Page 1

Operating Instructions

Page 2

Page 2

ecom-B

Index Page

Important Hints 4

1. Instrument Design 6

2. Switch on Instrument 7

3. Choose a storage location 8

4. Gas Analysis

4.1. Measurement Preparations 9

4.2. Gas Analysis 9

4.3. Draft Measurement 11

4.4. Soot...Oil trace 12

4.5. Record and print Measurement Result 12

4.6. After Measurement 13

5. Mean value (option) 14

6. Measurement Routines (option)

6.1. Atmospheric Boilers 15

6.2. Fan Burners

6.2.1. Gas Fan Burners 19

6.2.2. Oil Fan Burners 22

6.3. Diagnosis gas 24

7. Pressure Tests (option) 26

8. Adjustment 33

9. Control 36

10. Data processing

10.1. Communication 37

10.2. Data processing with App 38

11. Maintenance Tips 39

12. Technical Data 41

13. FAQ 42

Page 3

ecom-B Page 3

___________________________

Congratulations!

With your purchase you have decided on a high-quality product of

ecom GmbH.

Get to know the product before you start using it while reading carefully the following instructions of use and the safety indications. Use

the product only as described and only for the given areas of application in order to ascertain its longevity.

___________________________

Page 4

Page 4

ecom-B

Important Hints

The ecom

-

B meets the requirements

of the DIN EN 50379 Part 2.

The ecom

-

B may not be used for continuous

emission control!

Following minimum times must be kept to get

correct measurement results:

-1 Minute for fresh air calibration

-2 Minutes to get stable measurement results

Following substances affect the function of the

instrument:

-solvent containing gases as in:

- cleaning agents

- fat remove agents

- wax polish

- adhesives

-Formaldehyde

Settings on fireplaces should just be made by

professionals who are experienced with the

function and adjustments of fireplaces!

1. Charge the battery

regularly (Charge not

used instrument min. once a month)!

2. Never store the instrument with unloaded

battery!

Page 5

ecom-B Page 5

Do not lock fresh air opening

for fresh air pump!

Fresh air opening

Remove probe tube

completely before

starting gas analysis!

Page 6

Page 6

ecom-B

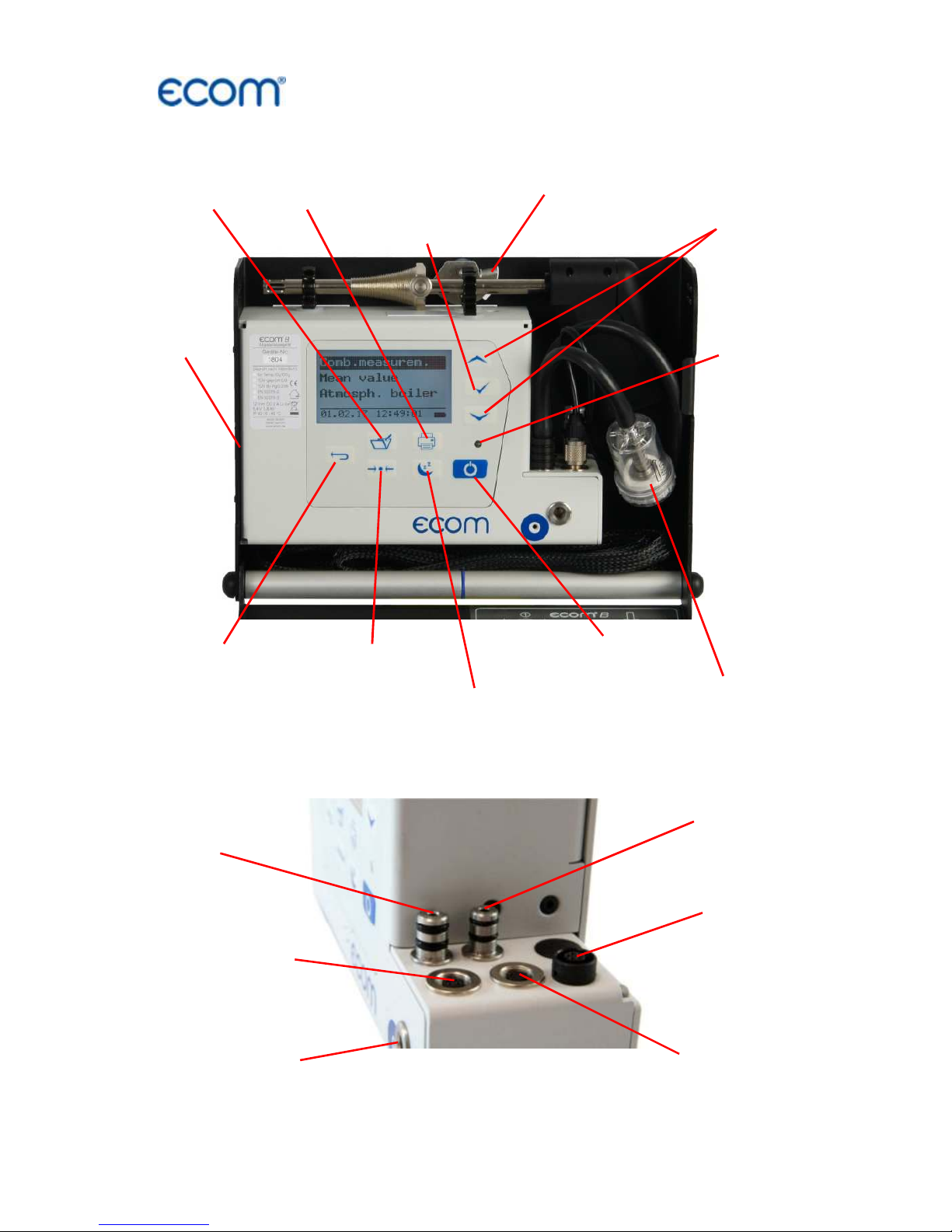

1. Instrument Design

Air

temperature

connection

ESC key

(quit/

exit menu)

Gas temperature

connection

RS232

interface

Gas

connection

Draft

connection

Pressure

connection

Charging

socket

Enter button

(confirm

selection)

Cursor control

(up/down/scroll)

Store

key

Print

key

Instrument

ON/OFF

CAL key

Standby

key

Unlocking

front flap

IR diode

(for IR

printer)

