Page 1

FHT 80b Wall Thermostat and

FHT 8V Wireless Actuator

Installation and User Guide

Product Codes EHC-FH02 and EHC-FH03

1

Page 2

Intended Use! 3

Description and Function! 4

Safety Information! 7

Inserting / Replacing the Batteries on FHT 80b! 8

Control Panel! 9

Wall Mounting of the FHT 80b! 9

Mounting of the FHT 8V Valve Actuator! 12

Programming the System! 15

Special Functions! 21

Replacing the batteries! 33

Troubleshooting! 36

Handling! 37

Maintenance and cleaning! 37

Information about radio operation! 37

Technical Data! 38

Disposal! 39

2

Page 3

1. Intended Use

The radio-controlled radiator thermostat set comprises of three components:

• the FHT 80b Wall Thermostat (heating control),

• the FHT8V Actuator (valve operating mechanism), and

• the FHT 80TF Door / Window Contact Sensor (sold separately).

The system is used for temperature control in individual rooms in which the

heat that dissipates from radiators is controlled by reducing the flow of hot

water in the heating system.

The FHT 80b heating control measures the room temperature by means of

an integrated sensor and transmits the corresponding control data to up to

eight FHT 8V valve operating mechanisms (i.e. max. 8 radiators per room)

The FHT 80b can analyze the status signals (window open/closed) of up to

four FHT80 TF door/window contact sensors and, in order to save energy

when a room is aired, automatically reduce the temperature down to a socalled ‘Window open’ temperature, when the room’s window is opened.

The FHT 80b also facilitates a bi-directional radio connection with the

FHZ 1000 House Central Unit.

Any other use (e.g. in cooling systems, floor heating systems, etc.) is not

permitted and may lead to severe damages.

3

Page 4

2. Description and Function

Compared with simple mechanical thermostats (a.k.a. TRVs), the radiocontrolled radiator thermostat systems have a number of advantages:

• the split between the radiator-mounted valve operating mechanisms and the

freely positionable operation and control units (e.g. the FHT 80b heating

control which is part of the scope of supply) makes it possible to perform

settings easily.

• the programming option makes it possible to adapt the system to the

lifestyle of its users, so that the room is always comfortably warm when it is

used. When the room is not used, the temperature may be reduced

automatically to save energy, i.e. the often cumbersome manual opening and

closing of heating valves is no longer required.

• the system is equipped with an integrated calcification protection. Once

every week (time can be set) the valve operating mechanism opens and

closes the valve to prevent blocking of the valve by lime deposits.

2.1.Operating principle

In the FHT 80b heating control, the room temperature is measured and

compared to the desired temperature (set either by means of the time

program or manually). The difference is used to calculate how far the valve

has to be opened or closed to obtain the desired temperature. Using time

interval of approximately two minutes, the radio commands are sent to the

FHT 8V valve operating mechanism mounted on the radiator. This valve

operating mechanism then reduces or increases the heat. Heating up of a

room takes some time, depending on the size of the radiators. If the desired

temperature is changed, the room temperature changes with a certain delay.

Deviations between the desired value and the room temperature may also be

caused by various disturbance variables, such as draughts, other sources of

heat in the room, or an insufficient supply of heat from the heating boiler.

Temperature measurement within the control is very exact (deviation <1*C).

To avoid any unnecessary operation of the valve, e.g. when the room

temperature changes temporarily because a door is opened, several

measured values are averaged during the two minutes communication gap.

The heating control’s integrated receiver also allows the FHT 80b to receive

the status signals from up to four FHT 80TF door/window contact sensors.

4

Page 5

Changes (‘Window open’ or ‘Window closed’) are signaled to the heating

control within a time period of about 1 minute. This allows the heating control

to adjust the temperature after an average of 30 seconds, in order to save

energy when, for example, a room is aired.

2.2.Safety code

The radio signal is protected by a safety code consisting of two parts. This

safety code protects the system against interference from other radio

systems and ensures that several radio-controlled radiator thermostat

systems can be operated separately in a household. Each part of the code

comprises 100 setting options. This means that there are 10,000 different

safety codes available. To ensure communication between the heating control

and the valve operating mechanism/s the same safety code has to be set for

all devices in a room.

To ensure communication between the heating control and the valve

operating mechanism(s) the same security code has to be set for all devices

in a room. A random security code is set by the manufacturer.

When supplied as a set (heating control and valve operating mechanism) the

valve operating mechanism is preset to the heating control’s security code.

If you purchased the heating control and valve operating mechanism

separately (or you want to use additional valve operating mechanisms for a

heating control), then the security code has to be transmitted to each of the

valve operating mechanisms. See section 9.4. or section 9.5.

The security code is also used for communicating with the FHZ 1000 central

unit and the FHT 8W Heat Demand Relay.

The FHT 80TF door/window contact sensors are equipped with a randomly

generated factory default code that cannot be changed. Since there are over

16 million different possible codes, changing the code of the door/window

contact sensor is not necessary; duplication is virtually impossible.

5

Page 6

2.3.Information on the range

The transmission power is less than 10mW, much below that of a mobile

phone which may have a transmission power 200 times as great. Adverse

effects on sensitive people and animals are not to be expected.

The wireless radiator thermostat system uses the 868MHz range, which is

also used by other radio services. Therefore devices that operate on the

same or neighboring frequencies may restrict both its operation and its range.

The specified range of up to 100m (to the ‘FHT8V’ valve operating

mechanism) or up to 300m (to the ‘FHZ1000’) is the free-field range, which

means the range with visual contact between the transmitter and receiver. In

practice, however, walls, ceilings, etc. between the transmitter and the

receiver may affect and reduce the range.

Other causes of reduced ranges:

• All types of high-frequency interference

• Any buildings or vegetation

• Conductive metal parts that are located near the devices or within or

near their transmission path, for example, radiators, metallised

insulation glass windows, reinforced concrete ceilings, etc.

• Influence on the radiation pattern of antennas due to the distance from

the transmitter or receiver to conductive surfaces or objects (also to

human bodies or the ground)

• Broadband interference in urban areas that reduces the signal-to-noise

ratio; the signal is no longer recognised due to this ‘noise’

• Interference radiation resulting from insufficiently shielded electronic

devices, for example, operating computers or similar

6

Page 7

3. Safety Information

The warranty will lapse for damage due to non-compliance with these

operating instructions. We shall not be held liable for any consequential

damage or loss! We shall not accept liability for damage to property or

personal injury caused by incorrect handling or non-compliance with the

safety instructions. Any claim to warranty will lapse in such cases.

3.1.General

Do not use this product in hospitals or medical institutions. The product does

only emit relatively weak radio signals. These radio signals could, however,

lead to malfunctions in life-supporting systems. The same may possibly apply

to other areas.

The product must only be used in dry indoor areas, it must be protected from

moist and water.

The product is not a toy and must be kept out of the reach of children.

For safety and licensing (CE) reasons, unauthorized conversion of and/or

modifications to the product are not permitted.

Do not leave the packaging material lying around carelessly. Plastic film and/

or bags, polystyrene parts, etc. can be dangerous in the hands of children.

Handle the product with care. It can be damaged through impact, blows, or by

being dropped even from a low height.

3.2.Batteries and accumulators

• Keep batteries / accumulators out of the reach of children;

• Make sure to insert the batteries/accumulators with the correct polarity;

• Do not leave the batteries lying around in the open; there is a risk of them

being swallowed by children or pets. If swallowed, immediately contact a

doctor.

• Leaking or damaged batteries/accumulators may cause burning if they

come into contact with the skin. For this reason you should use suitable

protective gloves when handling batteries.

• Do not short-circuit batteries/accumulators, and do not throw batteries/

7

Page 8

accumulators into a fire. There is a risk of explosion!

• Do not disassemble batteries / accumulators!

• Do not recharge normal batteries. There is a risk of explosion!

• In case of longer periods of non-use (e.g. during storage) remove the

inserted batteries/accumulators to avoid damage by a leaking battery/

accumulator.

