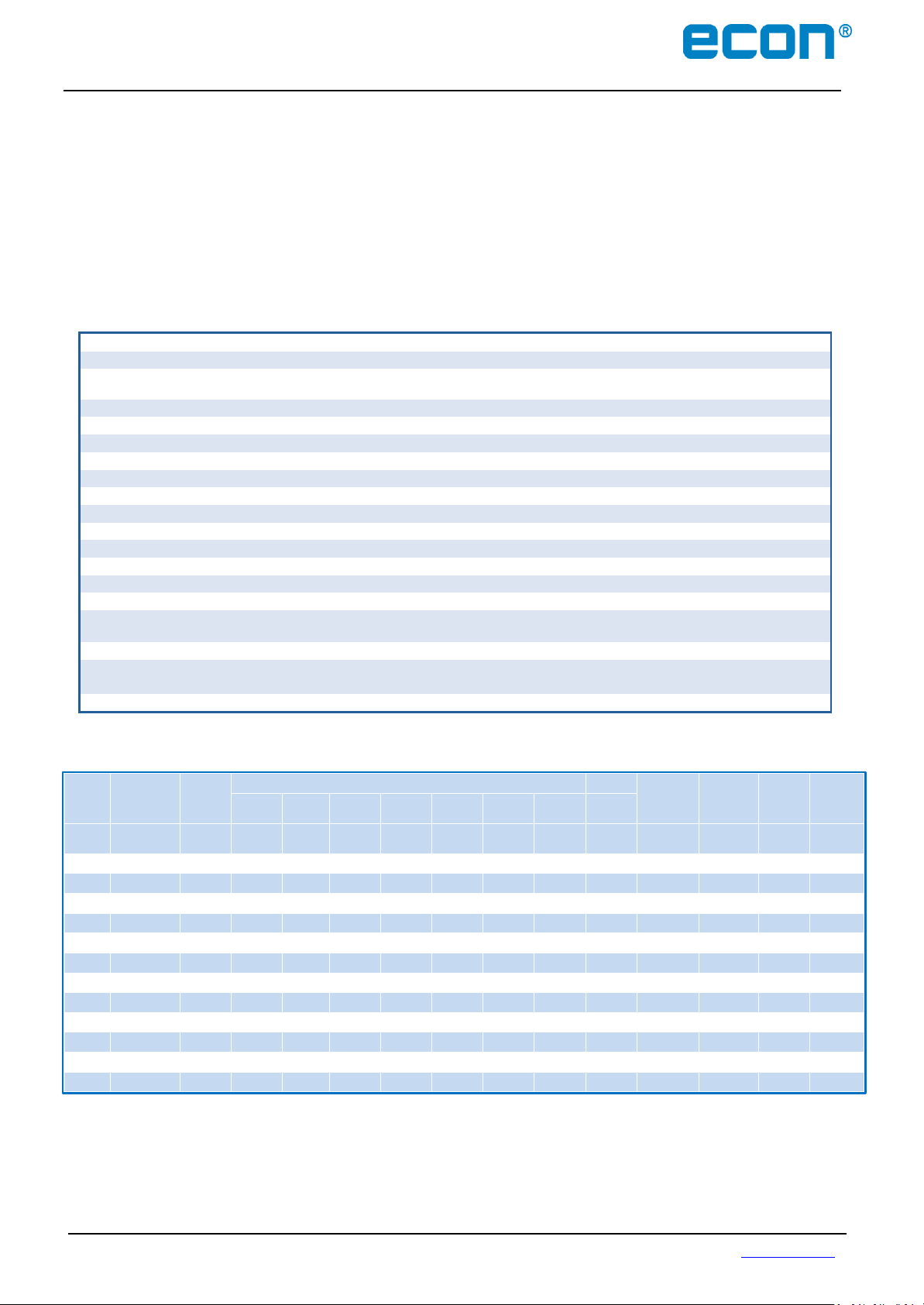

3.1.1 Standard Technical Data

3.1.2 ELA Actuator Versions and Additional Technical Data

Notes: 1. Operation time of 115V 1Ph actuators is 112/93 s/90°.

2. 24VAC actuators have 24VDC motors.

3. 115VAC and 230VAC ±5% according to IEC 60034-1

4. Duty ratings: ELA80 and ELA100 in 380 VAC/3Ph – S4-70% and 440 VAC/3Ph - S4-40%.

5. Maximum power at 3 Phase: S4-70%: 164 W and S4-40%: 348 W.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 6

Page 8

EXD Flameproof enclosure

EXTB Dust ignition proof

WTA Watertight enclosure (IP68 (10m/72hr) Nema 6P

ATS Additional torque switches (SPDT x 2ea, 230VAC – 16A)

EXT Rotating extension - 120°, 180° or 270° (90° is standard)

ALS Additional limit switches (SPDT x 2ea, 230VAC – 16A)

PIU Potentiometer unit (0~1KΩ)

PCU Proportional control unit (input, output 0~10 VDC, 4~20mA DC)

CPT

Current position transmitter (output 4~20mA DC)

ADCM AC/DC Multi-board

SICU Semi-Integral Control Unit (LCU-B + IMS + phase protect indicator) (5W max.)

ICU Intelligent Digital Control Unit (LCU-C + IMS + auto phase discriminator) (5W max.)

PRB ProfiBus (5VDC, 0.1A max., in redundant configuration, multiplied by 2)

MOB ModBus (5VDC, 0.1A max., in redundant configuration, multiplied by 2)

Intermittent duty S4

The duty is a sequence of identical cycles which consist of starting time, operation time with constant

load and rest period. The rest period allows the machine to cool down so that thermal equilibrium is

not reached. The relative on-time at S4-25% or S4-50% is limited to 25% and 50% respectively.

Heating Element

Self-regulating

Voltage Range (ELA80~100) (based on the power supply)

115V 5W 4.5KΩJ

230V 5W 18KΩJ

24V DC 5W 200ΩJ

12V DC 5W 47ΩJ

Voltage Range (ELA150~3000) (based on the power supply)

115V 10W 2KΩJ

230V 10W 8KΩJ

24V DC 10W 100ΩJ

12V DC

10W 27ΩJ

Installation & Operation Manual Proven Quality since 1892

3.1.3 ELA-Series Options

3.1.4 Duty Cycle

Duty cycle rating according IEC60034-1 S4. See table in paragraph 3.1.2 for rating figures.

Exceeding the actuator’s rated duty cycle may cause thermal overload.

3.1.5 Space Heater

Condensation in the actuator is possible due to wide fluctuation of the ambient temperature. The

heater integrated in the control unit prevents this in general.

Ceramic housing with thermostat to prevent over heating with 60℃ set temperature.

3.1.6 Hand Wheel and Declutching

ELA-series actuators are provided with a declutchable manual override

system.

In order to manually operate the actuator, pull the manual

override lever towards the hand-wheel until. It will remain in position.

Turn the hand-wheel until the valve reaches the required position.

Turn clockwise to close and counter-clockwise to open.

Note: The manual override lever returns automatically to auto-

position when the actuator is operated electrically.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 7

Page 9

Body

Handwheel

Top cover

Lever

Window & Indicator

Mechanical

travel stops

Actuator base and

Driving bushing

Conduit

entries

Body

Gear box including

Driving bushing

Mechanical

travel stops

Handwheel

Top cover

Lever

Window & Indicator

Actuator base

Installation & Operation Manual Proven Quality since 1892

3.1.7 Lubrication

ELA-series are totally enclosed units with a permanent lubricated gear train (Moly EP Grease). Once

installed, lubricating the actuator should not be required. However, periodic preventative maintenance will

extend the operating life time of the actuator.

3.2 External Parts for Standard Models

3.2.1 ELA80 - 1200

3.2.2 ELA2000 - 3000 (Actuator + Gear Box)

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 8

Page 10

Motor

Terminal

block

Torque switch

assembly

Capacitor

Limit switch

assembly

Installation & Operation Manual Proven Quality since 1892

3.3 Internal Parts for Standard Models

3.3.1 ELA80 - 3000

Note: ELA80 and ELA100 do not have a torque switch provision!

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 9

Page 11

Installation & Operation Manual Proven Quality since 1892

4 INSTALLATION

4.1 Pre-installation

Please check if the electric power supply corresponds with your specification and the information on

the actuator type plate.

Make sure the power supply has been switched off before you start wiring the actuator.

4.1.1 Use in General Service

Verify the actuator’s nameplate to ensure that model number, torque output, operating speed, voltage

and enclosure type are correct before installation or use.

It is important to verify that the torque output of the actuator is appropriate for the torque requirements

of the valve and that the duty cycle of the actuator is appropriate for the intended application.

Make sure the power supply has been switched off before the actuator is being wired.

4.1.2 Use in Potentially Explosive Atmosphere

Model: ELA80 ~ ELA3000

Type of Enclosure : IECEx: Ex db IIB T4 Gb and Ex tb IIIC T135°C Db

ATEX: II 2 G Ex db IIB T4 Gb and II 2 D Ex tb IIIC T135°C Db

Ambient Temperature: -20°C (-4°F) up to +60°C (140°F)

WARNING:

Read this installation, operation and maintenance manual carefully

and completely before attempting to install, operate, or troubleshoot

the ELA

CAUTION:

Installation, commissioning, maintenance, repairs and modification work

may only be performed by qualified personnel with extensive knowledge on

how to work on explosion-proof electrical equipment.

actuator.