Condensate

pad

Page 7

ecom-B Page 7

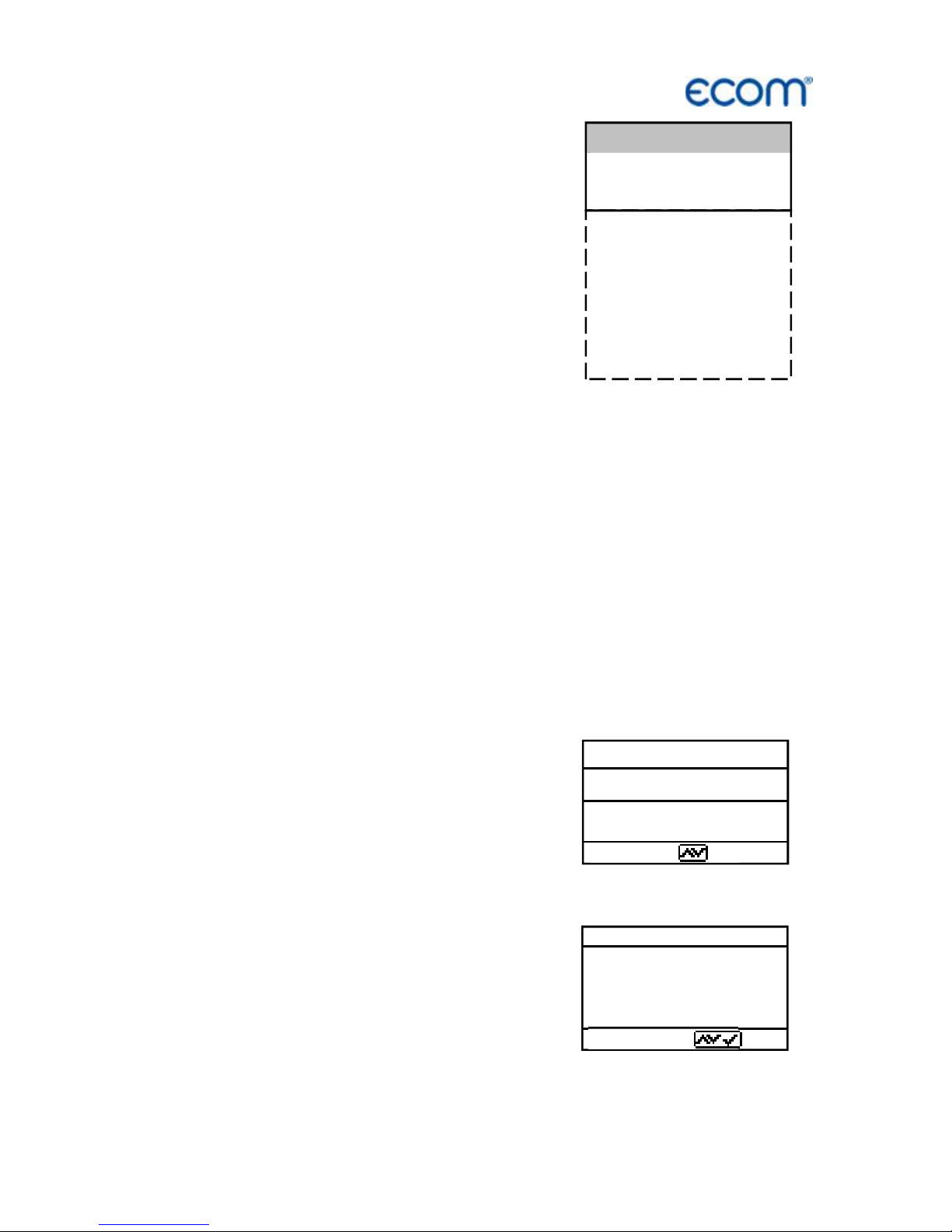

2. Switch on Instrument

After switch on the instrument (press <I/0>)

the main menu appears on the display.

There will be displayed sub-menus with

following functions (not visible sub-menus

could be displayed by scrolling with arrow

keys):

Comb. measure. : operate combustion measurement

(Mean value : operate mean value measurement)*

(Atmospheric boiler : operate routine for atmospheric boilers)*

(Fan burner : operate routine for fan burners)*

(Diagnostic gas : operate routine for gas fireplaces)*

(Pressure tests : pressure tests according to TRGI)*

(Data processing : assign measurements / Data transfer)*

Adjustments : change adjustments of instrument

Control : check operating status of instrument (* = Option)

To perform measurements, select with the cursor keys the sub-menu

"Gas analysis" and confirm with <Enter>. The instruments starts

then a 1- minute calibration phase and the fuel types selection list is

displayed. The following fuel types acc. to 1

st

BImSchV are available:

Fuel oil (B)

Natural gas (B)

City gas (B)

Coke oven gas (B)

Liquid gas (B)

Use the cursor keys to select the desired

fuel type and confirm with <Enter>. The

instrument will then enquire if you wish to

use the data bank (only with option „Data

processing“).If you want to assign the

sampled data to a specific plant, so choose

„YES“ with the cursor keys and confirm

with <Enter>. („NO“ = measurement will

be performed without assignment).

Comb.measure.

Mean value

Atmosph. boiler

Burn. w. blower

Diagnosis gas

Pressure tests

Data processing

Adjustment

Control

Type of fuel

Fuel oil (B)

CO2max : 15.4

A1-fact.

: 0.50

Select with

↑↓ Data processing

NO

Are you sure?

Continue with :

↑↓

↵↵↵↵

Page 8

Page 8

ecom-B

3. Input or select a data record (Option)

The ecom-B has 300 storage locations

(option). In order to call up a data record

with data are already stored in the instrument or to create a new file, choose a data

record with the Cursor keys and confirm

with <Enter>

If you are choosing an empty data record, a designation (max. 16

indications) can be assigned. Proceed as follows:

-choose a keyboard with the <CAL.> key (5 keyboards are available)

-select a character with the keys <Store> (left), <Print> (right) and

the Cursor keys <up/down> (selected character is black deposits)

-take over the character with <Enter>

-repeat procedure, until desired designation is complete

-if you want to correct a character, proceed as follows:

-interrupt the selection with <Standby>

-select the character with the keys <Store> (left), <Print> (right)

and the Cursor keys <up/down>

-activate the selection with <Standby> and select the correct

character

-turn to Combustion measurement with 2 x <ESC> , „Comb. meas-

urem.“ and <Enter>.

If you are choosing a data record with data, you can call up the data

with <Enter> / <Store> / <Enter>. Now you can view the data with

the Cursor keys <up/down>.

Memory number 0

Data record

is empty !

Confirm with :

↑↓

↵↵↵↵

Page 9

ecom-B Page 9

4. Combustion Measurement

4.1 Prepare Combustion Measurement

Prepare instrument for measurement operation by making all connections (T-Room sensor and T-Gas, GAS and DRA of the 3chamber hose). Make sure that:

-the condensate pad has sufficient capacity

-the condensate pad is not soiled darker than no. 3 on the soot scale

4.2. Gas Analysis

Once the calibration cycle is over, the instrument enters the measurement mode. The measurement values could be displayed on 4

screen pages (3 x gas analysis; 1 x draught measurement – change

with curser keys):

Just position the probe in the exhaust pipe once the

calibration phase is over!

To obtain accurate measurement values it’s

important to re-calibrate the instrument after each

measurement (at the latest after one hour)!

O2 4.0 %

CO2 12.5 %

CO 30 ppm

Lambda 1.23

T.Gas 166 °C

T.Air 20 °C

Losses 7.0 %

Eta 93.0 %

O2 4.0 %

CO2 12.5 %

T.Air 20 °C

T.Gas 212 °C

O2 4.0 %

CO2 12.5 %

CO 30 ppm

Lambda 1.23

Condensate pad

Page 10

Page 10

ecom-B

The position of the measured and calculated values (gas analysis)

can be selected freely on the display. To change the position or the

composition, please proceed as follows:

-with <Enter> / <Display values> / <Enter> activate the first line on

the display

-choose with curser key the measured or calculated value

-with <Enter> activate the next line on the display and so on

-with <ESC> or <Enter> in the last line you leave this process.

The values for CO

2

, Efficiency, Losses, Lambda and the Dew Point

are calculated values. They just can be calculated when realistic

figures for the basic values like O

2

and the temperature are available.

It must be assured that:

O

2

< 20,5 % and T.Gas – T.Air > + 5°C

The dew point can just be calculated correctly if in the menu “Adjustments / Air pressure” the current barometric air pressure has

been entered. If the combustion gas temperature falls below the dew

point /between 25 and 65°C) the efficiency will be calculated with

condensation gain. In this case a (C) is displayed behind the efficiency . Correct measurement values are displayed after a delay of 1

to 1,5 minutes necessary for the gas transport to the sensors and to

establish a stable electrochemical reaction in the sensors. For storage and printing wait for the values to become stable. If the gas value still fluctuates for more than 2 ppm, the reason could be in an

unstable draft condition in the gas channel.

Once the measurement values are stable

and the results can be printed, press

<store> to transfer the values to the temporary memory. Data will be stored here for

later printout (the values of the temporary

memory could be checked by pressing

<Enter> / <store> / <Enter>. While checking the values the gas pump will be

switched off in order to spare the sensors.

(back with <ESC>).

O2 4.0 %

CO2 12.5 %

CO 30 ppm

Lambda 1.23

T.Gas 166 °C

T.Air 20 °C

Losses 7.0 %

Eta 93.0 %

Measurement stored

in temporary memory

Page 11

ecom-B Page 11

CO-switch-off without purging pump

The internal program protects the CO-sensor for overload. In case

the limit of 2000 ppm (CO sensor without H

2

) is exceeded the gas

pump will be switched off. Remove the probe off the combustion gas.

Then press the key <CAL>. The gas pump turns on and purges the

instrument with fresh air. After sufficient purge time the unit switches

back to measuring mode (put the probe in the combustion gas).

CO-switch-off with purging pump (option)

The internal program protects the CO-sensor for overload. In case

the limit of 4000 ppm (CO sensor with H

2

) is exceeded a second

pump switches on and purges the sensor with fresh air. After sufficient purging time (blinking: "CO"), the sensor can be brought back

to the measurement mode with <Enter> / <CO MV ON/OFF> / <En-

ter> (the sensor can also manually be switched off by pressing <Enter> / <CO MV ON/OFF> / <Enter>).

