Page 1

Operating Instructions

The ecom-EN3 meets the requirements of the

DIN EN 50379 Part 2.

Page 2

SAFTEY INSTRUCTIONS

Please observe all safety instructions in this manual carefully, in order to avoid danger and

damage to people and property values.

REGULATIONS

The ecom-EN3 meets the requirements of:

- DIN EN 50379 Part 2

- VDI 4206 Sheet 1

Observe the relevant, valid standards, regulations and guidelines when working with the

instrument!

TARGET GROUP

This manual is intended exclusively for authorized professionals.

WARNING

Adjustments at burners and boilers should be made only by specialists who

are familiar with these installations.

Symbols

WARNING

Indicates that personal injury, or even life-threatening injury, may occur.

DANGER

Indicates how the hazard can be avoided.

Indicates that material damage can occur.

Indicates how the hazard can be avoided.

In both cases it is stated how the danger can be avoided.

Hints

Hints are marked with an information symbol.

Text sections marked with an arrow call for an action.

Page 2 ecom-EN3

Page 3

WARNING

The ecom

-

EN3 is explicitly NOT intended for the following applications:

or processes

DANGER

The following substances impair the instrument´s operation:

- Formaldehyde

Information on the instrument

INTENDED USE

The ecom-EN3 is designed for the following applications:

- Analysis of exhaust gases from combustion processes in combustion engines

and combustion plants in the context of control measurements

- Analysis of pressure differences in combustion engines and combustion plants

- CONTINUOUS analysis of exhaust gases from combustion processes

- Use as a safety device or safety alarm device in gaseous environments

- Solvent-containing vapours from cleaning agents,

degreasers, wax polishes, adhesives

The unauthorized use leads to the exclusion of any liability claims.

LIFE EXPECTANCIES SENSORS AND BATTERY

Following life expectancies apply to sensors and battery:

- O2 sensor: approx. 4 years

- CO sensor: approx. 4 years

- Li-Ion battery: approx. 2 years

CE DECLARATION OF CONFORMITY

The product complies with the relevant directives and is therefore CE marked. The

conformity declaration can be requested from the manufacturer.

HINT

Strong electromagnetic fields can impair the function of the measuring instrument.

Make sure that the measuring instrument is not exposed to strong

electromagnetic radiation sources.

DISPOSAL

- Dispose the packaging material of the instrument in an environmentally sound manner.

- Old electrical equipment must be disposed in an environmentally sound manner by an

authorized body. On request, we take back your old instrument purchased from us

and guarantee for an environmentally friendly disposal.

- Defective batteries can be dispensed both at the factory and at the collection

points of public waste disposal companies or at points of sale for rechargeable

batteries!

ecom-EN3

Page 3

Page 4

WARNING

Electric shock!

Current

-

carrying components at

open housing

!

instrument from the mains supply at all poles.

Before opening the instrument housing, disconnect the

WARNING

DANGER

The instrument is operated with a Li-Ion battery!

The replacement of the battery must be carried out only by qualified

personnel or by an ecom authorized service center.

Electrostatic discharge!

Electrostatic discharge can lead to damage to electronic components!

Before handling the housing, ensure that you are unloaded. To do

this, touch a grounded component (eg water pipes, radiators, etc.).

Page 4 ecom-EN3

Page 5

ecom-EN3

Page 5

Page 6

Content

Information on the instrument 3

1. Instrument Design 8

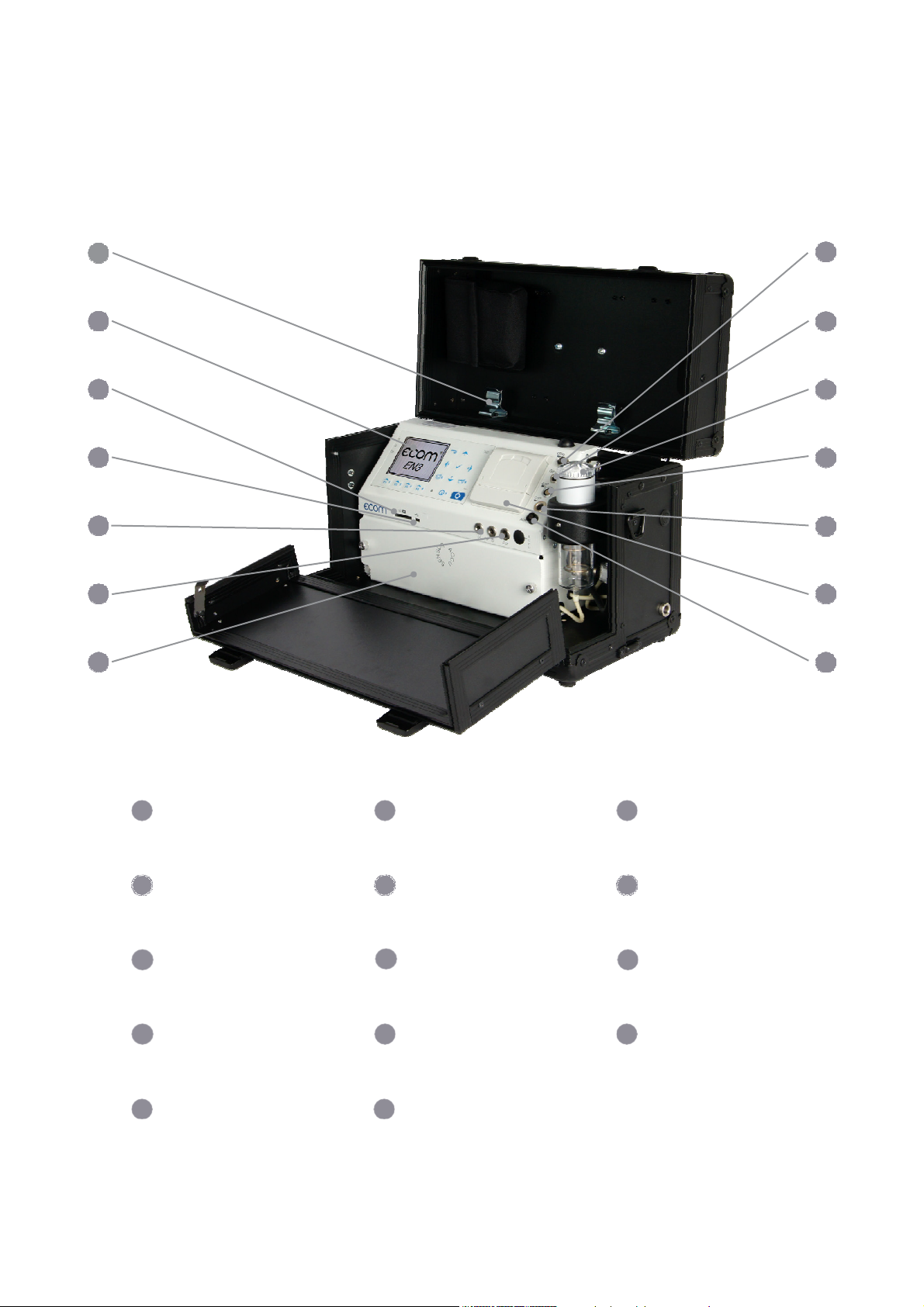

1.1 ecom-EN3/-R, Transport variant aluminium-framed transport case 8

1.2 ecom-EN3-F, Transport variant professional case 9

1.3 ecom-EN3, Keyboard controls 10

1.4 ecom-EN3, Connections at the instrument 11

1.5 ecom-EN3, Option heated probe for soot measurement 12

1.6 ecom-EN3, Option hand soot pump set 13

1.7 Gas Cooler (Option) 14

1.8 Data Memory 15

1.9 ecom-EN3, Option Interfac Wi-Fi (WLAN) 16

1.10 ecom-EN3, Option interface BLE (Bluetooth Low Energy) 16

2. Measurement Preparations 17

2.1 Turn on the instrument and check the battery 17

2.2 Navigation in the menu 18

2.3 Calibration of the sensors, use of the database and fuel type selection 19

3. Carry out gas analysis 21

4. Measurement procedure gas analysis 22

4.1 Gas analysis 22

4.1.1 Adaptation of the displays for gas analysis 23

4.1.2 Positioning the probe, search the core stream 23

4.1.3 Printing measured values 24

4.1.4 CO-Overload Protcektion 25

4.2 Measurement procedure gas analysis: CO measurement 26

4.3 Measurement procedure gas analysis: O2 Check 27

4.4 Measurement procedure gas analysis: Draught measurement 27

4.5 Measurement procedure gas analysis: Flow measurement pitot tube (option) 28

4.6 Measurement procedure gas analysis: Soot...Oil trace 28

4.6.1 Soot measurement 29

4.6.2 Oil trace 29

4.7 Measurement procedure gas analysis: Data processing 30

4.7.1 Create new 30

4.7.2 Memory number 31

4.7.3 Search word 32

5. Measurement procedure mean values 33

6. Measurement procedure Diagnostics 35

6.1 Fault diagnostic 35

6.2 delta-T Measurement 37

6.3 Heating Check (option) 38

6.4 4 Pa Measurement (option) 41

6.5 Pressure Tests (option) 42

6.5.1 Pressure Test 43

6.5.2 Loading Test 44

6.5.3 Tightness Test 45

6.5.4 Usage property 46

Page 6 ecom-EN3

Page 7

7. After Measurement 48

7.1 Save measurement, print measurement 48

7.2 To-Dos before switching off 49

8. Control 50

9. Adjustments 51

10. Data processing 56

10.1 Storage on MM card 56

10.2 Data logger 57

10.3 Data connection to PC 58

10.3.1 Data recording with PC Software ecom-DAS NT 2 58

10.3.2 Data recording with PC Software ecom-DAS 5 59

10.3.3 Data recording with PC Software: Import and Export of Data 60

10.4 Data recording with App via WiFi 61

10.5 Data recording with App via BLE 62

11. Maintenance Tips 63

11.1 Fine dust filter 63

11.2 Gas sensors 64

11.3 Probe and tubing 64

11.4 Printer paper 65

11.5 Air leak test 66

12. Technical Data 67

ecom-EN3

Page 7

Page 8

1. Instrument Design

1

2

3

1

2

3 4 5 6

7

10

12

14

1.1 ecom-EN3/-R, Transport variant aluminium-framed transport case

Holding clamp for

the probe

Graphic display

Slot for multi-media

card (SD)

8

9

11

13

Page 8

4

Connection USB

7

Battery and sensors

compartment

10

Condensation trap (with

peltier cooler) with fine

dust filter

13

Integral thermal printer

5

Connections for Pa

pressure sensor

8

Connection sampled gas

11

Connection gas temperature

14

Connection AUX

6

9

12

Connection pressure

Connection draught

Connection air

temperature

ecom-EN3

Page 9

1 2

3

4 5 6 7

11

13 14

6

10

11 12

13

14

Connection USB

1.2 ecom-EN3-F, Transport variant professional case

Holding clamp for

1

the probe

Battery and sensors

2

compartment

Graphic display

3

8

9

10

12

4

7

ecom-EN3

Connection

Pressure

Condensation trap

(with Peltier cooler)

with fine dust filter

Connection air

temperature

Connections for Pa

5

pressure sensor

Integral thermal printer

8

Connection draught

Connection AUX

Slot for multi-media

card (SD)

Connection sampled gas

9

Connection gas

temperature

Page 9

Page 10

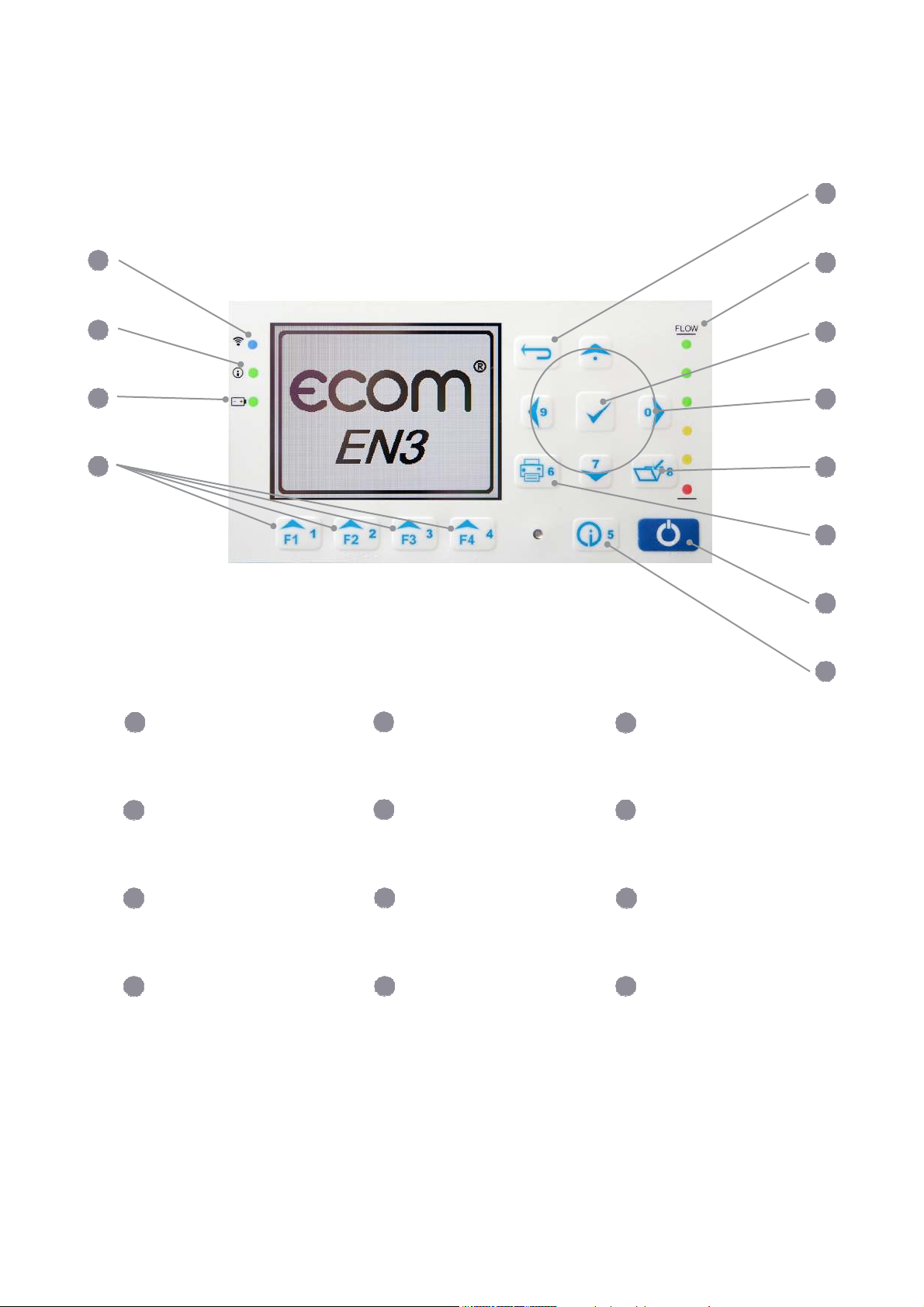

1.3 ecom-EN3, Keyboard controls

5 8 9 10 11 12

8 9

10

11 12

Battery LED to display the

Enter key (confirm

1

6

2

7

3

4

Connection LED (active with

1

existing BT or WiFi connection)

Info LED to display the

2

device status

3

charge state

Page 10

Function key (function

4

shown on display)

7

selection)

Print key

ESC key (quit/exit menu)

5

Digital flowmeter

6

Cursor keys

Save key

(Up/Down/Right/Left/Scroll)

ON / OFF key

Info key (access to control

menu)

ecom-EN3

Page 11

4

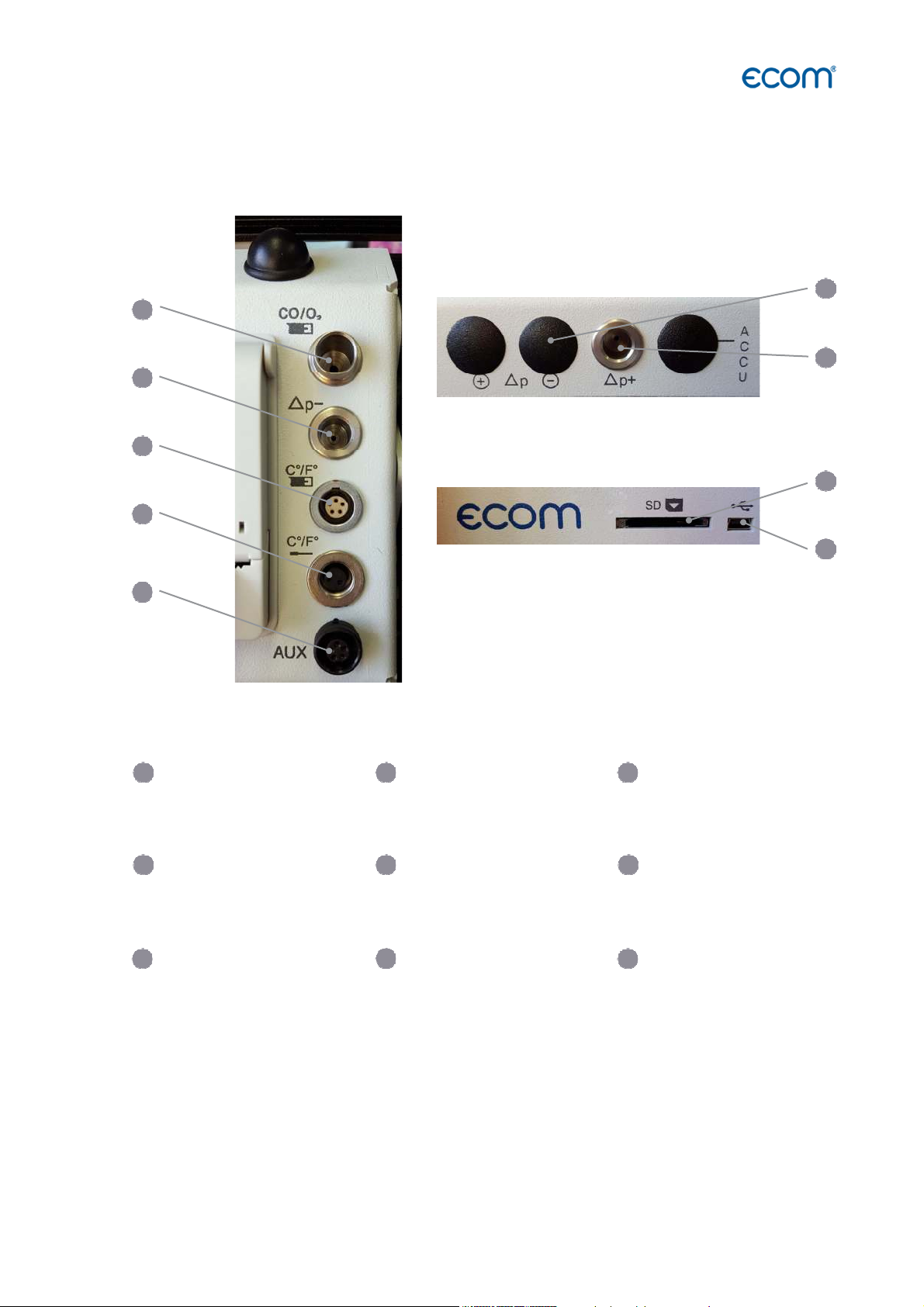

1.4 ecom-EN3, Connections at the instrument

1

2

3

4

5

1

Connection sampled gas Connection draught

2 3

Connection gas temperature

6

7

8

9

Connection air temperature Connection AUX Connection Pa-Sensor

7 9

Connection pressure

ecom-EN3

5 6

8

Slot for multi-media

card

Connection

USB

Page 11

Page 12

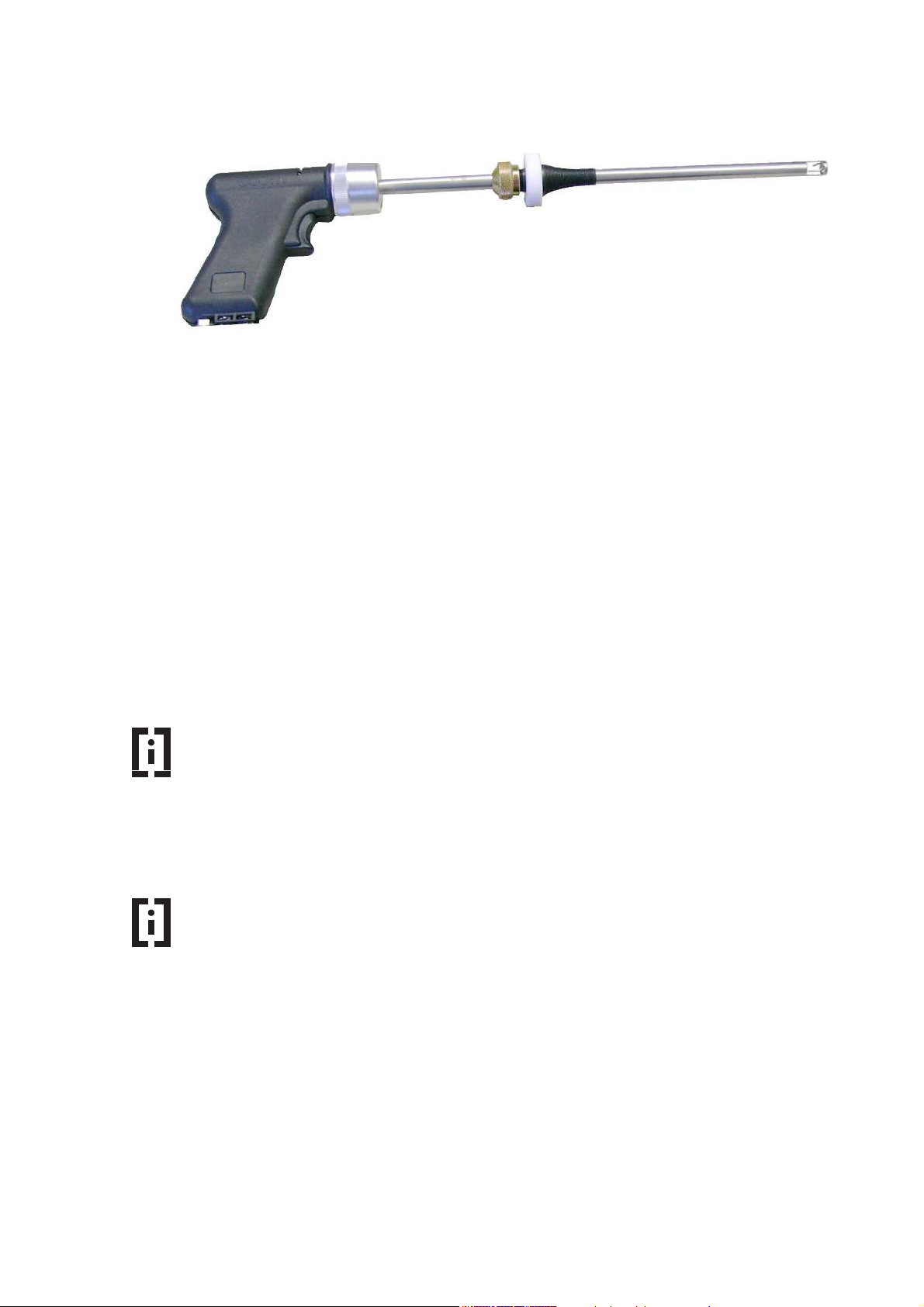

1.5 ecom-EN3, Option heated probe for soot measurement

Heated probe for soot measurement

In order to perform a measurement of the soot content in the flue gas from oil firing systems,