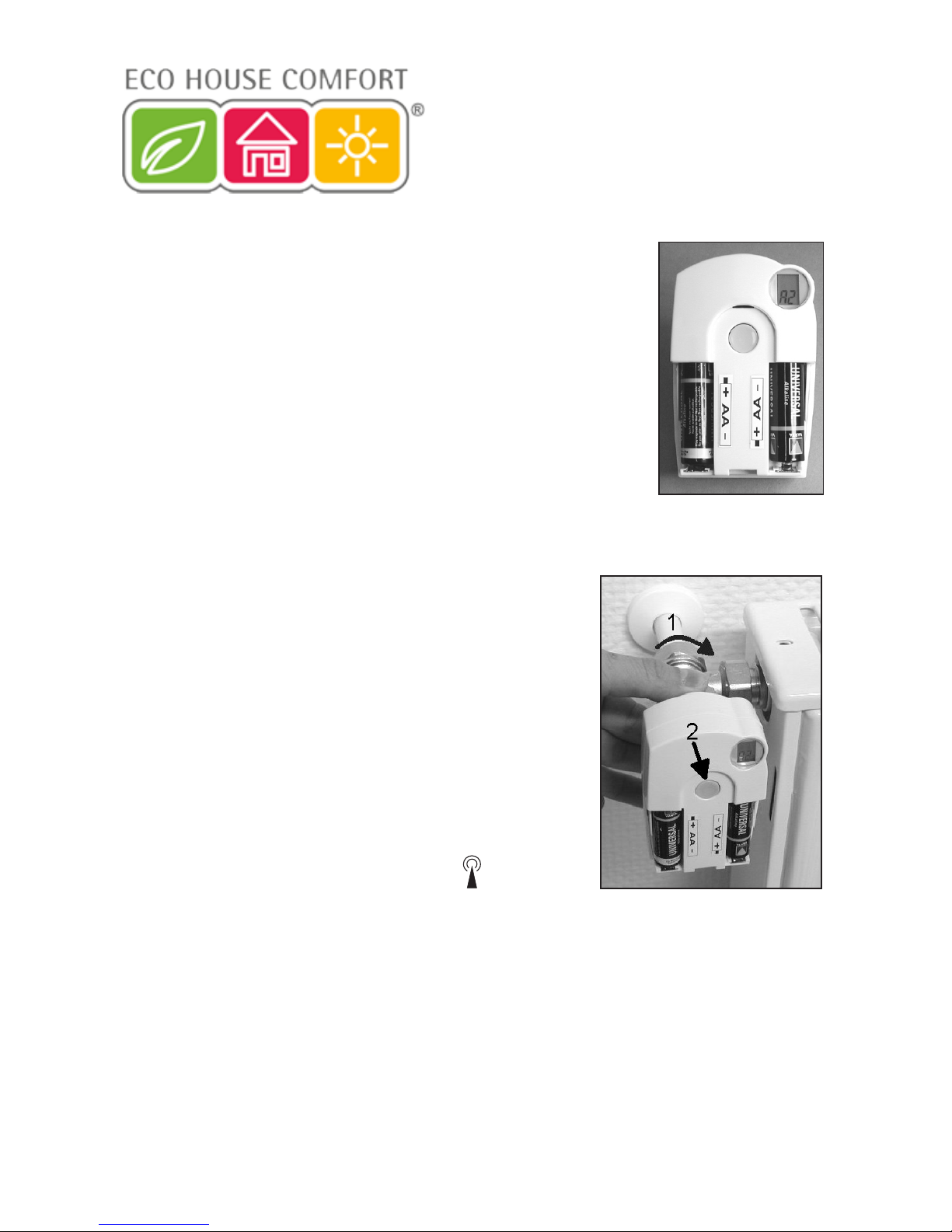

4. Inserting / Replacing the Batteries on FHT 80b

• Slide down and remove the wall holder on the back of the heating control.

• Slide down and remove the cover of the battery compartment (in direction of

the imprinted arrow on the cover).

• Insert two LR6 (Mignon/AA) batteries; pay attention to the correct polarity.

Look into the battery compartment for an illustration of the correct polarity

(make sure to insert the batteries correctly to avoid damage to the electronic

components of the heating control).

We recommend to use high-quality alkaline batteries only. Operation of

the heating control using accumulators or conventional zinc-carbon

batteries is possible, however the operating time and radio range of the

heating control will be reduced.

• Close the battery compartment.

• The heating control performs a short display test. After the display test, you

have to set date and time).

• If the battery symbol (“

h¬IS¬DISPLAYED¬ON¬THE¬,#¬DIS-

“) is displayed on the LC display, the battery

voltage is low and the batteries should be replaced as soon as possible.

The same applies, if the radio range decreases or if data are no longer

displayed on the LC display.

8

Page 9

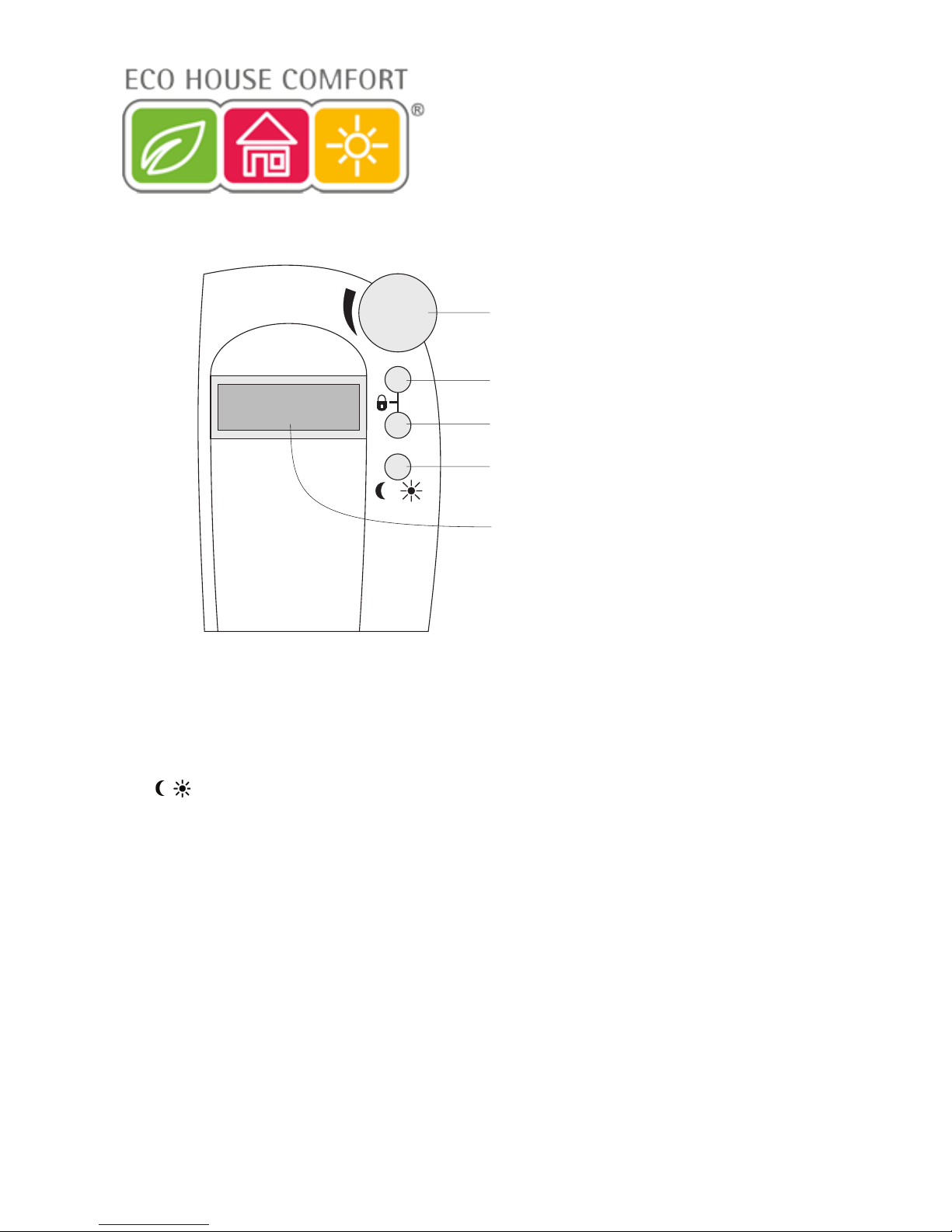

5. Control Panel

7. Control panel

Figure 1

A Scroller for settings

B ‘FUNKTION’ button

C ‘PROG’ button

D ‘

’ button

E LCD

A

D

C

E

B

F

U

N

K

T

I

O

N

P

R

O

G

6. Wall Mounting of the FHT 80b

6.1. Choosing an appropriate mounting location:

Make sure to choose an appropriate location for the mounting of the FHT 80b

heating control. This has to meet the following requirements:

• chose central position in the room where the temperature is to be controlled;

• easy access for convenient operation;

9

Page 10

• mounting at eye level for easy reading of the display;

• no mounting on a badly insulated outer wall;

• no direct sunlight;

• no interference from heat sources such as radiators, TV sets, lamps,

refrigerators,etc;

• no mounting next to a window;

• greatest possible distance to metal objects to avoid any unnecessary

reduction of the operating range

6.2. Mounting the wall holder

Proceed as follows to mount the wall holder:

• Remove the wall holder on the back of the heating control, slide it down for

this;

• Place the wall holder vertically against the wall with the round side pointing

up (see picture);

• Mark the positions of the bores through the two slotted

holes;

• Depending on the type of wall drill two 6 mm holes and

insert suitable dowels. When drilling the bores and

tightening the screws make sure not to damage any

power lines or gas or water pipes, etc.!

• Fix the wall holder using the enclosed screws. Pay attention

that the two recessed slotted holes for the screws point in

your direction;

• If not already done so, insert the batteries into the heating control before

you slide the heating control on the wall holder;

• Sliding of the heating control on the wall holder is now possible from the top.

6.3.Setting the Date and Time

• If the display is protected by a foil, remove it;

• If batteries have not been inserted yet, proceed as de- scribed in chapter 4

to insert them. After inserting the batteries an automatic display test is performed (all segments and displays of the LC display are displayed for several

seconds). After the display test you may set the year, the month, the day, the

hours and the minutes on the heating control.

