Page 1

Operating Instructions

Page 2

Page 2

ecom-

J2KN

pro

TECH

Index Page

Important hints 4

1. Instrument design

1.1. Basic module 6

1.2. Control module 7

2. Gas flow scheme 8

3. 2-stage Peltier cooler 9

4. Heated sampling system 10

5. Converter (option) 11

6. Power supply 13

7. Radio communication basic/control module 14

8. Data record 15

9. Starting 16

10. Input or selection of combustion plants 18

11. Flue gas analysis

11.1. Gas analysis 21

11.2. Flow measurement (option) 25

11.3. Pressure measurement (option) 26

11.4. Soot dot...Oil trace (option) 27

11.5. Measurement record and printout 29

11.6. Mean value measurement 30

11.6. After measurement 32

12. Adjustments 33

13. Control 39

14. Data processing

14.1. Communication 40

14.2. Automatic Measurement 41

14.3. Data logger 42

14.4. Data logging with DASNT2 43

14.5. Data processing with DAS5 43

14.6. Data processing with App 44

15. Diagnostics

15.1. Fault diagnostic 45

15.2. dT-measurement 47

16. Maintenance tips 48

17. Technical data 52

18. FAQ 53

Page 3

ecom-

J2KN

pro

TECH

Page 3

___________________________

Congratulations!

With your purchase you have decided on a high-quality product of

ecom GmbH.

Get to know the product before you start using it while reading carefully the following instructions of use and the safety indications. Use

the product only as described and only for the given areas of application in order to ascertain its longevity.

___________________________

Page 4

Page 4

ecom-

J2KN

pro

TECH

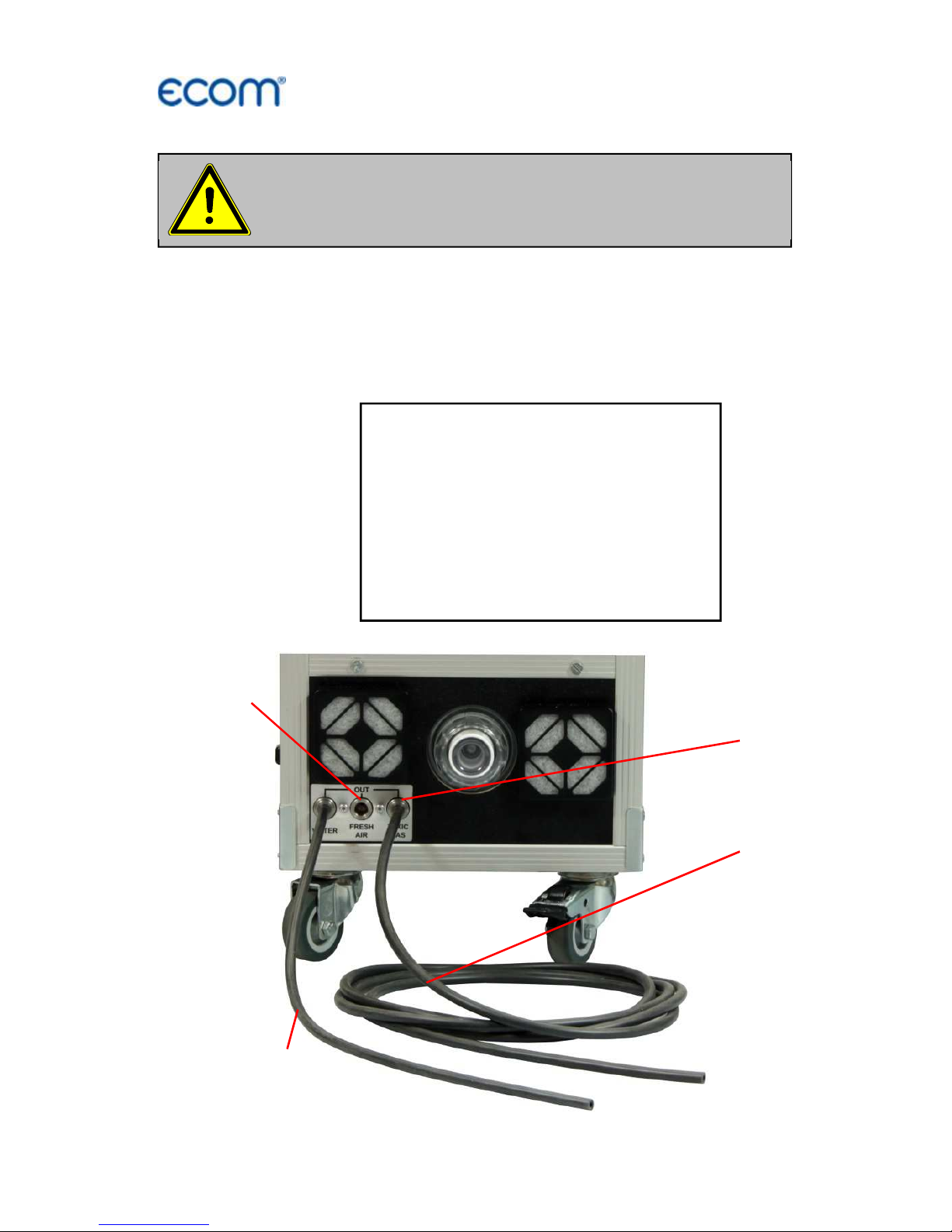

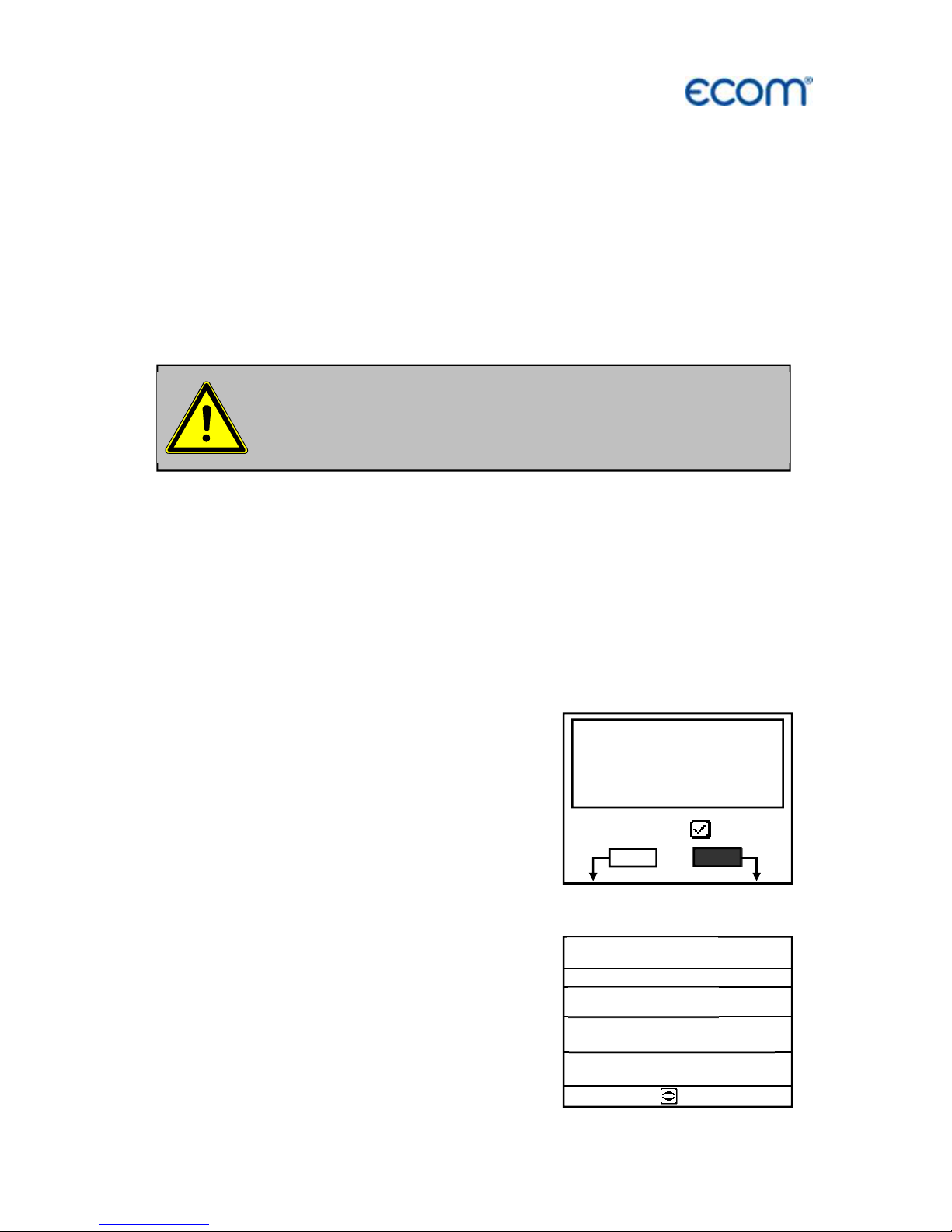

Important hints

To exclude any risk to persons, it is necessary to connect the sample

gas outlet (TOXIC GAS) of the instrument with the flue gas hose to

the flue gas duct.

Please confirm after successful connection the security message at

the instrument with <OK>.

Please connect flue gas hose to flue

gas duct before starting!

S

ecurity

message

:

Please confirm (OK) before

starting, that the sample gas outlet

(TOXIC GAS) has been connected

through the flue gas hose to the

flue gas duct!

Sample gas outlet

(TOXIC GAS)

Flue gas hose

Condensate

hose

Fresh air

connection

Page 5

ecom-

J2KN

pro

TECH

Page 5

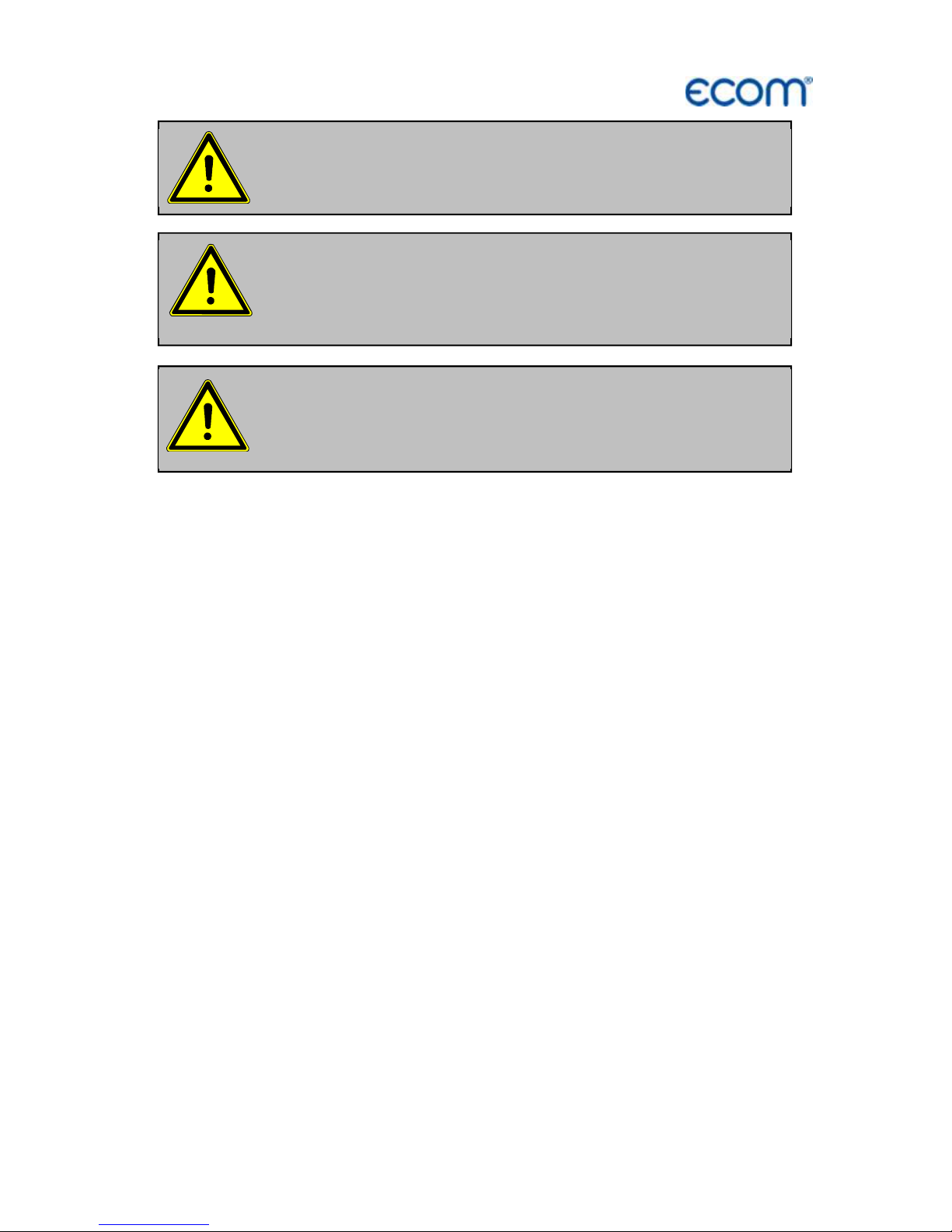

Before starting connect the condensate hose

(possibly collect condensate in a vessel)!