4.2 Actuator Mounting

Note: Prior to mounting, the part-turn actuator must be checked for any damage.

Damaged parts must be replaced by original spare parts

Mounting is most easily done with the valve shaft pointing vertically upwards. But mounting is also

possible in any other position.

The ELA-series electric actuators are supplied with a female double square drive output. The

ISO5211 bolt patterns are provided for actuator mounting. The actuator drive bush can be replaced or

removed for machining easily.

It is mandatory for the actuator to be firmly secured to a robust mounting bracket or t o be mou n t ed

directly to the valves’ ISO mounting pad. High tensile bolts or studs with spring locking washers must be

used.

The valve stem must be in line with the actuator output drive to avoid side loads to the shaft. To avoid

backlash play between the actuator, mounting bracket and valve is not allowed.

CAUTION:

Do not attempt to work on your ECON actuator without first shutting off the power supply

Do not attach ropes or hooks to the hand wheel for li fti ng purposes

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 10

Page 12

Threaded bolt

holes 4x

Pitch

Installation & Operation Manual Proven Quality since 1892

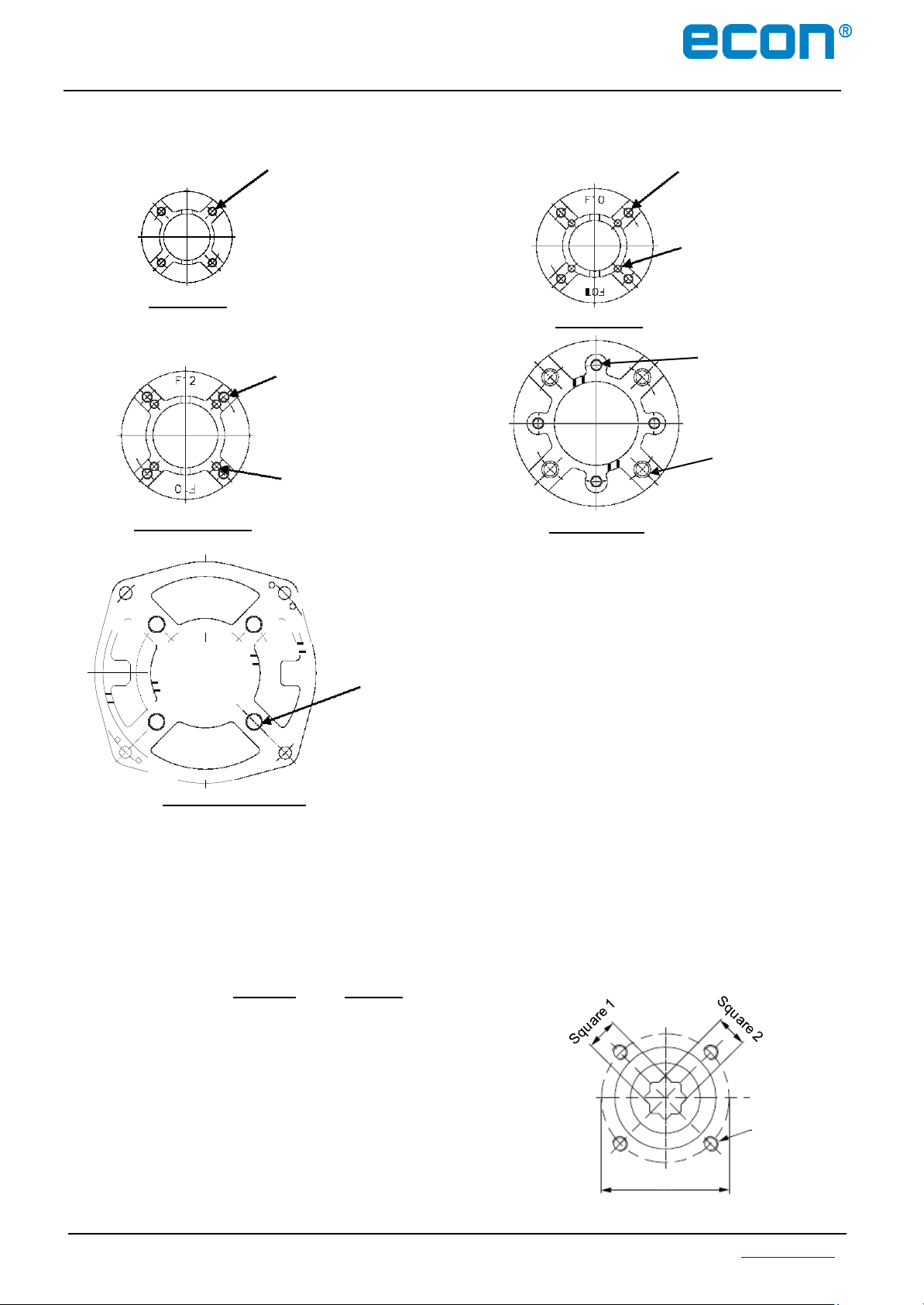

4.2.1 Actuator Mounting Base Details (ISO 5211)

4-M8TAP

D.P12

P.C.D Ø 70

ELA80/100

ELA300/500/600

(ISO 5211 F07)

4-M12TAP

D.P18

P.C.D Ø 125

(ISO 5211 F12)

4-M10TAP D.P15

P.C.D Ø 102

(ISO 5211 F10)

ELA150/200

ELA800/1200

4-M10TAP D.P15

P.C.D Ø 102

(ISO 5211 F10)

4-M8TAP

D.P12

P.C.D Ø 70

(ISO 5211 F07)

4-M12TAP D.P18

P.C.D Ø 125

(ISO 5211 F12)

4-M16TAP D.P24

P.C.D Ø 140

(ISO 5211 F14)

4-M20TAP D.P30

P.C.D Ø

(ISO

165

5211 F16

ELA2000/2700/3000

4.2.2 Actuator Drive Bushing

ELA actuators have a Double Square (star) driving bush, which can be replaced by another dimension to

fit the valve stem. This means that the actuators are suitable for valves with a parallel or diagonal stem

connection. Also drive bushings with a double-D shape or round shape with keyway are available as an

option. Hereunder the ELA-versions with standard connection

found:

Standard Optional

ELA80 DS 17mm DS 9-11-14-16mm

ELA100 DS 17mm DS 9-11-14-16mm

ELA150 DS 17mm DS 11-14-19-22mm

ELA200 DS 17mm DS 11-14-19-22mm

ELA300 DS 22mm DS 14-17-19-27mm

ELA500 DS 27mm DS 14-17-19-27mm

ELA600 DS 27mm DS 14-17-19-27mm

ELA800 DS 27mm DS 22mm

ELA1200 DS 27mm DS 22-30mm

ELA2000 DS 36mm DS 27-46-55mm

ELA2000 DS 36mm DS 27-46-55mm

ELA3000 DS 46mm DS 27-36-55mm

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 11

)