10

Page 11

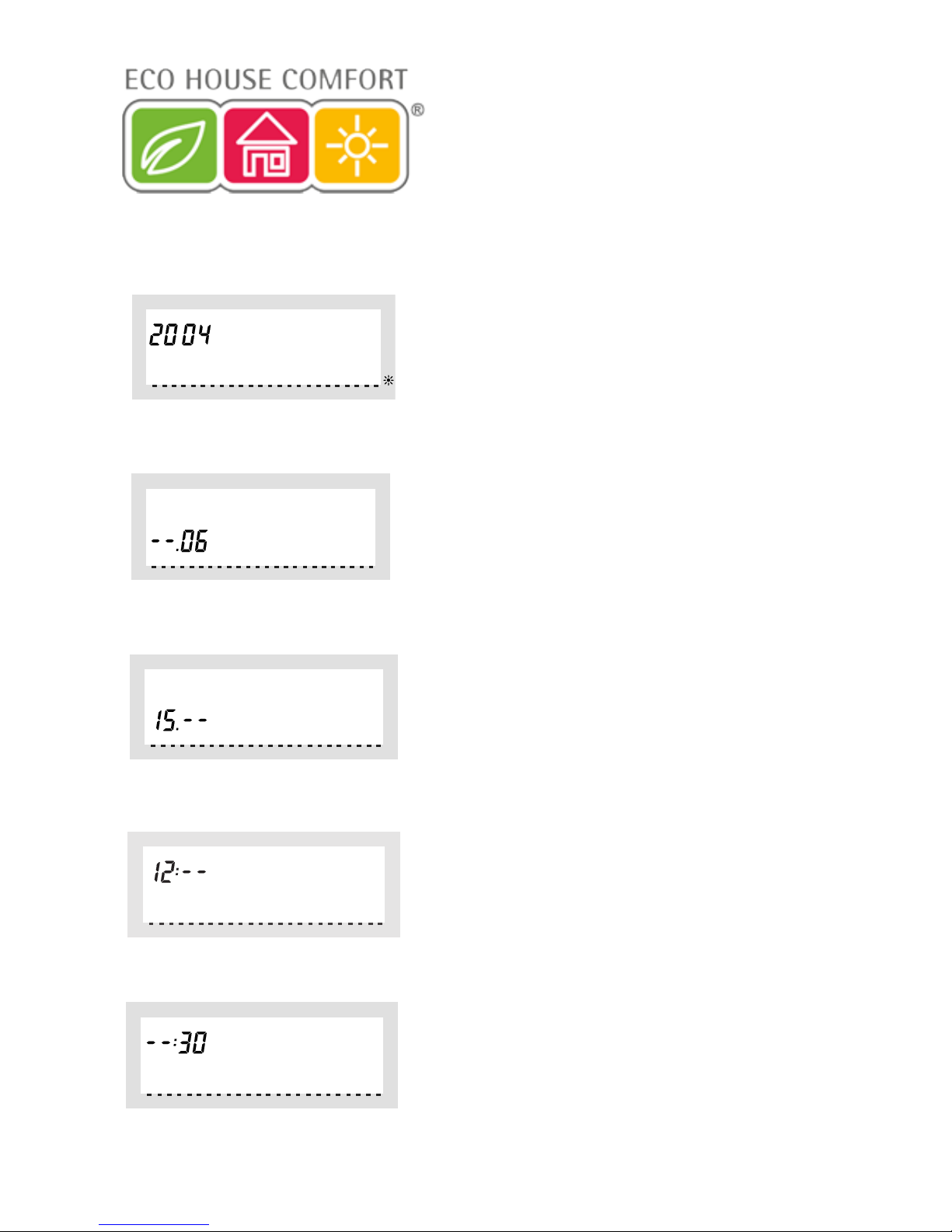

Use the selection wheel to change the displayed values. To confirm your

selection, briefly press the “PROG” key.

• After inserting the batteries the year is displayed:

Use the selection wheel to set the desired

year. To confirm your setting, briefly press the

“PROG” key.

• The month is displayed:

Use the selection wheel to set the desired

month, and con- firm your setting again by

pressing the “PROG” key.

• The day is displayed:

Use the selection wheel to set the desired

day, and confirm your setting by pressing the

„PROG” key.

• The hours are displayed:

Use the selection wheel to set the desired

hour, and confirm your setting by pressing

the “PROG” key.

• The minutes are displayed:

Use the selection wheel to set the desired

minutes, and confirm your setting by

pressing the “PROG” key.

¬3ETTING¬OF¬DATE¬AND¬TIME

MO

DI MI

DO

FR

SA

SO

0

6

12

18

24

Pro g

MO

DI MI

DO

FR

SA

SO

0

6

12

18

24

¬3ETTING¬OF¬DATE¬AND¬TIME

MO

DI MI

DO

FR

SA

SO

0

6

12

18

24

Pro g

MO

DI MI

DO

FR

SA

SO

0

6

12

18

24

MO

DI

MI

DO

FR

SA

SO

0

6

12

18

24

MO

DI MI

DO

FR

SA

SO

0

6

12

18

24

MO

DI

MI

DO

FR

SA

SO

MO

DI

MI

DO

FR

SA

SO

0

6

12

18

24

MO

DI MI

DO

FR

SA

SO

0

6

12

18

24

MO

DI

MI

DO

FR

SA

SO

0

6

12

18

24

MO

DI

MI

DO

FR

SA

SO

0

6

12

18

24

MO

DI MI

DO

FR

SA

SO

0

6

12

18

24

MO

DI

MI

DO

FR

SA

SO

0

6

12

18

24

11

Page 12

• The LCD then displays ‘Sync’, the current security code and ‘120’. The

heating control counts down from ‘120’ in steps of 1 second and then returns

to the normal operating mode.

During this time the heating control cannot be

operated. The heating control now synchronizes

its operation with the valve operating

mechanisms.

Please make a note of the displayed security code on

a slip of paper and write the name of the room, in

which the heating control is installed, underneath the

code. You will need this information if you intend to

register the heating control to a ‘FHZ1000’ home radio

central unit.

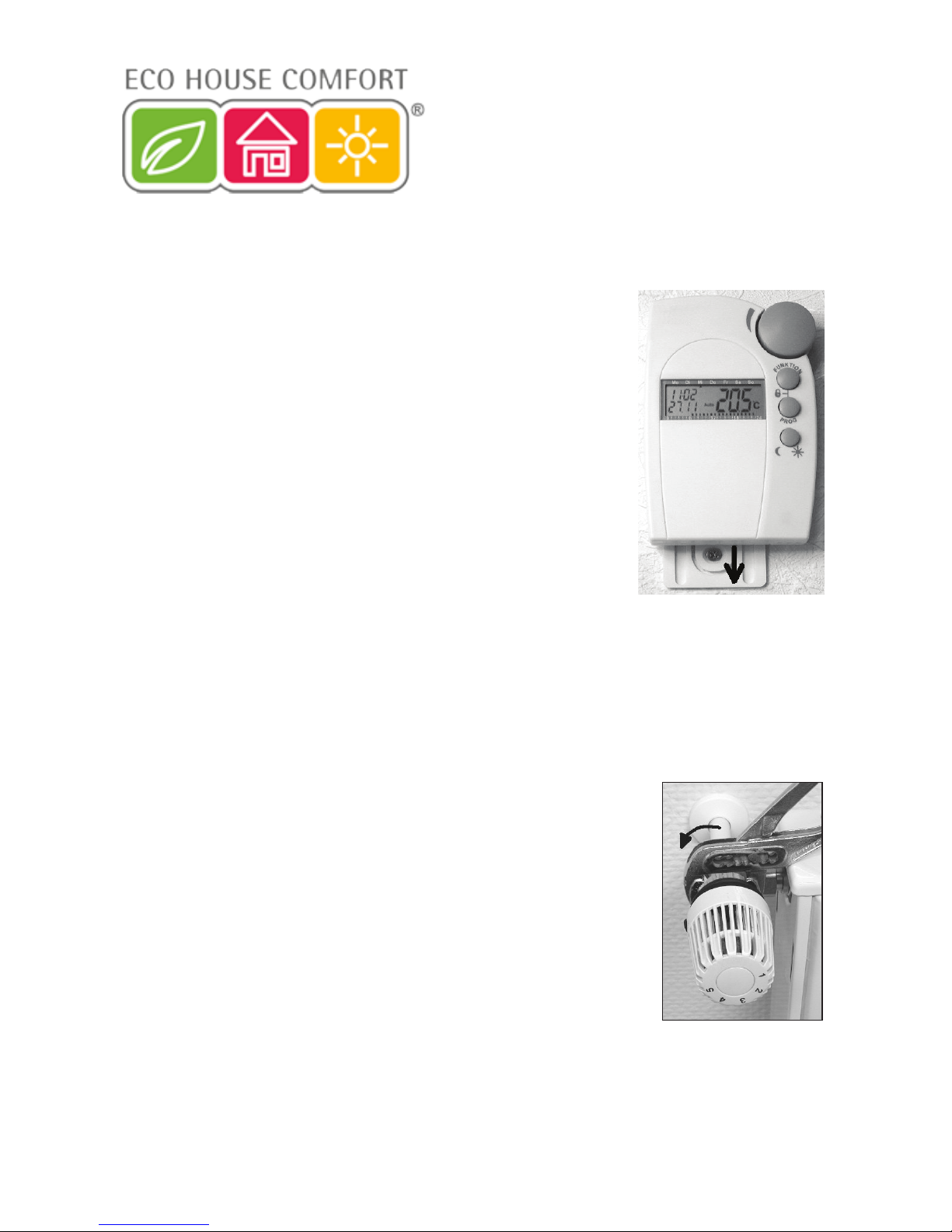

• Slide the heating control onto the wall holder from

above until it snaps into place. See figure on the right.

7. Mounting of the FHT 8V Valve Actuator

7.1. Remove the old Thermostatic Head

• Remove the old mechanical thermostat;

• If necessary, use multi grip pliers to loosen seized

screws by turning them counterclockwise (see picture on

the right).

7.2. Insert the batteries in the valve operating mechanism

• Remove the battery compartment cover of the valve

operating mechanism by sliding it down.

• Insert two AA batteries into the battery compartment. Make sure to insert the

batteries with the correct polarity, see illustration in the battery compartment

12

Page 13

and figure on the right side.

• “C1” is displayed first, followed by a two digit number,

“C2”, and another two-digit number. These two numbers

are the currently stored safety code of the valve

operating mechanism (e.g. 11 and 22 = safety code

1122).

• An acoustic signal is generated, and“A1”is displayed.

• The valve operating mechanism fully retracts the

control pin to facilitate mounting.

