Page 1

P/N 466-5422 • REV A • 24APR2018 © 2018 United Technologies Corporation. All rights reserved

TX-E251 Long-Range Extended Battery Life DWS

PLEASE SEE REVERSE SIDE FOR IMPORTANT PRODUCT WARNINGS AND DISCLAIMER INFORMATION.

Description

The TX-E251 Long-Range Extended Battery Life DWS is a sensor intended for

installation on doors, windows, and other objects that open and close. The

sensor transmits signals to the control panel when a magnet mounted near the

sensor is moved away from or closer to the sensor. The TX-E251 features a

high capacity CR2 lithium battery for extended battery life, and maximum

performance output power for long range applications. The sensor features two

separate zones: zone 1 can be used for either of the two reed switches, and

zone 2 can be used as an external contact option. The sensor is also equipped

with a cover tamper switch for additional security.

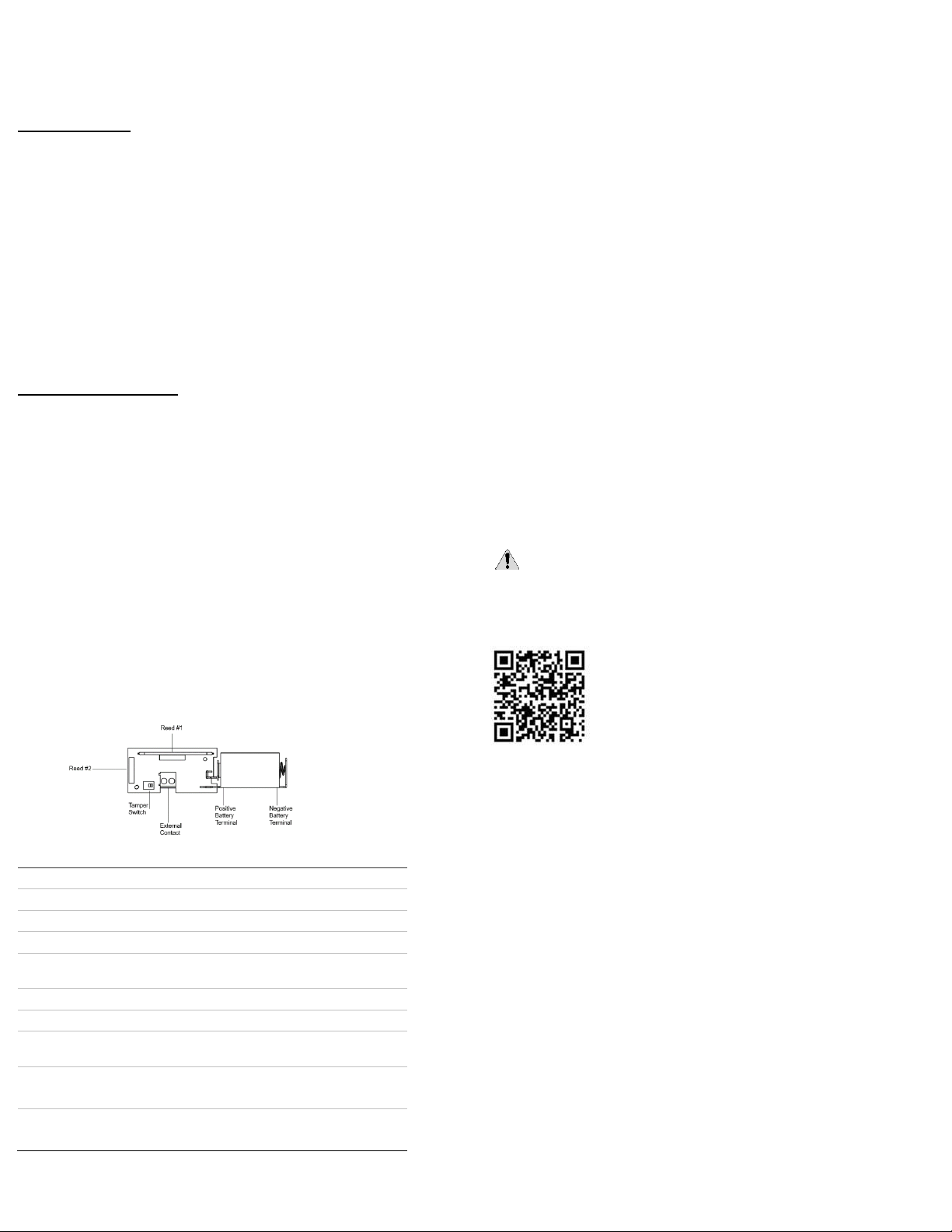

Figure 1: TX-E251

Reed Switch Enrolling

To enroll the TX-E251 into the panel for utilization of the transmitter’s reedswitches, follow these steps:

1) Place the panel into program mode, then go to Learn Sensors menu.

Refer to your specific alarm panel manual for details on these

menus.

2) Remove the battery pull tab to auto-enroll. Then select the

appropriate sensor group and number.

3) If the panel does not respond upon removing the battery pull tab,

disengage the case cover from the back housing by sliding, then

remove and replace the battery until the panel responds.

External Contact Enrolling

To enroll the TX-E251 into the panel for utilization of the transmitter’s external contact, follow these steps:

1) Remove the battery OR make sure the pull tab is still in place

between the positive battery terminal and the battery contact.

2) Connect the external contact in the restored state (4.7K for normally

closed, or open circuit for normally open).

3) Install the battery OR remove the pull tab, and install and lock the top

cover on to the sensor.

4) Place the panel into program mode, then go to Learn Sensors menu.

Refer to your specific alarm panel manual for details on these

menus.

5) To auto–enroll the external contact into the panel, change the state

of the external contact to the faulted state (open circuit for normally

closed contact or 4.7K for a normally open contact).

