Page 1

Operating Instructions

Page 2

Page 2 ecom-DP3

Index Page

1. Application and components 3

2. Design ecom-DP3 5

3. Connection of components 7

4. Data processing

4.1. Data storage 8

4.2. Edit customer 8

4.3. Select customer 9

5. Control programs

5.1. Setup control programs 11

5.2. Natural gas

5.2.1. Stress test 14

5.2.2. Tightness check 15

5.2.3. Usability check 16

5.3. Liquid gas

5.3.1. Tightness check 18

5.3.2. Pressure test 19

5.3.3. Pressure test 0 – 40 bar 20

5.4. Drinking water (option)

5.4.1. Drinking water plant (wet)

5.4.1.1. Function test 21

5.4.1.2. Pressure test 22

5.4.1.3. Extended test 23

5.4.2. Drinking water plant (dry)

5.4.2.1. Tightness check 24

5.4.2.2. Stress test 25

5.5. Heating (option) 26

5.6. Sewage (option) 27

6. More measurements

6.1. Single measurement 28

6.2. Heating Check (option) 29

6.3. 4Pa measurement (option) 32

6.4. Pressure check 33

7. Adjustments 34

8. Control (system test) 36

9. Technical Data ecom-DP3 37

10. Maintenance tips 38

Page 3

ecom-DP3 Page 3

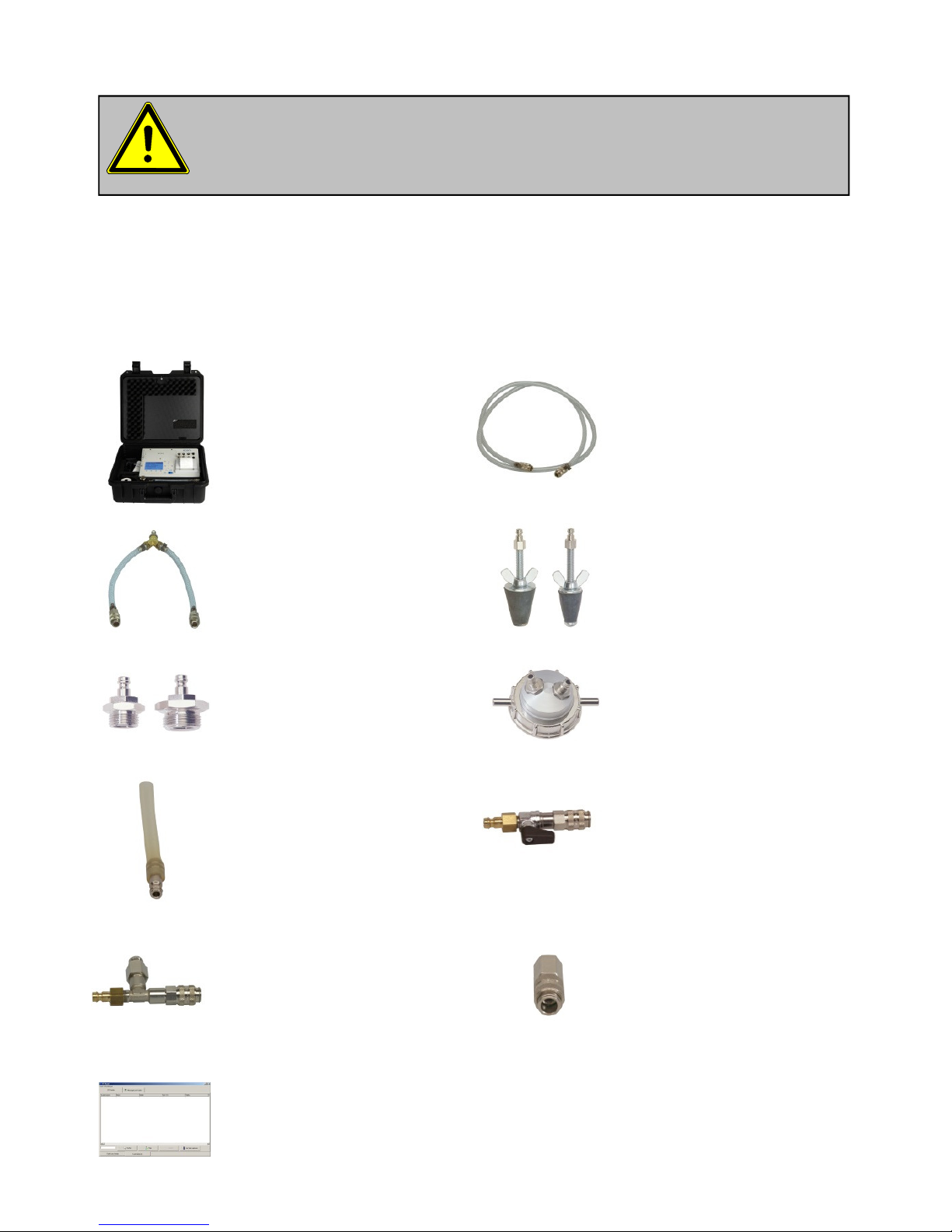

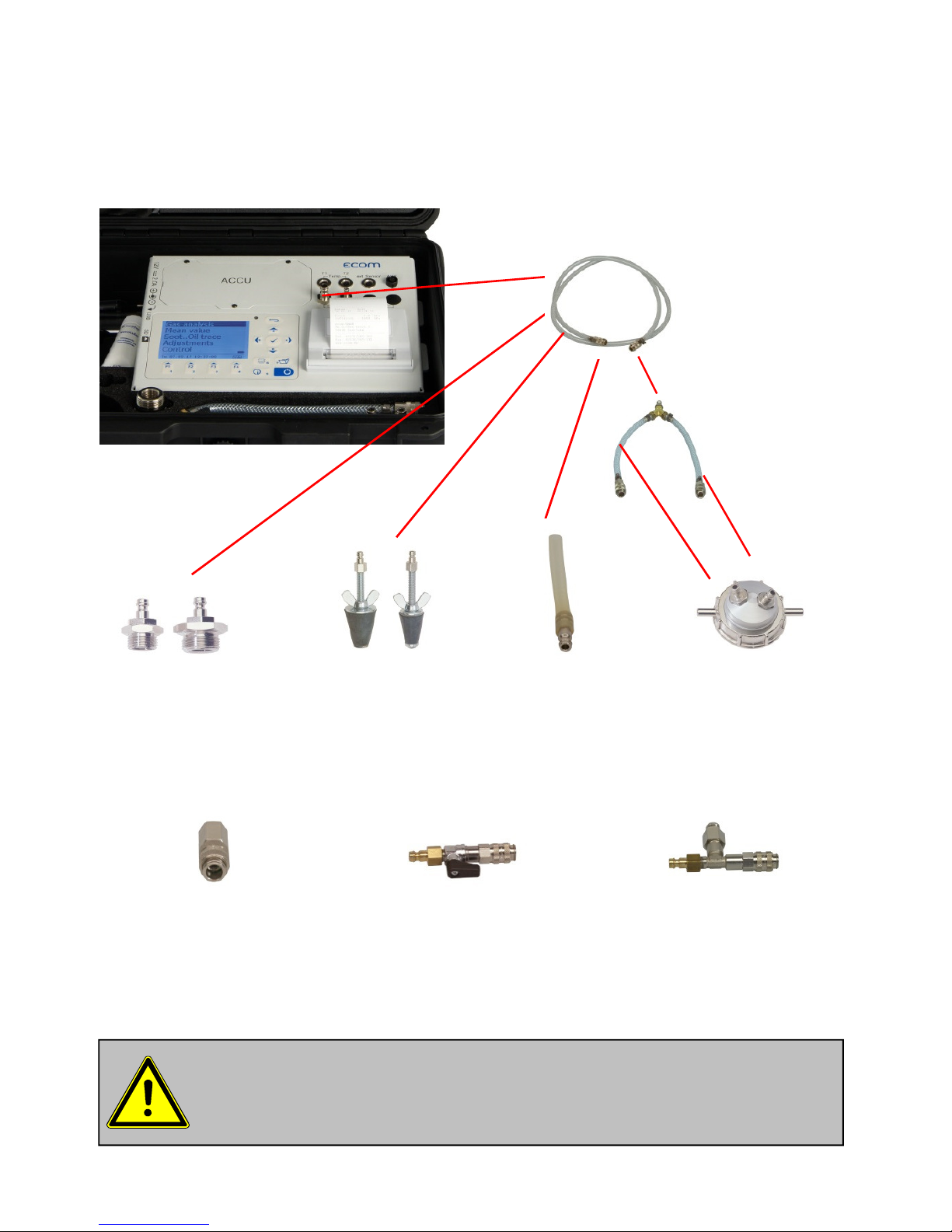

1. Application and components

The ecom-DP3 easies tightness tests. Besides gas pressure measurements,

tightness checks as well as leakage volume determination according to DVGWTRGI 2018 can be performed. The following components belong to the ecom-

DP3 set:

Standard

By works at gas pipes please respect

the legal safety instructions!