• Now“A2” is displayed.

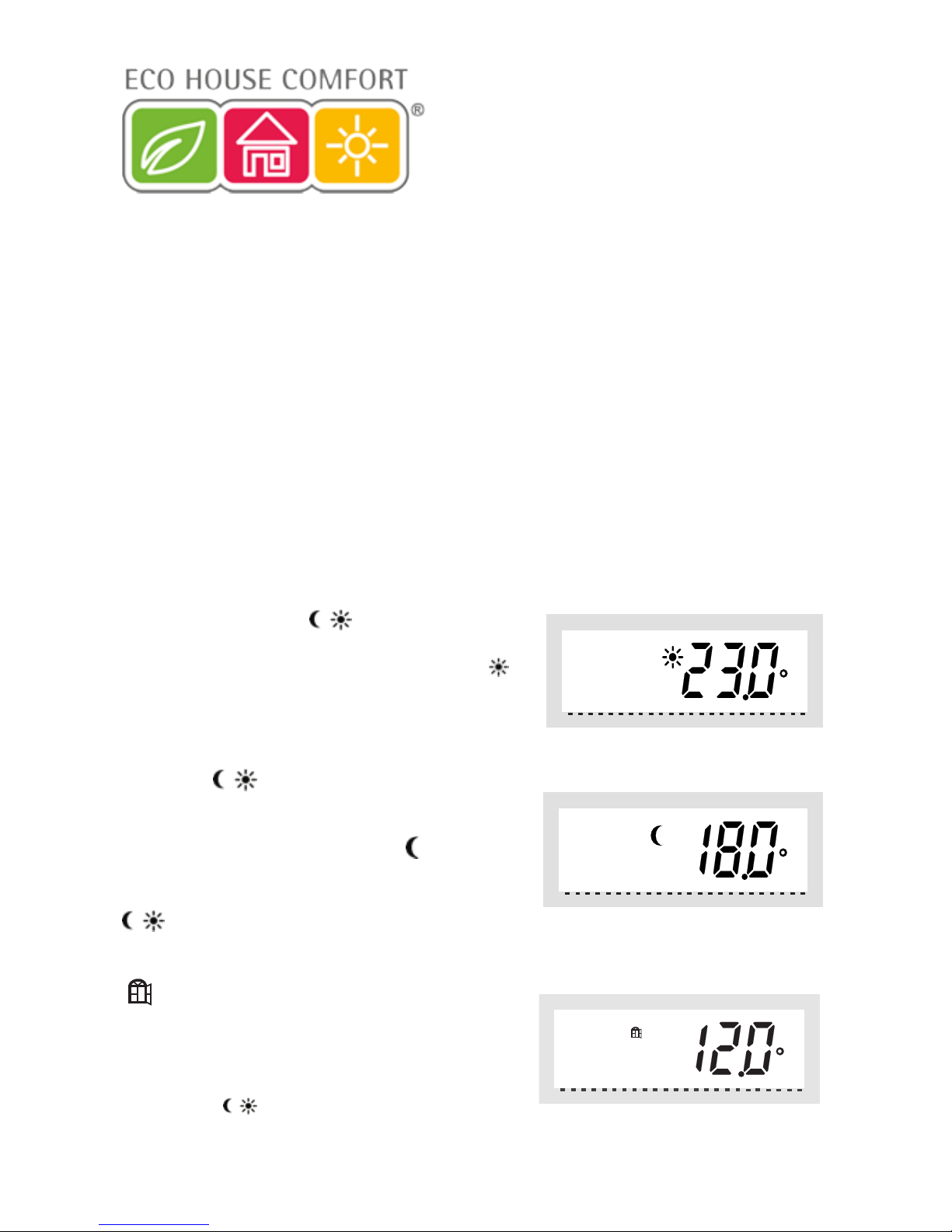

7.3. Mounting the valve operating mechanism on the radiator

• Manually turn the coupling nut to fasten the valve

operating mechanism on the valve (“1” in the

figure on the right side). When using valves by

“Danfoss” mount one of the adaptors enclosed on

the valve first. The figures on the next page show

the adaptors that have to be used for each valve.

Additional adaptors for other valves may be

purchased separately.

• Briefly press the (2) key on the valve operating

mechanism once (see figure on the right side).

• “A3” is displayed on the LC display of the valve

operating mechanism, and the valve is closed.

• On the display, the antenna symbol

then blinks on the display and

Figure 11

flashes

and “0%” is displayed.

• Close the battery compartment.

Please note:

If you purchased the valve operating mechanism separately and not as part

of a set comprising a heating control and valve operating mechanism, for

example, then the security code must first be transmitted. This is described in

detail in section 9.4.).

• The valve operating mechanism acknowledges receipt of the first wireless

protocol with a signal tone.

13

Page 14

• The antenna symbol is now permanently displayed.

• This completes the installation and you can now adapt the pre-programmed

settings to your individual needs.

Please note:

• Proceed as described above, if you wish to install further valve operating

mechanisms.

• Afterwards, the number of radiators/valve operating mechanisms must be

set on the heating control (section 9.4.) and the security code must be

transmitted (section 9.5.).

ber of valve operating mechanisms that are used for the

heating control first, before you transmit the safety code

to the valve operating mechanism.

s¬¬ 4HE¬ VALVE¬ OPERATING¬ MECHANISM¬ ACKNOWLEDGES¬ RECEP-

tion of the first radio log with an acoustic signal.

s¬¬ 4HE¬ANTENNA¬SYMBOL¬IS¬PERMANENTLY¬DISPLAYED

s¬¬ )NSTALLATION¬IS¬NOW¬lNISHED¬AND¬YOU¬MAY¬ADAPT¬THE¬PRE-

programmed settings to your individual needs.

Proceed as described above for mounting of further valve

operating mechanisms. Next, you have to set the number of

valve operating mechanisms and transmit the safety code .

Adaptors for valves of other manufacturers may be pur-

chased separately (they are not enclosed in the scope of

supply).

RAVL

RAV

RA

After snapping-on the adaptors for the valves of the types

“RAV” and “RA” on the valve

body fix the adaptors with the

enclosed screws and nuts.

For valves of the type “RAV”

additionally put the cylindrical extension piece onto the

valve pin.

%XAMPLES¬OF¬h$ANFOSSv¬ADAPTORS

14

Page 15

8. Programming the System

8.1. Setting the comfort temperature, lowering temperature and the

‘Window open’ temperature

When the automatic mode has been activated and switching between the

lowering temperature and the comfort temperature is performed

automatically, a bar in the lower part of the display indicates the time of day at

which the temperature will be set to the comfort temperature.

A sun symbol on the display indicates that the comfort temperature is active;

a moon symbol indicates that the lowering temperature is active.

If one or several FHT 80TF door/window contact sensors are installed in a

room, then the so-called ‘Window open’ temperature is automatically

activated after the monitored door or monitored window has been opened

(irrespective of which operating mode has been set).

Proceed as follows to change the settings:

Press and hold the ‘ ’ button longer than

3 seconds. The comfort temperature is

displayed on the LCD. The sun symbol ‘ ’

blinks.

Use the scroller to set the desired comfort temperature. To confirm briefly

press the button.

The lowering temperature is then displayed

on the LCD. The moon symbol blinks.

Use the scroller to set the desired lowering

temperature. To confirm briefly press the

button.

The LCD displays the ‘Window open’ temperature. The door/window symbol

’ blinks.

’ blinks.

blinks.

Use the scroller to set the ‘Window open’

temperature you require. To confirm briefly

press the ‘ ’ button.

“ key for more than 3 seconds.

MO

DI MI

DO

FR

SA

SO

C

0

6

12

18

24

MO

DI MI

DO

FR

SA

SO

C

0

6

12

18

24

“ key for more than 3 seconds.

MO

DI MI

DO

FR

SA

SO

C

0

6

12

18

24

„ key.

MO

DI MI

DO

FR

SA

SO

C

0

6

12

18

24

Use the scroller to set the desired comfort temperature. To confirm briefly press the

‘

’ button.

’ blinks.

C

0

6

12

18

24

MO DI MI DO FR SA SO

Figure 18

Use the scroller to set the desired lowering temperature. To confirm

briefly press the

‘

’ button.

’ blinks.

C

0

6

12

18

24

MO DI MI DO FR SA SO

Figure 19

15

Page 16

The heating control now returns to the normal operating mode.

8.2.Setting / changing the weekly profile

The time for automatic switching between the comfort temperature and the

lowering temperature can be set separately for each day of the week. That

way you may adapt the desired room temperature to your individual lifestyle.

For each day of the week, four switching times (comfort temperature on,

lowering temperature on, comfort temperature on, lowering temperature on)

can be set. These 4 switching times can be different for each day of the

week. This makes it possible to start heating later on weekends or on certain

days of the week.

• Briefly press the “PROG” key.

• “Prog” is displayed

MO

DI MI

DO

FR

SA

SO

0

6

12

18

24

Prog

• Use the selection wheel to select the day for which you want to change the

time program. You may either select each day of the week individually (MO,

DI, MI, DO, FR, SA, SO) or program a combination of days (block), i.e.:

- weekend (SA, SO)

- weekdays (MO, DI, MI, DO, FR)

- all days (MO, DI, MI, DO, FR, SA, SO)

This option facilitates and speeds up the programming process.

Briefly press the “PROG” key to confirm your selection of a weekday or a

block of days (weekend, weekdays, all days).

• The time when the comfort temperature will be switched on is displayed:

MO

DI MI

DO

FR

SA

SO

0

6

12

18

24

Prog

16

Page 17

Use the selection wheel to select the time when control of the comfort

temperature is to be started. On the bottom of the LC display a scale is

displayed to facilitate orientation (long marks = comfort temperature is active).