To ensure sufficient airflow, a minimum distance

of 0.5 m must be kept to walls or objects!

Adjustments at burners and boilers

should be

made only by specialists, who are familiar

with this installations!

Page 6

Page 6

ecom-

J2KN

pro

TECH

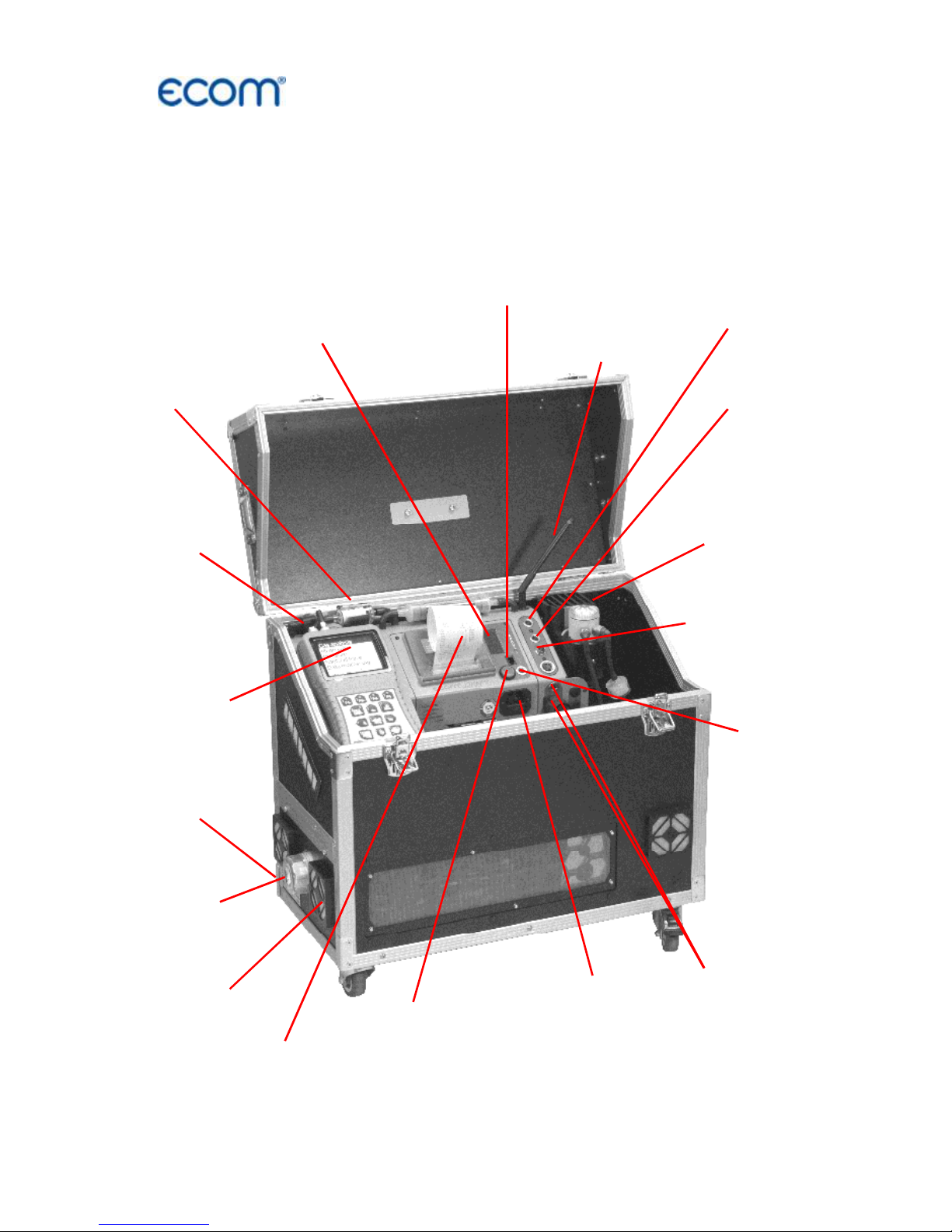

1. Instrument design

1.1. Basic module

Connection mains

power plug

with fuse

(630 mA / 250 V)

Connection

heated probe

PTFE

filter 2

Connection

air

temperature

Condensate trap

with gas cooler 1

and fine dust filter

Connection

gas hose

Connection

pressure

Connection

draught

Radio antenna

Cable socket

by wire transfer

basic / control modules

Integral

printer

PTFE

filter 1

Control

module

(see next page)

Info display

(see chapter Control)

Basic

ON / OFF

Converter

cartridge

Fresh

air 1

Fresh

air 2

Page 7

ecom-

J2KN

pro

TECH

Page 7

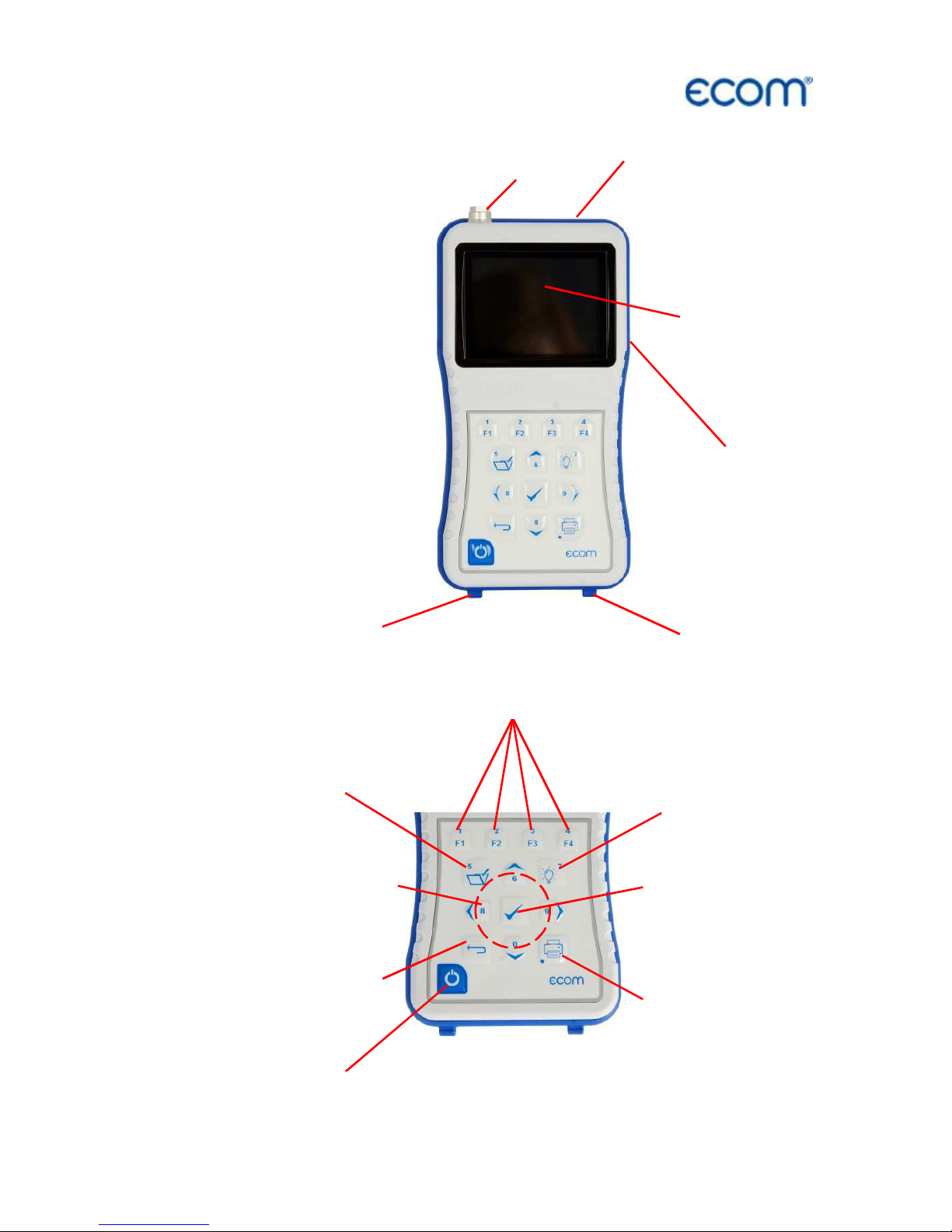

1.2. Control module

Slot for Multi-

Media-Card

Graphics

Display

Connection

USB

Connection

keyboard

Connection air

temperature

Socket for connection

cable by wire

transfer basic

ESC key

(quit/

escape menu)

In the input mode,

the keys are used

for numerical in-

puts

OK key

(confirm

selection)

Cursor keys

(Up/Down/Right/

Left/Scroll)

Measurement

values recording

Print key

(access to print-

ing menu)

Switch ON/OFF

control module

Display back-

lit ON/OFF

Function keys

(function shown on display)

Page 8

Page 8

ecom-

J2KN

pro

TECH

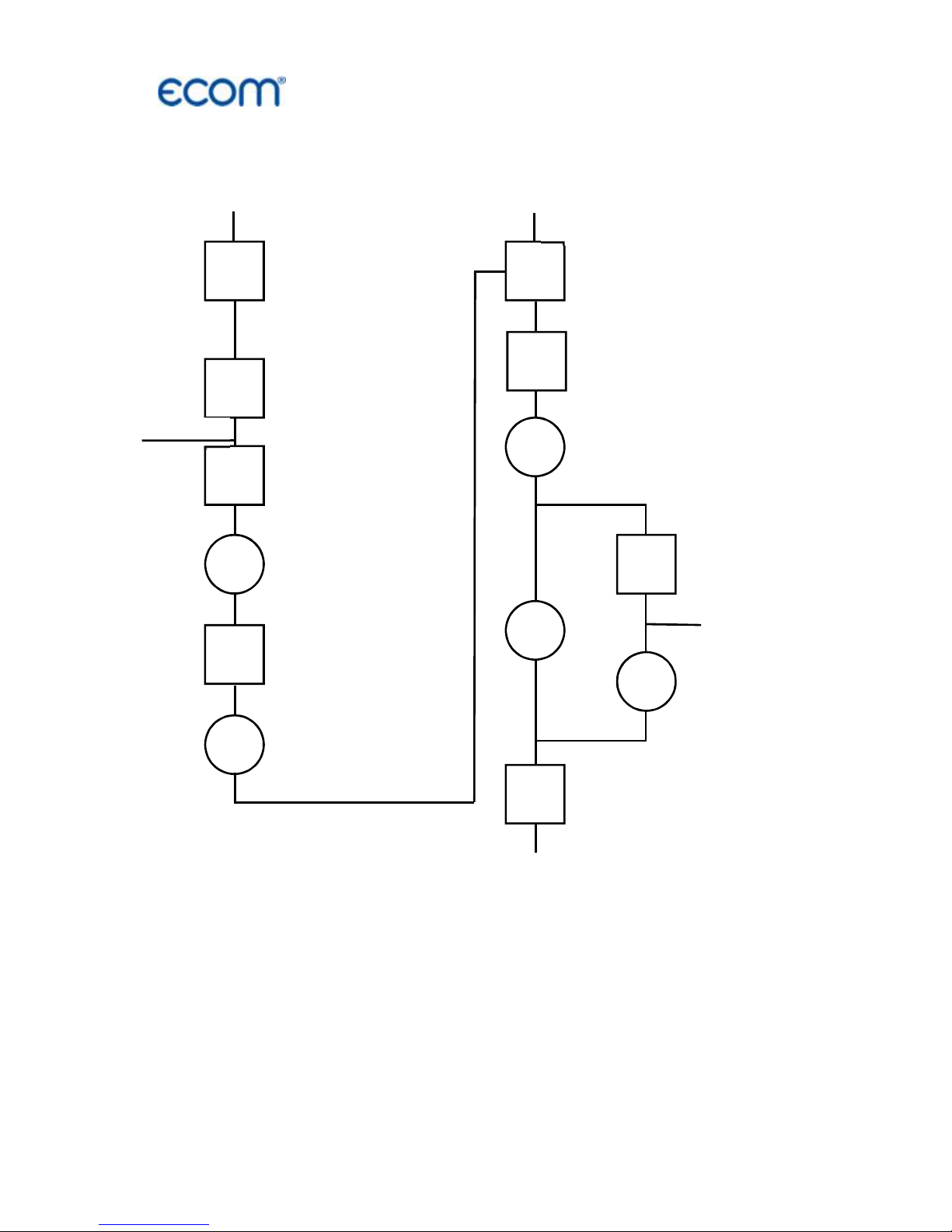

2. Gas flow scheme

Sample gas outlet

(TOXIC GAS)

Gas cooler 1

(with filter and

safty filter)

