Page 1

ECOM America Ltd, 1628 Oakbrook Drive, Gainesville, GA 30507

Toll free (877) 326-6411 Phone (770) 532-3280 Fax (770) 532-3620

w w w . ec o musa.com

Operations Manual

version 3.6.2

Page 2

Page 2

Page 3

Page 3

Table of Contents Page(s)

J2KN PRO DESIGN AND HOW IT WORKS

1. Important Things to Remember …………………………………………4

2. Instrument Design

2.1. J2KN Pro Base Unit………………………………………………5

2.2. Remote Display Unit …………………………………………….6

2.3. Accessories…………………………………………………………7

2.4. Consumables……………………………………………………….8

3. Peltier Cooler ..…………………………………………………………………9

4. Gas Path Diagram…………………………………………………………….10

5. Power Supply…………………………………………………………………..11

6. Radio Communication……………………………………………………….12

EMISSIONS ANALYSIS AND RECORDING

7. J2KN Pro Start-up…………………………………………………………….13

8. Emissions Measurement

8.1 Gas Analysis ...……………………………………..………………14-15

8.2 Printing……………………………………………………………….16

8.3 Soot Test..……………………………………………………………17

9. Capturing Data on Memory Card…………………………………………18

10. Averaging Tests ……………………………………………………………….19

11. Software Communication.........................................................20

12. Frequently Asked Questions ....................................................21-22

13. Draft/Pressure………………………………………………………………...23

MAINTENANCE AND ANALYZER SETTINGS

14. Adjustments…………………………………………………………………….23-24

14.1 Internal..…………………………………………………………..25-26

15. Control..……………………….…………………………………………….27

16. Maintenance Tips

16.1 Filters......................................................................28-29

16.2 Sample Line and Probe............................................29

16.3 Sensors ..................................................................29-30

16.4 Printer Paper...........................................................30

16.5 Changing the Fuse...................................................30

SERVICE & CALIBRATION

17. How to Change Sensors

17.1 O2 Sensor................................................................31

17.2 A5F CO Sensor.........................................................32-33

17.3 MEM CO Sensor........................................................34

17.4 NO, NO2, SO2, & High CO Sensors ...........................35-37

18. How to Calibrate Sensors.........................................................38-39

TECHNICAL INFORMATION

19. Flow Velocity Measurement (Option).......................................40

20. Technical Data.........................................................................41

21. Description of Data on Memory Card........................................42

22. Calculations.............................................................................43

Page 4

Page 4

1. Important Things to Remember

The J2KN Pro meets the requirements of EPA

CTM-030 and CTM-034 and ASTM D-6522 test-

ing protocols for portable emission analyzers.

In order to receive accurate measurements,

please allow reading to stabilize

for at least 2 minutes.

The J2KN Pro is not suitable for continuous

emission testing. Please allow at least 10

minutes of fresh air purge for each hour of

testing.

The following substances may cause damage

to the electrochemical sensors:

Cleaning agents

Degreasers

Wax polishes

Adhesives

Formaldehyde

1. Charge the battery after each use

2. Always store unit with fully charged battery

3. Charge the battery at least once a month if

not in frequent use

Page 5

Page 5

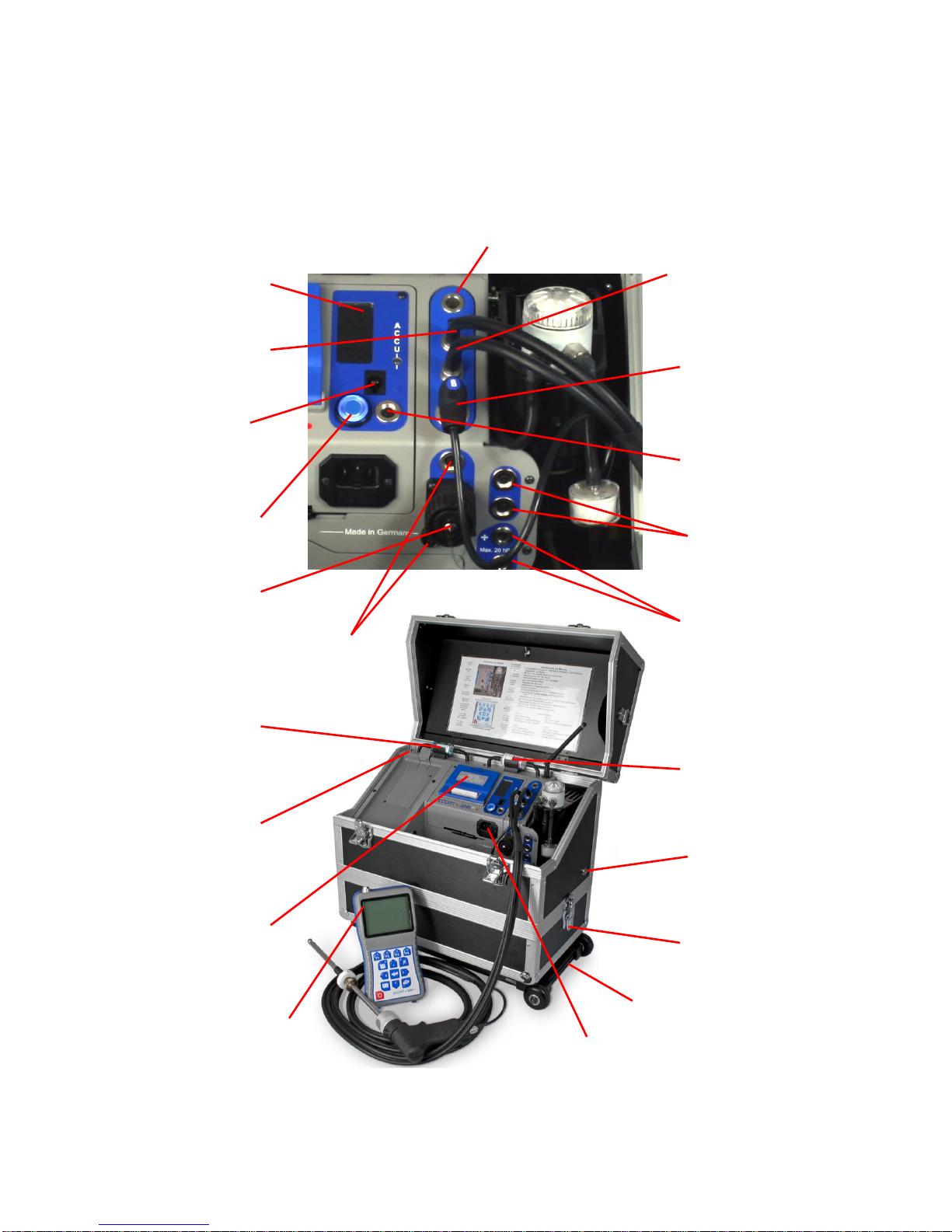

2. Instrument Design

2.1 J2KN Pro Base Unit

Ambient air

temperature

sensor

Thermocouple

connection

Main gas

connection

Draft/Pressure

connection

Draft/Pressure

connection

Water trap

drain hose

connection

On-board

printer

Filter for

IR bench

(if applicable)

Remote Display

Unit

(see next page)

Power cord

socket

Info display

(see 15. Control)

ON / OFF

button

Analogue

inputs

(optional)

Auxiliary

temperature

connections

Nox/SOx

filter for

CO sensor

Pitot tube

connections

(see 19. Flow

Measurement)

Data cable

connection

(used by ECOM

personnel only)

Under case

(optional)

Trolley w/ wheels

(optional)

Heated line power

supply connection

(optional)

Fresh Air

Bypass Switch

(Pro IN only)