a filter paper is introduced into the exhaust path of the probe where the soot deposits during

the measurement.

On the basis of the deposited amount of soot on the filter paper (blackening), it is possible to

compare optically with a scale, which is the soot number. This makes it possible to evaluate

the amount of soot in the flue gas.

The filter paper is heated in the probe to prevent the flue gas from cooling too much. This

cooling of the flue gas would lead to condensation of water vapour from the flue gas and will

distort the result of the measurement.

Hint

As an alternative to the heated probe, a hand soot pump can be used. The

possible condensation of water vapour is however not prevented with a hand

soot pump.

Hint

For further information on the procedure for soot measurement with the heated

probe, please refer to chapter "4.7 Soot...Oil trace"

Page 12

ecom-EN3

Page 13

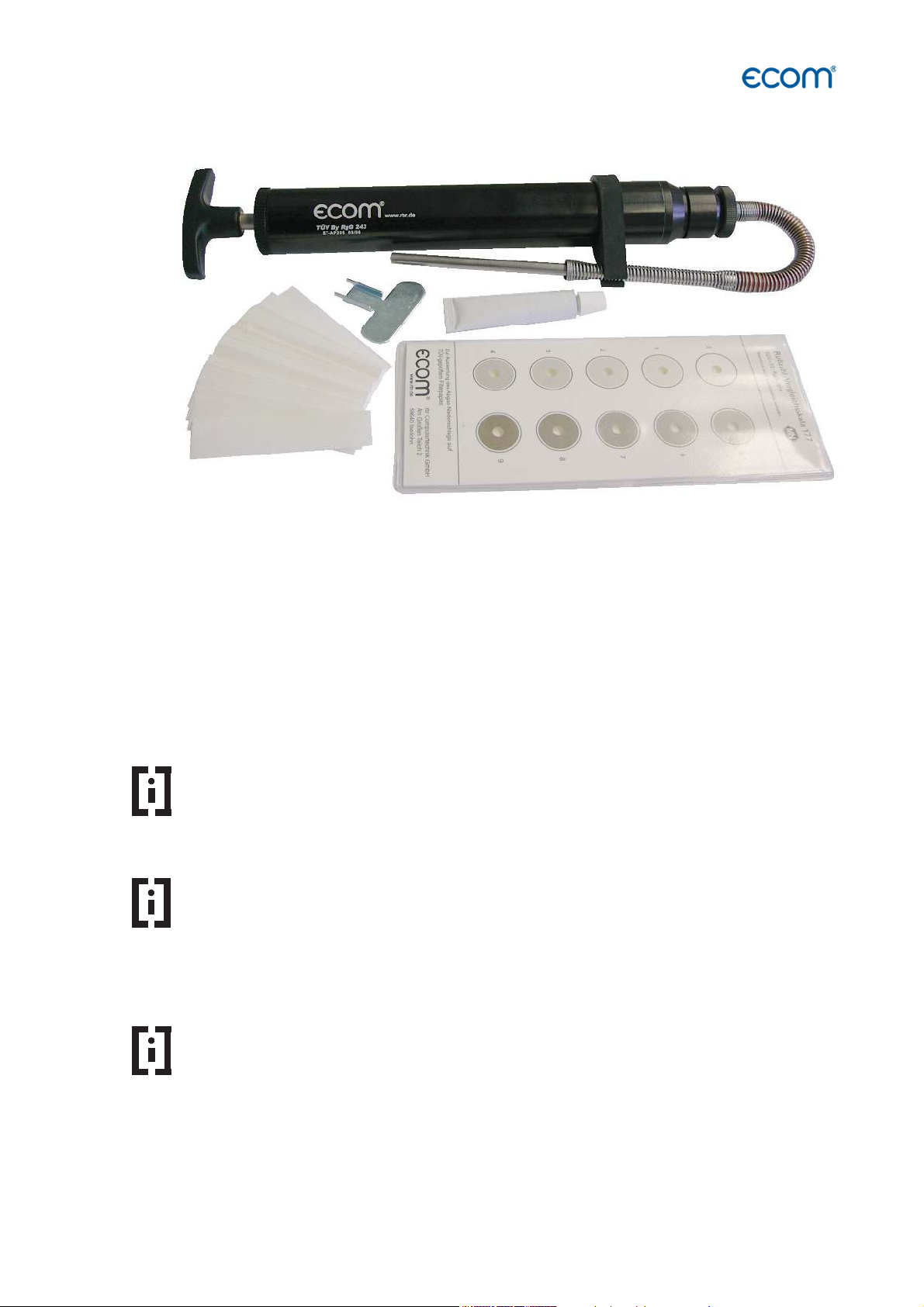

1.6 ecom-EN3, Option hand soot pump set

Hand soot pump set

In order to perform a soot measurement in the flue gas from oil firing systems, a hand soot

pump can be used.

By a prescribed number of suction strokes with the hand soot pump, a defined amount of flue

gas is drawn through an inserted filter paper. On the basis of the deposited amount of soot

on the filter paper (blackening), it is possible to compare optically with a scale, which is the

soot number. This makes it possible to evaluate the amount of soot in the flue gas.

Hint

The hand soot pump is TÜV tested and characterized by high quality in its

processing and construction. This guarantees a long-term reliable function.

Hint

As an alternative to the hand soot pump, a heated probe can be connected

directly to the measuring instrument. With this heated probe, the possible

condensation of water vapour and thus falsification of the measuring result

can be reliably prevented.

Hint

For further information on the procedure for soot measurement with the hand

soot pump, please refer to the manual for the hand soot pump set.

ecom-EN3

Page 13

Page 14

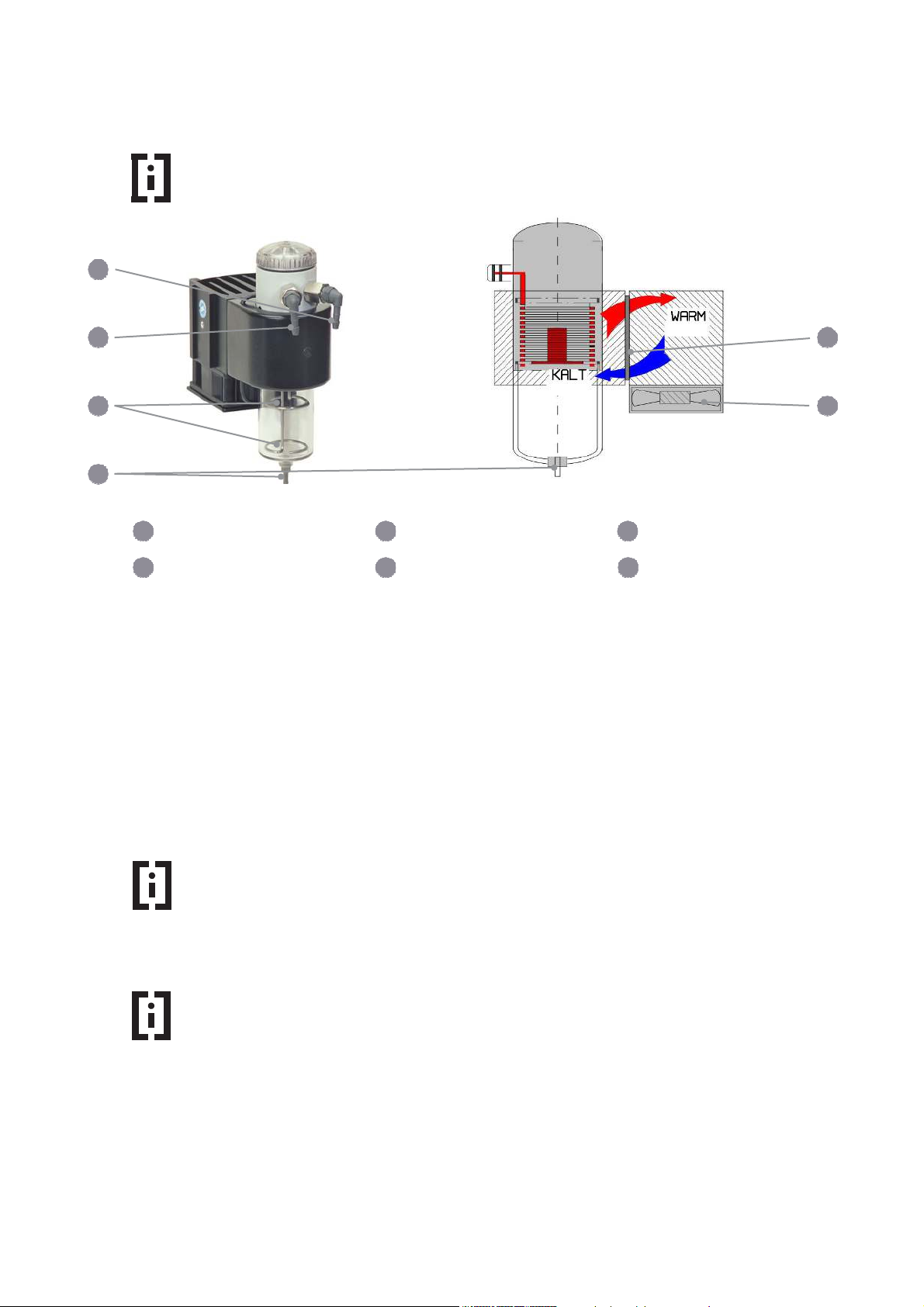

1.7 Gas Cooler (option)

6 1 4

Hint

The ecom-EN3-F transport variant professional case is standard with a gas

cooler.

1

2

3

4

5

Gas outlet Gas inlet Level monitoring

Condensate

evacuation

Exhaust gas with a temperature over the steam dew point (35 - 65 °C) is flown spiral via a

long gas path thru a surface coated metal body with good thermal conductivity. The gas

radiates its heat to this metal body. A Peltier element (semi-conductor cooling element) flown

by a continuous current is thermal connected with this body and with a second metal body

with cooling ribs and ventilation slots.

The flow thru the Peltier element creates a heat transfer from WARM to COLD, drains the

heat of the metal body flown by gas and conveys it to the outer cooling body. This heat is

conveyed thru a vertical forced ventilation to the surrounding air.

The condensation issued by the heat loss of the gas drops in a receptacle and is pumped out

on request by a periodically working hose pump.

2 3

5 6

Peltier element Fan

Hint

When the gas cooler is active, the power requirement of the instrument

increases considerably. Therefore the cooling capacity of the gas cooler in the

battery operation is reduced.

Hint

The gas cooler can be deactivated in battery operation.

To deactivate the activated gas cooler, press the <Enter>

key when the measuring menu is active. Choose the menu

point "Peltier I / 0" and press the <Enter> key again.

To reactivate the deactivated gas cooler, repeat the

above steps.

Page 14

ecom-EN3

Page 15

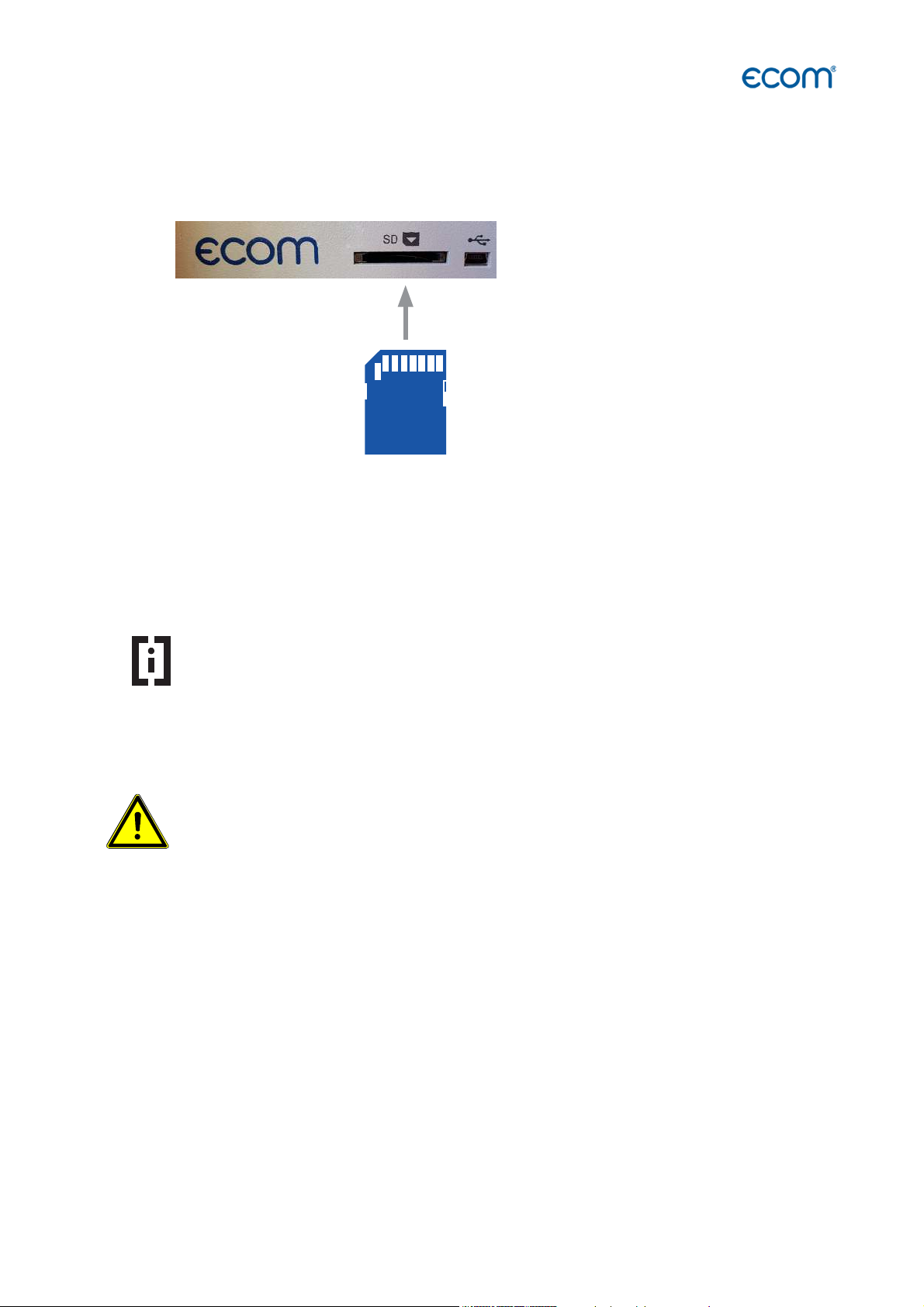

1.8 Data Memory

When an SD card is inserted into the device, point measurements and data logger records

can be stored.

Insert SD card as shown

°

To start point measurements or data logger records, insert the SD card as

shown in the SD card slot and let it fully engage.

WARNING

All values of a point measurement are stored in a text file with the name "J2KDV-xx.txt". The

text file is stored automatically in the main directory of the SD card.

All values of a data logger record are stored in a csv file with the naming

"J2KDL-xx.csv". Sequential files are automatically numbered from 0 ... 99.

The data in the text file and the csv file are stored in the same structure.

You will find further information on the data format in the chapter "Technical data".

The files can be transferred to a PC using a card reader. Both file types can be imported or

opened using MS Excel.

Hint

The SD card must have the following characteristics:

- min. card volume 32 MB - max.32 GB (UHC)

- card formatted on 16 bit FAT or FAT32

Never pull out cards during data record - data loss and damaging of the multimedia-card are possible!

ecom-EN3

Page 15

Page 16

1.9 ecom-EN3, Option Interface Wi-Fi (WLAN)

If the instrument is equipped with the Wi-Fi option, this interface can be used to display the

current measured values in an App of ecom. The following functions can be used in the App:

- Live display of current measured values

- Export of stored measured values as * .pdf or * .csv

- Activate the function "Print measured values" on the measuring instrument

- Activate the function "fresh air purge CO sensor" on the measuring instrument

Hint

For the start-up of the Wi-Fi interface and for further information on the

corresponding settings, please refer to the chapter "Adjustments".

1.10 ecom-EN3, Option interface BLE (Bluetooth Low Energy)

If the device is equipped with the BLE option, this interface can be used to display the current

measured values in an App of ecom. The following functions can be used in the App:

- Live display of current measured values

- Export of the stored measured values as * .pdf or * .csv

- Activate the function "Print measured values" on the measuring instrument

- Activate the function "fresh air purge CO sensor" on the measuring instrument

Hint

For the start-up of the BLE interface and for further information on the

corresponding settings, please refer to the chapter "Adjustments".

Page 16

ecom-EN3

Page 17

2. Measurement Preparations

Hint

Make sure that before each measurement

- the device has no visible defects

- the measuring system is tight (see leak test chapter 11.5)

2.1 Turn on the instrument and check the battery

The instrument is switched on with the <I / 0> key.

Hint

After switching on the instrument or before starting a measurement, check the

charging status of the battery.

Check the charging status of the battery in the status line and /

or in the menu "Control".

The instrument is supplied with charging power supply. The instrument can also be operated

with the internal battery for an extended period of time.

When recharging the battery is necessary, the instrument will emit a battery warning. This is

done acoustically and via a message in the display.

Hint

The battery warning is activated when the battery voltage is less than 6.5

V. Less than 6.0 V the operation with battery is no longer possible

The operation must continue via the charging power

supply.

WARNING

ecom-EN3

The instrument is operated with a Li-Ion battery!

The battery must be replaced only by qualified personnel or by ecom or an

ecom authorized service center.

