Page 1

Copyright © Ecolink I ntelligent Te chnology

1

Z-Wave

®

Thermostat

TBZ500

Battery Powered

Z-Wave Thermostat

Installation &

Operation Guide

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 1 24-02-2021 18:55

Page 2

Copyright © Ecolink Intellig ent Tech nology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 2 24-02-2021 18:55

2

Page 3

24-02-2021 18:55

3

Table of Contents:

Thermostat Features ..................................................... 4

Standard HVAC System Connections .............................. 4

Thermostat compatible HVAC Systems ........................... 5

Battery Powered Operation ............................... 5

24VAC Powered Operation .............................. 5

Installation Steps .......................................................... 6

Remove Existing Thermostat ........................................ 6

Color Wiring Table ......................................... 6

Wiring Colors ................................................................ 7

Install Back Panel .............................................................. 7

Single Transformer System ........................................... 7

Separate Transformer HVAC System ........................... 8

Thermostat Setup .......................................................... 8

Standard System Settings ................................ 8

Two stage Heat/Cool Systems .......................... 8

Single and Dual Transformer

Systems (Split Systems) ............................................... 9

Single Transformer System .............................. 9

Dual Transformer Systems ............................... 9

Heat Pump HVAC System Wiring ............................... 10

Thermostat Setup: Heat Pump HVAC Systems .......... 11

Single Stage Heat/Cool Systems ...................... 11

Two Stage Heat/Cool Systems ........................ 11

Mount the Thermostat ................................................ 12

Battery Powered Thermostat ........................... 12

Thermostat Setup: Configure for HVAC System ........ 13

Preset HVAC System Settings ......................... 13

Changing the HVAC System Setup .................... 13

Entering Menu Mode .................................... 13

Thermostat Menu Screen .............................. 14

Menu Mode Navigation ............................. 14

System Setup Menu ..................................... 14

Advanced Systems Settings Menu ................................. 15

Settings Menu Table ...............................

15 – 17

Copyright © Ecolink Intellig ent Technology

Z-Wave Installation.....................................................

18

Adding the thermostat to a Z-Wave network ......

18

Removing the thermostat from

a Z-Wave network .....................................

18

Operation Instructions ...............................................

19

Backlight and Button Operation ......................

19

System Operation Modes ...............................

19

Stage Indicators ..........................................

19

Setting the System Mode ...........................................

20

System Modes ...........................................

20

Setting the Heating or

Cooling Temperature Setpoint .................................

21

Setpoint Change ........................................

21

Setpoint Push............................................

21

Setting the Fan Mode .................................................

22

Thermostat Menu Mode .............................................

22

Thermostat Setup Menu ...............................

23

Thermostat System Menu .............................

23

Z-Wave Menu ............................................

23

INFO Menu ...........................................23

Thermostat Operation ................................................

24

Minimum Run Tim (MRT) ..............................

24

Minimum Off Time (MOT) .............................

24

Z-Wave Operation ..........................................................

24

Thermostat Battery Operation ........................

24

Thermostat 24VAC Operation ........................

24

Adding the thermostat to a Z-Wave network ......

25

Removing the thermostat from

a Z-Wave network .....................................

25

Z-Wave Command Classes ................................................

26

Compliance Statement ..................................................

27

Limited Warranty ........................................................

27

Return Policy ...............................................................

27

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 3

Page 4

TBZ500 BATTERY POWERED Z-WAVE THERMOSTAT

INSTALLATION INSTRUCTIONS

The Z-Wave Thermostat (TBZ500) is a programmable, Z -Wave communicating thermostat. It can be powered using 24VAC (if

both “R”&”C” wires are available at the thermostat) or using four (4) AA batteries. Using Z-Wave technology, end users have the

ability to use many Z-Wave enabled control panels and Z-Wave hubs to control the thermostat, configure programming settings,

as well as to display current conditions in the home or office.

Features Include:

• A fixed format display with white backlight

• Heating and cooling setup display options

• System mode (OFF, Heat, Cool,Auto, E-Heat)

• Fan mode control and display (Auto, ON)

• Changeover type for Heat Pump (HP) systems

• On-screen setup of HVAC type, Fan type

• F/C mode, and sensor calibration

Compatible with 24 VAC gas, oil, or electric heating and air conditioning systems;

or gas millivolt heating systems DO NOT USE ON 120VAC SYSTEMS!

Standard Systems

• 1 Stage Heating and Cooling

• 2 Stage Heating and Cooling

Heat Pump Systems

• 1 Stage Heating and Cooling

• 2 Stage Heating and Cooling

• 2nd or 3rd Stage Aux Heating (Electric Heat Strips)

Installation Outline

• Step 1 Remove Existing Thermostat

• Step 2 Install TBZ500 Thermostat

• Step 3 Setup Thermostat to match System Type

• Step 4 Install into Z-Wave Network

Copyright © E colink Intelligent Technology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 4 24-02-2021 18:55

4

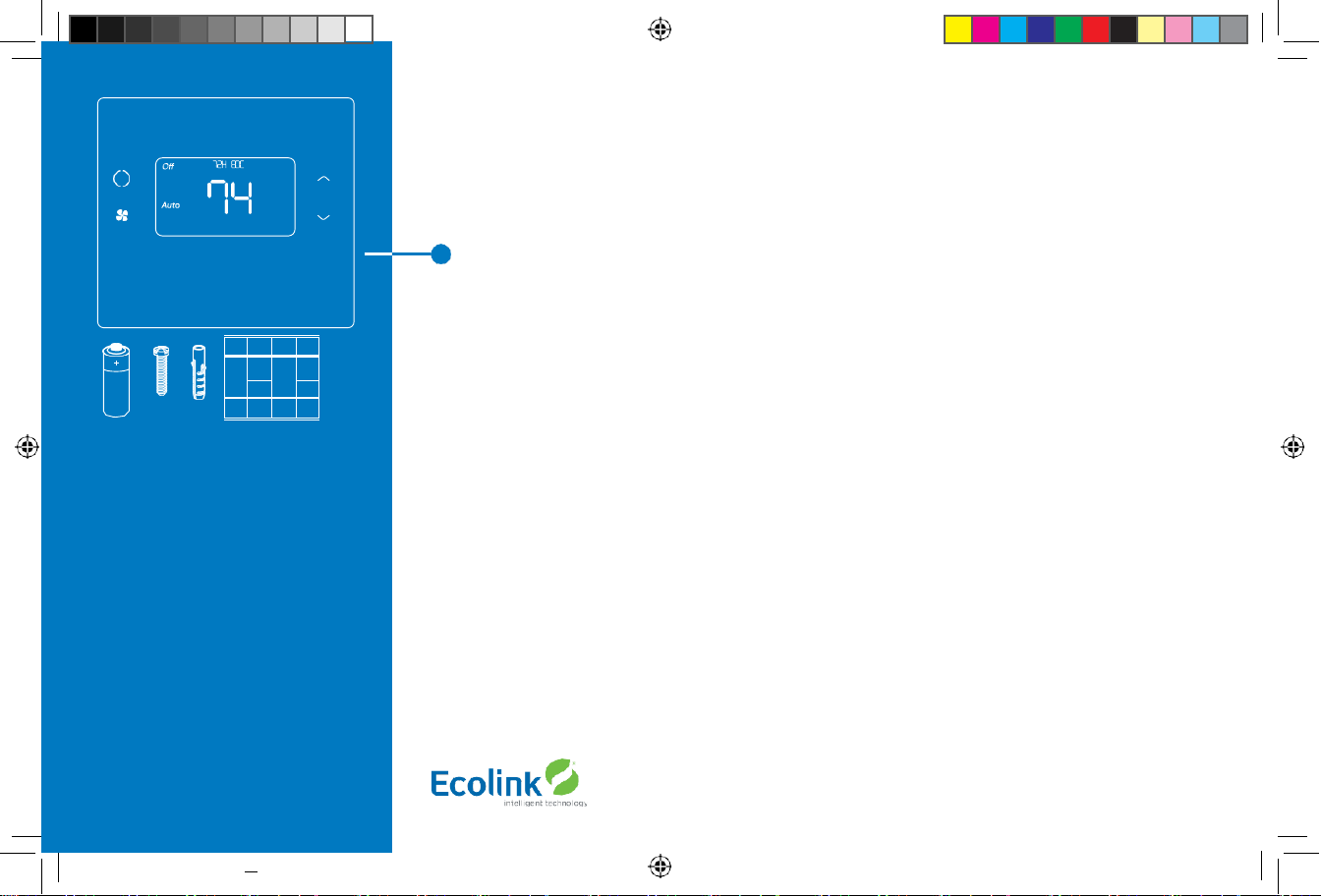

Box Contents

• 1 Z-Wave Thermostat

• 1 Sheet Adhesive Wiring Labels

• 2 Plastic Wall Anchors

• 2 Phillips Screws

• 4 AA Batteries

Figure 1.

Z-Wave Thermostat Front View

1x 4x 2x 2x

Page 5

24-02-2021 18:55

5

TBZ500 THERMOSTAT AT A GLANCE

This thermostat is compatible with most HVAC systems, including the following:

• 24VAC systems Note: requires both the 24VAC R and C (“common”) wires unless battery powered.

• Standard gas/oil/electric heating systems

- 1 stage heating and cooling

- 2 stage heating and cooling

• Heat Pump systems:

- 1 stage heating and cooling

- 2 stage heating and cooling

- 2nd or 3rd stage Auxiliary heating (heat strips)

• Do NOT use for systems with line voltage controls (120/240VAC) The thermostat can either be powered by batteries or

24VAC.

Battery Powered Operation

The thermostat can be powered by four AA Alkaline batteries. The thermostat will operate for approximately two years on four

AA Alkaline batteries depending on the frequency of user operations and backlight operation. Always use Alkaline batteries and

replace all four at the same time with NEW batteries.

