Page 1

Installation & Operation Manual

Proven Quality since 1892

Content

1. ERIKS operating companies

2. Product description

3. Requirements for maintenance staff

4. Transport and storage

5. Function

6. Application

7. Installation

8. Maintenance

9. Service and repair

10. Assembly

11. Possible danger

12. Troubleshooting

13. Removal

1. ERIKS operating companies

ECON safety relief valves are being delivered by several ERIKS operating companies on a

worldwide basis. In this manual these will be referred to as ‘ERIKS’, the individual terms of

delivery of the ERIKS operating company having executed the order are applicable.

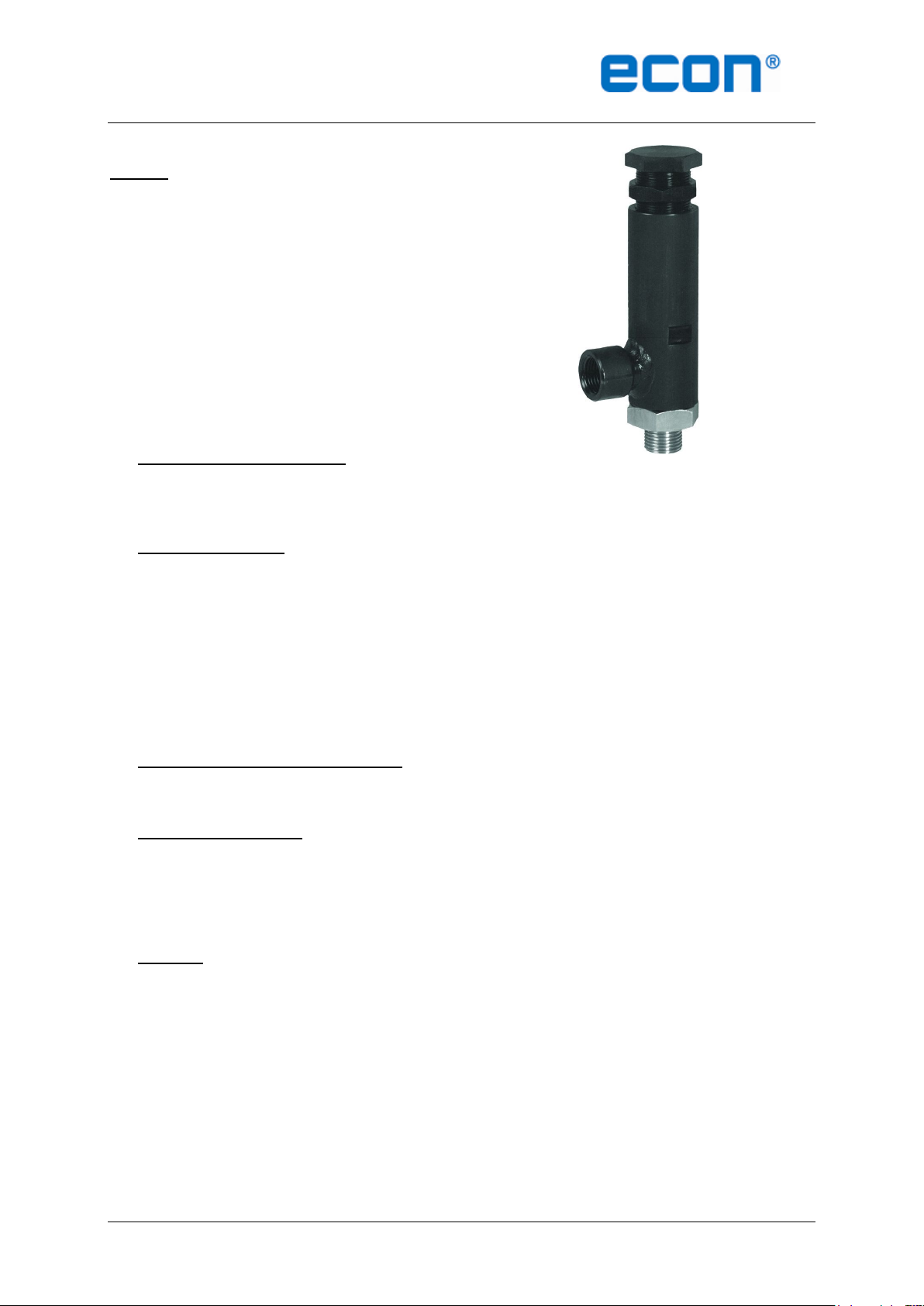

2. Product description

The ECON safety relief valves have very precise fabricated sealing surfaces and conductivity, to

guaranty a good function. For this reason, safety relief valves have to be handled very careful.