Hose connector

with quick

-fitting

ecom-DP3

Pressure measurement

instrument with automatic

check programmes

Connection hose

2,8 m long, with quickfittings

High-

pressure test

stopples

3/8“ auf 1/2“ und

3/8“ auf 3/4“

with qui

ck-fittings

One-pipe counter cap

for gas meters G4/G6

with quick

-fitting

Conic test stopples

1/2“ - 3/4“ and

3/4" – 1 1/4",

with quick

-fittings

Y-Piece

with quick

-fittings

Ball valve

with quick

-fitting

Connecting piece

with

safety valve

with quick

-fitting

Plug

with quick

-fitting

Software „DP3Report“

to create inspection

reports

Page 4

Page 4 ecom-DP3

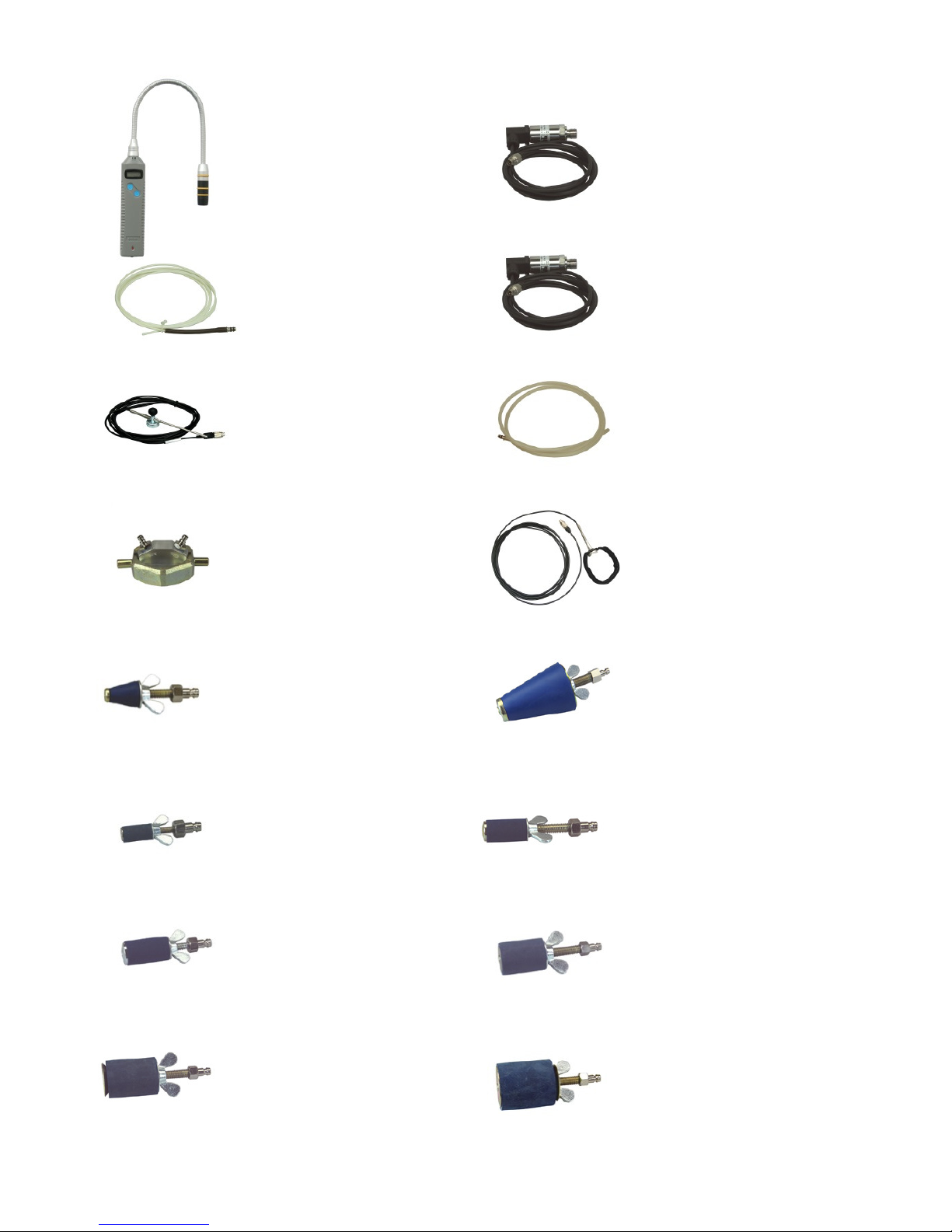

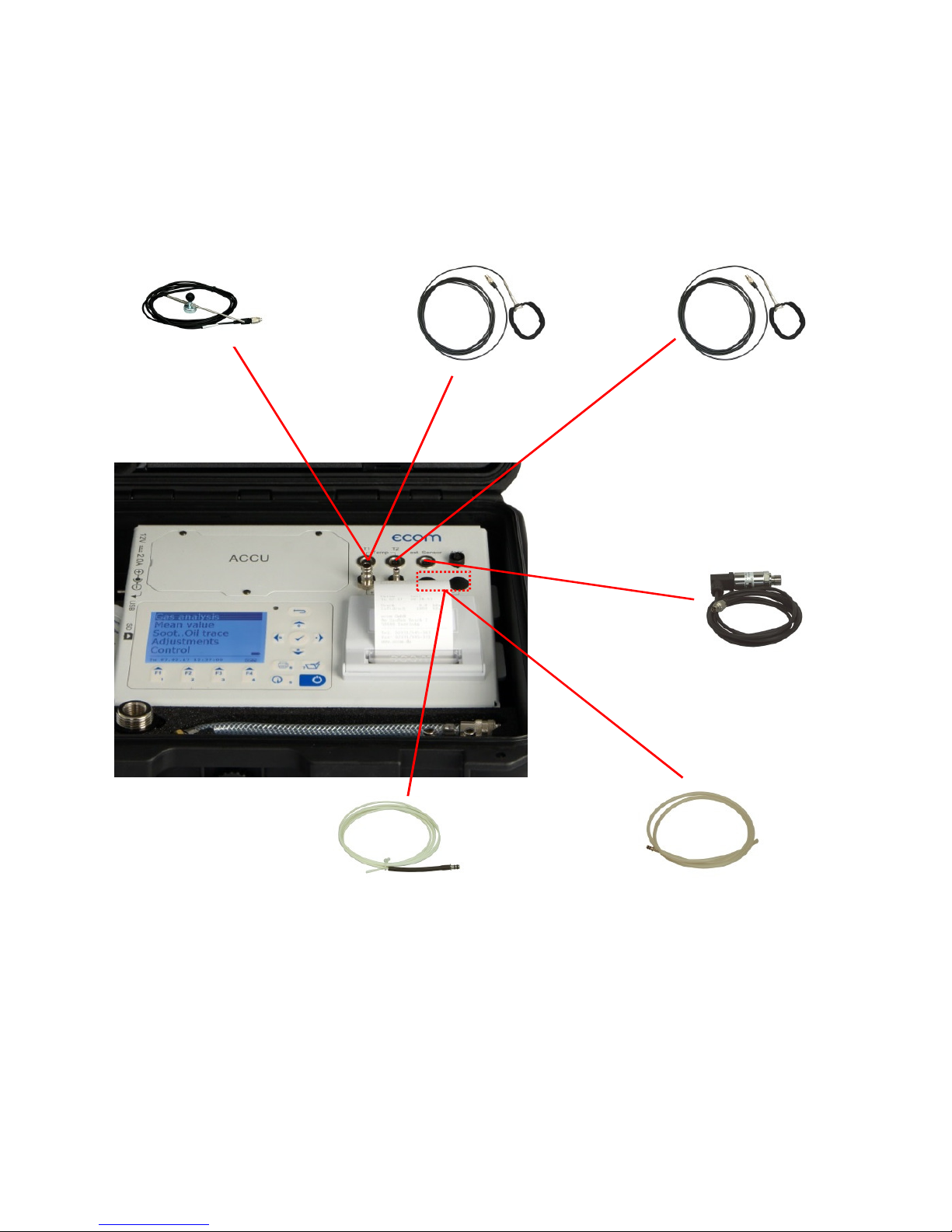

Optionen / Zubehör

Gasspürgerät

ecom-LSG

for identification of

leakages at gas pipes

(Item no.: 102145)

External pressure

sensor (0 – 20 bar)

with conne

ction cable

(Item no.: 102158)

2 x Capillary hose

for 4-Pa-Test

2 x Silicone hose

for small pressure

measurement

External room temperature sensor

with connection cable

(Item no.: 102156)

External pipe temperature sensor

with

connection cable

(Item no.: 12019)

One-pipe counter cap

for gas meters G10/G16

with quick

-fitting

(Item no.: 102705)

Test stopple conic

12 – 22 mm

with quick

-fitting

(Item no.: 102706)

Test stopple cylindrical

diameter 14,5 mm

with quick

-fitting

(Item no.: 102708)

Test stopple cylindrical

diameter 24 mm

with quick

-fitting

(Item no.: 102710)

Test stopple cylindrical

diameter 41 mm

with

quick-fitting

(Item no.: 102712)

External pressure

sensor (0 – 40 bar)

with connection cable

(Item no.: 103932)

Test stopple conic

35 – 65 mm

with

quick-fitting

(Item no.: 102707)

Test stopple cylindrical

diameter 19 mm

with quick

-fitting

(Item no.: 102709)

Test stopple cylindrical

diameter 35 mm

with quick

-fitting

(Item no.: 102711)

Test stopple cylindrical

diameter 52mm

with

quick-fitting

(Item no.: 102713)