Z-Wave Operation when Battery Powered

Important Note: If the thermostat is installed on a Z-Wave network, while it is battery powered, it does not work as a Z-Wave

repeater.

24VAC Powered Operation

Powering the thermostat with 24VAC power requires both the C wire (24VAC common wire - typically blue)

and the R wire (24VAC hot wire - typically Red). If the C wire is not available, then batteries are required.

Note! If the thermostat is powered from 24VAC, do not install batteries!

Z-Wave Operation when 24VAC powered

If the thermostat is installe

d on a Z-Wave network while it is 24VAC powered, it

operates as an always-on Z-Wave repeater.

Copyright © Ecolink Intellig ent Technology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 5

Page 6

TBZ500 24VAC OR BATTERY POWERED Z-WAVE THERMOSTAT

INSTALLATION INSTRUCTIONS

Installation Steps

• Remove old thermostat.

• Install TBZ500

• Set up the thermostat for the HVAC system

• Enroll on Z-Wave network

Remove Existing Thermostat

• Turn off power to the HVAC system.

Usually at the HVAC system or the circuit breaker panel.

• Remove cover of old thermostat to expose the wiring terminals.

• Take a picture of the wiring terminals! This will help with troubleshooting later if needed.

• Mark the wires attached to the terminals with the wiring labels included.

• Use the terminal labels and not the wiring color to mark the wires.

• Remove the old thermostat base.

• Caution! Do not let the wires slip into the wall.

NOTE: Taking a picture is critical if problems are encountered. This will allow reinstallation of the old thermostat

and will help with troubleshooting later if needed.

Terminal

Typical Wire Color

Function

Y YELLOW

Cool

W

WHITE

Heat

G GREEN

Fan

R RED

24VAC Return

C

BLUE

24V Common (typically BLUE). When the wire is present,

the thermostat can be powered without batteries.

When the wire is absent, the thermostat must be powered by batteries.

Copyright © E colink Intelligent Technology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 6 24-02-2021 18:55

6

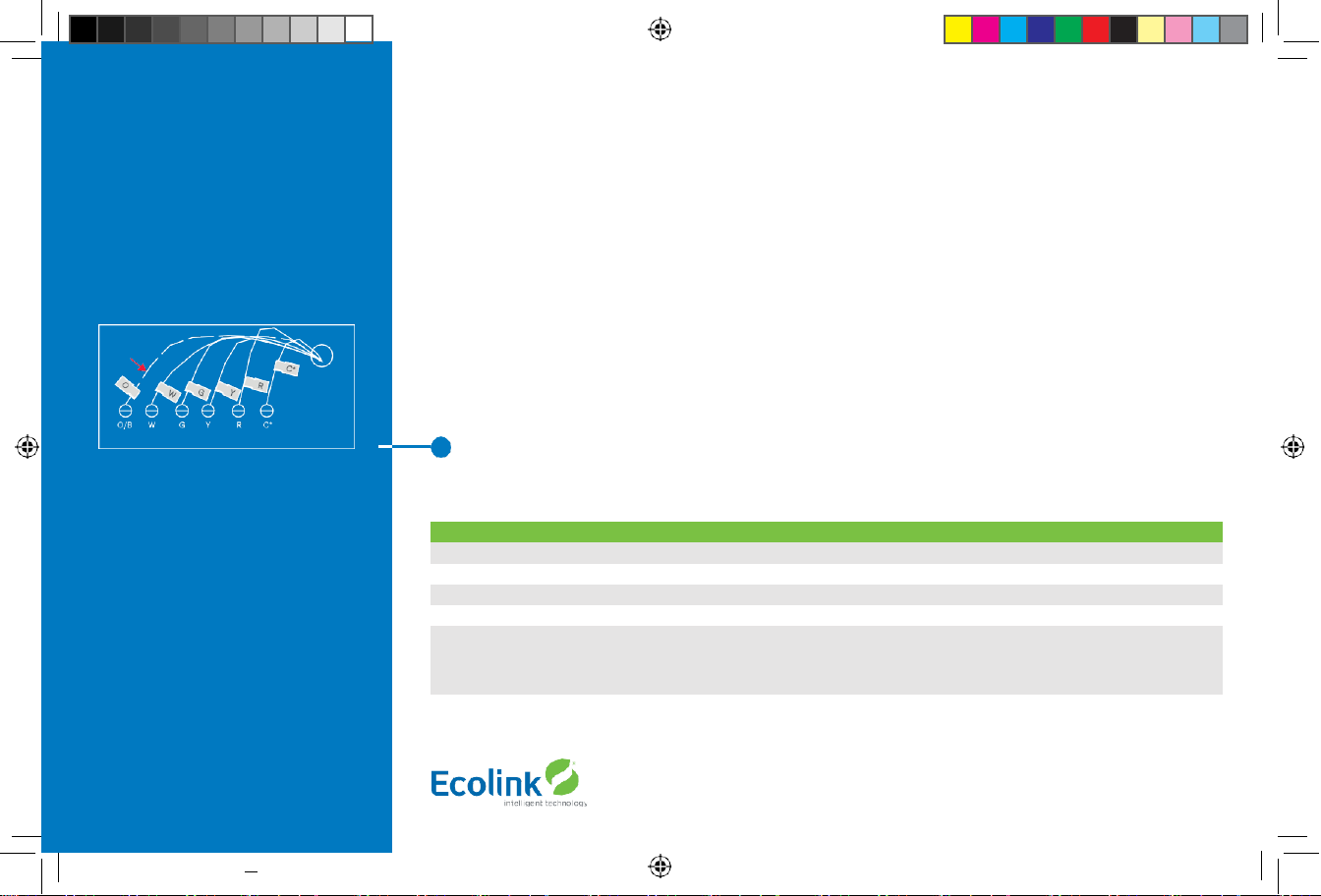

Old thermostat wiring terminals

*Note:

The C wire (24V common) may not be

present.

If C wire is not present, the TBZ500 must be

powered by batteries.

If the C wire is present, DO NOT INSTALL

BATTERIES in the TBZ500.

Mark the wires according to the terminal

markings. There may be additional wires

such as Y2, W2.

If y ou have RC and/or RH connections, see

below. Other wires are not used.

Heat Pump

Systems only

Page 7

Wiring Colors

While the thermostat terminal markings are intended to match the wire color, (R=RED, G=GREEN, W=WHITE, Y=YELLOW) be sure

to follow the terminal marking when marking the wires, even if the wire color doesn’t match.

WARNING: If the existing thermostat is a mercury-containing device, it must be disposed of in compliance with

federal, state, and local regulations. Many states and/or local agencies have collection or exchange programs or

hazardous waste collection programs for mercury containing devices.

For more information, see the U.S. Environmental Protection Agency website at:

http://www.epa.gov/osw/hazard/wastetypes/universal/mce.htm

For Canada: Environment Canada and Disposing of Mercury Products at:

https://www.ec.gc.ca/mer

cure- mer

cury/default.asp?lang=En&n=F111AAC6-1

Install the Back Panel

Remove the back panel of the thermostat by gently prying back panel from the thermostat.

• Mount the thermostat base to the wall using the wall anchors and screws provided.

• Level as needed.

• Connect the wires according to the HVAC system type as below.

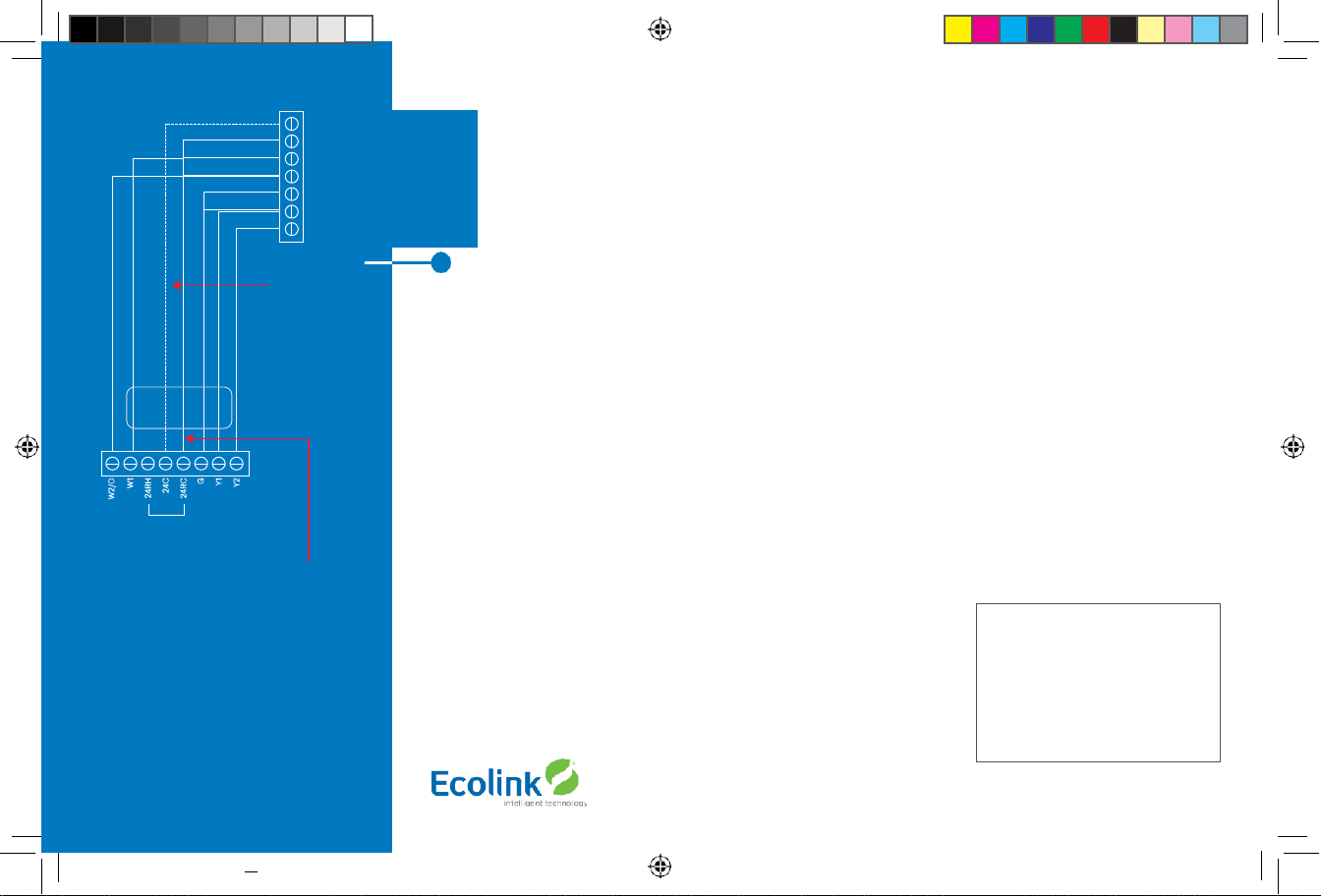

Standard Gas/Electric HVAC System Wiring

Single stage heating and cooling

R vs RC and RH Connections:

Single Transformer HVAC Systems.

Typical modern central HVAC installations have a integrated heating and cooling system with a single 24VAC transformer. For

these systems, there is only one 24VAC “R” wire and it can connect to either the RC or RH terminal on the thermostat. The

thermostat is supplied with an RC-RH jumper installed.

Do not remove the jumper for common transformer HVAC systems.

Copyright © Ecolink Intellig ent Technology

TBZ500_manual_8_5x5_5_inch

Combined_RDN1240221.indd 7 24-02-2021 18:55

R

G

C*

7

Factory insta lled RC and RH jumper

Connect the wires as marked from the HVAC

system to the corresponding terminals on

the thermostat back.

*C wire (24VAC common) may not be

present. If not, batteries must be installed.

Y W

Page 8

Orange White

Blue

Red

Green

Black/

brown

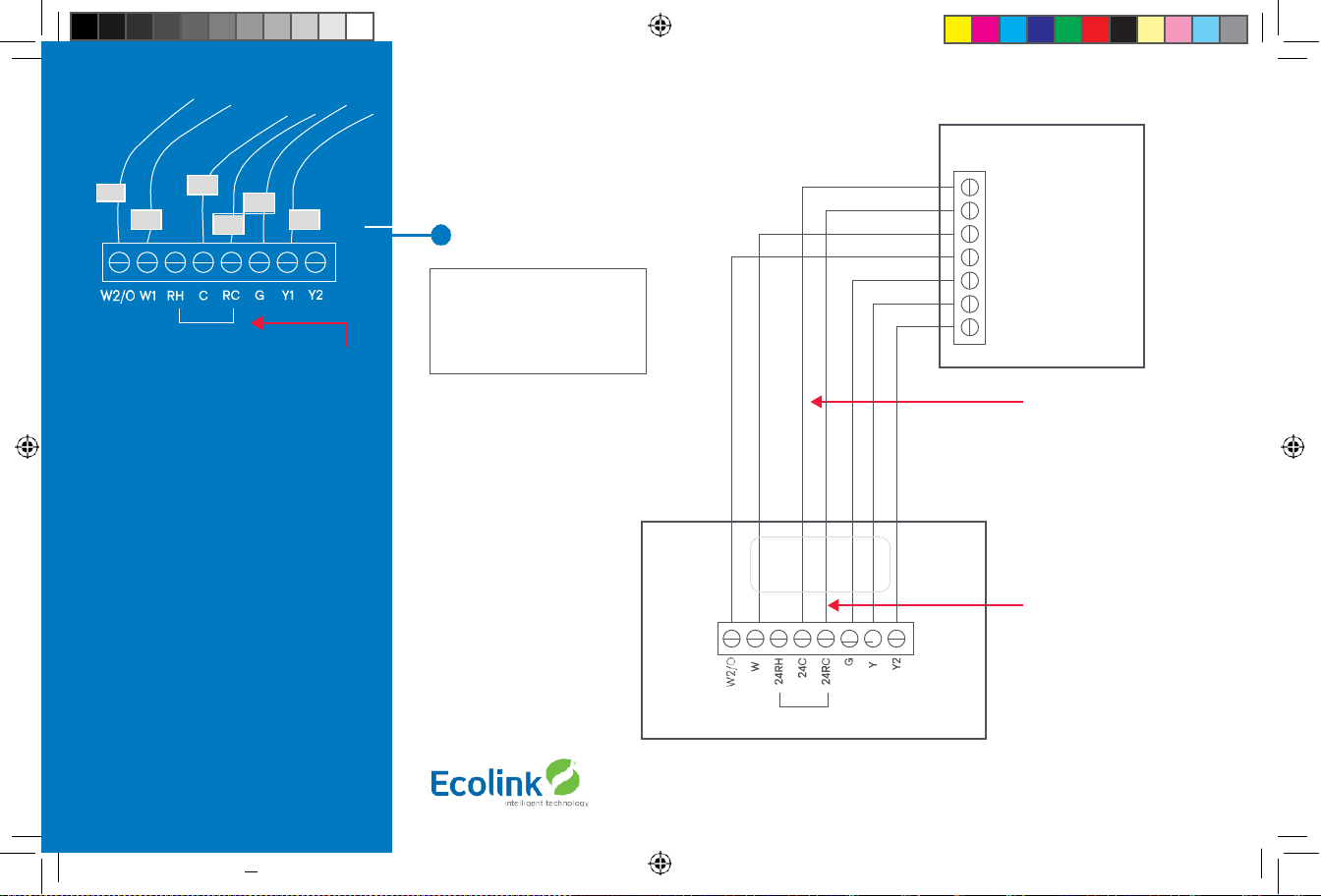

Separate Transformer HVAC Systems.

Some installations may have separate heating and cooling systems with separate 24VAC transformers. For those

systems there will be a separate “R” wire for the heating system (RH) and cooling system transformers (RC).

To c

onnect separate transformer systems, FIRST REMOVE THE SUPPLIED RH-RC JUMPER. Then

connect the heating “R” wire to the RH terminal and the cooling “R” wire to the RC terminal on the

thermostat.

Thermostat Setup:

Standard Gas/Electric HVAC Systems

• For Single Stage Heat/Cool Systems:

Go to the Menu screen by pressing and holding the FAN button for 5 seconds Press the down arrow to select

the SYSTEM menu and press Select.

Set the following:

• SYSTEM TYPE: Set to STANDARD

• FAN TYPE:

Set to

GAS

for typical gas furnace (fan is controlled by the furnace) Set to

ELECTRIC

for electric heat (fan on with heat call)

For Two Stage Heat/Cool Systems:

• Go to ADVANCED SYSTEMS SETTINGS menu.

• From the

Setup menu

screen, press and hold the Fan and Down arrow buttons for 5 seconds.

Use the Down arrow button to select the following:

- 2ND STAGE HEAT ENABLE:

Enable second stage heating output If a single stage heating system,

leave this set to N

If a 2 stage heating system, set to Y to enable.

- 2ND STAGE COOL ENABLE: Enable second stage cooling output

If a single stage cooling system, leave this set to N.

If a two stage cooling system, set to Y to enable.

Copyright © Ecolink Intellig ent Tech nology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 8 24-02-2021 18:55

mon

C 24VAC Com

R 24VA C Retu

Heat Stage 1

Heat Stage 2

G Fan

Y1 Compress

Y2 Compress

8

Factory installed RC/RH jumper

For single transformer systems, connect R wire

to either RC or RH terminal. They are connected

together by the factory installed jumper.

For systems with separate heating & cooling

transformers, connect Heating R to RH and

Cooling R to RC. NOTE! REMOVE THE FACTORY

INSTALLED RC/RH JUMPER.

C wire is not required

for battery operation.

C wire is required for

24VAC operation.

Yellow

Default Thermostat Setup:

•

Type: Standard HVAC

•

Fan Type: Gas Heat

•

1 Stage heatin g

•

1 Stage cooling

No Setup change required

for this configuration

Page 9

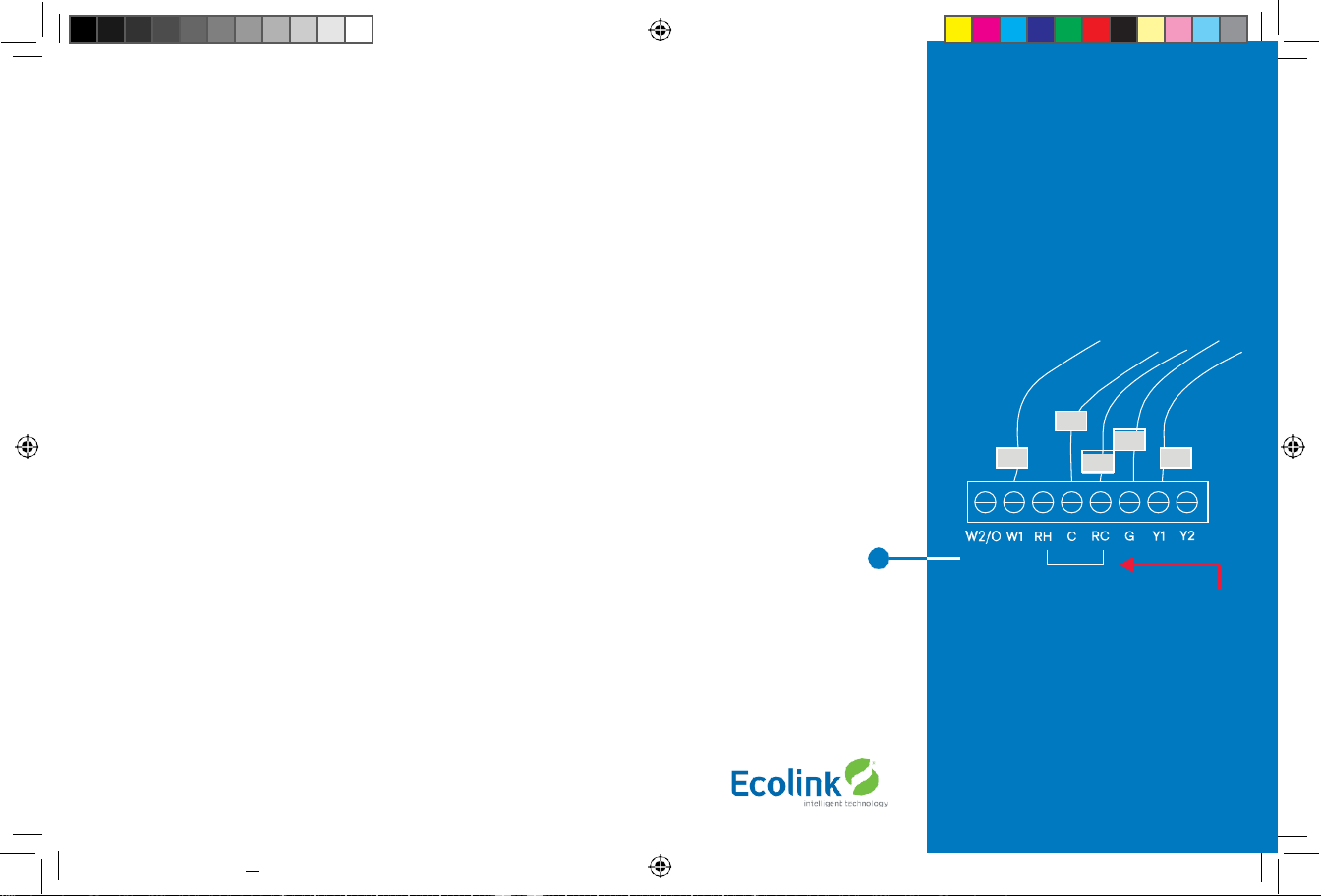

Wire Terminal

SINGLE AND DUAL TRANSFORMER SYSTEMS (SPLIT SYSTEMS)

HVAC systems may have one or two transformers. The “R” wire connects differently

depending on the system.

G

Connec t to the G terminal

C

Connec t to th e C terminal. C wire (24VAC common) may not be present. If not present,

batteries MUST be installed.

NOTES:

Ensure that the appropriate wires are screwed into the termin al blocks firmly. Gently pull on the wires to confirm

the connection. Push all excess wiring back into the wall opening.

Connect the wires from the HVAC system to the corresponding terminals on the thermostat back

terminal block. Use the table below as a guideline for connecting the wires.

Y or Y1 Connec t to the Y1 terminal

COOL Rc

Connec t to RC terminal

HEAT Rh

Connec t to RH ter minal

W2

Connec t to W2 terminal (2-stage system only)

IMPORTANT!:

for separate rc/rh sy stems, the internal rc=rh jumper must be cut on the back of the thermostat’s printed circuit board.

Single Transformer System

Most HVAC systems have a single 24VAC

transformer. For these systems, there is

only one “R” wire and it can be connected

to either the thermostat’s RC or RH

terminal as these are internally jumpered

together. If installing a Standard HVAC

system, connect the wires from the HVAC

system to the corresponding terminals

on the thermostat back terminal block.

Use the table below as a guideline

for connecting the wires.

Dual Transformer Systems

For HVAC systems that have separate

heating and cooling systems, each with

their own 24VAC transformers, there will

be an “R” wire from the heating system

and an “R” wire from the cooling system.

For dual transformer systems, connect

the “C” wire from the cooling system to

the thermostat’s “C” terminal.

DO NOT

CONNECT THE “C” WIRE FROM THE

HEATING SYSTEM.

Copyright © Ecolink Intelligent Technology 9

TBZ500_manual_8_5x5_5_inch

Combined_RDN1240221.indd 9 24-02-2021 18:55

W or W1

Connec t to W1 termin al

C

Connec t to C terminal (Cooling System C Wire, NOT Heatin g System C Wire)

G

Connec t to the G terminal

Connec t to the Y2 termin al (2-stage systems only)

Y2

W

Connec t to the W1 termin al

R

Connec t to either RC or RH terminals (Except for Dual Transformer Systems, See Next Page)

Connec t to the Y1 terminal

Y Terminal

Wire

Page 10

White

10

Heat Pump HVAC System Wiring

Single stage heating and cooling

Typical thermostat wiring colors.

Caution: verify that original wiring

matches. Colors may be different.

Blue

Red

Green

Yellow

Black/

brown

Heat Pump HVAC System

Thermostat connection

C 24VAC Common R

24VAC Return

W1 Aux Heat

O Changeover Valve

G Fan

Y1 Compressor Stage 1 Y2

Compressor Stage 2

Thermostat back

Factory installed RC/RH jumper

Most Heat Pump

systems have the C wire

and the thermostat can be

power by the 24VAC from

the HVAC system.

Batteries are not required

for 24VAC powered systems.

If there is not a C wire

installed, the thermostat

MUST be powered from

batteries.

Connect the R wire to either

the RC or RH terminal.

DO NOT REMOVE THE

RC/RH JUMPER

Copyright © Ecolink Intellig ent Tech nology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 10 24-02-2021 18:55

Y W

R

G

C*

Factory installed RC and RH jumper.

Do not re move

Connect the wires as marked from the HVAC

system to the corresponding terminals on

the thermostat back.

*C wire (24VAC common) Heat Pump

systems usually have the C wire connected

to the thermostat. If there isn’t a C wire,

batteries must be installed.

** O (Orange) or B (Brown) wire (changeover

valve) connect to the W2/O terminal on the

thermostat.

NOTE: Be sure to set the correc t changeover

operation (O = changeover with Cool, B =

changeover with Heat) in the SETUP menu.

Connect the R wire to either RC or

RH terminal.

Orange

Note!

If you get heating

when you expected cooling

or vice versa, change the

Change Over type to the

opposite setting.

O**

Page 11

24-02-2021 18:55

11

THERMOSTAT SETUP:

Heat Pump HVAC Systems

For Single Stage Heat/Cool Systems:

Go to the Menu screen by pressing and holding the FAN button for 5 seconds Press the down

arrow to select the SYSTEM menu and press Select. Set the following:

System type:

Set to HEAT PUMP

Change over:

For changeover with cooling systems (Orange wire): set to WITH COOL (most common and default setting) For

changeover with heating systems (Brown wire): set to WITH HEAT

You must configure the thermostat’s changeover valve setting to work correctly with your HVAC system.

Check your system information to be sure and note the color of original thermostat wire and the terminal it was connected to.

No matter what the old stat connection was (O or B), connect the wire to the thermostats W2/O terminal.

For Two Stage Heat/Cool Systems:

Go to ADVANCED SYSTEMS SETTINGS menu. From the Setup menu screen, press and hold the Fan and Down arrow buttons for

5 seconds. Use the Down arrow button to select the following:

Auxheat:

If you have auxiliary heat strips, set this to Y to enable. (Default is Y)

2nd stage head enable:

Enable second stage heating outputs If a single stage heating system,

leave this set to N. If a two stage heating system, set to Y to enable.

2nd stage cool enable:

Enable second stage cooling outputs If a single stage cooling system,

leave this set to N. If a two stage cooling system, set to Y to enable.

Copyright © Ecolink Intellig ent Technology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 11

Page 12

Install batteries

Watch polarity!

Finish Wiring

If you have additional wires for 2 stage systems (W2, Y2), see the wiring diagrams on page 5 and 6.

Check that the wires are screwed into the terminal blocks firmly. Gently pull on the wires to confirm

the connection. Push all the excess wiring back into the wall.

Mount the Thermostat

24VAC Powered Thermostat: If the thermostat is 24VAC powered (24VAC common “C” wire is connected), DO NOT INSTALL

BATTERIES!

• Install the thermostat on to the base.

• After all connections are made and thermostat is mounted, turn on power to the HVAC system/thermostat by either

re-energizing the circuit breaker in the breaker panel or by plugging in the HVAC system back in to the 120VAC wall outlet.

• Battery Powered Thermostat:

If the thermostat is battery powered (NO 24VAC common “C” wire connected), install 4 NEW

Alkaline AA batteries into the back of the thermostat.

• Install the thermostat on to the base.

• After all connections are made and thermostat us mounted, turn on power to the HVAC system/thermostat by either

re-energizing the circuit breaker in the breaker panel or by plugging in the HVAC system back in to the 120VAC wall outlet.

Copyright © Ecolink Intellig ent Tech nology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 12 24-02-2021 18:55

12

Page 13

THERMOSTAT SETUP: CONFIGURE FOR HVAC SYSTEM

The thermostat must be set up for the correct HVAC system type and configuration for proper operation.

Preset HVAC System settings

The thermostat is preset for the following typical HVAC system configuration:

• HVAC system type: Standard gas/electric

• HVAC fan type: Gas heat

• HVAC heating stages: one

• HVAC cooling stages: one

If the thermostat is installed on this type HVAC system, the System setup does not need to be changed.

Installation is complete

For thermostats installed on a Heat Pump HVAC system or any HVAC configuration other than the preset settings, the System

settings need to be changed in the SYSTEM setup menu to match the HVAC system.