Page 17

Page 18

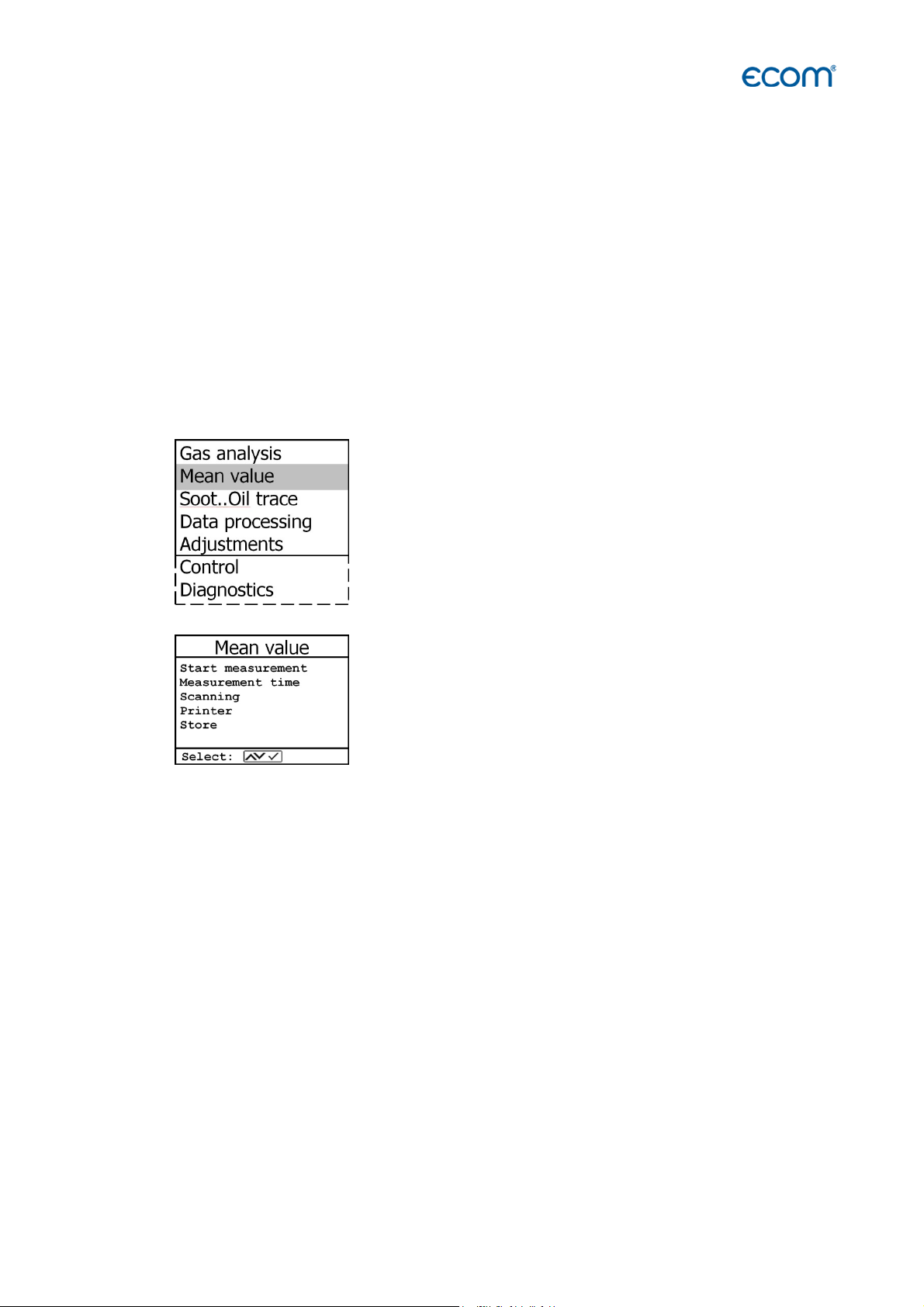

2.2 Navigation in the menu

Gas analysis

When the instrument is switched on, the start screen is displayed, followed by the main menu.

Soot..Oil trace

Data processing

Adjustments

Control

Diagnostics

menu. Hidden submenus can be displayed by scrolling with

the arrow keys.

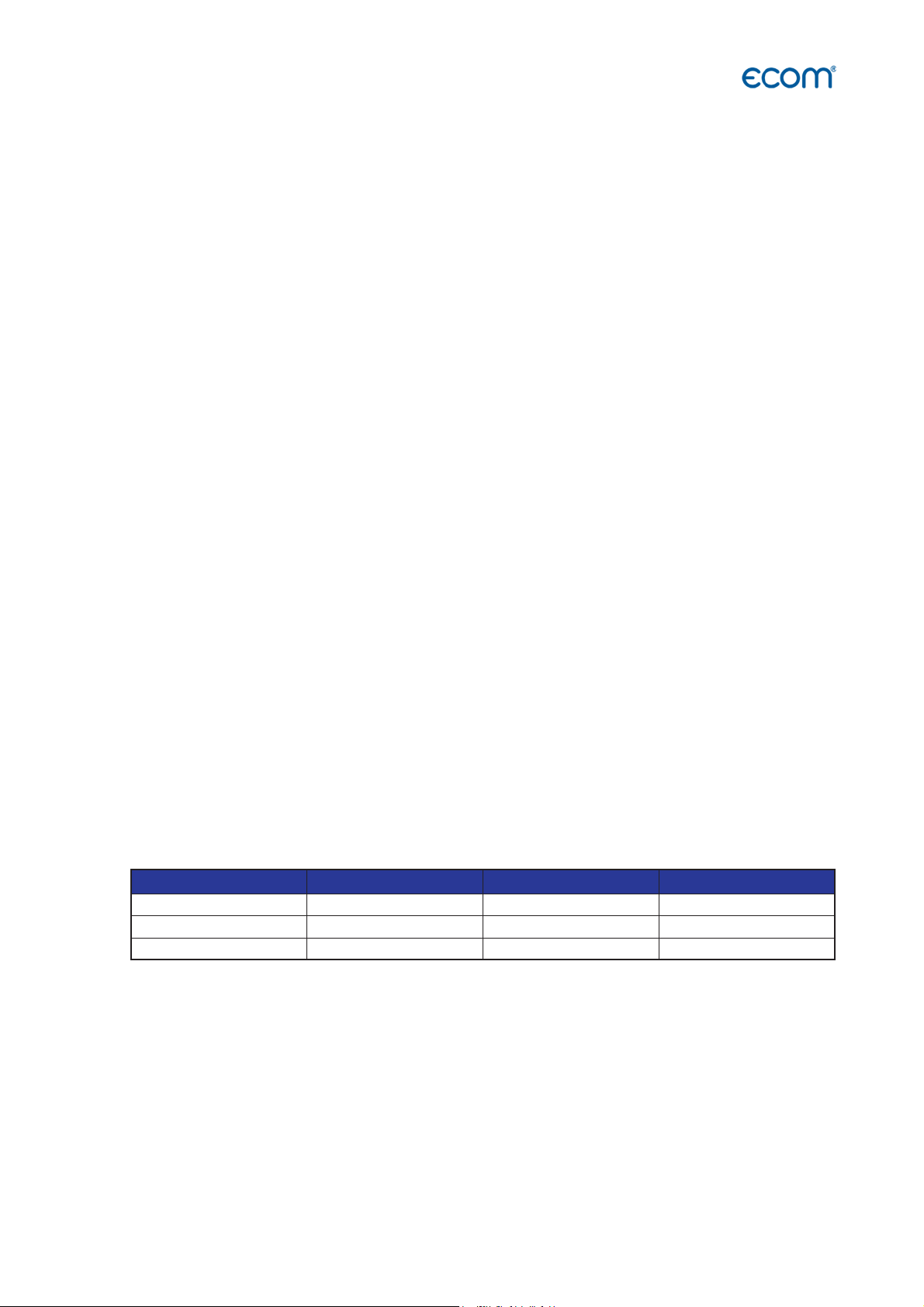

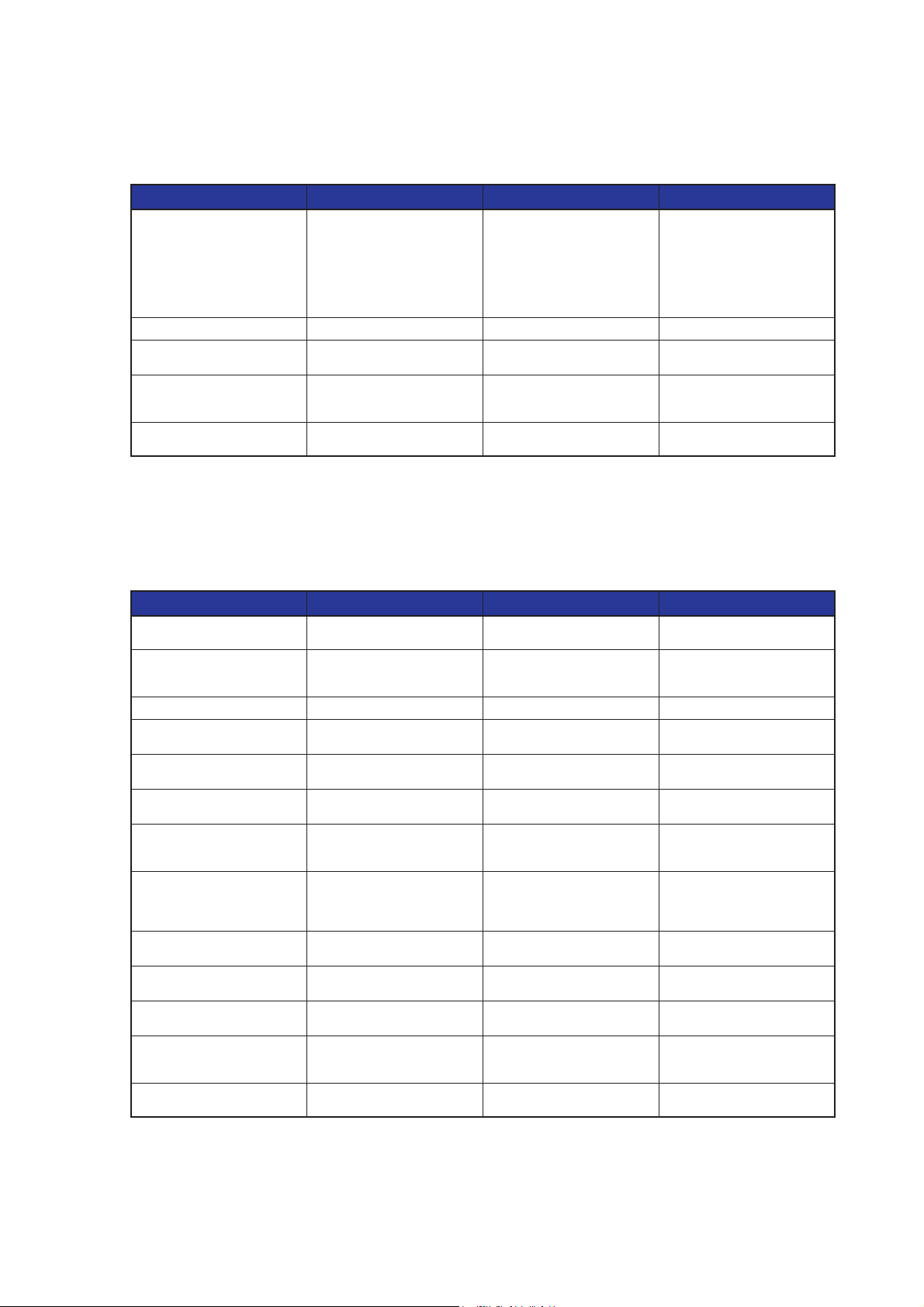

Menu Meaning Comment

Up to 5 submenus are displayed simultaneously in the main

Gas analysis Perform gas analysis

Mean value Perform gas analysis with mean value calculation

Soot...Oil trace Input of soot measurement results Start soot measurement (units with soot

Data processing Assign measurements / Data transfer only with inserted MM card

Adjustments Modify instrument adjustments

Control Check operation state of instrument

Diagnostics - Read-out of firing automate Only with ecom-AK

- delta-T measurement

- Heating check

- 4 Pa test

measurement)

Page 18

ecom-EN3

Page 19

YES

NO

CO2max

A1

B

15.4 0.50 0.007

Select:

2.3 Calibration of the sensors, use of the database and fuel type selection

Before you can start the measurement procedures, the instrument performs the following

steps:

1. Automatic adjustment of the sensors (calibration phase)

2. Query: Use of the database

3. Query: Selection of the fuel type

Select the sub-menu "Gas analysis" and confirm with <Enter>.

The instrument starts the automatic calibration of the sensors (calibration phase). This

calibration phase is completed after 60 s.

Hint

Position the probe only in the exhaust pipe when the calibration phase of 60 s

has been completed!

While the calibration phase is active, the query for using the

Do you wish to

use the data

processing?

Select:

database is displayed:

If the measured values of the subsequent gas analysis are to

be assigned to a plant or a customer, confirm the query with

"Yes".

Press the <F1> key.

For the following steps see chapter "4.8 Data processing during the measurement"

If the measured values of the subsequent gas analysis are not to be assigned to a plant or to

a customer, e.g. for a fast control measurement, confirm the query with "No".

Press the <F1> key.

Then select which fuel type is used in the combustion.

Fuel type

Fuel oil

To scroll through the list of fuel types stored in the

instrument, scroll up or down with the arrow keys.

Select the appropriate fuel by confirming with the

<Enter> key.

ecom-EN3

Page 19

Page 20

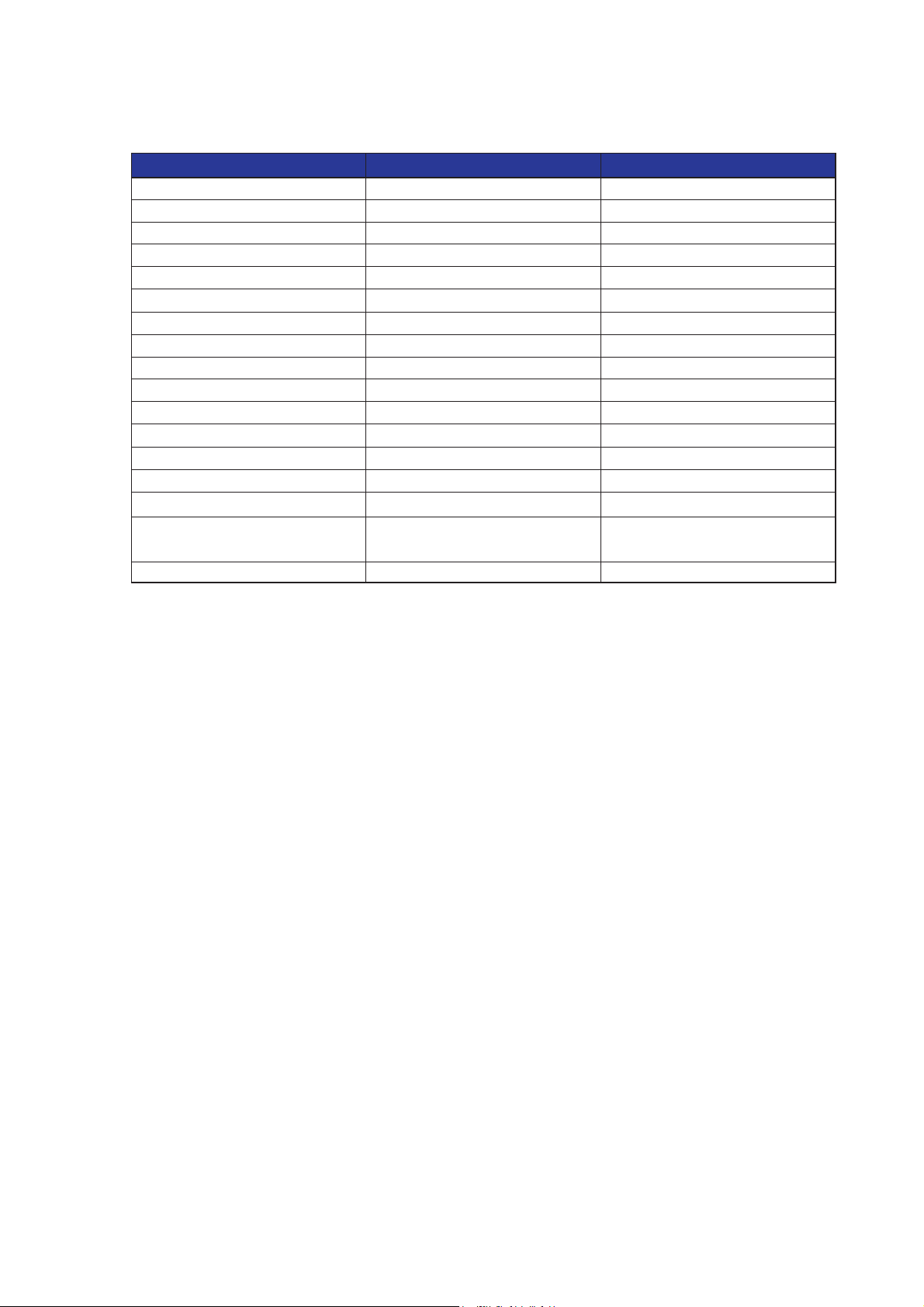

The following fuel types are stored in the instrument as standard:

Fuel type CO2 max Factor A2 Factor B

Fuel oil 15,4 0,68 0,007

Natural gas 11,8 0,66 0,009

City gas 11,7 0,63 0,011

Coke oven gas 10,2 0,60 0,011

Liquid gas 14,0 0,63 0,008

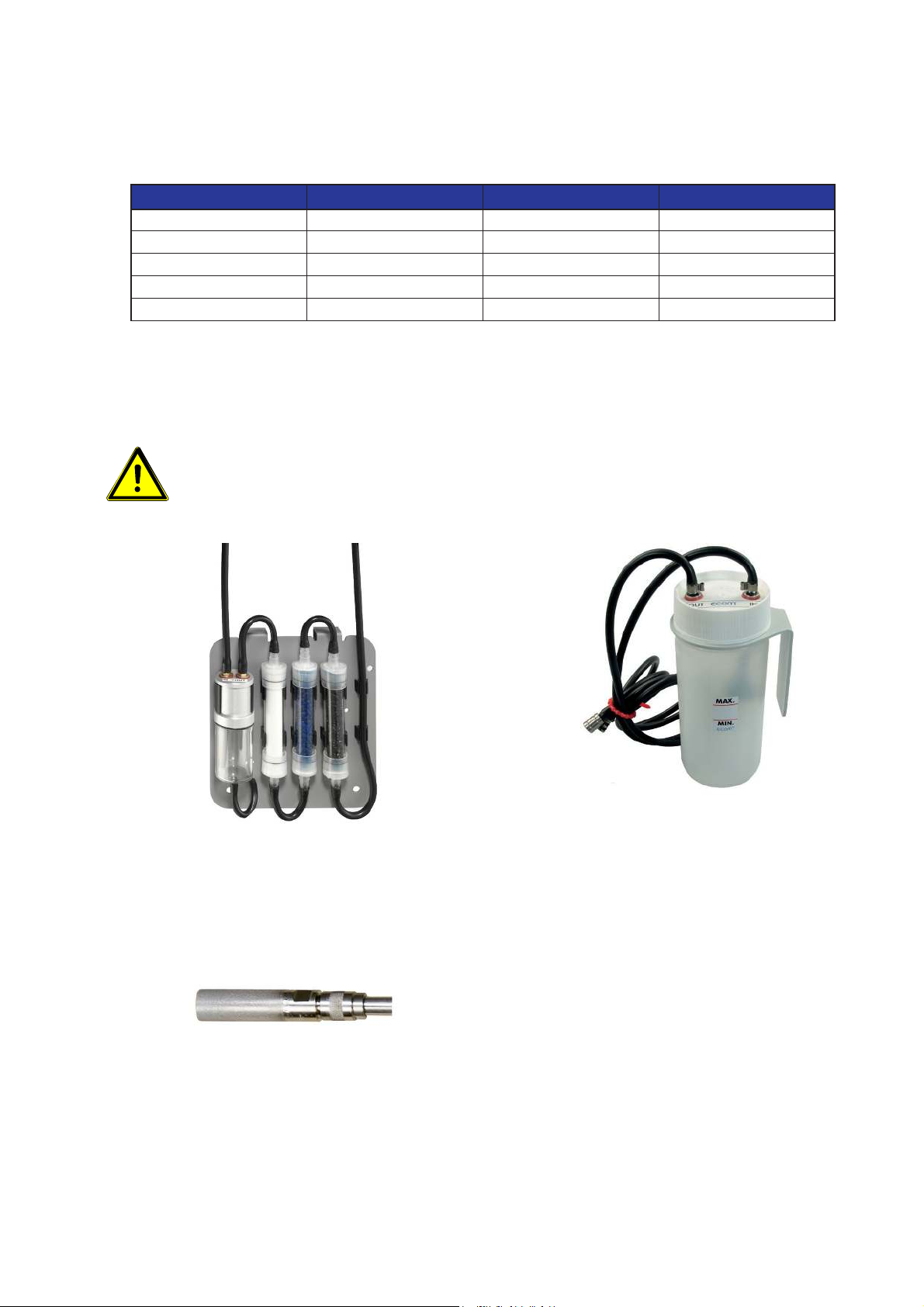

WARNING

For the combustion of solid fuels (wood / pellets / wood chips), a filtering

device recommended by ecom must always be used (see illustration)!

