Page 1

©2012 ecobee

477 Richmond Street West | #210

Toronto | Ontario | M5V 3E7 | Canada

Toll free 1.877.932.6233

www.ecobee.com

MA-EMSSi-01-rev1

Page 2

EMS Si

Manual

Page 3

CONTENTS

GETTING STARTED 1

Before You Begin 2

HVAC System Compatibility Information 3

Approvals 4

FCC Compliance Statement 4

Specications 5

Wiring Requirements 6

INSTALLING THE EMS Si 7

Step 1. Power O HVAC Equipment 7

Step 2. Remove Existing Thermostat 7

Step 3. Install the EMS Si 7

Step 4. Connect the Wiring 9

Step 5. Power On HVAC Equipment 20

NAVIGATING THE MENUS 20

Using the Navigation Buttons 20

CONFIGURING THE HVAC SETTINGS 22

Equipment 22

Thresholds 25

Reset HVAC Equipment Settings 29

Performing a Hardware Reset 29

Rebooting the EMS Si 30

Conguring Reminders and Alerts 31

Alerts 32

Page 4

AUTOMATION 34

Setting Up the Sensor Inputs 34

CONNECTING TO THE INTERNET 38

Setting Up WiFi and Obtaining a Registration Code 39

Conguring a Web Portal Account 40

USING YOUR EMS Si 42

System Mode 43

Fan 43

Weather Forecast 45

Cleaning the EMS Si 45

CONFIGURING YOUR EMSSi 46

Conguring Personal Preferences 46

Utility CPP Setting 50

WiFi 52

Creating Your Weekly Schedule 53

Using the Weekly Schedule Editor 54

Scheduling a Calendar Event 55

3-YEAR LIMITED WARRANTY 57

END-USER SOFTWARE LICENSE AGREEMENT 59

Page 5

Page 6

GETTING STARTED

Welcome

The ecobee Energy Management System Si (EMS

Si) is the newest technology designed for the

commercial market. It is ideal in applications

where a simple programmable Thermostat does

not provide adequate controls and functionality

and a full-scale building automation system is

too complex and cost prohibitive. The ecobee

EMS Si is user-friendly, reduces a building’s

operating costs, and delivers increased energy

conservation.

From their EMS Web Portal, users can remotely

monitor, identify, analyze and troubleshoot

performance issues; manage the temperature

and operational settings from a central location;

and take action without having to send a

technician on-site.

The ecobee EMS Si can maximize any building’s

eciency, reduce energy consumption and

deliver signicant cost savings

Technical Support

Our technical support team is available to

answer your questions at 1.877.932.6233, or via

email at support@ecobee.com.

1

Page 7

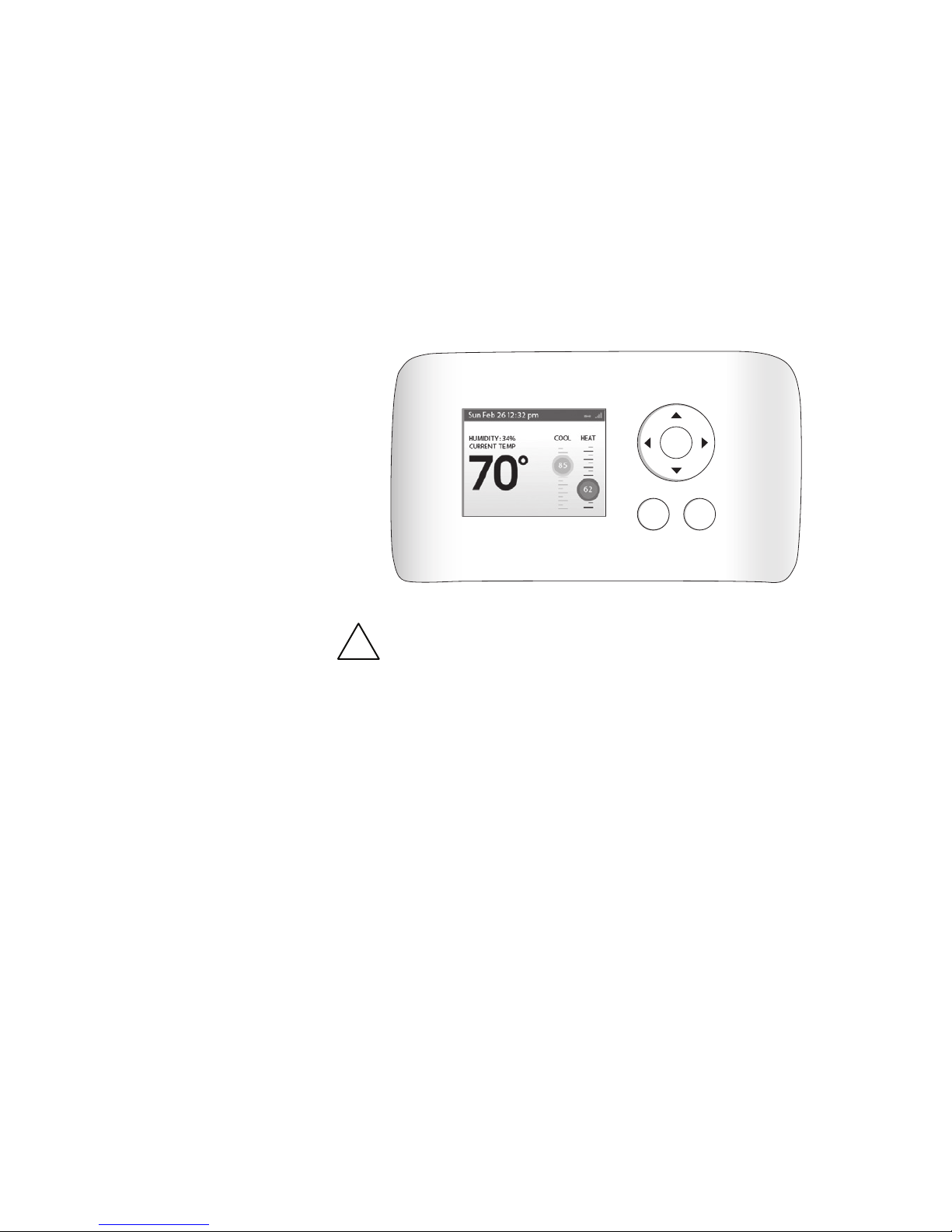

Before You Begin

This product is intended to be installed by

trained service professionals.

This manual explains the procedures for

installing the ecobee EMS Si. Please read it

carefully before beginning the installation.

The EMS Si is designed to be mounted on the

wall in a convenient location.

Caution: Disconnect electric power to the HVAC

system before installing this product. Failure

to do so could result in electric shock and/or

equipment damage.

All wiring must conform to your local electrical

code.

Mercury Notice: This product does not contain

mercury. If you are replacing a product that

does contain mercury, contact your local

waste-management authority for disposal

instructions. Do not discard the old product in

the regular trash.

ecobee

OK

MENU BACK

!

2

Page 8

HVAC System Compatibility

Information

The EMS Si is designed to operate with lowvoltage heating and cooling systems. It is not

designed for use with line-voltage or millivolt

heating and cooling systems.

The EMS Si supports:

Up to 2 heat and 2 cool stages on a

conventional system.

Up to 3 heat and 2 cool stages on a heat

pump system.

The ecobee EMS Si supports the following

equipment:

Equipment Supported?

Gas/Oil/Electric heating Yes

(up to two stages)

Heat pump with auxiliary heat Yes

(up to three stages)

Geothermal Heat Pump Yes

Dual fuel systems Yes

Standard electric cooling Yes

(up to two stages)

Boilers Yes

Sensors with dry contact outputs Yes

3

Page 9

Approvals

This product was designed and built in accordance

to RoHS directive 2002/95/EC and contains no

hazardous substances as dened by this directive.

FCC Compliance Statement

This equipment has been tested and found to

comply with the limits for Class B digital devices,

pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against

harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications.

However, there is no guarantee that interference

will not occur in a particular installation. If this

equipment does cause harmful interference to radio

or television reception, which can be determined

by turning the equipment o and on, the user is

encouraged to try to correct the interference by one

or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment

and receiver.

Connect the equipment to an outlet on a dierent

circuit from the receiver.

Consult the dealer or an experienced radio/TV

contractor for help.

To satisfy FCC/IC RF exposure safety requirements,

a separation distance of 8 inches (20 cm) or more

should be maintained between this device and

persons. To ensure compliance, operation at closer

than this distance is not allowed.

4

Page 10

FCC ID: WR9EBSTAT IC: 7981A-EBSTAT

Warning: Changes or modications not expressly

approved by ecobee Inc. could void the user’s

authority to operate the equipment.

Specications

Temperature ranges

Heat: 45 to 79 °F (7 to 26 °C)

Cool: 45 to 92 °F (14 to 33 °C)

Display: 40 to 100 °F (5 to 37 °C)

Sensitivity: +/- 1 °F (0.5 °C)

Operating: 32 to 130 °F (0 to 55 °C)

Humidity Range

Display: 20 to 90% R.H.

Sensitivity: +/- 5% R.H.

Operating: 5 to 95% R.H (non-condensing)

Dimensions

Thermostat: 5.5”W x 3.25”H x 1”D

(139.5mm H x 82.5mm W x 25mm D)

Power

24 VAC (3VA minimum)

5

Page 11

Wiring Requirements

The following table shows the maximum wire lengths allowed:

Thermostat to HVAC Equipment

18 AWG 20 AWG 22 AWG

128 ft/380 m 80 ft/240 m 50 ft/150 m

Terminal Description and Electrical Ratings

Terminal Description Voltage Current Max

N/C Unused N/A N/A

Y 1st stage compressor 30V AC 3A

W (O/B) 1st stage heating 30V AC 3A

or reversing valve

changeover

G Fan 30V AC 3A

RC Cool transformer * 30V AC 3A

RH Heat transformer * 30V AC 3A

C Common 30V AC 3A

Y2 2nd stage compressor 30V AC 3A

W2 (AUX) 2nd stage heating or 30V AC 3A

1st stage auxiliary heat

R1+ Input 1+ Dry contact only

R1- Input 1- Dry contact only

R2+ Input 2+ Dry contact only

R2- Input 2- Dry contact only

* Factory jumper installed between RC and RH. Remove jumper

for 2-transformer applications. See wiring diagrams for additional

information.

6

Page 12

INSTALLING THE EMS Si

There are 5 steps to install the ecobee EMS Si:

Step 1. Power O HVAC Equipment

Step 2. Remove Existing Thermostat

Step 3. Install the EMS Si

Step 4. Connect the Wiring

Step 5. Power On HVAC Equipment

Step 1. Power O HVAC Equipment

Before disconnecting the existing thermostat, or installing the

EMS Si, disconnect the power to the heating and air conditioning

equipment.

Step 2. Remove Existing Thermostat

Disconnect the wires to the existing thermostat and remove

it from the wall (if you are installing the EMS Si in the same

location).

Step 3. Install the EMS Si

The ideal location for the thermostat is approximately 5 ft (1.5 m)

above oor level in the main living area.

Do not install the thermostat:

Close to sources of heat such as incandescent lights

Near supply heating/cooling sources

In direct sunlight

On exterior, non-insulated or poorly insulated walls

In the kitchen or other areas of potentially high heat and/or

humidity

7

Page 13

In an area that could restrict air ow

To install the thermostat:

1. Gently separate the backplate from the thermostat.

2. Place the thermostat backplate on the wall. Make sure that

any existing wires can be inserted through the opening for the

wiring.