Page 6

Page 6

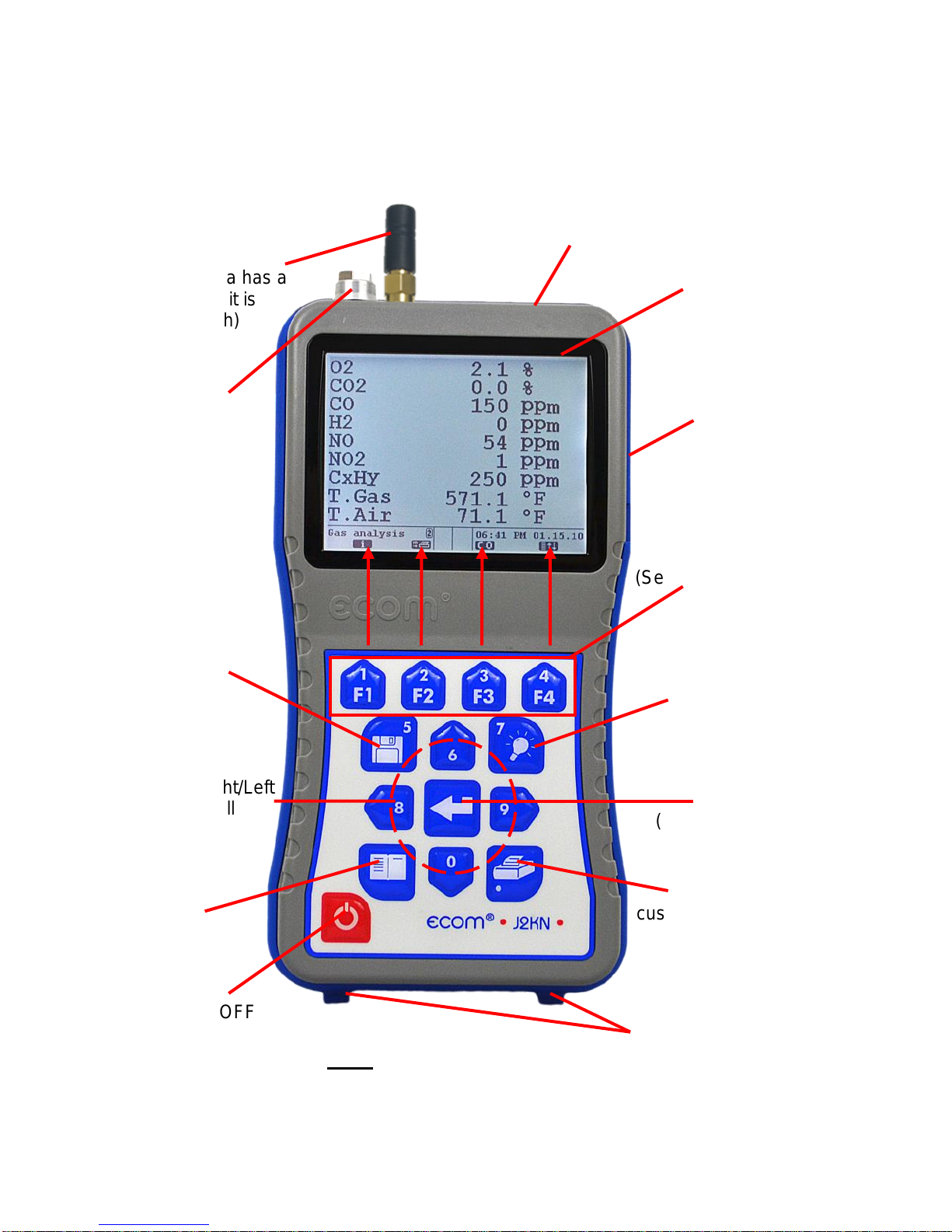

2. Instrument Design (continued)

2.2 J2KN Pro Remote Display Unit

Escape

Note: All keypad buttons

are used for input of num-

bers 0-9 and decimal point

OK

(press to confirm)

Up/Down/Right/Left

and Scroll

Capture data

Press to add

custom text to printout

(Press F2 to

print normally)

ON/OFF

Display

Backlight

ON/OFF

Function Keys

(See 8.1 Gas Analysis)

Memory card slot

LCD display

screen

USB

connection

Data cable sockets

(used by ECOM per-

sonnel only)

WiFi antenna

(If your antenna has a

pink band, it is

Bluetooth)

Air temperature

connection

(not an antenna)

Page 7

Page 7

2.3 Accessories

e-Comply Testing Software

Part no. 9038001H

(Records mass emissions in

g/bhp-hr, lbs/hr, & tons/year)

Calibration Gas Kits

Part no. available upon request

Probe Shield

Part no. 3025006G

(Recommended for high temp

applications to protect grip)

15ft/30ft Heated Sample Line

Part no. 7952501H

(Custom lengths available

from 0 to 100ft)

Tail Pipe Probe Assembly

Part no. 7126631H

(Recommended for tail pipes

when inserting 180 into stream)

Flex-Tip Probe Assembly

Part no. 7129601H

(Recommended for hard-toaccess sampling ports)

Page 8

Page 8

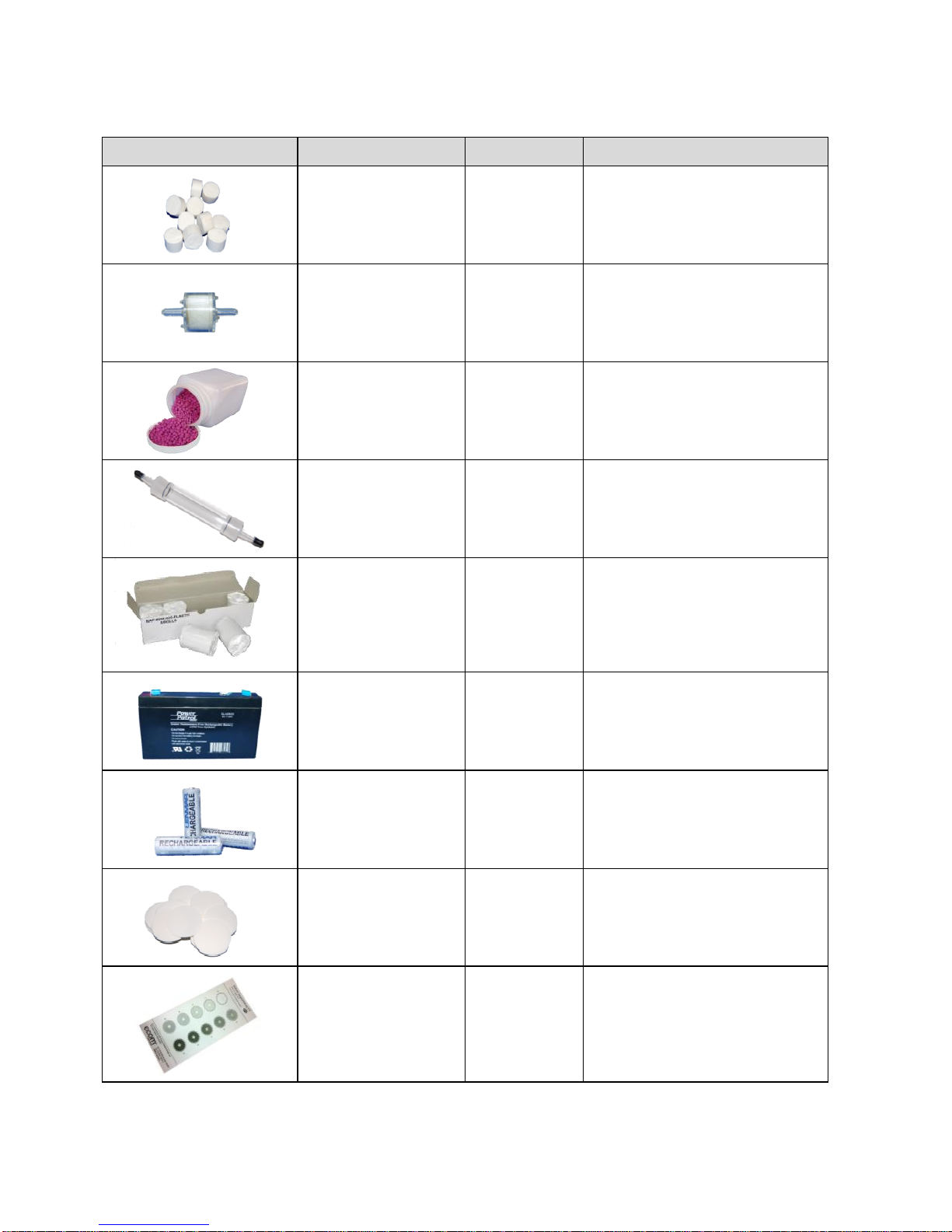

2.4 Consumables

PART

PART #

DESCRIPTION

Particulate

Filter (10/PK)

3015840G

10/PK - Particulate

filter located on top of

water trap assembly

In-line Smoke

Filter (1 EACH)

7118501H

1 EACH - Standard 3/4"

in-line filter in clear

plastic casing.

NOx/SOx Filter

Media (1LB)

3014457G

1LB - NOx/SOx filter

media refill container

(purple beads)

NOx/SOx

Media Tube

7128601H

NOx/SOx Media Tube

Thermal Onboard Printer

Paper (5/PK)

7927401H

5/PK - Printer paper for

on-board thermal

printer

J2KN-Pro Main

Battery

7929101H

Main Battery

J2KN-Pro

Remote Display

Batteries (3/PK)

7929201H

3/PK - Battery Pack for

Remote Display

Soot Test Paper

(200/PK)

3003168G

200/PK - Round smoke

test filters for smoke

dot test

Soot Test Chart

3002970G

Soot Test Chart with 09 Grayness Scale

*Please consult the J2KN Pro Parts List PDF for a list of all parts.