and possible double square options can be

Page 13

Installation & Operation Manual Proven Quality since 1892

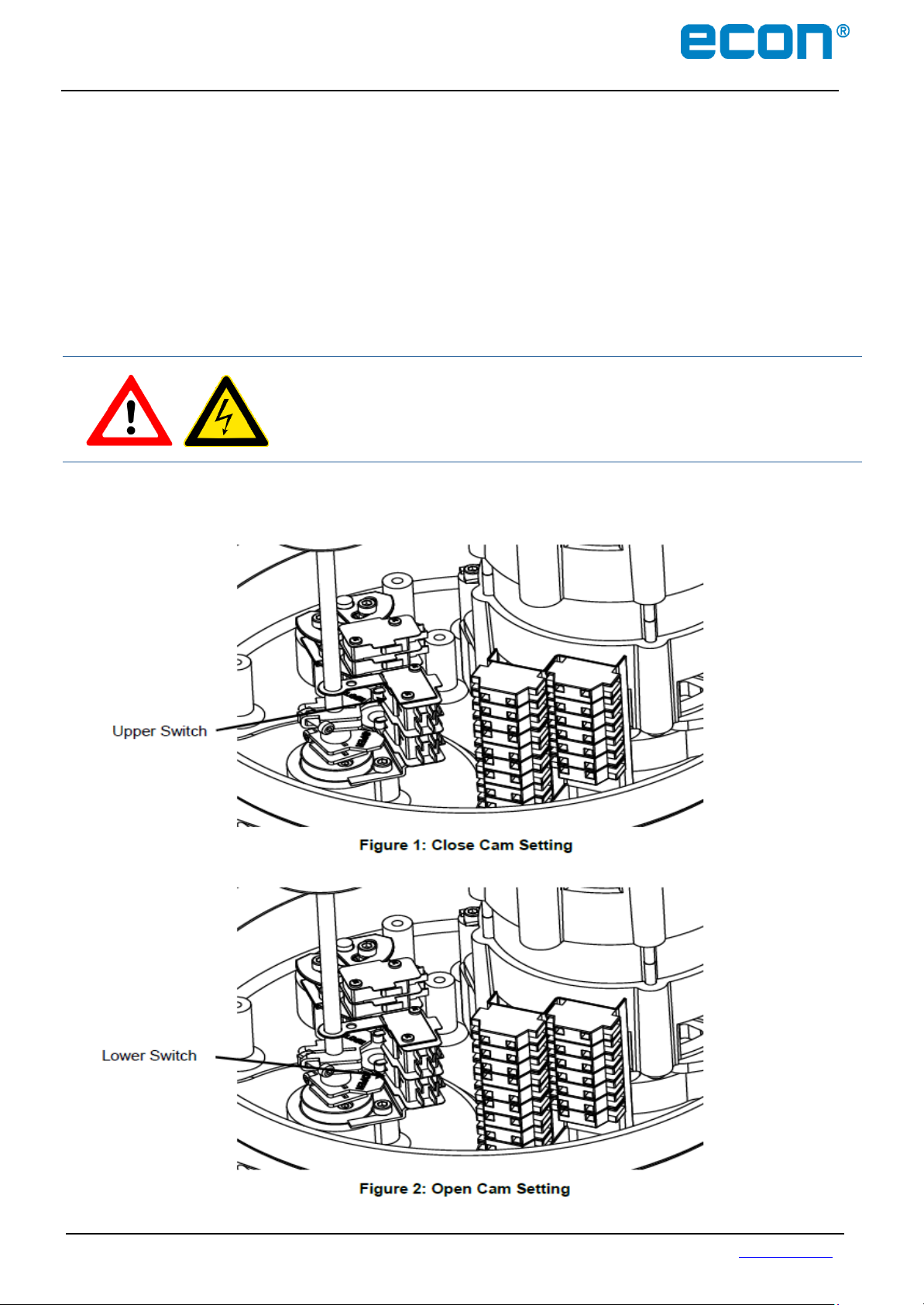

4.3 Limit Switch Setting

Rotate the hand wheel of the actuator manually to the fully closed position of the valve.

Use an Allen key, loosen the set screw of the CLOSE limit switch cam

Rotate the CLOSE cam CW until the limit switch ‘clicks’ (see Figure 1)

Tighten the set screw with the Allen key

Manually rotate the hand wheel of the actuator to the fully opened position of the valve

Use an Allen key to loosen the set screw of the OPEN limit switch cam

Rotate the OPEN cam CCW until the limit switch ‘clicks’ (see Figure 2)

Tighten the set screw with the Allen key.

DANGER:

HAZARDOUS VOLTAGE.

Make sure all incoming power is disconnected before setting the limit switches

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 12

Page 14

Installation & Operation Manual Proven Quality since 1892

4.4 Torque Switch Setting

The torque spring, which detects the variation of torque during the operation, is installed to prevent

damaging the valve and actuator under overload conditions. If an overload of the actuator occurs, the

torque switch will be activated and the actuator stops immediately.

The torque switches are set by manufacturer on the production site. If re-setting is necessary, please

contact the ECON actuator distributer before setting the torque switch.

CAUTION:

Do not reset t h e torque switch to a setting higher than the maximum setting

stated by the manufacturer.

4.5 Counter-Clockwise to Close Setting

Standard actuators are normally set to clockwise rotation to close. However, the rotation can be

reversed to counter-clockwise to close by simply reconfiguring the wiring as follows:

Reverse wiring on the main terminal block: 9 & 10 as well as 11 & 12.

Adjust the visual indicator to suit the counter-clockwise rotation.

If a PCU card is installed:

Reverse P1 (orange) and P3 (grey) on the PCU board.

Move the actuator manually to the half-open position and push the auto-reset button once.

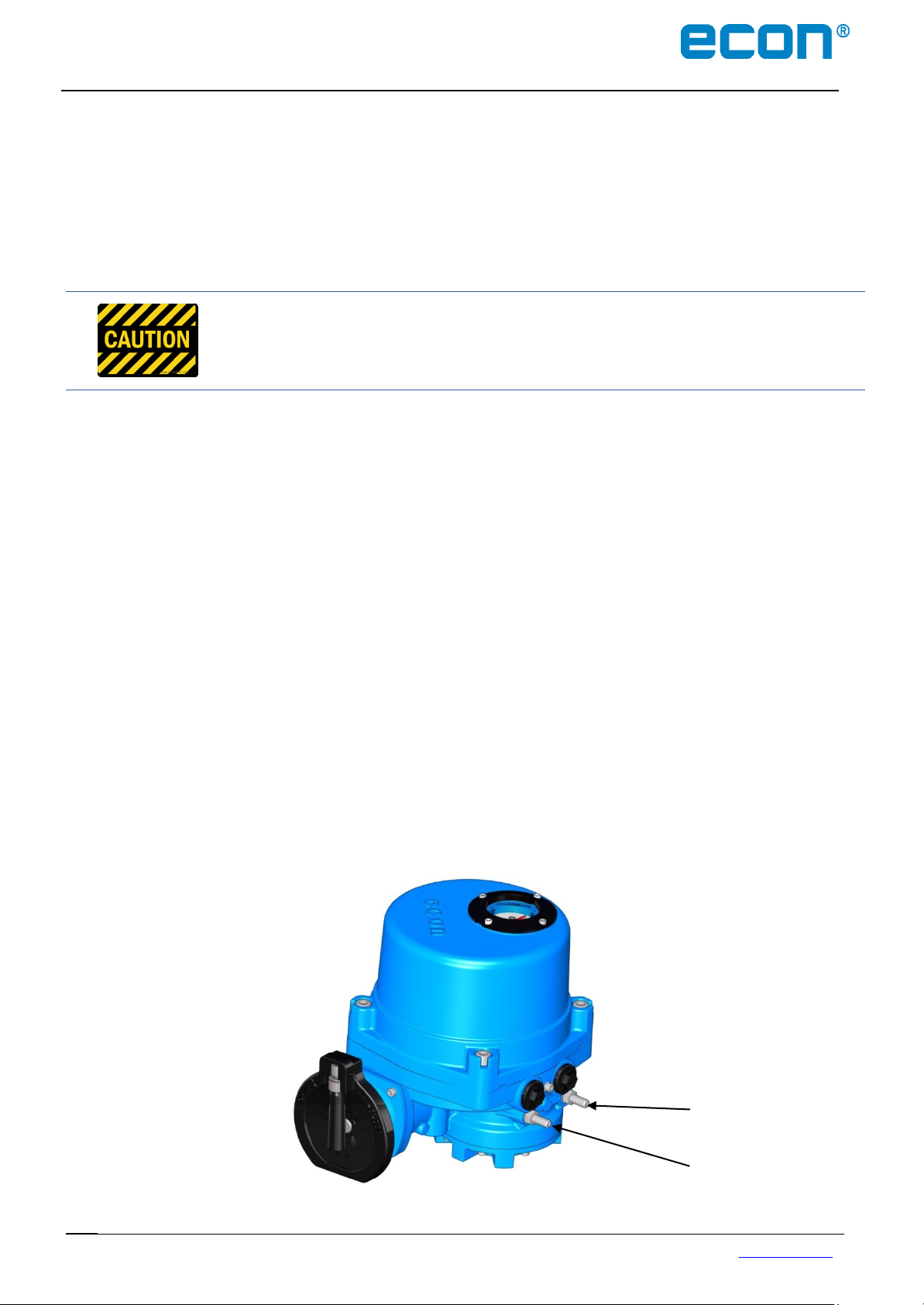

4.6 Mechanical Travel Stop Adjustment

Loosen both (open and close) travel stopper bolt nuts.

Operate the actuator manually by turning the hand wheel (the clutch lever must be

switched to “manual” first) to the closed position until the “close” open limit switch is being

activated.

Tighten the close travel stopper bolt until resistance is felt. (In this position the close travel

stopper bolt should not be able to travel any further).

Loosen back the close travel stopper bolt by only one turn and tighten the close travel stopper

bolt nut.

Repeat the same operation for setting of the open travel stopper bolt.

CLOSE TRAVEL

STOPPER BOLT

OPEN TRAVEL

STOPPER BOLT

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 13

Page 15

14 | P a g e

Model

CPT

Power

230(115) VAC ±5%, 50/60Hz 2VA Max

Output Signal

4~20mA DC

Output Impedance

750Ω Max

Resolution

Min 1/1000

Position Conversion Accuracy

±0.5 ~ ±1.5%

Ambient Temperature

-20°C (-4°F) up to +70C (158°F)

Ambient Humidity

90% RH Max (Non-condensing)

Dielectric Strength

1 s at (Rated VAC x 2 + 1000) x 1.2

(from Input to power ground)