Briefly press the “PROG” key to confirm the starting time.

• On the LC display the time when the lowering temperature is to be activated

is displayed:

MO

DI MI

DO

FR

SA

SO

0

6

12

18

24

Prog

MO

DI MI

DO

FR

SA

SO

0

6

12

18

24

Prog

Use the selection wheel to select the time when control of the lowering

temperature is to be started.

Briefly press the “PROG” key to confirm the starting time.

• Repeat the steps described above to program the second comfort

temperature time and the second lowering temperature time.

If one of the switching times is not to be used, turn the selection wheel to the

right side until four bars are displayed (“--:--”, bars are displayed next to the

displayed time 23:50 hrs).

MO

DI MI

DO

FR

SA

SO

0

6

12

18

24

Prog

If you set the second comfort temperature time to „--:--“ the setting of the

second lowering temperature time is irrelevant, since no data are changed.

In all, you may set two periods of time for comfort temperature, e.g. from 6.00

to 9.00 hrs and from 16.00 to 23.00 hrs.

After setting of the second lowering temperature time and confirming the

setting by pressing the „PROG” key the normal operating mode is active

again.

17

Page 18

The scale displayed on the bottom of the LC display follows the changes as

they are being made, i.e. the effect on the day profile is immediately visible.

Please note that the temperature at the end of the previous day is not

displayed. This means that it may be that the heating phase at the end of the

previous day is continued the next day. However, this is not displayed during

programming!

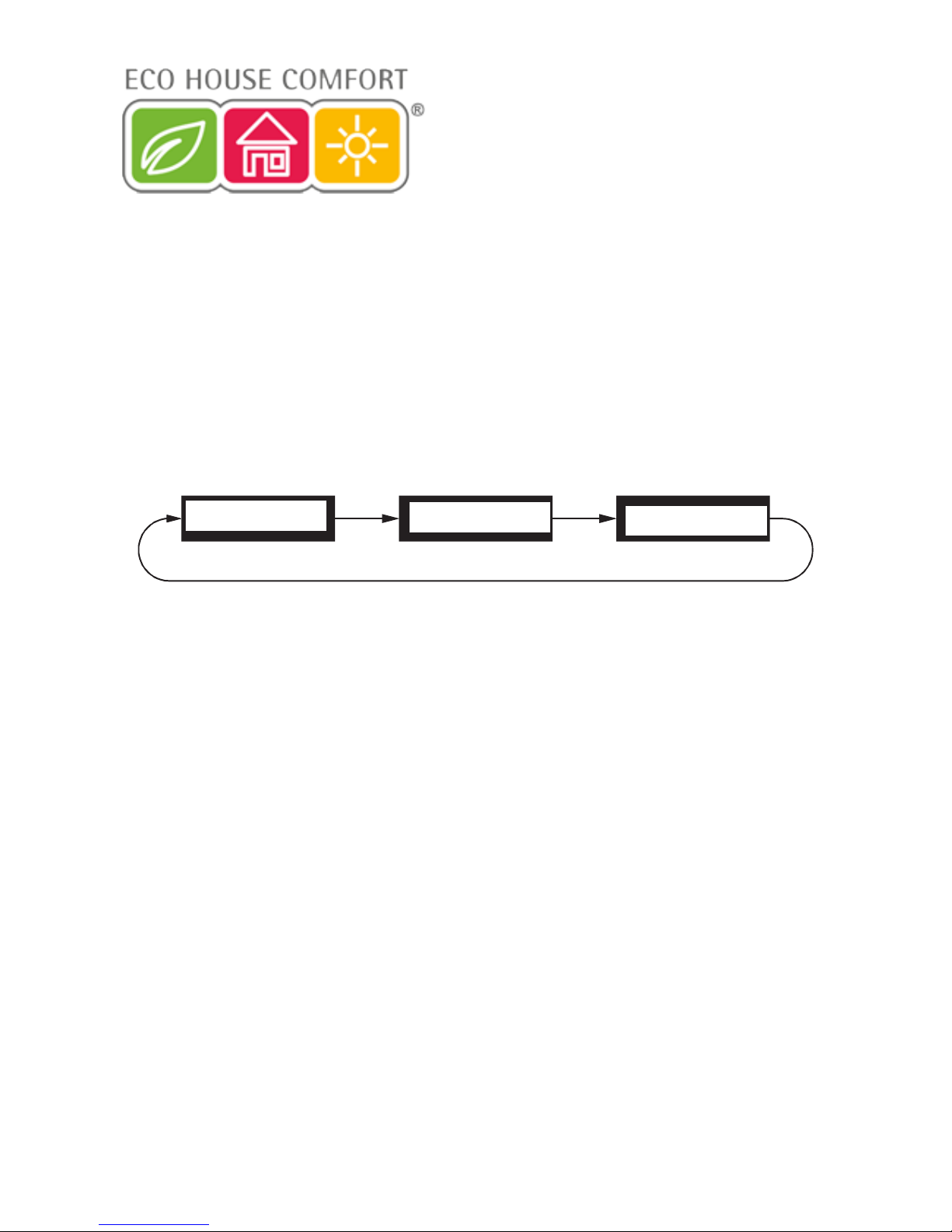

8.3. Operating modes

Press the “FUNKTION” key to change the operating mode. Press this key

several times to scroll through the different operating modes:

)F¬YOU¬ SET¬ THE¬ SECOND¬COMFORT¬ TEMPERATURE¬TIME¬ TO¬ uh¬

the setting of the second lowering temperature time is irrel-

evant, since no data are changed.

In all, you may set two periods of time for comfort temper-

ature, e.g. from 6.00 to 9.00 hrs and from 16.00 to 23.00

hrs.

After setting of the second lowering temperature time and

confirming the setting by pressing the „PROG” key the nor-

mal operating mode is active again.

4HE¬SCALE¬DISPLAYED¬ON¬THE¬BOTTOM¬OF¬THE¬,#¬DISPLAY¬FOLLOWS¬

the changes as they are being made, i.e. the effect on the

day profile is immediately visible.

Please note that the temperature at the end of the previ-

ous day is not displayed. This means that it may be that

the heating phase at the end of the previous day is con-

tinued the next day. However, this is not displayed during

programming!

C¬/PERATING¬MODES

Press the “FUNKTION” key to change the operating mode.

Press this key several times to scroll through the different

OPERATING¬MODES

Automatikbetrieb

Manueller Betrieb

Urlaub/Party-

Funktion

Automatic operation Manual operation Holiday/party

function

• Automatic operation

In the automatic operating mode (display “Auto” on the LC display) the room

temperature is controlled according to the set program for the weekday.

The temperature history for the current weekday is displayed on the bar scale

on the bottom of the display.

A temporarily temperature change can be set easily with the selection wheel.

The next time a regular temperature change is scheduled the thermostat will

then automatically return to the time-controlled program.

• Manual operation

In the manual operating mode (display “Manu”) the heating control maintains

the set temperature. An automatic time-controlled change will not be

performed.

This function is identical to the function of a conventional thermostat.

• Holiday/party function

In this operating mode (display of suitcase symbol) the temperature is kept at

a certain fixed value for a defined period of time (e.g. the duration of a party

18

Page 19

or a holiday). After this, the heating control automatically switches to the

automatic mode.

Setting the holiday/party function:

• Select this operating mode with the “FUNKTION” key and set the period of

time this function is to be active. During the following 24 hours the

temperature will be reduced every 30 minutes (party function). After 24 hours

the temperature will be reduced every day (holiday function). Set the day you

will return from your holidays. As of this day and starting at 0.00 hrs heating

will be performed with the normal time program.

• Confirm your setting of the desired period of time by briefly pressing the

“PROG” key.

• Use the selection wheel to set the desired temperature. If you select a

different operating mode with the “FUNKTION” key, you will automatically quit

the holiday/party mode.

8.4. Key lock (for keys and selection wheel)

The heating control is equipped with an integrated key lock for the keys and

the selection wheel, to protect the device from unintentional operation (i.e. by

children).

Activating the key lock

• To activate the key lock, simultaneously press the keys “FUNKTION” and

“PROG”.

• “LOC” is displayed briefly on the

display, all operating functions are

blocked.

Deactivating the key lock

• To deactivate the key lock, simultaneously press the two keys “FUNKTION”

and “PROG” until “LOC” is no longer displayed (after about 2 seconds).

• All operating functions are available again.

8.5. Switching between comfort temperature and lowering temperature

’ appears in the display) with the ‘FUNKTION’

button and set the period of time this function is to be active.

During the following 24 hours the temperature will be reduced in stages every 30 minutes

(party function). Furthermore, the temperature will be reduced every day (holiday function).

Set the day you will return from your holiday. As of 12 midnight on this day heating is then

carried out using the normal time program.

If you select a different operating mode using the ‘FUNKTION’ button, you will

automatically quit the holiday/party mode.

‘

LOCLOC

LOCLOC

LOC’ appears briefly on the LCD and all the operating functions are now locked.

0

6

12

18

24

MO DI MI DO FR SA SO

Auto

Figure 25

19

Page 20

If a room is used at different times than set in the time program, you may

change the temperature any time using the scroller. You can also switch

directly from the comfort temperature to the lowering temperature by pressing

the ‘ ’ button.

8.6. Heating Pause

Switching off the heating during the summer conserves the actuator’s

batteries and extends the service life of the batteries.

During the heating pause the valve is opened completely and remains in this

position. However, the weekly decalcification cycle is still carried out.

Proceed as follows to activate the heating pause:

• Press the ‘FUNKTION’ button to switch to the ‘Manu’ operating mode.