Changing the HVAC System Setup

To change the thermostats HVAC system settings, first select the Menu Screen and then select the SYSTEM menu. Follow

instructions below to access the SYSTEM menu.

Entering Menu Mode

To change the System setup, go to the thermostats Menu Mode a

nd select SYSTEM. From there select the correct HVAC se

tting

s

t

o match the installati

on type. Press a

nd hold the FAN button to enter the Me

nu Mode. SETUP is the first menu item displayed

.

Press the down button to advance to the SYSTEM screen.

Note:

To conserve battery life, the thermostat

backlight turns off after a short time of

no activity.

The first press of any button will turn

on the backlight but will not initiate

any action other than turning on the

backlight. Press the button again to

initiate the action desired. If the backlight

is already on, button presses work with

the first press.

Copyright © Ecolink Intelligent Technology 13

TBZ500_manual_8_5x5_5_inch

Combined_RDN1240221.indd 13 24-02-2021 18:55

Page 14

Menu choices are displayed in

the Status Display Line.

Press

“Select”

to enter the

selected menu

Press

“Done”

to exit back to

the Main Thermostat Screen

Use the Up/Down buttons to

change to the desired menu item,

then press

“Select”

Not sure which Changeover type?

Check the existing thermostat conne ctions

to help determine this.

•

If the origina l syste m had an orange wire

connected to the

“O” terminal, then this

is a

“changeover with cool”

system.

•

If there was a brown wire connecte d to

the

“B”

terminal, then this is a

“change

over with heat”

system.

•

Set the Change Over setting accordingly.

(Caution: These are typical wiring colors/

connections and may differ)

• If heating comes on when cooling is

expected or vice versa, change the

“Change Over Type”

to the opposite

setting.

14

Thermostat Menu Screen

Menu Mode Navigation

When the thermostat Menu Screen is displayed, use the

Up or Down arrow buttons to scroll through the following

options:

• Setup

(user preference settings)

• System

(HVAC system setup)

• Zwave

(install/uninstall from Z-Wave network)

• Info

(firmware versions and Z-Wave network

information)

Select SYSTEM setup

To change the HVAC system default settings, use the down

arrow to progress to the SYSTEM menu item and press

“Select”.

SYSTEM setup menu

The SYSTEM menu is used to set up the thermostat for the

correct HVAC system type.

• System type

- For Standard Gas/Electric systems, select “Standard”.

This is the default setting.

- For Heat Pump systems, use the Up/Dn arrows to

change to “Heat Pump”

- Press Select to set.

- Press Done to exit

• Fan type (For Standard HVAC systems only)

- Fan type depends on the heating system type.

- For Gas heat: select “GAS”. This is the default setting.

- For Electric heat: use the Up/Dn arrows to change to

“ELECTRIC”.

- Press Select to set

- Press Done to exit

• Changeover type (For Heat Pump HVAC systems only)

The changeover (or reversing) valve is used to change from

heating to cooling operation. It is either a changeover with

cooling type (Orange wire) or changeover with heating

type (Brown wire). Most are changeover with cooling, which

is the default setting.

- For Changeover with Cooling systems (Orange wire),

select “WITH COOL”. This is the default setting.

- For Changeover with Heating systems (Brown wire),

use the Up/Dn arrows to change to “WITH HEAT”.

- Press Select to set

- Press Done to exit

Copyright © Ecolink Intellig ent Tech nology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 14 24-02-2021 18:55

Page 15

24-02-2021 18:55

15

ADVANCED SYSTEM SETTINGS MENU

The Advanced System Settings Menu provides for addition system setup options. These settings can affect system operation

and should only be changed by qualified HVAC installers.

• To access the Advanced System Settings menu, first press and hold the Fan button to get to the MENU screen. Continue to

hold down the Fan button and press and hold the Down Arrow button for 5 seconds.

• The first menu item in the Advance System Settings menu “Display Lock”, will be displayed. Use the Up/Down arrow buttons

to scroll through the menu options to the desired setting.

• Press “Select” (Mode) button to change a setting. Once it begins to flash, use the Up/Down buttons to select the desired

setting.

• Press the SELECT button to accept the new setting (flashing will stop).

Copyright © Ecolink Intelligent Techn ology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 15

Feature

Description

Range Default

Setting

Display Lock

Allows the thermosta t buttons to be locked. When the buttons are locked, none

of the thermostat buttons will function as normal. To unlock the thermostat

when Display Lock is enabled, press and hold the FAN button for 5 seconds to

access the Setup screen (it’s the only button that works in the lock mode). Access

the Advanced Settings Menu (as above) to turn the Display Lock off.

Y or N N

Test Mode

Test mode shortens th e system built-in delays (like MOT and MRT)

Y =

Test mode on. Reduces all delays to 10 seconds

for quicker system testin g

N =

Test mode off. Normal system delays

Y or N N

Aux Heat Enable

(Heat Pump Sys-

tems only)

**Becomes availab le when System Type: Heat Pu mp is selected in standard menu.

Enables the auxiliary heat o peration.

Typicall y the au xiliary heat will be heat-strips in a heat pump system.

Y or N Y

2nd Stage Heat

Enable

Enables the second stage heat operation

Y or N Y

2nd Stage Cool

Enable

Enables the second stage cool operation

Y or N Y

Minimum run

time

Sets the Minimum Run Time (MRT) delay before a heating/cooling cycle can turn

off.Sets heating/coolin g cycle time. Preven ts rapid on/off cycling.

1-9

3

Page 16

Feature

Description

Range

Default

Setting

Minimum Off time

Sets the Minimu m Off Time (MOT) delay before another heating/cooling cycle

can begin. Provides compressor short cycle protection. “Wait” is displayed on

screen when active.

5-9 Minutes

5

Heat Setpoint

Max.

Sets the maximum heating setpoint value.

Will not ramp or accept setpoints higher than this maximum

55F to 96F (4C

to 43C)

90F (32C)

Cool Setpoint Min.

Sets the minimum cooling setpoint value

60F to 99F

60F (15C)

(6C-45C)

Heat Blower Off

Sets the system blower delay off time after a heat call ends (fan purge)

0 to 9 seconds

0 (off)

Delay

Cool Blower Off

Sets the system blower delay off time after a cool call ends (fan purge)

0 to9 seconds

0 (off)

Delay

Heat - Cool Delta

Sets the minimum separation between heatin g and cooling setpoints.

Note:

3 to 15

3F (1C)

Attempts to lower cooling setpoint below the heating setpoint will PUSH the

degrees

heating setpoint down to maintain this separation. The same applies to setting

the heating setpoint above the cooling setpoint, it will PUSH the cooling set-

point up to maintain the setpoint delta separation

Heating Stage 1 on Sets the delta from setpoint that stage 1 heating starts

1 to 6 degrees

1

Threshold

Heating Stage 1

Sets the delta from setpoint that stage 1 heating stops. Stage 1 turns off at

0 to 5 degrees

0

Off Threshold

setpoint + Delta Stage 1.

Heating Stage 2 Sets the delta from setpoint that stage 2 heating starts

2 to 7 degrees

2

On Threshold

Heating Stage 2

Sets the delay from setpoint that stage 2 heating stops. Stage 2 turns off at

0 to 6 degrees

0

Off Threshold

setpoint + Delta Stage 2.

Aux Heat On Sets the delta from setpoint that stage 3 heating starts

3 to 8 degrees

3

Threshold

Aux Heat Off Sets the delta from setpoint that stage 3 heating stops.

0 to 7 0

Threshold

Stage 3 turns off at setpoint + Delta Stage 3

degrees

Cooling Stage 1 Sets the delta from setpoint that stage 1 cooling starts.

1 to 7 1

On Threshold

degrees

Copyright © Ecolink Intellig ent Tech nology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 16 24-02-2021 18:55

16

Page 17

24-02-2021 18:55

17

Feature

Description

Range

Default

Setting

Cooling Stage 1

Off Threshold

Sets the delta from setpoint that stage 1 cooling stops. Stage 1 turns off at

setpoint - Delta Stage 1

0 to 6 degrees

0

Cooling Stage 2

On Threshold

Sets the delta from setpoint that stage 2 cooling starts.

2 to 8 degrees 2

Restore Defaults Restores all settings to factory defaults. Press Yes to restore defaults

Press No to exit and not restore defaults

Y or N

N

Factory Default

Please use this procedure only when the Z-Wave Primary Controller is missing or otherwise inoperable. To reset the

TBZ500’s Z-Wave parameters to Factory Settings (both Z-Wave and HVAC settings):

1. Remove power from the TBZ500.

2. Restore power to the TBZ500.

3. When “TBZ500” appears on the screen, hold down the MODE and FAN buttons at the same time.

4. Release the buttons when RESET appears on the Status Line.

5. Once the TBZ500 resets the Z-Wave and HVAC settings, a DONE confirmation message will appear on the screen before the thermostat self-reboots.

Copyright © Ecolink Intelligent Techn ology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 17

Cooling Stage 2

Off Threshold

Sets the delta from setpoint that stage 2 cooling stops.

Stage 2 tu rns off at setpoint - Delta Stage 2.

0 to 7 degrees

0

Page 18

Z-Wave Installation

Adding the thermostat to a Z-Wave network.

6. Follow the instructions provided with your system for enrolling the thermostat.

7. Press and hold the FAN button on the Thermostat until the screen changes to the Menu screen.

8. Press the UP button until ZWAVE is shown in the Status Display line then press Select.

9. INSTALL should be shown on the status line.

10. When instructed by your system installation to add the thermostat to the network press the “Select” button to install.

Wait until SUCCESS or FAILED is shown on thestatus

display.

11. Press Done on the Thermostat to exit the ZWAVE screen.

12. Press Done on the Thermostat again to exit the Menu screen.

13. Once enrolled on your system’s network, continue to follow the instructions provided to complete the enrollment and

naming of the thermostat.