Page 5

ecom-DP3 Page 5

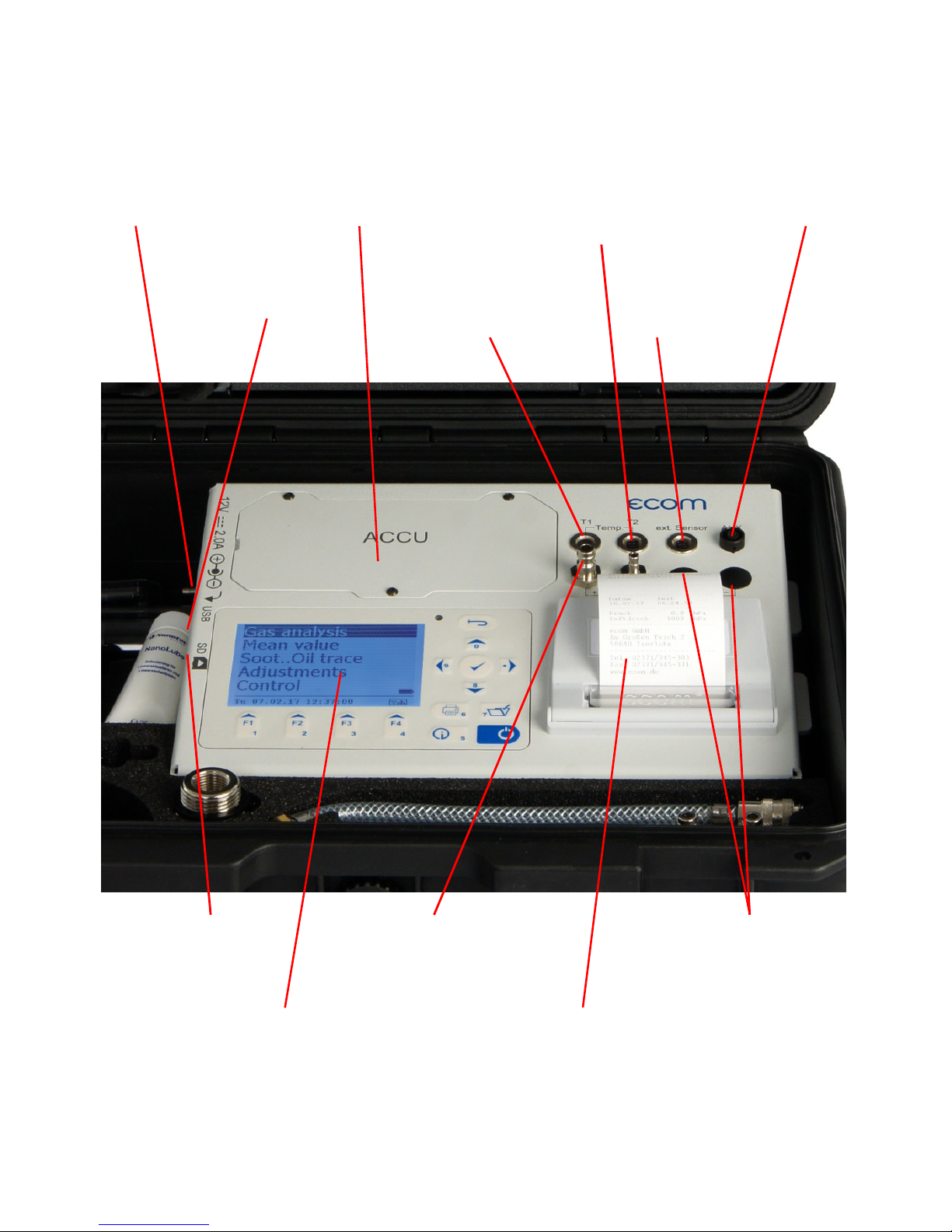

2. Design ecom-DP3

Connection

tightness checks

Pmax = 1500 hPa

Connection small

pressure measurement

(option)

Connection

loading unit

Grafic display

Integral printer

Slot for multi-

media card

USB connection

Accu

compartment

Connection

temperature

sensor 2

Connection

external

pr

essure sensor

Connection

AUX

Connection

temperature

sensor 1

Page 6

Page 6 ecom-DP3

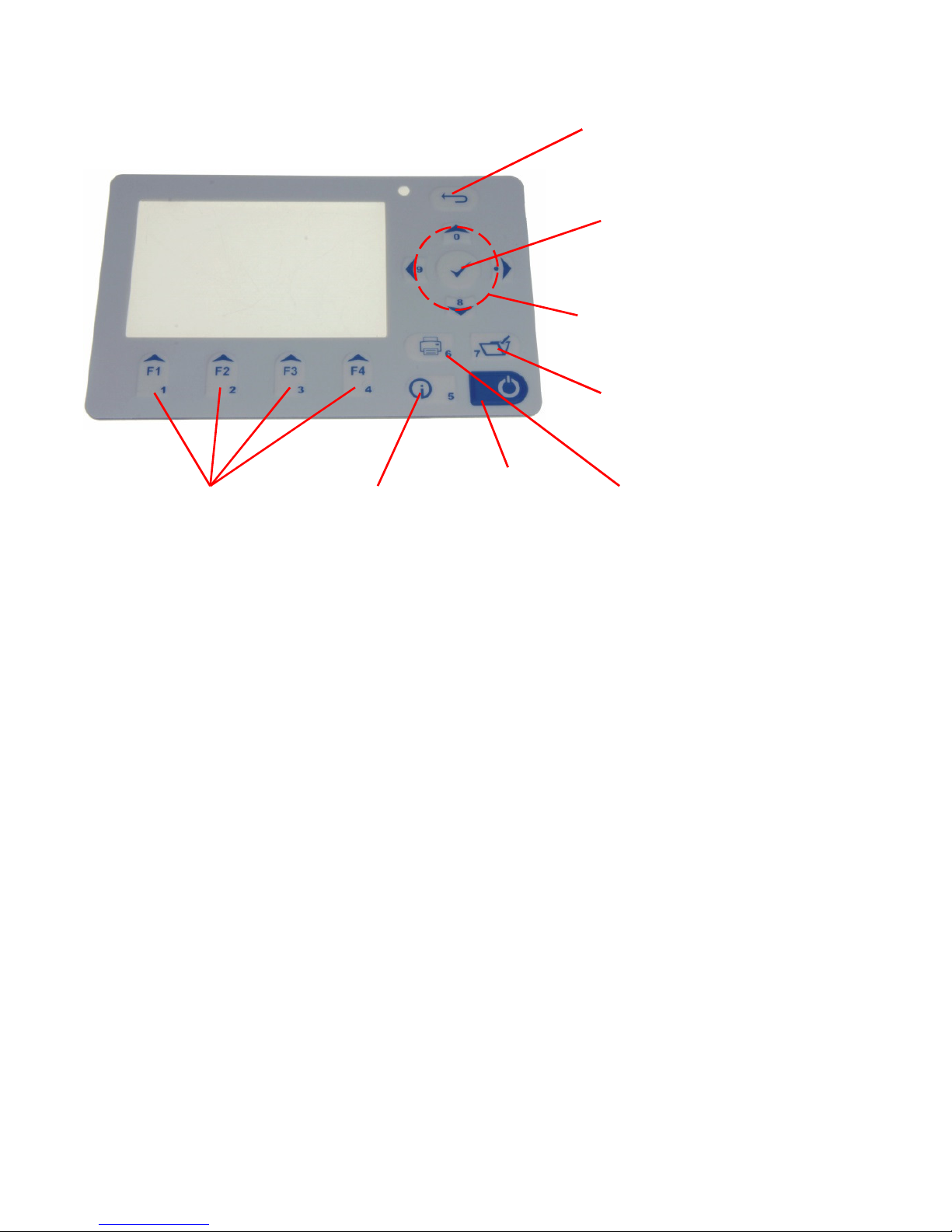

Keyboard

ESC key

(quit/

exit menu)

In the input mode, the keys are

used for numerical inputs

Enter key

(confirm

selection)

Cursor keys

(Up/Down/Right/

Left/Scroll)

Values

recording

Print key

(access to

printing menu)

ON / OFF

key

Info key

(access to

control menu)

Function keys

(function shown on

display)

Page 7

ecom-DP3 Page 7

3. Connection of components

Please connect the components as shown on below plan.

Connection hose

for connection on „ P high 1 + “

at the ecom-DP3

ecom-DP3

Y-piece

for the connection of 2

line sections

(f.e. with onepipe counter

cap)

Hose

connector

for connection

at measuring

nipple of the

plant

High-pressure

test stopples

for connection

at screw connections

One-pipe counter cap

for

the connection

in place of the

gas meter

Conic test

stopples

for connection

at line ends

Ball valve

for connection of external

devices for pressure

build-up

Connecting piece

with

safety valve

for connection of external

devices for pressure

build-up

Plug

to check the tightness

of the ecom-DP3

Never connect external devices for the pressure build-up

without connecting piece with safety valve!

Page 8

Page 8 ecom-DP3

Option

External pressure sensor

(0 – 20 bar or 0 – 40 bar)

for checking heating and

drinking water plants (connection „ext. Sensor“)

ecom-DP3

2 x Capillary hose

to measure the differ-

ence pressure with the

4-Pa-Test (connection

„P low 2“)

2 x Silicone hose

for small pressure and

flow measurements with

f.e. pitot probe (connection „P low 2“)

External room temperatur sensor

to measure the room

temperature during the

test (connection „T1“)

External pipe temperature sensor

to measure the pipe

temperature during the

test (connection „T1“)

External pipe temperature sensor

to

measure the pipe

temperature during the

test (connection „T2“)

Page 9

ecom-DP3 Page 9

4. Data processing

4.1. Data storage

The measurements made with the equipment can be assigned to a customer. For

each customer a file with file name is created on the memory card (e.g.:

DP3_0001.DAT). Into this file all measurements belonging to the customer are

written.

The files can be transferred to the PC using a card reader. With the software

"DP3Report" a protocol for each check can be made. The following conditions

must be fulfilled for using a multi media card:

- min. card volume 32 MB - max.32 GB (UHC)

- card formatted on 16 bit FAT or FAT32

- SD cards from SanDisk recommended

- PC with card reader

4.2. Edit customer

If the instrument gets switched on and a SD or MM

Card with no customer data is inserted the inquiry

follows whether you would like to edit a customer. If

the measurement is to be assigned to a customer,

press the key <F1> (<F4> = no: Measurement is

made without allocation). Proceed as follows:

-select line to be filled out with the cursor keys

<up/down> and confirm with <Enter>

-select keyboard <F3>

(4 keyboard are available)

-select a character with the cursor keys

<up/down/right/left>

(selected character is black deposited)

-take over the character with <Enter> (the last

character can be deleted with <F2>)

-repeat the procedure, until the desired designation

is complete

-if a character is to be corrected, proceeded as

follows:

-interrupt the character selection with <F4>

No customer

existing!

Create new

YES

NO

Never pull out cards during data record - data loss and damaging

of the data carrier possible!

Customer number

Name

Street

ZIP/City

DP3_0001.DAT

Tel.

Others

Page 10

Page 10 ecom-DP3

-select the character to be corrected with the

cursor keys <right/left>

-activate the character selection with <F4> and

correct the character

-return to line selection with <F1> and choose

the next line

If all necessary lines are filled out, a file is created

with <F1>. With <ESC> you can leave to select a

control program.