The marking makes the identification of the valve easier and contains:

- size

- set pressure

- maximum temperature Tmax

- heat number

- ECON logo + figure number

- year of fabrication

- CE marking and identification number of the inspection authority

3. Requirements for maintenance staff

The staff assigned to assembly, operating and maintenance tasks should be qualified to carry out

such jobs and in any circumstance, ensure personal safety

4. Transport and storage

Transport and storage should always be carried out with the disc complete closed and the safety

relief valve should be protected against external forces, influence and destruction. The safety relief

valve should be stored in an unpolluted space and should also be protected against all

atmospheric circumstances. There should be taken care of the temperature and humidity in the

room, in order to prevent condensate formation.

5. Function

ECON safety relief valves have as function to protect the system against excessive pressure. At a

safety relief valve, the following pressures can occur:

- Working pressure, the pressure in the system

- set pressure, the adjusted pressure at which the safety relief valve under normal use

circumstances is opening. The forces on the disc are in balance.

- colt test pressure, the adjusted static inlet pressure, at which the safety relief valve on the

test bench starts to open.

- back pressure, the sum of pressure built up in the vent line when relief and the pressure in

the vent line when this is part of a system with a higher pressure than the ambient

pressure.

Measured pressures are barg pressures.

ECON safety relief valves Fig. 1514, 1515 and 1516 www.eriks.com

Rev. 4

Page 2

Installation & Operation Manual

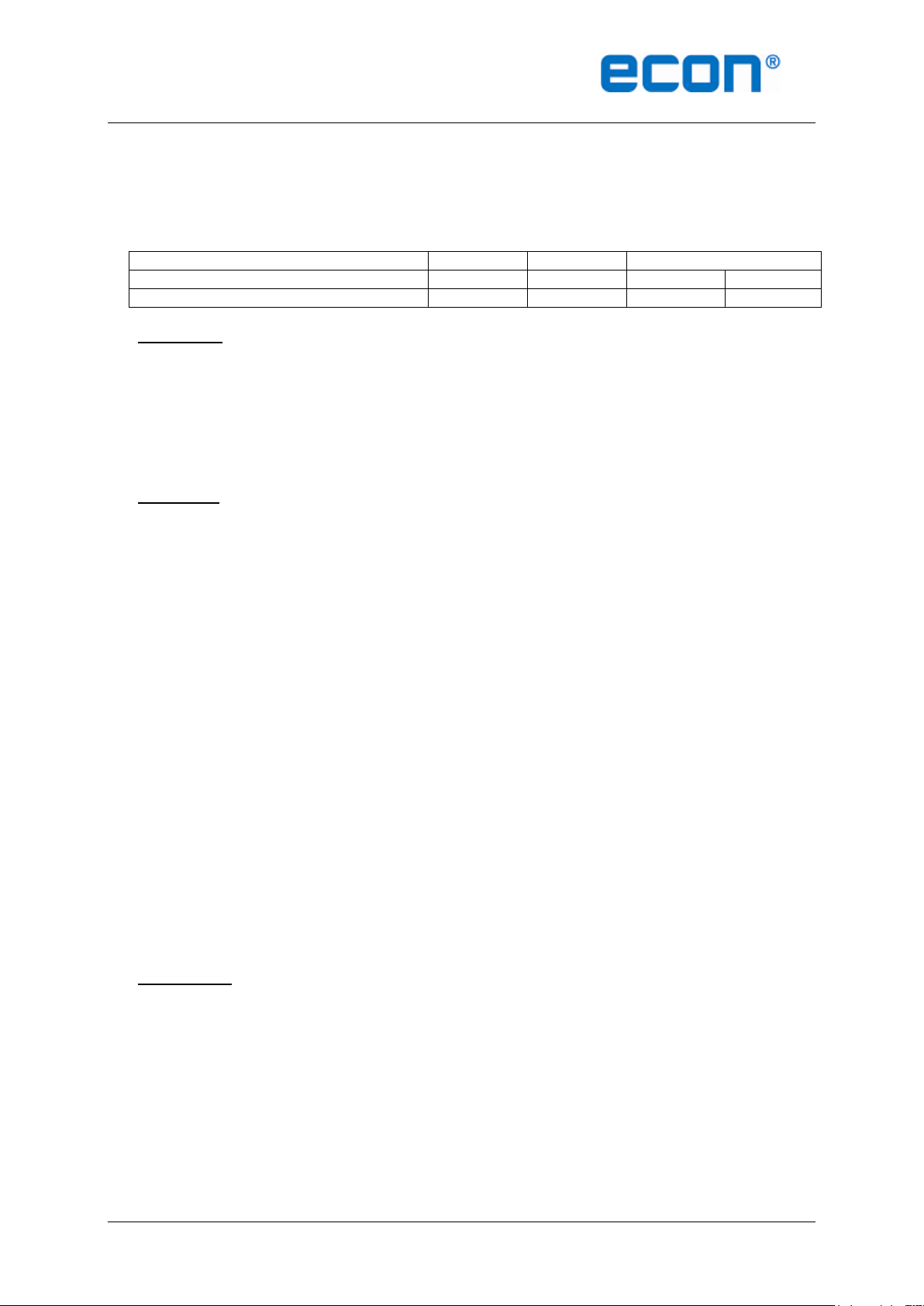

Fig.1514

Fig.1515

Fig.1516

Max./min. allowable Pressure P (bar)

20/0

42/0

130/0

200/0

Max./min. allowable Temperature T (°C)

160/0

200/0

200/0

20/0

Proven Quality since 1892

For a correct working of the safety relief valve, the outlet of the system may certainly not give any

back pressure (OPEN outlet).

Rules for the pressure relief valves under pressure.

6. Application

ECON safety relief valves with threaded connection are mainly applied in the process industry as

a relief valve for thermal expansion. Suitable for gasses and liquids. This type of safety valve is

also suitable as an overflow for the use of extreme conditions e.g. aggressive or abrasive media, it