3. Using the backplate as a template, mark the location of the

mounting holes on the wall as shown below.

4. Move the backplate out of the way and make holes where

indicated in step 3. The mounting holes can accommodate a #6

pan-head screw. It is recommended to use the included fasteners

to ensure proper tting of the front housing.

5. Use the included drywall plugs (or other suitable anchors) to

ensure the thermostat can be mounted securely to the wall.

6. Fasten the backplate to the wall using the screws provided (or

other suitable screws).

Y N/C

W

O/B

GRCRHCY2R1+R1-R2+R2-

W2

AUX

The solid color indicates mounting holes

8

Page 14

9

Step 4. Connect the Wiring

You need to use low-voltage cable to connect the thermostat to the HVAC

equipment. Check the wiring diagrams on pages 8 to 17 for the number of

wires required.

Note: There is a factory installed jumper between R/H and R/C. Ensure any

unused wires do not have exposed bare copper conductors.

To connect the thermostat to the equipment:

1. Connect the wires as shown in the wiring diagrams.

2. Attach the EMS Si to the backplate. Ensure that the pins on the

thermostat align with the terminal block on the backplate.

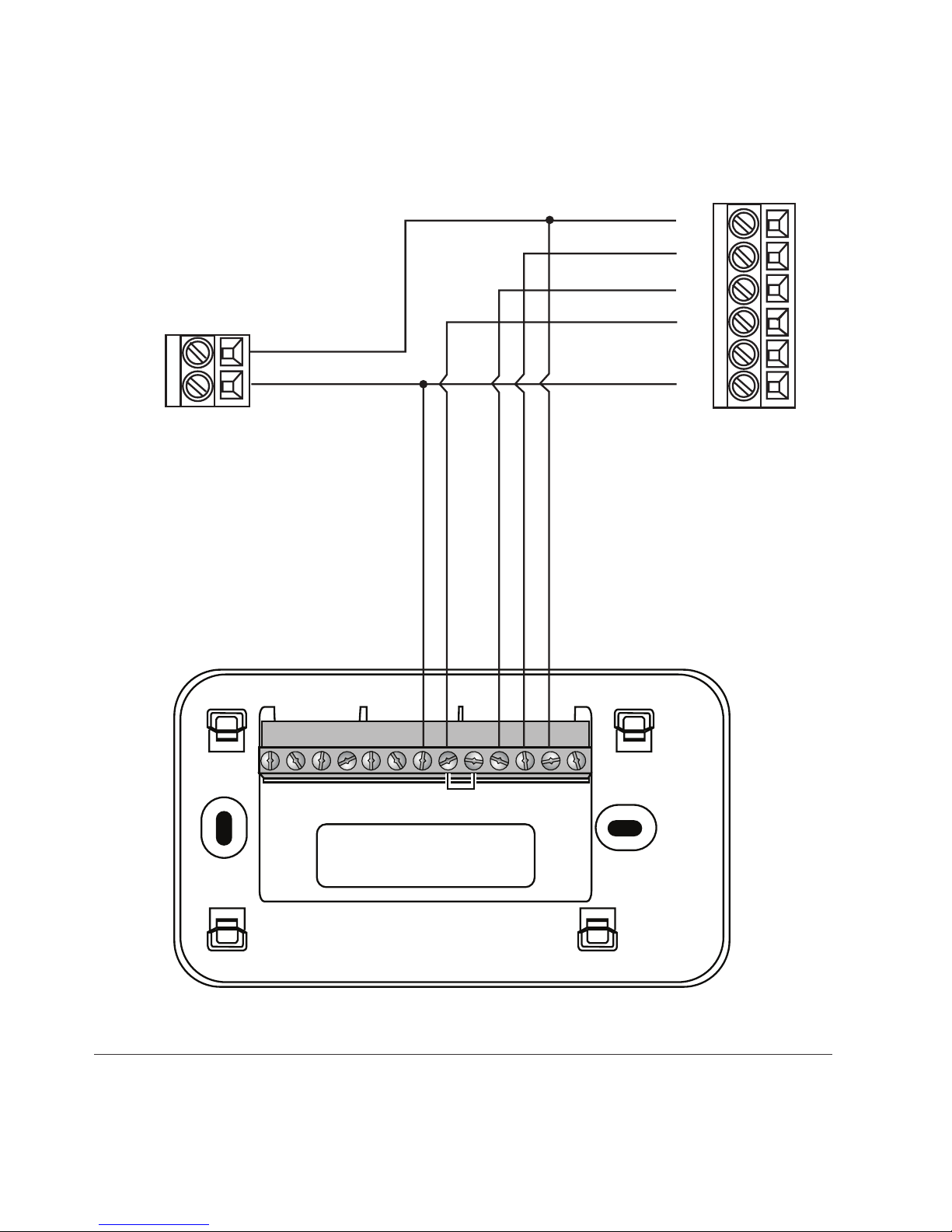

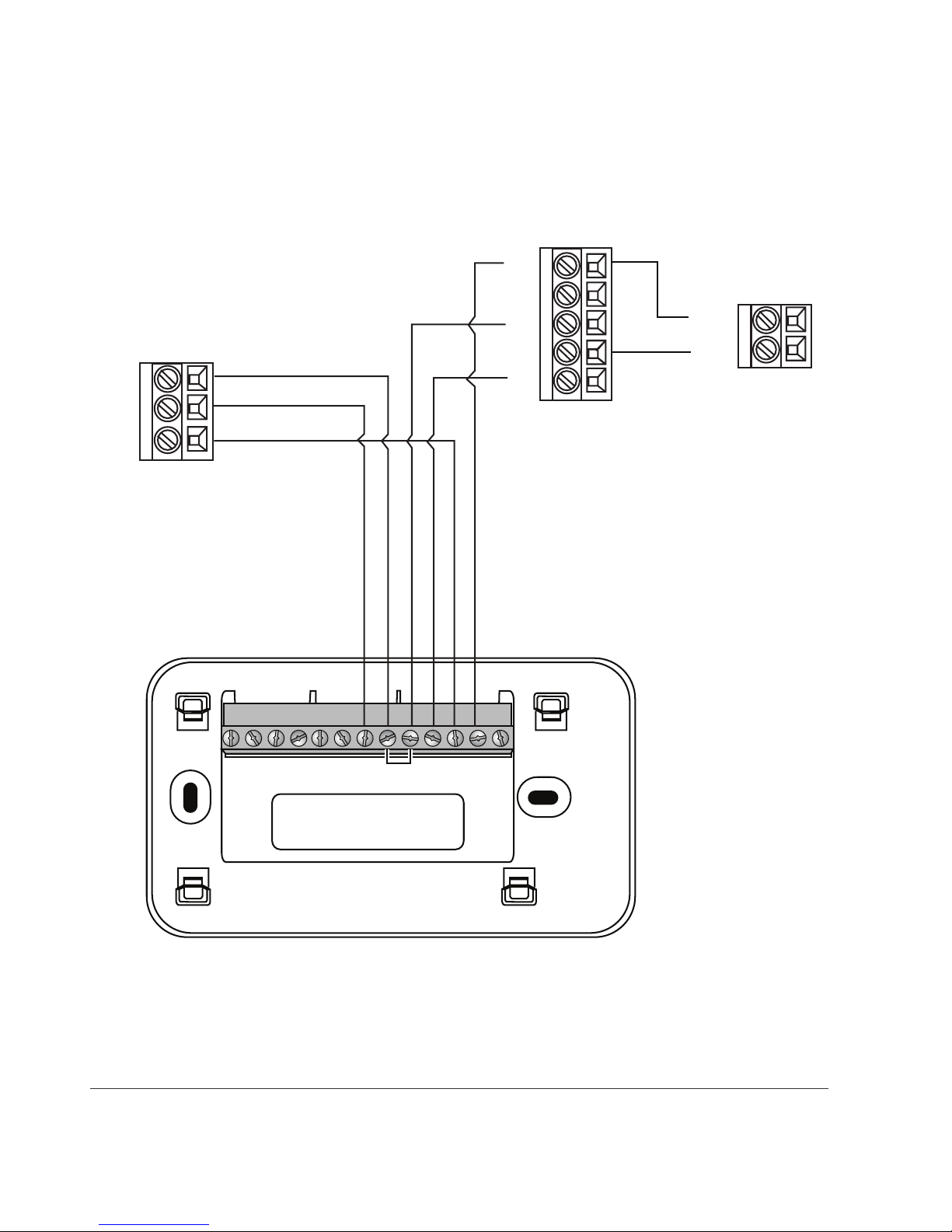

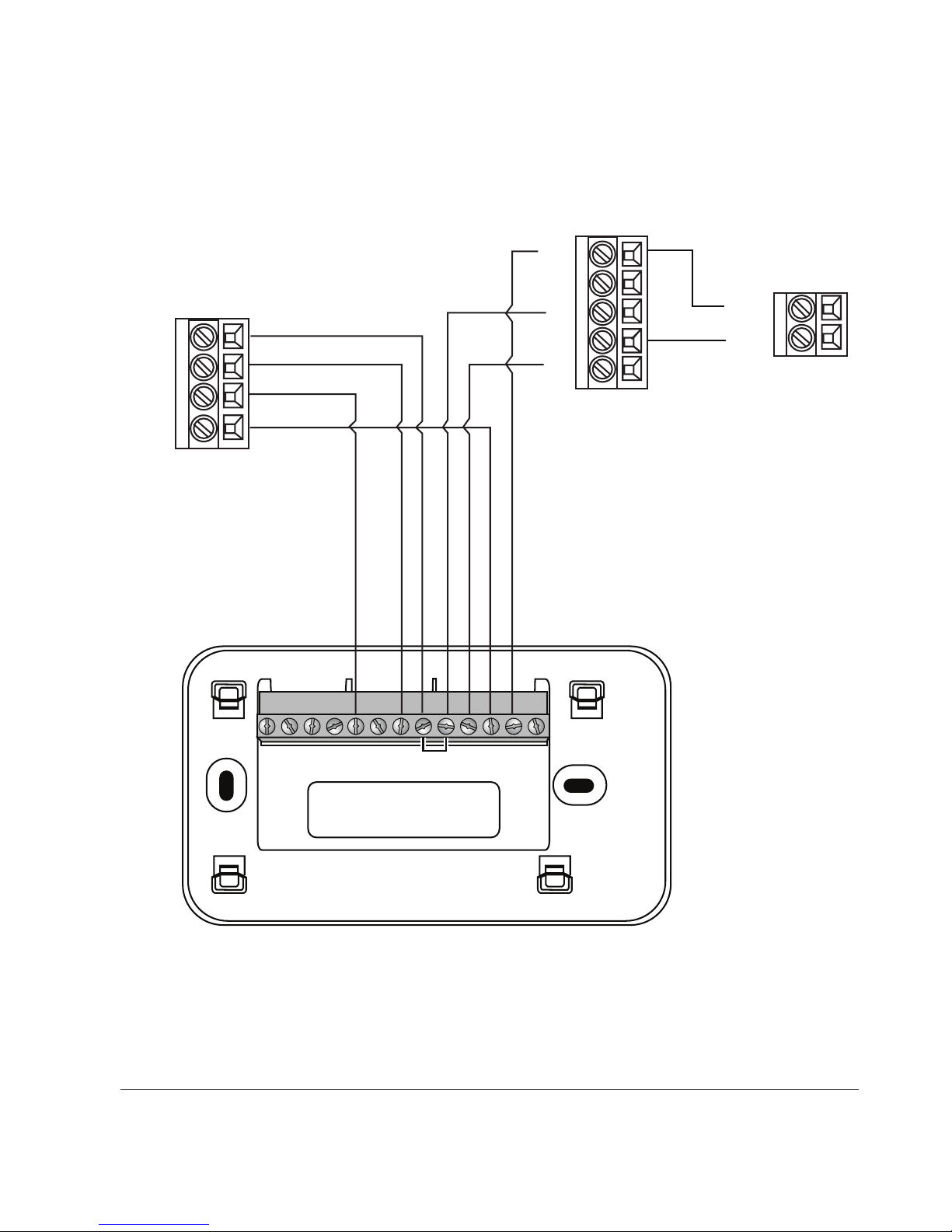

Wiring Diagrams

The following diagrams show how to connect the thermostat terminals to

various HVAC equipment.