Page 9

Page 9

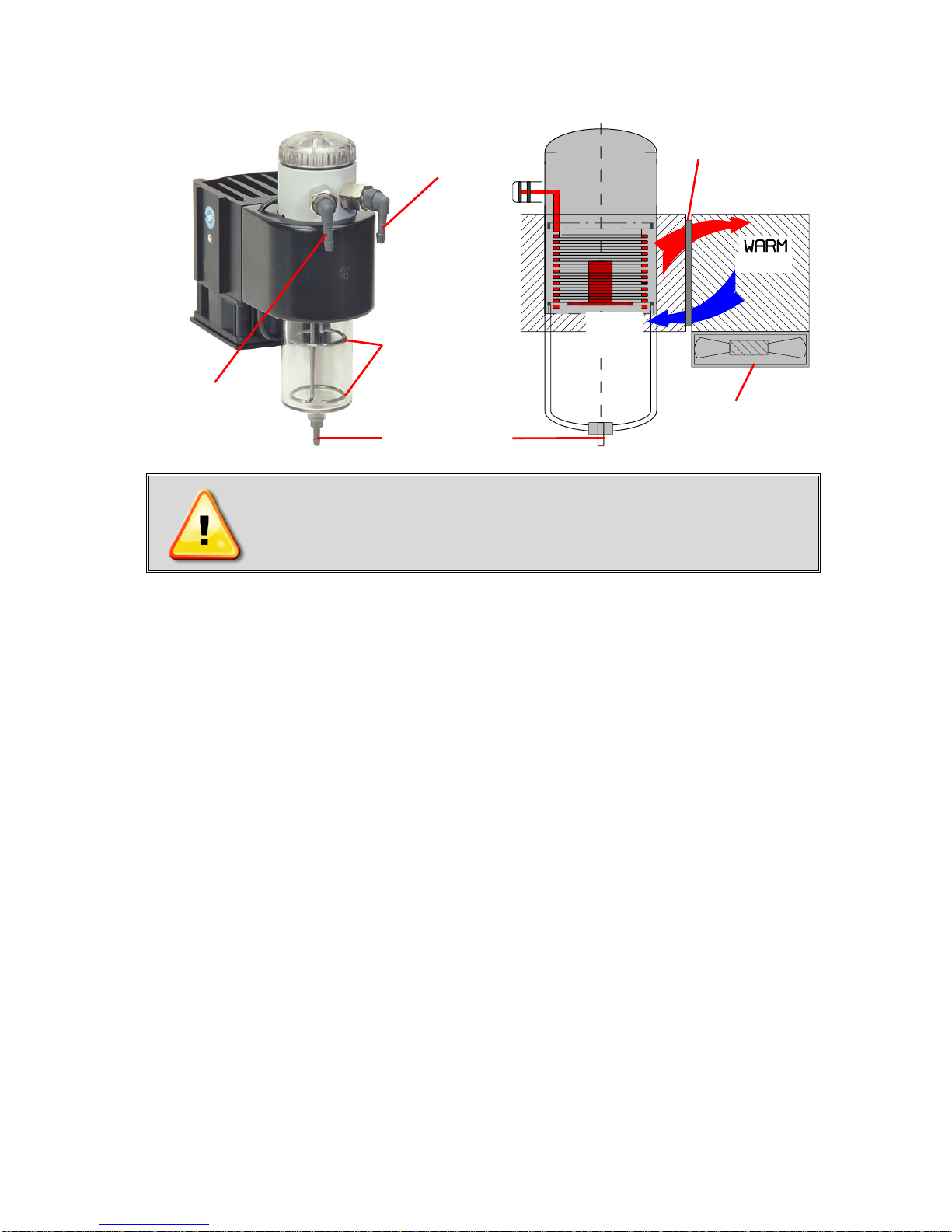

3. Peltier Cooler

J2KN Pro must be plugged in for the

Peltier cooler to operate.

Exhaust gas with a temperature above dew point is introduced into a spiralling gas path with a coated metal surface

of good thermal conductivity. The hot gas radiates its heat to

this metal coating, which is thermally connected to a Peltier

element and a second metal body with cooling ribs and ventilation slots. The flow thru the Peltier element creates a heat

transfer from WARM to COLD and this takes the heat from

the metal coating and transfers it to the outer cooling body.

The heat is then released to the surrounding air via a ventilation fan.

Condensation forms when the gas temperature drops below dew point. This moisture drains into the water trap bowl

and is pumped out by a peristaltic pump when the water

reaches a high enough level to link both monitoring electrodes.

The high speed pump allows for enough flow to avoid excess exposure time between the gas sample and water, so

that drop-out reactions (for example, NO2+H2O > H2NO3) do

not occur, which is necessary for measurement accuracy.

Fan

Peltier

Element

Gas

Outlet

Gas

Inlet

Water Level

Monitoring

Electrodes

Water drain

COLD

Page 10

Page 10

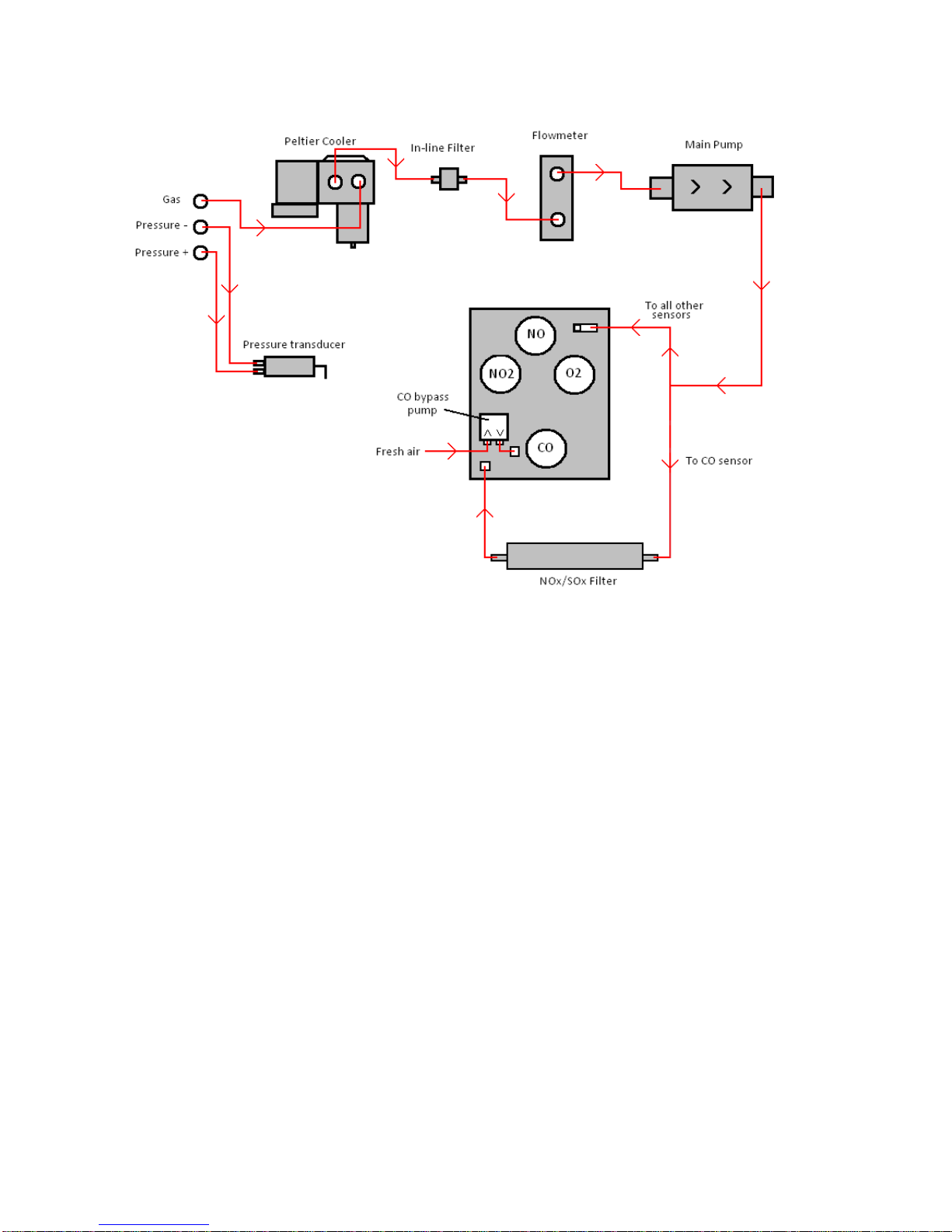

4. Gas Path Diagram

Response Time

After inserting the probe into the sample gas, there is a

short delay before the values start changing since the gas

has to pass through the sampling system. This is referred to

as response time, and it usually takes about 4-6 seconds for

the readings to start to change. Since the CO sensor has an

elongated gas path with the NOx/SOx filter (see diagram),

the response time for the CO is approximately 10 seconds.

Stabilization Time

Different from the response time is the stabilization time.

This is the time it takes for the sensors to build up a stable

electrochemical reaction in the electrolyte solution, and it

usually takes about 60-90 seconds for the readings to stabilize. NO2 readings may take slightly longer. For this reason,

wait 2-3 minutes for the readings to stabilize before printing

or recording emission results. Minor drifting of a few ppm can

be caused by minor pressure changes and may be negligible.

*All times listed here are based on using a 15ft sample line*

Page 11

Page 11

5. Power Supply

The J2KN Pro base unit has an internal power supply, and

it is recommended to always run the unit on AC power. For

testing locations where an AC plug-in is not available, the

instrument can be operated from 6-8 hours on battery power

when fully charged. Connecting the J2KN-Pro to AC power

charges the battery and is necessary to operate the Peltier

cooler and heated probe.

When the battery level gets low, the analyzer will start to

beep and display a low battery warning. The voltage reading

on the battery is displayed in the Control screen. The warning is activated when the charge drops below 6 V. When it

reaches 5.8V, the battery charge is not sufficient to power

the unit.

Only use batteries supplied by ECOM.

Contact ECOM with any questions.

The J2KN remote control unit is powered by 3 nickelmetal-hydride batteries (type AA). These batteries are recharged by docking the remote control unit onto the J2KN

base unit. To change the settings for recharging these batteries, go to:

Adjustments > Internal > Reload function > OK

1. Recharging function ON (<F1> = YES)

- Batteries slowly and carefully recharged

- Recommended for frequent use

2. Recharging function OFF (<F4> = NO)

- Batteries quickly recharged

- Recommended for occasional use

- Note: Battery run-time is reduced on quick charge!