• Turn the scroller clockwise until ‘On’ appears on the LCD.

8.7. Closing the valve

Select this operating mode, if you do not want to heat the room at all. The

valve is closed and remains in this position.

The valve is only opened, if the

temperature drops below 5°C (

danger of freezing). The weekly

decalcification cycle is still carried

out.

• Press the ‘FUNKTION’ button to

switch to the ‘Manu’ operating mode.

• Turn the scroller anti clockwise until ‘OFF’ appears on the LCD.

8.8. Emergency operation of the valve operating mechanism

If an error occurs that cannot be eliminated (because the batteries of the

heating control or valve operating mechanism are low and no new batteries

are at hand, for example) it may be necessary to operate the valve manually.

To do so, proceed as follows:

The valve is closed and remains in this position.

The valve is only opened, if the temperature drops below 5°C (danger of

freezing). The weekly decalcification cycle is still carried out.

OFFOFF

OFFOFF

OFF’ appears on the LCD.

0

6

12

18

24

MO DI MI DO FR SA SO

Manu

Figure 27

20

Page 21

• Remove both batteries from the valve operating

mechanism.

• Remove the control pin by pressing on the

position marked with a (1).

• Place the control pin onto the peg marked with a

(2).

• Turn the control pin:

- Clockwise = increase heat

- Anti clockwise = reduce heat

8.9. ‘Window Open’ detection

The installed FHT 80TF door/window contact sensors require no operation.

They detect when a window or a door has been opened and notify the

heating control by radio signal accordingly. The heating control then reduces

the target temperature to the ‘Window open’ temperature that has been set.

Likewise, when all the windows are closed, the heating control is notified of

this again by radio signal and restores the original temperature.

The temperature can also be changed manually to a different value at any

time while the window is open.

The FHT 80TF indicates that is has detected a change of state via its signal

LED:

1 long blink - Window opened

3 short blinks - Window closed

9. Special Functions

The heating control has several special functions. To access the special

functions menu press the ‘PROG’ button until ‘Sond’ appears on the LCD.

Then release the ‘PROG’ button.

Figure 27

21

Page 22

The special functions menu can only be accessed when the heating control is

in the normal operating mode (time and date are displayed on the left of the

display and the temperature is displayed on the right of the display).

The following special functions are available:

CALC - Setting the time for the decalcification cycle

°C°F - Selecting the temperature unit (°C or °F)

dAt - Date and time setting

CodE - For changing the radio transmission security code or setting codes for

new valve operating mechanisms

An A - Setting the number of valves controlled by the heating control or

extending the system

SYNC - Synchronising the valve operating mechanisms

tEst - Test function for radio transmission

StEL - Displaying the valve position

CEnT - Default setting for the radio connection to the House Central Unit

FEn - Door/window contact sensor’s menu

OFFS- Setting the offset (this option is only displayed, if there is more than

one valve operating mechanism)

9.1.Setting the decalcification time (‘CALC’)

The valve is completely opened and closed once a week. This prevents

deposits from blocking the valve. You can use the special ‘CALC’ function to

change the time at which the decalcification cycle is carried out.

• Press the ‘PROG’ button until ‘Sond’ is displayed. Then release the ‘PROG’

button.

• Use the scroller to select the special ‘CALC’ function.

• Confirm this by pressing the ‘PROG’ button.

22

Page 23

• Use the scroller to select the day of the week (arrow up symbol ‘’ beneath

the respective day of the week).

• Confirm the day of the week you

have selected by pressing the

‘PROG’ button. The time at which

the decalcification cycle will be

carried out now appears in the first

line of the LCD.

• Use the scroller to change the time.

• Confirm the decalcification time that

you have set by pressing the ‘PROG’

button. The heating control now returns

to the normal operating mode.

9.2.Selecting the temperature unit (‘°C°F’)

Here you can select whether the temperature is to be displayed in degrees

Celsius (°C) or degrees Fahrenheit (°F).

• Press the ‘PROG’ button until ‘Sond’ appears on the LCD (for special

function).

• Use the scroller to select the special ‘°C°F’ function.

• To confirm your selection, briefly press the ‘PROG’ button.

• You can use the scroller to switch between ‘°C’ and ‘°F’.

• To confirm your selection, briefly press the ‘PROG’ button. The heating

control now returns to the normal operating mode.

9.3. Setting the date and time (‘dAt’)

•

Press the ‘PROG’ button until ‘Sond’ appears in the LCD.

• Use the scroller to select the ‘dAt’ function.

• To confirm your selection, briefly press the ‘PROG’ button.

Carry out all further settings as described in section 6.3., page 10

CALCCALC

CALCCALC

CALC’ function to change the time at which the

SondSond

SondSond

Sond’ is displayed. Then release the ‘PROG’ button.

CALCCALC

CALCCALC

CALC’ function.

0

6

12

18

24

MO DI MI DO FR SA SO

Figure 29

CALCCALC

CALCCALC

CALC’ function to change the time at which the

SondSond

SondSond

Sond’ is displayed. Then release the ‘PROG’ button.

CALCCALC

CALCCALC

CALC’ function.

0

6

12

18

24

MO DI MI DO FR SA SO

Figure 29

day of the week).

at which the decalcification cycle will be carried out now appears in the first line of the LCD.

0

6

12

18

24

MO DI MI DO FR SA SO

Figure 30

23

Page 24

9.4. Setting the security code (‘CodE’)

To protect the heating control against interference from other radio systems

the device uses a two-part security code.

Each part of the code comprises 100 setting options. This means that a total

of 10,000 different security codes are available.

To ensure communication between the FHT 80b heating control and the

FHT 8V valve operating mechanism(s) the same security code has to be set

for all the devices in a room.

This is particularly important, if you use more than one valve operating

mechanism or you have not purchased a set (heating control and valve

operating mechanism).

Proceed as follows to change or set the code:

• Press the ‘PROG’ button until ‘Sond’ appears in the LCD.

• Use the scroller to select the ‘CodE’ function.

• To confirm your selection, briefly press the ‘PROG’ button.

The following information is displayed:

SondSond

SondSond

Sond’ appears in the LCD.

CodECodE

CodECodE

CodE’ function.

0

6

12

18

24

MO DI MI DO FR SA SO

Figure 31

• Use the scroller to select the first part of the code (a number between ‘000’

and ‘099’) and confirm your selection by briefly pressing the ‘PROG’ button.

• The following information is displayed:

SondSond

SondSond

Sond’ appears in the LCD.

CodECodE

CodECodE

CodE’ function.

0

6

12

18

24

MO DI MI DO FR SA SO

Figure 31

0

6

12

18

24

MO DI MI DO FR SA SO

Figure 32

• Use the scroller to select the second part of the code (a number between

‘000’ and ‘099’) and confirm your selection by briefly pressing the ‘PROG’

button.

24

Page 25

• The following information is displayed:

SondSond

SondSond

Sond’ appears in the LCD.

CodECodE

CodECodE

CodE’ function.

The following information is displayed:

0

6

12

18

24

MO DI MI DO FR SA SO

Figure 31

confirm your selection by briefly pressing the ‘PROG’ button.

0

6

12

18

24

MO DI MI DO FR SA SO

Figure 32

and confirm your selection by briefly pressing the ‘PROG’ button.

0

6

12

18

24

MO DI MI DO FR SA SO

Figure 33

Now you need to synchronise the (first) valve operating mechanism (‘001’ on

the display) to the new security code. Proceed as follows to carry out this

synchronisation:

• Remove the battery compartment cover of the (first) valve operating

mechanism by sliding it down.

• Press the button on the valve operating mechanism for approx. 3 seconds

until you hear 3 signal tones. The valve operating mechanism is now ready to

receive and ‘AC’ is displayed.

• Press the ‘PROG’ button on the ‘FHT80B’ heating control to start

transmitting the security code to the valve operating mechanism.

• The valve operating mechanism acknowledges that it has received the code

correctly with a tone sequence.

• Replace the valve operating mechanism’s battery compartment cover.

• The valve operating mechanism acknowledges that it has received the first

normal radio signal with a signal tone.

Now repeat these steps for all the other valve operating mechanisms in the

room (‘002’, ‘003’... on the display).

After the last valve operating mechanism has been coded the heating control

automatically returns to the normal operating mode.

If the heating control is used to control several valve operating mechanisms,

in other words, several radiators are located in one room, you should make a

note of which valve operating mechanism belongs to which radiator, that

means the number.

If coding of a valve operating mechanism fails (for example, due to bad

reception, a low battery or similar), the security code can be transmitted to

this valve operating mechanism again at a later time.

25

Page 26

• Proceed as described above and skip the valve operating mechanisms that

have already been coded by briefly pressing the ‘PROG’ button.

• If the LCD shows the number of a valve operating mechanism that has not

yet received a security code, press the control button on this valve operating

mechanism until ‘AC’ is displayed on the valve operating mechanism and you

hear 3 signal tones. Also see the information above.

• Now press the ‘PROG’ button on the heating control to get the heating

control to transmit the security code. The valve operating mechanism uses a

tone sequence to acknowledge that it has received the code correctly.

Afterwards, replace the valve operating mechanism’s battery compartment

cover. The valve operating mechanism uses a signal tone to acknowledge the

first receipt of a normal radio signal.