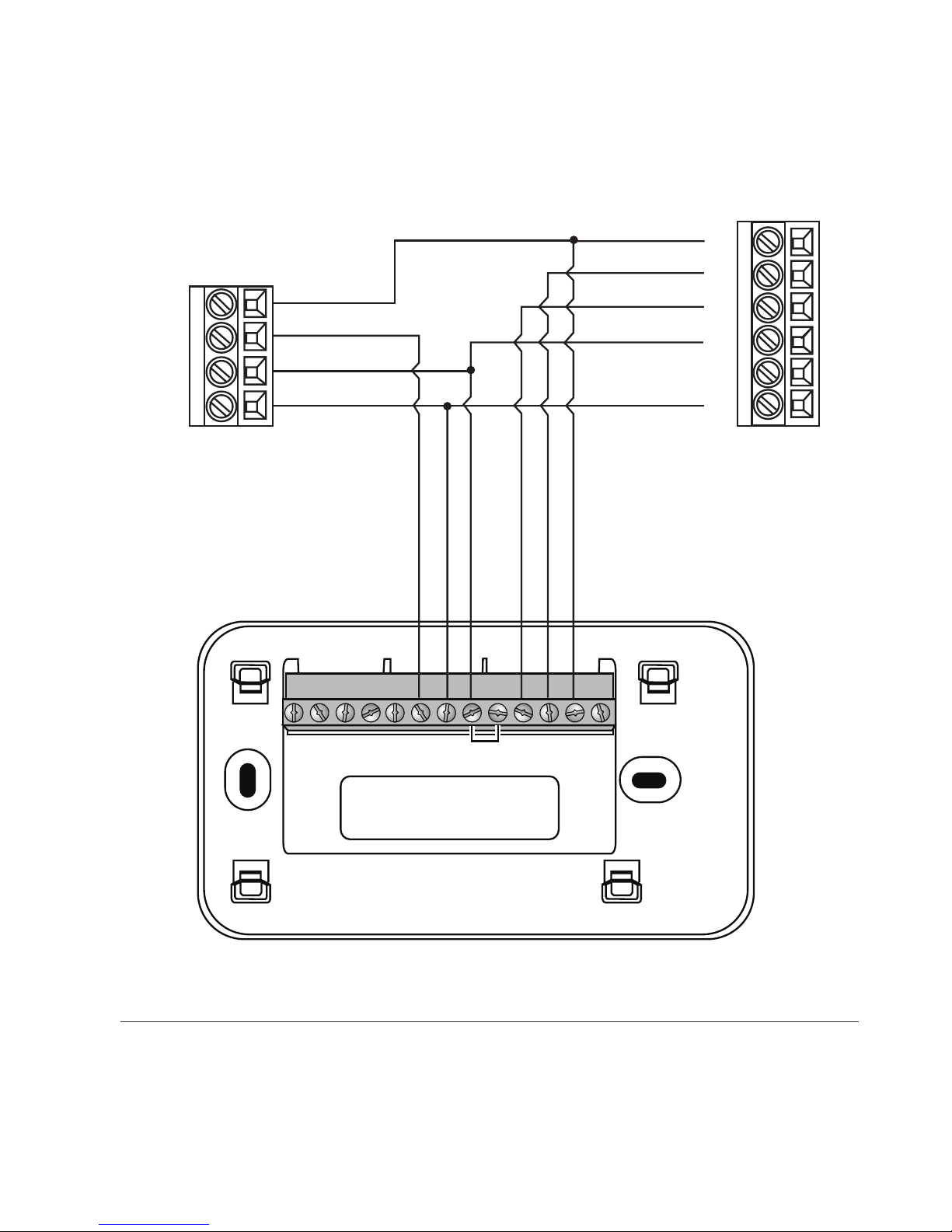

Page 15

10

YN/C

W

O/B

GRCRHCY2R1+R1-R2+R2-

W2

AUX

1-stage AC

C

24V

Y

G

R

W

C

HUM

1-stage Furnace

EMS Si Thermostat

Single stage heat/cool

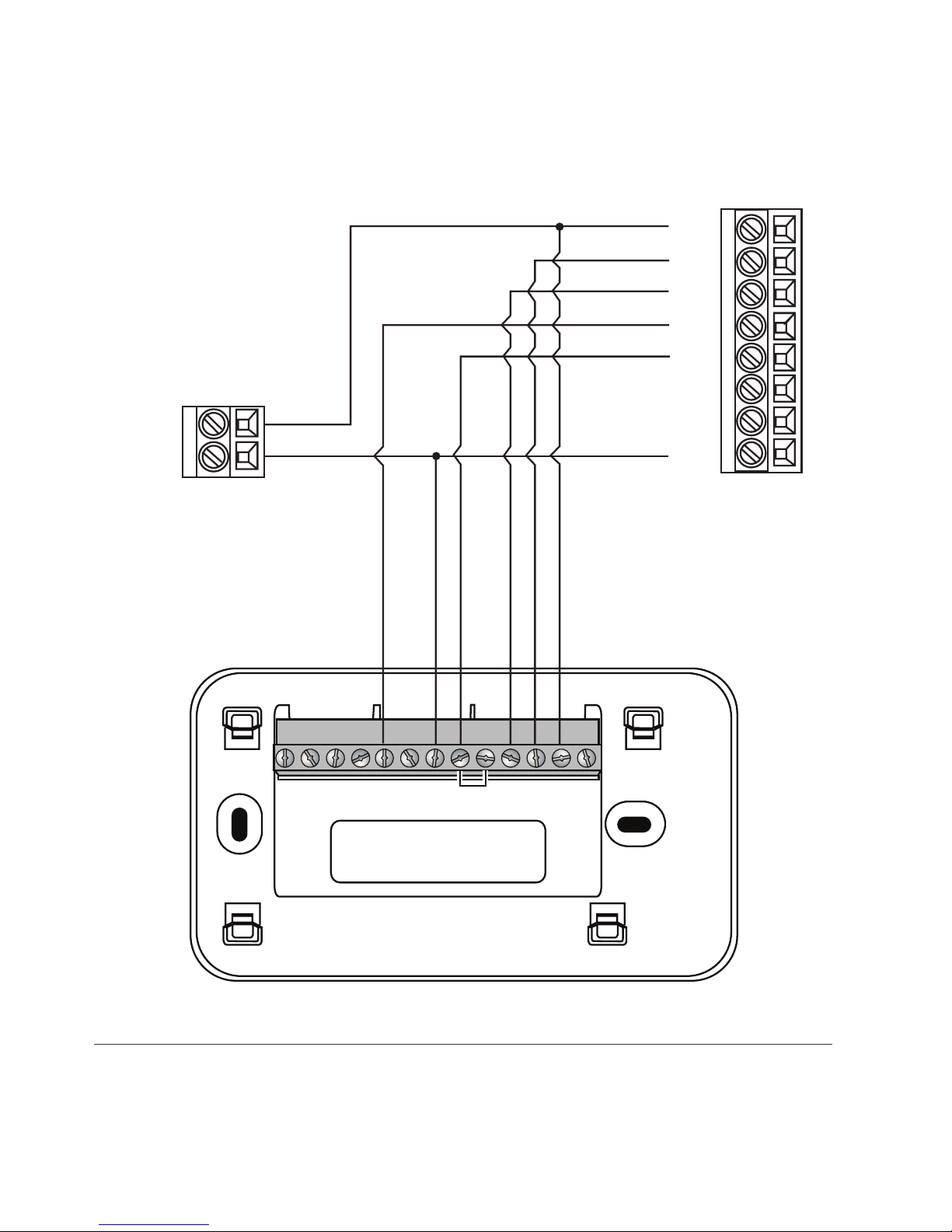

Page 16

11

YN/C

W

O/B

GRCRHCY2R1+R1-R2+R2-

W2

AUX

EMS Si Thermostat

2-stage AC

Y2

R

C

Y1

Y

G

R

W

C

HUM

1-stage Furnace

Single stage heat, dual stage cool

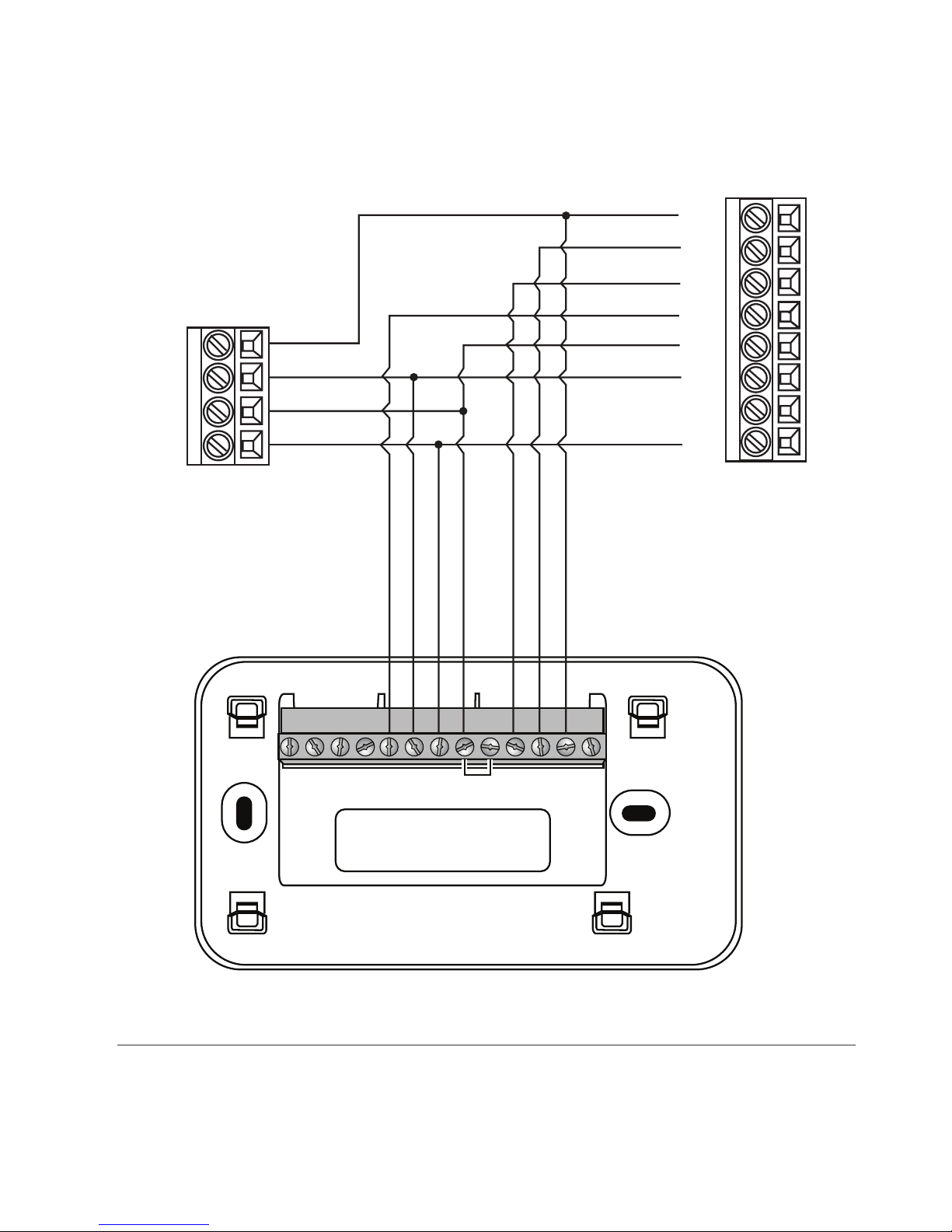

Page 17

12

YN/C

W

O/B

GRCRHCY2R1+R1-R2+R2-

W2

AUX

EMS Si Thermostat

Y1

G

W2

W1

HUM

C

R

Y2

2-stage Furnace

1-stage AC

C

24V

Dual stage heat, single stage cool

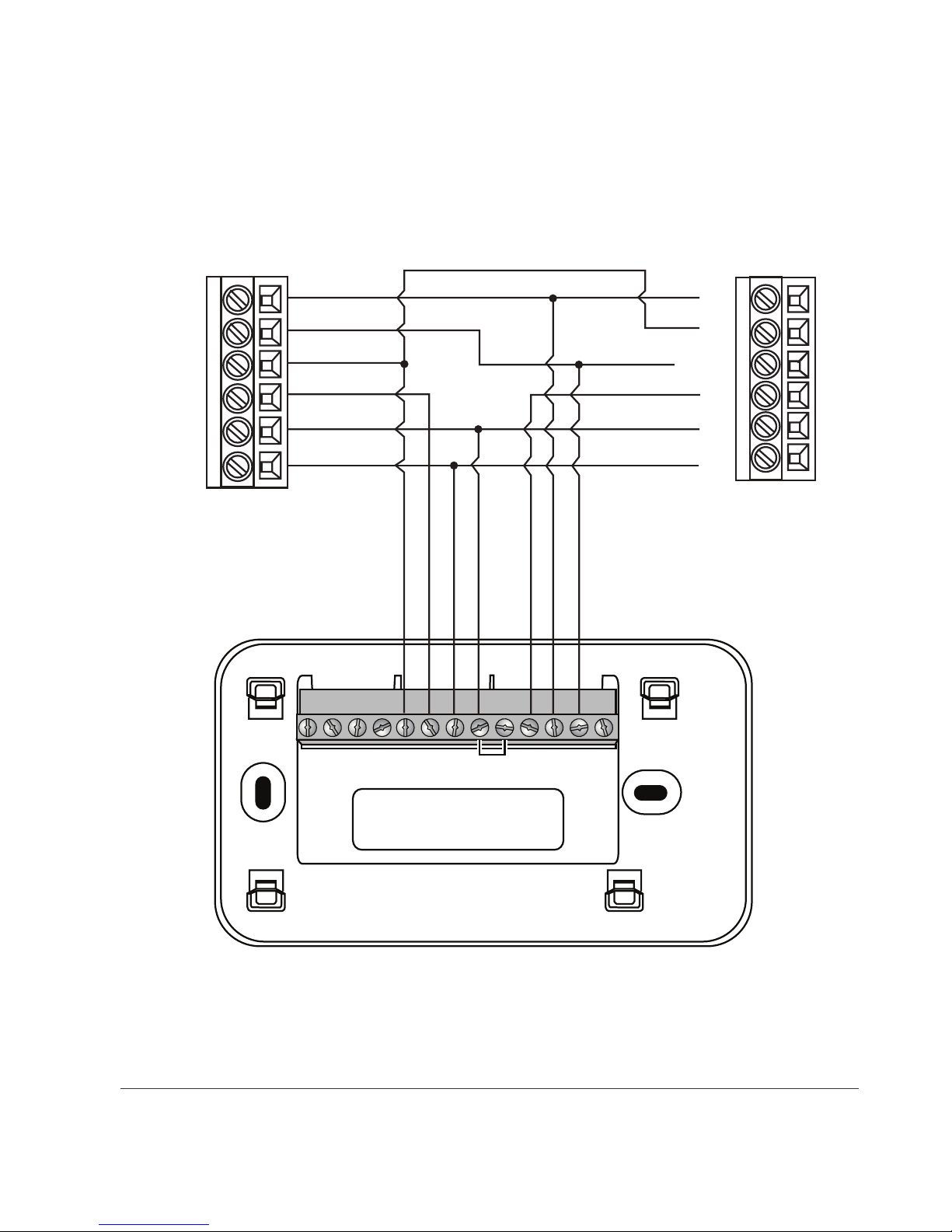

Page 18

13

YN/C

W

O/B

GRCRHCY2R1+R1-R2+R2-

W2

AUX

EMS Si Thermostat

Y1

G

W2

W1

HUM

C

R

Y2

2-stage Furnace

2-stage AC

Y2

R

C

Y1

Dual stage heat, dual stage cool

Page 19

14

YN/C

W

O/B

GRCRHCY2R1+R1-R2+R2-

W2

AUX

EMS Si Thermostat

O

W

Y/Y2

C

G

R

Air Handler

1-stage Heat Pump

W2

R

Y

C

O

Single stage heat pump with auxiliary heat

Page 20

15

YN/C

W

O/B

GRCRHCY2R1+R1-R2+R2-

W2

AUX

EMS Si Thermostat

O

W

Y/Y2

C

G

R

Air Handler

2-stage Heat Pump

W2

Y1

R

Y2

C

O

Dual stage heat pump with auxiliary heat

Page 21

16

YN/C

W

O/B

GRCRHCY2R1+R1-R2+R2-

W2

AUX

EMS Si Thermostat

1-stage AC

C

24V

Boiler

C

R

W

Y1

R

C

Y2

G

Air Handler

Boiler with air handler and single-stage cool

* Remove RH/RC factory jumper

C terminal to be connected to heating

transformer common

Page 22

17

YN/C

W

O/B

GRCRHCY2R1+R1-R2+R2-

W2

AUX

EMS Si Thermostat

1-stage AC

C

24V

2-stage Boiler

C

W2

R

W1

Y1

R

C

Y2

G

Air Handler

Dual stage boiler with air handler and single stage cool

* Remove RH/RC factory jumper

C terminal to be connected to heating

transformer common

Page 23

18

YN/C

W

O/B

GRCRHCY2R1+R1-R2+R2-

W2

AUX

EMS Si Thermostat

2-stage AC

C

Boiler

C

W

R

Y1

RR

C

Y2

Y1

Y2

G

Air Handler

Single stage boiler with air handler, dual stage cool

* Remove RH/RC factory jumper

C terminal to be connected to heating

transformer common

Page 24

19

YN/C

W

O/B

GRCRHCY2R1+R1-R2+R2-

W2

AUX

EMS Si Thermostat

2-stage AC

C

2-stage Boiler

C

W2

W1

R

Y1

RR

C

Y2

Y1

Y2

G

Air Handler

Dual stage boiler with air handler, dual stage cool

* Remove RH/RC factory jumper

C terminal to be connected to heating

transformer common

Page 25

Step 5. Power On HVAC

Equipment

After you’ve completed the wiring, you can

apply power to the heating and air conditioning

equipment. The EMS Si receives power from the

equipment and will automatically power on.

NAVIGATING THE MENUS

The EMS Si has an easy-to-read color screen

that displays all the information you need to

congure the thermostat. Use the navigation

buttons on the right to quickly change the

temperature, access features, and congure

settings.

Using the Navigation Buttons

The navigation buttons located on the right of

the EMS Si let you select options and control the

EMS Si.

▲ (up) On the Home screen, press ▲ to

increase the temperature set point by 1°F

(0.5°C). For menus, press ▲ to move up.

▼ (down) On the Home screen, press ▼ to

decrease the temperature set point by 1°F

(0.5°C). For menus, press ▼ to move down.