Filter plate for combustion of solid fuels Washing bottle for combustion of solid fuels

Probe prefilter

Page 20

ecom-EN3

Page 21

3. Carry out gas analysis

If the calibration has been successfully completed and all previous queries have been

answered, the instrument is ready for operation.

Hint

The following minimum times must be observed in order to obtain correct

measured values:

- 1 minute for fresh air calibration of the sensors

- 2 minutes for stable measured values at the instrument

Hint

To obtain accurate measurement values it’s important to re-calibrate the

instrument after each measurement (at the latest after one hour)!

- Switch off the instrument and wait for the switch off phase

- Switch on the device and refer to chapter "2. Measurement Preparations".

The current measured values of the active sensors are displayed in the measurement menu.

In addition, various measuring procedures are available:

Display Meaning Comment

Gas analysis 1 Display of 4 definable measured values Select the measured values with the <F4>

Gas analysis 2 Display of 4 definable measured values Select the measured values with the <F4>

Gas analysis 3 Display of 8 definable measured values Select the measured values with the <F4>

CO measurement Display of 4 measured values for testing CO with O2 reference Gas path check

O2 Check

Draught

measurement

Display of 3 measured values for testing the O2 in combustion air Set the zero point of the pressure sensor

Display of the measured value Draught / Pressure and storing a

reference value

To calibrate the sensors, proceed as follows:

key

key

key

with the <F4> key

While this measurement procedure is

active, the gas pump remains inactive

Set the zero point of the pressure sensor

with the <F4> key

Storing a reference value with <save>

Flow measurement

Display of 3 measured values for testing the flow inside an exhaust

pipe

Set the zero point of the pressure sensor

with the <F4> key

Enter the cross-section in the exhaust pipe

with the <F1> key

Hint

For a detailed description of the individual measuring procedures, see the

following sections.

ecom-EN3

Page 21

Page 22

4. Measurement procedure gas analysis

5 1 2 3

4 5

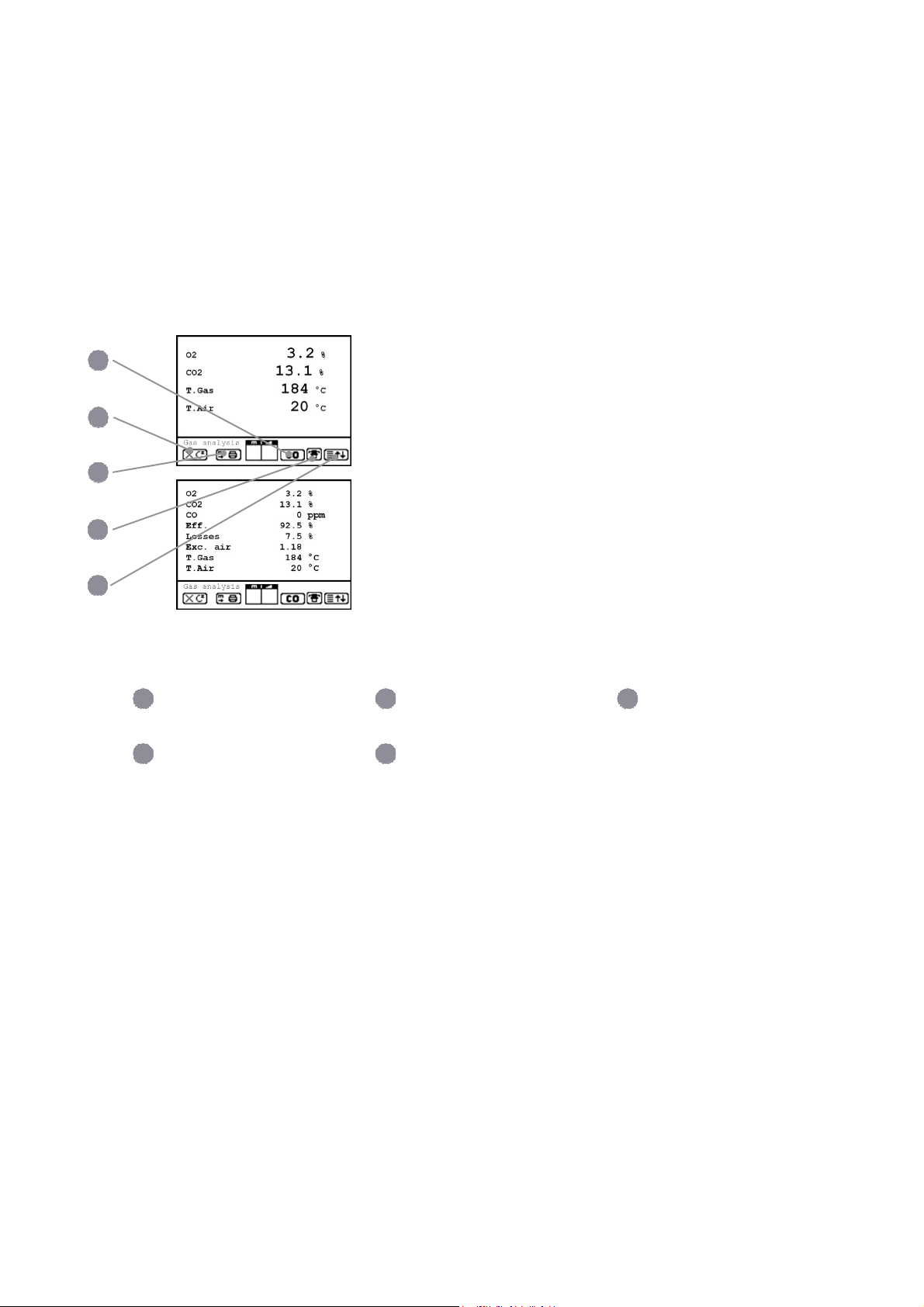

4.1 Gas analysis

The measurement procedure for gas analysis can be used for most control measurements in

order to determine the gas components, temperatures and ratios in the measured

combustion process.

Design of the measurement displays gas analysis 1..3

The following measurement displays are available for the gas analysis procedure:

Measurement display: Gas analysis 1 + 2

Measurement display: Gas analysis 3

1

Switch-off CO-Sensor

key <F3>

4

Symbol cooler ON /OFF

The following functions are available in all 3 measurement displays:

Pressing <F1> enables to switch, from the values display, to a menu point selected before or

on „Standby“ (see chapter Adjustments). Possible menu points are: Soot...Oil trace, Data

processing, View memory, Display values, Fuel type, Efficiency (K), Internal, Adjustments.

Furthermore you can switch back from any random menu point to the values display with

<F1>.

Press <F2> to print out the values simultaneously to their recording in the intermediate

memory.

Press <F3> to cut the CO sensor from the gas path so that it is protected against too high

concentrations.

Pressing <F4> also enables to switch, from the values display, to a menu point selected

before or on „Standby“ (see chapter Adjustments).

2 3

Hotkey key <F1>

Hotkey key <F4>

Store and print values

key <F2>

Page 22

ecom-EN3

Page 23

4.1.1 Adaptation of the displays for gas analysis

Hint

The position of the measured and calculated values (gas analysis sub-menu)

on the display pages is free selectable

For alteration of the existing succession, proceed as follows:

- Press <Enter> / „Display values“ / <Enter> to activate the function

- Select line with cursor keys (Up/Down)

- Select desired parameter with cursor keys (Right/Left)

- Repeat procedure until desired layout is completed

- Press <Enter> to deactivate the function

4.1.2 Positioning the probe, search the core stream

Hint

The correct positioning of the probe in the gas stream is necessary in order to

achieve an impressive measuring result.

To correctly position the probe in the gas stream, proceed as follows:

- Connect the probe hose to the device "connection gas temperature"

- Position the sampling probe in the exhaust channel, so that the thermocouple is fully

1

3

1

4

If an arrow in downwards direction is displayed, it means you move the probe away from the

core stream and the temperature sinks.

surrounded with the gas (see drawing).

Gas stream Protection bow Probe tip

2

3

Position the sampling probe in the exhaust channel

(Position in the hottest gas temperature area).

Observe trend for T.Gas in the measurement display.

As long as the display shows an arrow in upwards

direction, the measured temperature increases, it means

the probe tip moves towards the core stream center.

Core stream search

2

ecom-EN3

Page 23

Page 24

, efficiency, losses, excess air and dew point are calculated values. They can only be

CO

2

calculated if realistic values for the basic parameters like O2 and the temperatures are

available. It must be ascertained that:

O2 < 20,7 % and T.Gas - T.Air > 0 °C

are given. If the gas temperature falls below the dew point (between 25 and 65 °C), so

efficiency will be calculated with condensation gain. In this case a (K) is displayed after

„Efficiency“. Correct measurement values are displayed first after a short delay, necessary

for the gas transport and the build-up of a stable electrochemical reaction to the sensors.

This time period lasts approx. 1 to 1.5 minute. For recording, printout and evaluation, wait

until the values do not change anymore. If deviations higher than 2 ppm still occur by the gas

values, they can be due to unstable pressure conditions in the exhaust channel.

If the measurement values are stable and the results can

be printed out, press the key <Save> to transfer the

values in the intermediate memory (caution: store

separately gas analysis, CO, O2 check and draught

measurements). They will be kept there for a later printout

and, if need be, for a final data record storage.

1

Measurement stored in intermediate memory

4.1.3 Printing measured values

There are two ways to print measurements:

1. Print of the measurements stored in intermediate memory

To print the measured values stored in the previous step, press the <Print> key. The

complete content of the intermediate memory will be printed.

2. Printing the currently displayed values, including storage in intermediate memory

To print the measured values currently displayed, press the key <F2>. At the same time the

measured values are stored and overwrite existing intermediate stored values.

Hint

Use the option "Print the currently displayed values" to adjust the time of optimal

measurement results and to print them immediately.

Page 24

ecom-EN3

Page 25

WARNING

4.1.4 CO-Overload Protection

The CO sensor is protected against overload by the system.

If the limit of 4000 ppm at the CO sensor is exceeded, the internal additional fresh air purging

pump is switched on, which supplies fresh air to the CO sensor.

When the CO overload protection is active, the CO indicator flashes in the status bar of the

measurement screen, and the <Info> status LED changes from "green" to "red".

If the opening for the supply of fresh air to the CO sensor is closed, the

sensor can not be purged with fresh air and will be damaged or destroyed

during overload.

1

Do not lock fresh air opening for fresh air pump!

1

Fresh air opening

If the CO sensor has been purged sufficiently with fresh air (X disappears behind CO) and

the measured values are within the permissible range, the fresh air flushing pump is switched

off.

The CO indicator in the status bar of the measurement screen no longer flashes and the

status LED <Info> changes from "red" to "green".

Hint

The "CO automatic" option can be used to set how the fresh air flushing pump is

switched off after sufficient purging of the CO sensor:

- automatically

- must be triggered manually

To deactivate the CO automatic option, deactivate the

corresponding option in the menu Adjustments \ Internal \ COAutomatic with "No".

To switch off the fresh air flushing pump with the CO automatic

deactivated, press the <F3 <key.

ecom-EN3

Page 25

Page 26

Page 27

4.2 Measurement procedure gas analysis: CO measurement

The gas channel check, called also CO measurement, is used for the technical check of gasfired plants in regards of safety aspects. Hereby the CO concentration in the gas channel is

measured after the flow safety device and calculated on an undiluted value (oxygen rest

content in flue gas = 0%). As the gas conditions after the flow safety device are no more

homogeneous because of the flow in of secondary air and consequently the core stream

measurement can be erratic, the analysis of the exhaust gas is performed along the totality of

the exhaust pipe diameter. A multi-hole probe (optional accessory) is hereby used as

sampling probe.

The calculated value shown on the line „CO 0 %“ corresponds to the measured CO

concentration supposed the oxygen content would amount 0% by the same exhaust gas

volume. It is consequently the undiluted CO content in exhaust gas. If the values indication is

stable, press <Record> to store the result in the intermediate memory. If a printout of the

values should occur simultaneously to the recording in the intermediate memory press <F2>

(the complete content of the intermediate memory will be printed out).

1

Measurement stored in intermediate memory

4.3 Measurement procedure gas analysis: O2 Check

This measurement is performed by room-independent plants like gross calorific value plants.

It is determined if exhaust gas flows into the combustion air (O2 content drops down / CO

content can be present) and herewith influence on the combustion quality. For this analysis,

a special multi-hole probe (optional accessory) should be used. If the value indicated is

stable, press <Save> to store the value in the intermediate memory. If a printout of the values

should occur simultaneously to the recording in the intermediate memory, press <F2> (the

complete content of the intermediate memory will be printed out).

Measurement display: O2 Check

ecom-EN3

Page 27

Page 28

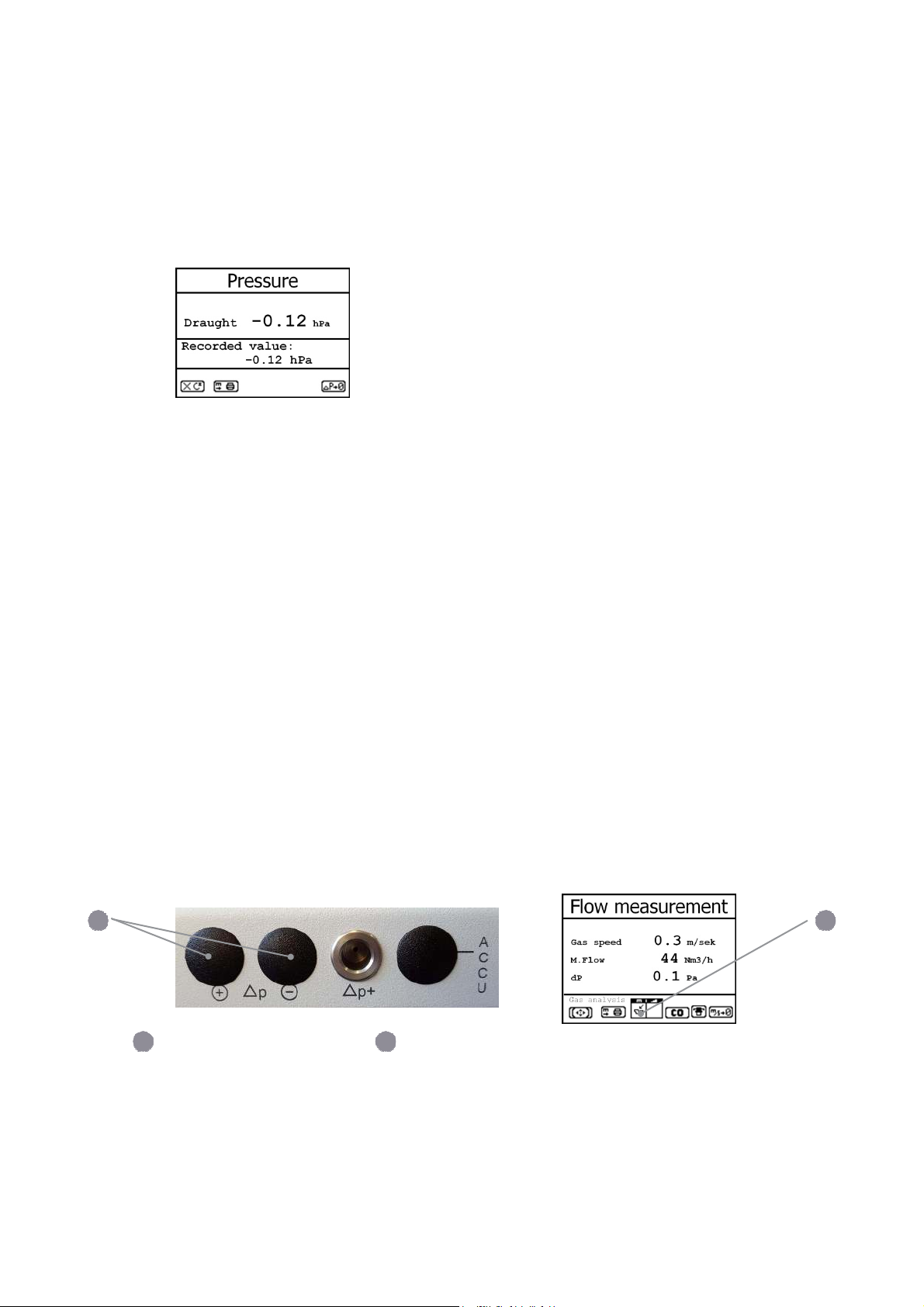

4.4 Measurement procedure gas analysis: Draught measurement

1

A trend indication for the draught conditions in the exhaust channel can already be viewed

during the gas analysis. Nevertheless the value for the chimney draught will not be stored

together with the gas values while pressing <Save> because the differential pressure sensor

tends to drifts because of its sensibility. For an exact measurement, it is consequently

advised to re-calibrate this sensor just before sampling and documenting the value.

The display shows the current value as well as the recommendation to re-set the zero point

of the sensor. Disconnect the draught hose from the instrument for a short moment and

press <F4>. The sensor is herewith re-calibrated.

Re-connect the draught tubing. The display shows the exact measurement value which can

be stored while pressing <Record> and added to those results previous stored in the

intermediate memory. The stored value is shown on the display. Press <ESC> to exit the

draught measurement menu.

4.5 Measurement procedure gas analysis: Flow measurement Pitot tube (option)

This measurement can be done with a Pitot tube. At first the pitot factor of the pitot tube must

be entered („Adjustments“ / „Internal“ / „Pitot factor“). After connecting the Pitot tube to the

instrument, the zero point of the sensor can be set with <F4>. With <F1> the cross section of

the flow channel can be entered (needed for calculation of the flow rate). After the Pitot tube

is positioned in the flow channel, the display shows the speed (m/s) and the flow rate

3

/h). If the value indicated is stable, press <Save> to store the value in the intermediate

(Nm

memory. If a printout of the values should occur simultaneously to the recording in the

intermediate memory, press <F2> (the complete content of the intermediate memory will be

printed out).

2

1

Connections for Pitot tube Measurement stored

2

in intermediate

memory

Page 28

ecom-EN3

Page 29

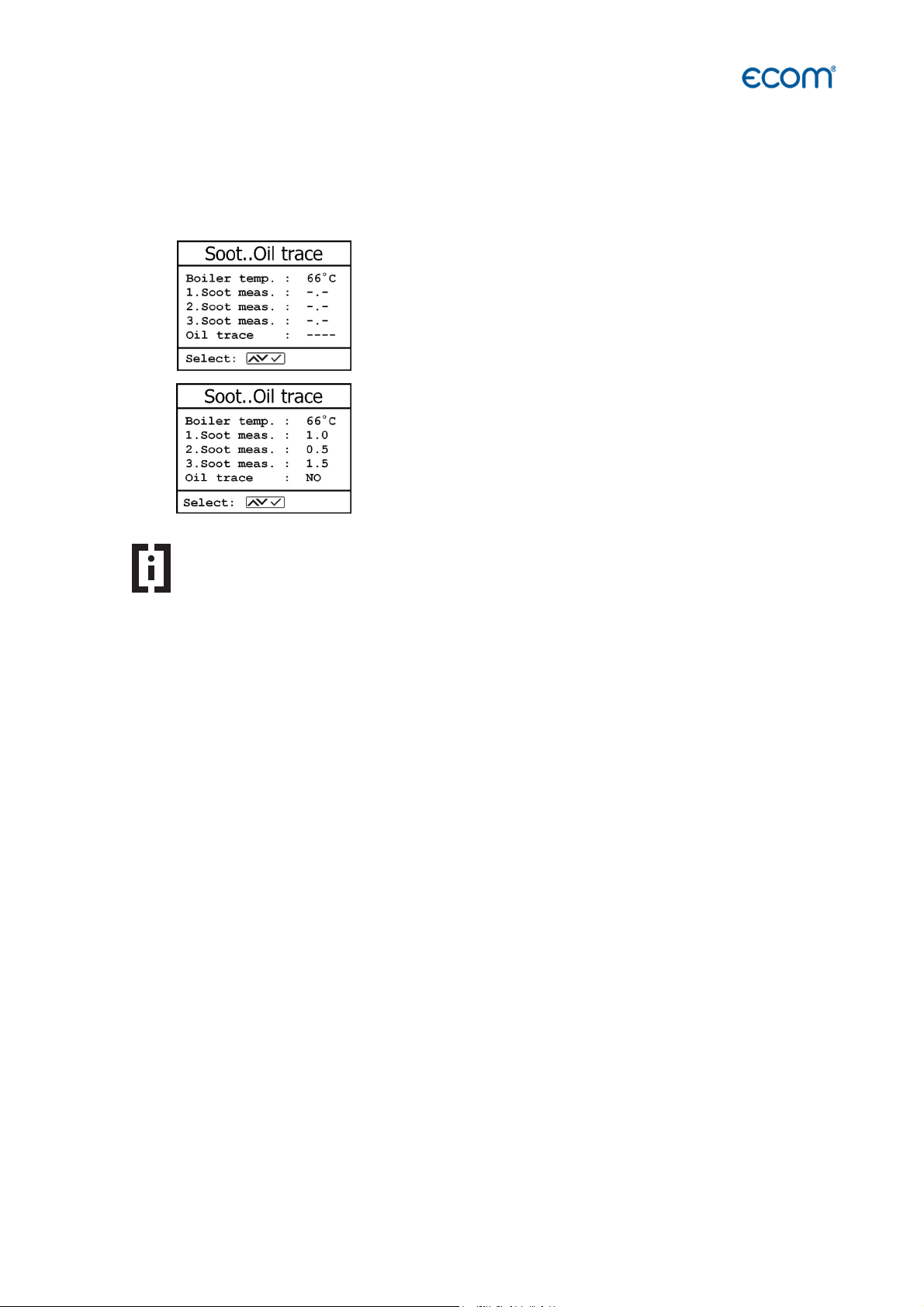

4.6 Measurement procedure gas analysis: Soot...Oil trace

The sub-menu "Soot...Oil trace" enables the input of measured results for boiler temperature,

soot dots and oil trace. Select the desired line on the display and activate the input with

<Enter>. The input for boiler temperature can be made one with help of the instrument

keyboard. Press <Enter> to store the value in the data record of the measurement.