is recommended to mention this at the ordering stage, to verify whether the valve is suitable.

The installation designer is responsible for the safety relief valve selection, suitable for the working

conditions. The valves are unsuitable, without written permission of an ERIKS company, to apply

for hazardous media as referred into Regulation (EC) No 1272/2008.

7. Installation

During the assembly of the ECON safety relief valves, the following rules should be observed:

- make sure before an assembly that the safety relief valves were not damaged during the

transport or storage.

- make sure that the applied safety relief valves are suitable for the working conditions,

medium used in the plant and the right system connections, according to pressure and

temperature limits as per the tag plate.

- before plant startup, especially after repairs carried out, flash out the pipeline, before

installing the safety relief valves.

- de safety relief valves should always be mounted side up, as mentioned by the vertical

flow direction (pressure under the disc).

- the body part which contains the spring and the adjustable bolt, may not be isolated,

because otherwise the spring gets to warm.

- the interior of the safety relief valve and pipeline must be free from foreign particles.

- the vent line should be for liquids mounted sloped. For gasses and damps the vent line

should be mounted slightly rising.

- the relief opening must be so located, that there cannot be any danger, because of the

blow-off pressure.

- install pipelines so that damaging transverse, excessive vibrations, bending and tensional

forces are avoided.

- the joints on the pipeline must not cause additional stress resulted from excessive

tightening, user shall select proper gaskets according the working temperature, working

pressure and medium.

- the safety relief valves can’t be operated, because they are working on the overpressure

of the medium.

8. Maintenance

Before starting any service jobs, make sure that the medium supply to the pipeline is cut off,

pressure was decreased to ambient pressure, the pipeline is completely cleaned and ventilated

and the plant is cooled down. Always keep safety instructions in mind and take all personal safety

precautions.

During maintenance, the following rules should be observed:

- always keep personal safety precautions in mind and always use appropriate protection

e.g. clothing, masks, gloves etc.