◀ (left) On the Home screen, if Auto mode is

enabled, press ◀ to switch between heat and

cool set points. For menus, press ◀ to go back

to the previous screen.

OK

20

Page 26

▶ (right) On the Home screen, if Auto mode

is enabled, press ▶ to switch between heat

and cool set points. For menus, press ▶ to

choose the currently highlighted option.

OK On a menu screen, press OK to choose

the currently highlighted option. If a

conguration option is selected, pressing OK

will keep its new value and return back to the

previous screen.

MENU Pressing MENU displays a list of all

available options. If a menu is currently

displayed, pressing MENU will cancel any

unsaved changes and return to the Home

screen.

BACK On a menu screen, press BACK to go

back to the previous screen.

On-Screen Keyboard

If you need to type in any information, an onscreen keyboard will appear. To enter a letter or

number, move to the character by pressing the

arrow keys and then press OK to select it.

Select

to enter capital letters; select

to enter commonly used symbols. If you

make a mistake, press

to delete the text .

To keep your changes, select

. To cancel

your changes, press BACK.

MENU

BACK

21

Page 27

CONFIGURING THE HVAC

SETTINGS

The rst step after installing the EMS Si is to

congure the settings for the various devices

(such as a furnace or air conditioner) that are

being connected.

Equipment

The Equipment settings let you congure the

devices connected to the thermostat.

Heat Pump

This section lets you congure a heat pump with

up to 2 heat/2 cool stages plus an auxiliary heat

source.

Geothermal heat pump Select Yes if you are

using a geothermal heat pump. This helps the

thermostat determine optimum performance

and default settings. If you select No, the

system will optimize the settings for an air-toair heat pump.

OB energize on cool If you choose Yes, the

reversing valve output (O/B terminal) will

activate when there is a call for cooling. If you

select No, the relay will activate when there is

call for heat.

Min Cycle O Time Congures the minimum

compressor o time between cycles (240 to

900 seconds).

Min Outdoor Temp Disables the compressor

when the outside air temperature reaches the

congured minimum setting. This performs

two functions. It prevents the compressor

To congure the

equipment settings:

From the Home screen,

press MENU.

Select Settings ▶

Installation Settings.

Select Equipment.

Congure the devices

connected to the EMS Si.

22

Page 28

from running when the outdoor temperature

is too low, thus resulting in damage to the

compressor. You can also set this value to

determine when you want the auxiliary heat

(if installed) to engage to help meet the

set temperature. The temperature range is

adjustable from 0 to 65 °F (–17.8 to 18.3 °C) or

can be completely disabled. Note: You need

an internet connection for this feature to

operate properly.

Allow HP with Aux Heat If you select Yes

and there is a source of auxiliary heat, it will

turn on in addition to the heat pump. The

heat pump will be energized for the rst 30

minutes. If, after 30 minutes, the set point

has not been met, the auxiliary heat will be

energized to assist the heat pump in meeting

the load.