1. Charge the battery after each use

2. Always store unit with fully charged battery

3. Charge the battery at least once a month if

not in use

Page 12

Page 12

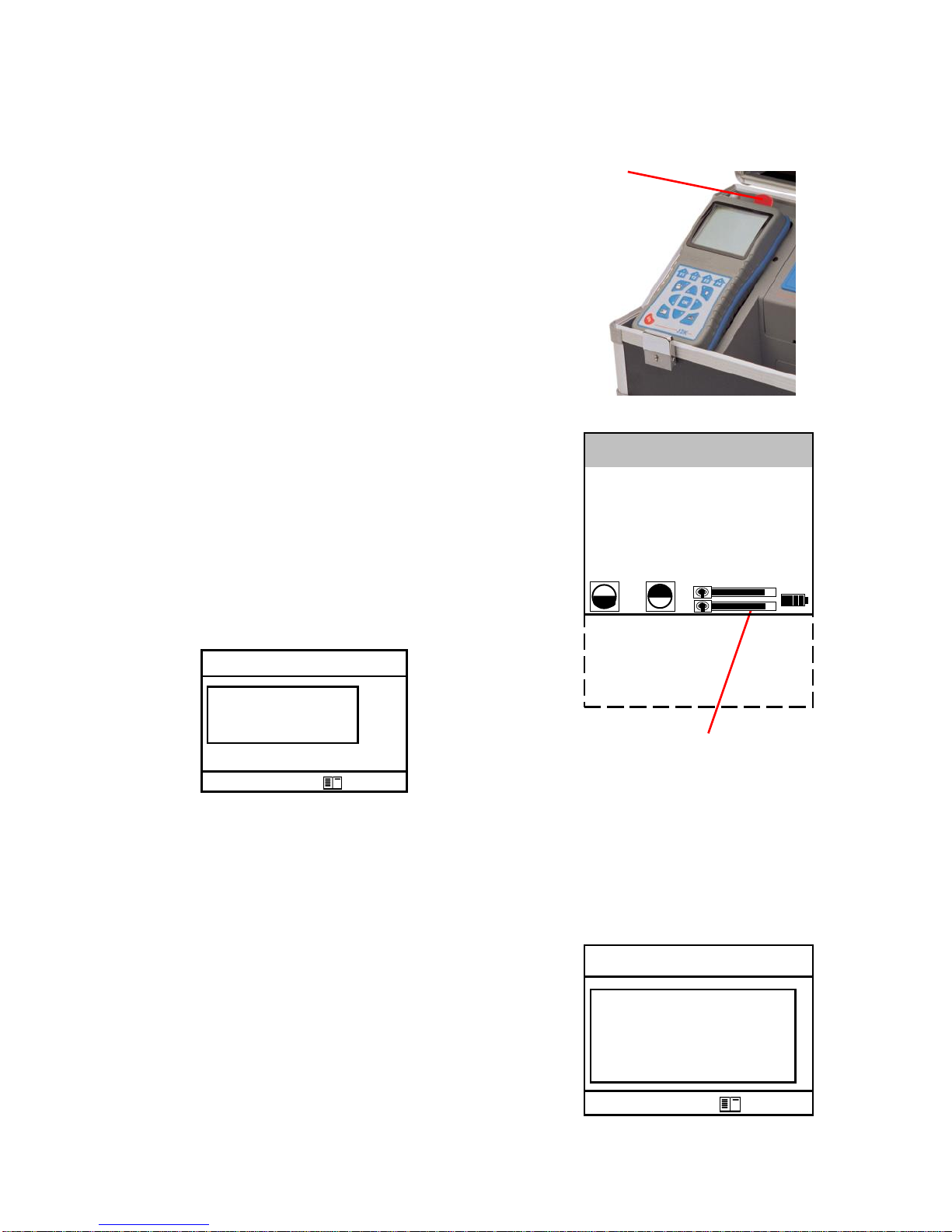

6. Radio Communication

The J2KN Pro base unit communicates wirelessly to the remote display

unit via radio transmisision. To unlock

the remote control unit, press on the tab

to unlock and release from the cradle on

the base unit.

The information exchange between

the remote control and base unit is

performed via radio transmission (915

MHz) with a coverage of approximately

100ft by free sight. The quality of the

radio transmission is documented by a

bar indication in the Main Menu.

If the J2KN base unit is switched off

and the remote control unit is on, the

display will show a message telling the

user to place the remote control unit

into the docking station (see below).

Troubleshooting Communication Issues

If there is interruption of the radio communication, an error

message is displayed (see below right). If this occurs frequently,

it may be necessary to re-sync the remote to the base unit:

1. Place remote unit into cradle

2. Go to Adjustments > Internal > RF

Connect > Standard > OK

3. The base and remote are now synced

4. Go to Adjustments > Internal > RF

Connect > Remote > OK

5. The remote can now be used as normal

Unlock

Bar indication

radio quality

-- ECOM-J2KN --

Radio connection

interrupted!

Use cable or

switch on basic

module!

Quit with:

-- ECOM-J2KN --

Place J2KN in

basic mod.!

Quit with:

Gas analysis

Averaging

Draft/Pressure

Soot Test

Automatic meas.

Adjustments

Control

Diagnostics

Page 13

Page 13

7. J2KN Pro Start-up

Make sure the probe is in fresh air when you

turn on the J2KN Pro.

1. Switch on the J2KN base unit and the remote control

unit. The Main Menu is displayed with 8 sub-menus:

- Gas analysis View gas readings & calculations

- Averaging Perform averaging tests

- Draft/Pressure Calibrate pressure sensor

- Soot Test Perform soot/smoke density test

- Automatic meas. Data logging onto memory card

(Pro Easy & IN) and set up automatic test cycles (Pro IN only)

- Adjustments Modify J2KN settings

- Control Diagnostic info/Calibration mode

- Diagnostics (Only used with ECOM AK tool)

2. Select Gas Analysis and press <OK>

3. Press Up/Down to select Fuel Type

and press <OK>

4. Analyzer will complete auto-zeroing

of all sensors, except the O2 sensor

which is calibrated to 20.9%

Fuel type

Gas-Natural

CO2max A1 B

11.7 0.35 0.006

Select: (

Radio Link

Quality Indicator

Battery Charging

Indicator

Display contrast:

Lighten F1

Darken F2

Gas analysis

Averaging

Draft/Pressure

Soot Test

Automatic meas.

Adjustments

Control

Diagnostics

Page 14

Page 14

8. Emissions Measurement

8.1 Gas Analysis

Calibrate the sensors before

each emission test for best results.

After the 1-minute auto-zeroing phase, the instrument switches

to Gas Analysis mode. The measurement values can be viewed

on 3 display pages: a zoomed in 4-line display and 2 full 9-line

displays. All line items are user-selectable (see Display Values

below). Press Up/Down to scroll between the pages.

Bypass Switch (Pro IN)..Turn on/off fresh air bypass to purge

Info Screen (Pro Easy)....View diagnostic info on Control screen

Quick Print............Prints on-screen measurement values

CO Bypass.............Manually turn on/off CO bypass pump

Display Lines.......Choose measurement values to display by

pressing F4 then Up/Down/Right/Left

To change F1 hotkey from default, go to

Adjustments > Internal > F1 Hotkey

Turn on CO bypass pump to protect CO

sensor from high concentrations

Pump automatically activates at 4000ppm!

To change F4 hotkey from default, go to

Adjustments > Internal > F4 Hotkey

Edit Display

Lines

<F4>

Control Screen (Pro Easy)

Purge Valve On/Off (Pro IN)

<F1>

F1:

F2:

F3:

F4:

Tip: To apply O2 correction, go

to Adjustments>Ref. O2 and input

your O2 correction % value. Then

go to Adjustments>Unit and change

unit to ppm %O2 corrected.

Quick Print

<F2>

CO Bypass

Pump ON/OFF

<F3>

O2 8.2 %

CO 431 ppm

NO 126 ppm

NO2 65 ppm

Gas Analysis 25.11.07

Page 15

Page 15

8.1 Gas Analysis (continued)

Heated Probe

If you are testing in a cold temperature environment, you

may require a heated probe so that condensation does not

form (or freeze) in the probe or probe grip. To turn on the

heated probe, go to Adjustments>Internal>Probe heat-

ing>F1. Remember to turn it off when the probe is not in

use, and allow the probe to cool before placing it in the case.

Core Stream Search

To obtain the most accurate gas

sample, the end of the probe should be

positioned in the center of the exhaust

stream or the “core stream.”

A + or – symbol displays in the core stream box (see figure above), indicating a trend towards positive or negative

temperature. As long as the display shows a + symbol, the

measured temperature is increasing and the probe tip is

moving towards the core stream. If a - symbol is displayed,

the measured temperature is decreasing and the probe tip is

past the core stream. Pull the probe back slightly to reach

the core stream, and adjust the probe cone so that the probe

is firmly in place.

Calculated Values

Calculated values include CO2, efficiency, losses, and excess air and are defined only when realistic values for O2 and

temperature are available. Otherwise, the values will dash

out on the display. For the calculated values to appear on the

display, the O2 concentration must be less than 20.5%

O

2

< 20.5 % and T.Gas - T.Air > +5°C

When these conditions are met, all calculations will display.

Gas temp. trend indicator

O2 8.2 %

CO 431 ppm

NO 126 ppm

NO2 65 ppm

Gas analysis

Gas stream

Probe tip

Thermocouple hook

Page 16

Page 16

8.2 Printing

Quick Print

The easiest and quickest way to print is to press <F2> for

quick print, which immediately prints the measurement values

currently on the screen. This also saves a snapshot to memory.

Print in Timed Intervals or Print an Average Over Time

To print in timed intervals (for example, every 10 seconds or

each minute) or to print an average over time, please refer to

10. Averaging Tests.

Print from Memory

1. Press 5/Save (disk icon)

2. Press Print key (printer icon)

3. Select Start printout

4. Press 5/Save to clear memory

Measurement recorded

Print with Text (i.e. site and equipment)

1. Press Print key (printer icon) to display printing options

2. Select Insert Text and press OK to select first line of text

(maximum 6 lines of text, 20 characters per line)

3. Using the directional keys and OK, select the alphanumeric

characters to insert text. Press F3 to change grid to lower case,

numbers, or other characters. To delete a character, press F4 to

toggle up then F2 to delete. Press F1 to accept text. If you wish

to insert more lines of text, select the next line and repeat.