4.3. Draft Measurement

The gas measurement mode already provides a trend indication of

the draught conditions in the combustion gas channel. As the pressure sensor is very sensitive and tend to drift, the value will not be

recorded by pressing <store>. It is therefore recommended to recalibrate this sensor prior to the actual measurement and results printing.

The current value will be displayed as well

as the remark to reset the zero point of the

sensor. Therefore disconnect the draught

hose from the instrument and press the key

<CAL>. By this the sensor is calibrated.

Connect the draught hose again with the

instrument. The exact measurement value

is displayed now and can be stored by

pressing <store> and added to the other

values already in the temporary memory.

The stored value will appear on the display.

Draught

Draft

-0.12 hPa

Val.: - . - - hPa

Set zero point

CAL.

Draught

Draft

-0.12 hPa

Val.: -0.12 hPa

Set zero point

CAL.

Page 12

Page 12

ecom-B

4.4. Soot...Oil trace

Under „Soot...Oil trace“ the measurement results for boiler temperature, soot number and oil derivative can be entered. Select the corresponding line in the display and activate the entry by <Enter>. The

input for boiler temperature and soot number (3 measurements) can

be done as follows:

-select with the keys <store> (left) and <Print> (right) the position

which should be changed (corresponding field is blinking)

-enter the designated number with the curser keys <up/down>

By pressing the key <Enter> the entry will be transferred to the data

record of the measurement. The result of the oil derivative checking

will be documented as follows:

-set cursor to line „Soot...Oil trace“

-select the result with the key <Enter>

(“No”, “Yes” or “- - - “)

When all necessary entries have been made the entry can be closed

by pressing the key <ESC>. The measurement is now completed.

4.5. Record and print Measurement

After scrolling back to the gas measurement with the cursor keys <up/down> the

measurement can be transferred to the

internal memory with <Enter> / <Store to

memory> / Enter> (after successful storage an “M” will appear right down in the

display). Finally a print-out (IR printer required) of the results can be made (key

<Print>).

After the gas analysis, please transfer the recorded

data (intermediate memory) into the internal

instrument memory otherwise the values will

get lost by instrument switch-off!

Soot...Oil trace

T.Boiler --- °C

1.Soot meas. ---

2.Soot meas. ---

3.Soot meas. --Oil trace ---

Input:

↵↵↵↵

Display/Memory

Memory

Store to memory

Display values

CO MV ON/OFF

Continue with:

↑↓

↵↵↵↵

Page 13

ecom-B Page 13

Please care for a frictionless (direct sight) connection between the

sending diode and the receiving diode on the printer. The maximal

distance between both units should not exceed ca. 40 cm otherwise

a trouble free transfer is no more ascertained in any case.

4.6. After Measurement

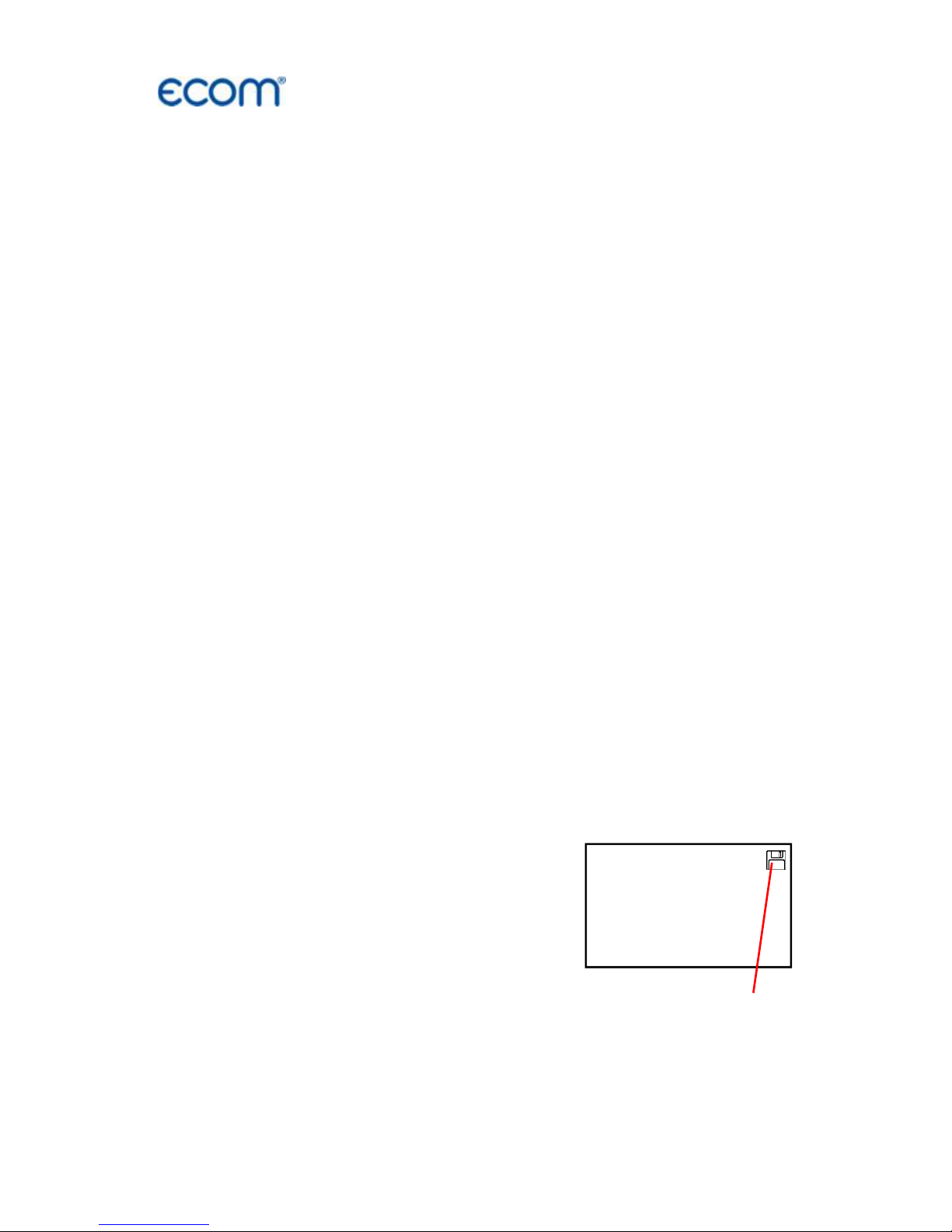

Stow probe and probe tube in the device (only devices with aluminium cover) as follows:

1. Attach the probe to the designated fixation.

2. Slide the probe tube starting at the probe into the space between

device and case. Pass the hose here alternately from right to left and

from left to right.

Let the probe cool down before

stowing them!

probe tube

Probe

Storage space for

probe tube

Probe fixation

sending diode

receiving diode

Page 14

Page 14

ecom-B

5. Mean value (option)

By mean value measurement function, measurements can be sampled within an adjustable time frame and mean values can be calculated. Should the several measurement values or the mean value

result be stored a storage place has to be selected as described in

chapter 4.

Once the fresh air calibration is completed, select the menu point „Mean

values“. Before starting, the parameters „Measurement time“ and „Scan-

ning“ should be checked or modified if

need be. The meaning is respectively:

- Measurement time = Time frame

during which the mean values will

be sampled

- Scanning = Time interval between the

measurements considered for mean

value calculation

„Measurement time“ and „Scanning“

can be adjusted as follows:

- select menu point and confirm with

<Enter>

- set the desired time using the cursor keys

After adjustment / control the measurement can be started by

<Start> / <Enter>. With the cursor keys <up/down>, it is possible to

switch between current and average readings. The measurement

can be interrupted by pressing <Standby> (pressing <Standby>

again sets the measurement continued).

Comb.measure.

Mean value

Atmosph. boiler

Burn. w. blower

Diagnosis gas

Pressure tests

Data processing

Adjustment

Mean value

Start

Meas. time

Scanning

Continue with :

↑↓

↵↵↵↵

Page 15

ecom-B Page 15

6. Measurement Routines (Option)

The ecom-B provides measurement routines that makes standard

checking on atmospheric boilers and fan burners easier.