Heated filter

Heated hose

Electrochemical

sensors

PTFE Filter 1

NDIR Standard

Gas cooler 2

PTFE filter 2

NDIR Advanced

PAS/

UV

CLD

Converter

Gas pump 1

Gas pump 2

Fresh air 2

Fresh air 1

Flue gas duct

Ozon

Page 9

ecom-

J2KN

pro

TECH

Page 9

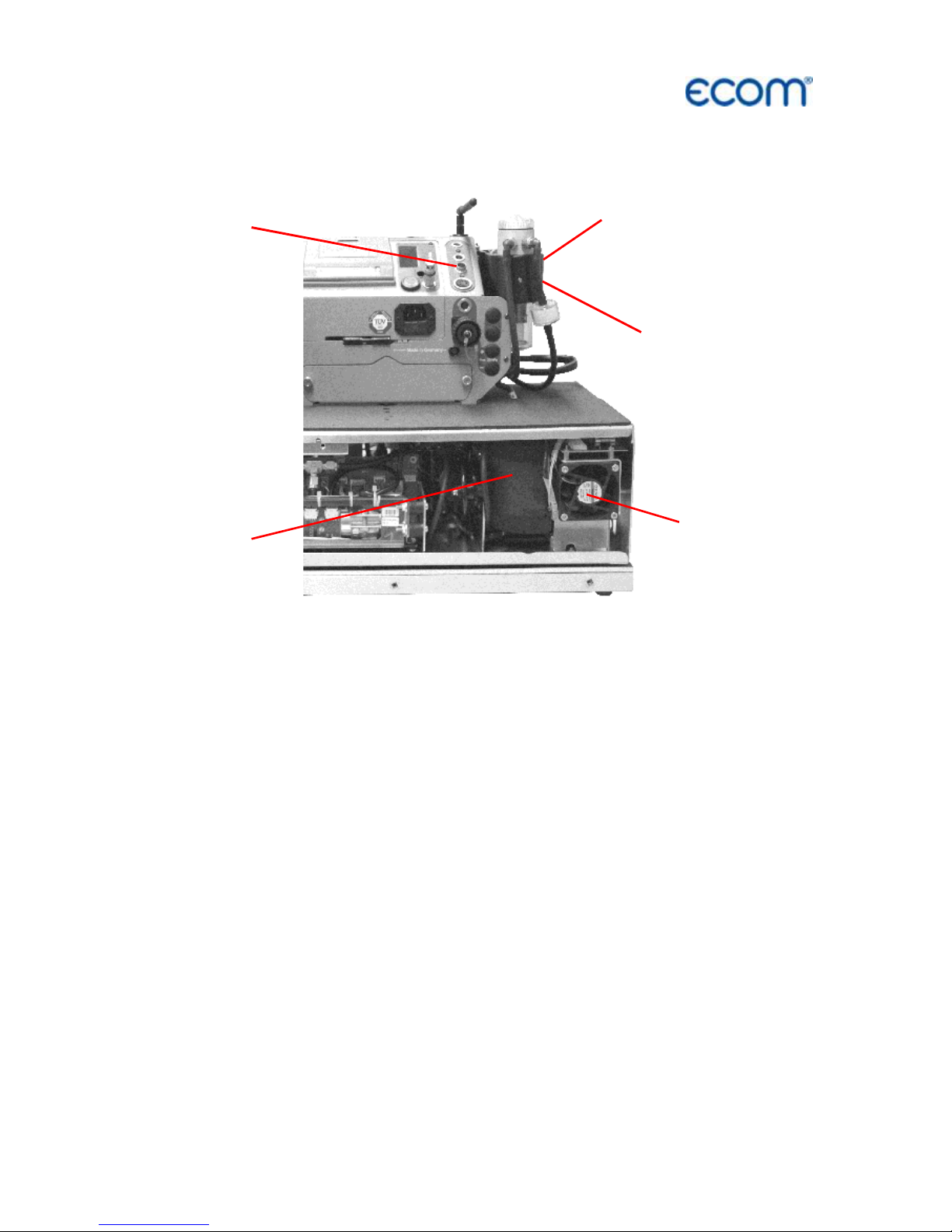

3. 2-stage Peltier cooler

Flue gas with a temperature above the dew point is sucked spiral via

a long gas path thru a surface coated metal body with good thermal

conductivity. The gas radiates its heat to this metal body

A Peltier

element (semiconductor cooling element) flown by a continuous

current is thermally connected with this body and with a second

metal body with cooling ribs and ventilation slots. The current thru

the Peltier element creates a heat transfer from hot to cold, drains

the heat of the metal body flown by gas and transfers it to the outer

cooling body. This heat is transferred thru ventilation to the

surrounding air.

The condensation issued by the heat loss of the gas drops in a

receptacle and is pumped out by a permanent working hose pump.

The sucking capacity of the gas conveying pump avoids a sufficient

dwell time of the gas with the condensate, so that wash out reactions

(NO

2+H2

O > H2NO3) do not take place. At the cooler outlet the gas

has a temperature of ca. 5 °C with a relative saturation of nearly 100

% relative humidity (corresponds to a water steam content < 7 g/ m

3

).

Fan 1

Gas

cooler 1

Gas

inlet

Gas

cooler 2

Fan 2

Page 10

Page 10

ecom-

J2KN

pro

TECH

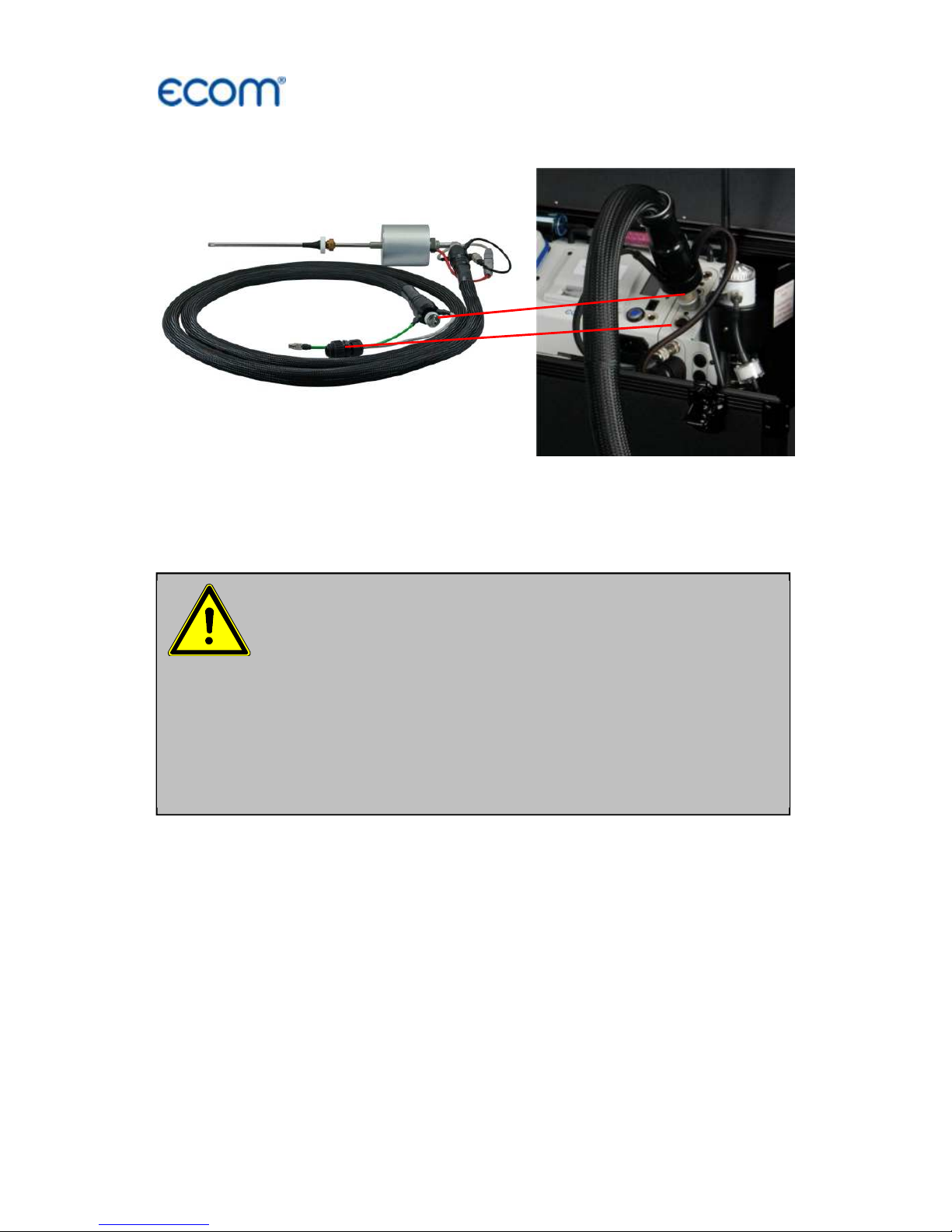

4. Heated sampling system

By using a heated sampling system (option) is possible to measure

water-soluble substances (NO

2

and SO2) without washout. A built-in

hot gas filter protects the instrument especially for long-term

measurements from fouling. The maximum exhaust gas temperature

when using the heated sampling system is 500 ° C.

Please note:

- Do not bend the tube

- Heated tube has to be cooled out after the

measurement

- Heated tube may not be folded too tight

(use the whole under case)

- Do not put the heated tube in water

- Clean or replace PTFE filter regularly

Direct connection at the front

of the J2KNpro TECH

Heated sampling system

Page 11

ecom-

J2KN

pro

TECH

Page 11

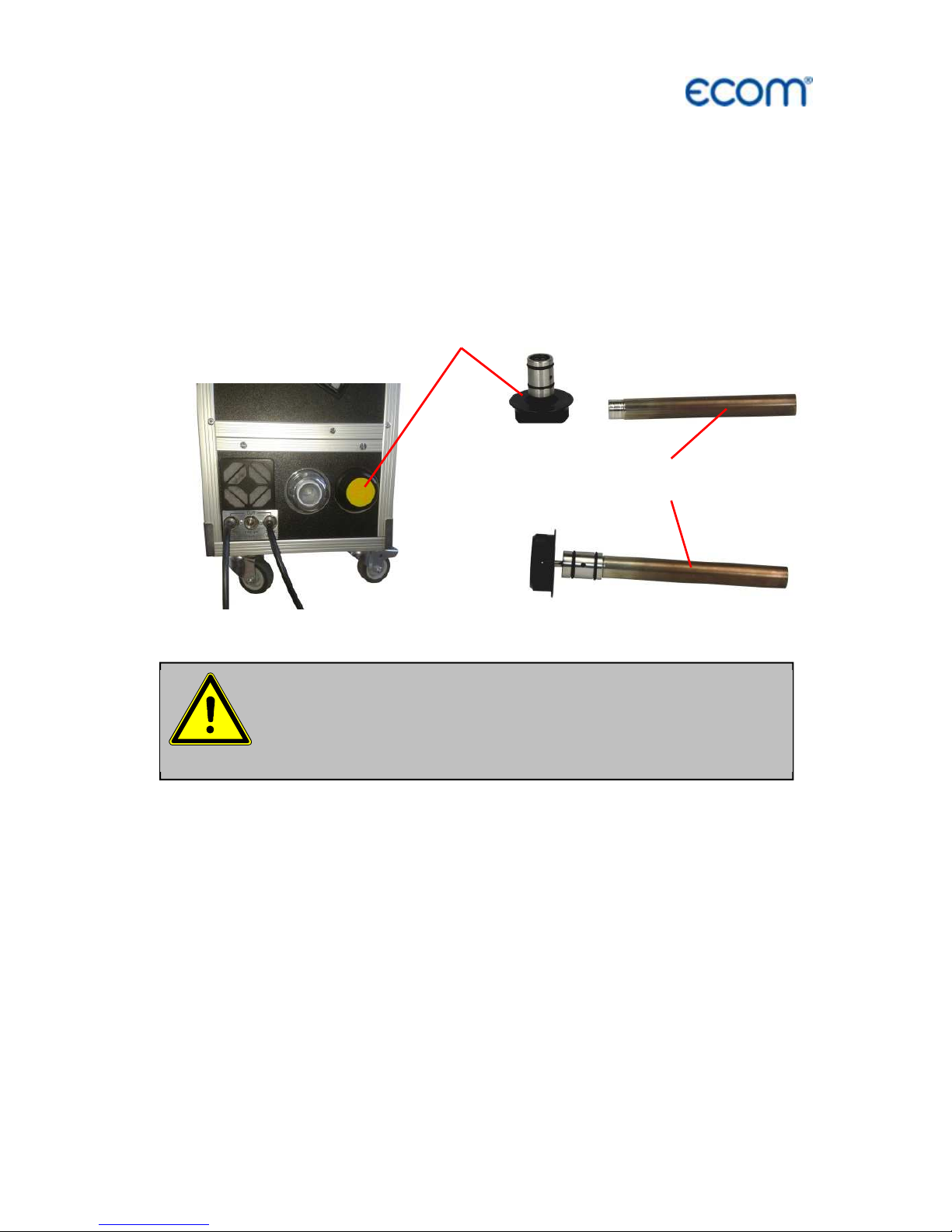

5. Converter (option)

The NO2 / NO Converter converts catalytically the NO2 content of

the sample gas into NO. For this purpose, the sample gas is passed

through a converter cartridge from stainless steel having a catalyst

filling. This conversion allows an indirect measurement of NO2

(switch function key <F1> at the control unit to toggle between NO

and NOx measurement).

Replace reactor cartridge

:

Replace the reactor cartridge if the conversion rate from NO2 => NO

falls below the required value. Changing the reactor cartridge is

possible without tools in a very short time. We recommend turning off

the instrument and letting cool down for approximately 1 hour before

changing the cartridge. This minimizes the hazard of burning. There

is also the possibility of changing cartridges in a heated instrument,

but the converter cartridge has a temperature of about 200 ° C.

The converter cartridge is hot! Touching may cause

severe burns! Wear suitable protective gloves and

protect the converter cartridge against access!