6) If the panel does not respond, then repeat steps 1 through 5.

External Contact Wiring

Use the following specifications for the external contact:

• Maximum wire length: 26 ft. (8 m).

• Wire: Stranded, 22-gauge (0.7112 mm).

• Switches: Hermetically sealed external switches (sealed reed

switches) that supply a minimum 250 ms open or close on alarm.

Note: Do not connect more than five external contacts to a door/window

sensor.

Caution: You must install the provided EOL resistor at the external detection

device for proper supervision.

You can wire the sensor terminal blocks with leads from an external contact

(Figure 2). The door/window sensor provides alarm and tamper indication. Wire

the external contact with one end-of-line (EOL) resistor in series with the

external contact.

This gives the following readings for each configuration:

Normally closed:

• Zero ohm/short = Tamper

• 4.7 Kohm = Normal

• Open = Alarm

Normally open:

• Zero ohm/short = Tamper

• 4.7 Kohm = Alarm

• Open = Normal

Figure 2: External Contact Wiring

Mounting

Included with this device is double sided tape for the transmitter and magnet,

as well as screws if a more secure method of mounting is preferred. Choose a

suitable location for the sensor by following the procedure in the section

“Testing the Sensor” ensuring desired signal strength is achieved. Note that it is

recommended the transmitter be installed on the stationary or non-moving part

of the installation (frame) and the magnet installed on the moving object (door).

Where possible, install sensors within 100 ft. (30 m) of the panel. While a

transmitter may have an open-air range of 500 ft. (150 m) or more, the

environment at the installation site may have a significant effect on operational

range. Changing a sensor location may improve wireless communication.

For reliable bonding with the provided double sided tape, ensure the surface is

clean and dry. Apply the tape to the backside of the sensor, and then to the

Page 2

P/N 466-5422 • REV A • 24APR2018 © 2018 United Technologies Corporation. All rights reserved

desired location. Apply firm pressure for several seconds. When mounting with

double sided tape, ensure temperatures are above 50°F and will remain above

50°F for at least 24 hours to ensure proper bond. After 24 hours, the bond will

hold at lower temperatures.