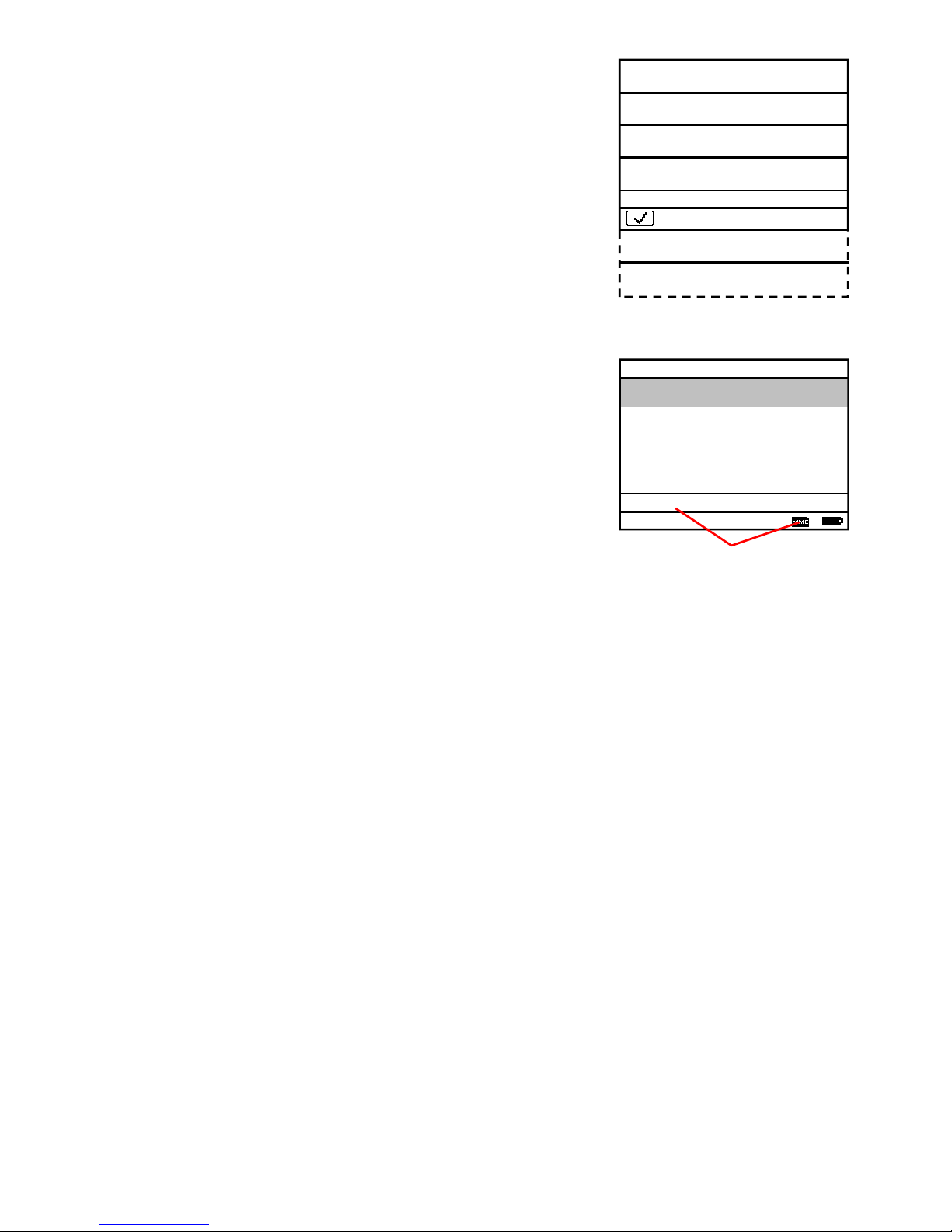

4.3. Select customer

With the help of the software „DP3Report“ customer

data can be stored for the use at the DP3 on SD or

MM Card. If the instrument gets switched on and a

SD or MM Card with customer data is inserted a

customer for allocation can be selected with "Search

for/Scroll" / <Enter>:

Scroll:

Select „Scroll“, if you want to find the customer with the help of the cursor keys

<up/down>. Further functions are:

<F1> = to the first customer

<F2> = 10 customers forward

<F3> = 10 customers backward

Search for:

Select „Search for“, if you want to find the customer by the input of at least 3

connected characters. Edit 3 characters as described in the chapter before and

start the search with <Enter>. All agreements with the character sequence are

picked out. The selection can be paged through with <F3> (with <F1> to the beginning of the selection).

If the desired customer is found, select with <Enter>. With „View/Modify“ the

customer data can be viewed and modified.

Format:

This function is usually needed by initial adjustment of the instrument at our factory (preparation of SD or MM Card for data recording).

Caution: All stored values will be cancelled! Please switch instrument after

formatting off and on again!

Search for/Scroll

Create new

View/Modify

Format

Fr 20.01.12 09:50:33

Cus

tomer data

DP3_0001.DAT

Customer is selected

Customer number

123456789

Name

Customer 1

Street

Street 1

ZIP/City

11111 City 1

DP3_0001.DAT

Tel.

123456789

Others

Customer 1 Others

Page 11

ecom-DP3 Page 11

5. Control programs

After switching on of the instrument the following pre-programmed control programs are available:

Natural gas:

-Stress test acc. to TRGI 2018

-Tightness check acc. to TRGI 2018

-Usability check acc. to TRGI 2018

Liquid gas:

-Tightness check

-Pressure test

Drinking water:

-Drinking water plant (wet) acc. to DIN EN 806-4:

-Function test

-Pressure test

-Extended test

-Drinking water plant (dry) acc. to DIN EN 806-4:

-Tightness test

-Stress test

Heating:

-Heating installation acc. to DIN 18380

Sewage:

-Sewage installation acc. to DIN 1610

More measurements:

-Pressure check (arbitrary pressure)

In menu „Adjustments“ / „Setup checks“ the parameters for the control programs can be adjusted:

5.1. Setup control programs

Scroll with the cursor keys <up/down> to the menu

„Adjustments“. Activate the menu with <Enter>.

Scroll with the cursor keys <up/down> to the menu

point „Setup checks“ and activate with <Enter>.

The following parameters can be adjusted:

Pressure check (arbitrary pressure):

-Stabilisation time (0 - 10 min, default: 0 min)

-Measurement time (0 - 6000 min, default: 0 min)

Respect the „Technical Rules for Gas installations“!

Natural gas

Liquid gas

Drinking water

Heating

Sewage

More measurement

Adjustments

Data storage

Fr 20.01.12 09:50:33

Setup checks

Set clock

Paper feeding

Print contrast

Displ. contrast

Key beep

Language: English

Pitot factor

Scan data logger

Printout

Select:

Adjustments

Page 12

Page 12 ecom-DP3

Stress test acc. to TRGI 2018:

-Stabilisation time (1 - 10 min, default: 1 min)

-Measurement time (10 - 120 min, default: 10 min)

-Test pressure (900 - 1500 hPa, default: 1000 hPa)

Tightness check acc. to TRGI 2018:

-Stabilisation time installation lower 100 Liter (1 - 20 min, default: 10 min)

-Measurement time installation lower 100 Liter (9 - 120 min, default: 10 min)

-Stabilisation time installation 100 bis 200 Liter (20 - 40 min, default: 30 min)

-Measurement time installation 100 bis 200 Liter (19 - 120 min, default: 20 min)

-Stabilisation time installation higher 200 Liter (50 - 70 min, default: 60 min)

-Measurement time installation higher 200 Liter (29 - 120 min, default: 30 min)

-Test pressure (15 - 500 hPa, default: 150 hPa)

Usability check acc. to TRGI 2018:

-Stabilisation time (5 - 240 min, default: 10 min)

-Measurement time (2 - 30 min, default: 5 min)

-Reference pressure (10 - 100 hPa, default: 23 hPa)

Function test drinking water plant (wet) acc. to DIN EN 806-4:

-Stabilisation time (0 - 120 min, default: 30 min)

-Measurement time (1 - 120 min, default: 15 min)

-Test pressure (0.01 – 20.00 bar, default: 6.00 bar)

Pressure test drinking water plant (wet) acc. to DIN EN 806-4:

-Stabilisation time (0 - 120 min, default: 0 min)

-Measurement time (1 - 120 min, default: 30 min)

-Test pressure (0.01 – 20.00 bar, default: 11.00 bar)

Extended test drinking water plant (wet) acc. to DIN EN 806-4:

-Stabilisation time (0 - 120 min, default: 0 min)

-Measurement time (1 - 240 min, default: 120 min)

-Test pressure (0.01 – 20.00 bar, default: 5.50 bar)

Tightness test drinking water plant (dry) acc. to DIN EN 806-4:

-Stabilisation time (0 - 120 min, default: 0 min)

-Measurement time (1 - 240 min, default: 120 min)

-Test pressure (1 - 2000 hPa, default: 150 hPa)

Stress test drinking water plant (dry) acc. to DIN EN 806-4:

-Stabilisation time (0 - 120 min, default: 0 min)

-Measurement time (1 - 120 min, default: 10 min)

-Test pressure (0.01 – 5.00 bar, default: 1.00 bar)

Heating plant acc. to DIN 18380:

-Stabilisation time (0 - 120 min, default: 0 min)

-Measurement time (1 - 240 min, default: 120 min)

-Test pressure (0.01 – 20.00 bar, default: 10.00 bar)

Sewage plant acc. to DIN 1610:

-Stabilisation time (0 - 100 min, default: 0 min)

-Measurement time (1 - 120 min, default: 30 min)

-Test pressure (1 - 2000 hPa, default: 200 hPa)

Page 13

ecom-DP3 Page 13

Tightness check liquid gas:

-Stabilisation time (0 - 60 min, default: 10 min)

-Measurement time (0 - 60 min, default: 10 min)

Test pressure (0 - 1000 hPa, default: 100 hPa)

Pressure test liquid gas:

-Stabilisation time (0 - 60 min, default: 10 min)

-Measurement time (0 - 60 min, default: 20 min)

-Test pressure (0 - 1500 hPa, default: 1000 hPa)

Pressure test 0 – 40 bar liquid gas:

-Stabilisation time (0 - 120 min, default: 10 min)

-Measurement time (1 - 240 min, default: 10 min)

-Test pressure (0 - 40 bar, default: 10 bar)

Each parameter can be adjusted the same way:

1. Select the parameter with cursor keys <up/down>

2. Press <Enter> to activate

3. Use numerical keys to input the value

To adjust the standard value press <F2>

Pressure check

min

10 min

Stabilisation

time

Please use the

Numeral keys!

20

Pressure check

Standard value : F2

10 min

Stabilisation time

Select:

Page 14

Page 14 ecom-DP3

5.2. Natural gas

5.2.1. Stress test

The stress test acc. to DVGW – TRGI Process

Instructions G 600 at gas pipes (operation pressure

up to 100 hPa) is registered as a control pragram in

the ecom-DP3. Proceed as follows:

1. Scroll with the cursor keys <up/down> in the

menu "Natural gas" to the menu point „Stress

test“. Activate the menu point with <Enter>.

2. Check if necessary the values of stabilisation time,

measurement time and test pressure with <F1>

(back with <ESC>).

3. Lock the gas pipe with a suitable adapter (test

stopple, high pressure stopple or one-pipe counter

cap).

4. Connect the components as described in

chapter 3.