14. The

indicator should be shown on the Thermostat Main screen indicating the thermostat has successfully been

enrolled into the Z-Wave network.

Removing the thermostat from a Z-Wave network.

It may be necessary to remove and/or reinstall the thermostat from a Z-Wave network if the thermostat has been previously

installed on another network. Follow the instructions supplied with your Z-Wave system to remove/uninstall a Z-Wave device.

When the system instructs you to press and release the Z-Wave button on the thermostat, follow these steps:

1. Press and hold the FAN button for 3 seconds until the Menu screen is displayed.

2. Press the UP arrow button to scroll to the “ZWAVE” menu.

3. Press “Select” to select the ZWAVE screen.

4. The display will show “REMOVE” in the text line.

5. Press “Select” to perform the remove action.

6. “WAIT” will be displayed in the text line. The remove operation is in process.

7. “SUCCESS” will be display when the thermostat has been excluded from the network.

8. Press “Done” to exit back to the thermostat screen.

9. Thermostat is now ready to be added to any Z-Wave network.

Copyright © Ecolink Intellig ent Tech nology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 18 24-02-2021 18:55

18

Page 19

Fan Mode indicators

System Mode indicators

TBZ500 24VAC OR BATTERY POWERED Z-WAVE THERMOSTAT

OPERATION INSTRUCTIONS

Backlight and Button Operation

The thermostat backlight is normally set to go out after 10

seconds of no button presses to conserve battery power. If

the backlight is off, the first button press of any button will

only turn on the backlight. Once the backlight is on, the

buttons function normally.

System Operation Modes

displayed = System is ON and heating.

If flashing, minimum run time (MRT) is active

displayed = System is ON and cooling.

If flashing, minimum run time (MRT) is active

Stage Indicators

• “1” = Stage 1 heating or cooling is ON

• “2” = Stage 2 heating or cooling is ON

• “3” = Stage 3 heating (Aux Heat) is ON

For Heat Pump systems only:

• “Heat-E” = Emergency heat mode active

Copyright © Ecolink Intellig ent Technology

TBZ500_manual_8_5x5_5_inch

Combined_RDN1240221.indd 19 24-02-2021 18:55

TBZ500 Display

19

Text Information Display Line

Low Battery indicator

Display Lock indicator

Z-Wave Network Installed indicator

Heating/Cooling Mode Selection

Button Mode Status

Backlit Display

Text Display Line

Temperature Setting Touch Buttons:

Warmer

Room Temperature

Cooler

Fan Mode Selection

Page 20

SETTING THE SYSTEM MODE

Press MODE

button to change

system mode

System Modes

• Off:

System is off. No heating or cooling will come on. If system was on, it will turn off immediately.

• Heat:

Only heating will occur.

• Cool:

Only cooling will occur.

• Auto:

Heating or cooling will come on according to the heating and cooling setpoints. The system will

automatically switch between heating and cooling modes as needed to maintain the setpoints.

• Special Heat Pump Mode:

Emergency Heat.

• Heat-E:

An additional system mode, “Heat-E” for Emergency Heat will be displayed if the HVAC System Type is set to Heat

Pump. If there is a compressor failure with the Heat Pump system, setting the mode to Emergency Heat will allow the

supplemental Aux Heat to come on first whenever there is a call for heating. It also disables the compressor output to

prevent further damage to the HVAC system.

Caution!

Emergency Heat should only be used for emergencies until the HVAC system can be repaired. Running the system in

Emergency Heat mode is commonly the most expensive mode since only the electric heat strips are bei ng used instead of the

more efficient heat pump compressor.

20

Copyright © Ecolink Intellig ent Tech nology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 20 24-02-2021 18:55

Page 21

SETTING THE HEATING OR COOLING TEMPERATURE SETPOINT

Setpoint Change

To change the setpoint, press the Up or Down arrow buttons. The screen will switch to the setpoint change screen (as above)

and show the current setpoint of the current heating or cooling mode. Adjust setpoint temperature up or down with the arrow

buttons.

Note! When in the Setpoint Change screen, pressing the MODE button will switch the setpoint being displayed between

the Heat and Cool setpoints.

Setpoint Push:

The cooling setpoint cannot be set below the heating setpoint. The thermostat will “push” the heating setpoint

lower if the cooling setpoint is set below the current heating setpoint. A 3 degree separation is maintained between the heating

and cooling setpoints. The same is true for raising the heating setpoint above the cooling setpoint. The thermostat will “push”

the cooling setpoint up to maintain the 3 degree separation.

Setpoint being

changed

Press MODE button to

change from the heat

setpoint to the cool

setpoint

Press “Done” (FAN button)

to set the setpoint and exit

back to the main thermostat

screen or wait for the screen

to automatically time out.

Copyright © Ecolink Intellig ent Technology

TBZ500_manual_8_5x5_5_inch

Combined_RDN1240221.indd 21 24-02-2021 18:55

21

Lower Temperature

Pressing the Up or Down buttons

will change the setpoint 1 degree. Press

and hold the button to

ramp the setpoint.

Raise Temperature

Press the Up or Down arrow buttons to

set the desired temperature setpoint

Press either Up or Down

arrow button to go to

the Setpoint Change

screen

Page 22

Use the UP/DOWN bu ttons to

select the desired menu item

SETTING THE FAN MODE

Fan Modes

• Auto:

Fan automatically operated by the HVAC system. (normal setting)

• On:

Manual Fan mode. Fan stays on until mode is changed back to Auto,independent of the heating or cooling system

operation.

THERMOSTAT MENU MODE

The Thermostat has a menu of setup and information

displays. To change to the Me

nu Mode, press a

nd hold th

e

FAN button for 5 seconds. The display will change to the

Menu Mode and display the Setup screen. Use the Up/

Down arrow buttons to scroll through other menu items.

Press and hold the FAN button for 5 seconds to go to

the

Menu Mode screen

Copyright © Ecolink Intellig ent Tech nology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 22 24-02-2021 18:55

22

Press “Done” to go back to the

Thermostat Main Screen

Menu item display

Press “Select” to go to the

selected menu item screen

Press the FAN button to

change the Fan mode

Page 23

SETUP menu

User preference settings.

• Fahrenheit or Celsius.

Select the temperature display mode.

• Backlight timeout.

Sets the time from last button press that the backlight will turn off. Range: 10 (default) -30 seconds. Note: long backlight

timeouts will reduce battery life. If the thermostat is powered from 24VAC, the backlight timeout can be set to “0” which wil l

keep the backlight on continuously.

• temperature sensor calibration.

Change the temperature calibration by +/- 7 degrees. Use the Up/Down arrow buttons to change to the desired temperature

displayed.

• Status Line Display.

Select Setpoints or Relative Humidity to be displayed on the upper status line.

SYSTEM menu

• System type

Select the system type, STANDARD or HEAT PUMP TYPE (Standard systems only).

• Select fan type:

gas

(typical default setting) or

electric

• Change over type

(Heat Pump systems only).

Select the Changeover type: Changeover WITH COOL (typical default setting) or Changeover WITH HEAT.

Z-WAVE menu

This menu item allows the thermostat to be enrolled to the Z-Wave network. Follow the instructions shown

in the Z-Wave® Operation section (page 18) to enroll the Thermostat onto the network.

INFO menu

The INFO menu displays information about the thermostat. Use the Up/Dn buttons to scroll through the

various items.

Menu Mode Screen

• Setup

(user preference settings)

• System

(HVAC system setup)

• Zwave

(Z-Wave network install or

remove)

• Info

(Displays thermostat version

and setup info)

Thermostat information displayed:

• Version:

Thermostat firmware

version

• Zwave:

Z-Wave firmware

version

• Node ID:

Z-Wave Node ID

• Home ID:

Z-Wave Home ID

• System type:

displays current

System Type settings (Standard or

Heat Pump)

• If System Type =

Standard

FAN TYPE displays current Fan Type

setting

• If System Type =

Heat Pump

CHANGEOVER TYPE displays current

Change Over valve (reversing valve)

setting

• AC or Battery Powered:

AC POWER

will be displayed if power by 24VAC

Copyright © Ecolink Intelligent Technology 23

TBZ500_manual_8_5x5_5_inch

Combined_RDN1240221.indd 23 24-02-2021 18:55

Page 24

THERMOSTAT OPERATION

Minimum Run Time (MRT)

The thermostat has a Minimum Run Time (MRT) delay after the start of any heating or cooling call. This minimum run time assures

even heating and cooling cycles. The MRT will keep the system on, even if it reaches the setpoint room temperature, or you

change the setpoint to a temperature that would satisfy the call, until the MRT expires. Changing the Mode to OFF will cancel

the MRT and the system will turn off immediately. The MRT can be adjusted in the Advanced Settings menu of the thermostat.

Note:

When MRT is active, the heating or cooling icon will be flashing.

Minimum Off Time (MOT)

The thermostat has a Minimum Off Time (MOT) delay after any heating or cooling cycle ends. This delay prevents rapid heating/

cooling cycles and also provides “short cycle protection” for the system compressor. This delay may be noticeable when you

change a setpoint and it does not respond immediately due to the MOT delay timer preventing the system from restarting. The

MOT delay time can be adjusted in the Advanced Settings menu of the thermostat but there is a minimum of a 5 minute delay

to assure compressor protection.

Note:

When MOT is active, the thermostat Status Display shows “WAIT”.

Z-WAVE® OPERATION

Thermostat Battery Operation:

If the thermostat is installed in a Z-Wave network while powered by batteries, it will be enrolled

as a Z-Wave FLiRs type device. This is a power saving mode that conserves the batteries by keeping the radio asleep most of the

time. However, in this mode, the thermostat does not act as a repeater/router in the Z-Wave network.