Reactor fastener

Reactor cartridge

Page 12

Page 12

ecom-

J2KN

pro

TECH

How to change the reactor cartridge:

- Stop sample gas flow (deactivate NOx measurement).

- Before opening the reactor fastener make sure that no toxic or

dangerous gases or components are provided within the gas way.

(Purge the tubes with inert gas or air).

- Turn the reactor fastener counter anticlockwise up to the end of the

thread.

- Pull out the fastener with the reactor cartridge carefully.

- Let the cartridge cool down if needed.

- Pull the reactor cartridge out carefully from the reactor fastener

(wear protective gloves).

- Replace new reactor cartridge to the reactor fastener.

- Push the cartridge carefully to the reactor opening and turn the

reactor fastener clockwise up to the end of the thread.

Use only spare parts and

consumables from ecom!

Page 13

ecom-

J2KN

pro

TECH

Page 13

6. Power supply

The basic module of the ecom-J2KN

pro

TECH is delivered with

internal loading unit. The connection of the power plug is needed to

operate the instrument.

The control module of ecom-J2KN

pro

TECH is powered by 3 nickelmetal-hydride accumulators (type AA). In case of need, the

accumulators can be recharged by docking the control module to the

basic module.

Used accumulators can be returned to us or brought

to recycling stations of public waste disposal compa-

nies respectively accumulators selling stores!

Never use batteries, to operate the control

module of the ecom-J2KN

pro

TECH!

Page 14

Page 14

ecom-

J2KN

pro

TECH

7. Radio communication basic / control module

Thanks to the detachable control

module the basic module can be

monitored wireless. The basic module

can be unlocked as follows:

1. Press to unlock.

2. Tip control module forwards

3. Release control module from basic

module

The information exchange between

control and basic module is performed

via radio transmission (868 MHz) with

coverage of approx. 70 m (by free

sight). The quality of the radio

transmission is documented by a bar

indication in the main menu of the

instrument (long bar = good radio

communication).

By interruption of the radio

communication, an error message is

displayed. By persisting disturbances of

the radio communication, a cable

(option) can take over the transfer

(connection betwen socket DATA on

control unit and socket DATA on basic

module).

If the basic module is switched off and

the control module not, so the display

will show an error message inviting to

fix the control module in its docking

station (helps also not to forget the

control module). Observe this order, quit

with <ESC> and finally switch off the

control module.

Gas

analysis

Pressure

Soot..Oil trace

Data processing

Adjustments

Control

Diagnostics

Unlocking

Bar indication

radio quality

-- ECOM-J2KN --

Radio connection

interrupted!

Use cable or

switch on basic

module!

Quit

with:

-- ECOM-J2KN --

Place J2KN in

basic mod.!

Quit with:

Page 15

ecom-

J2KN

pro

TECH

Page 15

8. Data record

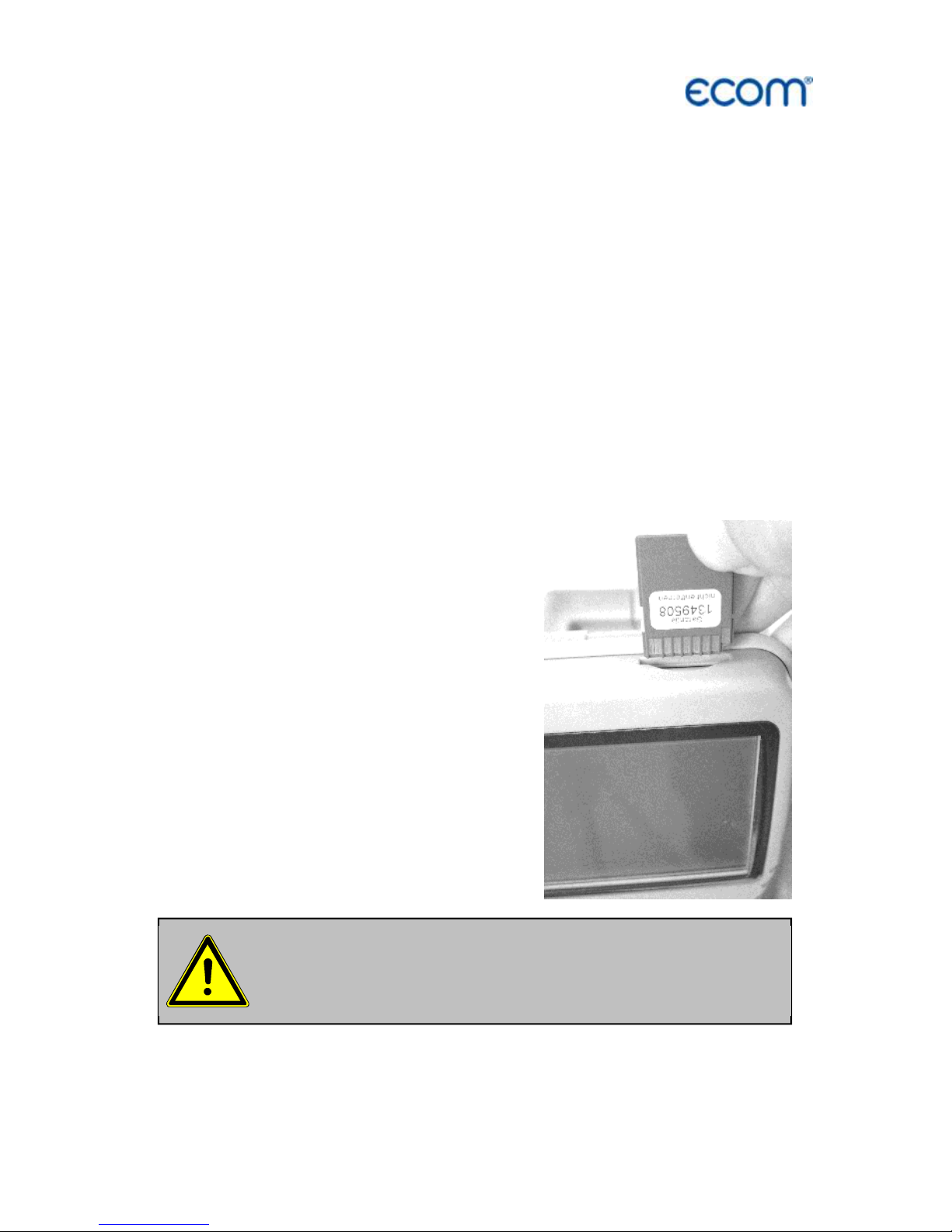

The multi-media card enables the storage of both punctual

measurements and data logger records.

The values of punctual measurements are written in a text file

(J2KDV.txt). Those of data logger records in a csv file (J2KDL-xx.csv

/ xx = records numbered consecutively).

Both file types have the same structure and can be imported

respectively opened in Excel. See chapter „Technical Data“ for data

format information. The files can be transferred on the PC using a

card reader. The following conditions must be fulfilled for using a

multimedia card:

- ecom-J2KN

pro

TECH

- min. card volume 32 MB - max.32 GB (UHC)

- card formatted on 16 bit FAT or FAT32

- SD cards from SanDisk recommended

- PC with card reader

Insert the multi-media card as shown.

Take care that the card does not stand

out and hooks on.

Never pull out cards during data record

- data loss

and damaging of the data carrier possible!

Page 16

Page 16

ecom-

J2KN

pro

TECH

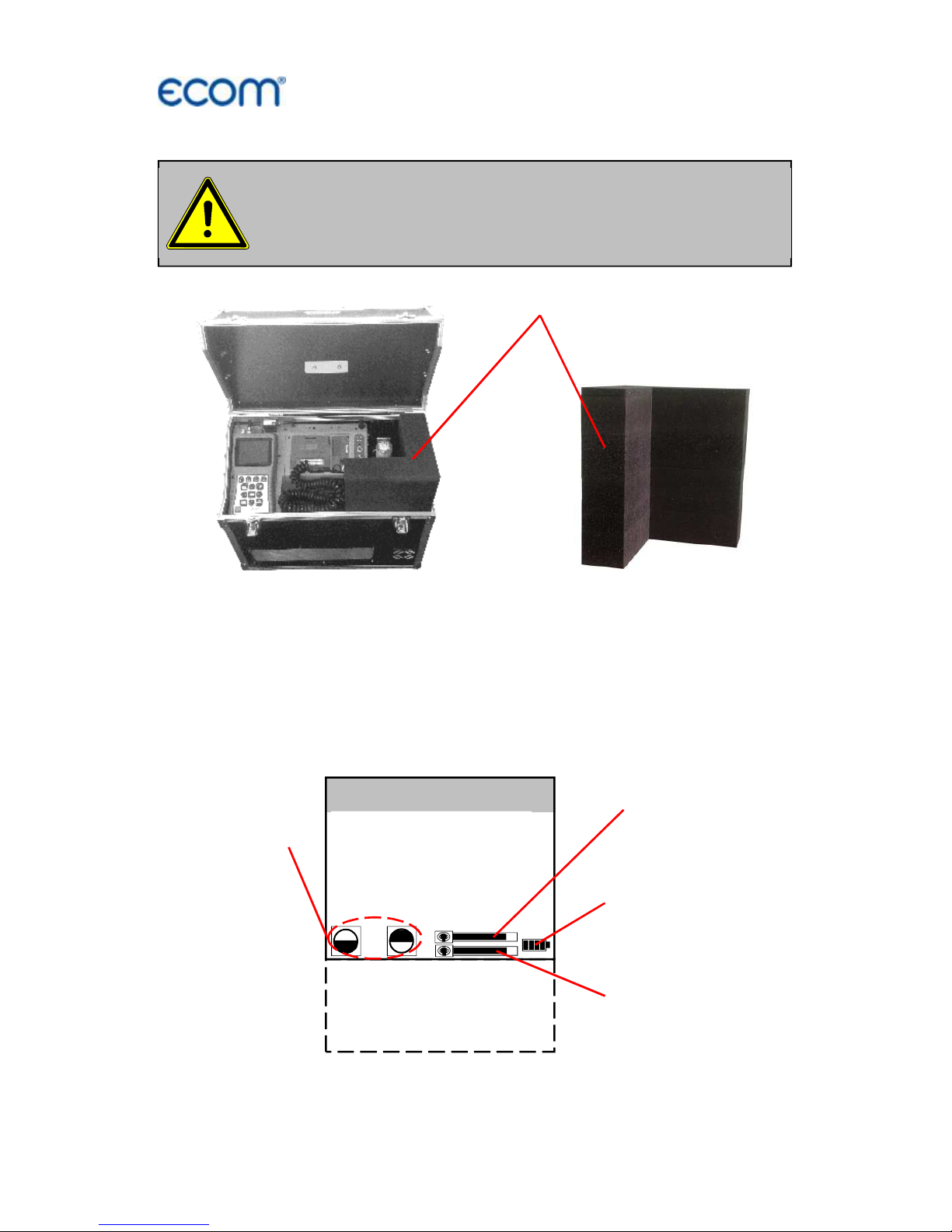

9. Starting

Once the control module has been switched on (key <I/0>), the main

menu is displayed.

8 sub-menus with the following functions are displayed (non-visible

sub-menus can be called up scrolling the arrow keys):

Before starting up please remove

the transport protection!

Transport protection

Gas analysis

Mean value

Pressure

Soot..Oil trace

Data processing

Adjustments

Control

Diagnostics

Bar indication

radio quality

Bar indication

transfer quality

Battery voltage

(charging status)

Display con-

trast adjusta-

ble with

F1 and F2

Page 17

ecom-

J2KN

pro

TECH

Page 17

- Gas analysis : Perform gas analysis

- Mean value : Measurement with mean value calculation

- Pressure : Perform draught or pressure measurement

- Soot...Oil trace : Input of soot measurements results

- Data processing : Assign measurements / Load or send data

- Adjustments : Modify instrument adjustments

- Control : Check operation state of instrument

- Diagnosis : Read-out of firing automats

(only in connection with ecom-AK) /

dT-measurement

If measurements are carried out first the basic module has to be

turned on (switch below the info display). Select the sub-menu "Gas

analysis" with the cursor keys and confirm with <OK>. The

instrument starts with a warm-up phase (max. 30 min.). After the

sensors are at operating temperature, a 15-minute stabilization

phase follows followed by a 3-minute calibration with fresh air.

Simultaneously, the message appears asking if you want to use the

data processing. If you want to assign the sampled data to a specific

plant, so press <F1> (<F4> = no: measurement will be performed

without assignment).

Fuel types acc. to 1

st

BImSchV*:

Fuel oil (B)

Natural gas (B)

City gas (B)

Coke oven gas (B)

Liquid gas (B)

Use the cursor keys to select the

desired fuel type and confirm with

<OK>.

* Country specific fuel types programmable on demand.

Make sure that the instrument is turned on in

clean air, because the zero point of the sensors

will be updated with fresh air!

Fuel type

Fuel oil (B)

CO2max

A1 B

15.4

0.50

0.007

Select:

Do you wish to

use the data

processing?

YES Quit with

! NO

Page 18

Page 18

ecom-

J2KN

pro

TECH

Input number

25.11.2017

Please use the

numeral keys!