5. Start the control program with <Enter> (the pump

of the instrument is building up the adjusted pressure).

6. Wait for stabilisation time (if the pressure remains

in the range „test pressure - 10%" during stabilisation

time, so the measurement time will start). If necessary the stabilisation time can be terminated with

<F1>.

7. Once the measurement time is over, the result is

displayed and can be printed with <Print>.

8. If the menu „Stress test“ is selected again, so

the result can be called up with <F4> (as long as the

ecom-DP3 is switched on) or a new measurement

can be started with <F1>.

Stress test

1Bar/1000hPa TRGI 2018

Stabilisation time

Res. time: 58sec

Pressu 1003.1hPa -0.8hPa

Temp. 22.6°C 0.3°C

Start Difference

1002.3hPa

Stress test

1Bar/1000hPa TRGI 2018

Measur. in process

Res. time: 9:25min

Pressu 1002.3hPa 0.0hPa

Temp. 22.6°C 0.0°C

Start Difference

1002.3hPa

Stress test

1Bar/1000hPa TRGI 2018

Set value 1000hPa

is built up!

902.3hPa

1min

10min

Stress test

1Bar/1000hPa TRGI 2018

Connect!

Forward w.:

Set value 1000

hPa

0.0hPa

Stress test

1Bar/1000hPa TRGI 2018

Measurement 10:00min

Ini. Press 1002.3hPa

Fin. Press 1002.3hPa

Difference 0.0hPa

Ini. temp. 22.6°C

End temp. 22.6°C

Difference

0.0°C

Forward w.:

Stress test

1Bar/1000hPa TRGI 2018

Start new

measurement?

Select:

YES

NO

Page 15

ecom-DP3 Page 15

5.2.2. Tightness check

The tightness check acc. to DVGW – TRGI Process

Instructions G 600 at gas pipes (operation pressure

up to 100 hPa) is registered as a control pragram in

the ecom-DP3. Proceed as follows:

1. Scroll with the cursor keys <up/down> in the

menu "Natural gas" to the menu point „Tightness

check“. Activate the menu point with <Enter>.

2. Adjust the gas pipe volume with <F2> (lower

100L, 100L..200L or higher 200L).

3. Check if necessary the values of stabilisation time,

measurement time and test pressure with <F1>

(back with <ESC>).

4. Lock the gas pipe with a suitable adapter (test

stopple, high pressure stopple or one-pipe counter

cap).

5. Connect the components as described in

chapter 3.

6. Start the control program with <Enter> (the pump

of the instrument is building up the adjusted pressure).

7. Wait for stabilisation time (if the pressure remains

in the range „test pressure - 10%" during stabilisation

time, so the measurement time will start). If necessary the stabilisation time can be terminated with

<F1>.

8. Once the measurement time is over, the result is

displayed and can be printed with <Print>.

9. If the menu „Tightness check“ is selected again,

so the result can be called up with <F4> (as long as

the ecom-DP3 is on) or a new measurement can be

started with <F1>.

Tightness check

150hPa (acc. TRGI 2018)

Stabilisation time

Res. time: 9:58min

Pressu 153.1hPa -0.8hPa

Temp. 22.6°C 0.3°C

Start Difference

152.3hPa

Tightness check

150hPa (acc. TRGI 2018)

Measur. in process

Res. time: 9:25min

Pressu 152.3hPa 0.0hPa

Temp. 22.6°C 0.0°C

Start Difference

152.3hPa

Tightness

check

150hPa (acc. TRGI 2018)

Set value 150hPa

is built up!

140.3hPa

10min

10min

Tightness check

150hPa (acc. TRGI 2018)

Measurement

10:00min

Ini. Press 152.3hPa

Fin. Press 152.3hPa

Difference 0.0hPa

Ini. temp. 22.6°C

End temp. 22.6°C

Difference

0.0°C

Forward w.:

Tightness check

150hPa (acc. TRGI 2018)

Start new

measurement?

Select:

YES

NO

Tightness check

150hPa (acc. TRGI 2018)

Connect!

Forward w.:

Set value

150hPa

lower 100L

0.0hPa

Page 16

Page 16 ecom-DP3

5.2.3. Usability check

The usability check acc. to DVGW – TRGI Process

Instructions G 600 at gas pipes (operation pressure

up to 100 hPa) is registered as a control pragram in

the ecom-DP3. Proceed as follows:

1. Scroll with the cursor keys <up/down> in the

menu “Natural gas" to the menu point „Usability

check“. Activate the menu point with <Enter>.

2. The measurement becomes prepared. The piston

is brought into its initial position.

3. Connect the components as described in

chapter 3.

4. Open gas shut-off valve of the installation. As

soon as the operating pressure of the plant is recognized, the system is aired out and the instrument

starts automatically the stabilisation time. If necessary the stabilisation time can be terminated with

<F1>.

5. Close gas shut-off valve after stabilisation time.

The measurement of the leak rate begins with <En-

ter>.

Usability check

acc. to TRGI 2018

Connect tubes!

Open gas shut-off valve!

Measuring starts once ope.

pressure is identifed

0.0hPa

Usability check

acc. to TRGI 2018

Stabilisation time

Res. time: 9:58min

24.15hPa

Usability check

acc. to TRGI 2018

Measur. in process

Time: 1:25min

Leak rate 1.52l/h

Pressu 24.11hPa

Temp. 24.3°C

Forward w.:

Usability check

acc. to TRGI 2018

Lose gas shut-off

valve now!

Continue with <Enter>

24.11hPa

U

sability check

acc. to TRGI 2018

Air is

getting removed

from system!

Measuring then starts

automatically!

Quit with:

Usability check

acc. to TRGI 2018

Measuring in preparation

Do not connect

any tubing!

Quit with:

Page 17

ecom-DP3 Page 17

6. After measuring time the installation must be

brought back into its original condition (remove hoses and open gas shut-off valve).

7. After the pressure in the instrument reduced itself

(or after pressing <Enter>), the result is displayed

and can be printed with <Print>.

8. If the menu „Usability check“ is selected again,

so the result can be called up with <F4> (as long as

the ecom-DP3 is on) or a new measurement can be

started with <F1>.

Usability check

acc. to TRGI 2018

Measurement 5:00min

Leak rate 1.51l/h

Ini. temp. 22.6°C

End temp. 22.6°C

Difference

0.0°C

Forward w.:

Usability che

ck

acc. to TRGI 2018

Start new

measurement?

Select:

YES NO

Usability check

acc. to TRGI 2018

Measurement completed!

Remove tubes!

Continue with <Enter>

Forward w.:

Page 18

Page 18 ecom-DP3

5.3. Liquid gas

5.3.1. Tightness check

The tightness check acc. to TRF at liquid gas pipes

is registered as a control pragram in the ecom-DP3.

Proceed as follows:

1. Scroll with the cursor keys <up/down> in the

menu "Liquid gas" to the menu point „Tightness

check“. Activate the menu point with <Enter>.

2. Check if necessary the values of stabilisation time,

measurement time and test pressure with <F1>

(back with <ESC>).

3. Lock the gas pipe with a suitable adapter (test

stopple, high pressure stopple or one-pipe counter

cap).

4. Connect the components as described in

chapter 3.

5. Start the control program with <Enter> (the pump

of the instrument is building up the adjusted pressure).

6. Wait for stabilisation time (if the pressure remains

in the range „test pressure - 10%" during stabilisation

time, so the measurement time will start). If necessary the stabilisation time can be terminated with

<F1>.

7. Once the measurement time is over, the result is

displayed and can be printed with <Print>.

8. If the menu „Tightness check“ is selected again,

so the result can be called up with <F4> (as long as

the ecom-DP3 is on) or a new measurement can be

started with <F1>.

Liquid gas

Tightness check

Connect!

Forward w.:

Set value 100

hPa

0.0hPa

Liquid gas

Tightness check

Stabilisation time

Res. time: 9:58min

Pressu 103.1hPa -0.8hPa

Temp. 22.6°C 0.3°C

Start Difference

102.3hPa

Liquid gas

Tightness check

Measur. in process

Res. time: 9:25min

Pressu 102.3hPa 0.0hPa

Temp. 22.6°C 0.0°C

Start Difference

102.3hPa

Liquid gas

Tightness check

Set value 100hPa

is built up!

92.3hPa

10min

10min

Liquid gas

Tightness check

Measurement 10:00min

Ini. Press 102.3hPa

Fin. Press 102.3hPa

Difference 0.0hPa

Ini. temp. 22.6°C

End temp. 22.6°C

Difference

0.0°C

Forward w.:

Liquid gas

Tightness check

Start new

measurement?

Select:

YES

NO

Page 19

ecom-DP3 Page 19

5.3.2. Pressure test

The pressure test acc. to TRF at liquid gas pipes is

registered as a control pragram in the ecom-DP3.

Proceed as follows:

1. Scroll with the cursor keys <up/down> in the

menu "Liquid gas" to the menu point „Pressure

test“. Activate the menu point with <Enter>.

2. Check if necessary the values of stabilisation time,

measurement time and test pressure with <F1>

(back with <ESC>).

3. Lock the gas pipe with a suitable adapter (test

stopple, high pressure stopple or one-pipe counter

cap).

4. Connect the components as described in

chapter 3.

5. Start the control program with <Enter> (the pump

of the instrument is building up the adjusted pressure).

6. Wait for stabilisation time (if the pressure remains

in the range „test pressure - 10%" during stabilisation

time, so the measurement time will start). If necessary the stabilisation time can be terminated with

<F1>.

7. Once the measurement time is over, the result is

displayed and can be printed with <Print>.

8. If the menu „Pressure test“ is selected again, so

the result can be called up with <F4> (as long as the

ecom-DP3 is on) or a new measurement can be

started with <F1>.

Liquid gas

Pressure test

Stabilisation time

Res. time: 9:58min

Pressu 1003.1hPa -0.8hPa

Temp. 22.6°C 0.3°C

Start Difference

1002.3hPa

Liquid gas

Pressure test

Measur. in process

Res. time: 9:25min

Pressu 1002.3hPa 0.0hPa

Temp. 22.6°C 0.0°C

Start Difference

1002.3hPa

Liquid gas

Pressure test

Set

value 1000hPa

is built up!