Hint

To use the automatically soot measurement, you have to select the fuel type

oil!

4.6.1 Soot measurement

The soot dot measurement is to be performed with the optional heated pistol grip probe

which heating function prevents the filter paper to become wet because of the humidity

issued by the combustion condensate. The filter paper slot is hereby heated up to approx.

70 °C. Switch hereto the probe heating of the pistol grip probe while selecting „Adjustments /

Internal / Probe heating / <F1>“.

Insert a filter paper in the paper slot. Select the line „1st Soot meas.“. Press <Enter> to start

the measurement. The display shows the volume to be sucked and the pump starts sampling.

If the soot dot analysis are made with a manual pump the sucking procedure can be

interrupted while pressing <F4> (result value can immediately be entered).

Once 1,63 litre has been sucked in, the instrument will instruct to input the opacity degree.

Release the filter paper from the probe slot. Compare the greyness with the opacity scale.

Input the result using the numerical keys and press <Enter>. Repeat this procedure until all 3

soot dot analysis are completed. The mean value will be calculated and automatically stored.

4.6.2 Oil trace

The result of the oil trace check will be documented as follows:

- Place cursor on line "Oil trace"

- Consign the result with <Enter> ("No", "Yes" or "- - - ")

Once all inputs have been entered, press <ESC> to exit the menu. The measurement is now

complete.

ecom-EN3

Page 29

Page 30

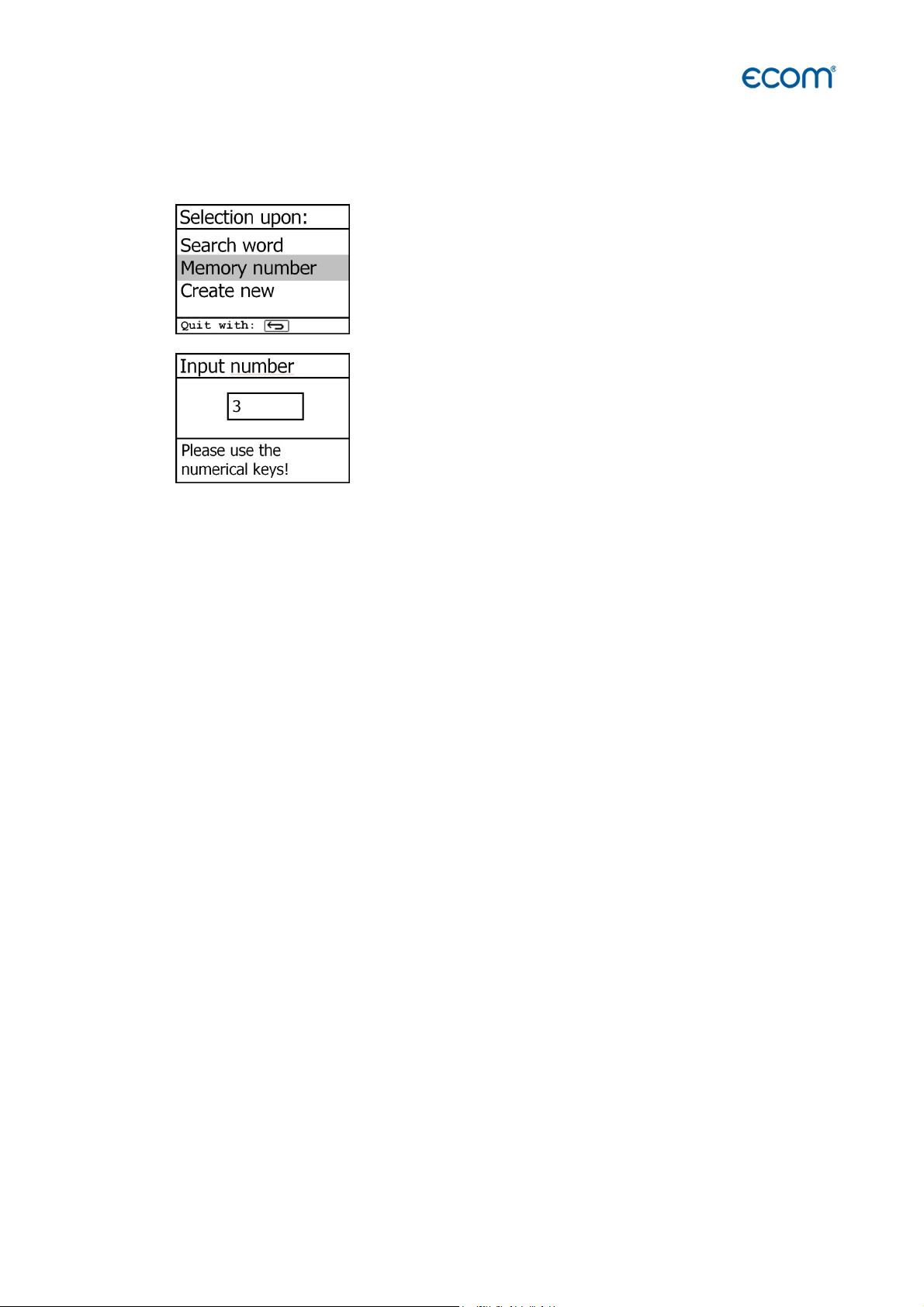

4.8 Measurement procedure gas analysis: Data processing

To call up plant data already recorded or to create a new file, the following possibilities are available:

4.8.1 Create new

(is automatically selected by first use of a MM card)

To create a new file, a numerical number should be assigned. Select „Create new“ and

confirm with <Enter>. Input a random number (max. 16 figures) using the keyboard:

- use the cursor keys <Up/Down/Right/Left> to select

the figure (selected figure outlined by a black background)

- press <Enter> to accept the figure (press <F2> to delete

the last figure if needed)

- repeat this procedure until the desired number is complete.

Example: "25.09.2009"

Tip: We suggest a date-related input to easily find the data

record later on via the search function.

After confirming with <F1> it is possible to enter a text via the keyboard (max. 6 lines

with 20 characters each) which is printed out and can be used for data processing

purposes. Proceed as follows:

- select text line 1 using the cursor keys <Up/Down> and confirm with

<Enter>

- select with <F3> the keyboard mode (4 keyboard modes are available)

- select with the cursor keys <Up/Down/Right/Left> the desired

character (selected character outlined by a black background)

- press <Enter> to accept the character

(press <F2> to delete the last character)

- repeat this procedure until the desired text is complete.

- proceed as follows to correct a character:

- press <F4> to interrupt the character selection

- use the cursor keys <Right/Left> to select the character requiring correction

- activate with <F4> the character selection and correct character

- return with <F1> to character selection and call up next line for

process

The input is closed with <ESC> and the next available data record is activated. Press

<ESC> to return to the gas analysis menu.

Memory number: For check of the plant already stored in the instrument, the selection

upon record number is most appropriate.

Page 30

ecom-EN3

Page 31

4.8.2 Memory number

For check of the plant already stored in the instrument, the selection upon record number is

most appropriate.

Select „Memory number“ and confirm with <Enter>. Input a

random data memory number:

Example: "3" for data record number 3

Press <Enter> once the input is completed to call up said data memory number. The cursor

keys <Up/Down> enable the check of the record numbers.

Press <F1> to select the first memory number.

Press <F2> to select the last memory number.

Press <F4> to delete the content of the selected memory number.

Press the <Enter> to select the currently displayed memory number and store the following

measurements under this memory number.

Finally press <ESC> to start the gas analysis.

ecom-EN3

Page 31

Page 32

4.8.3 Search word

Measurement available

If the plant code is known, it is possible to find the plant data stored with help of a search

machine. Select hereto "Search word" and confirm with <Enter>. Using the software

keyboard, input at least 3 connected figures of the plant

After input completion, press <F1> to start the search. All files matching this code will be

filtered. The resulting selection can be scrolled using the cursor keys:

- <F1> for selection start

- <F2> for selection end

1

Example: "25.09" for plant code 25.09.2009

Once found, activate the desired data record with <Enter>. The last measurement on this

plant can be viewed pressing <Enter> / „View memory“ / <Enter>.

All measured and calculated values can be called up on 5 display pages, using the cursor

keys to step thru.

Press <ESC> to escape the previous measurement data and the recording of the current data

can start.

Page 32

ecom-EN3

Page 33

5. Measurement procedure mean values

By mean value measurement function, measurements can be sampled within an adjustable

time frame and mean values can be calculated. Should the several measurement values or

the mean value result be stored a storage place has to be selected as described in chapter 7.

If the function “Store” is activated, based on this storage place all measurements will be

written consecutively on the next storage places. If the function “Store” is not activated, the

mean value result can be stored on MMC with <Print> / „Memory -> M.

Once the fresh air calibration is completed, select the menu point „Mean values“. Before

starting, the parameters „Measurement time“, „Scanning“, „Printer“ and „Record“ should be

checked or modified if need be. The meaning is respectively:

- Measurement time = Time frame during which the mean values will be sampled

- Scanning = Time interval between the measurements considered for mean value

calculation

- Printer = Documentation of measurements serving to the mean value calculation

- Store = All measurements for mean value calculation will be stored

„Measurement time“ and „Scanning“ can be adjusted as follows:

- select menu point and confirm with <Enter>

- set the desired time using the numerical keys:

0.01 = 1 sec = minimal value

59.59 = 59 min : 59 sec = maximal value

- confirm with <Enter>

The settings for „Printer“ can be changed as follows:

- select menu point and confirm with <Enter>

- select desired adjustment with cursor keys

- confirm with <Enter>

The setting for „Store“ can be changed as follows:

- select menu point and confirm with <Enter>

- activate memory function with <F1> or

- deactivate it with <F4>

ecom-EN3

Page 33

Page 34

By ‘Start measurement’ / <Enter> the evaluation of the measurement values will be started.

On the display the actual mean values will be shown (will be updated with new measurement

values / switch to the actual values with cursor keys <up/down>). It is possible to scroll

through the values with the cursor keys <right/left>. With <F2> you can interrupt and with

<F4> stop the measurement.

After finishing the measurement time a protocol of the results with all mean values can be

printed (key <Print>).

Page 34

ecom-EN3

Page 35

1/0 = Continuous phase

RM = Fan motor

OV

= Oil preheater

RZ = Ignition

BV1 = Valve 1st stage

BV2 = Valve 2st stage

FL = Flame identified

Err = Disturbance

ecom

-

EN3 ecom

-AK

3

11

4

7

10

5

11

6. Measurement procedure Diagnostics

6.1 Fault diagnostic

The ecom-EN3 is able to receive and to process information provided via cable transfer by

the ecom-AK (read-out head for digital firing automates).

Out of the main menu, select the sub-menu "Fault diagnostic" and confirm with <Enter>.

The ecom-EN3 tries to establish a connection with the ecom-AK (display message:

„Search in process“).

By successful attempt, the current burner operation stand is displayed as a graphic on the

display. The operation stand can be recorded (max. 120 sec). Press <Enter> to initiate a new

recording (reset).

1

2

4

Recording of operation stand (max. 120 sec.):

6

7

8

9

10

ecom-EN3

Reset = Starts a new recording (confirm with <Enter>)

1

Model name Ignition is active Engine on

Oil heater/

2 3

5 6

Operation voltage

Air pressure monitor is on

Flame signal min Flame identified Valve 2 is on

8

9

11

Valve 1 is on

Recording of operation stand

(max. 120 sec.)

Flame signal is

Page 35

Page 36

Use the cursor keys (Up/Down) to call up further data of the firing automate. On the 2nd display page

the current error and the number of burner starts are displayed.

1

2

1

Current error Number of burner starts at a

4

Error statistics (number of

errors)

2

total resp. since reset of firing

automate

5

Monitoring times of firing automate

Last 2 errors (Satronic) Last 5

errors (Siemens) (Scroll errors

using <Right/Left>)

The 3rd display lists information about error history (type

3

and volume of information depending on firing automat).

4

5

The 4th display page lists information about the

monitoring times (type and volume of information

depending on firing automate).

Page 36

ecom-EN3

Page 37

6.2 delta-T Measurement

With the ecom-EN3 a difference temperature measurement is possible. For measurements at

pipes (e.g. water-in and water-out of heating systems), special temperature sensors are

needed, available from your authorized ecom agency. Out of the main menu point

"Diagnostics" select the sub-menu "dT measurement" and confirm with <Enter>.

The instrument indicates the temperature T1 (sensor at connection „Gas temperature“), the

temperature T2 (sensor at connection „Air temperature“) and the difference between both

temperatures (T1 - T2). Press <Save> to store the result in the intermediate memory. A

printout can be started with <Print>.

1

Measurement stored in intermediate memory

ecom-EN3

Page 37

Page 38

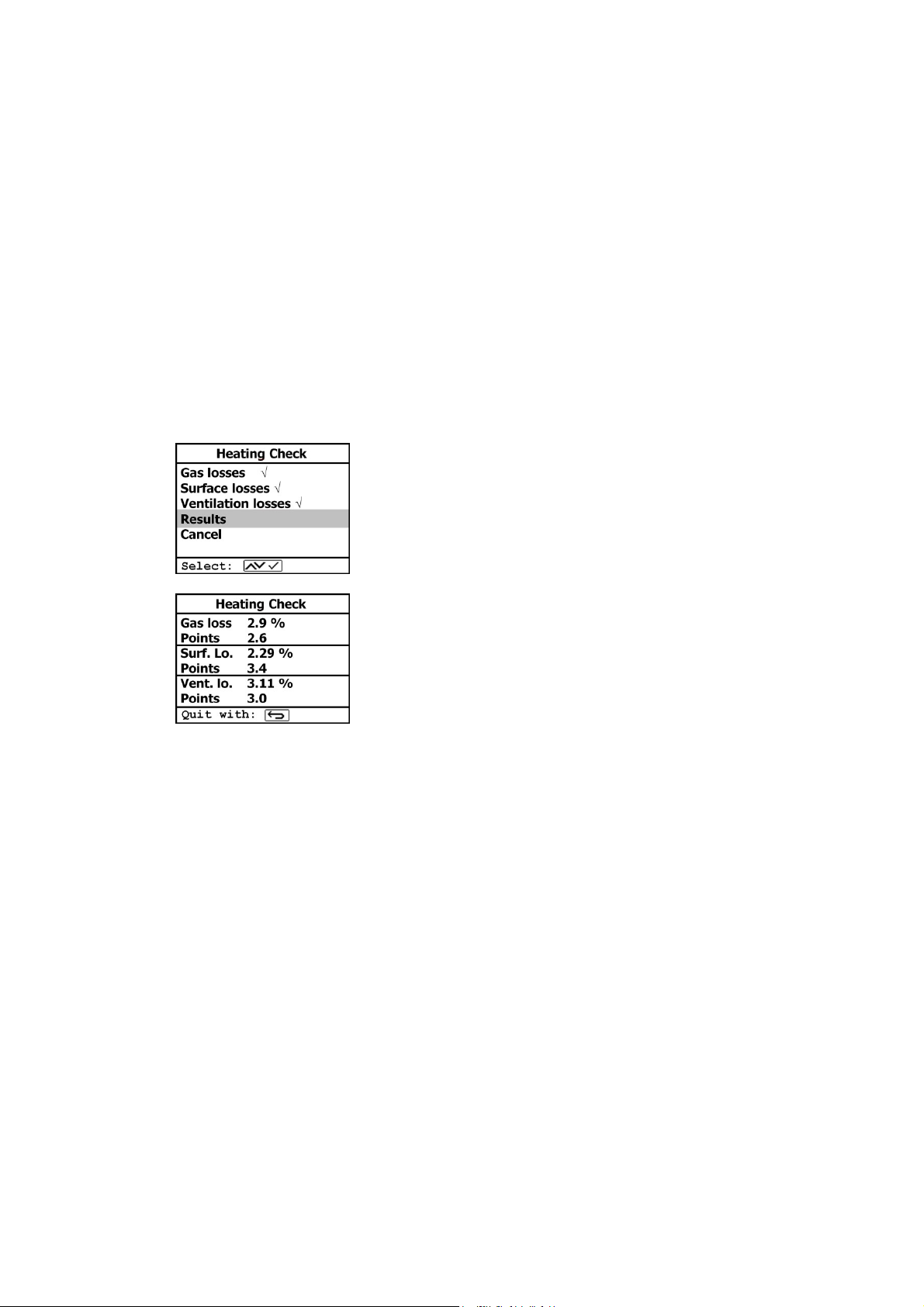

6.3 Heating Check (option)

The heating check is a simple, expressive process to evaluate a complete heating plant (heat

production, distribution and transfer) from the energetic point of view. Hereby the single plant

components get inspected by the heating engineer in a combination of measurements and

visual assessment and valued in regards of their energetic quality acc. to a negative point

system of maximum 100 points. The higher the score, the farer the current plant is away from

the desirable energetic stand and the higher the energy saving potential would be if

modernization measures are conducted. In combination with the special probes required

hereto, the ecom-EN3 is able to perform the measurement of the heating check parameters:

gas losses, ventilation losses and surface losses. Out of the main menu point "Diagnostics",

select the sub-menu "Heating Check" and confirm with <Enter>.

The gas losses measurement is to be performed with the

instrument´s sampling probe in the gas core stream after

menu call up. Once the measurement is recorded with

<Save> (disk symbol) the conversion of the measurement

results in negative points is available under the menu

point „Results“.

The surface losses measurement is performed by a temperature sensor specific for surfaces.

The temperature difference between boiler surface and room temperature (air temperature

sensor) is determined and the percentage loss is calculated. Once the menu point is called

up, the boiler performance must be inputted. To easy the measurement width, depth and

height of the boiler can also be entered (dimensions will be memorized for surface

calculation). Please proceed as follows:

- activate respective input window with <Enter>

- inputs values using the keys numerical function

- confirm input with <Enter> or:

- adjust values using the cursor keys <Right/Left>

Page 38

ecom-EN3

Page 39

If no boiler dimensions are inputted, press <F1> (Start) to activate the measurement

recording. Here the dimensions for all surfaces must be inputted.

Press <F3> (Start + ->) to start the real measurement. Proceed as follows:

- select surface (boiler side) to be measured with <F1> or <F2>

- position surface sensor record temperature difference with <Memory>

- up to 10 values can be recorded per surface out of which a mean value will be

calculated automatically

- if need be, cancel measurements with <F4>

- repeat this procedure for each surface

Flow probe

ecom-EN3

Once all surface temperatures have been determined, quit the menu with <ESC>. The

surface losses get automatically calculated. The value conversion in negative points is

available in the menu point „Results“.