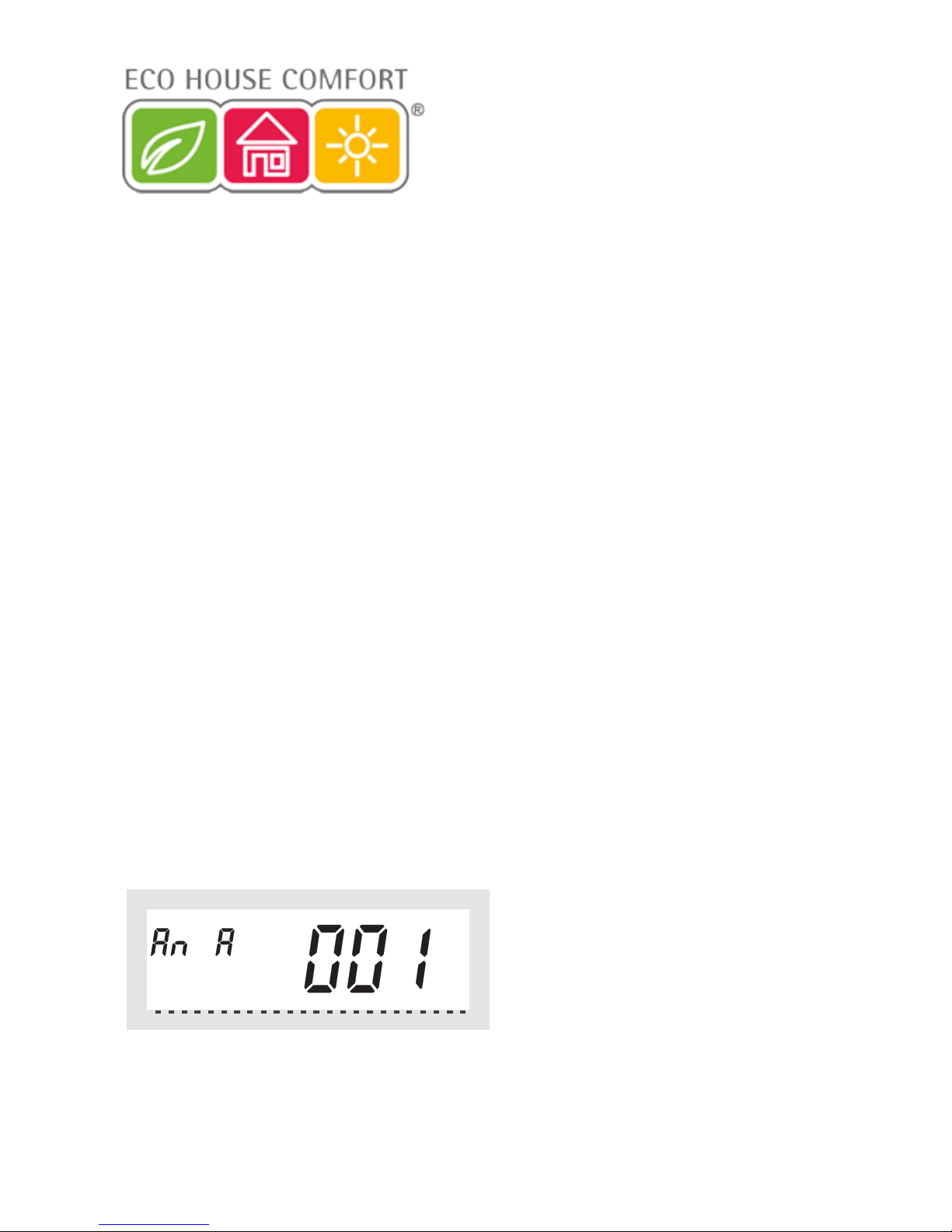

9.5.Setting the number of valve operating mechanisms (‘An A’)

You use this menu item to set the number of radiators (valve operating

mechanisms) to be controlled when the heating control is used to control

several valve operating mechanisms in one large room, for example.

If you install an additional valve operating mechanism, you must ensure that

this valve operating mechanism is assigned the same security code as the

valve operating mechanisms, which are already installed.

• Press the ‘PROG’ button until ‘Sond’ appears in the LCD.

• Use the scroller to select the special ‘An A’ function.

• To confirm your selection, briefly press the ‘PROG’ button.

• The following information is displayed:

An AAn A

An AAn A

An A’)

If you install an additional valve operating mechanism, you must ensure that

this valve operating mechanism is assigned the same security code as the

valve operating mechanisms, which are already installed.

SondSond

SondSond

Sond’ appears in the LCD.

An AAn A

An AAn A

An A’ function.

0

6

12

18

24

MO DI MI DO FR SA SO

Figure 34

• Use the scroller to set the number of radiators (1 to 8) and confirm your

setting by briefly pressing the ‘PROG’ button.

26

Page 27

The (first) valve operating mechanism is now synchronised to the new

security code. ‘CodE SynC 001’ appears on the heating control’s LCD.

Repeat the following 6 steps (see next page) for each installed valve

operating mechanism:

1. Remove the battery compartment cover of the (first) valve operating

mechanism by sliding it down and out.

2. Press the button on the valve operating mechanism for approx.3 seconds

until you hear 3 signal tones. The valve operating mechanism is now ready

to receive and ‘AC’ is displayed.

3. Press the ‘PROG’ button on the heating control to start transmitting the

heating control’s security code to the valve operating mechanism.

4. The valve operating mechanism acknowledges that it has received the

code correctly with a tone sequence.

5. Replace the valve operating mechanism’s battery compartment cover.

6.Thevalveoperatingmechanismacknowledgesthatithasreceivedthefirstnorm

alradio signal with a signal tone.

Repeat these 6 steps for all the other valve operating mechanisms that are

located in the room (‘002’, ‘003’ ... on the display) according to the number of

valve operating mechanisms that has been set.

Once all the valve operating mechanisms have been coded the heating

control automatically returns to the normal operating mode.

You can skip any valve operating mechanisms that have already been

synchronised / programmed to the heating control’s security code.

All you need to do is briefly press the ‘PROG’ button on the heating control

(do not open the respective valve operating mechanism/do not press the

button on the valve operating mechanism!)

9.6. Synchronising the valve operating mechanisms (‘SYnC’)

When this menu item is selected, the heating control starts to signal (for

approx. 2 minutes) to all the valve operating mechanisms that they should resynchronise.

27

Page 28

Afterwards the normal transmission program is continued and the valve

operating mechanisms generate a signal tone as soon as they receive the

first correct signal.

• Press the ‘PROG’ button until ‘Sond’ appears in the LCD.

• Use the scroller to select the special ‘SynC’ function.

• To confirm your selection, briefly press the ‘PROG’ button.

• The LCD then displays the security code and the heating control counts

down from ‘120’ in steps of 1 second. After these 120 seconds the heating

control returns to the normal operating mode.

9.7. Test mode (‘tESt’)

You can use this function to check whether all the valve operating

mechanisms receive the radio signal correctly. The addressed valve

operating mechanisms acknowledge correct reception with an acoustic

signal. Use the scroller to select the valve operating mechanisms to be

tested.

If the large display shows a ‘0’, then all the receivers are tested, otherwise,

only the valve operating mechanism assigned to the displayed number is

tested. The timer in the left corner of the display counts down to the time at

which the next test cycle is to be started.

• Press the ‘PROG’ button until ‘Sond’ appears in the LCD.

• Use the scroller to select the special ‘tESt’ function.

• To confirm your selection, briefly press the ‘PROG’ button.

• Use the scroller to select the valve operating mechanism/s to be tested.

• Press the ‘PROG’ button to quit the test function.

h) Displaying the valve position (‘StEL’)

When you select this menu item the heating control’s LCD indicates

how far the valve is opened

as a percentage (only for valve operating mechanism 1).

• Press the ‘PROG’ button until ‘Sond’ appears in the LCD.

• Use the scroller to select the special ‘StEL’ function.

• To confirm your selection, briefly press the ‘PROG’ button.

28

Page 29

• The display shows the valve opening as a percentage (only possible for

valve operating mechanism 1).

• Press the ‘PROG’ button to quit this function.

9.8.Connecting to the home radio central unit (‘CEnt’)

You only require this special function, if you want the heating control to work

with a new FHZ1000 central unit or no central unit at all, in other words, you

wish to unregister the heating control from the central unit.

Radio communication between the heating control and the central unit is also

protected by the heating control’s security code. For this purpose the

respective heating control is ‘registered’ with the central unit.

To ensure that the heating control only works with your central unit and not

with your neighbor's central unit, for example, the heating control can only be

registered with one central unit.

If you want to register the heating control with another central unit, then you

must first to re- enable the heating control. 3 different settings are possible:

‘On’: Heating control is registered with the central unit

‘Off’: No radio communication with the central unit. Registration is not

possible.

‘nA’: Heating control is enabled for registration with the central unit

To set, proceed as follows:

• Press the ‘PROG’ button until ‘Sond’ appears on the LCD.

• Use the scroller to select the special ‘CEnt’ function.

• To confirm your selection, briefly press the ‘PROG’ button.

• The LCD displays the current setting (‘On’, ‘Off’, ‘nA’).

• Use the scroller to select the setting you require (‘On’, ‘Off’, ‘nA’) and

confirm your selection by pressing the ‘PROG’ button.

The heating control then returns to the normal operating mode.

29

Page 30

9.9. Querying the status of a door/window contact sensor (‘FEn’)

You can use the ‘FEn’ special function menu to request the current status of a

FHT 80TF door/ window contact sensor. You can also use this menu to newly

register or delete door/window contact sensors.

Proceed as follows to access the door/window contact sensor’s menu:

• Press the ‘PROG’ button until ‘Sond’ appears on the LCD.

• Using the scroller, select the special ‘FEn’ function.

• To confirm your selection, briefly press the ‘PROG’ button.

• The LCD shows the status of the door/window contact sensor stored at

the first memory location:

FEnFEn

FEnFEn

FEn’)

FEnFEn

FEnFEn

FEn’ special function menu to request the current status of a ‘FHT80TF’ door/

SondSond

SondSond

Sond’ appears on the LCD.