Thermostat 24VAC Operation:

If the thermostat is installed in a Z-Wave network while powered by 24VAC, it will be enrolled as

an always-listening device and can act as a router node in the Z-Wave network.

Caution!

Once installed in a Z-Wave network, if you change how the thermostat is powered (from batteries to 24VAC or vice

versa), you must remove and re-enroll the thermostat in the Z-Wave network for it to work correctly.

Copyright © Ecolink Intellig ent Tech nology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 24 24-02-2021 18:55

24

Page 25

24-02-2021 18:55

25

SmartStart Inclusion – Adding the thermostat to a Z-Wave Network

The TBZ500 is SmartStart enabled and can be added into a Z-Wave network by scanning the Z-Wave QR Code present on

the product with a controller providing SmartStart inclusion. No further action is required and the SmartStart product

will be added automatically within 10 minutes of being switched on in the network vicinity. The SmartStart QR code can

be found on the back of the thermostat, side of the package, or also inserted as an insert card/sticker. The sticker

contains the full DSK string. It’s important that if you plan to use DSK that you keep this label in a safe place you’ ll

remember. If your system does not support SmartStart, you can still enroll your thermostat using classic inclusion.

Classic Inclusion - Adding the thermostat to a Z-Wave network.

1. Follow the instructions provided with your system for enrolling the thermostat.

2. Press and hold the

FAN button

on the Thermostat until the screen changes to the Menu screen.

3. Press the UP button until ZWAVE is shown in the Status Display line then press Select.

4. INSTALL should be shown on the status line.

5. When instructed by your system installation to add the thermostat to the network press the “Select” button to install.

Wait until SUCCESS or FAILED is shown on thestatus display.

6. Press Done on the Thermostat to exit the ZWAVE screen.

7. Press Done on the Thermostat again to exit the Menu screen.

8. Once enrolled on your system’s network, continue to follow the instructions provided to complete the enrollment and

naming of the thermostat.

9. The

indicator should be shown on the Thermostat Main screen indicating the thermostat has successfully been

enrolled into the Z-Wave network.

Removing the thermostat from a Z-Wave network.

It may be necessary to remove and/or reinstall the thermostat from a Z-Wave network if the thermostat has been previously

installed on another network. Follow the instructions supplied with your Z-Wave system to remove/uninstall a Z-Wave device.

When the system instructs you to press and release the Z-Wave button on the thermostat, follow these steps:

1. Press and hold the FAN button for 3 seconds until the Menu screen is displayed.

2. Press the UP arrow button to scroll to the “ZWAVE” menu.

3. Press “Select” to select the ZWAVE screen.

4. The display will show “REMOVE” in the text line.

5. Press “Select” to perform the remove action.

6. “WAIT” will be displayed in the text line. The remove operation is in process.

7. “SUCCESS” will be display when the thermostat has been excluded from the network.

8. Press “Done” to exit back to the thermostat screen.

9. Thermostat is now ready to be added to any Z-Wave network.

Copyright © Ecolink Intellig ent Technology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 25

Page 26

Z-WAVE COMMAND CLASSES

Z-Wave Command Classes

TBZ500

COMMAND_CLASS_BASIC

•

COMMAND_CLASS_ZWAVEPLUS_INFO_V2

•

COMMAND_CLASS_ANTITHEFT_V2

•

COMMAND_CLASS_ASSOCIATION_GRP_INFO

•

COMMAND_CLASS_ASSOCIATION_V2

•

COMMAND_CLASS_BATTERY

•

COMMAND_CLASS_DEVICE_RESET_LOCALLY

•

COMMAND_CLASS_FIRMWARE_UPDATE_MD_V2/V3

•

- V3

COMMAND_CLASS_MANUFACTURER_SPECIFIC_V2

•

- V2

COMMAND_CLASS_MULTI_CMD

•

COMMAND_CLASS_POWER_LEVEL

•

COMMAND_CLASS_SENSOR_MULTILEVEL_V5

•

- V5

COMMAND_CLASS_THERMOSTAT_FAN_MODE

•

COMMAND_CLASS_THERMOSTAT_FAN_STATE

•

COMMAND_CLASS_THERMOSTAT_MODE_V3

•

- V3

COMMAND_CLASS_THERMOSTAT_OPERATING_STATE_V2

•

- V2

CCOMMAND_CLASS_THERMOSTAT_SETPOINT_V2/V3

•

- V3

COMMAND_CLASS_VERSION_V2

•

COMMAND_CLASS_SECURITY_2

•

COMMAND_CLASS_TRANSPORT_SERVICE_V2

•

COMMAND_CLASS_SUPERVISION

•

COMMAND_CLASS_CONFIGURATION_V2

•

- V2

Copyright © Ecolink Intellig ent Tech nology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 26 24-02-2021 18:55

26

Page 27

24-02-2021 18:55

27

Association groups

The TBZ500 supports 3 groups and 5 associations per group.

Group 1 Association Alerts are to notify an associated device of a thermostat generated change. Thermostat generated changes are those

changes that originate at or by the thermostat. The general classifications of thermostat generated changes are:

• User interface changes – Setpoints, Mode, Fan Mode, Occupied Mode

• Operational changes – Operating State, Fan State (See Configuration parameter #24 for details)

• COMMAND_CLASS_CONFIGURATION changes – See the COMMAND_CLASS_CONFIGURATION table for additional unsolicited alerts

• Setpoint Push – When a setpoint is pushed to maintain the HC-Delta separation

• Battery Status when the battery reaches the predefined thresholds

Group 2 Association Alerts will send a BASIC_SET 0xFF when a Cool Call starts and a BASIC_SET 0x00 when the Cool Call ends

Group 3 Association Alerts will send a BASIC_SET 0xFF when a Heat Call starts and a BASIC_SET 0x00 when the Heat Call ends

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 27

Page 28

Z-Wave Configurations

There are configuration parameters accessible via the COMMAND_CLASS_CONFIGURATION.

Note all temperature related parameters are in degrees F.

Config

Parameter

#

Description

Length

(bytes)

Send

Unsolicited

on change

Default

Value

Read values

Write values

1

System Type 4

1 N 0

0 = Standard 1 = Heat Pump

0 = Standard 1 = Heat Pump

2

Fan Type 4

1 N 0

0 = Gas (No fan w/Heat) 1 =

Electric (Fan w/Heat)

0 = Gas (No fan w/Heat), 1 =

Electric (Fan w/Heat)

3

Change Over Type 4

1 N 0

0 = CO w/cool 1 = CO w/heat

0 = CO w/cool 1 = CO w/heat

4

2nd Stage Heat Enable 4

1 N 0

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

5

Aux Heat Enable 4

1 N 1

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

6

2nd Stage Cool Enable 4

1 N 0

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

7

C/F Type

1 N 1

0 = Centigrade

1 = Fahrenheit

0 = Centigrade

1 = Fahrenheit

8

MOT 5

1 N 5

5-9

5-9 9 MRT 5

1 N 3

3-9

3-9

10

Setpoint H/C Delta

1 N 3

3-15

3-15

11

H Delta Stage 1 ON

1 N 1

1-6

1-6

12

H Delta Stage 1 OFF

1 N 0

0-5

0-5

13

H Delta Stage 2 ON

1 N 2

2-7

2-7

14

H Delta Stage 2 OFF

1 N 0

0-6

0-6

15

H Delta Aux ON

1 N 3

3-8

3-8

16

H Delta Aux OFF

1 N 0

0-7

0-7

17

C Delta Stage 1 ON

1 N 1

1-6

1-6

Page 29

Config

Parameter

#

Description

Length

(bytes)

Send

Unsolicited

on

change

Default

Value

Read values

Write values

18

C Delta Stage 1 OFF

1 N 0

0-5

0-5

19

C Delta Stage 2 ON

1 N 2

2-7

2-7

20

C Delta Stage 2 OFF

1 N 0

0-6

0-6

21

Mechanical Status 3

2 Y

MECH_H1 0x0001

MECH_H2 0x0002

n/a

0x15

MECH_H3 0x0004

MECH_C1 0x0008

MECH_C2 0x0010

PHANTOM_F 0x0020

MECH_F 0x0040

MANUAL_F 0x0080

Reserved 0x0100

22

SCP Status 3 1 Y

STATE_HEAT 0x01

STATE_COOL 0x02

n/a

0x16

STATE_2ND 0x04

STATE_3RD 0x08

STATE_FAN 0x10

STATE_LAST 0x20

STATE_MOT 0x40

STATE_MRT 0x80

23

Autosend Enable Bits

2 N

0x205F

TEMPERATURE

(CC_SENSOR_MULTILEVEL)

0x0001

0x17

SETPOINTH

(CC_THERMOSTAT_SETPOINT)

0x0002

When set, the

corresponding

SETPOINTC

(CC_THERMOSTAT_SETPOINT)

0x0004

report is sent out

unsolicited

MODE

(CC_THERMOSTAT_MODE)

0x0008

when a changed is

detected, to

FANMODE

(CC_THERMOSTAT_FAN_MODE)

0x0010

the nodes in the

association list

FANSTATE (CC_THERMOSTAT_FAN_STATE) 0x0020

OPERATINGSTATE (CC_THERMOSTAT_OPERATING_STATE) 0x0040

SCHEDENABLE (CC_CONFIGURATION #38) 0x0080

SETBACK (CC_CONFIGURATION #40) 0x0100

RUNHOLD (CC_CONFIGURATION #39) 0x0200

DISPLAYLOCK (CC_CONFIGURATION #24) 0x0400

0x0800

0x1000

BATTERY

6

(CC_BATTERY) 0x2000

MECH STATUS (CC_CONFIGURATION #21) 0x4000

SCP STATUS (CC_CONFIGURATION #22) 0x8000

24

Display Lock 3

1 Y 0

0 = unlocked

0 = unlocked

1 =locked

1 = locked

Page 30

Config

Parameter #

Description

Length

(bytes)