6.1. Atmospheric Boilers

Select from the main menu the sub menu „Atmosph. Boilers” and

press <Enter>. The table of fuel types will be displayed. Following

fuel types can be selected:

Natural gas (B)

Town gas (B)

Coke gas (B)

Liquid gas (B)

Select with the arrow keys the corresponding fuel type and confirm by pressing <En-

ter>. The measurement “Draft / Pressure”

is displayed. To operate the measurement

(0 – 100 hPa) the draught hose must be

connected. In case of deviations of the

zero point it could be reset by pressing

<CAL>.

Connect the draught hose to the instrument. After the pressure has stabilised it

can be stored by pressing <store> for later

printout. By pressing the key <store> again

the value will be deleted. Using the cursor

<down> it could be get to the next measurement.

Operate the following pressure measurement as described above. Not needed

measurements can be skipped by using

the cursor key <down> (these will not be

printed).

Type of fuel

Natural gas (B)

CO2max : 11.8

A1-fact. : 0.37

Select with

↑↓

Atmosph. boiler

Connection pressure

24.7 hPa

Val.: 24.7 hPa

Set zero point

CAL.

Atmosph. boiler

Flow pressure

21.1 hPa

Val.: 21.1 hPa

Set zero point

CAL.

Atmosph. boiler

Nozzle pres pa. load

4.4 hPa

Val.: 4.4 hPa

Set zero point

CAL.

Atmosph. boiler

Nozzle pres fu. load

13.1 hPa

Val.: 13.1 hPa

Set zero point

CAL.

Page 16

Page 16

ecom-B

Another feature of the ecom-B is to determine the thermal capacity brought to the

boiler. For this the gas meter has to be

observed. By pressing <Enter> a stopwatch can be started and stopped. The

amount of gas consumed in the meantime

is necessary for calculation and is entered

as follows:

1. Select the position which should be

changed with the keys <store> (left) and

<Print> (right) (corresponding field flashes)

2. Set the value by using the cursers <up /

down>.

After setting and confirmation by pressing

<Enter> the result of the calculation will be

displayed and stored. Calculation can be

repeated if needed. For calculation following heating values are taken:

Natural gas (B) = 9,53 kWh/m

3

Town gas (B) = 5,00 kWh/m3

Coke gas (B) = 4,83 kWh/m

3

Liquid gas (B) = 25,90 kWh/m

3

By using the curser <down> it can be

scrolled to the next measurement „Pres-

sure free“. Here is the option for another

pressure measurement.

At the next point of the routine (Curser

<down>) is the option of determination of a

temperature difference (W. Temp. warm –

W. Temp. cold).

Atmosph. boiler

W. Temp. cold

22 °C

Val.: 22 °C

Continue with : ↑↓

Atmosph. boiler

Press. free

14.3 hPa

Val.: 14.3 hPa

Set zero point

CAL.

Atmosph. boiler

Gas flow rate

- - . - m3/h

Perfo. - - . - kW

Start :

↵↵↵↵

Atmosph. boiler

Gas flow rate

Time: 1 sec

Continue with :

↵↵↵↵

Atmosph. boiler

Gas flow rate

4.9 m3/h

Perfo. 46.7 kW

Start :

↵↵↵↵

Atmosph. boiler

Gas flow rate

0.100 m3

↑↓

↵

↵ ↵

↵

← →

Page 17

ecom-B Page 17

For determination of the two temperatures

the T-Room probe is used (waterproof

version).

Storage of the measurement values (after

getting stable) is done by the key <store>.

By using the curser <down> it can be

scrolled to the next measurement “Temp

free”. Here is the option for another temperature measurement.

After storing the temperatures the COmeasurements are next. By pressing the

curser <down> a 1-minute calibration cycle

starts for flashing the sensors with fresh

air. During calibration cycle the probe must

not be positioned in the combustion tube.

After calibration cycle the CO-content of

the surrounding air can be determined. Use

the probe to check the area around the

boiler. Beside the stored value (press key

<store>) the instrument stores the maximum CO-value of the measurement.

Next point of the routine (curser key

<down>) is the CO-value in the combustion tube of the boiler which is determined.

For measurement the probe must be positioned in the combustion tube. Apart from

the stored value the maximum CO-value of

the measurement is stored.

Atmosph. boiler

CO ambient

6 ppm

Val.: 6 ppm

CO max: 9 ppm

Atmosph. boiler

CO flue gas

21 ppm

Val.: 21 ppm

CO max: 26 ppm

Atmosph. boiler

W. Temp. warm

48 °C

Val.: 48 °C

Continue with : ↑↓

Atmosph. boiler

Difference

26 °C

Continue with : ↑↓

Atmosph. boiler

Temp. free

34 °C

Val.: 34 °C

Continue with : ↑↓

Page 18

Page 18

ecom-B

After storing the CO-values the next point

are the draught measurements (curser key

<down>). For exact measuring it’s recommended to reset the sensor to zero. Remove the draught hose off the instrument

and press <CAL>. The zero point of the

sensor is set now. After the draught has

stabilised it can be stored for later printout

by pressing the key <store>:

At the end of the measurement routine

(curser down) it is checked whether a gas

leakage at the unit could be determined.

Confirmation could be done by using the

key <Enter> (yes / no).

The printout (IR printer required) of all results of the measurement routine could be

done by pressing <Print>.

Atmosph. boiler

Draft

-0.04 hPa

Val.: -0.04 hPa

Set zero point

CAL.

Atmosph. boiler

Gas leakage

No

Change:

↵↵↵↵

Page 19

ecom-B Page 19

6.2. Fan burners

Select from the main menu the sub menu “Fan burner” and press

<Enter>. The table of fuel types will be displayed. Following fuel

types can be selected:

Natural gas (B)

Town gas (B)

Coke gas (B)

Liquid gas (B)

Select with the arrow keys the corresponding fuel type and confirm by pressing <En-

ter>.

6.2.1. Gas fan burners

Selecting a gas fuel type the routine starts

with the measurement “Connecting pres-

sure”. To operate the measurement (0 –

100 hPa) the draught hose must be connected. In case of deviations of the zero

point it could be reset by pressing <CAL>.

Connect the draught hose with the instrument. After the pressure has stabilised it

can be stored by pressing <store> for later

printout. By pressing the key <store> again

the value will be deleted. Using the cursor

<down> it could be get to the next measurement.

Operate the following pressure measurement as described above. Not needed

measurements can be skipped by using

the cursor key <down> (these will not be

printed).

Type of fuel

Natural gas (B)

CO2max : 11.8

A1-fact. : 0.37

Select with

↑↓

Burn. w. blower

Connection pressure

22.1 hPa

Val.: 22.1 hPa

Set zero point

CAL.

Burn. w. blower

Nozzle pres fu. load

13.0 hPa

Val.: 13.0 hPa

Set zero point

CAL.

Burn. w. blower

Nozzle pres pa. load

6.4 hPa

Val.: 6.4 hPa

Set zero point

CAL.

Burn. w. blower

Flow pressure

18.7 hPa

Val.: 18.7 hPa

Set zero point

CAL.

Page 20

Page 20

ecom-B

Another feature of the ecom-B is to determine the thermal capacity brought to the

boiler. For this the gas meter has to be

observed. By pressing <Enter> a stopwatch can be started and stopped. The

amount of gas consumed in the meantime

is necessary for calculation and is entered

as follows:

1. Select the position which should be

changed with the keys <store> (left) and

<Print> (right) (corresponding field flashes)

2. Set the value by using the cursers <up /

down>.

After setting and confirmation by pressing

<Enter> the result of the calculation will be

displayed and stored. Calculation can be

repeated if needed. For calculation following heating values are taken:

Natural gas (B) = 9,53 kWh/m

3

Town gas (B) = 5,00 kWh/m3

Coke gas (B) = 4,83 kWh/m

3

Liquid gas (B) = 25,90 kWh/m

3

By using the curser <down> it can be

scrolled to the next measurement „Pres-

sure free“. Here is the option for another

pressure measurement.

At the next point of the routine (Curser

<down>) is the option of determination a

temperature difference (W. Temp. warm –

W. Temp. cold). For determination of the

two temperatures, the T-Room probe is

used (waterproof version).

Burn. w. blower

W. Temp. kalt

21 °C

Val.: 21 °C

Continue with : ↑↓

Burn. w. blower

W. Temp. warm

54 °C

Val.: 54 °C

Continue with : ↑↓

Burn. w. blower

Press. free

4.5 hPa

Val.: 4.5 hPa

Set zero point

CAL.