4. Press twice to return to Gas Analysis

5. When ready to print, press <F2> for quick print

6. To clear text from printout, press Print key, select Insert Text,

select text line, press F4 to toggle up, move the cursor to the

right of the text, and press F2 to delete each character.

Wait for the measurement values to stabilize

for at least 2 minutes before printing the

results.

O2 8.2 %

CO 431 ppm

NO 126 ppm

NO2 65 ppm

Gas Analysis

Recorded!

Page 17

Page 17

8.3 Soot Test

The soot test is a measure of soot or

smoke density in the exhaust sample.

The soot test must be performed with the heated probe turned

on in order to prevent the filter paper from becoming wet due to

condensation. To turn probe heating on, go to

Adjustments > Internal > Probe heating > F1

J2KN Pro must be plugged in for the probe

heating function to activate. Allow 3 minutes

for the probe to heat up before soot test.

Soot Test Procedure

1. Turn on probe heating: Adjustments>Internal>Probe heating>F1

2. Press the trigger on the probe handle to open the filter slot

and insert a filter paper (will insert about half-way)

3. Select the line 1st. Soot meas

4. Press <OK> to start the measurement.

The display shows flow volume and the

pump starts sampling

5. Once 1.63 liters have been sucked in,

the J2KN-Pro will prompt to input the

opacity number

6. Press the trigger on the probe handle

to open filter slot and pull out the filter

paper

7. Compare the greyness on the filter paper with the soot test

chart 0-9 opacity scale

8. Input the number and press <OK>

9. Repeat steps 2-8 until all 3 soot tests are completed. The

mean value will be calculated and automatically stored.

10. Turn off probe heating: Adjustments->Internal->Probe heating->F4

Select NO for Oil trace.

Remember to let the probe cool down

before putting it back in the case.

Soot Test

Average: -.-

Boiler temp.: ---°F

1st Soot meas.: -.2nd Soot meas.: -.3rd Soot meas.: -.-

Oil trace : ----

Soot Test

Mean value: 5.0

Boiler temp.: 166°F

1st Soot meas.: 5.0

2nd Soot meas.: 4.5

3rd Soot meas.: 5.5

Oil trace : NO

Page 18

Page 18

9. Capturing Data on Memory Card (2GB max)

Data Logging in Timed Intervals

1. Go to Automatic Meas. > Save to MM

Card. This is the time interval that each

data point is recorded to the memory card

(min. 1sec, max 255sec). Input desired

amount in seconds and press OK.

2. Select Datalogger > “Start dl? Are you

sure?” > Press F1

3. Analyzer is now in Datalogging mode. The

blinking disk in the top right corner indicates that the analyzer

is currently logging data. Press to return to the main menu

and select Gas Analysis to view real-time measurements.

4. To complete data logging and save the file, press to return

to the main menu, go to Automatic Meas. > Datalogger >

“Finish dl? Are you sure?” > Press F1.

Capturing Data Snapshots On-Demand

1. Go to Automatic Meas. > Save to MM Card and input 255.

2. Select Datalogger > “Start dl? Are you sure?” -> Press F1

3. Press to return to the main menu and go to Gas Analysis

to view real-time measurements.

4. Press 5 (disk symbol). You will see an X over the disk icon

in the top right corner. This is normal and expected.

5. When you are ready to capture the first data point, press 5

(disk symbol), wait 2 seconds, and press 5 again. The

data point was captured during the 2 second interval.

6. Repeat step 5 for all desired data points.

7. To complete data collection and save the file, press to

return to the main menu, go to Automatic Meas., select

Datalogger -> “Finish dl? Are you sure?” -> Press F1.

Each data file will be saved separately as J2KDL-00, J2KDL-01, etc.

Open in Microsoft Excel. You can also import the data from the SD

card into ECOM’s free DAS 5 software to create formal reports.

Page 19

Page 19

10. Averaging Tests

The Averaging function allows you to take a sample of

emissions data and compute an average over time.

1. Go to Averaging -> Select Meas. Time

2. Input total measuring time in minutes or

seconds (for seconds, press decimal 1st)

3. Select Scanning and input interval time

in minutes or seconds

For example: If the Meas. Time is 1 minute and the

Scanning time is 10 seconds, the mean value will take

into account 6 scans and find the average

4. Select Printer and choose from the following options:

No Value. This prints only the final averaged values.

Each Value. This prints a snapshot for every scan.

Each Value of 2, 3, etc. This prints a snapshot for every

other scan, every third scan, etc.

5. Do not select Store. Please leave to default.

6. Select Start Measurement.

Mean value measurement has initiated.

Press up/down to toggle between mean

value and real-time results. You will see

the time counting down in the bottom

left of the display screen.

7. After the Meas. Time has elapsed, press Print key to print

averaged results if it does not print automatically

8. Press , select Averaging, and press F1 to quit

averaging calculation

Start measurement

Meas. time

Scanning

Printer

Store

Averaging

Quit with:

O2 3.2 %

CO2 13.1 %

CO 0 ppm

Eta 92.5 %

Losses 7.5 %

Lambda 1.18

T.Gas 184 °C

T.Air 20 °C

Averaging 25.11.07

15:59 min

Page 20

Page 20

11. Software Communication

If you need help with installation or operation of your DAS

or e-Comply software, please consult the User Manual for your

software product. If you are having trouble communicating

from the analyzer to a computer, please check the following:

Adjustments > Internal > RF Connect

Make sure it is in Remote setting.

Adjustments > Internal > USB

For both DAS and e-Comply, make sure the Baud rate is

38400 and the Protocol is enhanced.

Adjustments > Internal > WLAN (if applicable)

If you have WiFi communication problems, refresh the WiFi

signal by selecting Auto Connect > F1. You will see the IP

address dash out and come back again. Note: You can’t connect to both the software and mobile app simultaneously.

Adjustments > Internal > Bluetooth (if applicable)

For both DAS and e-Comply, make sure the Baud rate is

9600 and the Protocol is enhanced. To reset the Bluetooth

signal on your computer, right-click on > Show Bluetooth

Devices > Right-click on BT connection> Remove Device. Now

click Add a Device and re-connect to the analyzer. PIN=1234

If communication issues persist, re-sync the remote & base

1. Place remote unit into cradle. Go to Adjustments >

Internal > RF Connect and select Standard.

2. The base and remote are now synced.

3. Change the RF Connect setting back to Remote.

4. The remote can now be used as normal.

If all else fails, do a hard reset of the analyzer:

1. Power down the analyzer.

2. Disconnect analyzer from AC power.

3. Open the battery drawer and disconnect the lead from the

battery (white plastic clip). Wait at least 1 minute.

5. Reconnect the battery, reconnect the power cord, and

restart analyzer. You have just completed a hard reset.

Page 21

Page 21

12. Frequently Asked Questions

Where do I find important instrument information?

How long is the life span of the

sensors?

Which sensors can I exchange?

The instrument shows the error

message “O2 sensor 0 mV“

The instrument shows the error

message “T-Gas“ or “T-Air“

The instrument shows wrong or

inaccurately CO2 values

Can I change the printout?

In the Control screen, all important instrument information is shown (e.g. battery voltage, sensor values, serial number, next service date, operation hours, etc.).

The life span depends on the operating hours

and the instrument equipment. The life span

of the toxic sensors (CO, NO, SO2, NO2) is

affected by high gas concentrations or insufficient purging. The life span for these sensors

is on average 3 years. The life span of the O2

sensor is independent of the operating hours

and amounts to approximately 2 years.

The following sensors are exchangeable:

- O2 sensor

- CO sensor (pre-calibrated available)

- NO sensor (pre-calibrated available)

- NO2 sensor (pre-calibrated available)

- SO2 sensor (pre-calibrated available)

The O2 sensor must be changed.

Note: The error messages can be bypassed by

pressing . Calculations that rely on these

temperatures will not display.

Possible reasons could be:

- Cable is broken (at the plug)

- T-Air sensor error – check all connections

- T-Gas sensor error – check all connections

- Thermocouple is defective

Possible reasons could be:

- O2 is defective (CO2 values are calculated

from O2 value)

- Pump is not working correctly

- Air leakage in the gas path

- Peltier cooler is clogged

Yes, go to Adjustments > Internal > Printout

Page 22

Page 22

12. Frequently Asked Questions (continued)

If you have any further questions, do not hesitate to contact

the ECOM America Service Department at 770-532-3280

J2KN-Pro cannot be

switched on

J2KN-Pro doesn’t print all of

the values I want

Pump flow seems too low

The water is not pumping

out of the water trap bowl

When trying to connect using

software, the analyzer is not

connecting to my PC.

No flow is getting to the

sensors

J2KN-Pro display is blank

when I turn it on but the

analyzer is clearly powered

on

My memory card is not working

- Check the main power cable

- Check the fuse (located inside the power socket)

- Recharge the batteries for a minimum of 8 hours

(Battery could be completely discharged)

You must press F2 (quick print) while in Gas

Analysis to print all of the values on the screen.

Any dashed out values will not print. The button

with the printer icon is only for printing from

memory.

Check all hose connections for tearing/cracking

and check Peltier cooler for blockage

Check the white peristaltic tubing to make sure it’s

not pinched. If necessary, open up the unit and

check the rollers in the white housing. Call ECOM

service for assistance.