If you select No, the heat pump will be

energized for up to 2 hours. If after 2 hours the

set point has not been met, the thermostat

will shutdown the heat pump and energize

the auxiliary heat to meet the set point. This

option should also be used for installation

where the heat pump evaporator coil is

downstream from the source of auxiliary heat.

This setting is only available the Comp to

Aux Temp Delta and Comp to Aux Runtime

settings are both set to Auto (default)

23

Page 29

Furnace

Allows you to enable and congure up to a

2-stage conventional heat source. If you have

selected a heat pump as your primary source,

this feature allows you to congure the 1st stage

of auxiliary heat connected to the system.

Furnace Type Allows you to congure the

type of furnace. This helps the thermostat

optimize its algorithms based on the type

of fuel and typical characteristics of the

chosen system. Choose the option that

best represents the type of heating system

installed.

Heat Fan Control Congures the furnace fan

to be controlled by the EMS Si or the HVAC

system during heat cycles. Normally the HVAC

system controls the fan during heat cycles.

Air Conditioner

Congures up to 2 stages of air conditioning. If

you require a second stage, you must enable the

Y2 relay.

24

Page 30

Thresholds

This section congures the temperature and

time thresholds associated with the heating and

cooling equipment.

You must congure the Equipment settings

(page 10) before setting the thresholds. Only the

applicable threshold settings will be displayed

(i.e. if no air conditioner is congured, you will

not see the options related to air conditioners).

Allow Auto Heat/Cool

Enabling this option allows the user to select

auto change-over as a system mode.

Heat/Cool Min Delta

The minimum dierence between the heat

mode set temperature and the cool mode set

temperature when the system mode is in auto

change-over. The delta is adjustable from 2 to 10

°F (1.1 to 5.5 °C). The default value is 5 °F (2.8 °C).

Compressor Settings

Min Cycle O Time Congures the

compressor o time between cycles. This

ensures the compressor does not short cycle

(which could aect the operating life of the

system). This time is adjustable from 240–900

seconds.

Min Outdoor Temp Congures the minimum

outside air temperature at which the

compressor will be disabled. This performs

two functions. It prevents the compressor

from running when the outdoor temperature

is too low, thus resulting in damage to the

compressor. You can also set this value to

determine when you want the auxiliary heat

To congure threshold

settings:

From the Home screen,

press MENU.

Select Settings ▶

Installation Settings.

Select Thresholds.

Congure the

temperature threshold

settings.

25

Page 31

(if installed) to engage to help meet the

set temperature. The temperature range is

adjustable from 0 to 65 °F (–17.8 to 18.3 °C) or

can be completely disabled. Note: You need

an internet connection for this feature to

operate properly.

Aux Heat Settings

Max Outdoor Temperature Congures the

maximum outdoor temperature threshold.

Above this level, the auxiliary heat will not

be activated. The temperature is adjustable

from 0 to 80 °F (26.5 °C) in increments of 0.5°F

(0.5°C). The default value is 70°F (21°C).

Common Heat/Cool Settings

Heat Dierential Temp The minimum

dierence between the current temperature

and set temperature before the system calls

for heat. A smaller dierence means shorter

cycle times, whereas a larger dierence results

in longer cycle times. The temperature range

is adjustable form 0 to 3 °F (-17.5 to 26.5 °C) in

0.5°F (0.5°C) increments.

Heat Dissipation Time The amount of time

the fan will run after the heat set point has

been reached and the call for heat has been

turned o. Running the fan for a period of

time allows for any heated air left in the ducts

to circulate throughout the home. The time is

adjustable from 0 to 900 seconds. The default

value is 30 seconds.

Cool Dierential Temp The minimum

dierence between the current temperature

and set temperature before the system calls

for cool. A smaller dierence means shorter

cycle times, whereas a larger dierence results

26

Page 32

in longer cycle times. The temperature range

is adjustable from 0 to 3 °F (0.3 to 1.7 °C) in

0.5°F (0.3°C) increments.

Cool Dissipation Time The amount of time

the fan will run after the cool has been turned

o. Running the fan for a period of time allows

for any cooled air left in the ducts to circulate

throughout the home. The time is adjustable

from 0 to 900 seconds. The default value is 30

seconds.

Advanced Settings

These options customize how long each stage

will run before the next stage turns on. You may

also program when a particular stage is turned

on based on the temperature delta between the

set temperature and the current temperature.

Reverse Staging If enabled, the thermostat

will cycle down from the higher stages so

that as it approaches set point it will only be

running in stage 1. The HVAC equipment will

start in stage 1. As the stage 1 temperature

delta is exceeded, the second stage will

engage. Once the equipment has brought

the current temperature back to within the

heat or cool dierential setting, stage 2 will

disengage and stage 1 will remain running

until the set point is meet.

Stage 2 Temp Delta The minimum dierence

between the current temperature and the set

temperature that will activate the auxiliary

heat (regardless if the maximum run time of

the previous stage was reached). Options are

Auto (default) and 1 to 10 °F (0.6 to 5.6 °C).

Stage 1 Max Runtime The maximum amount

of time stage 1 will run before engaging the

27

Page 33

next stage. Options are Auto (default) and 10

to 120 minutes.

Comp to Aux Temp Delta The maximum

amount of time this stage will run before

engaging the next stage. Options are Auto

(default) and 1 to 10 °F (0.6 to 5.6 °C).

Comp to Aux Runtime The minimum

dierence between the current temperature

and the set temperature that will activate this

stage (regardless if the maximum run time of

the previous stage was reached). Options are

Auto (default), Disabled, and 1 to 10 °F (0.6 to

5.6°C).

Cool Min On Time Sets the minimum

equipment run time in cool mode: 1 to 20 min

(default is 5 min).

Heat Min On Time Sets the minimum

equipment run time in heat mode: 1 to 20 min

(default is 5 min).

Temp Correction

Lets you program an oset between the real

temperature at thermostat and the displayed

temperature. If you nd that the temperature

where the thermostat is located does not

represent the room temperature, change the

oset to compensate for the dierence. The

correct temperature is adjustable from +/- 10°F

in 0.5°F (0.3°C) increments.

Installer Code

To prevent accidental modications to the

installation settings, you can enable a 4-digit

installer code. This code is pre-programmed to

3262.

28

Page 34

Test Equipment

These options let you test the wiring and

connections of the devices connected to the

thermostat by turning them on or o.

The equipment will turn o when you exit the

menu.

Warning: Compressor protection and

minimum run-time features are not

enforced while in this mode.

Reset HVAC Equipment Settings

You can quickly restore all HVAC equipment

settings on the EMS Si back to their factory

defaults. Any user setting (not related to the

equipment installed) will remain unchanged.

If you need to reset the entire thermostat back

to its original factory default settings, including

user settings and registration, select Reset All

Settings instead.

Performing a Hardware Reset

In rare circumstances, static electricity or power

surges may interrupt the operation of the

thermostat, forcing a hardware reset.

To test the equipment:

From the Home screen,

press MENU.

Select Settings ▶

Installation Settings.

Select Test Equipment.

Select OK.

Test the equipment

connected to the

thermostat by turning each

component on and o.

!

To reset the EMS Si:

From the Home screen,

press MENU.

Select Settings ▶ Reset.

Select HVAC Equipment

Settings.

Select Ye s.

29

Page 35

Rebooting the EMS Si

You can reboot the EMS Si by pressing the

physical hardware reset button, located through

an opening in the bottom left corner of the EMS

Si. Rebooting will not alter programming or

conguration options.

Reset button

30

Page 36

Conguring Reminders and

Alerts

The Reminders and Alerts list displays the

reminders and alerts described below.

HVAC Service

The HVAC Service (maintenance) reminder

generates an alert telling the homeowner that

regularly scheduled maintenance is required.

This alert, along with technician contact

information can be displayed on the screen.

If homeowners register their thermostats, the

reminders will be emailed to them and be

displayed in the web portal.

You can set the Last Service date, turn the

Reminder On or O, and to set the Frequency of

the maintenance interval in months.

Furnace Filter

Generates an alert for cleaning or changing

the lter. You can set the Last Filter Change

date, turn the Reminder On or O, and set the

Frequency of the maintenance interval.

UV Lamp

Sets the reminder period for cleaning or

replacing the UV lamp. You can set the Last

Lamp Change date, turn the Reminder On or

O, and set the Frequency of the maintenance

interval.

To congure Reminders

and Alerts

From the Home screen,

press MENU.

Select Reminders and

Alerts.

Congure the Reminder

and Alert settings as

required.

31

Page 37

Alerts

The EMS Si can generate alerts if the

temperature in the home goes over or under a

pre-programmed level. This protects the home

from damage due to freezing and/or excessive

heat.

This alert, along with optional technician contact

information will be displayed on the screen. If

the homeowner registers the thermostat, the

alert will be emailed to them and be displayed in

the web portal.

Low Temp Alert Sets the temperature at which

the thermostat will generate a Low Temperature

Alert. The range can be:

O – no alert will be generated.

Set temperature range of 35 to 68 °F (1.5 to

20 °C).

High Temp Alert Sets the temperature at which

the thermostat will generate a High Temperature

Alert. The range can be:

O – no alert will be generated.

Set temperature range of 60 to 104 °F (15.5

to 40 °C).

Display Alerts on Thermostat

Select No if you do not want any of the alerts

to be displayed on the EMS Si screen. Alerts will

continue to be displayed on the web portal and

sent via email.

32

Page 38

Enable Heating/Cooling Alerts

Select No to disable alerts for heat/cool error

conditions. If disabled, alerts indicating that the

system failed to heat or cool will not be appear

in the screen, web portal, or emails.

List of Alerts

Below is a complete list of alerts. Depending

on your conguration, some of these may not

apply.

Furnace Air

Filter

UV Lamp

Low Temp Alert

High Temp Alert

Heat Not

Responding

Cool Not

Responding

Maintenance

Reminder

Auxiliary Heat Run

Time

Auxiliary Outdoor

Temperature

Furnace lter needs to be

cleaned or changed.

UV lamp needs to be changed.

Temperature in the home is too

low.

Temperature in the home is too

high.

The system has failed to heat

the home.

The system has failed to cool the

home.

HVAC system due for regular

maintenance.

Auxiliary heat source is running

too often.

Your EMS Si auxiliary heat has

been called to run when the

outdoor temperature exceeds

the programmed set point.

33

Page 39

AUTOMATION

The EMS Si can be congured to perform actions

based on the status of its 2 dry contact inputs.

You can have multiple actions per input. You

can also have the same input perform dierent

actions when it is open or closed. For example, if

a window sensor is open, you can congure the

system to adjust the temperature set point and

disable the AC.

Setting Up the Sensor Inputs

The EMS Si system supports 2 dry contact inputs

(R1 and R2). In order to use them, you need to

ensure they are correctly congured.

Name

To enable, simply enter a name for this input (i.e.

Door sensor). To disable this input, delete the

name.

Type

Denes the type of input (only Dry Contacts are

supported in this version).

Actions...

Lets you to view the current state and edit action

options for a sensor. To add a new action, select

Add New Action.

State Congure if the circuit (contact) is Open

or Closed.

Type Select the action to perform from the

list:

To congure sensors and

automation

From the Home screen,

press MENU.

Select Settings ▶

Installation Settings.

Select Sensors.

Select the dry contact you

want to view or edit.