Sensor Testing

The sensor test verifies proper communication between the sensor and the

panel/receiver. The sensor should be tested prior to permanent installation, as

well as weekly. To test the sensor, refer to the specific panel/receiver

documentation and do the following:

1) Put the panel/receiver into sensor test mode

2) Open the door/window the sensor is installed on – the sensor will

then transmit a signal

3) Listen for the siren beeps to determine the appropriate response

4) Exit sensor test mode when proper communication between the

sensor and panel/receiver has been verified

Replacing the Battery

The TX-E251 comes pre-installed with a single GPI CR2 Lithium battery that

provides 10 years of battery life under normal usage conditions. When the

battery is low, a signal will be sent to the control panel. To replace the battery,

do the following:

1) With the sensor mounted, slide the case cover up or down

(depending on the orientation of the sensor) to unlock the case cover

from the base. Pull the case cover away from the sensor to reveal the

battery.

2) Remove the existing battery and re-install a new Panasonic CR2

battery. When inserting the battery, pay close attention to the battery

polarity indicators to ensure proper placement of the battery (positive

end of battery should be facing towards the circuit board and

antenna).

3) Replace the case cover and slide to lock. An audible click should be

heard when the cover engages in the locked position correctly.

Figure 3: Circuit Board Layout

TX-E251

RF Frequency

319.5 MHz – (Crystal Based)

Compatibility

Interlogix 319.5 MHz control panels/receivers

Battery Type

CR2 (GPI)

Typical Battery Life

Up to 10 years at 68° F (20° C)

Operating

Temperature Range

32° to 120°F (0° to 49°C)

Relative Humidity

0-85% non-condensing

Supervisory Interval

64 Minutes

Storage Temperature

Range

-30 to 140°F (-34 to 60°C)

Regulatory

Conforms to ANSI / UL Std 634

Certified to ULC Sub C634

Dimensions

3.25” x 1.13” x 0.88”

FCC Compliance Statement

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may

not cause harmful interference, and (2) this device must accept any interference received, including interference that may

cause undesired operation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Changes or modifications not expressly approved by UTC Fire and Security could void the user’s authority to operate the

equipment.

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the following two

conditions: (1) this device may not cause interference, and (2) this device must accept any interference, including

interference that may cause undesired operation of the device.

Cet appareil est conforme avec Industrie Canada exempts de licence standard RSS (s). Son fonctionnement est soumis aux

deux conditions suivantes: (1) cet appareil ne doit pas provoquer d'interférences et (2) cet appareil doit accepter toute

interférence, y compris celles pouvant causer un mauvais fonctionnement de l'appareil.

In accordance with FCC requirements of human exposure to radiofrequency fields, the radiating element shall be installed

such that a minimum separation distance of 20 cm is maintained from the general population.

Conformément aux exigences d'Industrie Canada en matière d'exposition humaine aux champs de radiofréquences,

l'élément rayonnant doit être installé de telle sorte qu'une distance minimale de 20 cm soit maintenue par rapport à la

population générale.

FCC: XQC-TXE251

IC: 9863B- TXE251

This Class B digital apparatus complies with Canadian ICES-3B.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Contact information

For contact information, visit us online at www.interlogix.com.

For technical support, see www.interlogix.com/support

Copyright

Copyright © 2018 United Technologies Corporation. All rights reserved.

Trademarks

Interlogix is a registered trademark of United Technologies Corporation. Interlogix is part of UTC Climate, Controls & Security, a

unit of United Technologies Corporation.

Product Warnings and Disclaimers

WARNING: CHOKING HAZARD - Small parts. Keep away from children.

THESE PRODUCTS ARE INTENDED FOR SALE TO, AND INSTALLATION BY, AN EXPERIENCED SECURITY

PROFESSIONAL. UTC FIRE & SECURITY CANNOT PROVIDE ANY ASSURANCE THAT ANY PERSON OR ENTITY

BUYING ITS PRODUCTS, INCLUDING ANY “AUTHORIZED DEALER”, IS PROPERLY TRAINED OR EXPERIENCED TO

CORRECTLY INSTALL SECURITY RELATED PRODUCTS.

For more information on warranty disclaimers and product safety information, please check

https://firesecurityproducts.com/policy/product-warning or scan the following code:

Loading...

Loading...