Burn. w. blower

Gas flow rate

- - . - m3/h

Perfo. - - . - kW

Start :

↵↵↵↵

Burn. w. blower

Gas flow rate

Time: 1 sec

Continue with :

↵↵↵↵

Burn. w. blower

Gas flow rate

4.2 m3/h

Perfo. 40.0 kW

Start :

↵↵↵↵

Burn. w. blower

Gas flow rate

0.100 m3

↑↓

↵

↵ ↵

↵

← →

Page 21

ecom-B Page 21

Storage of the measurement values (after

getting stable) is done with the key

<store>.

By using the curser <down> it can scrolled

to the next measurement “Temp free”.

Here is the option for another temperature

measurement.

After storing the temperatures the measurement of the combustion gases are next.

By pressing the curser <down> a 1-minute

calibration cycle starts for flashing the sensors with fresh air. During calibration cycle

the probe must not be positioned in the

combustion tube. After calibration cycle,

the combustion measurement at part capacity can be started. For measurement

the probe must be positioned in the combustion tube. Measurement will be stated

by pressing <Enter>. After 90 seconds the

measured values will be automatically

stored for later printout.

Next point of the routine is the combustion

measurement at full capacity by pressing

<Enter>. Also here the values will be

measured after 90 seconds.

After finishing the combustion measurement the CO-value of the surrounding air

can be determined. Use the probe to check

the area around the boiler. Besides the

stored value (press <store>) the instrument stores the maximum CO-value of the

measurement.

Burn. w. blower

CO ambient

5 ppm

Val.: 5 ppm

CO max: 9 ppm

Burn. w. blower

Difference

33 °C

Continue with : ↑↓

Burn. w. blower

Temp. free

37 °C

Val.: 37 °C

Continue with : ↑↓

CO2

9.6 %

O2 4.0 %

CO 30 ppm

Eta 93.0 %

T.Gas 166 °C

T.Luft 20 °C

Parti. load

Start :

↵↵↵↵

CO2

9.6 %

O2 4.0 %

CO 30 ppm

Eta 93.0 %

T.Gas 166 °C

T.Luft 20 °C

Full load

Start :

↵↵↵↵

Page 22

Page 22

ecom-B

At the end of the measurement routine

(curser <down>) it is checked whether a

gas leakage at the unit could be determined. Confirmation could be done by using the key <Enter> (yes / no).

The printout (IR printer required) of all results of the measurement routine could be

done by pressing <Print>.

6.2.2. Oil fan burner

Using Heating oil (B) as fuel type the routine starts by determining the oil flow and

the thermal capacity brought to the boiler.

Open the menu <Oil pressure> by pressing <Enter>. Enter the measured oil pressure as follows:

1. Use the keys <store> (left) and <Print>

(right) to come to the positions which

should be changed (corresponding field is

flashing).

2. Set the number by using the curser

keys.

After setting and pressing <Enter> the submenu nozzle size will be opened. Enter the

used nozzle size like described above.

After setting and pressing <Enter> the

result of the calculation will be displayed.

The calculation can be repeated if needed.

For calculation following heating values are

taken:

Heating oil (B) = 11,86 kWh/kg

Burn. w. blower

Gas leakage

No

Change :

↵↵↵↵

Burn. w. blower

Oil rate

- - . - kg/h

Perfo. - - . - kW

Input :

↵↵↵↵

Burn. w. blower

Oil rate

2.5 kg/h

Perfo. 29.7 kW

Input :

↵↵↵↵

Burn. w. blower

Oil press.

12.00 bar

↑↓

↵

↵ ↵

↵

← →

Burn. w. blower

Nozz. size

0.60 Gal/h

↑↓

↵

↵ ↵

↵

← →

Page 23

ecom-B Page 23

At the next point of the routine (curser

<down>) there is the option of determination of a temperature difference (W. Temp.

warm – W. Temp. cold). For determination

of the two temperatures the T-Room probe

is used (waterproof version).

Storage of the measurement values (after

getting stable) is done by the key <store>.

By using the curser <down> it can be

scrolled to the next measurement “Temp

free”. Here is the option for another temperature measurement.

After storing the temperatures, the measurement of the combustion gases follows.

By pressing the curser <down> a 1-minute

calibration cycle starts for flashing the sensors with fresh air. During calibration cycle

the probe must not be positioned in the

combustion tube. After calibration cycle,

the combustion measurement at part capacity can be started. For measurement

the probe must be positioned in the combustion tube. Measurement will be started

by pressing <Enter>. After 90 seconds the

measured values will be automatically

stored for later printout.

Next point of the routine is the combustion

measurement at full capacity by pressing

<Enter>. Also here the values will be

measured after 90 seconds.

The printout (IR printer required) of all results of the measurement routine could be

done by pressing <Print>.

Burn. w. blower

W. Temp. cold

21 °C

Val.: 21 °C

Continue with : ↑↓

Burn. w. blower

W. Temp. warm

54 °C

Val.: 54 °C

Continue with : ↑↓

Burn. w. blower

Difference

33 °C

Continue with : ↑↓

Burn. w. blower

Temp. free

37 °C

Val.: 37 °C

Continue with : ↑↓

CO2

12.5 %

O2 4.0 %

CO 30 ppm

Eta 93.0 %

T.Gas 166 °C

T.Air 20 °C

Parti. load

Start :

↵↵↵↵

CO2

12.5 %

O2 4.0 %

CO 30 ppm

Eta 93.0 %

T.Gas 166 °C

T.Air 20 °C

Full load

Start :

↵↵↵↵

Page 24

Page 24

ecom-B

6.3. Diagnosis gas

Select from the main menu the sub menu “Diagnosis Gas” and

press <Enter>. The table of fuel types will be displayed. Following

fuel types can be selected:

Natural gas (B)

Town gas (B)

Coke gas (B)

Liquid gas (B)

Select with the arrow keys the corresponding fuel type and confirm by pressing <En-

ter>.

First the thermal capacity brought to the

boiler can be determined with the ecom-B.

For this the gas meter has to be observed.

By pressing <Enter> a stopwatch can be

started and stopped. The amount of gas

consumed in the meantime is necessary

for calculation and is entered as follows:

1. Select the position which should be

changed with the keys <store> (left) and

<Print> (right) (corresponding field flashes)

2. Set the value by using the cursers <up /

down>.

After setting and confirmation by pressing

<Enter> the result of the calculation will be

displayed and stored. Calculation can be

repeated if needed. For calculation following heating values are taken:

Natural gas (B) = 9,53 kWh/m

3

Town gas (B) = 5,00 kWh/m

3

Coke gas (B) = 4,83 kWh/m

3

Liquid gas (B) = 25,90 kWh/m

3

Type of fuel

Natural gas (B)

CO2max : 11.8

A1-fact. : 0.37

Select with

↑↓

Diagnosis gas

Gas flow rate

- - . - m3/h

Perfo. - - . - kW

Start :

↵↵↵↵

Diagnosis gas

Gasdurchsatz

2.0 m3/h

Perfo. 19.1 kW

Start :

↵↵↵↵

Diagnosis gas

Gas flow rate

Time: 1 sec

Continue with :

↵↵↵↵

Diagnosis gas

Gas flow rate

0.100 m3

↑↓

↵

↵ ↵

↵

← →

Page 25

ecom-B Page 25

After determination of the burning capacity

the next point of the routine is the COmeasurement. By pressing the curser

<down> a 1-minute calibration cycle starts

for flashing the sensors with fresh air. During calibration cycle the probe must not be

positioned in the combustion tube. After

calibration cycle the CO-content of the

surrounding air can be determined. Use the

probe to check the area around the boiler.

Beside the stored value (press key

<store>) the instrument stores maximum

CO-value of the measurement.

Next point of the routine (curser key

<down>) the CO-value in the combustion

tube of the boiler is determined. For measurement the probe must be positioned in

the combustion tube. Apart from the stored

value the maximum CO-value of the measurement is stored.

After storing the CO-values the next point

are the draught measurements (curser key

<down>). For exact measuring it’s recommended to reset the sensor to zero. Remove the draught hose off the instrument

and press <CAL>. The zero point of the

sensor is set now. After the draught has

stabilised it can be stored for later printout

by pressing the key <store>.