Congure the sensor

settings as required.

To create a new action,

select Add New Action.

34

Page 40

Do Nothing No specic action will occur.

Switch to Occupied* Switches the system

to the Occupied program when the input

is activated.

Switch to Unoccupied* Switches the

system to the Unoccupied program when

the input is activated.

* The Economizer and/or Occupancy relay

outputs, if congured, will also be switched

to the appropriate state when this input is

congured and activated.

Shutdown Compressor The compressor

(both for AC or Heat pump) will shutdown

and remain shutdown until this input is

cleared

Shut down AC The air conditioning system

will shutdown and will remain shutdown

until this input has cleared

Adjust Temperature The heat and/

or cool set points will be adjusted by a

preprogrammed amount. It will revert back

to the original set point when the input has

cleared.

Turn On Fan The fan will be set to On. It

will revert back to its original settings when

the input is cleared.

Disable Auxiliary Heat The auxiliary heat

equipment will be disabled. It will be reenabled when the input is cleared.

Shutdown All HVAC All equipment will be

disabled. It will be re-enabled when the

input is cleared.

Disable All Heat All heat equipment will

be disabled. It wil be re-enabled when the

35

Page 41

input is cleared.

Send Alert Enables the system to send an

alert when the input has been activated.

Send Update Log Enables the system to log

when this input is activated.

Activation Delay Congures time delay from

when the input detects the active state to

when the action programmed in the Type

section is performed by the system. For

example, if you connect a door sensor to the

input and program a 5 minute activation

delay, the door will need to open and remain

open for 5 minutes before the thermostat

takes action.

Deactivation Delay Congures a time delay

from when the input detects the inactive

state to when the system reverts back to its

normal operating conditions. For example, if

you connect a door sensor to the input and

program a 5-minute deactivation delay. The

door will remain closed for 5 minutes before

the thermostat will revert back to the normal

operating condition.

Min Action Duration Congures the

minimum amount of time the system will

perform this action. This timer will run its

course regardless of whether the input has

reverted back to its normal state and the

deactivation timer has expired. This option

is useful for applications where you want

to run a device (i.e., fan or compressor) for

a minimum amount of time after the input

has been activated rather then using the

deactivation delay. This ensures the fan or

motor does not short cycle.

36

Page 42

If Adjust Temperature is chosen as the Type

you will also be presented with the following

options:

Decrease Heat Temp Allows you to program

the number of degrees that the heat set

temperature will be adjusted by once an

input has been activated. A positive number

increases the heat set point and a negative

number decreases the heat set point

Increase Cool Temp Allows you to program

the number of degrees that the cool set

temperature will be adjusted by once an

input has been activated. A positive number

increases the cool set point and a negative

number decreases the cool set point.

In both cases this oset will apply to the

set point temperature at the time of the

activation of the input. As the system

switches between program periods (i.e.,

occupied, unoccupied, etc) this oset will

be maintained. Once the input has been

switched back to the inactive state the set

temperature will revert back to the normal

limits.

Delete this Action Removes the congured

action.

37

Page 43

CONNECTING TO THE

INTERNET

Connect your EMS Si to the Internet so you can

control it from your own personalized, secure

ecobee Web Portal, smartphone, or tablet.

From the Web Portal, you can:

Program, congure and control your EMS Si.

Control your EMS Si from anywhere you have

Internet access (including smartphones and

tablets).

Use local weather data to maximize energy

savings.

Receive important alerts and reminders about

your heating and cooling system.

Note: To connect your system to your personalized

ecobee Web Portal you must have a broadband

Internet connection and a wireless 802.11 b/g/n

(WiFi) home network.

38

Page 44

Setting Up WiFi and Obtaining a

Registration Code

The EMS Si uses your home WiFi network to

connect to the Internet. First, enable WiFi on the

EMS Si (see instructions to the right).

The EMS Si will display a list of available

networks, along with an indication of the signal

strength (the more bars, the better) and whether

encryption is used.

If your home network is not listed, or if the

signal strength is very low, try adjusting the

antenna on your wireless router. If that doesn’t

improve the signal, try moving your router

closer to the EMS Si.

Once your network has been detected, select

it from the list. If the network is encrypted,

you will be asked to enter a password for that

network. This is the password you created when

the wireless router was rst set up.

After you provide the password, your EMS Si

will automatically connect to the Internet. A

chain link on the screen indicates you have

established a connection with the ecobee web

servers.

Write down the registration code as you will

need it when conguring your Web Portal

account. You can leave the code displayed on

the screen while you continue with the next

step.

To set up WiFi:

From the Home screen,

press MENU.

Select Register Thermostat.

Select Continue.

Select WiFi Settings.

Select WiFi Radio ▶

Enabled.

Select your network from

the list.

If prompted, enter your

network password.

The EMS Si will

automatically connect to

the Internet and display a

registration code.

Write down the registration

code; you will need it in the

next step.

39

Page 45

Having Trouble?

If you are having trouble connecting to the

Internet or nding your WiFi network, you may

need to congure your network parameters

manually. See WiFi on page 52.

Conguring a Web Portal

Account

After setting up WiFi on your EMS Si and

obtaining the registration code, you need to

congure your Web Portal account.

1. From a web browser on a PC, visit

www.ecobee.com and click on the LOGIN link.

2. Click REGISTER THERMOSTAT.

3. Click the EMS Si.

4. Click Create a new account.

(If you already have a Web Portal, click Register

to an existing account, enter your email address

and password, and proceed to step 6).

40

Page 46

5. Enter your address, contact, and user account

information. Click Submit.

Your EMS Si is now registered. You can now

monitor and control your EMS Si from the Web

Portal or from your smartphone or tablet.

Re-registering the EMS Si

There are times when you may need to reregister your EMS Si. For example, if you are

a new homeowner who has just moved to a

home with an existing EMS Si. To re-register

your EMS Si, reset the registration and redo the

registration process.

To reset your

registration:

From the Home screen,

press MENU.

Select Settings ▶ Reset.

Select Reset Registration.

Conrm the reset by

selecting Yes .

41

Page 47

USING YOUR EMS Si

The bright, easy-to-read screen on your EMS Si

makes it simple to review and adjust the settings

any time you want.

Adjusting the Temperature

You can easily adjust the temperature without

changing the EMS Si’s programming by pressing

the arrow keys when the Home screen is

displayed.

Press ▲ to increase the temperature set point

by 1°F (0.5°C).

Press ▼ to decrease the temperature set

point by 1°F (0.5°C).

If the EMS Si is set to Auto mode, press ◀ to

select the Cool setting.

If the EMS Si is set to Auto mode, press ▶ to

select the Heat setting.

Once you’ve adjusted the temperature, the

screen indicates that you are currently holding

the set temperature rather than running a

program.

The EMS Si will hold the new temperature for the

duration you specied in the Hold Action option

during the initial setup (see Hold Action on page

15) or until you press OK.

If you are using Auto mode, note that there is a

minimum dierence allowed between heat and

cool set temperatures. The system will prevent

you from setting the temperatures to within

these limits. See the EMS Si Installation Manual

for information about conguring the minimum

temperature dierence settings.

42

Page 48

System Mode

This menu sets your system to use heat, cool, or

auto mode:

Cool The system will turn on the air

conditioner when the current temperature

rises above the set temperature.

Heat The system will turn on the heat when

the current temperature drops below the set

temperature.

Auto The system is in Auto-changeover

mode and will activate the heating or cooling

systems to keep your home within the desired

range of set temperatures.

Auxiliary Heat Only The system will only

use the auxiliary or back-up heat source to

maintain the heat set point temperature (only

appears if auxiliary heat is congured).

O The system is o and will only display the

current temperature.

Fan

This menu displays the current furnace fan

setting:

On Forces the fan to run continuously,

regardless of the weekly schedule

programming. The fan will also run if the

system mode is O.

Auto Turns on the fan when the system is

heating or cooling your home, or to satisfy the

minimum fan “on” time.

When you switch between Auto and ON in fan

control, the EMS Si will prompt you with the

following:

To change system mode:

From the Home screen,

press MENU.

Select System Mode.

Select your temperature

mode: Heat, Cool, Auto

or O.

To change fan settings:

From the Home screen,

press MENU.

Select Fan.

Congure your fan settings.

43

Page 49

Hold 2 hours The fan will switch to this

setting but revert back to weekly schedule

after 2 hours.

Hold 4 hours The fan will switch to this

setting but revert back to weekly schedule

after 4 hours.

Indenite The fan will switch to this setting

and will only revert back if you do so

manually .

Until Next Transition The fan will switch to

this setting but will revert back when the

program switches to the next period.

Update Schedule The fan will update the

current schedule with this new fan setting.

After the fan mode is changed and you return

to the home screen, the EMS Si will indicate

that it is in a Hold state. The temperature

setting will also be set to Hold. Press OK

to revert the fan mode back to the weekly

schedule fan and temperature settings.

Minimum “On” Time Sets a minimum amount

of time per hour that the furnace fan will run.

This improves air circulation and results in a

more consistent temperature than with the

Auto setting while being more cost-eective

than the On setting.

44

Page 50

Weather Forecast

Displays the current outdoor temperature and

weather conditions for your registered location.

Note that when you register, it’s important to

select your location accurately, as ecobee will

use your local weather data to optimize your

heating and cooling. You must register your EMS

Si for this feature to operate.

Cleaning the EMS Si

You can clean the EMS Si’s screen by spraying

water or any mild, non-abrasive household

cleaner on to a clean cloth. Wipe the surface of

the screen with the dampened cloth.

Note: Do not spray any liquids directly onto your

EMS Si.

To view the weather

forecast:

From the Home screen,

press MENU.

Select Weather Forecast.

Press OK to switch between

the 4-day and 24-hour

forecast.

45

Page 51

CONFIGURING YOUR

EMSSi

This section describes how congure the

personal preferences, temperature settings, and

operation of your EMS Si. There are three key

steps:

Congure Personal Preferences

Set up Reminders and Alerts

Create your Weekly Schedule

Note: You can also congure your EMS Si from

your personalized Web Portal. Simply open a web

browser, go to ecobee.com, and log in.

Conguring Personal

Preferences

The Preferences menu has settings for

personalizing your EMS Si.

Name

You can customize the name of your EMS Si to

suit your needs (i.e. Main Floor). This is useful

if you have multiple systems or zones. You can

view and edit your EMS Si name in the About

menu on your EMS Si and also in your online

Web Portal.

Temperature Display

Select Temperature Display to select Fahrenheit

(°F) or Celsius (°C).

To congure personal

Preferences:

From the Home screen,

press MENU.

Select Settings ▶

Preferences.

Adjust each option to your

personal preferences.

46

Page 52

Date and Time

Select Date & Time to:

Set the current date.

Set the current time.

Select a 12-hour or 24-hour time format.

Select your time zone.

Enable or disable daylight savings

adjustments.

If you are connected to the Internet, the time

and date are programmed automatically.

Brightness

The color screen has adjustable backlight

brightness. You can control the intensity when

the screen is active (i.e., when you are pushing

buttons) and when the display is in standby

mode (idle screen).

Select Brightness to:

Set the Active brightness intensity.

Set the Standby (idle screen) brightness

intensity.

Set the minimum time the EMS Si will stay in

active brightness before switching to standby

brightness.