Insulation Resistance

Above 500V DC 30MΩ

Vibration

10g, 0~34Hz

P1

P2

P3

Installation & Operation Manual Proven Quality since 1892

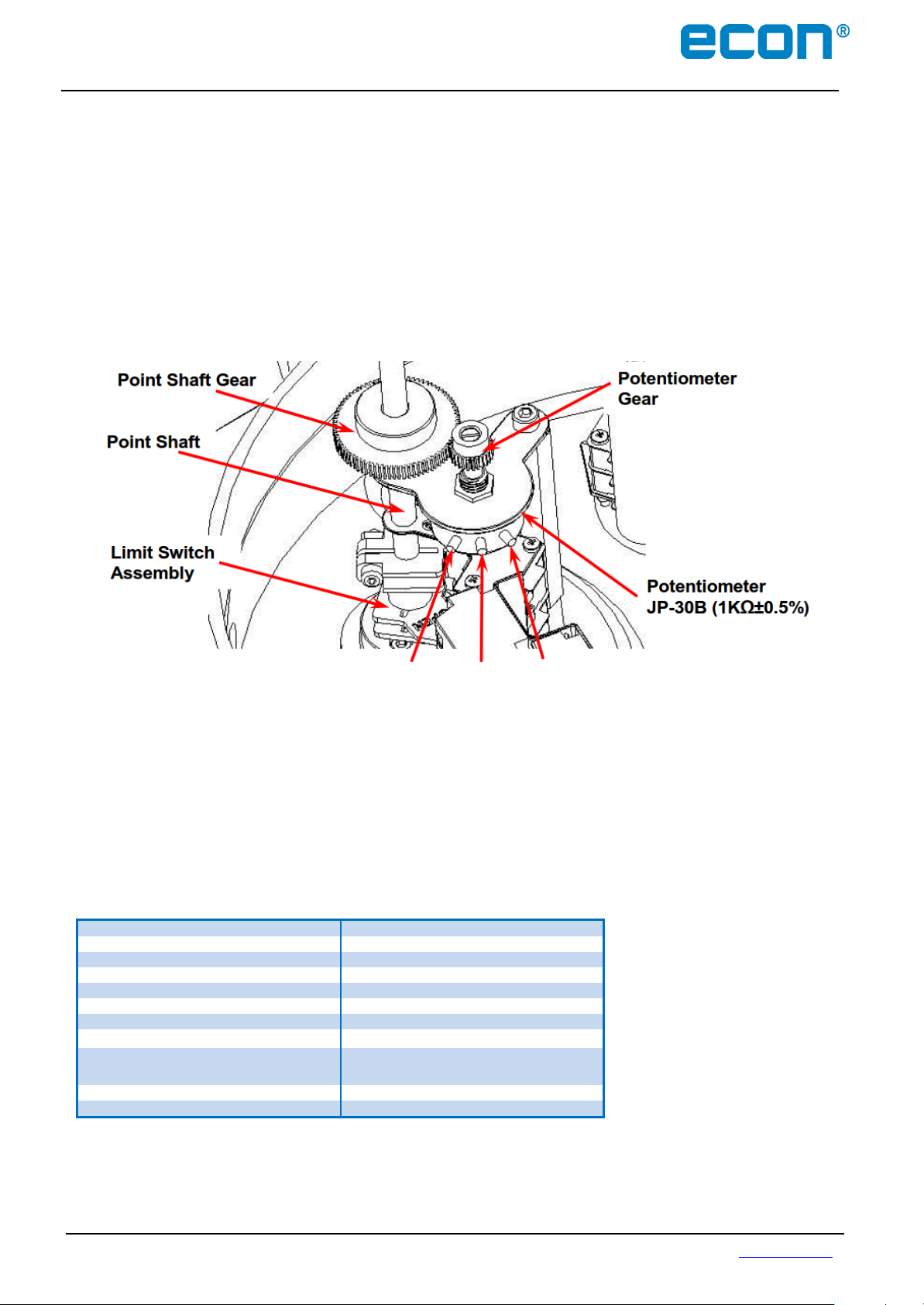

4.7 Setting Potentiometer (Optional)

The potentiometer has been calibrated at the factory. However, if re-calibration is required, proceed as

follows:

Manually rotate the hand wheel of the actuator to the fully closed position.

While measuring the resistance between P1 (black) and P2 (blue), gently rotate the

Potentiometer Gear until it reaches between 80 - 120 Ω (100 Ω preferred), by using a flat head

screw driver.

Engage the Potentiometer Gear into the Point Shaft Gear and use an Allen key to fasten the

locking bolt of the Potentiometer Gear.

4.8 Current Position Transmitter – CPT (Optional)

The potentiometer is used for the actuator signal feedback . It reads a resistance value w h i c h

corresponds with the

indicates the current position of the

si

gnal.

current position of the actuator and transfers i t to the CPT card.

actuator throughout the complete stroke by a 4 – 20mA output

The CPT

4.8.1 Standard Features

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 14

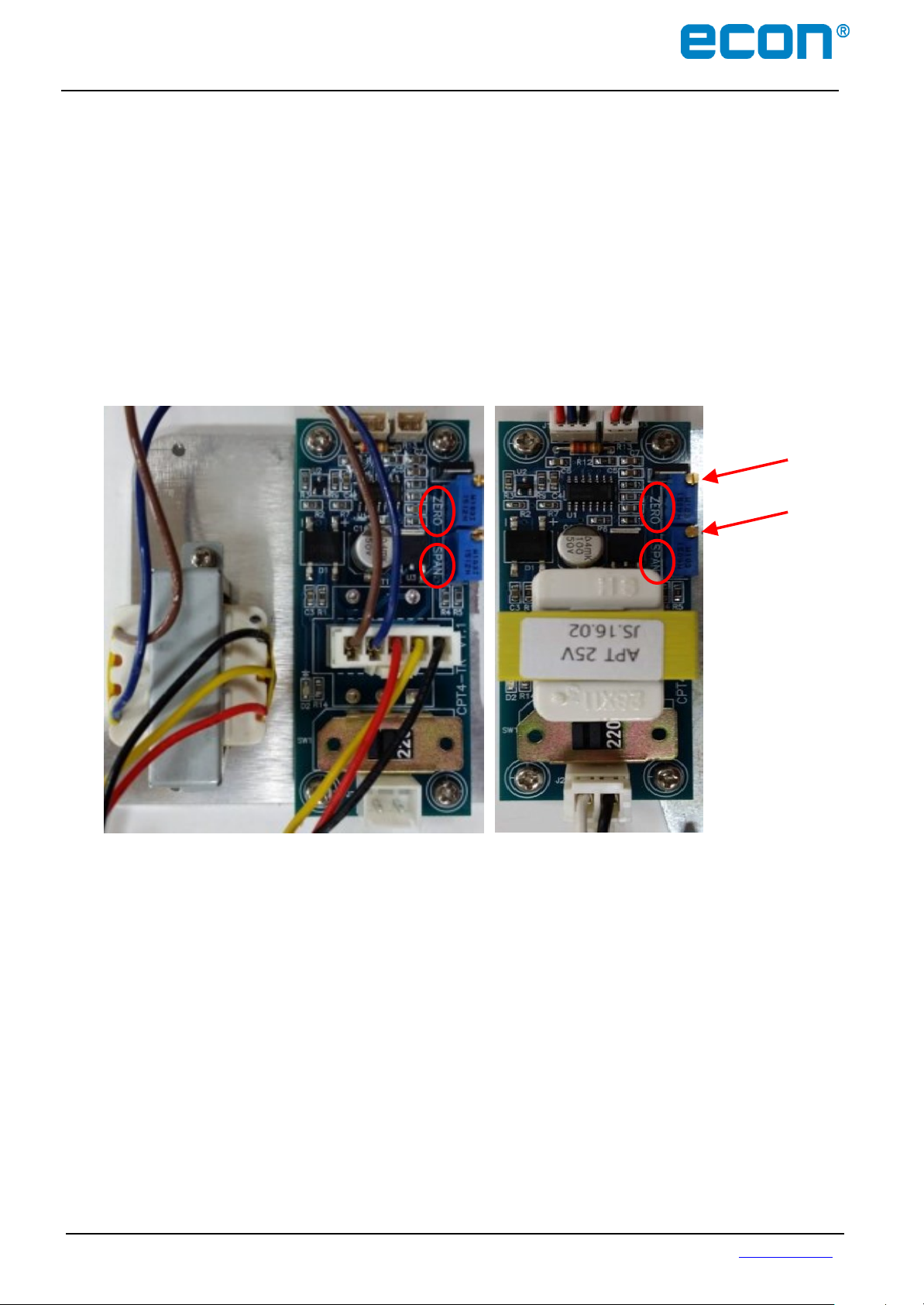

Page 16

Zero dial

Span dial

Installation & Operation Manual Proven Quality since 1892

4.8.2 Calibration of Zero and Span - CPT

The settings of Zero and Span have been calibrated at the factory. However, if re-calibration is required,

proceed as follows:

Apply power (or use the manual override) to move the actuator to its fully closed position

(clockwise rotation).

When the actuator is in the fully closed position, adjust the ZERO close setting on the CPT board

until an output value of 4mA is achieved.

Apply power (or use the manual override) to move the actuator to its fully open position

(counter- clockwise rotation).