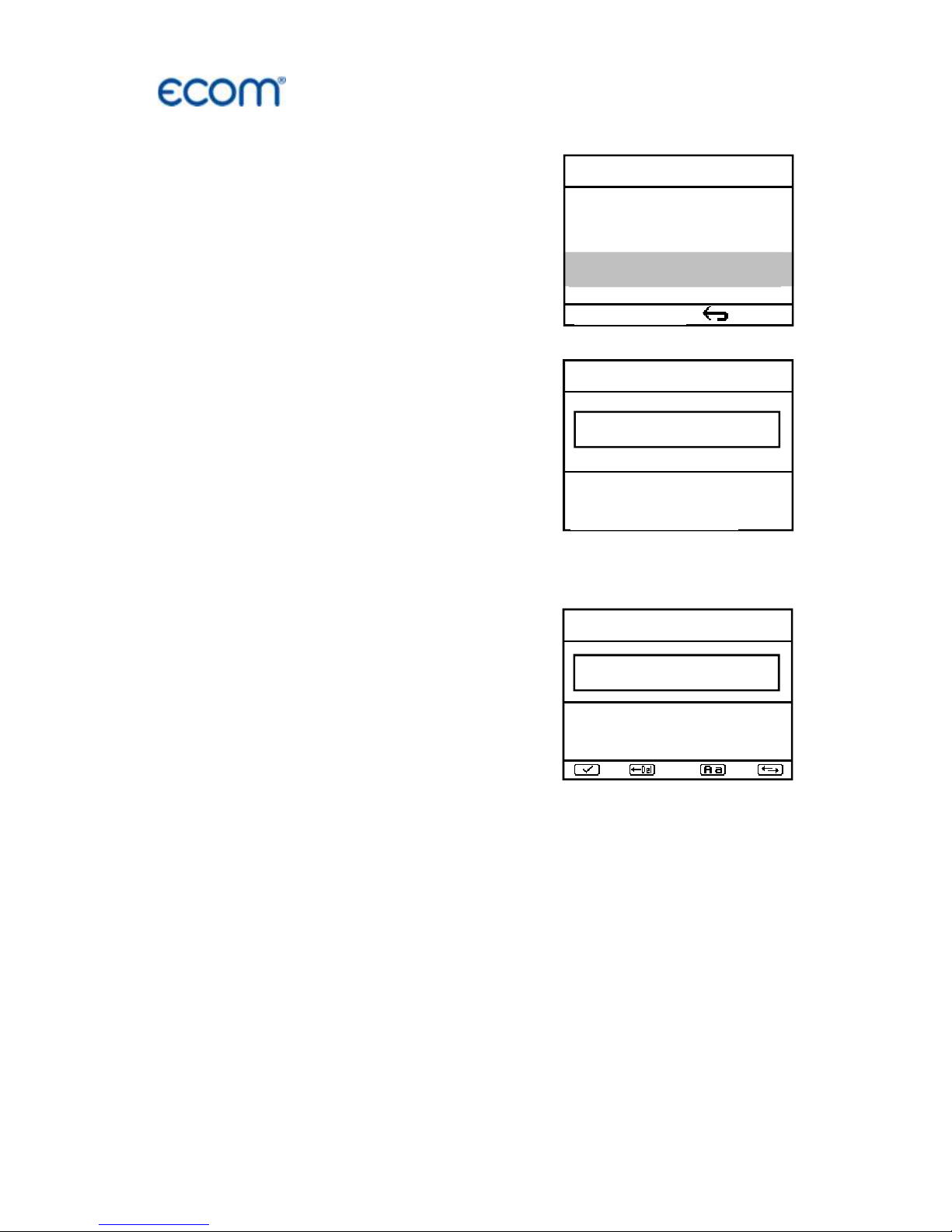

10. Input or select plant specific data

To call up plant data recorded in the

ecom-J2KN

pro

or to create a new file,

the following possibilities are available:

Create new (is automatically selected

by first use of a MM card): To create a

new file, a numerical number can be

assigned.

-Select „Create new“

-Confirm with <OK>.

-Input a number (max. 16 numbers):

Example: "25.11.2017"

Tip: We suggest a date-related input to easily find the data record

later on via the search function (search per date).

After confirming with <OK> it is possible

to enter a text (max. 6 lines with 20

indications) with a software keyboard

(for print out or data processing).

Proceed as follows:

-choose Text line 1 with the cursor keys

<up/down> and confirm with <OK>

-select keyboard (4 keyboards are available) with <F3>

-select with the cursor keys <up/down/right/left> a character

(selected character is black deposited)

-choose the character with <OK> (the last character can be deleted

by pressing <F2>)

-repeat procedure, until line is complete

-if you want to correct a character, proceed as follows:

-interrupt choosing characters with <F4>

-select character with the cursor keys <right/left>

-activate choosing characters with <F4> and set a new character

-select the next line after pressing <F1>

You can close the text input with <ESC>. Activate the next free record number with <OK> and start flue gas measurement with <F1>.

Insert Text

25.11

A B C D E F G H I J K L M

N O P Q R S T U V W X Y Z

Ä Ö Ü .

- ( ) [ ] { }

Selection upon:

Search word

Memory number

Create new

Quit with:

Page 19

ecom-

J2KN

pro

TECH

Page 19

Record number: For check of the plant

already stored in the instrument, the

selection upon record number is most

appropriate.

- Select „Record number“

- Confirm with <OK>.

- Input a random record number:

Example: "1" for record number 1

- Press <OK> once the input is completed to call up said data

record number. The cursor keys <Up/Down> enable the check of

the record numbers.

- Press <F1> to select the first record number and <F2> for the last.

- Press <F4> to delete the content of the selected record number.

- Press <OK> to activate the record number.

- Finally press <F1> to start the gas analysis.

Memory number

1

Please use the

numeral keys!

Selection upon:

Search word

Memory number

Create new

Quit with:

Page 20

Page 20

ecom-

J2KN

pro

TECH

Search word: If the plant code is known, it is possible to find the

plant data stored with help of a search machine.

-Select "Search word" and press <OK>.

-Input with software keyboard 4 related

figures of the plant code:

Example: "25.11"

for plant code 25.11.2017

-Press <F1> after input to start the

searching process. All possible

correspondences with these figures

sequence will be filtered. The selection

can be stepped thru with the arrow keys

(<F1> for selection beginning, <F2> for

selection end)

-Press <OK> to activate once the desired

data block is found

-Press / „View“ / <OK> to view the

previous analysis at this plant

All measured and calculated values can

be called up on 4 display pages using the

arrow keys to step thru.

Press <F1> to quit the previous measurement and start recording of

the current measurement values.

Memory number 1

25.11.2007

Data record 12:15:53 25.11.17

Further pages:<↑↓> Memory number 1

Gas analysis 12:15:53 25.11.17

Further pages:<↑↓> Memory number 1

O2 3.2 %

CO2 13.1 %

CO 0 ppm

Eff. 92.5 %

Losses 7.5 %

Exc. air 1.18

T.Gas 184.4 °C

T.Air 20.3 °C

Draught -0.03 hPa

CO measurement 12:15:53 25.11.17

Further pages:<↑↓> Memory number 1

O2 17.5 %

CO 0% 738 ppm

CO 123 ppm

Lambda 7.00

O2 value in air

O2 value in air 12:15:53 25.11.17

Further pages:<↑↓> Memory number 1

O2 19.5 %

CO 3 ppm

Zug 0.01 hPa

Soot..Oil trace

Mean value

: 0.5

Boiler temp. : 65°C

1st Soot meas.: 0.5

2nd Soot meas.: 0.3

3rd Soot meas.: 0.7

Oil trace : NEIN

dT measurement

dT measurement 12:15:53 25.11.17

Further pages:<↑↓> Memory number 1

T1 70.4 °C

T2 56.3 °C

dT 14.1 °C

Measurement

available

Search word

25.11

A B C D E F G H I J K L M

N O P Q R S T U V W X Y Z

Ä Ö Ü .

- ( ) [ ] { }

Memory number 1

25.11.2017

End with : !

F1:First record

F2:Last record F4:Delete

Page 21

ecom-

J2KN

pro

TECH

Page 21

11. Flue gas analysis

11.1. Gas analysis

After warm-up and calibration phase, the instrument switches over to

the measurement mode. The gas measurement values can be

viewed on different display pages. Use the cursor keys to scroll the

pages.

With <F1> you can switch from the measured value display to a

menu or selected before (see chapter Adjustments). Possible menu

options are: Soot... Oil trace, Data processing, Adjustments, Control,

Fuel type, Standby, Purge, Eff. (C), Memory -> M, CLD NO <-> NOx,

WLAN, Pressure. Further you can switch with <F1> from any menu

back to the measured value display.

With <F2> you can print and store the measured values into the

intermediate memory at the same time.

With <F3> you can switch off the CO sensor, in order to protect the

sensor against too high concentrations (only required for

electrochemical CO sensor). The automatic disconnection will switch

off the CO sensor at approx. 2500 ppm (also for CO IR).

With <F4> you can switch from the measured value display to a

menu selected before (see chapter Adjustments). Possible menu

options are: Soot... Oil trace, Data processing, Adjustments, Control,

Fuel type, Standby, Purge, Eff. (C), Memory -> M, CLD NO <-> NOx,

To compensate a possible sensor drift, it is

important to calibrate the instrument with fresh

air at regular Intervals!

Hotkey

<F1>

Hotkey

<F4>

Store and print

measured

values <F2>

Switch off

CO-Sensor

<F3>

O2 3.2 %

CO2 13.1 %

T.Gas 184.4 °C

T.Air 20.3 °C

Gas analysis

25.11.07

Page 22

Page 22

ecom-

J2KN

pro

TECH

WLAN, Display values, Pressure. Further you can switch with <F1>

from any menu back to the measured value display.

The position of the measured and calculated values (gas analysis)

on the display pages is free selectable (choose „Display values“ for

<F4> Hotkey). For alteration of the existing succession respectively

personal listing, proceed as follows:

-Press <F4> to activate the function.

-select the line with the cursor keys <up/down>,

-select the measured or calculated value with the cursor

keys <right/left>,

-repeat this procedure until all modifications are completed.

-Press <F4> to deactivate the function.

Instruments with magnetic valve and fresh air connection

Instruments that are equipped with magnetic valve technology and

fresh air connection are able to be purged or calibrated with fresh air

without taken out the probe out of the flue gas duct:

For fresh air purging, press the <Enter> key from the measured

value display, select the menu item "Fresh air purge" and press the

<Enter> key again. The fresh air purging can be ended with <F3> in

the measured value display.

For fresh air calibration, press the <Enter> key from the measured

value display, select the menu item "Re-Calibration" and press the

<Enter> key again. After the following query has been answered

with "YES" (<F1>), the 1-minute calibration phase starts.

Core stream search

Position the sampling probe in the exhaust channel so that the

thermocouple is fully surrounded with the gas.

Page 23

ecom-

J2KN

pro

TECH

Page 23

Perform the measurement in the core stream of the exhaust gas

channel (probe placed in the highest gas temperature area).

A trend indication for T.Gas easies the core stream search. As long

as the display shows a + symbol, the measured temperature

increases, it means the probe tip moves towards the core stream. If

a - symbol is displayed, pull the probe out of the core stream and the

temperature sinks. If no temperature change is shown for at least 3

seconds, so the trend indication will be deleted.

CO

2

, efficiency, losses, excess air and dew point are calculated

values. They can only be calculated if realistic values for the basic

parameters O

2

and temperatures are available. It must be

ascertained that:

O

2

< 20,5 % and T.Gas - T.Air > + 5 °C

are given. The dew point can only be calculated accurately if, in the

menu "Adjustments", the current barometric air pressure value has

been entered. This value cannot be determined by the ecom-

J2KN

pro

. If the gas temperature falls below the dew point (between

25 and 65 °C), ETA will be calculated with condensation. In the

display (C) appears behind ETA.

Correct measurement values are displayed first after a short delay,

necessary for the gas transport and the build-up of a stable

electrochemical reaction at the sensors. This time period lasts

approx. between 1 and 1.5 minute. For recording, printout and

evaluation wait until the values do not change anymore. If deviations

higher than 2 ppm still occur by the gas values, they can be due to

unstable pressure conditions in the exhaust channel.

Core stream

search

T.Gas °C

Gas analysis

25.11.17

180.4

Zoom Display:

Adjust parameter

with Cursor keys

<right/left>

Page 24

Page 24

ecom-

J2KN

pro

TECH

If the measurement values are stable

and the results can be printed out, press

the key <Record> (disc symbol) to

transfer the values in the intermediate

memory (caution: store gas analysis

and CO measurement values

separately). The values are stored for a

later printout and, if need be, for a final

data record storage.

If a printout of the values should be made simultaneously to the

intermediate recording, so press <F2> (the complete content of the

intermediate memory will be printed).

Measurement stored in

intermediate memory

O2 3.2 %

CO2 13.1 %

T.Gas 184.4 °C

T.Air 20.3 °C

Gas analysis 25.11.17

recorded!

Page 25

ecom-

J2KN

pro

TECH

Page 25

11.2. Flow measurement (option)

This measurement can be done with a

pitot tube. At first the pitot factor of the

pitot tube must be entered

(„Adjustments“ / „Internal“ / „Pitot

factor“). After connecting the pitot tube

to the instrument, the zero point of the

sensor can be set with <F4>. With <F1>

the cross section of the flow channel

can be entered (needed for calculation

of the flow rate). After the pitot tube is

positioned in the flow channel, the

display shows the speed (m/s), the flow

rate (Nm

3

/h) and the differential

pressure (Pa). If the value indicated is

stable, press <Record> to store the

value in the intermediate memory. If a

printout of the values should occur

simultaneously to the recording in the

intermediate memory, press <F2> (the

complete content of the intermediate

memory will be printed out).