- be alert that the temperature still can be very high or low and can cause burns.

- check the safety relief valve on all possible leaking possibilities.

ECON safety relief valves Fig. 1514, 1515 and 1516 www.eriks.com

Rev. 4

Page 3

Installation & Operation Manual

Proven Quality since 1892

- check if all bolts and nuts, are still fastened.

- check if the disc still opens and closes in a proper manner.

- the thickness of the body must be checked to ensure safety operation at an interval of at

least three months.

9. Service and repair

All service and repair jobs should be carried out by authorized staff, using suitable tools and user

shall use valve parts, bolt and nut of the same size and material as the original one.

- weld repair and drilling of the valve is forbidden.

- it is forbidden to replace the bolt, nut or packing when the valve is under pressure.

- after replacement, service or blow-off pressure adjustment, it is necessary to check the

safety relief valve on good functioning and tightness of all connections.

- after installation, the safety relief valve should be checked and maintained periodically at

least every 3 months, depending on the medium.

10. Assembly

The assembly of the spring according drawing D31761 goes as follows:

- take care that the pin pos.7 is fitted in the bush pos.3 and the spring plate pos.8 is

mounted on the pin of pos.7

- mount the right spring pos.9 on the spring plate pos.8

- place the spring plate pos.10 on the spring

- screw the adjustable bolt pos.11 with the nut pos.12 in the body pos.1 Now we can

tension the spring

- after adjustment on the right pressure, the adjusting bolt has to be fixed by the nut. This

happens when we turn/fixe the nut against the body.

- after adjustment, when required, the safety relief valve can be sealed by ERIKS or by

another approval authority.

The springs are classified according the pressure range. The choice of the spring depends on the

set pressure. After disassemble one should take care that the right spring and other parts stick

together with the safety relief valve.

11. Possible dangers

Leakage can cause danger of the safety and health of persons, animals and goods. Even when

the safety relief valve is functioning well, there can occur dangers which one must take into

account.

Following dangers can occur:

- the safety relief valve blows off and abrasive, poisoned, colt or hot medium can escape.

This can be prevented by making a shield or to move the outlet. One can also collect the

medium in a tank.

- the safety relief valve leaks and abrasive, poisoned, colt or hot medium can escape. This

can be prevented by making a shield or to move the outlet. One can also collect the

medium in a tank.

- the safety relief valve is wrong calculated or is not working alright and because of cracking

abrasive, poisoned, colt or hot medium can escape

- injury by hot, colt or sharp parts. This can be avoid by shielding or isolation.

- the medium can freeze, at the start-up of the safety relief valve and blocking the disc.

Thinking is particular of the temperature fall, which occurs when gasses expand.

- a dangerous noise level, when the medium blows off.

- medium that escapes very fast out of the outlet

- chemical burns, injury or poisoning because of left behind medium in the valve. This can

be avoid by flushing the installation, before assembly.

ECON safety relief valves Fig. 1514, 1515 and 1516 www.eriks.com

Rev. 4

Page 4

Installation & Operation Manual

Problem

Possible cause

Corrective measures

Safety relief valve doesn’t work

The safety relief valve is wrong

calculated, for example the

blow-off pressure is wrong

New calculation and adjustment

of the safety relief valve is

necessary

The safety relief valve is

cracked because of overload

Replace the safety relief valve,

new calculation and adjustment

of the safety relief valve is

necessary

Piping system clogged

Check piping system

Leakage across valve seat

Disc not properly closed

Check disc opening function

Seat damaged by foreign

particles

Replace the valve

Medium contaminated

Clean the valve and install a dirt

screen

Leakage at the connection

Thread connection not right

Check the connection

Proven Quality since 1892

12. Troubleshooting

It is essential that the safety regulations are observed when identifying the fault.

13. Removal

All dismantled and rejected valves cannot be disposed with household waste. The valves are

made of materials which can be re-used and should be delivered to designated recycling centers.

ECON safety relief valves Fig. 1514, 1515 and 1516 www.eriks.com

Rev. 4

Page 5

Installation & Operation Manual

Proven Quality since 1892

ECON safety relief valves Fig. 1514, 1515 and 1516 www.eriks.com

Rev. 4

Loading...

Loading...