902.3hPa

1min

10min

Liquid gas

Pressure test

Measurement 10:00min

Ini. Press 1002.3hPa

Fin. Press 1002.3hPa

Difference 0.0hPa

Ini. temp. 22.6°C

End temp. 22.6°C

Difference

0.0°C

Forward w.:

Liquid gas

Pressure test

Start new

measurement?

Select:

YES

NO

Liquid gas

Pressure test

Connect!

Forward w.:

Set value

1000

hPa

0.0hPa

Page 20

Page 20 ecom-DP3

5.3.3. Pressure test 0 – 40 bar

The pressure test 0 - 40 bar at liquid gas pipes is

registered as a control pragram in the ecom-DP3.

Proceed as follows:

1. Scroll with the cursor keys <up/down> in the

menu "Liquid gas" to the menu point „Pressure

test 0 – 40 bar“. Activate the menu point with <Enter>.

2. Check if necessary the values of stabilisation time,

measurement time and test pressure with <F1>

(back with <ESC>).

3. Connect the external pressure sensor to the liquid

gas pipe.

4. Connect the external pressure sensor as described in chapter 3.

5. Start the control program with <Enter> (the pump

of the instrument is building up the adjusted pressure).

6. Wait for stabilisation time (if the pressure remains

in the range „test pressure - 10%" during stabilisation

time, so the measurement time will start). If necessary the stabilisation time can be terminated with

<F1>.

7. Once the measurement time is over, the result is

displayed and can be printed with <Print>.

8. If the menu „Pressure test 0 – 40 bar“ is selected again, so the result can be called up with <F4>

(as long as the ecom-DP3 is on) or a new measurement can be started with <F1>.

Liquid gas

Pressure test 0 – 40 bar

Stabilisation time

Res. time: 9:58min

Pressu 11.13bar -0.08bar

Temp. 22.6°C 0.3°C

Start Difference

11.05bar

L

iquid gas

Pressure test 0 – 40 bar

Measur. in process

Res. time: 9:25min

Pressu 11.05bar 0.00bar

Temp. 22.6°C 0.0°C

Start Difference

11.05bar

Liquid gas

Pressure test 0 – 40 bar

Set value 11.00bar

Built up pressure!

10.23bar

10min

30min

Liquid gas

Pressure test 0 – 40 bar

Measurement 10:00min

Ini. Press 11.05bar

Fin. Press 11.05bar

Difference 0.0bar

Ini. temp. 22.6°C

End temp. 22.6°C

Difference

0.0°C

Forward w.:

Liquid gas

Pressure test 0 – 40 bar

Start new

measurement?

Select:

YES

NO

Page 21

ecom-DP3 Page 21

5.4. Drinking water (option)

5.4.1. Drinking water plant (wet)

5.4.1.1. Function test

The function test acc. to DIN EN 806-4 at drinking

water pipes is registered as a control pragram in the

ecom-DP3. Proceed as follows:

1. Scroll with the cursor keys <up/down> in the

menu "Drinking water / Drinking water plant wet"

to the menu point „Function test wet“. Activate the

menu point with <Enter>.

2. Check if necessary the values of stabilisation time,

measurement time and test pressure with <F1>

(back with <ESC>).

3. Connect the external pressure sensor to the

drinking water pipe.

4. Connect the external pressure sensor as described in chapter 3.

5. Start the control program with <Enter> and and

built up the adjusted pressure.

6. Wait for stabilisation time (if the pressure remains

in the range „test pressure +/- 10%" during stabilisation time, so the measurement time will start). If necessary the stabilisation time can be terminated with

<F1>.

7. Once the measurement time is over, the result is

displayed and can be printed with <Print>.

8. If the menu „Function test wet“ is selected

again, so the result can be called up with <F4> (as

long as the ecom-DP3 is on) or a new measurement

can be started with <F1>.

Drinking water plant

Funkcion test wet

Stabilisation time

Res. time: 29:58min

Pressu 6.13bar -0.08bar

Temp. 22.6°C 0.3°C

Start Difference

6.05bar

Drinking water plant

Funkcion test wet

Measur. in process

Res. time: 14:25min

Pressu 6.05bar 0.00bar

Temp. 22.6°C 0.0°C

Start Difference

6.05bar

Drinking water plant

Funkcion test wet

Set value 6.00bar

Built up pressure!

5.23bar

30min

15min

Drinking water plant

Funkcion test wet

Measurement 15:00min

Ini. Press 6.05bar

Fin. Press 6.05bar

Difference 0.0bar

Ini. temp. 22.6°C

End temp. 22.6°C

Difference

0.0°C

Forward w.:

Drinking water plant

Funkcion test wet

Start new

measurement?

Select:

YES

NO

Page 22

Page 22 ecom-DP3

5.4.1.2. Pressure test

The pressure test acc. to DIN EN 806-4 at drinking

water pipes is registered as a control pragram in the

ecom-DP3. Proceed as follows:

1. Scroll with the cursor keys <up/down> in the

menu "Drinking water / Drinking water plant wet"

to the menu point „Pressure test wet“. Activate the

menu point with <Enter>.

2. Check if necessary the values of stabilisation time,

measurement time and test pressure with <F1>

(back with <ESC>).

3. Connect the external pressure sensor to the

drinking water pipe.

4. Connect the external pressure sensor as described in chapter 3.

5. Start the control program with <Enter> and and

built up the adjusted pressure.

6. Wait for stabilisation time (if the pressure remains

in the range „test pressure +/- 10%" during stabilisation time, so the measurement time will start). If necessary the stabilisation time can be terminated with

<F1>.

7. Once the measurement time is over, the result is

displayed and can be printed with <Print>.

8. If the menu „Pressure test wet“ is selected

again, so the result can be called up with <F4> (as

long as the ecom-DP3 is on) or a new measurement

can be started with <F1>.

Drinking water plant

Pressure test wet

Stabilisation time

Res. time: 9:58min

Pressu 11.13bar -0.08bar

Temp. 22.6°C 0.3°C

Start Difference

11.05bar

Drinking water plant

Pressure test wet

Measur. in process

Res. time: 29:25min

Pressu 11.05bar 0.00bar

Temp. 22.6°C 0.0°C

Start Difference

11.05bar

Drinking water plant

Pressure test wet

Set value 11.00bar

Built up pressure!

10.23bar

10min

30min

Drinking water plant

Pressure test wet

Measurement 30:00min

Ini. Press 11.05bar

Fin. Press 11.05bar

Difference 0.0bar

Ini. temp. 22.6°C

End temp. 22.6°C

Difference

0.0°C

Forward w.:

Drinking water plant

Pressure test wet

Start new

measurement?

Select:

YES

NO

Page 23

ecom-DP3 Page 23

5.4.1.3. Extended test

The extebded test acc. to DIN EN 806-4 at drinking

water pipes is registered as a control pragram in the

ecom-DP3. Proceed as follows:

1. Scroll with the cursor keys <up/down> in the

menu "Drinking water / Drinking water plant wet"

to the menu point „Extended test wet“. Activate the

menu point with <Enter>.

2. Check if necessary the values of stabilisation time,

measurement time and test pressure with <F1>

(back with <ESC>).

3. Connect the external pressure sensor to the

drinking water pipe.

4. Connect the external pressure sensor as described in chapter 3.

5. Start the control program with <Enter> and built

up the adjusted pressure.

6. Wait for stabilisation time (if the pressure remains

in the range „test pressure +/- 10%" during stabilisation time, so the measurement time will start). If necessary the stabilisation time can be terminated with

<F1>.

7. Once the measurement time is over, the result is

displayed and can be printed with <Print>.

8. If the menu „Extended test wet“ is selected

again, so the result can be called up with <F4> (as

long as the ecom-DP3 is on) or a new measurement

can be started with <F1>.

Drinking water plant

Extended test wet

Stabilisation time

Res. time: 9:58min

Pressu 5.63bar -0.08bar

Temp. 22.6°C 0.3°C

Start Difference

5.55bar

Drinking water

plant

Extended test wet

Measur. in process

Res. time: 1:59std

Pressu 5.55bar 0.00bar

Temp. 22.6°C 0.0°C

Start Difference

5.55bar

Drinking water plant

Extended test wet

Set

value

5.50bar

Built up pressure!

5.23bar

10min

120min

Drinking water plant

Extended test wet

Measurement 2.00std

Ini. Press 5.55bar

Fin. Press 5.55bar

Difference 0.0bar

Ini. temp. 22.6°C

End temp. 22.6°C

Difference

0.0°C

Forward w.:

Drinking water plant

Extended test wet

Start new

measurement?

Select:

YES

NO

Page 24

Page 24 ecom-DP3

5.4.2. Drinking water plant (dry)

5.4.2.1. Tightness check

The tightness check acc. to DIN EN 806-4 at drinking

water pipes is registered as a control pragram in the

ecom-DP3. Proceed as follows:

1. Scroll with the cursor keys <up/down> in the

menu "Drinking water / Drinking water plant dry"

to the menu point „Tightness check dry“. Activate

the menu point with <Enter>.

2. Check if necessary the values of stabilisation time,

measurement time and test pressure with <F1>

(back with <ESC>).

3. Lock the gas pipe with a suitable adapter (test

stopple, high pressure stopple or one-pipe counter

cap).

4. Connect the components as described in

chapter 3.

5. Start the control program with <Enter> (the pump

of the instrument is building up the adjusted pressure).

6. Wait for stabilisation time (if the pressure remains

in the range „test pressure +/- 10%" during stabilisation time, so the measurement time will start). If necessary the stabilisation time can be terminated with

<F1>.

7. Once the measurement time is over, the result is

displayed and can be printed with <Print>.

8. If the menu „Tightness check dry“ is selected

again, so the result can be called up with <F4> (as

long as the ecom-DP3 is on) or a new measurement

can be started with <F1>.

Drinking water plant

Tightness check dry

Stabilisation time

Res. time: 9:58min

Pressu 153.1hPa -0.8hPa

Temp. 22.6°C 0.3°C

Start Difference

152.3hPa

Drinking water plant

Tightness check dry

Measur. in process

Res. time: 1:59std

Pressu 152.3hPa 0.0hPa

Temp. 22.6°C 0.0°C

Start Difference

152.3hPa

Drinking water plant

Tightness check dry

Set value 150hPa

is built up!