Check these 3 items:

1-Adjustments -> Internal -> RF Connect… Make

sure it is in Remote setting

2-Adjustments -> Internal -> Bluetooth… See

section 12.1 Internal for the correct setting

3-Adjustments -> Internal -> USB… See section

12.1 Internal for the correct setting

Check all connections and bypass the water trap to

pinpoint if the lead is in the water trap

Display contrast may be set incorrectly – press F2

many times after you turn on the remote unit to

see if screen comes back

Verify that you have a memory card storage of

between 32MB and 32GB

Hint: If you have several J2KN-Pro analyzers, you

can find the source of an error by exchanging the

accessories (probe, hose, temperature sensor, etc.)

Page 23

Page 23

13. Draft/Pressure

A trend indication for the draft conditions in the exhaust

channel is displayed in the Gas Analysis screen. Note that the

pressure sensor tends to drift because of its sensitivity, and it

is necessary to calibrate the sensor immediately before sampling to get an accurate measurement.

To calibrate, go to Draft/Pressure.

The current value is displayed. Disconnect the draft hose from the J2KN for a

short moment and press <F4>.

The pressure sensor is now calibrated.

Reconnect the draft hose. The display shows the current draft measurement value. This can be stored into

intermediate memory by pressing

5/Save. The stored value is shown on

the display. Press to quit the differential pressure menu.

14. Adjustments

Most of the settings of the J2KN-Pro

that are user-selectable can be changed

in Adjustments in the Main Menu.

Auto-Zero (J2KN-Pro IN only)

Press <OK> to set new zero points

for sensors. Before using this function,

the sensors must be flushed with fresh

air, and the J2KN-Pro IN must be in a

fresh air environment during the autozero phase.

Unit

The default setting for gas concentration units is ppm

(parts per million). The options for units include:

Auto-Zero

Unit

Mass Emission

Ref. O2

Fuel type

Set clock

Paper feed

Internal

Air Leak Test

Quit with:

Page 24

Page 24

14. Adjustments (continued)

Mass Emissions

The J2KN-Pro calculates mass emissions in units of lbs/hour, tons/year,

or gr/bhp. First, under Adjustments, set the Unit to ppm and choose

the correct Fuel Type. Then select Mass Emission and press <OK>.

Press up/down to select the correct unit.

For lbs/hour or tons/year:

For gr/bhp:

-If fuel flow is known, press F2 to

input Fuel consumption (scf/hr for

gaseous fuel & gal/hr for liquid fuel)

-If fuel flow is known, press F2 to input Fuel

consumption (scf/hr for gaseous fuel &

gal/hr for liquid fuel)

-If fuel flow is not known, press F4 to

input mmBTU/hr for a calculated

fuel consumption

-If fuel flow is not known, press F4 to input

mmBTU/hr for a calculated fuel consumption

-No need to input Horsepower@test

-Press F3 to input Horsepower@test

-Press <OK> to accept

-Press <OK> to accept

Ref. O2

Enter the reference %O2 value using

the number keys and decimal point.

The conversion equation is shown to

the right. You must then change the

Unit to %O2 corrected.

Fuel type

Options for fuel type include natural gas, propane, butane, diesel, oil,

coal, and wood. This is necessary for CO2 and Mass Emissions calcs.

Set clock

Set time and date

Paper feed

Press <OK> to start paper feed and to end paper feed

Air leak test

Cover the end of the probe with the yellow cap supplied with the unit and

press <OK> to start checking the sampling system for air leaks.

E

ref

= E

meas

*

21 - O

2 ref.

21 - O

2 meas.

ppm parts per million

mg/m3 milligrams per cubic meter

mg/kWh %O2 Corrected milligrams per kilowatt-hours corrected to O2%

mg/MJ %O2 Corrected milligrams per megajoules corrected to O2%

ppm %O2 Corrected parts per million corrected to O2%

mg/m3 %O2 Corrected milligrams per cubic meter corrected to O2%

lbs/mmBTU %O2 Corrected pounds per million BTU corrected to O2%

Page 25

Page 25

14.1 Internal

(Go to Adjustments > Internal)

Print contrast

Choose print contrast from 0-9

Reload function

Choose remote unit battery recharging

settings (see 5. Power Supply)

Key beep

Press F1/F4 to turn key beep on/off

Graphic menu

Press F1/F4 to turn graphic menu on/off

Probe heating

Press F1/F4 to turn probe heating on/off

for soot measurement test (see 8.3 Soot

Measurement Test)

Power saving mode

Press F1/F4 to turn on/off power saving

mode, which turns off the Peltier cooler

and the heated probe option

Language: English

Press OK to choose between French and English

F1 Hotkey

Press Up/Down to choose F1 shortcut (see 8.1 Gas Analysis)

F4 Hotkey

Press Up/Down to choose F4 shortcut (see 8.1 Gas Analysis)

Eff.(C)

Press F1/F4 to turn on/off the efficiency calculation with and without condensation

C/F

Press up/down to choose your temperature unit and then press OK

RF-connect

-Standard: choose this option to sync the base and remote units if

radio communication problems occur

-RF-connection: do not choose this option

-Remote: allows for remote operation of controller (default)

Printout contrast

Reload function

Key beep

Graphic menu

Probe heating

Power saving mode

Language: English

F1 Hotkey

F4 Hotkey

Eff.(C)

°C/°F

RF-connect

USB

Bluetooth

Pitot Factor

Printout

Quit with:

Page 26

Page 26

14.1 Internal (continued)

USB

For DAS 5 & e-Comply: Set Baud rate to 38400

Set Protocol to Enhanced

WLAN (if applicable)

Wireless Local Area Network. If you have internal WiFi, this

option will appear and the IP address will display at the bottom

-Access point: turn on/off internal WiFi

-Auto connect: if turned on, WiFi will intitiate upon start-up

-Channel: change the WLAN channel if interference occurs

(If WiFi communication errors occur, go to this screen and select Access point and press F1. This will refresh the IP address.)

Bluetooth (if applicable)

For DAS 5 & e-Comply: Set Baud rate to 9600

Set Protocol to Enhanced

The first time you connect to a computer

via Bluetooth, use “1234” pairing PIN.

Pitot factor

(See section 19. Flow Velocity Measurement)

Printout

This feature allows you to add 8 lines of text at the bottom of

the printout at 20 characters per line. Usually this is reserved

for company information such as company name, address,

phone number, and website. (To add a special note for a specific test, please see 8.2 Printing.)

To change printout text, press Up/Down to select the line you

would like to edit. Press F4 to toggle up and down between the

insert text box and the alphanumeric grid. Using the directional

keys and OK, select the characters to insert text. Press F3 to

change grid to lower case, numbers, or other characters. To

delete a character, press F4 to toggle up, then F2 to delete.

Press F1 to accept text and continue to the next line.

Page 27

Page 27

15. Control

The electrochemical sensors change their output values

over time based on frequency of use. The J2KN-Pro is programmed to monitor the sensors and correct drifts. If the

drifts and the correlated measurement errors increase, an error message is displayed and it is time to change the sensor.

The control menu displays the status of the sensors, batteries, radio quality, error count, number of times the J2KN-Pro

has started up, and other analyzer information.

Info Display

2.24

ltr /

min

Main pump is running

Fresh air valve is open

CO purging is running

Gas cooler ready for use

Heated line ready for use

Heated head ready for use

Probe heating is switched on

Gas flow

(liters per minute)

Radio mode

Battery operation

Calibration phase

O2 10744 mV

CO 7 mV

Batt 4.50 V

Bat.B 6.09 V

Operation hours : 8.45 hrs

Serial no. : J2KN 12345

Service tel. : 02371-945-5

Programm version : V3.0 / 12.07.10

Next unit check : 20.04.11

Control

20

4.2 /s

4.2 /s

0.0 /s

1 X

22 ppm

4 X

11 X

-rbr- Messtechnik O2 10744 mV

Am Großen Teich 2 CO 7 mV

58640 Iserlohn Batt 4.50 V

--------------------- Bat.B 6.09 V

Tel.: 02371-945-5

Fax : 02371-40305

eMail : info@rbr.de

Operation hours : 8.45 hrs

Serial no. : J2KN 12345

Service tel. : 02371-945-5

Programm version : V3.0 / 12.07.10

Next unit check : 20.04.11

Control

Company name

on printout

(editable)

Serial number

Firmware

version

Radio quality

Radio frame

rate (sent)

Radio frame

rate (received)

USB frame rate

Battery voltage

Batt. = remote

Batt.B = base

Operation hours

Recommended

maintenance date

CO bypass coun-

ter

PPM hours of CO

sensor

Error counter

J2KN start-up

counter

Millivoltage of

sensors

(see section 16.3)

Page 28

Page 28

16. Maintenance Tips

Only use sensors, filters, and filter media

provided by ECOM. Do not use desiccant!

16.1 Filters

Particulate filter (water trap filter)

Unscrew the cover of the water trap and check the particulate filter for grayness. Change the filter when it is dark gray.

Tip: use the elbow piece as a reference since it is dark gray.

In-line smoke filter

The round in-line smoke filter should be checked periodically

for grayness. Change the filter when it is dark gray. Tip: use

the elbow piece as a reference since it is dark gray.

NOx/SOx filter

The CO sensor has an independent gas path (see 4. Gas

Path Diagram) which includes a potassium permanganate

chemical filter for filtering SO2 and NOx from the gas sample.

Color change: purple -> brown -> grey-> white

Filter media should be changed once it has turned grey!