The ventilation loss measurement is performed by a flow probe 30 sec. after burner switchoff. This measurement can be performed at the earliest 5 min. after instrument´s switch-on as

the pressure sensor requires this period of time for stabilization. Once the menu is called up,

the values for air pressure, external temperature, boiler performance and exhaust gas pipe

diameter must be inputted. Hereto proceed as follows:

- open respective window with <Enter>

- input figures using numerical function of keys

- confirm input with <Enter> or:

- adjust values using the cursor keys <Right/Left>

Page 39

Page 40

Press <F1> (Start) prior to going thru the following steps to start the measurement:

- release tubing of the flow probe

- wait for zeroing of pressure sensor

- re-connect tubing of the flow probe

- position flow probe into exhaust gas pipe

(observe mark for flow direction)

- switch off burner and simultaneously press <F1> or:

- press <F2> to activate timer (5 sec.) and switch off burner by beep

- after approx. 30 sec. the measurement value converted in negative points is

available

An overview of the measurements is available under „Results“. Press <Print> to print them

out.

Page 40

ecom-EN3

Page 41

6.4 4 Pa Measurement (option)

The simultaneous operation of room-dependent firing place and air evacuation system can

lead to dangerous low pressure conditions. With the ecom-EN3 it is possible to check the low

pressure limit value of 4 Pa and to document in a diagram the time course of the low

pressure value. Once the menu point is called up, the measurement is to be performed as

follows:

- connect capillary hose for room where burner is installed to „-“

- connect capillary hose for reference place (staircase or outside air to „+“

- operate firing and evacuation systems with maximal performance

- open window resp. connection door to burner room and check the correct

evacuation of the exhaust gases

- zero pressure sensor with <F4>

- position capillary hose for reference location

- start record pressure value course with <F1> (Start) (an acoustical signal is issued

every 30 sec. which can be deactivated / re-activated pressing <F2>)

- record pressure by opened window resp. connection door

- close window resp. connection door after approx. 30 sec. and check low pressure

- after approx. 30 sec. open window resp. connection door and check zero point

- close window resp. connection after approx. 30 sec. and check low pressure

- after approx. 30 sec. re-open window or connection door and check zero point

- after approx. 30 sec. close window resp. connection door and check low pressure

Once the measurement time is completed, the diagram can be viewed on the display (use

<F3> to emphasize illustration 1x, 2x, 4x, 8x times or A for automatic). Start a printout if

needed with <Print>.

ecom-EN3

Page 41

Page 42

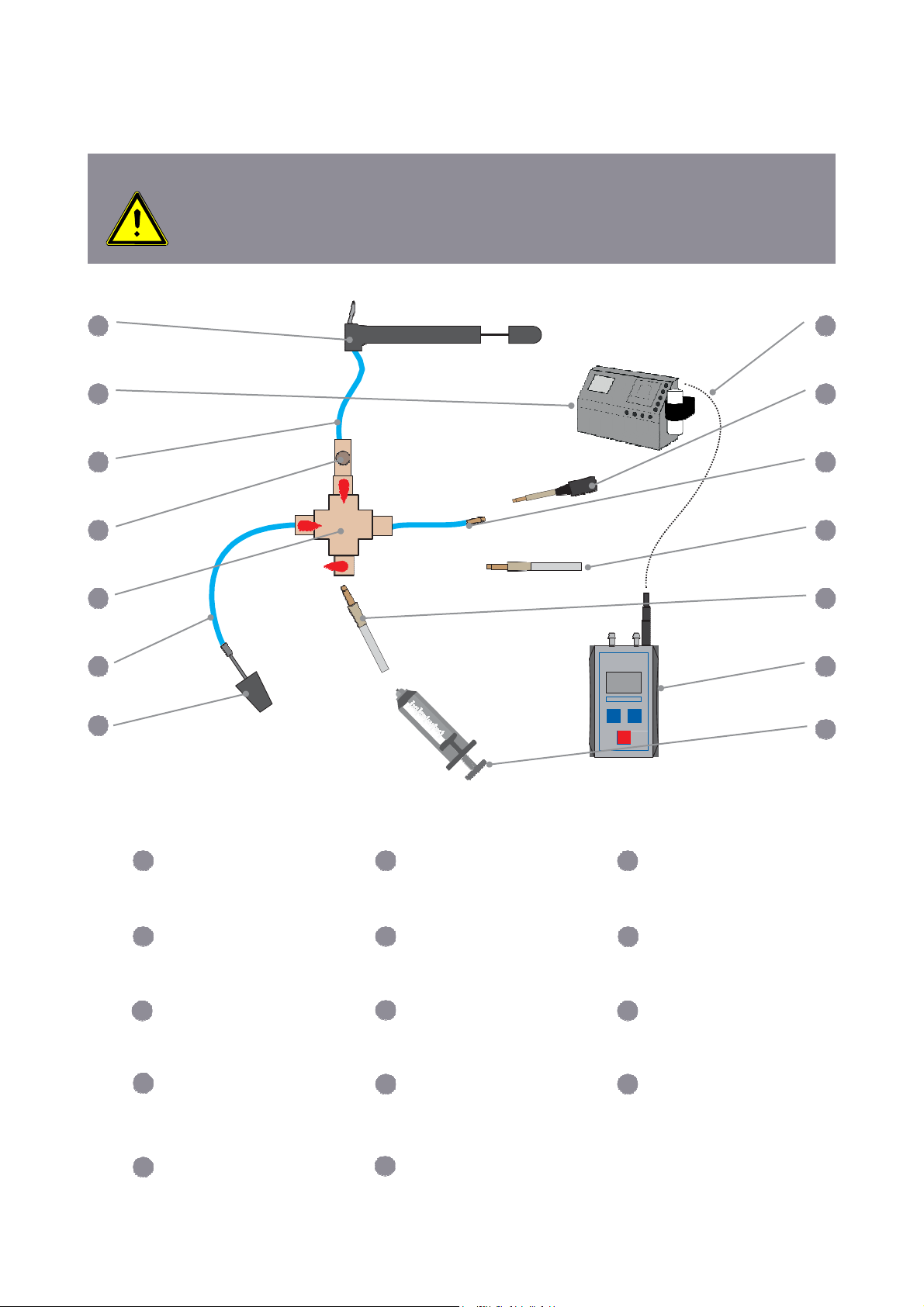

6.5 Pressure Tests (option)

WARNING

1.

2.

Use only air or inert gas for check!

Respect the „Technical Rules for Gas installations“!

10 11 12

10 11 12

7

14

13

14

1

2

3

4

5

6

1

Air pump

4

Safety valve

7

Conic test stopple, One-pipe

counter cap or High-pressure

test stopple

Connection hose

(ecom-EN3 / UNO Cross piece)

ecom-UNO (only for Loading

and Tightness Test)

2

ecom-EN3

5

Cross piece

8

Electrical connection

ecom-EN3 / UNO

Connection ecom-UNO

(+)

3

Connection hose

(Pump - Cross piece)

6

Connection hose (Gas

system - Cross piece)

9

Connection ecomEN3 (delta p-)

Connection Squirt or Soot

pump

Syringe

8

9

13

Page 42

ecom-EN3

Page 43

The following measurement procedures are available in the Pressure tests menu:

- Pressure Test

- Loading Test

- Tightness Test

- Usage property

In the menu Pressure Tests / Setup adjustments can be made for each measurement

procedure.

6.5.1 Pressure Test

The “Pressure Test” up to 100 hPa is deposited as a measurement routine in the ecom-EN3.

Proceed as follows:

1. Close the conduit with a suitable adapter (test stopple, high-pressure

stopple or one-pipe counter cap).

2. Connect the components as described before.

3. Scroll with cursor keys <Up/Down> to the menu “Pressure Test”. Activate with

<Enter>.

4. Create the pre-adjusted test pressure (max. 100 hPa) with the air pump.

5. Interrupt the connection to the air pump (switch-off the ball valve) and start “Pressure

Test” with <Enter>.

6. Wait for stabilization time (the measurement will start automatically).

7. Once the measurement time is over, the result is displayed and can be printed by

pressing <Print>.

8. If the menu “Pressure Test” is selected again, so the result can be called

up with <F4> (as long as the ecom-EN3 is on) or a new measurement

can be started with <F1>.

The following adjustments can be made in the menu Pressure Tests / Setup for the procedure

"Pressure Test":

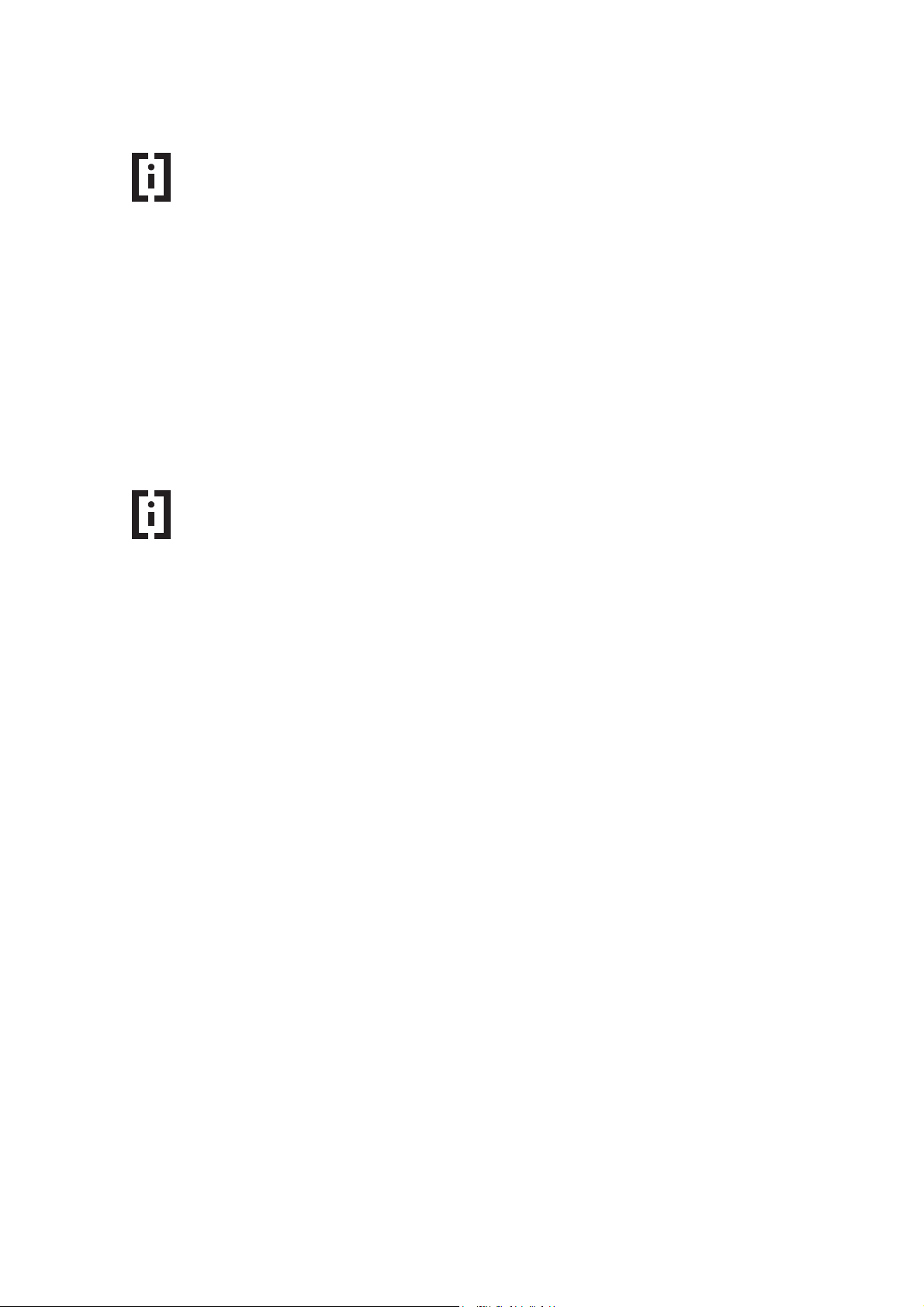

Parameter Meaning Adjustment Factory setting

Stabilization time

Measurement time

ecom-EN3

1 … 120 min 1 min

1 … 120 min 5 min

Page 43

Page 44

6.5.2 Loading Test

The „Loading Test“ acc. to DVGW – TRGI Process Instructions G 600 by pipes (operation

pressure up to 100 hPa) is deposited as a measurement routine in the ecom-EN3. Proceed as

follows:

1. Connect the ecom-UNO to the connection AUX of the ecom-EN3.

2. Close the conduit with a suitable adapter (test stopple, high-pressure

stopple or one-pipe counter cap).

3. Connect the components as described before.

4. Scroll with cursor keys <Up/Down> to the menu „Loading Test“. Activate with

<Enter>.

5. Create the pre-adjusted test pressure with the air pump (the unit beeps as soon as

the pressure level is achieved).

6. Interrupt the connection to the air pump (switch-off the ball valve).

7. Wait for stabilization time (if the pressure remains in the range „test pressure +/10% during stabilization time, so the measurement will start).

8. Once the measurement time is over, the result is displayed and can be printed by

pressing <Print>.

9. If the menu „Loading Test“ is selected again, so the result can be called up with

<F4> (as long as the ecom-EN3 is on) or a new measurement can be started with

<F1>.

The following adjustments can be made in the menu Pressure Tests / Setup for the procedure

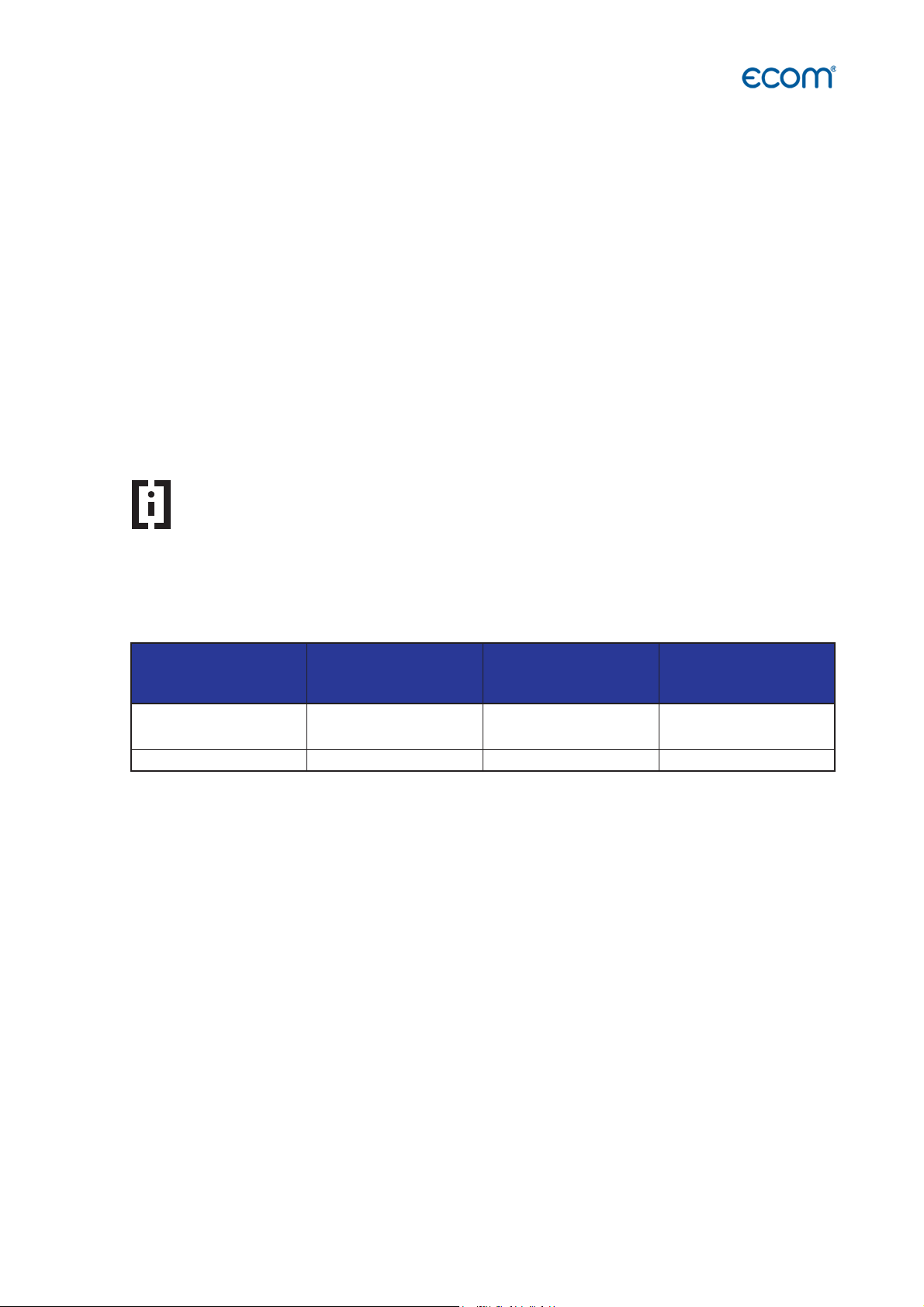

"Loading Test":

Parameter Meaning Adjustment Factory setting

Stabilization time

Measurement time

Test pressure

1 … 240 min 1 min

10 … 240 min 10 min

90 … 1200 hPa 1000 hPa

Page 44

ecom-EN3

Page 45

6.5.3 Tightness Test

The „Tightness Test“ acc. to DVGW – TRGI Process Instructions G 600 by pipes (operation

pressure up to 100 hPa) is deposited as a measurement routine in the ecom-EN3. Proceed as

follows:

1. Connect the ecom-UNO to the connection AUX of the ecom-EN3.

2. Close the conduit with a suitable adapter (test stopple, high-pressure

stopple or one-pipe counter cap).

3. Connect the components as described before.

4. Scroll with cursor keys <Up/Down> to the menu „Tightness Test“. Activate

with <Enter>.

5. Create the pre-adjusted test pressure with the air pump

(the unit beeps as soon as the pressure level is achieved).

6. Interrupt the connection to the air pump (switch-off the ball valve).

7. Wait for stabilization time (if the pressure remains in the range „test

pressure +/- 10% during stabilization time, so the measurement will start).

8. Once the measurement time is over, the result is displayed and can be

printed by pressing <Print>.

9. If the menu „Tightness Test“ is selected again, so the result can be called up

with <F4> (as long as the ecom-EN3 is on) or a new measurement can be

started with <F1>.

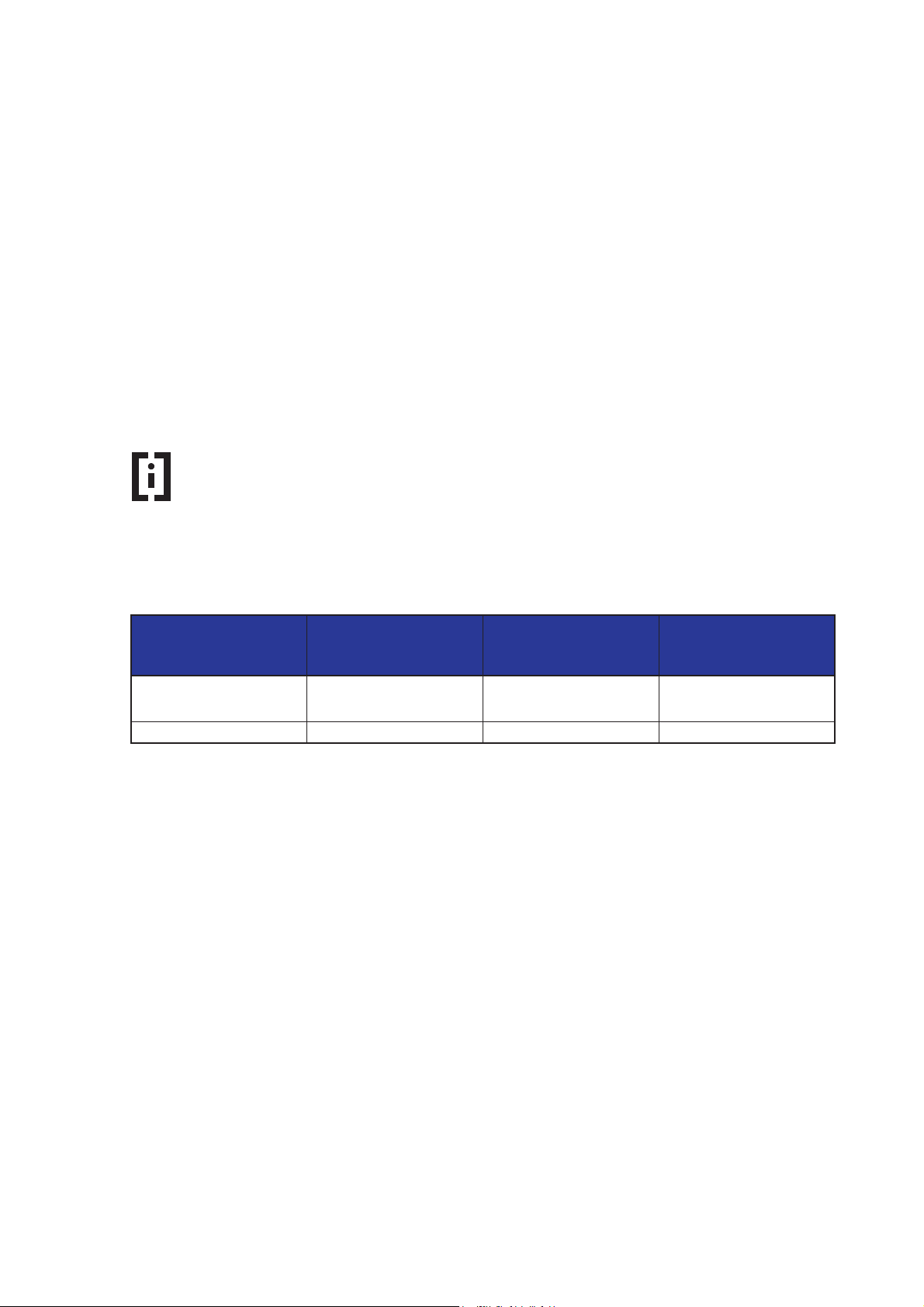

The following adjustments can be made in the menu Pressure Tests / Setup for the procedure

"Tightness Test":

Parameter Meaning Adjustment Factory setting

Stabilization time

Measurement time

Test pressure

1 … 120 min 1 min

10 … 120 min 10 min

90 … 160 hPa 150 hPa

ecom-EN3

Page 45

Page 46

6.5.4 Usage property

The „Usage property“ acc. to DVGW – TRGI Process form G 624 by conduits is memorised as

a measurement routine by the ecom-EN3.