When the actuator is in the fully open position, adjust the SPAN open setting on the CPT board until

an output value of 20mA is achieved.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 15

Page 17

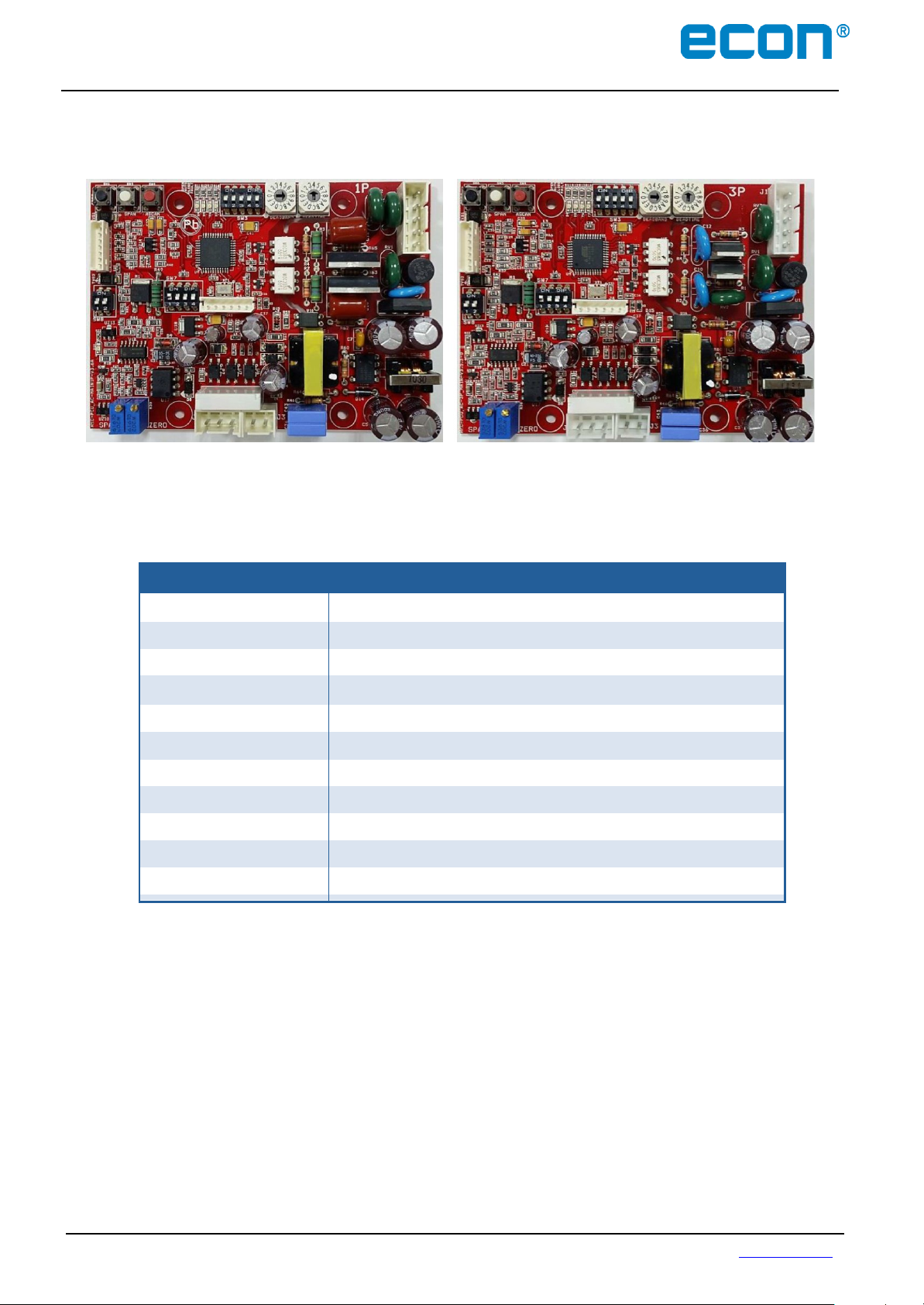

PCU-A Features

Model

PCU-A (1P and 3P)

Power

85 ~ 260 VAC Free Voltage ± 10%, 50/60Hz 4 VA Max

Input Signal

4~20mA DC, 1~5V DC, 2~10V DC, 0~5V DC, 0~10V DC

Input Impedance

250Ω

Output Signal

4~20mA DC, 1~5V DC, 2~10V DC, 0~5V DC, 0~10V DC

Output Impedance

250Ω Max

Output Contact

1 (Fault monitor)

Deadtime Adjustment

0.05~7.5 seconds

Deadband Adjustment

0.0625~1mA (0.0625mA + step no. x 0.0625mA, 15 steps total)

Ambient Temperature

-10°C (14°F) up to +70°C (158°F)

Ambient Humidity

90% RH Max (non-condensation)

PCU-A 1P

PCU-A 3P

Installation & Operation Manual Proven Quality since 1892

4.9 PCU-A – Proportional Control Unit Alternating Current (Optional)

PCU-A (1P and 3P) High performance Controller, using a 10 bit A/D converter and 8 bit

microprocessor technology.

The factory settings of the PCU card are normally set according to the customer requirements at the

time of order. However, we strongly recommend that input power, signal input selection and DIP switches

are to be verified prior to the actuator start up.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 16

Page 18

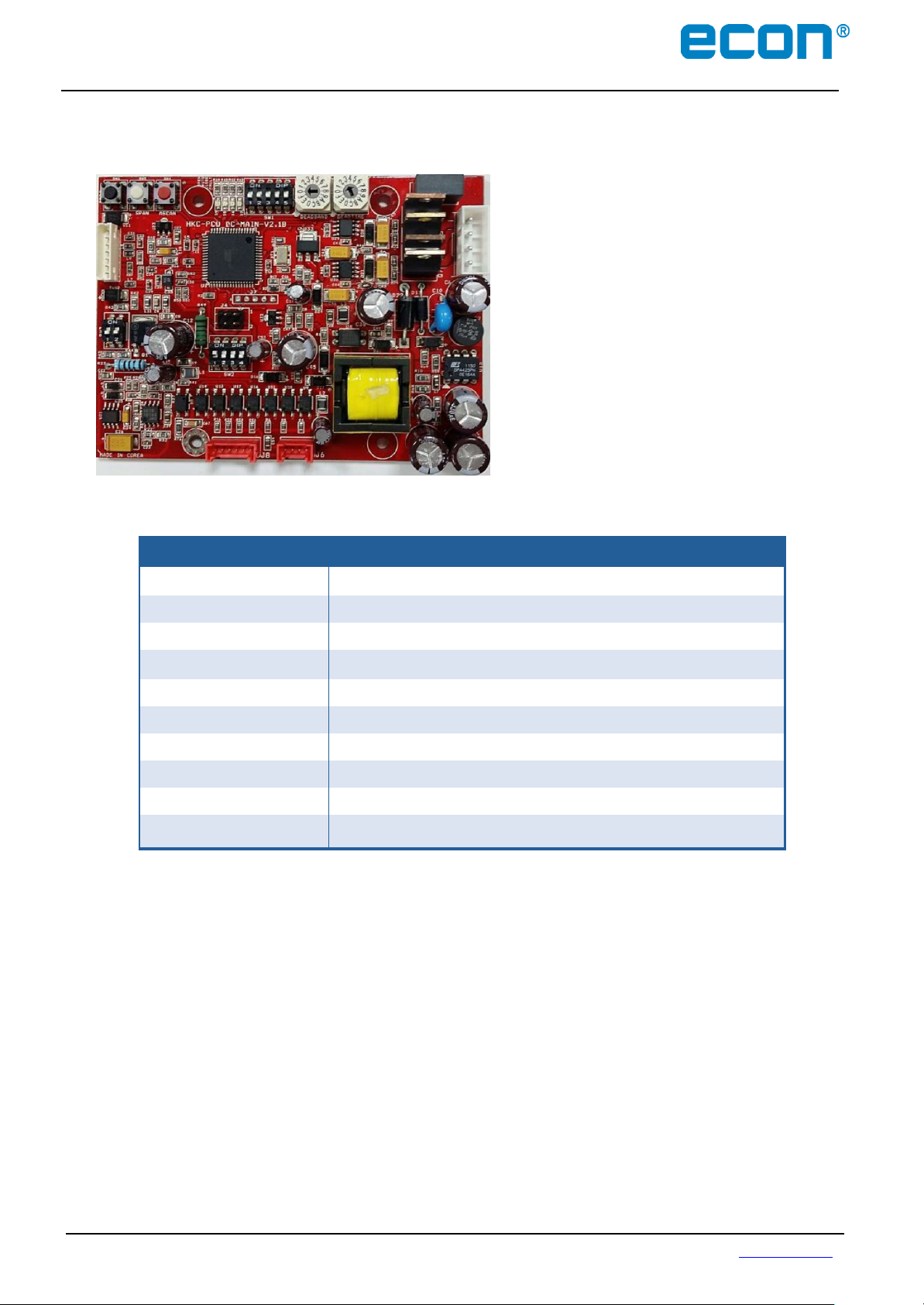

PCU-D Features

Model

PCU-D

Power

24V DC Voltage ± 15% (36V DC Max)

Input Signal

4~20mA DC, 1~5V DC, 2~10V DC, 0~5V DC, 0~10V DC

Input Impedance

250Ω

Output Signal

4~20mA DC, 1~5V DC, 2~10V DC, 0~5V DC, 0~10V DC

Output Impedance

250Ω Max

Deadtime Adjustment

0.05 ~ 7.5 seconds

Deadband Adjustment

0.0625~1mA (0.0625mA + step no. x 0.0625mA, 15 steps total)

Ambient Temperature

-25°C (-13°F) up to +80°C (176°F)

Ambient Humidity

90% RH Max (non-condensation)

Installation & Operation Manual Proven Quality since 1892

4.10 PCU-D – Proportional Control Unit Direct Current (Optional)

PCU-D High Performance Controller, using a

10 bit A/D converter and 8 bit microprocessor

technology

The factory settings of the PCU card are normally set according to the customer requirements at the

time of order. However, we strongly recommend that input power, signal input selection and DIP switches

are to be verified prior to the actuator start up.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 17

Page 19

LED

State

Indication

Blue

On

Power on (auto)

Flickering

Auto calibrating

Green

On

Fully closed

Flickering

Closing

Red

On

Fully open

Flickering

Opening

Yellow

On

Manual mode

Flickering

Fault indication, either:

- no input signal

- wrong input wiring

- wrong PIU setting

Installation & Operation Manual Proven Quality since 1892

4.10.1 LED Signal Indication

4.10.2 Setting PCU Functions

A) Selecting Input

Note: If not specified, the factory setting of the input signal is 4 - 20mA.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 18

Signal (SW7 on PCU-A or SW2 on PCU-D)

User can select different types of input signals by adjusting the DIP switches as follows:

DC

Input Signal

Switch

4 - 20mA DC

1 - 5V

2 - 10V DC

0 - 5V DC

0 - 10V DC

60 Hz (not applicable for PCU-D)

50 Hz (not applicable for PCU-D)

Page 20

Input signal switch No. 3

(PCU-A SW7 or

PCU-D SW2) “ON”

0 – 10V DC

Input signal switch No. 3

(PCU-A SW7 or

PCU-D SW2) “OFF”

2 – 10V DC

Input signal switch No. 3

(PCU-A SW7 or

PCU-D SW2) “ON”

0 – 5V DC

Input signal switch No. 3

(PCU-A SW7 or

PCU-D SW2) “OFF”

1 – 5V DC

Installation & Operation Manual Proven Quality since 1892

B) Selecting Output Signal (SW8 on PCU-A or SW3 on PCU-D)

User can select different types of output signals by adjusting the DIP switch as follows:

4 - 20mA DC

Output Signal

Switch

Note 1: If not specified, the factory setting of the output signal is 4 - 20mA.