Particulate filter

In-line smoke filter

Elbow piece

Page 29

Page 29

16.1 Filters (continued)

Ventilation filter

The ventilation filter should be changed if the filter has a

darkness of 2-3 on the soot chart scale. Use a screwdriver to

pry open the filter holder from the slots on each side. Change

the filter cartridge and refasten the filter holder.

Ventilation filter

Filter cartridge

Filter holder

16.2 Sample Line and Probe

The sample line and probe should be cleaned regularly to

release particle deposits and to prevent early wearing due to

corrosion.

To clean the hose, disconnect from the analyzer end and

the probe end, blow out the line with short bursts of air from

an air compressor, and hang up to dry overnight so that excess water may drain out.

16.3 Sensors

During the J2KN-Pro start-up procedure, each sensor is zeroed using fresh air as the reference point, except for the O2

sensor which is calibrated to 20.9%. The status of each sensor is permanently monitored by the instrument. The sensor’s

life span is shortened by the exposure to high concentration

gases above the measurement range. The output values of

the sensors should be in the range of:

O2 OO/105 (white) 11000 mV to 13000 mV

O2 5FO (black) 17000 mV to 24000 mV

All others -100 mV to +100 mV

If an error message is displayed during the start-up phase

and cannot be cleared despite several restart attempts,

please call an authorized service center for troubleshooting

advice.

Slots

Page 30

Page 30

16.3 Sensors (continued)

The CO sensor is protected from exposure to high concentrations by the automatic CO bypass pump. If the limit

value of 4000 ppm is exceeded, a second pump switches on

and purges the sensor with fresh air.

14.4 Printer Paper

To change the printer paper, please follow these steps:

1. Release the printer cover

2. Take out the used paper roll

3. Remove the used paper roll from the shaft and place the

new paper roll onto the shaft

4. Insert the paper end into the black ribbon cartridge slot

5. Feed approximately 2 inches of paper by going to

Adjustments > Paper feed and pressing <OK>

6. Place new paper roll and shaft back into place

7. Insert the paper end into the blue printer cover slot

8. Close the printer cover

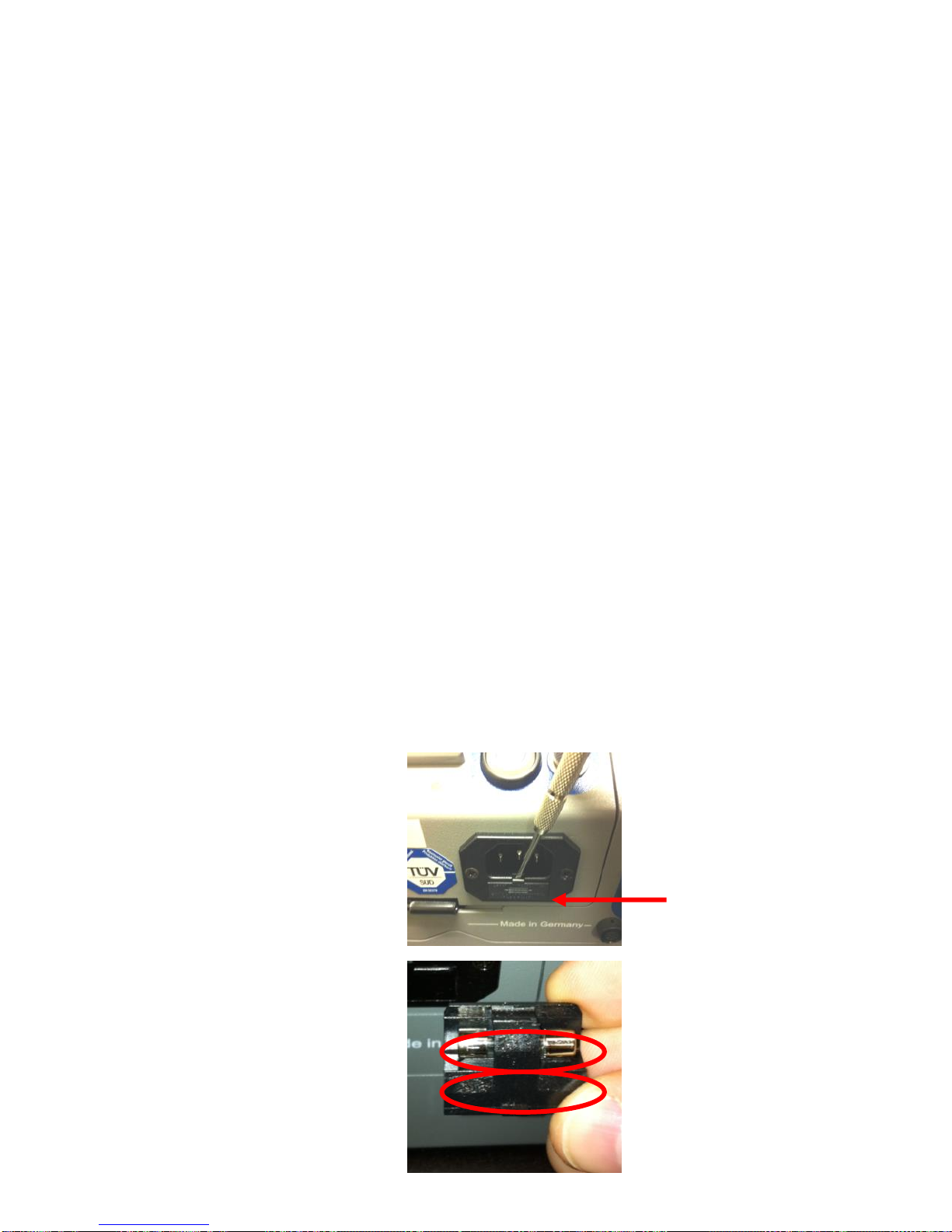

16.5 Changing the Fuse

A 1 amp fuse is located in a small drawer just below the

power cord socket. If the J2KN-Pro is not powering up when

plugged into AC power, this may be due to a blown fuse. To

change the fuse, please follow these steps:

1. Use a small

screwdriver to

release the fuse

drawer

2. Take out the

spare fuse and

insert into the

active fuse spot

3. Re-insert fuse

drawer

Fuse drawer

Active fuse (exposed)

Spare fuse (hidden)

Page 31

Page 31

17. How to Change Sensors

17.1 How to Change O2 Sensor

Step 1:

Use a T-10

torx wrench

to remove

screws from

O2/CO cover

plate

Step 2:

The O2

sensor is

attached to

2 wires,

located

below the

CO sensor

Step 3:

Disconnect

the lead

wires and

unscrew

counter

clockwise

until loose,

then pull

directly out

Step 4:

Install new

O2 sensor

by screwing

clockwise

until locked

& reconnect

wires

Improper installation voids warranty!

Please mark connector when removing old

sensor and insert new sensor into correct

connector to prevent destruction of the

sensor and main board.

Step 5: Replace O2/CO cover plate and tighten screws with a T-10 torx

wrench

Step 6: Turn on analyzer and select Gas Analysis to start self-calibration

of O2 sensor to 20.9% in ambient air (must be in fresh air)

Page 32

Page 32

17.2 How to Change A5F CO Sensor

Step 1:

Use T-10 torx

wrench to

remove

screws from

O2/CO cover

plate

Step 2:

The A5F CO

sensor is in

gray

housing

attached to

a ribbon

cable

Step 3:

Disconnect

ribbon cable

from CO

sensor

Step 4:

Remove CO

sensor using

coin or

fingers

Turn 45

degrees

counter

clockwise

and pull

directly out

(continued on next page)

Improper installation voids warranty!

Please mark connector when removing old

sensor and insert new sensor into correct

connector to prevent destruction of the

sensor and main board.

Page 33

Page 33

17.2 How to Change A5F CO Sensor (continued)

Step 5:

Pop open the

gray cap

using a small

screwdriver

Use the side

of the housing as a

leverage

point

Step 6:

After the

cap is

removed,

slide the

sensor out

of the

housing as

shown here

Step 7:

Remove the

board from

the sensor

using a small

screwdriver

Warning! PTC

embedded in glue

Pry from beneath the

dried glue so the PTC

does not separate from

the board

Failure to do so may

destroy PTC

Step 8: Place board onto new sensor

Step 9: Insert new sensor into gray housing and replace cap by

snapping into place

Step 10: Insert new sensor into analyzer, turn 45 degrees clockwise

to lock into place and replace ribbon cable

Step 11: Replace O2/CO cover plate and tighten screws with T-10

torx wrench

Step 12: Calibrate your new CO sensor using certified calibration gas

Page 34

Page 34

18. How to Calibrate Sensors

For best results, the calibration gas concentration should be as

close to the expected levels of emissions as possible. However,

because each sensor is linear through a nominal range, one calibration

gas concentration can be used for a reasonably wide range of emission

levels. For applications with extremely low or extremely high levels of

emissions, you will need to tailor your calibration gases accordingly.

Fully charge analyzer:

Place unit on charge the night before you plan to use analyzer to

ensure full charge of battery.

Initiate analyzer:

1. Attach T-gas thermocouple, sample line, and power cord.

2. Switch on analyzer.

3. Select Gas Analysis on main menu.

4. Select Fuel Type, press OK.

5. Allow instrument to complete self-calibration/auto-zero sequence.

Put analyzer in calibration mode:

1. Press to return to main menu and go down to select Control.

2. While in the Control screen, swipe calibration magnet over the Cal

Magnet sticker, located at bottom left of keypad.

3. The analyzer is now in calibration mode. You will see the sensor

readings with a cursor that you can move up and down. The O2%

reading is located at the bottom of the screen.