Hold Action

Whenever you manually adjust the set

temperature, the EMS Si will indicate you are

in a “Hold” mode. You can select how long the

EMS Si will hold the new temperature before

reverting back to the regular program:

47

Page 53

Hold 2 hours

Hold 4 hours

Until next transition Thermostat will hold

temperature until the next program period.

Indenite Thermostat will hold temperature

until you press OK.

Update Schedule When you adjust the set

temperature, the system will update the

temperature in the Weekly Schedule for the

current period.

Ask Me Every time you adjust the set

temperature you will be asked which of the

options you would like to choose.

Quick Save Settings

In Quick Save mode, your system will

automatically increase (in cool mode) or

decrease (in heat mode) the temperature set

point by the pre-congured amount.

Quick Save mode can only be activated from

the Web Portal or from the ecobee smartphone/

tablet application.

Access Control

You can protect your EMS Si so that certain

features will require the user to enter a 4-digit

access code. Use the arrow keys to highlight a

number and then press OK. When you are done,

select Save. The access control will be required

once the idle screen is displayed.

To disable this feature, delete the number by

selecting

multiple times.

48

Page 54

You can also congure the level of access

control:

Restrict All Access Unauthorized users will

only be able to view the home screen and the

weather information.

Restrict Details Access The code is required

to access the Details screen.

Restrict Program Access The code is

required to view and modify the EMS Si’s

Weekly Schedule.

Restrict Vacation Access The code is

required to view and create a Vacation.

Restrict QuickSave The code is required to

exit QuickSave mode from the Web Portal.

In all cases, once the code is enabled, it will be

required to access any of the list items in the

Settings menu, with the exception of the About

screen. Once a valid code has been entered on

the EMS Si, access to restricted features will be

allowed until the EMS Si backlight timer has

expired.

Temperature Range

You can congure the EMS Si so only a specic

heat and/or cool set point range is permitted.

Heat Temp Range Press ▲ or ▼ select the

maximum heat set point then press OK.

Users will not be able to set the EMS Si to a

temperature above this limit.

Cool Temp Range Press ▲ or ▼ to select the

minimum cool set point and then press OK.

Users will not be able to set the EMS Si to a

temperature below this limit.

49

Page 55

Recovery Options

Recovery options allow the EMS Si to learn

how your heating and cooling system works,

taking into account infrastructure, weather and

historical operating performance so that your

home is a comfortable temperature as soon as

you walk in the door.

Smart Recovery Heat The EMS Si will start

heating at the optimum time to ensure the set

point is reached at the programmed time.

Smart Recovery Cool The EMS Si will start

cooling at the optimum time to ensure the set

point is reached at the programmed time.

Random Start Heat Programming a time

in this section will produce a random delay

when there is call for heat. In applications with

multiple heating systems, this prevents all

the systems from activating at the same time

(thus creating a peak power demand). Press ▲

or ▼ to select a delay time and then press OK.

Random Start Cool Programming a time

in this section will produce a random delay

when there is call for cooling. In applications

with multiple cooling systems, this prevents

all systems from activating at the same time,

(thus creating a peak power demand). Press ▲

or ▼ to select a delay time and then press OK.

Utility CPP Setting

This section is only applicable if your utility

company is running a Critical Peak Pricing

program that you have agreed to be a part of.

Contact your local electrical utility company for

information about programs in your area.

50

Page 56

CPP Response

Your utility may send voluntary events to your

EMS Si. You can choose to Always Accept these

events. In which case, you would just be notied

that an event is in progress. Or if you choose Ask

Me, when the Utility issues an event, you will be

asked if you want to participate.

If you do not acknowledge the event prior to the

start, the system will default to yes.

Preferred Strategy

During a Critical Peak Pricing event the Utility

may select an energy saving strategy, or allow

you to use your preferred strategy. Select from

one of the options as your preferred energy

saving strategy to be used during Critical Peal

Pricing events.

Absolute Temperature Set a specic heat

and cool set point to be used when an event

is initiated by the Utility company. If the

set point at the time of the event is more

favorable (lower in heat mode or higher in

cool mode) than what you have programmed,

the EMS Si will use the more favorable set

point for the duration of the event.

Relative Temperature Program a

temperature set back (heat) or set forward

(cool) from your existing set point. For

example, if you program a 4 °F set forward,

and your current cool set point is 76 °F, during

an event your EMS Si set point will change to

80 °F until the event has expired.

System O If this option is selected, the EMS

Si will turn o heating and cooling for the

duration of this event.

51

Page 57

Duty Cycle This option allows you to

program the maximum amount of time the

system will run during a 1 hour period. For

example, if you select 30%, the air conditioner

will run for a maximum of 18 (0.3 x 60)

minutes regardless of whether the set point

has been met. 0% essentially turns the system

o, whereas 100% runs the system at full

capacity.

WiFi

The EMS Si supports WiFi 802.11 b/g/n. Use the

Advanced Conguration option in the WiFi

menu to congure your network parameters.

Choose the network from the list or manually

add a new one (i.e. if your network does not

broadcast its SSID).

You will then be able to view and congure the

following network parameters:

DHCP (select Disabled to use a static IP

Address; if unsure, leave DHCP Enabled)

SSID

Encryption (WEP, WEP128, WPA, or WPA2)

Password (if encryption is used)

WiFi Channel

IP Address and IP Subnet

Gateway

Primary and Secondary DNS

If you need to specify your EMS Si’s MAC address

in your router’s conguration, you can obtain it

from the About menu.

To congure WiFi

manually:

From the Home screen,

press MENU.

Select WiFi.

Adjust the network options

for your home network.

52

Page 58

Creating Your Weekly Schedule

Your heating and cooling needs change

depending on the time of day and day of the

week. For example, if there’s no one in the house

during the workday you might want to let the

temperature go up in the summer, to reduce

energy used by the air conditioning system, and

down in the winter, to reduce heating energy.

By default, the EMS Si includes two congurable

periods:

Occupied Represents the period when the

building or area is occupied.

Unoccupied Represents the period when the

building or area is unoccupied.

The EMS Si learns how your building’s heating

and cooling equipment perform. Intelligent

algorithms combine weather data, your HVAC

equipment run times and occupancy schedules

to optimize performance and maximize energy

savings.

To view your weekly

schedule:

From the Home screen,

press MENU.

Select Weekly Schedule.

Your weekly schedule is

shown on the screen.

53

To edit your weekly

schedule:

Display your Weekly

Schedule.

Press OK.

Select the Day.

Select the Time, Heat or

Cool Setting.

Press

▲ or ▼ to adjust the

the value. Press

◀ or ▶ to

toggle between columns.

Press OK.

Select Save and Continue.

Select any other days of

the week that will also use

the new settings. Use the

navigation keys to switch

between days and press OK

to select a day.

Select Continue. The new

schedule is displayed on the

screen.

Page 59

If your schedule changes, you can quickly and

easily update the EMS Si settings on the device

itself or online through your Web Portal.

Using the Weekly Schedule

Editor

The Weekly Schedule editor lets you to set

specic times, temperatures and furnace fan

settings for each day of the week.

If your system is enabled for auto change-over

mode, the heat and cool set temperatures will

automatically be adjusted to ensure a minimum

dierence.

Adding New Periods

To accommodate for your varying schedule you

can add additional program periods in your

week. For example if you come home for lunch

during the week or want dierent settings for

the weekend, you would simply add one of the

existing periods at the allocated time and day or

create a completely new one.

Disable a Period

To disable a period entirely, select the period’s

Time and then select Disable.

To add a new period:

Display the schedule for a

day and select Add New.

Select Create New Item.

Enter a name for the new

period and select Save.

If your house is in-use

during this period, select

Yes ; otherwise select No.

Select Enable.

Select the new time and

press OK.

The new period is added.

54

Page 60

Scheduling a Calendar Event

The EMS Si’s Calendar Event feature helps

you conserve energy while you are away for

extended periods of time. It also ensures your

building is comfortable when you return.

A calendar event includes a name, start date and

time, as well as the end date and time. You can

enter any number of uniquely named vacations.

Other vacation features to choose from include:

ecobee optimize

Select Yes to have the EMS Si automatically

set your Heat Temperature, Cool Temperature,

System Mode and Furnace Fan settings to

maximize energy conservation.

Select No to manually congure Heat

Temperature, Cool Temperature and Fan

settings. These settings will be remembered the

next time you create a calendar event.

Is Occupied

Select Yes, if during the calendar event the

building or area will be occupied.

Heat Temperature

Programs the set temperature when the system

is in Heat mode (i.e., when the furnace is on). Set

a lower temperature to save energy.

Cool Temperature

Programs the set temperature when the system

is in Cool mode (i.e., when the air conditioner

is on). Set a higher temperature to save energy.

You can also choose to turn o your cooling

system while you are away to save more energy.

To schedule a calendar

event:

From the Home screen,

press MENU.

Select Calendar Events.

Select Add Event.

Enter a Name.

Enter the Start and End

dates and times of your

calendar event.

55

Page 61

Fan

Toggles the fan setting between ON and Auto.

ON The fan runs all the time regardless of

programming or if there is a call for heat or

cool. The fan will also run if the System Mode

is OFF.

Auto This option turns the furnace fan on but

only when the system is heating or cooling

your home, or to satisfy the minimum fan run

time as programmed.

Fan Min On Time This feature allows you to

determine a minimum time per hour that the

furnace fan will run. It results in increased air

circulation and a more consistent temperature

within the home, and is more cost eective

than choosing the ON fan setting.

In either mode, the EMS Si will ensure that when

your calendar event ends, the EMS Si will revert

to the regular settings.

Note: If you were running your regular program

prior to the start of your calendar, on your return,

the EMS Si will restore your building to those

settings. If you were in Hold mode prior to the start

of your calendar event, the EMS Si will restore the

home to whatever the set temperature was just

prior to your calendar event.

56

Page 62

Delete Event

You can delete individual or all calendar events:

To remove an individual vacation event,

display the details about the vacation event,

then select Delete Event ▶ Yes.

To remove all vacation events, display the

Calendar Event menu and select Delete All

▶ Yes.

3-YEAR LIMITED

WARRANTY

ecobee warrants that for a period of three (3)

years from the date of purchase by the consumer

(“Customer”), the ecobee EMS Si (the “Product”) shall

be free of defects in materials and workmanship

under normal use and service. During the warranty

period, ecobee shall, at its option, repair or replace any

defective Products, at no charge. Any replacement and/

or repaired device are warranted for the remainder of

the original warranty or ninety (90) days, whichever is

longer.

If the product is defective, call Customer Service at

1-877-932-6233. ecobee will make the determination

whether a replacement product can be sent to you

or whether the product should be returned to the

following address: ecobee Customer Service, 477

Richmond Street West, #210, Toronto, ON M5V 3E7,

Canada. In the event of a failure of a Product, Customer

may:

(a) if Customer did not purchase the Product directly

from ecobee, contact the thir

d party contractor

from whom the Product was purchased to obtain

an equivalent replacement product, provided the

contractor determines that the returned Product is

defective and Customer is otherwise eligible to receive a

replacement product;

(b) contact ecobee directly for service assistance at

57

Page 63

1-877-932-6233 and ecobee will make the determination whether an advance equivalent

replacement Product can be sent to Customer with return shipping supplies (in which

case a hold shall be put on Customer’s credit card for the value of the replacement

Product until ecobee has received the defective Product). Product should be returned

to the following address: ecobee Customer Service, 477 Richmond Street West, #210,

Toronto, ON M5V 3E7, Canada. If the returned Product is found by ecobee to be

defective and Customer is otherwise eligible to receive a replacement product, no

amount shall be charged to Customer’s credit card; or

(c) ship the defectiv

e Product directly to ecobee, in which case Customer shall contact

ecobee directly at 1-877-932-6233, so ecobee can make the required shipping

arrangements. Upon receipt of the defective Product, ecobee will ship an equivalent

replacement product to Customer, provided the returned Product is found by ecobee to

be defective and Customer is otherwise eligible to receive a replacement product.