140.3hPa

10min

120min

Drinking water plant

Tightness check dry

Measurement 2.00std

Ini. Press 152.3hPa

Fin. Press 152.3hPa

Difference 0.0hPa

Ini. temp. 22.6°C

End temp. 22.6°C

Difference

0.0°C

Forward w.:

Drinking water plant

Tightness check dry

Start new

measurement?

Select:

YES

NO

Drinking water plant

Tightness check dry

Connect!

Forward w.:

Set value 150hPa

0.0hPa

Page 25

ecom-DP3 Page 25

5.4.2.2. Stress test

The stress test acc. to DIN EN 806-4 at drinking

water pipes is registered as a control pragram in the

ecom-DP3. Proceed as follows:

1. Scroll with the cursor keys <up/down> in the

menu "Drinking water / Drinking water plant dry"

to the menu point „Stress test dry“. Activate the

menu point with <Enter>.

2. Check if necessary the values of stabilisation time,

measurement time and test pressure with <F1>

(back with <ESC>).

3. Connect the external pressure sensor to the

drinking water pipe.

4. Connect the external pressure sensor as described in chapter 3.

5. Start the control program with <Enter> and built

up the adjusted pressure.

6. Wait for stabilisation time (if the pressure remains

in the range „test pressure +/- 10%" during stabilisation time, so the measurement time will start). If necessary the stabilisation time can be terminated with

<F1>.

7. Once the measurement time is over, the result is

displayed and can be printed with <Print>.

8. If the menu „Stress test dry“ is selected again,

so the result can be called up with <F4> (as long as

the ecom-DP3 is on) or a new measurement can be

started with <F1>.

Drinking water plant

Sress test dry

Stabilisation time

Res. time: 9:58min

Pressu 3.13bar -0.08bar

Temp. 22.6°C 0.3°C

Start Difference

3.05bar

Drinking water plant

Sress test dry

Measur. in process

Res. time: 9:25min

Pressu 3.05bar 0.00bar

Temp. 22.6°C 0.0°C

Start Difference

3.05bar

Drinking water plant

Sress test dry

Set value 3.00bar

Built up pressure!

2.23bar

10min

10min

Drinking water plant

Sress test dry

Measurement 10:00min

Ini. Press 3.05bar

Fin. Press 3.05bar

Difference 0.0bar

Ini. temp. 22.6°C

End temp. 22.6°C

Difference

0.0°C

Forward w.:

Drinking water plant

Sress test dry

Start new

measurement?

Select:

YES

NO

Page 26

Page 26 ecom-DP3

5.5. Heating (option)

The test of heating installations acc. to DIN 18380 is

registered as a control pragram in the ecom-DP3.

Proceed as follows:

1. Scroll with the cursor keys <up/down> to the

menu point „Heating“. Activate the menu point with

<Enter>.

2. Check if necessary the values of stabilisation time,

measurement time and test pressure with <F1>

(back with <ESC>).

3. Connect the external pressure sensor to the

drinking water pipe.

4. Connect the external pressure sensor as described in chapter 3.

5. Start the control program with <Enter> and built

up the adjusted pressure.

6. Wait for stabilisation time (if the pressure remains

in the range „test pressure +/- 10%" during stabilisation time, so the measurement time will start). If necessary the stabilisation time can be terminated with

<F1>.

7. Once the measurement time is over, the result is

displayed and can be printed with <Print>.

8. If the menu „Heating“ is selected again, so the

result can be called up with <F4> (as long as the

ecom-DP3 is on) or a new measurement can be

started with <F1>.

Heating

Stabilisation time

Res. time: 9:58min

Pressu 3.13bar -0.08bar

Temp. 22.6°C 0.3°C

Start Difference

3.05bar

Heating

Measur. in process

Res. time: 1:59std

Pressu 3.05bar 0.00bar

Temp. 22.6°C 0.0°C

Start Difference

3.05bar

Heating

Set value 3.00bar

Built up pressure!

2.23bar

10min

120min

Heating

Measurement 2.00std

Ini. Press 3.05bar

Fin. Press 3.05bar

Difference 0.0bar

Ini. temp. 22.6°C

End temp. 22.6°C

Difference

0.0°C

Forward w.:

Heating

Start new

measurement?

Select:

YES

NO

Page 27

ecom-DP3 Page 27

5.6. Sewage (option)

The test of sewage installations acc. to DIN 1610 is

registered as a control pragram in the ecom-DP3.

Proceed as follows:

1. Scroll with the cursor keys <up/down> to the

menu point „Sewage“. Activate the menu point with

<Enter>.

2. Check if necessary the values of stabilisation time,

measurement time and test pressure with <F1>

(back with <ESC>).

3. Connect the testing balloons as described.

4. Start the control program with <Enter> and built

up the adjusted pressure.

5. Wait for stabilisation time (if the pressure remains

in the range „test pressure +/- 10%" during stabilisation time, so the measurement time will start). If necessary the stabilisation time can be terminated with

<F1>.

6. Once the measurement time is over, the result is

displayed and can be printed with <Print>.

7. If the menu „Sewage“ is selected again, so the

result can be called up with <F4> (as long as the

ecom-DP3 is on) or a new measurement can be

started with <F1>.

Sewage

Stabilisation time

Res. time: 9:58min

Pressu 153.1hPa -0.8hPa

Temp. 22.6°C 0.3°C

Start Difference

152.3hPa

Sewage

Measur. in process

Res. time: 9:25min

Pressu 152.3hPa 0.0hPa

Temp. 22.6°C 0.0°C

Start Difference

152.3hPa

Forward w.:

Sewage

Set value

150hPa

Built up pressure!

140.3hPa

10min

10min

Sewage

Measurement 10:00min

Ini. Press 152.3hPa

Fin. Press 152.3hPa

Difference 0.0hPa

Ini. temp. 22.6°C

End temp. 22.6°C

Difference

0.0°C

Forward w.:

Sewage

Start new

measurement?

Select:

YES NO

Page 28

Page 28 ecom-DP3

6. More measurements

6.1. Single measurement

Beside the control programs the ecom-DP3 can be

used also to measure pressures, temperatures and

flow rates. Under „More measurements / Single

measurment“ all measured values are displayed on

a view. The measurement of the flow rate is made

with a pitot tube (connection P low 2).

If the measured values should be printed, press the

key <record> (disk symbol) to transfer the values in

the intermediate memory. The values can be printed

with the help of the <print> key (printer symbol). If a

printout of the values should be made simultaneously to the intermediate recording, so press <F2> (the

intermediate memory will be printed).

After selection of a customer, a data logging of all

measured values can be started (and also stopped)

with <F3>. The interval time for the data logging can

be adjusted under „Adjustments / Scan data log-

ger“. With the help of the software „DP3Report“ the

data can be converted into a format readable for

Microsoft Excel.

T1 23.2 °C

T2 23.1 °C

DT 0.1 °C

Druck 20.4 hPa

Extern 4.00 bar

dP 12.8 Pa

V.Gas 2.5

m/sek

We

01.02.12 09:17:55

T1 23.2 °C

T2 23.1 °C

dT 0.1 °C

Pressure 20.4 hPa

Ext. 4.00 bar

dP 12.8 Pa

V.Gas 2.5

m/sec

We 01.02.12 09:17:55

Measurement stored in

intermediate memory

Data logger is

started

T1 23.2 °C

T2 23.1 °C

dT 0.1 °C

Pressure 20.4 hPa

Ext. 4.00 bar

dP 12.8 Pa

V.Gas

2.5 m/sec

We

01.02.12 09:17:55

Page 29

ecom-DP3 Page 29

6.2. Heating Check (Option)

The heating check is a simple, expressive process to evaluate a complete heating

plant (heat production, distribution and transfer) from the energetic point of view.

Hereby the single plant components get inspected by the heating engineer in a

combination of measurements and visual assessment and valued in regards of

their energetic quality acc. to a negative point system of maximum 100 points.

The higher the score, the farer the current plant is away from the desirable energetic stand and the higher the energy saving potential would be if modernisation

measures are conducted.

In combination with the special probes required hereto, the ecom-DP3 is able to perform the measurement of the heating check parameters: ventilation

losses and surface losses. Out of the main menu

point "More measurements", select the sub-menu

"Heating Check" and confirm with <Enter>.

With the menu point “Gas losses” gas loss values

can be converted to negative point system. The gas

loss value can be edit with the numerical keyboard.

After input the result is calculated with <Enter> and

stored in „Results“.

The surface losses measurement is performed by

a temperature sensor specific for surfaces. The temperature difference between boiler surface and room

temperature (air temperature sensor) is determined

and the percentual loss is calculated. Once the menu

point is called up, the boiler performance must be

inputed. To easy the measurement width, depth and

height of the boiler can also be entered (dimensions

will be memorized for surface calculation). Please

proceed as follows:

- activate respective input window

with <Enter>

- inputs values using the keys numerical

function

- confirm input with <Enter>

or:

- adjust values using the cursor

keys <Right/Left>

Gas losses

Surface losses

Ventilation losses

Results

Cancel

Heating Check

Select:

Temperature sensor

for surfaces

P.Boiler 24.5 kW

Width 1.20 m

Depth 1.20 m

Hight 1.20 m

Modify:

Surface loss

Start

Start

Page 30

Page 30 ecom-DP3

If no boiler dimensions are inputed, press <F1> (Start) to activate the measurement recording. Here the dimensions for all surfaces must be inputed.

Press <F3> (Start + ->) to start the real measurement. Proceed as follows:

- select surface (boiler side) to be

measured with <F1> or <F2>

- position surface sensor

- record temperature difference with

<Memory> - up to 10 values can be

recorded per surface out of which a

mean value will be calculated

automatically

- if need be, cancel measurements

with <F4>

- repeat this procedure for each surface

Once all surface temperatures have been determined, quit the menu with <ESC>.

The surface losses get automatically calculated. The value conversion in negative

points is available in the menu point „Results“.

The ventilation loss measurement is performed by

a flow probe 30 sec. after burner switch-off. This

measurement can be performed at the earliest 5 min.

after instrument´s switch-on as the pressure sensor

requires this period of time for stabilisation. Once the

menu is called up, the values for air pressure, external temperature, boiler performance and exhaust gas

pipe diameter must be inputed . Hereto proceed as

follows:

- open respective window with <Enter>

- input figures using numerical function of keys

- confirm input with <Enter>

or:

- adjust values using the cursor keys <Right/Left>

Flow probe

Wid. --- m

Hei. --- m

Surf --- m2

T.S. --- °C

T.A. --- °C

T.S. 21.5 °C

T.A. 21.5 °C

Surface losses

Store

Surfa.