Check for air leaks:

1. To check for air leaks, you must introduce a gas with zero O2%

through the entire sample train. This is necessary to check that the

system has no leaks to atmosphere. We recommend NO gas

balanced in N2 because you can check for air leaks and calibrate the

NO sensor at the same time (2 birds, one stone). If you have a

CO/NO mix balanced in N2, you can use this as your leak check gas

as well (3 birds, one stone).

2. To connect the calibration gas cylinder to the analyzer, use one of

the following three set-ups:

Page 35

Page 35

18. How to Calibrate Sensors (continued)

On-Demand Regulator: (Recommended) Use an on-demand

regulator which uses the analyzer pump draw to establish flow.

Connect the on-demand regulator to the sample train and open

the cylinder valve. The analyzer pump controls the flow as to not

over or under pressurize the sensors.

Adjustable Flow Meter: Connect an adjustable flow meter to the

sample train and measure the pump draw. Then connect the gas.

Use the cylinder valve for course adjustments and the flow meter

for fine adjustments to match the flow of the pump draw.

Vented Flow Meter: Connect a vented flow meter to the sample

train and connect the gas. Open the cylinder valve until a small

amount of gas is exiting through the vented flow meter. This

prevents air from entering system and allows pump to control

internal pressure within analyzer.

3. After you have connected the gas to the analyzer, watch the O2

reading until it is 0.0%. If it does not reach 0.0%, you may have

an air leak. Troubleshoot the source of the leak and correct it. It is

also possible that the system is tight but your O2 sensor is aged.

4. Do not proceed to calibrate the analyzer until you have verified that

the O2 reading goes down to 0.0%!

Calibrate your analyzer:

1. Apply the gas and wait for the reading to stabilize. (If you used a

cal gas for the leak test, the readings should be stabilized already.)

2. After the reading has stabilized, you may calibrate the sensor. To

calibrate, move the cursor beside the target sensor and press OK.

Input the concentration value from the gas cylinder and press OK.

3. The reading will change to the calibration gas value. Watch the

reading to make sure it doesn’t drift. If it does, wait until it stabilizes and re-calibrate. If it keeps drifting, the sensor may be aged.

4. After you have verified calibration, disconnect the gas.

5. Repeat steps 1-4 for each sensor.

6. After the calibration is complete, allow the analyzer to flush with

fresh air for 5 minutes or until readings are below 10 ppm.

Page 36

Page 36

19. Flow Velocity Measurement (Option)

Stack flow or exhaust gas flow can be measured by the

J2KN-Pro using a special flow probe. If you are using a standard

ECOM probe, set this to 0.93.

First, the Pitot factor must be entered in the Adjustments

menu to get the correct flow rate calculation. Input 0.93 for the

Pitot factor if you are using a standard ECOM probe. To do this,

go to:

Adjustments > Internal > Pitot factor

After connecting the Pitot tube to the

analyzer, go to Flow Measurement

Press <F4> to set the zero point of the

flow sensor.

Press <F1> to input the cross section

of the stack or exhaust stream, which

is required for the flow rate calculation.

Position the Pitot tube in the stack or

exhaust stream.

The display will show the speed (m/s),

flow rate (Nm3/h) and differential pressure (Pa). After the values have stabilized, press <F2> to print the results.

*Call ECOM at 877-326-6411 if you would like the flow measurement

option added to your J2KN-Pro. You will have to get a return authorization number and send the analyzer to our service department in Gainesville, Georgia, USA.

V.Gas 0.4 m/sek

M.Flow 44 Nm3/h

dP 0.1 Pa

Flow measurem.

25.11.07

Flow measurement

Connections for

pitot tube

Measurement stored in

intermediate memory

Page 37

Page 37

20. Technical Data

Parameter Range Principle

O2 0 ... 21.0 vol-% Electrochemical

CO 0 ... 4000 ppm Electrochemical

CO% (Option) 4000 ... 63000 ppm Electrochemical

NO 0 ... 5000 ppm Electrochemical

NO2 0 ... 500 ppm Electrochemical

SO2 (Option) 0 ... 5000 ppm Electrochemical

CxHY (Option) 0 ... 4.00 vol-% (CH4) Catalytic

CxHY (Option) 0 ... 2000 ppm (C3H8) Infrared

CxHY (Option) 0 ... 3.00 vol-% (CH4) Infrared

CO% (Option) 0 ... 63000 ppm Infrared

CO2 (Option) 0 ... 20.0 vol-% Infrared

Air pressure 300 ... 1100 hPa DMS bridge

CO2 0 ... CO2max Calculation

T-Gas 0 ... 1000 °C NiCr/Ni

T-Air 0 ... 99 °C Semi-conductor

Differential pressure 0 ... +/- 100 hPa DMS bridge

Efficiency 0 ... 120 % Calculation

Losses 0 ... 99.9 % Calculation

Excess air 1 ... Calculation

Op. Temp: 20-122°F

CO sensor purges thru separate fresh air pump

Electronic water trap monitoring with Peltier cooler

Power Supply Main Power 110V...60 Hz / 220V...50 Hz

Base Unit Battery 6V/7.0 AH Lead Acid

Remote Unit Batteries AA Nickel Metal Hydride (set of 3)

Pump Flow rate of 2.0+ lpm

On-board Printer Thermal printer / 58mm paper width

Display Screen LCD Display with Backlight

Dimensions (LxWxH) (Pro Easy) 17.5 x 9.75 x 12 inches

(Pro IN) 20 x 9.75 x 12 inches

Weight (Pro Easy) 28 lbs with sampling system

(Pro IN) 29 lbs with sampling system

Subject to technical changes

V3.6.2 / January 2015

Page 38

Page 38

21. Description of Data Fields using J2KN-Pro

Data Logging onto Memory Card

File format: J2KDL-xx.csv (comma-separated-values)

Column

Description

Remark / Example

A

Date

DD.MM.YYYY

B

Time

HH:MM:SS

C

O2 in vol.%

0.0 – 21.0

D

CO in ppm

0 – 4000

E

NO in ppm

0 – 4000

F

NO2 in ppm

0 – 500

G

SO2 in ppm

0 – 5000

H

CO converted*

CO corrected to reference O2%

I

NO converted*

NO corrected to reference O2%

J

NO2 converted*

NO2 corrected to reference O2%

K

NOX converted*

NOx corrected to reference O2%

L

SO2 converted*

SO2 corrected to reference O2%

M

T. Gas in °C or °F

0 – max temp.

N

T. Air in °C or °F

0 – max temp.

O

Draft in hPa

0.00 – 20.00

P

CO2 in vol.%

0.0 – 25.0

Q

Efficiency in %

0.0 – 120.0

R

Losses in %

0.0 – 100.0

S

Excess air

> 1.00

T

Dew point in °C or °F

0 – max temp.

U

Poisoning index

> 0.0

V

O2 (gas channel check) in vol.%

0.0 – 21.0

W

CO (gas channel check) in ppm

Related to 0.0 vol.% O2

X

CO (gas channel check) in ppm

Measured value

Y

O2 (O2 check) in vol.%

0.0 – 21.0

Z

T. Boiler

0 - 999

AA

T. Sensor

0 - 99

AB

O2 reference %

0.0 – 21.0

AC

Unit

0=ppm 1=mg/m3 2=mg/kWh 3=mg/MJ

AD

Norm

N = corrected to reference O2%

AE

Fuel type number

Index acc. to instrument table

AF

Fuel type text

Text acc. to instrument table

AG

Soot 1

0.0 – 9.9

AH

Soot 1

0.0 – 9.9

AI

Soot 1

0.0 – 9.9

AJ

Oil trace

0=no 1=yes

AK

20 characters text

AL

20 characters text

AM

16 characters text

AN

Serial number

AO

CO (O2 check) in ppm

AP

Zug (O2 check) in hPa

AQ

CxHy

AR

Number copy data

AS

T1 (T-measurement)

AT

T2 (T-measurement)

AU

Velocity

m/s

AV-AW

Comma

Reserved

AX

Comment text

AY

Comment text

AZ

Comment text

BA

Comment text

BB

H2 in ppm

BC

H2 converted*

H2 corrected to reference O2%

BD

Sensor # 6 in ppm

BE

Sensor 6 converted *

Sensor 6 corrected to reference O2%

BF

dP (velocity) in Pa

0 – 1000.00

BG

Air pressure in hPa

300 – 1100

BI-BM

Mass emissions

lbs/hr, gr/bhp, tons/year

BQ

Internal flow in lpm

0.00-3.00

* converted to unit (column AC) and converted on O2 ref. (Column AB) when column AD = N

Page 39

Page 39

22. Calculations

Note: A1, B, CO2max & Eta

max

are constants based on fuel type.

Excess Air (Lambda) Range=1-infinity

Excess air =

21

21 – O2 measured

Combustion Efficiency (Eta) Range=0-99.9%

Efficiency = Eta

max

- ( A1

+ B) x (T

Gas

– T

Air

)

CO2

Carbon Dioxide (CO2) Range=0-CO2max

CO2 = CO2 max

X (21 – O2 measured)

21

Losses Range=0-99.9%

Losses = 100 – Efficiency

O2 Correction Range=0-max

E

O2%

= E

meas

*

21 - O

2

reference

21 - O

2

measured

Page 40

Page 40

RUGGED. RELIABLE. ACCURATE.

ECOM AMERICA LTD

1628 OAKBROOK DRIVE

GAINESVILLE, GA 30507

TOLL FREE (877) 326-6411

PHONE (770) 532-3280

FAX (770) 532-3620

ecom.info@ecomusa.com

w w w . e c o m u s a . c o m

Loading...

Loading...