Connections for

pitot tube

Measurement stored in

intermediate memory

V.Gas

0.4 m/sec

M.Flow

44 Nm3/h

dP 0.1 Pa

Flow measurem. 25.11.17

recorded!

Flow measurement

Page 26

Page 26

ecom-

J2KN

pro

TECH

11.3. Pressure measurement (option)

A trend indication for the draught conditions in the exhaust channel

can already be determined during the gas analysis. Nevertheless the

value for the chimney draught will not be stored together with the gas

values while pressing the key <Memory>.

Indeed the difference pressure sensor tends to drifts because of its

sensibility and, for an exact measurement it is consequently advised

to re-calibrate the sensor immediately before sampling and

documenting the value.

Access the menu while selecting the

sub-menu "Pressure". The current

value is displayed as well as the

instruction to adjust the zero point of the

sensor. Release hereto the draught

hose from the instrument for a short

moment and press <F4>. The sensor is

herewith re-calibrated.

Fix the draught hose again. The display

shows the exact measurement value

which can be stored while pressing

<Memory> and added to the previous

results in the intermediate memory. The

stored value is shown on the display.

Press <ESC> to quit the differential

pressure measurement menu.

For this option a

probe

type SB is required!

Pressure

-

0.12

hPa

--.-- hPa

New 0

point

Pressure

-

0.12

hPa

-

0.12 hPa

New 0

point

Measurement stored in

intermediate memory

Page 27

ecom-

J2KN

pro

TECH

Page 27

11.4. Soot...Oil trace (option)

The sub-menu "Soot...Oil trace"

enables the input of measured results

for boiler temperature, soot dots and oil

trace. Select the line „Boiler temp.“

and press <OK> to activate the input.

The input can be made using the

numerical keys. Press <OK> to store

the value in the data record of the

measurement.

The soot dot measurement is to be performed with the optional

heated pistol grip probe which heating function prevents the filter

paper to become wet because of the humidity issued by the

combustion condensate. The filter paper slot is hereby heated up to

approx. 70 °C. Switch hereto the probe heating of the pistol grip

probe while selecting „Adjustments / Internal / Probe heating /

<F1>“.

Proceed as follows:

-Switch on the probe heating while selecting „Adjustments / Probe

heating / <F1>“.

-Insert a filter paper in the paper slot.

-Select the line „1st. Soot meas.“.

-Press <OK> to start the measurement. The display shows the

volume to be sucked and the pump starts sampling.

If the soot dot analysis are made with a manual pump the sucking

procedure can be interrupted while pressing <F4> (result value can

immediately be entered).

Once 1,63 litres has been sucked in, the instrument will instruct to

input the opacity degree. Proceed as follows:

-Release the filter paper from the probe slot.

For this option a

probe

type SB is required!

Soot..Oil trace

Mean value

:

-.- Boiler temp.: 66°C

1st Soot meas.: -.2nd Soot meas.: -.3rd Soot meas.: -.Oil trace : ----

Page 28

Page 28

ecom-

J2KN

pro

TECH

-Compare the greyness with the opacity scale.

-Input the result using the numerical keys and press <OK>.

-Repeat this procedure until all 3 soot dot analyses are completed.

The mean value will be calculated and automatically stored.

The result of the oil trace check is to be documented as follows:

-Set the cursor on the line "Oil trace".

-Input the result with <OK>

("NO", "YES" or "- - - ")

-Press <ESC> to quit the menu once all necessitated inputs have

been entered. The measurement is now completed.

Get the probe cooled down before putting

it back in its fixation!

Soot..Oil trace

Mean value

:

1.0 Boiler temp.: 66°C

1st Soot meas.: 1.0

2nd Soot meas.: 0.5

3rd Soot meas.: 1.5

Oil trace : NO

Page 29

ecom-

J2KN

pro

TECH

Page 29

11.5. Measurement record and printout

Press <Print> (printer symbol) to enter

the printing menu. The sampled data

can be checked one more time („View

memory“, <OK> and scroll with the

cursor keys).

The software keyboard enables the

input or correction of the 6 x 20character text. Select hereto „Input

text“, press <OK> and input text (see

page 13).

Press „Memory -> M“ and <OK> to

store the all data -if correct- in the

internal memory or on the multi-media

card. Once the transfer is completed, a

"Memory symbol" appears on the

bottom right of the display. The entered

text will only be recorded in the data

record by use of the multi-media card.

Select „Start printout“ and press

<OK>) to start a printout.

Press <ESC> to turn back to the gas

analysis menu.

Once the gas analysis is completed, transfer the va

l-

ues recorded in the intermediate memory to the

Multi-Media-Card otherwise they could get

lost by switch-off of the instrument!

Memory symbol

Start printout

View memory

Memory -> M

Insert Text

--

ECOM

-

J2KN

--

Quit with:

Start printout

View memory

Memory -> M

Insert Text

--

ECOM

-

J2KN

--

Quit with:

Start printout

View memory

Memory -> M

Insert Text

--

ECOM

-

J2KN

--

Quit with:

Start printout

View memory

Memory -> M

Insert Text

--

ECOM

-

J2KN

--

Quit with:

Page 30

Page 30

ecom-

J2KN

pro

TECH

11.6. Mean value measurement

By mean value measurement function measurements can be taken

in an adjustable time frame and mean values can be calculated.

Should the several measurement values or the mean value result be

stored a storage place has to be selected as described in chapter 7.

If the function “Store” is activated, based on this storage place all

measurements will be written consecutively on the next storage

places. If the function “Store” is not activated, the mean value result

can be stored on MMC with <Print> / „Memory -> M.

After run through fresh air calibration

the menu point “Mean value” can be

chosen. Before the mean value

measurement can be started the

settings for “Meas.time”, “Scanning”,

“Printer” and “Storage” should be

checked and if necessary be changed.

The meanings are:

-Meas. time = Time frame in which the

mean values will be calculated

-Scanning = time between the

measurements taken for mean value

calculation

-Printer = logging of measurements

taken for mean value calculation

-Store = all measurements for mean

value calculations will be stored

“Measurement time” and “Scanning” can be adjusted as follows:

-select menu point and confirm with <OK>

-with the numeric keys set the desired time:

0.01 = 1 sec. = minimum value

59.59 = 59 min and 59 sec. = maximum value

-confirm with <OK>

Gas analysis

Mean value

Pressure

Soot..Oil trace

Data processing

Adjustments

Control

Diagnostics

Start measurement

Meas. time

Scanning

Printer

Store

Mean value

Quit with:

Page 31

ecom-

J2KN

pro

TECH

Page 31

The setting for “Printer” can be changed as follows:

-select menu point and confirm with <OK>

-select desired setting with the curser keys

-confirm with <OK>

The setting for “Store” can be changed as follows:

select menu point and confirm with <OK>

activate storage function with <F1>

deactivate storage function with <F4>

By ‘Start measurement’ / <OK> the

evaluation of the measurement values

will be started. On the display the actual

mean values will be shown (will be

updated with new measurement values

/ switch to the actual values with cursor

keys <up/down>). It is possible to scroll

through the values with the cursor keys

<right/left>. With <F2> you can

interrupt and with <F4> stop the

measurement.

After finishing the measurement time a protocol of the results with all

mean values can be printed (key <Print>).

O2 3.2 %

CO2 13.1 %

CO 0 ppm

Eff. 92.5 %

Losses 7.5 %

Exc. air 1.18

T.Gas 184.4 °C

T.Air 20.3 °C

Mean value 25.11.17

15:59 min

Page 32

Page 32

ecom-

J2KN

pro

TECH

11.7. After measurement

Fold radio antenna before

closing the case!

Get the heated sampling system cooled down

before putting it back in its case!

Radio antenna

Heated sampling

system

Please place transport protection

before transport!

Transport protection

Page 33

ecom-

J2KN

pro

TECH

Page 33

12. Adjustments

Additionally to the ecom-J2KN

pro

TECH

functions described previously, various

adjustments can be made in the

instrument.

From the main menu select the submenu "Adjustments" and confirm with

<OK>. A selection of modifiable

parameters, adjustable according to the

application, is displayed.

Place the cursor on the desired line and

press <OK> to call up or modify the

adjustment.

The modifiable parameters are:

Calibr. sensors:

-Select calibration menu ("Calibr. sensors" <OK>)

-Choose sensor with cursor keys and confirm with <OK>

-CO / NO / NO2 / SO2 etc. calibration

(Important: Span gas must get pressure-free to the instrument!)

-Flow with span gas

-Wait for stabilisation of value

-By drift press <OK>

-Set correct value with number keys

-Confirm input with <OK>

-T. Gas / T. Air calibration

-Create reference temperature

-By drift press <OK>

-Set correct value with number keys

-Confirm input with <OK>

-Pressure calibration

-Set draught sensor on 0 with <F4> key

-Create reference pressure

-By drift press <OK>

-Set correct value with number keys

-Confirm input with <OK>

Calibr. sensors

Re-Calibration

Unit

Second unit

Ref. O2

Fuel type

Set clock

Paper feed

Internal

Tightness test

Quit with:

Page 34

Page 34

ecom-

J2KN

pro

TECH

-Soot measurement calibration

-Connect suitable reference principle for volume determination

-Insert filter paper

-Confirm with <OK>

-Start soot measurement with <OK>

-After 1,63 l volume has been sucked, press again <OK>

(operation time of the pump will be memorised)

-Press <ESC> to return to the main menu

Unit (adjustment with cursor keys):

-Calculation of gas concentrations in:

-ppm = volume concentration (parts per million)

-mg/m

3

= mass concentration per volume unit

-mg/kWh (undiluted) = mass concentration per power unit

-mg/MJ (undiluted) = mass concentration per power unit

-ppm (undiluted) = volume concentration (parts per million)

-mg/m

3

(undiluted) = mass concentration per volume unit

Undiluted:

-Conversion of the gas concentration on selected reference oxygen:

-mg/kWh and mg/MJ are always calculated on 0% O2 basis

-Conversion formula:

E

ref

= E

meas

*

21 - O

2ref

21 - O

2meas

Page 35

ecom-

J2KN

pro

TECH

Page 35

Second unit (adjustment with cursor keys):

-two different unit for one gas concentration possible

Ref. O

2

(for ppm and mg/m

3

units - Input after <OK> pressing):

-Input of O

2

reference value O

2ref

Fuel type (press <OK> to access selection list):

-Modification of adjusted fuel type (e.g. by measurements at

combination plants)

Set clock (press <OK> to access setting menu):

-Correction of internal clock with cursor keys

Paper feed (press <OK> to activate paper feeding):

-Paper feed line by line

Tightness test (Start with <OK>):

-Leakage test of gas system of the

ecom-J2KN

pro

TECH

-Lock probe with a plug and start

test with <OK>

Internal (press <OK> to open menu):

-Further instrument settings:

Printout contrast (0..9)

(press <OK> to access input menu):

-Printer contrast adjustment

Recharging function

(<F1> for ON / <F4> for OFF):

-Recommended setting = OFF

Key beep (<F1> for ON / <F4> for OFF):

-Acoustical signal by key pressing

Print contraste

Reload function

Key beep

Graphic menu

Probe heating

Low power mode

Language: English

F1 Hotkey

F4 Hotkey

Eff.(C)

RF-connect. only

USB

Bluetooth

WLAN

Pitot factor

Printout

Quit with:

Page 36

Page 36

ecom-

J2KN

pro

TECH

Graphic menu (<F1> for ON / <F4> for OFF):

-Activation of graphic mode

Low power mode (<F1> for ON / <F4> for OFF):

-Switching on / off the probe heating and the gas cooler at battery

operation

Probe heating (<F1> for ON / <F4> for OFF):

-ON/OFF switch for probe heating for soot measurement

Language: English

-Info about language (3 languages selectable)

F1 Hotkey (Choose after pressing <OK>):

-Change the menu you get to after pressing <F1> in measured value

display

F4 Hotkey (Choose after pressing <OK>):

-Change the menu you get to after pressing <F4> in measured value

display

Eff.(C) (<F1> for ON / <F4> for OFF):

-ON/OFF switch for calculation of efficiency with and without

condensation

RF-connect. only (Choose after pressing <OK>):

-Standard: no radio connection if control module is located

in basic module

-RF-connect. only: radio connection also if control module is

located in basic module

-Remote: without function

USB (selection after pressing <OK>):

-Adjustment of transfer speed (Cursor keys <Up/Down>) and

Protocol (Cursor keys <Right/Left>) for the USB interface

(connection USB):

-Protocol DAS = Protocol for the program DASNT

-Protocol Enhanced = Protocol for the program DAS5

Page 37

ecom-

J2KN

pro

TECH

Page 37

Bluetooth (selection after pressing <OK>):

-Adjustment of protocol for the Bluetooth interface with the cursor

keys <Right/Left>:

-Protocol DAS = Protocol for the program DASNT

-Protocol DAS (DELAY) = Protocol for giant display with

adjustable (Cursor keys <Up/Down>) delay (0 = low / 9 = high /

adjust to a value that shows a stable indication at the giant

display)

-Protocol Enhanced = Protocol for the program DAS5

WLAN (selection after pressing <OK>)

Instrument as Access Point (for connection with mobile terminals):

-(Start/Stop WLAN: manual switching of WLAN connection

– available only with deactivated Auto Connect)

-Access Point: (<F1> for ON / <F4> for OFF)

-(W.O.) Auto Connect: Automatically connection

(<F1> for ON / <F4> for OFF)

-Security: use password for connection

(<F1> for ON / <F4> for OFF)

the password is „1234567890“

-Channel: Input channel (1 – 13)

(selection after pressing <OK>)

Connection with existing network:

-(Start/Stop WLAN: manual switching of WLAN connection

– available only with deactivated Auto Connect)

-Existing Network: available only with deactivated Access Point

-(W.O.) Auto Connect: Automatically connection

(<F1> for ON / <F4> for OFF)

-Network scan: Search for available networks

(selection with <OK>)

-WPA password: Input of password for selected network

With first use of the Bluetooth connection to PC type

in the shown password!