-0-

Wid. 1.20 m

Hei. 1.20 m

Surf 1.44 m2

T.S. 40.5 °C

T.A. 21.5 °C

T.S. 42.5 °C

T.A. 21.5 °C

Surface losses

Store

Surfa.

-1-

Page 31

ecom-DP3 Page 31

Press <F1> (Start) prior to going thru the following steps to start the measurement:

- release tubing of the flow probe

- wait for zeroing of pressure sensor

- re-connect tubing of the flow probe

- position flow probe into exhaust gas pipe (observe mark for flow direction)

- switch off burner and simultaneously press <F1>

or:

- press <F2> to activate timer (5 sec.) and switch off burner by beep

- after approx. 30 sec. the measurement value converted in negative points

is available

An overview of the measurements is available under „Results“. Press <Print> to

print them out.

Gas loss 2.9 %

Points 2.6

Surf. Lo. 2.29 %

Points 3.4

Vent. lo. 3.11 %

Points 3.0

Heating Check

Quit with:

Gas losses

Surface losses

Ventilation losses

Results

Cancel

Heating Check

Select:

Page 32

Page 32 ecom-DP3

6.3. 4Pa measurement (option)

The simultaneous operation of room-dependent firing place and air evacuation

system can lead to dangerous low pressure conditions. With the ecom-DP3 it is

possible to check the low pressure limit value of 4 Pa and to document in a diagramme the time course of the low pressure value. Once the menu point is called

up, the measurement is to be performed as follows:

- connect capillary hose for room where burner is installed to „-“

- connect capillary hose for reference place (staircase or outside air to „+“

- operate firing and evacuation systems with maximal performance

- open window resp. connection door to burner room and check the correct

evacuation of the exhaust gases

- zero pressure sensor with <F4>

- position capillary hose for reference location

- start record pressure value course with <F1> (Start) (an acoustical signal is

issued every 30 sec. which can be deactivated / re-activated by pressing <F2>)

- record pressure by opened window resp. connection door

- close window resp. connection door after approx. 30 sec. and check low

pressure

- after approx. 30 sec. open window resp. connection door and check zero point

- close window resp. connection door after approx. 30 sec. and check low

pressure

- after approx. 30 sec. re-open window or connection door and check zero point

- after approx. 30 sec. close window resp. connection door and check low

pressure

Once the measurement time is completed, the diagramme can be viewed on the

display (use <F3> to emphasize illustration 1x, 2x, 4x, 8x times or A for automatic). Start a printout if needed with <Print>.

Page 33

ecom-DP3 Page 33

6.4. Pressure check

The pressure check (long term measurement up to

1500 hPa or 20 bar with external pressure sensor) is

registered as a control pragram in the ecom-DP3.

Proceed as follows:

1. Scroll with the cursor keys <up/down> in the

menu "More measurements" to the menu point

„Pressure check“. Activate the menu point with

<Enter>.

2. Check if necessary the values of stabilisation time,

measurement time and test pressure with <F1>

(back with <ESC>). If the measurement time is set to

0, thecontrol program runs until it is interrupted.

3. Lock the gas pipe with a suitable adapter (test

stopple, high pressure stopple or one-pipe counter

cap) or connect the external pressure sensor.

4. Connect the components as described in

chapter 3.

5. Start the control program with <Enter> and built

up the adjusted pressure.

6. If the internal sensor (up to 1500 hPa) is used, the

needed pressure can be built up with the internal

pump (switch on and off with <F3>).

7. Wait for stabilisation time. If necessary the stabilisation time can be terminated with <F1>.

8. Once the measurement time is over (or with <En-

ter> if measurement time = 0), the result is displayed

and can be printed with <Print>.

9. If the menu „Pressure check“ is selected again, so the result can be called

up with <F4> (as long as the ecom-DP3 is on) or a new measurement can be

started with <F1>.

Pressure check

1,5Bar/1500hPa long tes

Stabilisation time

Res. time: 58sek

Pressu 1003.1hPa -0.8hPa

Temp. 22.6°C 0.3°C

Start Difference

1002.3hPa

Pressure check

1,5Bar/1500hPa long tes

Measur. in process

Res. time: 9:25min

Pressu 1002.3hPa 0.0hPa

Temp. 22.6°C 0.0°C

Start Difference

1002.3hPa

Pressure check

1,5Bar/1500hPa long tes

Measurement

10:00min

Ini. Press 1002.3hPa

Fin. Press 1002.3hPa

Difference 0.0hPa

Ini. temp. 22.6°C

End temp. 22.6°C

Difference

0.0°C

Forward w.:

Pressure check

1,5Bar/1500hPa long tes

Start new

measurement?

Select:

YES

NO

Pressure check

1,5Bar/1500hPa long tes

Build up pressure

Forward w.:

0.0hPa

Page 34

Page 34 ecom-DP3

7. Adjustments

Additionally to those ecom-DP3 functions described

previously, various adjustments can be made in the

instrument. From the main menu, select the submenu "Adjustments" and confirm with <Enter>.

A selection of modifiable parameters, adjustable

according to the application, is displayed. Place the

cursor on the desired line and press <Enter> to call

up or modify the adjustment. The modifiable parameters are:

Setup checks

(press <Enter> to access input menu):

-Input of parameters for the check programs

Clock set (press <Enter> to access setting menu):

-Correction of internal clock with cursor keys

Paper feed (press <Enter> to activate paper feeding):

-Paper feed line by line

Print contrast (press <Enter> to access setting menu):

-Print contrast adjustment with cursor keys

Display contrast (press <Enter> to access setting menu):

- Display contrast adjustment with cursor keys

Key beep (<F1> for YES / <F4> for NO):

- Acoustical signal by key pressing

Language: English (change with <Enter>):

-Info about selected language (3 languages selectable)

Pitot factor (selection after pressing <Enter>):

-Input of Pitot factor for flow rate calculation (standard = 0.93)

Scan data logger (min 1 second / max. 59:59 minutes):

(press <Enter> to access menu):

-Input the interval time for data logging (1 sec = 0.01 min).

Printout (selection after pressing <Enter>):

-Text input for printout on measurement protocol (8 x 24 characters)

-Input the text of line 1 as follows:

1. Activate character selection list with <F4>.

2. Select keyboard type with <F3> (4 different keyboards available).

Setup checks

Set clock

Paper feeding

Print contrast

Displ. contrast

Key beep

Language: English

Pitot factor

Scan data logger

Printout

Select:

Adjustments

Page 35

ecom-DP3 Page 35

3. Use the cursor keys to select the desired character

(selected character is outlined by black background).

4. Confirm selection while pressing <Enter>.

5. Repeat procedure until desired text is complete.

6. Once input for line 1 is completed, deactivate the characters selection mode

with <F4> and move to the second line with the cursor key <Down>.

7. Once all lines have been processed as desired, exit the menu with <ESC>.

Page 36

Page 36 ecom-DP3

8. Control (system test)

In menu „Control“ (access with <Info> key) informations are displayed on 2 pages

(use cursor keys to scroll):

-software version

-serial number

-error amount

-operation hours since last service

-total operation hours

-operation hours pump

-distance of the piston

-date of the next recommended service

-phone number of the next service center

-accu voltage (charging status);

is displayed as a symbol in all menus:

Full charge Half charge Empty

System test (check of instrument tightness):

1. introduce system test with <Enter>

2. lock connection „P high 1 +“ with plug

3. start test with <Enter> (pressure is built up)

4. wait for result (approx. 2 min)

5. remove plug and leave with <Enter>

If the system is leaky,please contact your ecom partner.

Program version: V1.0 25.01.2012

Serial number : 4711

Error counter : 12

Further pages:

Operation hrs : 8.45 std

At a total : 18.75 std

Pump : 0.17 std

Cylinder (way) : 13 m

Next sevice : 25.01.2013

Service tel. : 02371/945

-

5

Programmversion: V1.0 25.01.2012

Geräte Nr. : 4711

Battery 6.73 Volt

Further pages:

Next sevice : 25.01.2013

Service tel. : 02371/945

-

5

Systemtest:

Page 37

ecom-DP3 Page 37

9. Technical Data ecom-DP3

Power supply: -battery: Lithium-Ions 6 V 4,6 Ah

-charger 230 V / 50 Hz~

Indication: -grafic display; backlit

-resolution 240 x 160 Punkte

-window approx. 79 x 53 mm

Pressure range: -0 - 1500 hPa

-0 - 20 bar (option / external sensor)

-0 - 10 hPa (option / Pa sensor)

Resolution: -0,1 hPa

-0,01 bar (option / external sensor)

-0,1 Pa (option / Pa sensor)

Leak rate: -0 - 8 l/h

Resolution: -0,1 l/h

Temperature: -2 x 0 -100 °C (option / external temperature sensor)

Resolution: -0,1 °C (option / external temperature sensor)

Dimensions (LxWxH): -approx. 380 x 430 x 170 mm

Weight: -complete with accessories approx. 9 kg

Ambient temperature: -0 to 50 °C

Page 38

Page 38 ecom-DP3

10. Maintenance tips

To secure the accuracy of your measuring instrument we recommend the annual

check by an authorized ecom partner. In the case of strong demand (e.g. permanent several hours of measurement per day, rough conditions etc.) shorter intervals between checks should be selected - please contact your ecom partner. All

ecom partners are listed under www.ecom.de.

Change printer paper roll

-Release the printer cover (press lock downwards).

-If necessary, extract the paper rest out of the printer. Hereto select

"Adjustments"/"Paper feed"/<Enter>.

-Remove the plastics tube of the previous roll.

-Insert the paper end in the slot under the transport roll (paper roll inner side

facing you while inserting the paper).

-Convey approx. 3 cm paper thru the printer ("Adjustments"/"Paper

feeding"/<Enter>).

-Lay the paper roll in the corresponding hollow.

-Insert the paper thru the slot of the printer compartment cover and close the

latest.

Subject to technical changes

V1.3 12.2018

ecom GmbH

Am Großen Teich 2

D-58640 Iserlohn

Telefon: +49 (0) 23 71 - 9 45-5

Telefax: +49 (0) 23 71 - 4 03 05

Internet: http://www.ecom.de

eMail: info@ecom.de

Unlocking

printer cover

Loading...

Loading...