At the end of the measurement routine

(curser down) it is checked whether a gas

leakage at the unit could be determined.

Confirmation could be done by using the

key <Enter> (yes / no).

The printout (IR printer required) of all results of the measurement routine could be

done by pressing <Print>.

Diagnosis gas

CO ambient

0 ppm

Val.: - - - ppm

CO max: 0 ppm

Diagnosis gas

CO flue gas

0 ppm

Val.: - - - ppm

CO max: 26 ppm

Diagnosis gas

Draft

-0.12 hPa

Val.: - . - - hPa

Set zero point

CAL.

Diagnosis gas

Gas leakage

No

Change :

↵↵↵↵

Page 26

Page 26

ecom-B

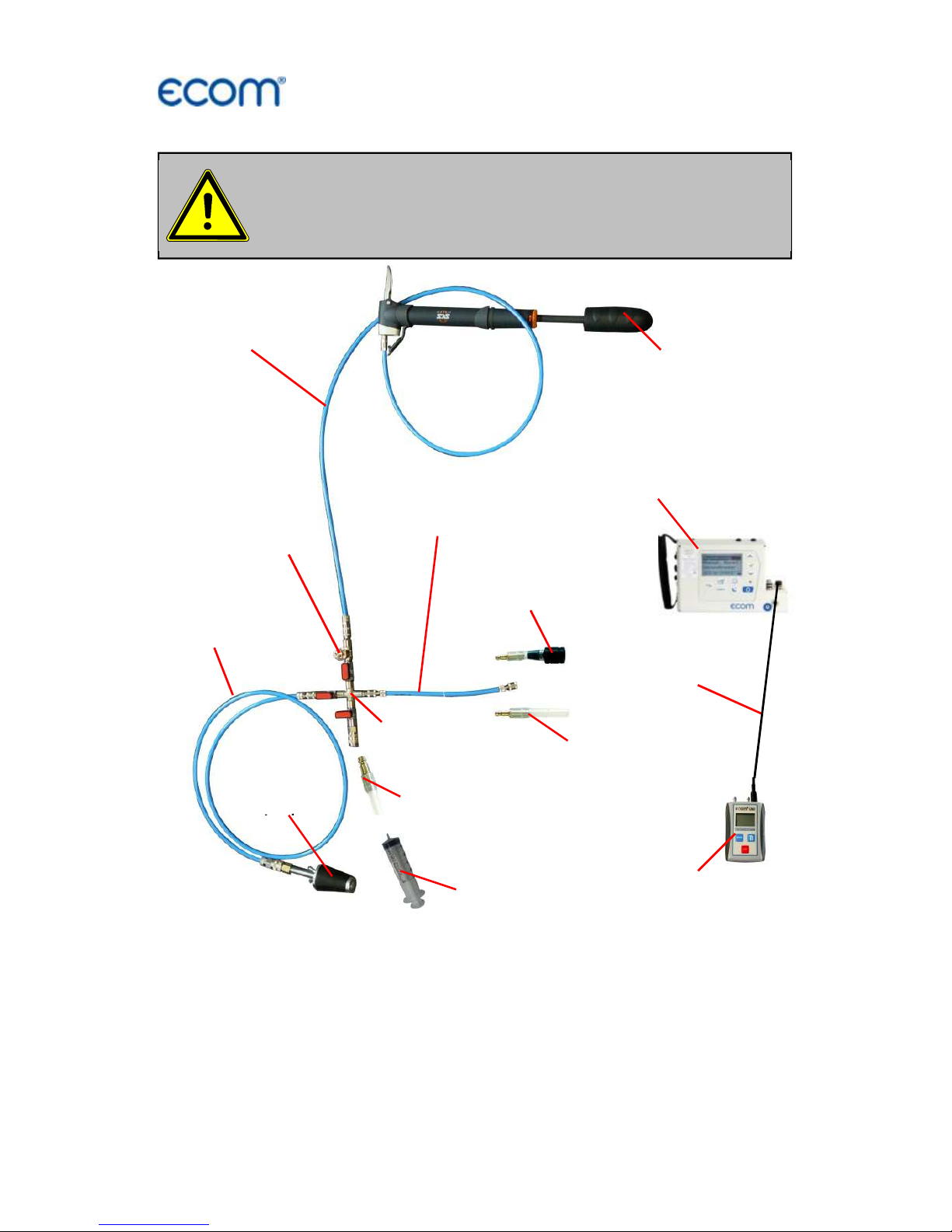

7. Pressure Tests (option)

1. Use only air or inert gas for check !

2. Respect the „Technical Rules for

Gas installations“!

Air pump

Connection hose

(Pump - Crosspiece)

Safety valve

Crospiece

ecom-B

Connection hose

(Gas system – Crospiece)

ecom

-

UNO

(only for Loading

and Tightness Test)

Squirt

Connection Squirt

or Soot pump

Connection

ecom-UNO (+)

Connection

ecom-

B (delta

p-)

Connection hose

(ecom-B/UNO –

Crospiece)

Electrical

connection

ecom-

B/UNO

Conic test stopple

or

One-pipe counter cap

or

High-pressure test

Page 27

ecom-B Page 27

Call up the menu „Pressure Tests“ with the pre-programmed

measurement routines „Pressure Test“, „Loading Test“, „Tight-

ness Test“ and „Usage property“. Parameters to each measurement routine can be adjusted in the menu „Setup“.

Setup

Scroll with cursor keys <Up/Down> until the menu “Setup”. Press

<Enter> to activate the menu. The following parameters can be ad-

justed for the corresponding measurement routine:

Pressure Test

- Stabilization time (1 - 10 min, default: 1 min)

- Measurement time (10 - 120 min, default: 5 min)

Loading Test

- Stabilization time (1 - 10 min, default: 1 min)

- Measurement time (10 - 120 min, default: 10 min)

- Test pressure (900 - 1200 hPa, default: 1000 hPa)

Tightness Test

- Stabilization time (1 - 10 min, default: 1 min)

- Measurement time (10 - 120 min, default: 10 min)

- Test pressure (90 - 160 hPa, default: 150 hPa)

Usage property

- Stabilization time (1 - 270 min, default: 1 min)

- Measurement time (10 - 240 min, default: 10 min)

- Test pressure (20 - 160 hPa, default: 50 hPa)

- Max. operation pressure (10 - 100 hPa, default: 23 hPa)

Each parameter can be adjusted the same way:

1. Select the parameter with cursor keys <Up/Down>.

2. Press <Enter> to activate.

3. select the digit with the keys <Store> (left), <Print> (right) and

adjust with the cursor keys <up/down>.

4. Confirm with <Enter>.

Page 28

Page 28

ecom-B

Pressure Test

The “Pressure Test” up to 100 hPa is deposited as a measurement

routine in the ecom-B. Proceed as follows:

1. Close the conduit with a suitable adapter (test stopple, highpressure stopple or one-pipe counter cap).

2. Connect the components as described before.

3. Scroll with cursor keys <Up/Down> to the menu “Pressure Test”.

Activate with <Enter>.

4. Create the pre-adjusted test pressure (max. 100 hPa) with the air

pump.

5. Interrupt the connection to the air pump (switch-off the ball valve)

and start “Pressure Test” with <Enter>.

6. Wait for stabilization time (the measurement will start automatically).

7. Once the measurement time is over, the result is displayed and

can be printed (IR printer required) by pressing <Print>.

8. If the menu “Pressure Test” is selected again, so the result can

be called up with “No” / <Enter> (as long as the ecom-B is on) or a

new measurement can be started with “Yes” / <Enter> (switching

from “No“ to “Yes“ with cursor keys <Up/Down>).

Page 29

ecom-B Page 29

Loading Test

The “Loading Test“ acc. to DVGW – TRGI Process Instructions G

600 at pipes (operation pressure up to 100 hPa) is deposited as a

measurement routine in the ecom-B. Proceed as follows:

1. Connect the ecom-UNO to the connection AUX of the ecom-B.

2. Close the conduit with a suitable adapter (test stopple, highpressure stopple or one-pipe counter cap).

3. Connect the components as described before.

4. Scroll with cursor keys <Up/Down> to the menu „Loading Test“.

Activate with <Enter>.

5. Create the pre-adjusted test pressure with the air pump (the unit

beeps as soon as the pressure level is achieved).