Page 38

Page 38

ecom-

J2KN

pro

TECH

Pitot factor (selection after pressing <OK>):

-Input of pitot factor for flow rate calculation (ecom flow probe =

0.93). If the flow rate calculation is not needed, set pitot factor to 0

Printout (selection after pressing <OK>):

- Text input for printout on measurement protocol (8 x 24 characters)

- Input the text of line 1 as follows:

1. Activate character selection list with <OK>.

2. Select keyboard type with <F3>

(4 different keyboards available).

3. Use the cursor keys to select the desired character

(selected character is outlined by black background).

4. Confirm selection while pressing < OK >.

5. Repeat procedure until desired text is complete.

6. Once input for line 1 is completed, deactivate the characters

selection mode with <F1> and move to the second line with the

cursor key <Down>.

7. Once all lines have been processed as desired, exit the menu

with <ESC>.

Page 39

ecom-

J2KN

pro

TECH

Page 39

13. Control

The sensors alter their output values along the operation period. The

programme controls the sensors and corrects drifts. If the drifts and

the correlated measurement errors increase, an error message is

displayed. In this case the corresponding sensor must be changed

by an authorised service centre. The control menu informs about the

current status values for the sensors as well as about (page 2 and 3

with cursor keys <up/down>):

ecom GmbH O2 10744 mV

Am Großen Teich 2

CO 7 mV

58640 Iserlohn Batt 4.50 V

--------------------- Bat.B 6.09 V

Tel.: 02371-945-5

Fax : 02371-40305

eMail : info@ecom.de

Operation hours : 8.45 hrs

Serial no. : J2KN 12345

Service tel. : 02371-945-5

Programm version : V3.0 / 12.07.16

Next unit check : 20.04.17

Control

Next service

centre

Serial number

Software

version

Radio quality

Sent frames

(radio)

Received

frames (radio)

Number of

frames (USB)

Accu voltage

control module

basic module

Operation

hours

Recommended

maintenance

date

Number of CO-

switch

-

offs

ppm hours of

CO sensor

Number of

errors

Number of

instrument

switch

-

ons

Date of last service

O2 10744 mV

CO 7 mV

Batt 4.50 V

Bat.B 6.09 V

Operation hours : 8.45 hrs

Serial no. : J2KN 12345

Service tel. : 02371-945-5

Programm version : V3.0 / 12.07.10

Next unit check : 20.04.17

Control

20

4.2 /s

4.2 /s

0.0 /s

1 X

22 ppm

4 X

11 X

O2 10744 mV

CO 7 mV

Batt 4.50 V

Control

Last service (history)

19.12.16 133 hrs

--.--.--

2.24

ltr /

min

Gas pump is running

Air valve is open

CO purging is running

Gas cooler ready for use

Heated hose ready for use

Sensors ready for use

Heated head ready for use

Gas flow

(liter per minute)

Radio mode

Calibration phase

Mains operation

(Battery operation

not possible)

Page 40

Page 40

ecom-

J2KN

pro

TECH

14. Data Processing

14.1. Communication

If a MM card is inserted in the slot, so it

will be used as record medium. The

menu „Data processing“ offers the

following functions:

Select:

For search or creation of plants files for measurement values

assignment (compare chapter “Input or selection of combustion

plants”).

View:

Recorded values to a selected plant can be viewed

(compare chapter “Input or selection of combustion plants”).

Memory (M):

Here all stored measurements (sorted

by record number) can be seen.

Individual measurement values can be

called as follows:

-Choose record number with the cursor

keys and confirm with <OK>

-Scroll with the cursor keys

-Leave record number with <ESC>

DRT <-> PC !:

Load data:

Enables the data import with USB cable

from e.g. ecom software “miniDV”

(available on our website

„www.ecom.de“). See chapter

„Technical Data“ for data format

information (please observe the transfer

options of your software!).

Select

View

Memory (M)

DRT <-> PC !

Format

Automatic measu.

Quit with:

DRT <

-

> PC !

Send dada

Load data

Quit with:

Date Time Fuel type

1 01.09.17 11:01:24 Fuel oil

2 01.09.17 11:02:34 Fuel oil

3 01.09.17 11:04:20 Fuel oil

4 01.09.17 11:07:44 Fuel oil

5 01.09.17 11:11:25 Fuel oil

6 01.09.17 11:23:02 Fuel oil

7 01.09.17 11:44:09 Fuel oil

8 01.09.17 11:53:13 Fuel oil

9 01.09.17 11:59:59 Fuel oil

10 01.09.17 11:59:59 Fuel oil

Select:

Page 41

ecom-

J2KN

pro

TECH

Page 41

Proceed as follows:

-Connect ecom-J2KN

pro

TECH and PC via USB cable.

-Select “Load data“ and confirm with <OK>.

-Answer the displayed question with YES (<F1>).

-Decide if the data recorded can be cancelled

(<F1> for YES / <F4> for NO).

-Start the data transfer on your PC.

Send data:

With this function the data records completed with measurement

values can be transferred to the PC programme (procedure similar to

chapter „Load data“).

Format:

This function is usually needed by the initial adjustment of the

instrument at our factory (preparation of internal memory for data

record).

Caution: All stored values will be cancelled!

14.2. Automatic measurement

The configuration of the ecom-J2KN

pro

TECH with operation

securing, self-regulating additional components like the condense

trap, the gas cooler and the magnetic valve technique permits even a

long term operation of the instrument. By setting time intervals for the

measurement the instrument switches autonomously to fresh air

purge after the measurement phase (gas will be sucked via the

connection fresh air) and operates a calibration phase for the

sensors.

This cycle repeats itself until the

automatic measurement will be finished.

For setting the time intervals select from

the menu “Data processing” the menu

item “Automatic measu.”. The time

intervals have following meanings:

Automatic measu.

Automatic

Data logger

Automatic time

120 min

Measurem.

time 115 min

Save to MMC 1 sek

CSV+Header

Quit

with:

Page 42

Page 42

ecom-

J2KN

pro

TECH

Automatic time (min. 10 minutes / max. 120 minutes)

Time interval from one calibration phase to the next one.

Measurement time (max. Automatic time minus 5 minutes)

Time interval within the automatic time in which the instrument

gather measurement values, i.e. in which the measurement gas will

be sucked. The difference between the measurement time and the

automatic time is used for purging the sensors with fresh air.

Save to MMC (min. 1 second / max. 255 seconds)

Adjustment of the interval time for data logger recordings.

CSV+Header (<F1> for ON / <F4> for OFF)

Adjustment of data logging with or without column headings.

Start the automatic measurement by setting the cursor to line

“Automatic” and pressing the key <OK> (on top right on the display

appears “A” for automatic).

14.3. Data logger

Here a Data logger record (“Data logger” and key <OK> / on top

right on the display appears the disk symbol) can be started or

finished (just available when using the multi-media card). With

<Memory> you can interrupt and continue the record (only in gas

analysis). For each recording one file will be written on the card. The

files will be numbered consecutively (J2KDL-00.csv, J2KDL-01.csv

and so on) and can be transferred to PC with a card reader. The

length of a dataset is 500 byte which means that on a 32 MB card

64000 measurements could be recorded.

Page 43

ecom-

J2KN

pro

TECH

Page 43

14.4. Data logging with DASNT2

In addition to data logger recordings the data could also be

transferred online via USB, Bluetooth (option) or via data interface to

the software "DASNT2". For the USB connection, a driver is

required. Software and USB driver are available free of charge from

the ecom website. The following transfer parameters must be set at

ecom-J2KNpro TECH ("Adjustments" /" Internal "/" USB "):

- 1200 Baud

- Protocol DAS

Please note the hints in the software manual.

14.5. Data processing with DAS5

To display and storage of measured values and measured value

gradients the software "DAS5" is available. With the help of a multimedia card customer and measurement data can be exchanged

between software and instrument. An online connection to store

measured values and measured value gradients is possible with

USB or WLAN. For the USB connection, a driver is required.

Software and USB driver are available free of charge from the ecom

website. The following transfer parameters must be set at ecomJ2KNpro TECH ("Adjustments" / "Internal " / "WLAN"):

- 1200-38400 Baud (setting as in the software "DAS5")

- Protocol Enhanced

For the wireless connection (WLAN), the following transfer

parameters have to be set at ecom-J2KNpro TECH ("Adjustments"

/ "Internal " / "WLAN"):

- Access Point = ON

- Auto Connect = ON

Please note the hints in the software manual.

Page 44

Page 44

ecom-

J2KN

pro

TECH

14.6. Data processing with App

To display and storage of measured values, the App “ecom

connect WiFi” for smartphones (iOS or Android) is available. Test

results are stored along with customer information in a pdf-file and

can be sent f.e. as email attachment. Links to free download of the

Apps can be found on the ecom website. For the wireless connection

(WLAN), the following transfer parameters must be set at ecomJ2KNpro TECH ("Adjustments" / "Internal" / "WLAN"):

- Access Point = ON

- Auto Connect = ON

Page 45

ecom-

J2KN

pro

TECH

Page 45

15. Diagnostics

15.1. Fault diagnostic

The ecom-J2KN

pro

TECH is able to

receive and to process information sent

via cable by the ecom-AK (read-out

head for digital firing automats).

In the main menu select the sub-menu

"Fault diagnosis" and confirm with

<OK>. The ecom-J2KN

pro

TECH tries to

get into contact with the ecom-AK

(message: „Searching“) Once the

connection is realized, the current

operation stand of the burner is shown

graphically on the display. The

operation stand can be recorded (max.

100 sec).

Press <OK> to start a new recording

phase (reset).

1/0

RM

OV

RZ

BV1

BV2

FL

Err

ON

Off

228

D K O 9 7 2 / 2 2

2.3 1.2

Ignition is

active

Flame

identified

Current

flame signal

Min. flame

signal

Model

name

Engine

on

Oil pre-warmer /

Air pressure

monitor is on

Operation

voltage

Valve 1

is on

Valve 2

is on

Recording of operation

stand (max. 100 sec):

1/0 = Continuous phase

RM = Fan motor

OV = Oil preheater

RZ = Ignition

BV1 = Valve 1st stage

BV2 = Valve 2nd stage

FL = Flame identified

Err = Disturbance

Reset = Start a new

recording (press <OK>)

ecom-AK

ecom-J2KN

pro

TECH

Cabel

connection

to AUX

Page 46

Page 46

ecom-

J2KN

pro

TECH

Use the <Up/Down> keys to call up further data of the firing

automat. The 2

nd

display page lists information about the disturbance

history (type and volume of information depending on firing automat).

The 3

rd

display page lists information about the monitoring times

(type and volume of information depending.

Number of burner

starts at a total resp.

since reset of firing

automat

Last 2 errors (Satronic)

Last 5 errors (Siemens)

Current error

Error statistics

(errors number)

Monitoring times of

firing automat

Error history

Number of startups total 677

Service counter actual 142

No error

No flame at the end 004 9:23 min

Of safty time 0.0 µA 227 V

Flame signal during 001 12 sec

Straylight check 2.2 µA 225 V

Total : 46

Straylight : 22

Safty time : 9

Loss of flame : 17

FT/LW : 0

Safty time 4.9 sec

Delay time valve 2 40.0 sec

Pre-ignition time 17.0 sec

Post-ignition time 20.0 sec

Delay straylight sup. 11.5 sec

Straylight supervision 5.0 sec

Rest time TSA 4.1 sec

Further pages:

Timing values

Page 47

ecom-

J2KN

pro

TECH

Page 47

15.2. dT measurement

With the ecom-J2KN

pro

TECH a difference temperature measurement

is possible. For measurements at pipes (e.g. in and out of heating

systems) special temperature sensors are needed, that can be

ordered from your responsible ecom distributor. Select from the main

menu point "Diagnostics" the submenu "dT measurement" and

confirm with <OK>.

The instrument indicates the

temperature T1 (sensor at connection

„gas temperature“), the temperature T2

(sensor at connection „air temperature“)

and the difference of both temperatures

(T1 - T2). With the key <Memory> the

result of the measurement are stored in

intermediate memory. A printout can be

started with <Print>.

T1 70.4 °C

T2 56.3 °C

DT 14.1 °C

DT-measurement 25.11.17

recorded!

dT measurement

Measurement stored in

intermediate memory

Page 48

Page 48

ecom-

J2KN

pro

TECH

16. Maintenance tips

To secure the accuracy of your measuring instrument we

recommend the annual check by an authorized ecom partner. All

ecom partners are listed under www.ecom.de.The following advices

will be of help for the daily check and maintenance of single parts or

assemblies:

Pre filter heated head

Loosen the bayonet lock (press and turn it 90 °) and check the state

of the pre filter. It should be changed when the filter has a grey color

(number 2-3 of the soot comparison scale).