Note 2: If the ELA150~3000, 115/230VAC actuators only will be operated by open and close

commands on terminal 11 and 12, the following procedure must be followed in order to select

the desired feedback signal:

• Select the output signal by adjusting the DIP switches as mentioned in this paragraph.

• Connect the power supply; Neutral on terminal 5 and Live on terminal 13.

• Make a link between terminal 13 and 14 and connect a multi-meter to terminal 17 and 18.

• Push “auto adjust” (red button on the circuit board) for 2 seconds.

• The actuator will now “auto adjust” itself.

• After the adjusting cycle has stopped, remove the link between 13 and 14.

• Now the actuator van be operated by giving the open and close commands on terminal 11

and 12. The feedback signal will be given on terminal 17 and 18.

• The feedback signal however still needs to be checked and if necessary adjusted. Therefor

measure the voltage or current on terminal 17 and 18, while opening and closing the

actuator. If necessary adjust the potentiometers “zero” and “span” on the bottom of the

circuit board until the output values are correct.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 19

Page 21

Auto-Full Switch

(Switch 3) On (up)

Signal: 4.3~4mA

Fully Closed

Signal: 19.7~20mA

Fully Open

Auto-Full Switch

(Switch 3) Off (down)

Signal: 4mA

Fully Closed

Signal: 20mA

Fully Open

CH 2 Switch

CH 1 Switch

Auto-Full Switch

Fail Open Switch

Fail Close Switch

Fail Position

Setting Switch

Installation & Operation Manual Proven Quality since 1892

C) Fail Position Setting (SW3 on PCU-A or SW1 on PCU-D)

User can select the fail position of the actuator in case of control signal failure by adjusting

the DIP switches as follows:

Fail

Close

Fail

Open

Fail Last

Position

D) Special Signal Setting for Fully Open and Fully Closed

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 20

Page 22

Zero

Button

Span

Button

ASCAN

Button

Installation & Operation Manual Proven Quality since 1892

E) Auto Setting

This function is used for automatic setting of the PCU card to the predefined limits.

First make sure that the actuator has been mounted correctly on the valve. Secondly check the

input power and also the input and output signals. Press t h e ASCAN button once. Regardless

the position of the actuator, the actuator will now

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 21

perform the Auto Setting motion:

1) The blue LED starts flickering

2) The red LED starts flickering for 5 seconds

indicating that the actuator is moving to the

open position

3) Pause for 2 seconds

4) The green LED starts flickering, indicating

that the actuator is moving to the fully

closed position

5) Pause (the green LED on) for 3 seconds

6) The red LED starts flickering, indicating that

the actuator is moving to the fully open

position

7) Pause (the red LED on) for 3 seconds

8) Moving back to the command position

Note:

Since the actuator is already set at the factory, no further settings are required

unless the user has made adjustments to the Limit Switch or the Potentiometer

settings.

F) Manual Operation

This function allows the user to manually operate the

actuator.

To access this function, press the ZERO (black)

and SPAN (white) buttons simultaneously for 2

seconds and the yellow LED will be lit to indicate that

the actuator is in Manual Operation mode.

Pressing the ZERO button will move the actuator

to the close position and pressing the SPAN button

will move the actuator to the open position.

If no operation occurs within 5 seconds, the PCU

automatically terminates the Manual Operation mode

or alternatively press the ZERO and SPAN buttons

simultaneously for 2 seconds. In both cases, the

yellow LED will be lit off to indicate the termination of

the Manual Operation Mode.

Note: During the Manual Operation mode, the input signal is ignored.

Page 23

Set-points

Adjustable Range

Fully Closed

3 – 8mA DC

Fully Open

16 – 21mA DC

ZERO

Button

SPAN

Button

CH 1

Switch(4)

CH 2 Switch

(Switch 5) On (up)

4mA DC

Fully Open

20mA DC

Fully Closed

CH 2 Switch

(Switch5) Off (down)

4mA DC

Fully Closed

20mA DC

Fully Open

Dial

0 1 2 3 4 5 6

7

sec

0.05

0.2

0.4

0.6

0.8

2.5

3.0

3.5

Dial 8 9 A B C D E F

sec

4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5

CH 2

Switch(5)

ASCAN

Button

Deadtime

Dial

Installation & Operation Manual Proven Quality since 1892

G) Customizing Set-points (CH 1 Switch)

This function is used when the user wants to set

different set-points for fully open and fully closed

positions.

For example, if the user wants to assign 5mA as

the set-point for the fully closed position, first of all

switch- on (move up) the CH1 switch (switch 4).

Supply a 5mA signal and push the ZERO button

once. Hereafter, the actuator will acknowledge the

5mA signal as the set-point for the fully closed

position and transmits a 4mA feedback signal.

Similarly, for setting the set-point for the fully open

position, supply the desired signal (for example,

19mA) and push the SPAN button once. Switchoff (move down) the CH1 switch to complete the

setting. After this action, the actuator will operate

according this new setting.

H) Reversal Acting (CH 2 Switch)

This function allows the user to reverse the input

and output signals for the operation of the actuator.

For standard operation (CH 2 switch down), the

input signal of 4mA operates the actuator to the fully

closed position and the actuator transmits the output

signal of 4mA. However, if the CH 2 switch is on (

up) the input signal of 4mA operates the actuator to

the fully open position and still transmits a 4mA

output signal.

Manually move the actuator to the half-open

position and push the ASCAN button once to

execute the Auto Setting (see 4.10.2 E). Supply

signal and check the operation.

I) Deadtime

The actuator will only start to move if the change of

the input signal value is greater than the deadband

set value (see 4.10.2 J) and when the signal value

is maintained for the duration of the deadtime time.

This prevents malfunction of the actuator caused

by unwanted signals in the input signal such as

noise and interferences.

Turning the Delay Time Dial in clockwise

direction will increase the deadtime time (Range

0.05 to 7.5 seconds).

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 22

Page 24

Dial

0 1 2

3

mA DC

0.0625

0.125

0.1875

0.25

Dial

4 5 6

7

mA DC

0.3125

0.375

0.4375

0.5

Dial

8 9 A

B

mA DC

0.5625

0.625

0.6875

0.75

Dial

C D E

F

mA DC

0.8125

0.875

0.9375 1

Deadband

Dial

Installation & Operation Manual Proven Quality since 1892

J) Deadband Dial

The deadband adjusts the limits of the valve’s

deviation between an actual position and a target

position. The dead band is set to 0.12mA DC

max.

Deadband indicates the extent of the reaction on

the input signal.

Low deadband setting may cause the actuator

to hunt or to unnecessarily respond to a

fluctuating input signal. If so, the deadband must

be increased.

Turning the Deadband Dial in clockwise direction

will increase the resolution (Range 0.0625mA to

1mA).

4.11 AC/DC Multi-Board (Optional)

A) Power Open-Close Terminal block

1 Power 24V AC/DC (DC + signal block)

2 None

3 None

4 Open signal

5 Close signal

6 Power 24V AC/DC (DC – signal block)

B) Power Input Switch

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 23

Page 25

Installation & Operation Manual Proven Quality since 1892

For AC Mode, #1 switch turn “ON”

and #2 switch turn “OFF”

DC Mode, #1 switch turn “OFF” and

#2 switch turn “ON”

Note: Don’t operate both switches #1 and #2 at the same time. It may damage the board

C) Motor Terminal Block

Red motor wire must be connected to block # 1

Black motor wire must be connected to block # 2

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 24

Page 26

Installation & Operation Manual Proven Quality since 1892

4.12 Rechargeable Battery Pack – RBP (Optional)

Warning

Please check if the electric power supply corresponds with your specification and the information on the actuator type

plate.

Make sure the power supply has been switched off before you start wiring the actuator.

The life time of the battery is 2 years, subject to operating time and environment. It should be replaced after 2 years in

order to guarantee a good working product.

After electric power has been supplied on terminal strip number 2 and 3, please connect number 1 and 4 with a jumper

as shown on the wiring diagram. Please make sure that number 1 and 4 are connected. This connection must be

maintained as long as the electric power supply is connected.