6. Interrupt the connection to the air pump (switch-off the ball valve).

7. Wait for stabilization time (if the pressure remains in the range

“test pressure +/- 10%” during stabilization time, so the measurement will start).

8. Once the measurement time is over, the result is displayed and

can be printed (IR printer required) by pressing <Print>.

9. If the menu “Loading Test“ is selected again, so the result can

be called up with “No” / <Enter> (as long as the ecom-B is on) or a

new measurement can be started with “Yes” / <Enter> (switching

from “No“ to “Yes“ with cursor keys <Up/Down>).

Page 30

Page 30

ecom-B

Tightness Test

The “Tightness Test“ acc. to DVGW – TRGI Process Instructions G

600 at pipes (operation pressure up to 100 hPa) is deposited as a

measurement routine in the ecom-B. Proceed as follows:

1. Connect the ecom-UNO to the connection AUX of the ecom-B.

2. Close the conduit with a suitable adapter (test stopple, highpressure stopple or one-pipe counter cap).

3. Connect the components as described before.

4. Scroll with cursor keys <Up/Down> to the menu „Tightness

Test“. Activate with <Enter>.

5. Create the pre-adjusted test pressure with the air pump (the unit

beeps as soon as the pressure level is achieved).

6. Interrupt the connection to the air pump (switch-off the ball valve).

7. Wait for stabilization time (if the pressure remains in the range

“test pressure +/- 10%” during stabilization time, so the measurement will start).

8. Once the measurement time is over, the result is displayed and

can be printed (IR printer required) by pressing <Print>.

9. If the menu “Tightness Test“ is selected again, so the result can

be called up with “No” / <Enter> (as long as the ecom-B is on) or a

new measurement can be started with “Yes” / <Enter> (switching

from “No“ to “Yes“ with cursor keys <Up/Down>).

Page 31

ecom-B Page 31

Usage property

The “Usage property“ acc. to DVGW – TRGI Process form G 624

at conduits is memorised as a measurement routine by the ecom-B.

The calculation of the leak rate happens automatically according to

the following equation and corresponds herewith to the procedure of

the DVGW-TRGI Process Form G 624:

VB = V/TM * ((PA + P1)/(PA + P2)-1) * PB/P1 * f

with: VB = Gas leak volume in operation state (l/h)

V = Pipe content in litres

TM = Measurement duration in hours

PA = Barometer stand in hPa

P1 = Test pressure at meas. beginning in hPa

P2 = Test pressure at measurement end in hPa

PB = Maximal gas operation pressure in hPa

f = Factor for consideration of gas type

Proceed as follows:

1. Close the conduit with a suitable adapter (test stopple, highpressure stopple or one-pipe counter cap).

2. Connect the components as described before.

3. Scroll with cursor keys <Up/Down> to the menu „Usage proper-

ty“. Activate with <Enter>.

4. Adjust the air pressure (PA) with cursor keys <Up/Down> and

confirm with <Enter>.

5. Choose the gas type (f) with cursor keys <Up/Down> and confirm

with <Enter>. The following gas types are recorded with their respective factors:

Natural Gas, Air, Town Gas, Propane, Butane, Hydrogen

6. Adjust the maximal operation pressure (PB) with cursor keys

<Up/Down> and confirm with <Enter>.

Page 32

Page 32

ecom-B

7. The pipe volume (V) is needed for the calculation of the leak rate.

The ecom-B offers two possibilities:

a. Type in pipe volume (V):

- Choose “No” at the inquiry “Calculate Volume automatically ?“

(switching from “No“ to “Yes“ with cursor keys <Up/Down>).

- Adjust pipe volume (V) with cursor keys <Up/Down> and confirm

with <Enter>.

b. Calculate pipe volume automatically (V):

- Choose YES at the inquiry „Calculate Volume automatically ?“.

- Connect the squirt or soot pump as described before.

- Open ball valve and wait until the pressure is stabilized.

- Choose squirt or soot pump with the key <CAL.>.

- Start volume calculation with <Enter>.

- Infer the test volume with squirt or soot pump. The decrease of

pressure must be min. 2 hPa (otherwise operate squirt or soot pump

several times).

- Close ball valve and confirm with <Enter>.

- Choose number of strokes with cursor keys <Up/Down> and confirm with <Enter>.

8. Create the pre-adjusted test pressure with the air pump (the unit

beeps as soon as the pressure level is achieved).

9. Interrupt the connection to the air pump (switch-off the ball valve).

10. Wait for stabilization time (if the pressure remains in the range

“test pressure +/- 10%” during stabilization time, so the measurement will start).

11. Once the measurement time is over, the result is displayed and

can be printed (IR printer required) by pressing <Print>.

12. If the menu “Usage property“ is selected again, so the result

can be called up with “No” / <Enter> (as long as the ecom-B is on)

or a new measurement can be started with “Yes” / <Enter> (switching from “No“ to “Yes“ with cursor keys <Up/Down>).

Page 33

ecom-B Page 33

8. Adjustment

In addition to the already described features of the ecom-B, various settings could

be made at the instrument. Select from the

main menu the sub-menu <Adjustment>

and confirm with <Enter>. A list of the possible settings is displayed and can be

changed according to usage. Scroll the

curser to the corresponding line and press

<Enter>:

Set clock

(setting can be made by pressing <Enter>):

-scroll with cursers (up / down) to the value

which should be changed

-activate the setting by pressing <Enter>

-set the time by using curser keys <up / down>

-confirm the setting by pressing <Enter>

-after finishing leave the menu with <ESC>

Display contrast (activate with <Enter>)

-set display contrast with curser (up / down)

-reset with <CAL>

Type of fuel (select after pressing <Enter>)

-change the fuel type

Unit (change with cursers (up / down)

-calculation of gas concentration in:

-ppm = volume concentration (parts per million)

-mg/m

3

= mass concentration unit

-mg/kWh 0,0 % = Mass concentration per capacity unit calculated

with reference O

2

-ppm 0,0 % = volume concentration (parts per million) calculated with

reference O

2

-mg/m

3

0,0 % = mass concentration per capacity unit calculated with

reference O

2

Set clock

Display contrast

Type of fuel

Unit

O2 refer.

Air press.

Keyboard beep

AUX(COM)

Bluetooth

Eta(C)

Printout

Page 34

Page 34

ecom-B

-calculated with reference O

2

– formula for the calculation:

O

2

Reference (set by pressing <Enter>):

-setting of reference oxygen value O

2ref

-reset by pressing <CAL>

Air pressure (set by pressing <Enter>):

-Input of barometric pressure for calculation of dew point

-Reset by pressing <CAL>

Keyboard beep (set with cursers <up / down>)

-set signal when hitting the keys

-reset by pressing <CAL>

AUX(COM) (adjustment via <CAL.>):

-Adjustment of transfer speed by data transfer via RS 232

(1200 -112500 Baud)

Online data (adjustment via cursor keys):

-Adjustment what kind of Data should be sent:

-No protocol: Data for program „miniDV“

-Remote: only for special applications

-DAS: Data for program „DASNT“ (1200 Baud)

The programs „miniDV“ und „DASNT“ are available free of charge

from the ecom website.

Bluetooth (option)

(<BLE> no adjustment needed):

-Online data = Remote

E

ref

= E

meas

*

21 – O

2ref

21 – O

2meas

Page 35

ecom-B Page 35

Eta(C) (adjustment via cursor keys):

- Efficiency calculation with or without condensation gain

Printout (set by pressing <Enter>)

-create a protocol feet (8 x 24 digits)

-put in the text for line one as follows:

1. activate symbol selection with <Standby>

2. select keyboard with <CAL.> (5 keyboards are available)

3. choose a symbol with <store> (left), <Print> (right) and

cursers <up / down>

4. take the symbol with <Enter>

5. repeat (2. - 4.) until line 1 is finished

6. deactivate choosing symbols with <Standby> and change with

curser <up> to line 2.