The calculation of the leak rate happens automatically ac-cording to the following equation

and corresponds herewith to the procedure of the DVGW-TRGI Process Form G 624:

VB = V/TM * ((PA + P1)/(PA + P2)-1) * PB/P1 * f

Parameter Meaning

VB Gas leak volume in operation state (l/h)

V Pipe content in litres

TM Measurement duration in hours

PA Barometer stand in hPa

P1 Test pressure at meas. beginning in hPa

P2 Test pressure at measurement end in hPa

PB Maximal gas operation pressure in hPa

f Factor for consideration of gas type

Proceed as follows:

1. Close the conduit with a suitable adapter (test stopple, high-pressure

stopple or one-pipe counter cap).

2. Connect the components as described before.

3. Scroll with cursor keys <Up/Down> to the menu „Usage property“. Activate with

<Enter>.

4. Choose the gas type (f) with cursor keys <Up/Down> and confirm with <Enter>.

The following gas types are recorded with their respective factors:

Gas

Natural Gas

Air

Town Gas

Propane

Butane

Hydrogen

5. Type in the maximal operation pressure (PB) with the instrument keyboard

and confirm with <Enter>.

Page 46

ecom-EN3

Page 47

6. The pipe volume (V) is needed for the calculation of the leak rate. The ecomEN3 offers two possibilities:

a. Type in pipe volume (V):

- Choose NO at the inquiry „Calculate Volume automatically ?“

- Type in pipe volume (V) with the instrument keyboard and confirm with <Enter>.

b. Calculate pipe volume automatically (V):

- Choose YES at the inquiry „Calculate Volume automatically ?“.

- Connect the squirt or soot pump as described before.

- Open ball valve and wait until the pressure is stabilized.

- Choose syringe or soot pump with the cursor keys <right/left>.

- Start volume calculation with <Enter>.

- Sample the test volume with squirt or soot pump. The decrease of pressure

must be min. 2 hPa (otherwise operate squirt or soot pump several times).

- Close ball valve and confirm with <Enter>.

- Choose number of strokes with the cursor keys < right/left > and confirm with

<Enter>.

7. Create the pre-adjusted test pressure with the air pump (the unit beeps as soon as

the pressure level is achieved).

8. Interrupt the connection to the air pump (switch-off the ball valve).

9. Wait for stabilization time (if the pressure remains in the range „test pressure +/10% during stabilization time, so the measurement will start).

10. Once the measurement time is over, the result is displayed and can be printed by

pressing <Print>.

11. If the menu „Usage property“ is selected again, so the result can be called up

with <F4> (as long as the ecom-EN3 is on) or a new measurement can be started

with <F1>.

The following adjustments can be made in the menu Pressure Tests / Setup for the procedure

"Usage Property":

Parameter Meaning Adjustment Factory setting

Stabilization time

Measurement time

Test pressure

Max. operation pressure

ecom-EN3

1 … 270 min 1 min

10 … 240 min 10 min

20 … 160 hPa 50 hPa

10 … 100 hPa 23 hPa

Page 47

Page 48

7. After Measurement

After the measurements have been completed, the following things have to be observed

BEFORE turning the instrument off.

7.1 Save measurement, print measurement

Hint

Once the gas analysis is completed and a memory place is chosen before, transfer

the values recorded in the intermediate memory on the MM card, otherwise they

would get lost by switch-off of the instrument!

proceed as follows

Hint

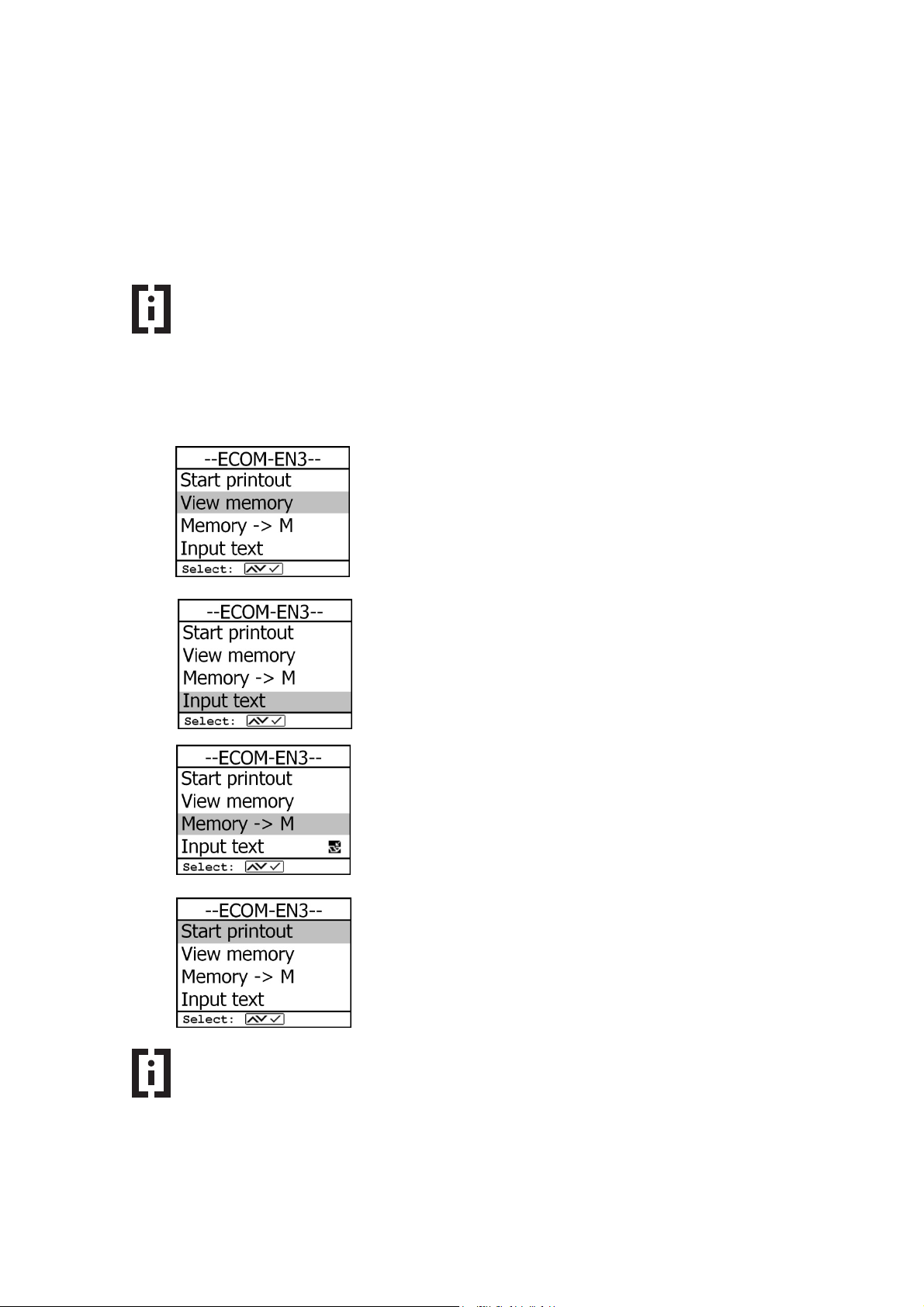

The functions „View memory“, „Memory -> M“ and „Input text“ can also be

selected out of the measurement mode with <Enter>.

To store measured values permanently on the MM card,

Press <Print> (printer symbol) to enter the printing menu.

The sampled data can be checked one more time („View

memory“, <Enter> and scroll with the cursor keys). The

cursor keys can be used to scroll through the

measurement screens.

By selecting the "Insert text" menu item, the plant

identifier can be entered or changed.

See chapter "Measurement procedure gas analysis: Data

processing" for more information.

All data correct? Then press „Memory -> M“ and <Enter>

to transfer them in the internal memory or on the MM card

("Symbol memory" is shown in black in the measurement

mode). The inputted text is taken over into the data record

only by transfer on MM card.

Select („Start printout“ and <Enter>) to print out the data.

Press <ESC> to turn back to the gas analysis mode.

To access these functions directly via the measurement screen,

press the <Enter> key.

Page 48

ecom-EN3

Page 49

7.2 To-Dos before switching off

Before switching off the device, the following points must be observed:

- Correct stowage of the probe

- Checking the fine dust filters

- Emptying the water trap

WARNING The hot probe can cause damage to the instrument or to the transport

system.

Let the probe cool down before stowing it!

WARNING Highly contaminated filters can affect the volumetric flow in the gas path and

therefore the measurement

Check the condition of the particle filter.

Replace the particle filter when the contamination of the filter

is equivalent to a soot number of approx. 2 - 3.

WARNING For instruments without automatic condensate emptying, condensation

water from the condensation tank can flow into the gas path inside the

instrument and damage the sensors.

Empty the condensate trap before transporting the

instrument.

(Only for devices WITHOUT automatic condensate emptying.)

Emptying the water trap as follows:

1. Pull the drain hose

2. Drain the condensate

3. Re-attach the drain hose

1 2 3

ecom-EN3

Page 49

Page 50

3

8. Control

The electrochemical sensors for gas analysis are submitted to a wearing process and do

age. They alter their output values along the time depending on the gas concentration, the

exposure time and the soiling grade of the sampled gas.

The program monitors the sensors and corrects drifts. But if the drifts and the correlated

measurement errors increase, an error message is displayed. In this case the corresponding

sensor must be changed by an authorized service centre.

The control menu informs about the current status values for the sensors. Further

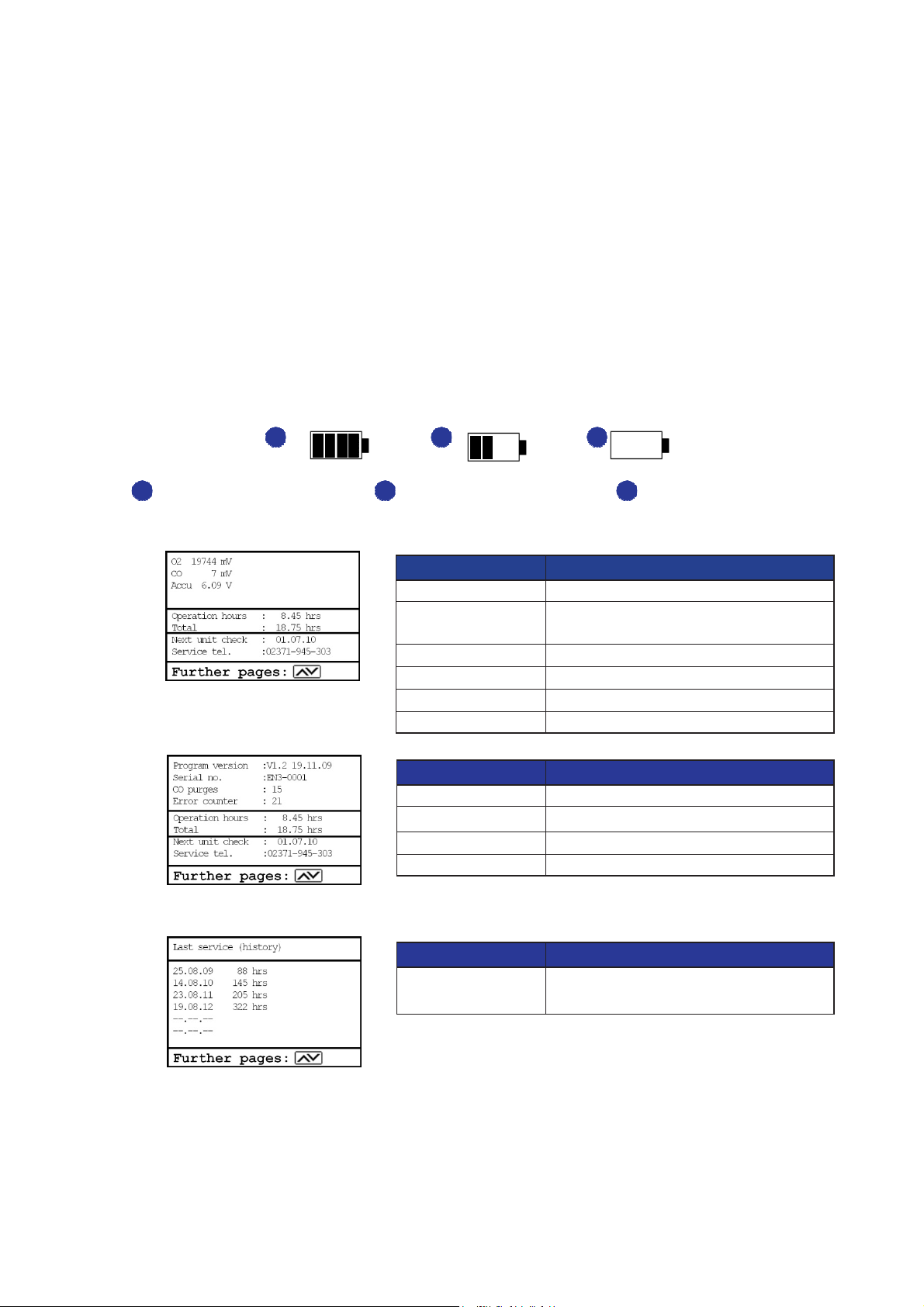

information is also consigned on 3 display pages (use cursor keys to scroll)

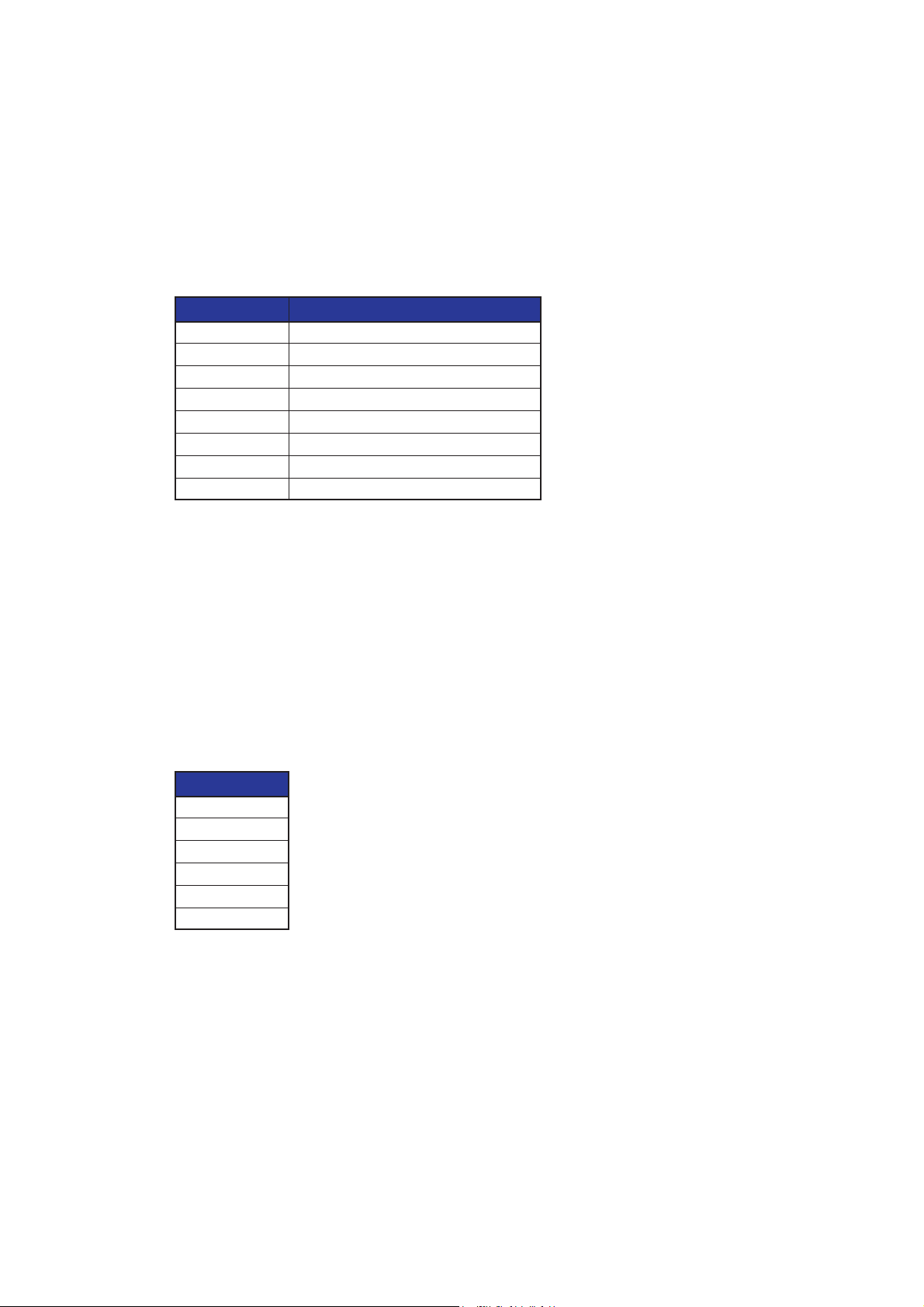

The following status values are available:

1

- battery voltage (charging status); is displayed as a symbol in all menus:

1 2

Full charge Half charge Empty

2

3

Parameter Meaning

[Sensor] #### mV Output voltage of the sensor

Akku #,## V Output voltage of the battery

Operation hours: Operation hours since last service

Total: Total operation hours

Next unit check: Date of the next recommended service

Service tel.: Phone number of the next service center

Parameter Meaning

Program version: Software version

Serial no.: Serial number of the instrument

CO purges: Amount of CO switch-offs

Error counter: Amount of errors

Parameter Meaning

Last service (history) Collection of the last maintenance

Page 50

ecom-EN3

Page 51

9. Adjustments

Additionally to those ecom-EN3 functions described previously, various adjustments can be

made in the instrument, which have an effect on the measurement procedures, the

functionality or the output and display of measured values.

Parameter Meaning Adjustment Factory setting

The following adjustments are available in the Adjustments menu:

Unit

Second unit

Ref. O2 Reference O2 0,0 … 21,0 % 0,0%

Calculation and display of gas

concentrations

Second calculation and display

of gas concentrations

ppm

mg/m³

mg/kWh (undiluted)

mg/MJ (undiluted)

ppm (undiluted)

mg/m³ (undiluted)

ppm

mg/m³

mg/kWh (undiluted)

mg/MJ (undiluted)

ppm (undiluted)

mg/m³ (undiluted)

Hint

The term "undiluted" refers to the conversion of the gas concentration to a

definable reference oxygen content according to the following formula:

E

= E

ref.

21-O2

Hint

mg/kWh and mg/MJ are always calculated on 0% O2 basis.