If the actuator will not be operated for a long period of time, please disconnect terminal strip number 1 and 4 in order to

extend battery life.

The battery must be discharged and charged regularly every 2 to 3 months.

4.12.1 General

The ECON actuator with Rechargeable Battery Pack (RBP) can be operated in Local or

Remote mode by using two selector switches on the local control unit. During power failure the actuator

can be operated 5 times by the battery pack. The actuator shows high reliability due to its self-checking c

apability. The local control unit shows the position of the valve,

status of the actuator and errors if occurring.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 25

Page 27

Items

Condition

Electric Power Supply

1 Phase – AC 115 V / 230 V 50/60Hz

Internal Voltage

Control Voltage : DC 24 V / 30 V

Voltage for Space Heater : AC 115/230 V

Power Consumption

40 VA

Temperature / Humidity

-20 ~ 70°C / 60 % RX, MAX.

Actuator functions by DIP

switch settings

DIP Switch setting

DIP switch 1

OFF

INCHING

ON

HOLD

DIP switch 2

OFF

Fault Contact Normal Open

ON

Fault Contact Normal Close

Power Fail action

DIP switch 3

DIP switch 4

FUNCTION

OFF

OFF

STOP

OFF

ON

CLOSE

ON

OFF

OPEN

ON

ON

NO POWER FAIL ACTION

Installation & Operation Manual Proven Quality since 1892

4.12.2 Features

The actuator unit can be operated in Local or Remote mode, also during power failure.

The DIP switch settings and functions can be found in the table in paragraph 4.

NORMAL MODE (on AC POWER): Battery LED blinks 1.5 seconds ON and 0.5 seconds OFF

BATTERY MODE (on BATTERY POWER) : Battery LED blinks 0.25 seconds ON and 1.75

seconds OFF

4.12.3 Specification

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 26

Page 28

5

7

6

4

8

9

10

12

3 2 1

11

Installation & Operation Manual Proven Quality since 1892

4.12.4 PCB Layout

1. DC Power Connector

2. Battery Connector

3. Battery Switch Connector

4. Limits / Torque Signal Connector

5. Remote Control Signal

6. Status Contactor

7. PCU Signal

8. Motor Connector

9. AC Power Monitor (option)

10. DIP Switches

11. Power check

12. Battery active switch

Note:

If the actuator does not work on battery power, despite of a fully charged battery and a jumper

has been placed on terminal strip connection number 1 and number 4, please press the battery

active switch (12).

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 27

Page 29

LED status

1. BLUE

BLINK

REMOTE MODULATING

MODE

ON

REMOTE MANUAL MODE

2.WHITE

OFF

AC POWER OFF

ON

AC POWER ON

3.GREEN

BLINK

CLOSING

ON

FULLY CLOSED

4.RED

BLINK

OPENING

ON

FULLY OPEN

5. AMBER

OFF

NO ERROR/FAULT

ON

ERROR message

6.BATTERY

(BLINKING)

GREEN

HIGH CHARGING

BLUE

MIDDLE CHARGING

RED

LOW CHARGING

RED STEADY ON

NO BATTERY

1

2

6

3

4

5

Installation & Operation Manual Proven Quality since 1892

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 28

Page 30

Local Operation

1. Put the selector switch into Local Mode.

2. Use the open/close switch to operate the actuator.

3. In Local Mode the LED indicators will show the below status:

RED LED – ON : Fully Open

GREEN LED – ON : Fully Close

RED or Green LED – Blinking : Opening or closing

Remote (Manual mode) Operation

1. Put the selector switch into Remote Mode.

2. Manual Mode is functional if terminal strip number 5 and 9 are NOT wired.

3. In Manual Mode the LED indicators will show the below status:

BLUE LED – Steady ON : Manual mode

For wiring diagrams see drawings D7907-3 RBP and D7907-4 RBP on page 41-49

Remote (Modulating mode) Operation

1. Put the selector switch into Remote Mode.

2. Modulating Mode is functional if terminal strip number 5 and 9 are wired.

3. In Modulating Mode the LED indicators will show the below status:

BLUE LED – Blinking: Modulating mode

4. For actuator operation please refer to the paragraph 4.10 (PCU settings).

For wiring diagram see drawing D7907-4 RBP+PCU on page 50

Battery Mode Operation

1. If the power supply has been switches off, the actuator will be powered by the battery.

2. LOCAL MODE: Operate the Open/Close switch in order to put the actuator in the open or closed

position.

3. REMOTE MODE: During power failure, the actuator will follow the power failure settings (DIP

switch settings – see paragraph 4.12.4)

4. NO FAIL ACTION : The actuator will operate the same way as if there was not power failure.

Installation & Operation Manual Proven Quality since 1892

4.12.5 Operations

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 29

Page 31

Item

Description

Input power

87V ~ 270V ac ±10% , 50/60Hz ±2% 4VA max.

Input power must match motor ratings

Communication

ProfiBus communication (RS-485 base)

Max. range

1000m @ 9.6 ~ 187.5 k Baud

Bit rate

Up to 12mega

Wiring terminals

SMW250-3P * 4 ( ProfiBus signal )

YW396-5P (Main power & Motor)

SMW250-8P (CTS, OTS, CLS, OLS contact input)

SMW250-6P (Firmware update connector)

SMW250-4P (Debug connector)

Visual indicators

Power white, blue LED

Fault yellow LED

Motor open red LED

Motor close green LED

Control configuration

PC software

Output contact

Triac 250V ac, 16A max. (Inductive load)

Ambient temperature

-10℃ ~ +60℃

Ambient humidity

90% RH max. (non-condensing)

ProfiBus PCB

Termination PCB

ModBus PCB

Installation & Operation Manual Proven Quality since 1892

5 FIELDBUS COMMUNICATION PROTOCOL

5.1 ProfiBus Contoller

The ProfiBus Controller is providing multiple communication

functions by using a 8 bit microprocessor and ProfiBus controller.

Providing the operator with actuator status information in order to

confirm if the ProfiBus device and actuator is working

correctly

The maximum transmission speed is 12Mbit/s.

Easily can be switched between PCU-version and ON-

OFF-version.

Providing System Redundancy by using dual ports and

high reliability.

LED lamps indicate the actuator status.

5.1.1 Specification

5.2 ModBus Controller

This clause explains the ModBus-RTU Slave

Module (MBRSM). Positioned at level 7 of the

OSI model, ModBus is an application layer

messaging protocol that provides client/server

communication between devices connected on

different types of buses or networks.

As a ModBus Serial Line protocol, ModBus-RTU

(Remote Terminal Unit) is a Master-Slave

protocol which takes place at level 2 (Data Link

layer) of the OSI model. The master initiates the

communication by transmitting the Function Code

(a ‘request’) to the address of a slave and after

receiving and processing the Function Code, the slave returns a message (a ‘response’).

The slaves shall not communicate with each other without the request of the master. Since the

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 30

Page 32

Installation & Operation Manual Proven Quality since 1892

MBRSM is based on the 2 wire (half-duplex) RS-485 communication, the network length limit or

the number of station should follow the standards of the RS-485 communication. To extend the

network, such as adding another segment, repeaters can be used. To ensure stability of the

network system, the network redundancy can be configured to slave redundancy.

ModBus manages the access of data simply and flexibly. ModBus supports two data types: A

Boolean value and an unsigned 16-bit integer. Generally, it is common for field devices to have

certain values defined as inputs while other values are outputs, such as current temperature or

valve position.

5.2.1 Specification

Communication Protocol: ModBus-RTU according to IEC 61158 and IEC 61784

Topology: Line topology with termination

Number of nodes: 32 nodes in each segment without repeater, with repeaters expandable to 247

Number of repeaters: Max. 9 with signal refreshing

Cable length: Max. 1.2 Km with Repeater 10 Km

Transfer Mode: RS-485

Transmission Medium: Twisted, shielded 2-Wire cable according to IEC 61158

Bus Access: Polling between master and slaves (query response)

Supported Baud Rates: 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200

Supported Parity Bit: Odd, Even, None

Supported Stop Bit: 1, 2

For more detail information, please refer to separate ModBus operation manual.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 31

Page 33

Installation & Operation Manual Proven Quality since 1892

6 OPERATION

6.1 Electrical Connections and Preliminary Test

WARNING:

If working in potentially explosive areas, observe the European

Standards EN 60079-14 “Electrical Installation in Hazardous Areas” and

EN 60079-17 “Inspection and Maintenance of Electrical Installations in

Hazardous Areas”. Work on the electrical system or equipment must

only be carried out by a skilled electrician himself or by specially

instructed personnel under the control and supervision of such an

electrician and in accordance with the applicable electrical engineering

rules.

For cable gland or conduit entries that are not used, user or installer

shall close those entries by certified blanking elements in order to

maintain the enclosure protection. Extra attention is required for

selecting the correct “Ex db IIC” or “Ex tb IIC” blanking elements.

For cleaning a dust ignition proof closure, a damp cloth shall be used.

An explosion proof enclosure must be treated with care. Seals and

sealing surfaces may not be damaged in any way. Do not jam during

assembly.

Dust ignition proof enclosures may not be charged with an electrostatic

load. It therefor shall be installed in such a way, that the risk from

electrostatic discharge and propagation brush discharge, caused by

rapid flow of dust, is avoided.

For testing purposes, loosen the bolts of the actuator cover and remove the cover.