7. after finishing the input for all lines leave the menu with <ESC>

Page 36

Page 36

ecom-B

9. Control

The electrochemical sensors used for gas analysis are submitted to

a wearing process and age. Along the operation period, they alter

their output values depending on the gas concentration, flow duration

and soiling degree of the measured gases. The programme controls

the sensors and corrects drifts. If drifts and the correlated measurements errors increase, an error message is displayed. In this case

the corresponding sensors must be changed by one of our authorised service centres. The actual status of the sensors is displayed in

the control menu. Additionally on two more pages will be displayed

(change the display pages by using the cursers):

-the battery voltage (charging status)

displayed in all menus as symbol:

Battery full Battery ½ full Battery empty

-the phone number of next service centre

-the serial number

-the software version

-the operation hours

-the date of last service

-the number of CO switch offs

-the number of error occurred

-Collection of the last maintenance

O2 1034 mV

CO -10 mV

Batt 6.42 Volt

Tel.No.

02371/945

-5

Ins.No. CL2-0009 V1.5

Further info with ↑↓

Measurements 1521

Service date 23.06.17

CO-Überläufe 0

Error counter 00

Tel.No.

02371/945

-5

Ins.No. CL2-0009 V1.5

Further info with ↑↓

Last service

26.06.16 103 hrs

10.06.15 073 hrs

31.05.14 035 hrs

-- . -- . --

-- . -- . -Further info with ↑↓

Page 37

ecom-B Page 37

10. Data processing

10.1. Communication

The menu „Data processing“ allows the

selection of the following functions:

Select:

This sub-menu enables to search for or

create a data record for the allocation of

measurement values (see chapter 3.).

Look at:

The recorded values of the selected data record can be viewed (see

chapter 3.).

Load data:

Possibility of data import e.g. from ecom software (available at

„www.ecom.de“ - check the transfer options of your software).

Proceed as follows:

1. Connect instrument and PC with a current RS232 cable.

2. Select “Load data“ and confirm with <OK>.

3. Answer following question with Yes (select with cursor keys).

4. Start the data transfer at the PC.

Send data:

The date record completed with values can be transferred to the PC

program using this function (procedure identical to „Load data“).

Format:

This function is normally only needed by the initial adjustment of the

instrument by the manufacturer (preparation of internal memory to

data receipt). Caution: All recorded values will get lost!

Data processing

Select

Look at

Load data

Send data

Format memory

Continue with :

↑↓

↵↵↵↵

Page 38

Page 38

ecom-B

10.2. Data processing with App

To display and storage of measured values, the "ecom Connect

App" for smartphones (iOS or Android) is available. Test results are

stored along with customer information in a pdf-file and can be sent

f.e. as email attachment. Links to free download of the Apps can be

found on the ecom website.

Page 39

ecom-B Page 39

11. Maintenance Tips

To secure the accuracy of your measuring instrument we recommend the annual check by an authorized ecom partner. In the case

of strong demand (e.g. permanent several hours of measurement

per day, rough conditions etc.) shorter intervals between checks

should be selected - please contact your ecom partner. All ecom

partners are listed under www.ecom.de. Do not use other sensor

than supposed by our factory and be aware that service done by

service stations not authorised by ecom will lead to expiration of any

warranty.

The following tips for the daily care of accessible parts and components should be helpful:

Condensate pad

Regularly check the condition of the condensate pad. It should be

changed:

- If it is soiled darker than no. 3 on the soot scale

- If its extension is on mark "MAX"

Replace the condensate pad as follows:

1. Remove hose from the cap and unscrew the cap

2. Unscrew the retaining bolt with spring

3. Replace old condensate pad against new

4. Scew on retain bolt with spring again

5. Scew on cap and replace the hose to the cap

Condensate pad

Page 40

Page 40

ecom-B

Sensors

Each time the instrument is switched on the sensors are calibrated

with fresh air. The instrument permanently monitors the condition of

the sensors. New sensors wear out from use in time due to reaction

(O2-sensor) and due to soiled gases respectively gases in concentrations beyond the nominal range (toxic sensors). The output values

of the sensors are (see menu “Control”):

O2 approx. 1500 mV

CO 0 mV (+/- 30)

If an error message is displayed during calibration cycle and does

not disappear after repeated calibrations the instrument must be

send to a service centre. The O2 sensor should show > 200 mV,

otherwise it should be changed.

The CO-sensor is protected by the internal program for overload. In

case the limit of 4000 ppm is exceeded the gas pump is switched off.

Power supply

The battery ensures a main power independent operation. The battery is automatically charged when the instrument is connected to

the main power supply. (Please do not interrupt the charging shortly

since the charging circuitry could operate faulty.) The recharge of the

battery should be done in any case if the voltage display (menu

“Control”) is less than 5.8 V (Instrument will stop working at 5.5 V).

Sampling probe and hose

Depending on the frequency of use the probe and the hose must be

cleaned regularly, thus in order to prevent particles from lodging and

early ware due to corrosion.

The hose can be cleaned after all connections on the instrument and

the probe itself have been switched off (use warm water and then

blow out to dry)

Page 41

ecom-B Page 41

12. Technical Data

Parameter Range Measurement principles

O

2

0 ... 21 vol.% electrochemical

CO (without H

2

) 0 ... 2000 ppm electrochemical

CO (with H

2

-option) 0 ...4000 ppm electrochemical

NO (Option) 0 ...5000 ppm electrochemical

CO

2

0 ...CO

2max

calculated

T-G 0 ... 500 °C NiCr-Ni

T-R 0 ... 100 °C semiconductor

Pressure 0 ... +/- 100 hPa DMS-bridge

Efficiency 0 ... 120 % calculated

Losses 0 ... 99,9 % calculated

Lambda 1 ... ∞

calculated

CO-undiluted (reference-O2; adjustable) calculated

Dew point of combustion gases calculated

Power Supply 110 - 230 V~ / 50 - 60 Hz;

Battery 6 V / 3,3 Ah

Display: graphic display, backlit

Size (W x H x D) 250 mm x 180 mm x 80 mm

Weight approx. 2,1 kg (complete with sampling system)

Application limits +5 °C to +40 °C;

max. 90 % RH, non-condensing

Subject to technical changes

V1.6 / 06.2018

ecom GmbH

Am Großen Teich 2

D-58640 Iserlohn

Phone: +49 (0) 2371 - 945-5

Fax: +49 (0) 2371 - 40305

Internet: http://www.ecom.de

eMail:

info@ecom.de

Page 42

Page 42

ecom-B

13. FAQ

Where do I find important instrument information?

How long is the life span of the

sensors?

Which sensors can I exchange?

The instrument shows the error

message „O

2

sensor 0 mV“!

The instrument shows the message „Check required“!

The instrument shows the error

message „T-Gas“ oder „T-Air“!

The instrument shows wrong or

inaccurately CO

2

values!

In the menu „Control“ all important instrument infor-

mations are shown (e.g. accu voltage, sensor values,

unit number, next service date, operation hours etc.).

With the arrow keys stands you can switch to the

second page.

The life span depends on the operating hours and

the instrument equipment. The life span of the toxic

sensors (CO, NO, SO

2

, NO2) is affected by high gas

concentrations and a not sufficient purging. The life

span for these sensors amounts to on the average

between 4 and 6 years. The life span of the O

2

sensor is independent of the operating hours and

amounts to approx. 4 years.

Please contact the next authorised service centre for

changing sensors.

The sensor must be renewed.

This message appears automatically every 12

months or after 250 operating hours. Note: This is a

recommendation to let check the instrument. The

instrument is however still ready for use.

Possible reasons could be:

- Cable is broken (at the plug)

- T-Air sensor is broken

- Thermocouple is broken

- Cable is defective

Note: The error messages can be ignored at the B by

pressing „Enter“. Calculations that depends on these

temperatures are not implemented.

Possible reasons could be:

- O

2

is defective (CO2 values are calculated from

the O

2

values)

- Pump is not working correctly

- Leakage in the gas way

- condensate trap / gas cooler is clogged

Page 43

ecom-B Page 43

Hint: If you have several instruments of the same type, you can locate an error by

exchanging the accessories (probe, hose, temperature sensor etc.).

If further questions or problems should arise, please contact the next authorised service centre.

My instrument cannot be

switched on!

My instrument does not print!

Can I change the printout?

- Please check the mains cable

- Please check the fuse

- Please check mains connection (Plug socket

switched on?)

- Please load the accumulator min. 8 hours

(Accumulator could be over-discharged)

Please check whether the printer paper is correctly

inserted. The thermal printer writes only on the thermally sensitive side. Please use always the correct

paper for the printer, you will prevent defects at the

printer. Please make sure that the printer is clean (no

chads in the drive).

You can change the printout (Menu: “Adjustments”).

Loading...

Loading...