* 21-O2

meas

ref.

meas

ppm

ppm

ecom-EN3

Page 51

Page 52

All parameters in the table on the

Settings for the USB interface

Parameter Meaning Adjustment Factory setting

The following adjustments are available in the Adjustments menu: (continuation):

Fuel type

Set clock Correction of internal clock

Paper feed

Internal

Air leak test

Modification of adjusted

fuel type

Paper feed line by line

Further instrument

settings

-- see following table--

Check the tightness of the

instrument see Chapter 11.5

Fuel oil

Natural gas

City gas

Coke oven gas

Liquid gas

Fuel oil

The following adjustments are available in the Adjustments / Internal menu:

Parameter Meaning Adjustment Factory setting

Print contrast

Key beep

Print contrast adjustment with

cursor keys

Acoustical signal by key

pressing

9 steps Step 5

Yes, No Yes

Language: ### Selected language system dependent

Colour scheme

F1 Hotkey

F4 Hotkey

Values options

CO-Automatic

USB

Bluetooth

WLAN

Pitot factor

Printout

Sets the colours used

Assign the link using the <F1>

key

Assign the link using the <F4>

key

Adustments for efficiency,

excess air and temperature

Enable / Disable CO sensor

switches on after purging

automatically

Settings for the Bluetooth

interface

Settings for the WiFi interface All parameters in the table on

Input of Pitot factor for flow rate

calculation

Settings for defining the printout All parameters in the table on

4 schemes to choose from Colour scheme 1

see Chapter 4.1 Standby

see Chapter 4.1 Display values

following page

On, Off On

All parameters in the table on

the following page

All parameters in the table on

the following page

the following page

0,20 - 2,00 0,93

the following page

Page 52

ecom-EN3

Page 53

Not available at all instruments

Excess Air as proportionate

Efficiency

calculation with or

On, Off

Unit of draught measurement

hPa, mmH2O, “H2O, PSI, mb

ar

The following adjustments are available in the Adjustments / Internal / Values options menu:

Parameter Meaning Adjustment Factory setting

Temperature

Excess air

number or in %

Eff.(C)

without condensation gain

°C or °F °C

proportionate number or % proportionate number

On

Draught

hPa

The following adjustments are available in the Adjustments / Internal / USB menu:

Parameter Meaning Adjustment Factory setting

Transfer speed

Protocol

1200 … 115200 Baud 38400 Baud

DAS = DAS NT 2

Enhanced = DAS 5

---- = no protocol

Enhanced

The following settings are predefined in the Settings / Internal / Bluetooth (BLE) menu and can

NOT be changed:

Parameter Meaning Adjustment Factory setting

Transfer speed

Protocol

115200 Baud 115200 Baud

Enhanced Enhanced

The following adjustments are available in the Adjustments / Internal / WLAN menu:

Parameter Meaning Adjustment Factory setting

Access Point

OR

Existing Network

Set whether the instrument is to

be used as a WiFi access point

OR

to connect to an existing WiFi

network

Access Point,

Existing Network

Access Point

ecom-EN3

Hint

The Access Point setting is necessary to connect the ecom-EN3 to mobile

devices (smartphones, tablets) via the Wi-Fi interface.

Activate "Access Point" to connect the ecom-EN3 with mobile

devices via WLAN / Wi-Fi.

Page 53

Page 54

The following settings are available in the Adjustments / Internal / WiFi menu if the instrument

has been defined as an access point:

Parameter Meaning Adjustment Factory setting

Start / Stop WLAN

(Without) Auto Connect

Channel

Activate the

WiFi interface

(available only with deactivated

Auto Connect)

Enable / Disable automatic

connection

Set which radio channel is to be

used for the communication

Start WiFi, Stop WiFi -

Yes, No Yes

1 … 13 1

Security

Assign a password to secure

the WiFi connection

Yes, No

Password entry

No

1234567890

The following settings are available in the Adjustments / Internal / WiFi menu if the instrument

has been defined as an existing network:

Parameter Meaning Adjustment Factory setting

Start / Stop WLAN

(Without) Auto Connect

Existing Network

WPA-Password

Activate the

WiFi interface

(available only with deactivated

Auto Connect)

Enable / Disable automatic

connection

Search for Existing Network

Assign a password to secure

the WiFi connection

Start WiFi, Stop WiFi -

Yes, No Yes

Password entry

The following adjustments are available in the Adjustments / Internal / Printout menu:

Parameter Meaning Adjustment Factory setting

Footer for the Printout

Selection of measurement and

calculation values for printout

8 x 24 signs

Hint

The footer of the printout can be defined as desired, e.g. to print out the

company address of the instrument user on every printout of the measured

values.

To adjust the footer of the printout, proceed as follows:

1. Activate character selection list with <F4>.

2. Select keyboard type with <F3>

(4 different keyboards available).

3. Use the cursor keys to select the desired character (selected

character is outlined by black background).

4. Confirm selection while pressing <Enter>.

5. Repeat procedure until desired text is complete.

6. Once input for line 1 is completed, deactivate the characters

selection mode with <F4> and move to the second line with the

cursor key <Down>.

7. Once all lines have been processed as desired, exit the menu with

<ESC>.

Page 54

ecom-EN3

Page 55

Hint

The number and order of the measured values on the printout can be defined as

desired.

To adjust the number and order of the measured values on the

printout, proceed as follows:

1. Use the <F1> key to activate the value selection

2. Navigate to the corresponding line <up / down>

3. Select the measured value by pressing the <Enter> key

The following measurement and calculation values can be selected for the lines of the

printout:

1 T.Air 26 CO mg/N 51 SO2 mg/kWh

2 T.Gas 27 CO mg/kWh 52 SO2 mg/MJ

3 T.Boiler 28 CO mg/MJ 53 H2

4 T.Sensor 29 NO ppm 54 H2S

5 O2 30 NO ppm/N 55 Gas speed

6 CO 31 NO mg 56 Mass flow

7 NO 32 NO mg /N 57 CO x% Italy

8 NO2 33 NO mg/kWh 58 Eff._Hs

9 NOx 34 NO mg/MJ 59 Difference Temperature

10 SO2 35 NO2 ppm 60 Not used

11 CxHy 36 NO2 ppm/N 61 H2 ppm

12 CO2 37 NO2 mg 62 H2 ppm/N

13 Efficiency 38 NO2 mg/N 63 H2 mg

14 Losses 39 NO2 mg/kWh 64 H2 mg/N

15 Excess Air 40 NO2 mg/MJ 65 H2S ppm

16 Dew point 41 NOx ppm 66 H2S ppm/N

17 Poison Index 42 NOx ppm/N 67 H2S mg

18 Draught 43 NOx mg 68 H2S mg/N

19 Soot 44 NOx mg/N 69 Air pressure

20 Oil trace 45 NOx mg/kWh 70 Not used

21 Blank Line 46 NOx mg/MJ 71 CO Unit 2

22 Line 47 SO2 ppm 72 NO Unit2

23 CO ppm 48 SO2 ppm/N 73 NO2 Unit 2

24 CO ppm/N 49 SO2 mg 74 NOx Unit 2

25 CO mg 50 SO2 mg/N 75 SO2 Unit 2

ecom-EN3

Page 55

Page 56

10. Data processing

10.1 Storage on MM card

Hint

When an MM card is inserted into the instrument, it is used to store measured

values and plant data. This storage must be triggered manually or can be

automated (data logger)

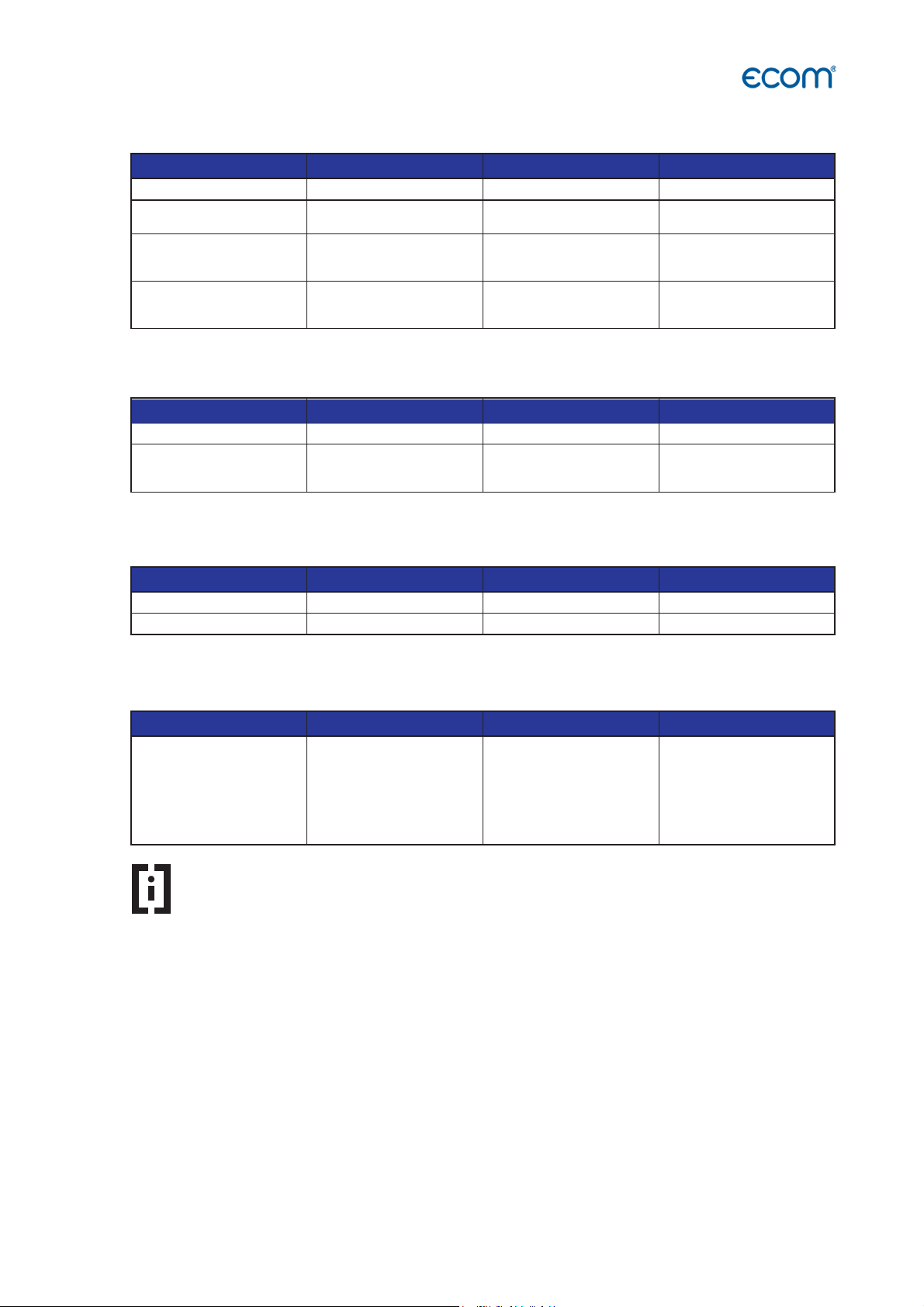

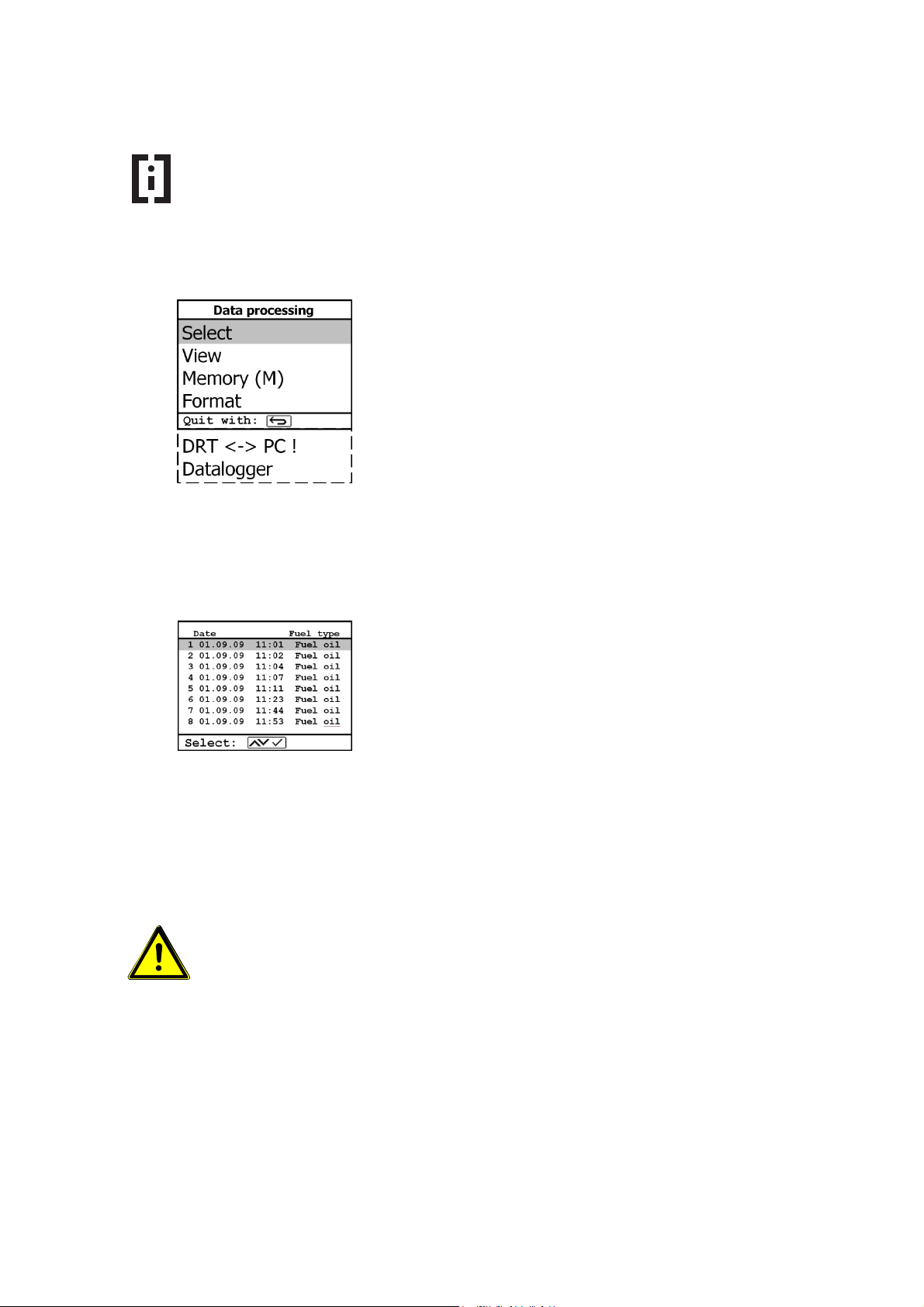

By selecting the menu item "Select", plants for the

assignment of measured values can be searched for or

set up (for further information see chapter "Measurement

procedure gas analysis: Data processing").

By selecting the menu item "View", stored measured

values can be viewed (for further information see chapter

"Measurement procedure gas analysis: Data

processing").

By selecting the menu item "Memory (M)", all stored

measurements (sorted by record number) can be viewed.

Single measurement results can be called up as

follows:

- Select desired record number with the

cursor keys and confirm with <Enter>

- confirm desired record number with

<Enter>

- Scroll with the cursor keys <up/down>

- Press <ESC> to exit

By selecting the "Format" menu item, the entire MM card can be formatted. This

function is usually needed by initial adjustment of the instrument at our factory

(preparation of MM card for data recording).

WARNING When the "Format" menu item is selected and confirmed, all stored data on

the MM card inserted in the instrument will be irrevocably deleted.

Select the menu item "Format" only if ALL data present on

the MM card are no longer required.

Page 56

ecom-EN3

Page 57

10.2 Data logger

When a MM card is inserted into the instrument, a data logger recording can be performed.

The measured values are stored one after the other on the MM card depending on the

recording interval set and are merged into a file with the format * .csv.

The measured values can be evaluated using MS Excel or open office CALC.

Hint

The data logger is ONLY available when a MM card is inserted into the

instrument.

To use the data logger, insert a MM card into the instrument.

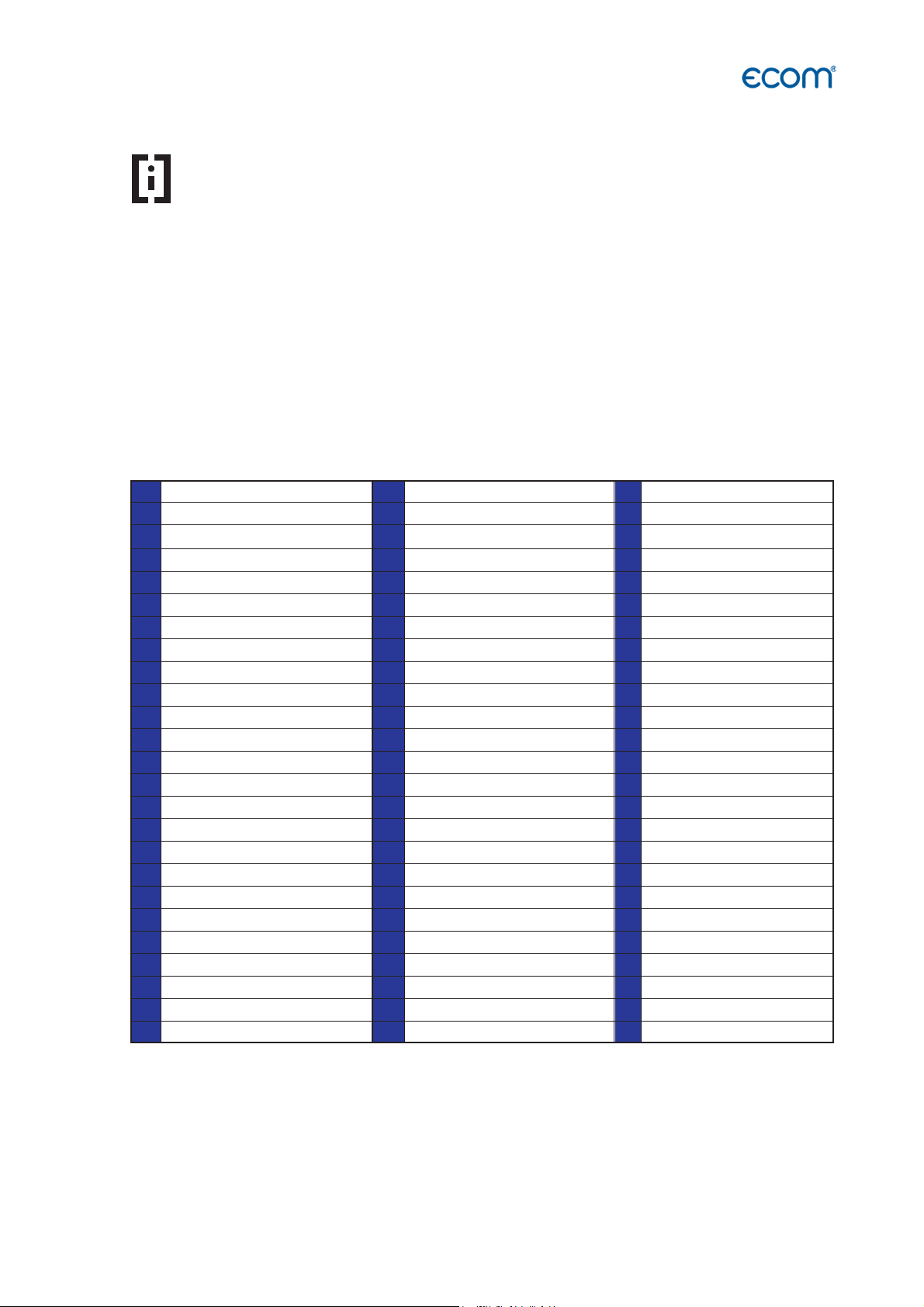

The following adjustments are available in the Data processing / Data logger menu:

Parameter Meaning Adjustment Factory setting

Data logger

Start, Stop Data logger

Yes, No No

Save to MMC Adjustment of the interval time

for data logger recordings

CSV-Header

Adjustment of data logging with

or without column headings

1 … 999 s 1 s

On, Off Off

If the data logger becomes active or becomes active again after an interruption, a new file is

created on the MM card, in which all subsequent measured values of the recording are

saved. The files have a predefined name and are numbered consecutively.

Hint

Each measurement is assigned its own file with collected measured values. Each

file is automatically named and numbered.

To select the correct data logger file use the date identification:

J2KDL-00.csv -- oldest file

J2KDL-01.csv

J2KDL-02.csv

J2KDL-XX.csv -- newest file

ecom-EN3

Page 57

Page 58