Send

Unsolicited on

change

Default

Value

Read values

Write values

26

Backlight Timer

1 N 20

10-30

10-30

33

Max Heat Setpoint

1 N 90

30F – 109F

30F – 109F

34

Min Cool Setpoint

1 N 60

33F – 112F

33F – 112F

38

Schedule Enable

1 N 0

0 = Disabled

1 = Enabled

0 = Disabled

1 = Enabled

40

Setback Mode 3

1 Y 0

0 = No Setback

2 = UnOccupied Mode

0 = No Setback

2 = UnOccupied Mode

41

Un-Occupied HSP 1

1 N 62

30F - 109F

30F - 109F

42

Un-Occupied CSP 1

1 N 80

33F – 112F

33F – 112F

43

Remote Sensor 1 Node Number

1 N 0

0-252

0= Disabled

0-252

0= Disabled

46

Remote Sensor 1 Temperature

1 N 0 n/a

48

Internal Sensor Temp Offset

1 N 0

-7 to 7

-7 to 7

49

R1 Sensor Temp Offset

1 N 0

-7 to 7

-7 to 7

52

Filter Timer (hours)

2 N 0

0-4000+

0-4000

53

Filter Timer Max (hours)

2 N 300

0-4000

0-4000

54

Heat Timer (hours)

2 N 0

0-4000+

0-4000

55

Cool Timer (hours)

2 N 0

0-4000+

0-4000

61

Fan Purge Heat

1 N 0

0-90

0-90

62

Fan Purge Cool

1 N 0

0-90

0-90

170

0xaa

Send Association Autosend with ACKs

1 N 1

0 = Send with no ACK request 1 = Send

with ACK request

0 = Send with no ACK request 1 = Send

with ACK request

171

0xab

Number of Heat Call Starts

4 N 0

0-0x7FFFFFFF

0-0x7FFFFFFF

172

0xac

Number of Cool Call Starts

4 N 0

0-0x7FFFFFFF

0-0x7FFFFFFF

173

0xad

Reboot Count

4 N 0

0-0x7FFFFFFF

0-0x7FFFFFFF

174

0xae

CPU runtime (sec) (battery mode

only)

4 N 0

0-0x7FFFFFFF

n/a

175

0xaf

Autosend Wakeup count

4 N 0

0-0x7FFFFFFF

0-0x7FFFFFFF

Page 31

Config

Parameter #

Description

Length

(bytes)

Send

Unsolicited on

change

Default

Value

Read values

Write values

176

0xb0

UI Wakeup count

4 N 0

0-0x7FFFFFFF

0-0x7FFFFFFF

177

Reserved

178

0xb2

Power Status

Bits are set according to power setup.

1

POWER_BATTERY 0x01 POWER_24VAC

0x02

PWR_ACINSTALL 0x10

PWR_BATINSTALL 0x20

PWR_FLIRS 0x40

n/a

179

0xB3

Battery Bank Voltage (%)

1 N

0-100

n/a

181

0xB5

Battery (%) Stat Shutdown threshold

1 0

0-50

0-50

182

0xB6

Battery (%) Radio Cutoff threshold

1 10

10-50

10-50

183

0xB7

Battery (%) LOWBATT Indicator

threshold

1 20

20-75

20-75

184

0xB8

Battery (%) Threshold value for

Midlevel

1 50

50-80

50-80

185

0xB9

Battery Report Timer (days)

1 N 1

0 = Disabled, 1 – 10

0 = Disabled, 1 – 10

186

0xBA

Temperature Delta Autosend

Threshold (how many degree change

from the last autosend)

1 N 2

1-5 (degrees)

1-5 (degrees)

187

0xBB

Periodic Temperature Send Interval

(min)

1 N 0

0 = Disabled, 1 – 120

0 = Disabled, 1 – 120

188

reserved

189

reserved

190

reserved

198

Reserved

4 N

n/a

221

Rutime-Stage1 Heat (sec)

4 N 0

0-0x7FFFFFFF

0-0x7FFFFFFF

222

Rutime-Stage2 Heat (sec)

4 N 0

0-0x7FFFFFFF

0-0x7FFFFFFF

223

Runtime-Aux Heat (sec)

4 N 0

0-0x7FFFFFFF

0-0x7FFFFFFF

224

Rutime-Stage1 Cool (sec)

4 N 0

0-0x7FFFFFFF

0-0x7FFFFFFF

225

Rutime-Stage2 Cool (sec)

4 N 0

0-0x7FFFFFFF

0-0x7FFFFFFF

226

Runtime-Fan Only (sec)

4 N 0

0-0x7FFFFFFF

0-0x7FFFFFFF

Page 32

Config

Parameter #

Description

Length

(bytes)

Send

Unsolicited on

change

Default

Value

Read values

Write values

227

Runtime-Standby (sec)

4 N 0

0-0x7FFFFFFF

0-0x7FFFFFFF

230

reserved

231

Status Display( 0 displays RH

on status line, 1 displays setpoints)

1 N 1

0,1 0,1

1 Setting the AWAY setpoints via the CONFIG command class does not maintain the delta-T separation

2

3 Config Parameters can be selectively Enabled to be Sent Unsolicited by setting the appropriate bits in the AutoSend Config Register #23

4 Any change to a Mechanical System setting may cause the current HVAC operation to abort and start an MOT

5 An MOT/MRT change will not take effect until the next MOT or MRT cycle

6 The battery alert enable only applies to the periodic battery report (config reg 185) and not the built in battery threshol d alerts (config regs 183, 184)

7 Schedule Enable (#38) must be enabled prior to setting this parameter

Copyright © Ecolink Intellig ent Tech nology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 28 24-02-2021 18:55

26

Page 33

24-02-2021 18:55

27

INFORMATION TO USER

FCC ID: WIB-TZW500 IC ID: 9374A-W500 FCC Compliance Statement

This device complies with part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) This device may not

cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause

undesired operation.

This equipment has be en tested and found to comply with the limits

for Class B digital devices, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment

generates uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference

to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

•

Re-orient or relocate the receiving antenna

•

Increase the separation between the equipment and receiver

•

Connect the equipment to an outlet on a different circuit from

the receiver

•

Consult the dealer or an experienced radio/TV contractor for

help.

Warning: Changes or modifications not expressly approved by

Ecolink Intelligent Technology Inc. could void the user’s authority

to operate the equipment.

(GB) This device complies with Industry Canada license-exempt RSS

standard(s). Operation is subject to the following two conditions:

(1) this device may not cause interference, and (2) this device must

accept any interference, including interference that may cause

undesired operation of the device.

(FR) C’et appareil est conforme la norme d’Industrie Canada exempts

de licence RSS. Son fonctionnement est soumis aux deux conditions

suivantes: (1) c’et appareil ne peut pas provoquer d’interférences,

et (2) c’et appareil doit accepter toute interférence, y compris les

interférences qui peuvent causer un mauvais fonctionnement de la

dispositif.

Copyright © Ecolink Intellig ent Technology

LIMITED WARRANTY

This limited warranty is provided by Ecolink Intelligent Technology

(“Ecolin k”) to you as the original purchaser of the product. Ecolink

warrants this product to be free from defects in material and

workmanship for a p eriod of one (1) year from the date of original

purchase. The determination of whether the product is defec tive shall

be mad e by Ecolink in its sole discretion with consideration given to

the overall perf ormanc e of the product. If Ecolink determines that any

product is defective, Ecolink’s sole obligation and your sole and exclusive

remedy shall be that Ecolink will replace the product.

This warranty does not apply to damage caused by shipping or handling,

or damage caused by acc ident, abuse, misuse, misapplication, ordinary

wear, improper maintenance, f ailure to follow instructions or as a result

of any unautho rized modifications. The foregoing limited warranty is

and shall be in lieu of any and all other warranties, whether expressed

or implied and of all other oblig ations or liabilities on the part of Ecolink.

Ecolink neither assumes responsibility for, nor au thoriz es any other

person purporting to act on its behalf to modify or to change this

warranty, nor to assume for it any other war ranty or liability concerning

this product. It is recommen ded that th e customer check their equipment

on a regular basis for proper operation.

Disclaimer and limitation of liability other than the limited warranty

above, Ecolink makes no other warranty or representation,

and hereby disclaims any and all implied warranties, including,

without limitation, the implied warranties of non-infringement,

merchantability and fitness for a particular purpose. You

acknowledge that you alone have determined that the product will

suitably meet the requirements of the intended use. in no event

shall Ecolink or any of its affiliates be liable for any incidental,

special, indirect, consequential, or multiple damages, including but

not limited to, lost profits, loss or damage to software or data, or

damage to equipment arising out of the use of any product, even if

Ecolink has been advised of the possibility of such damages. Further,

in no event shall the liability of Ecolink or its affiliaties exceed the

individual price of the product on which liability is asserted.

By the act of use, setup or assembly of the product, you accept all

resultin g liability . If you as th e purchaser or u ser are not prepared to

accept the liability associated with the use of the product, you are advised

to return the produ ct immediately in new and unused condition to the

place of purchase. Some states do not allow the exc lusion or limitation

of incidental or consequential damage, so the above limitations may not

apply to you.

RETURN POLICY

Please visit us at www.discoverecolink.c om/returns to view our return

policy. Th is produc t covered by one or more claims of patents found at:

http://sipcollc.com/patent-list/

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 27

Page 34

Copyright © Ecolink Intellig ent Tech nology

TBZ500_manual_8_5x5_5_inch Combined_RDN1240221.indd 28 24-02-2021 18:55

Loading...

Loading...