This warranty does not cover removal or reinstallation costs and shall not apply if the

damages were found to be caused by something other than defects in materials or

workmanship, including without limitation, if the Product:

was operated/stored in abnormal use or maintenance conditions;

was subject to abuse, neglect, electrical fault, improper handling, accident or acts

of nature;

was not installed by a licensed Heating Ventilating and Air Conditioning (HVAC)

contractor; or

was installed improperly.

ecobee’s sole responsibility shall be to repair or replace the Product within the terms

stated above. ECOBEE SHALL NOT BE LIABLE FOR ANY LOSS OR DAMAGE OF ANY KIND,

INCLUDING ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING,

DIRECTLY OR INDIRECTLY, FROM ANY BREACH OF ANY WARRANTY, EXPRESS OR

IMPLIED, OR ANY OTHER FAILURE OF THIS PRODUCT. Some US states and Canadian

provinces do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you.

limited to repair and replacement as set forth in this warranty statement. All express

and implied warranties for the product, including but not limited to any implied

limited to the three-year duration of this limited warranty. No warranties, whether

express or implied, will apply after the limited warranty period has expired. Some

US states and Canadian provinces do not allow limitations on how long an implied

58

Page 64

warranty lasts, so this limitation may not apply.

ecobee neither assumes responsibility for nor authorizes any other person purporting

to act on its behalf to modify or to change this warranty, nor to assume for it any other

warranty or liability concerning this product.

from jurisdiction to jurisdiction. If you have any questions regarding this warranty,

please write ecobee Customer Service, 477 Richmond Street West, #210, Toronto,

Ontario M5V 3E7, Canada.

END-USER SOFTWARE LICENSE

AGREEMENT

Please read the following carefully, as this end user software license agreement

(“EULA”) is a legal agreement between ecobee Inc., having its place of business at

477 Richmond Street West, #210, Toronto, ON, M5V 3E7, Canada, (”ecobee”) and you

(either an individual or the entity that you represent and referred to in this agreement

as “licensee”), The original purchaser of ecobee product (The “product” or “products”)

embedded with ecobee proprietary software (the “software”) concerning licensee’s

limited access to and use of the software. By using the product (including the software

embedded in the produ

ct), you are indicating your acceptance of, and you agree to be

bound by the terms and conditions of this EULA which shall govern your access and use

of the software. If you do not agree with the terms and conditions of this EULA, your

access to and use of the software will not be permitted and you may, within fourteen

days of the date of your purchase if the ecobee product, return the software together

with the product in its original packaging and sale condition to: (a) ecobee if you have

purchased the ecobee product directly from ecobee or; (b) to an ecobee authorized

reseller or distributor if you have purchased the ecobee product from such entities, and

the purchase price paid within fourteen days of its receipt of the return.

In consideration of the license fees paid by LICENSEE as part of the purchase price

of the ecobee Product and the mutual covenants contained herein and for other

acknowledged, ecobee and LICENSEE agree as follows:

1.

: For the purpose of this EULA, the following terms shall have the

meanings hereinafter provided:

“ecobee Web Portal” means the web site portal operated by ecobee to provide

certain services and functionality to registered users of ecobee Products.

“Error” means any program defect, error, bug or other failure of all or part of

the Software that results in the Software not conforming to, or performing in

59

Page 65

accordance with, its published specications.

“Software” means ecobee’s computer software program, which enables data

upload and download to and from the ecobee Web Portal using an ecobee

Product, including any Software Updates.

“User Manual” means the ecobee User Manual provided together with the

Product and Software.

“Software Updates” means updates or patches to the Software, including updates

intended to correct Errors and which may include enhancements and/ore

additional features to the Software, as may be provided or released by ecobee

from time to time to all of its customers at no charge.

2. Ownership of Software: LICENSEE acknowledges and agrees that, save and except

for the Software license explicitly granted by the EULA, all right, title and interest

in and to the Software and the User Manual is the sole and exclusive property of

ecobee and/or its licensors), as the case may be. ecobee reserves all rights not

expressly granted to LICENSEE hereunder, and for greater certainty, ecobee shall

retain all intellectual property and other proprietary rights in and to the Software

and the User Manual. Nothing in this EULA shall, or shall be deemed or construed

to, assign, transfer or convey to LICENSEE any title, rights or interest in or to any

intellectual property, including in or to the Software or User Manual, other than the

licenses specically and expressly granted herein.

3. Grant of Limited License: Upon LICENSEE’s use of the Product (and corresponding

acceptance of the terms and conditions of this EULA), ecobee hereby grants to

LICENSEE a limited, non-exclusive, personal, perpetual, non-transferable and

revocable license to use the Software embedded in the Product as and to the

extent described in this EULA for as long as LICENSEE complies with the terms

and condition of this EULA. ecobee reserves all rights not expressly granted to

LICENSEE. For certainty, this EULA does not apply to or govern LICENSEE’s use of or

access to the ecobee Web Portal or the ecobee Product, which are each governed

by and subject to separate terms and conditions.

4. Permitted Use: Pursuant to the Software license granted to LICENSEE under this EULA,

LICENSEE shall be permitted to: (a) use the Software embedded in the Product for

the purposes of using the Product only as intended and contemplated by the

User Manual, provided that the Software may only be used for its personal and

private use in connection with the use of the Product; and (b) use the User Manual

provided by ecobee solely as is necessary to operate and use the Software and

ecobee Product as and to the extent permitted thereunder and under this EULA.

5. License Transferable: This EULA shall be binding upon and shall ensure to the

benet of and be enforceable by each of the parties, their respective successors and

permitted assigns. LICENSEE may assign this EULA without the prior consent of

ecobee. ecobee may assign this EULA without the consent of LICENSEE at any time.

60

Page 66

6. Copy Restrictions: Unauthorized copying or distribution of Software or the User

Manual is expressly prohibited. LICENSEE may make a reasonable number of copies

of the User Manual to the extent reasonably required for its use of the Software and

Product as permitted by this EULA; provided that LICENSEE may not use the User

Manual separately from the Product or Software or for any purpose other than as

contemplated herein.

7. Use Restrictions: LICENSEE may not: (a) modify, adapt or otherwise change the

Software or in any way remove the Software from the Product for any reason or

use the Software separately from the Product for any reason or purpose; (b) to the

maximum extent permitted to be restricted by applicable law, reverse engineer,

decompile, disassemble, or otherwise in any manner deconstruct all or any part of the

Software; (c) create derivative works based on the Software or the User Manual; (d)

except as expressly permitted by the EULA, provide, disclose, sublicense, distribute,

transfer, assign or otherwise permit any third party to access, use, read or otherwise

gain access to the Software or User Manual (the Software and User Manual being the

condential information of ecobee); or (e) use Software to access or in conjunction

with any other thermostat monitoring services or products of any ecobee competitor.

8. Support: ecobee may in its discretion, without any obligation to do so and subject

to the limitations of this EULA, provide LICENSEE with help-desk telephone

support concerning LICENSEE’s use of the SOFTWARE to the extent provided for

in the Product Terms of Sale in connection with purchase and sale of the Product

and the Terms of Service entered into by you and ecobee, if any, in connection

with the thermostat monitoring and data management services provided by

ecobee in connection with the Product. Refer to the Product Terms of Sale and/or

the Terms of Service associated with the Product and related services for further

details on Software and Product support.

9. Relief: LICENSEE agrees that damages would not be an adequate remedy for any

breach of this EULA aecting or related to a breach or misappropriation of ecobee’

(or its or its third party licensors’) intellectual property rights in and to the Software

and User Manual. LICENSEE, and nothing in this EULA, shall interfere with, delay,

obstruct, or prevent ecobee from taking, or require ecobee to take, any steps prior to

taking action to seek an interim and interlocutory equitable remedy on notice or ex

parte to enforce any provision herein to protect its rights concerning the Software or

other intellectual or proprietary rights. LICENSEE agrees not to contest, object to, or

otherwise oppose an application for equitable relief by ecobee in such circumstances

and LICENSEE waives any and all immunities from any equitable relief to which it may

be entitled. Any such relief or remedy shall not be exclusive, but shall be in addition

to all other available legal or equitable remedies. LICENSEE agrees that the

provisions of this Section are fair and reasonable and are necessary to protect ecobee’

intellectual property rights.

10. Termination: This EULA is eective until and unless terminated. Subject to

Section 13, this EULA will terminate automatically if LICENSEE fails to comply with

61

Page 67

any provision of the License. If LICENSEE is a business entity or other entity, any

failure to comply with the terms and condition of this EULA by any individual

employed or engaged by such entity will be deemed a failure to comply by

LICENSEE. Upon any termination, LICENSEE shall destroy all copies of Software

and User Manual.

11. Warranty: (a)ecobee shall provide its standard Product and Software limited

warranty statement (“Customer Warranty”), which equally applies to the

Software embedded in the Product, and which is incorporated by reference

herein, with the Product for your benefit only. In the event of an Error in

connection with the Software, refer to the Customer Warranty and Terms

of Sale provided with the Product for further detail. (b) EXCEPT FOR THE

REPRESENTATIONS, WARRANTIES, AND COVENANTS EXPRESSLY CONTAINED

IN THIS EULA, THE PRODUCT TERMS OF SALE AND THE PRODUCT WARRANTY,

THE SOFTWARE AND SOFTWARE DOCUMENTATION AND ANY SUPPORT IS

PROVIDED ON AN “AS IS” BASIS, AND THERE ARE NO OTHER REPRESENTATIONS,

WARRANTIES, COVENANTS, OR CONDITIONS, EXPRESS OR IMPLIED (INCLUDING

ANY IMPLIED WARRANTIES OR CONDITIONS OF MERCHANTABLE QUALITY OR

FITNESS FOR A PARTICULAR PURPOSE AND THOSE ARISING BY STATUTE OR

OTHERWISE IN LAW OR FROM A COURSE OF DEALING OR USAGE OF TRADE),

INCLUDING, BUT NOT LIMITED TO, NON-INFRINGEMENT, CORRECTNESS,

FUNCTIONALITY, RELIABILITY, ACCURACY, CURRENTNESS, OPERATION, USE

OR THE RESULTS OF THE USE BY LICENSEE, THAT THE OPERATION OF THE

SOFTWARE WILL BE UNINTERRUPTED OR ERROR-FREE (OR THAT ALL ERRORS

CAN OR WILL BE CORRECTED) OR THAT THE SOFTWARE OR SOFTWARE

DOCUMENTATION WILL MEET LICENSEE’S REQUIREMENTS, ALL OF WHICH ARE

EXPRESSLY DENIED AND DISCLAIMED TO THE MAXIMUM EXTENT PERMITTED BY

LAW. SOME JURISDICTIONS DO NOT PERMIT LIMITATIONS ON OR EXCLUSIONS OF

CERTAIN IMPLIED WARRANTIES, OR THE EXCLUSION OR LIMITATION OF CERTAIN