Fine dust filter

Screw off the cover of the gas cooler 1 and check the state of the

fine dust filter. Change it once the filter has a grey colour (number 23 of the soot comparison scale).

Do not use other sensors or feelers from other

manufacturers otherwise the TÜV approval

will not be valid anymore!

Service made by service centres not authorised by

ecom GmbH will result in a complete

and immediate loss of any warranty!

Fine dust filter

Pre filter (PTFE / 2 µm) Bayonet lock

Page 49

ecom-

J2KN

pro

TECH

Page 49

Safety filter

Check the state of the safety filter. Change it once the filter has a

grey colour (number 2-3 of the soot comparison scale).

PTFE filter 1

Check the state of the PTFE filter. Change it once the filter has a

grey colour (number 2-3 of the soot comparison scale).

PTFE filter 2

Screw off the cover and check the state of the PTFE filter. Change it

once the filter has a grey colour (number 2-3 of the soot comparison

scale).

Safety filter

PTFE filter 2 (2 µm)

PTFE filter 1 (20 µm)

Page 50

Page 50

ecom-

J2KN

pro

TECH

Ventilation filter 1

The ventilation filter should be changed, if the filter is grey coloured

(number 2-3 of the soot comparison scale). Remove for this the filter

holder with the help of a screw driver (recesses on the right of and

left side). Change the filter cartridge and fasten the filter holder.

Ventilation filter 2

The ventilation filter should be changed, if the filter is grey colored

(number 2-3 of the soot comparison scale). Remove for this the filter

holder (pull it off). Change the filter cartridge and fasten the filter

holder.

No ventilation filter

Ventilation filter

Filter cartridge

Recesses

Filter holder

Ventilation filter

Page 51

ecom-

J2KN

pro

TECH

Page 51

Sensors

The sensors get calibrated with the reference gas fresh air by each

switch-on procedure. The state of the sensors is permanently

controlled by the instrument. If an error message is displayed during

calibration and cannot be eliminated despite several calibration

phases, so the instrument must be checked by a qualified and

authorised service centre.

SO

2

/NOx filter (only with electrochemical CO sensor)

In the tubing leading to the electrochemical CO sensor on the top of

the instrument there is a chemical filter for filtering SO

2

and NOx out

of the flue gas. The filter material is manganese-4-oxide granules

and should be changed once it has turned grey (colour change:

pink> brown> black> grey> white).

Probe and hose (only probe type SB)

Depending on the frequency of use, probe and hose should be

regularly cleaned in order to release particle deposits and to prevent

early wearing due to corrosion:

-Release the connections at the instrument and at the probe

grip to free the hose.

-Clean the hose (flow warm water in then dry respectively blow

water drops out).

Change printer paper roll

-Release the printer cover.

-If necessary, extract the paper rest out of the printer

("Adjustments" / "Paper feed" / <OK>).

-Remove the printer shaft and place the new paper roll on the

printer shaft.

-Insert the paper end in the slot (future printed side must be ahead).

-Press ("Adjustments" / "Paper feed" / <OK>) to transport ± 10 cm

paper thru the printer.

-Place the printer shaft back in the fixation.

-Insert the paper thru the cover of the printer compartment.

-Close the printer compartment while fixing the cover.

SO2/NOx filter

Page 52

Page 52

ecom-

J2KN

pro

TECH

17. Technical data

Parameter Range Principle

O

2

0 ... 21 vol.% Electrochemistry

CO (option) 0 ... 1000 ppm Infrared

CO (option) 0 ... 2500 ppm Electrochemistry

CO% (option) 2500 ... 63000 ppm Electrochemistry

NO (option) 0 ... 1000 ppm Chemiluminescence

NO (option) 0 ... 5000 ppm Electrochemistry

NO

2

(option) 0 ... 1000 ppm Photoacoustic

NO

2

(option) 0 ... 1000 ppm Electrochemistry

NO

2

/SO2 (option) 0 ... 100 (2000) ppm Ultraviolet

SO

2

(option) 0 ... 1000 ppm Infrared

SO2 (option) 0 ... 5000 ppm Electrochemistry

H

2

S (option) 0 ... 1000 ppm Electrochemistry

H

2

(option) 0 ... 2000 ppm Electrochemistry

C

xHy

(option) 0 ... 4 vol. % (CH4) Catalytic

C

xHy

(option) 0 ... 2000 ppm (C3H8) Infrared

C

xHy

(option) 0 ... 30000 ppm (CH4) Infrared

CO% (option) 0 ... 63000 ppm Infrared

CO

2

(option) 0 ... 20 vol. % Infrared

CO

2

0 ... CO

2max

Calculation

Air pressure 300 ... 1100 hPa DMS bridge

T-Gas 0 ... 500 °C NiCr/Ni

T-Air 0 ... 99 °C Semi-conductor

Differential pressure 0 ... +/- 100 hPa DMS bridge

Efficiency 0 ... 120 % Calculation

Losses 0 ... 99,9 % Calculation

Excess air 1 ... ∞ Calculation

Ref. O

2

adjustable 0 ... 21 vol.% Calculation

Taupunkt der Abgase Calculation

Power supply Mains power 230 V / 50 Hz~

Battery 7,2 V / 11,6 Ah

Dim. (L x H x D) 525 mm x 845 mm x 270 mm

Weight approx. 34 kg with heated sampling system

Application limits +5 °C to +40 °C;

max. 90 % RH, non-condensing

Subject to technical changes

V3.83 / 06.2018

Page 53

ecom-

J2KN

pro

TECH

Page 53

18. FAQ

Where do I find important instrument information?

The instrument shows the error

message „O2 sensor 0 mV“!

The instrument shows the message „Check required“!

The instrument shows the error

message „T-Gas“ or „T-Air“!

The instrument shows wrong or

inaccurately CO

2

values!

My instrument cannot be

switched on!

My instrument does not print!

Can I change the printout?

In the menu „Control“ all important instrument

information are shown (e.g. battery voltage,

sensor values, unit number, next service date,

operation hours etc.). With the arrow keys

stands you can switch to the second page.

The sensor must be renewed.

This message appears automatically every 12

months. Note: This is a recommendation to let

check the instrument. The instrument is however still ready for use.

Possible reasons could be:

- Cable is broken (at the plug)

- T-Air sensor is broken

- Thermocouple is broken

- Cable is defective

Note: The error messages can be ignored at

the J2KN

pro

TECH by pressing „OK“. Calculations that depend on these temperatures are

not implemented.

Possible reasons could be:

- O

2

is defective (CO2 values are calculated

from the O

2

values)

- Pump is not working correctly

- Leakage in the gas way

- Condensate trap / gas cooler is clogged

- Please check the mains cable

- Please check the fuse

- Please check mains connection (Plug socket

switched on?)

- Please load the accumulator min. 8 hours

(Accumulator could be over-discharged)

Please check whether the printer paper is

correctly inserted. The thermal printer writes

only on the thermally sensitive side. Please

use always the correct paper for the printer,

you will prevent defects at the printer. Please

make sure that the printer is clean (no chads

in the drive).

You can change the printout (Menu: Adjustments).

Page 54

Page 54

ecom-

J2KN

pro

TECH

Hint: If you have several instruments of the same type, you can locate an error by

exchanging the accessories (probe, hose, temperature sensor etc.).

If further questions or problems should arise, please contact the next authorised service centre.

Page 55

ecom-

J2KN

pro

TECH

Page 55

Description of dat

a record

ecom

-

J2KN

pro

TECH

with Multi Media Card

Format data logger records: J2KDL-xx.csv (separation mark between values = comma)

Format punctual measurements: J2KDV.txt (separation mark between values = comma)

Column

Description

Remark /

Example

A Date DD.MM.YYYY (also US-Version)

B Time HH:MM:SS (also US-Version)

C O

2

in vol.% 0,0 - 21,0

D CO in ppm 0 - 4000

E NO in ppm 0 - 5000

F NO

2

in ppm 0 - 1000

G SO

2

in ppm 0 - 5000

H CO converted*

I NO converted*

J NO

2

converted*

K NO

x

converted*

L SO

2

converted*

M T.Gas in °C or °F 0 - 500 (US-Version with other range in °F)

N T.Air in °C or °F 0 - 99 (US-Version with other range in °F)

O Draught in hPa 0,00 - 20,00

P CO

2

in vol.% 0,0 - 25,0

Q Efficiency in % 0,0 - 120,0

R Losses in % 0,0 - 100,0

S Excess air > 1,00

T Dew point in °C or °F 0 - 500 (US-Version with other range in °F)

U Poisoning index > 0,0

V O

2

(gas channel check) in vol.% 0,0 - 21,0

W CO (gas channel check) in ppm Related to 0,0 vol.% O

2

X CO (gas channel check) in ppm Measured value

Y O

2

(O2 check) in vol.% 0,0 - 21,0

Z T.Boiler 0 - 999

AA T.Sensor 0 - 99

AB O

2

reference 0,0 - 21,0

AC Unit 0=ppm; 1=mg/m

3

; 2=mg/kWh; 3=mg/MJ

AD Norm N = converted to O

2

ref.

AE Fuel type number Index acc. to instrument table

AF Fuel type text Text acc. to instrument table

AG Soot 1 0,0 - 9,9

AH Soot 1 0,0 - 9,9

AI Soot 1 0,0 - 9,9

AJ Oil trace 0=no; 1=yes;

AK 20 characters text

AL 20 characters text

AM 16 characters text

AN Serial number

AO CO (O

2

check) in ppm

AP Zug (O

2

check) in hPa

AQ CxHy

AR Number copy data

AS T1 (deltaT-measurement)

AT T2 (deltaT-measurement)

AU Velocity m/s

AV CO Environment CH-version = Kind of control

AW free CH-version = Load range

AX Comment text

AY Comment text

AZ Comment text

BA Comment text

BB H

2

in ppm CH version = Oil consumption

BC H

2

converted* CH version = Thermal output

BD Sensor 6 in ppm CH version = Operation hours counter

BE Sensor 6 converted * CH version = Code

BF dP (velocity) in Pa 0 – 1000,00

Page 56

Page 56

ecom-

J2KN

pro

TECH

BG Air pressure in hPa 300 – 1100

BH Unit 2 0=ppm; 1=mg/m

3

; 2=mg/kWh; 3=mg/MJ; 4=ppmN; 5=mg/m3; 6=--BI CO (Unit 2)

BJ NO (Unit 2)

BK NO

2

(Unit 2)

BL NO

x

(Unit 2)

BM SO

2

(Unit 2)

BN Analogue input 1

BO Analogue input 2

BP Sensor 7 in ppm

BQ Meas. gas volume in l/min

BR CO%

BS last column 0

* converted to unit (column AC) and converted on O

2

ref. (Column AB) when column AD = N

Page 57

ecom-

J2KN

pro

TECH

Page 57

Data transfer

ecom

-

J2KN

pro

TECH

to PC (USB)

The transfer occurs with 1200 - 38400 BAUD; 1 stop bit; no parity (ANSI character set)

CR / LF is send after each data record

Column

Description

Length

1-5 Storage number 5

6-7 Hour 2

8-9 Minute 2

10-11 Day 2

12-13 Month 2

14 Fuel type number (0 – 9) 1

15-19 T.Air in °C or °F 5

20-24 T.Gas in °C or °F 5

25-29 O

2

in vol.% (without comma) 5

30-34 CO in ppm 5

35 Draught (sign / - = minus; blank character = plus) 1

36-39 Draught in Pa 4

40 Oil trace (0 = no; 1 = yes 1

41 Soot 3 1

42 Soot 2 1

43 Soot 1 1

44-48 free 5

49-53 NO in ppm 5

54-58 T.Boiler 5

59-78 20 character text (1st display line) 20

79-98 20 character text (2nd display line) 20

99-114 16 character text (3rd display line) 16

115-116 2 signs (HEX $80, $00) 2

117-121 O

2

(CO measurement) in vol.% (without comma) 5

122-126 CO (CO measurement) in ppm related to 0,0 vol.% O

2

5

127-131 free 5

132-136 free 5

137-141 free 5

142-146 free 5

147-151 free 5

152-156 O

2

(O2 check) in vol.% (without comma) 5

157-161 CO (O

2

check) in ppm 5

162 Draught (O

2

check / sign / - = minus; blank character = plus) 1

163-166 Draught (O

2

check) in Pa 4

167-168 CR-LF (#13#10) 2

Data transfer PC to

ecom

-

J2KN

pro

TECH

(ANSI character set):

First send: $00 $01

Then send: 56 characters text

Then send: $80 $00

Once the

ecom

-

J2KN

pro

TECH

has processed the data, it sends $FF back. If the data volume is too large,

it sends another byte back. If the data transfer should be terminated, so just 60 byte $00 need to

be sent to the instrument.

Page 58

Page 58

ecom-

J2KN

pro

TECH

ecom GmbH

Am Großen Teich 2

D-58640 Iserlohn

Telefon: +49 (0) 23 71 - 9 45-5

Telefax: +49 (0) 23 71 - 4 03 05

Internet: http://www.ecom.de

eMail:

info@ecom.de

Loading...

Loading...