Make sure that the power supply voltage is in accordance with the information on the

nameplate of the actuator.

Cables shall be passed through the cable glands: M25 or NPT ¾” for “Ex db” versions. M25, M20

and NPT ¾” with M30 adapter shall only be applied for “Ex tb” versions.

Connect wires according to the enclosed wiring diagram (See Appendix I)

Manually move the valve to the half-open position. Then electrically operate the actuator to

the fully open position and check if the motor rotates in the correct direction. According to the

applicable standards, the actuator must be closing in counter-clockwise direction.

Test the actuator and check whether the limit switches work correctly

After testing, check if all cable glands are correctly tightened. Applicable cable glands must be

selected to meet the application’s condition. It is recommended to use at least IP67 cable glands.

Put the cover back on the actuator and tighten the bolts.

DANGER:

HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been

completed. Once the power is supplied to the actuator,

precautions must be taken if the cover is not mounted.

Note: For more information, refer to Appendix II

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 32

Page 34

Installation & Operation Manual Proven Quality since 1892

7 MAINTENANCE

7.1 Maintenance

WARNING:

Turn off all power before performing maintenance on the actuator.

POTENTIALLY HIGH PRESSURE VESSEL. Before removing or

disassembling your actuator, ensure that the valve or other actuated

device is isolated and not under pressure.

Under normal conditions, maintenance should be carried out at six month intervals. But when the

conditions are more severe, more frequent inspections may be advisable.

Ensure that the actuator is properly aligned with the valve (stem) or other actuated device

Ensure that all wires are insulated and connected properly

Ensure that all screws are present and tightened

Ensure that all internal electrical devices are clean (dry and free of dust)

Ensure that conduit connections are properly installed and are dry

Check the internal devices for any condensation

Check the power supply of the internal heater

Check the enclosure O-ring seals and verify that the O-rings are not pinched

Check the declutch mechanism

Visually inspect the open/close cycle

For Ex-actuators the cover seal O-ring needs to be inspected and replaced if damaged.

Inspect the identification labels for wear and replace it if necessary

Damaged or broken parts may only be replaced by genuine parts

WARNING:

Flameproof Enclosure! Before opening, ensure the absence of any

gas and voltage

Treat cover with care. Seals and sealing surfaces may not be damaged

or dirty in any. Do not jam the cover during mounting.

7.2 Tools

Metric Allen Key (Hex Wrench) × 1

Screw Driver × 1

Metric Spanner × 1

Wrench 200mm × 1

Wrench 300mm × 1

Wire Stripper Long Nose × 1

Multi-meter (AC, DC, Resistance) × 1

PCU Board Option: DC Signal Generator (4 – 20mA DC) × 1

In case a PCU-A or –D board has been mounted: DC signal generator (4-20mA DC) x 1

In case a PCU and CPT board has been mounted: mA Meter (0~25mA) x 1

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 33

Page 35

Installation & Operation Manual Proven Quality since 1892

8 TROUBLE SHOOTING

The following instructions are listed in the order of the most common difficulties encountered

during the installation and start-up.

► The actuator does not respond

Visually inspect the actuator and check if no damage has occurred during shipping and handling of

the actuator.

Verify the line voltage supplied to the actuator; it must match with the rating on the actuator’s

nameplate

Compare and check the internal wiring with the supplied wiring diagram of the actuator

Check the limit switch cams

► The actuator is supplied with power but does not operate

Verify the line voltage supplied to the actuator; it must match with the rating on the actuator’s

nameplate.

Make sure that the actuator output torque is greater than the required valve torque

Check the limit switch cams

Check if the torque switches have not been tripped

Check the mechanical travel stop adjustment

Check if the rotating direction matches (According to the applicable standards, valves and actuators

must open in counter-clockwise direction)

Check the internal wiring

Check for any corrosion and condensation. Electrical or mechanical devices may have been

affected

Verify if coupler/bracket is correctly installed and may not block the actuator rotation

► Actuator runs erratically

Check the ambient temperature

Verify that the duty cycle has not been exceeded

Check the position of the manual override lever

► Optional Equipment(s)

1) Potentiometer

Check the resistance value

Check the potentiometer gear for jamming

Check the ZERO and SPAN calibration and confirm input/output signal

Check the board for any damage

2) Current Position Transmitter

Verify the input signal

Check the configuration of the dip switches

Check the board for any damage

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 34

Page 36

Installation & Operation Manual Proven Quality since 1892

9 INSTALLATION AND MAINTENANCE TIPS

WARNING:

If working in potentially explosive areas, be sure to comply with the

standard EN 60079-14 “Electrical Installation in Hazardous Areas”

Work on an actuator with an open cover and which is under voltage,

may only be performed if there is no explosion danger for the duration

of the work.

In case of an explosion proof enclosure, the actuator may only be

opened in the absence of flammable gas, dust and voltage.

During operation, installation and maintenance, treat cover with care.

Seals and sealing surfaces may not be pinched, damaged or dirty in

any way. Damaged seals (O-rings) must be replaced.

Dust ignition proof enclosures may not be charged with an electrostatic

load. It therefor shall be installed in such a way, that the risk from

electrostatic discharge and propagation brush discharge, caused by

For any installation and maintenance work, the followings should be noted:

Check the actuator visually. Ensure that no external damage or changes are visible. The

electrical cables must not be damaged and wired correctly.

Cable entries, cable glands, plugs, etc. have to be checked whether they are correctly

tightened and sealed.

Check if the Ex-connections are correctly fastened.

Check for possible discoloration of the terminal strip and wires as this may indicate an

increased temperature.

Check the flame path seals of the explosion proof enclosures for any dirt and corrosion. Since

the dimensions of all Ex seals are strictly defined and inspected, no mechanical work shall be

performed on them.

All cables and motor protection elements have to be checked.

If any defects are detected during maintenance that may affect the safety, repair measures have

to be taken immediately.

Any kind of coating for sealing surfaces is not permitted.

When replacing parts, seals, etc., only original spare ones must be used.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 35

rapid flow of dust, is avoided.

CAUTION:

Regular inspection and maintenance should be performed by

qualified and trained personnel

If working in potentially explosive areas, be sure to comply with the

standard EN 60079-14 “Electrical Installations in Hazardous Areas”.

Working on the actuator that is in open position and under voltage

must only be performed if it is assured that there is no danger of

explosion for the duration of the work.

Pay attention to national regulations

Page 37

Installation & Operation Manual Proven Quality since 1892

APPENDIX 1 : Wiring Diagrams

DANGER: HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been completed.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 36

Page 38

Installation & Operation Manual Proven Quality since 1892

DANGER: HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been completed.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 37

Page 39

Installation & Operation Manual Proven Quality since 1892

DANGER: HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been completed.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 38

Page 40

Installation & Operation Manual Proven Quality since 1892

DANGER: HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been completed.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 39

Page 41

Installation & Operation Manual Proven Quality since 1892

DANGER: HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been completed.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 40

Page 42

Installation & Operation Manual Proven Quality since 1892

DANGER: HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been completed.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 41

Page 43

Installation & Operation Manual Proven Quality since 1892

DANGER: HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been completed.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 42

Page 44

Installation & Operation Manual Proven Quality since 1892

DANGER: HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been completed.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 43

Page 45

Installation & Operation Manual Proven Quality since 1892

DANGER: HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been completed.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 44

Page 46

Installation & Operation Manual Proven Quality since 1892

DANGER: HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been completed.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 45

Page 47

Installation & Operation Manual Proven Quality since 1892

DANGER: HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been completed.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 46

Page 48

Installation & Operation Manual Proven Quality since 1892

DANGER: HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been completed.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 47

Page 49

Installation & Operation Manual Proven Quality since 1892

DANGER: HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been completed.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 48

Page 50

Installation & Operation Manual Proven Quality since 1892

DANGER: HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been completed.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 49

Page 51

Installation & Operation Manual Proven Quality since 1892

DANGER: HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been completed.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 50

Page 52

Installation & Operation Manual Proven Quality since 1892

DANGER: HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been completed.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 51

Page 53

Installation & Operation Manual Proven Quality since 1892

DANGER: HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been completed.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 52

Page 54

Installation & Operation Manual Proven Quality since 1892

DANGER: HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been completed.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 53

Page 55

Installation & Operation Manual Proven Quality since 1892

DANGER: HAZARDOUS VOLTAGE. Electrical power must not be connected

until all wiring and limit switch adjustments have been completed.

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 54

Page 56

Installation & Operation Manual Proven Quality since 1892

APPENDIX II :

ELA80 - 100 Grounding

Internal Ground External Ground

Grounding

Terminal Block #1 should be used for internal ground

ELA150 - 3000 Grounding

Internal Ground External Ground

Terminal Block #1 should be used for internal ground

DANGER:

Flameproof Enclosure! Before opening, ensure that there

is no explosive gas or voltage

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

Rev.13 - January 7, 2019 55

Page 57

56 | P a g e

Installation & Operation Manual Proven Quality since 1892

If you have questions about this product,

Please contact the nearest ECON distributor.

You can find them on www.eriks.com

ERIKS Flow Control

Cypresbaan 63,

2908 LT Capelle aan den IJssel,

The Netherlands

Phone: +31 (0)10 284 1100

ECON actuator Fig. 7907, type ELA80 – 3000 www.eriks.com

REV.13 - January 7, 2019 54

Loading...

Loading...