FEnFEn

FEnFEn

FEn’ function.

location:

0

6

12

18

24

MO DI MI DO FR SA SO

Figure 35

The following status signals are possible:

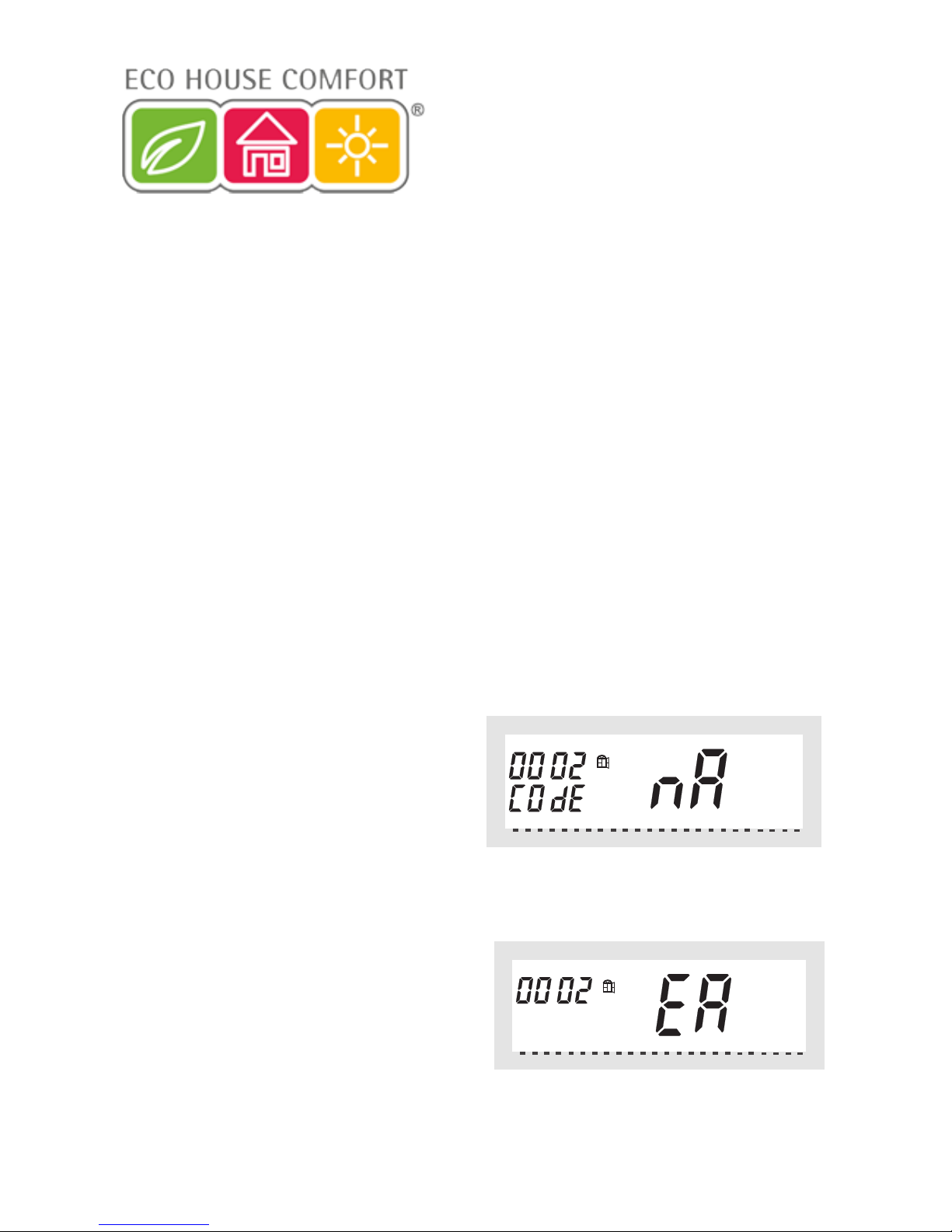

‘nA’: Not registered, in other words, no door/window contact sen- sor is

registered to this memory location

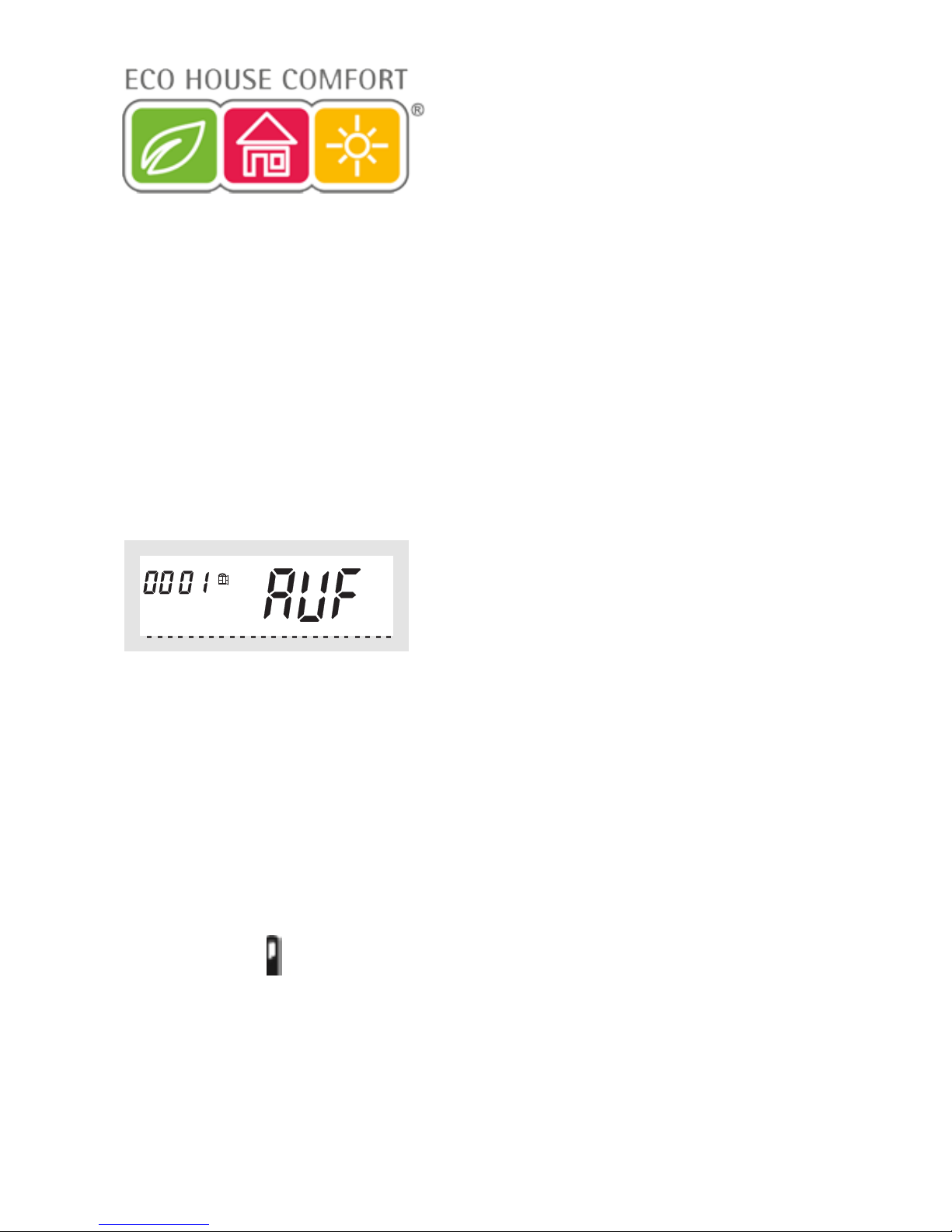

‘AUF’:The window is open

‘EA‘: Reception failure, in other words, no signals have been received from

the door/window contact sensor over a long period of time

no display: Window closed, reception OK

Battery symbol ‘ ’: This door/window contact sensor’s batteries are low and

must be replaced

30

Page 31

By turning the scroller you can select which of the four memory locations

should be displayed.

Briefly press the ‘PROG’ button to quit the door/window contact sensor’s

status indicator. The heating control returns to the normal operating mode.

9.9.10. Registering a door/window contact sensor

Proceed as follows to register a door/window contact sensor with the

FHT 80b heating control:

• The FHT 80b door/window contact sensor must be properly installed.

• Press the ‘PROG’ button until ‘Sond’ appears on the LCD.

• Using the scroller, select the special ‘FEn’ function.

• To confirm your selection, briefly press the ‘PROG’ button.

• Use the scroller again to select

the desired memory location.

• Keep the ‘FUNKTION’ button

pressed until ‘CodE’ appears on

the display:

• Now press the button located inside the door/window contact sensor’s

casing (‘TA1’) until the red LED lights up. Then release the button.

• The door/window contact sensor

transfers its coding to the

heating control.

• ‘EA’ now appear on the heating

control’s LCD:

• If no further door/window contact

sensors need to be registered, return to the normal operating mode by

pressing the ‘PROG’ button.

SondSond

SondSond

Sond’ appears on the LCD.

FEnFEn

FEnFEn

FEn’ function.

CodECodE

CodECodE

CodE’ appears on the display. See figure 36

on the next page.

0

6

12

18

24

MO DI MI DO FR SA SO

Figure 36

SondSond

SondSond

Sond’ appears on the LCD.

FEnFEn

FEnFEn

FEn’ function.

CodECodE

CodECodE

CodE’ appears on the display. See figure 36

on the next page.

0

6

12

18

24

MO DI MI DO FR SA SO

Figure 36

the red LED lights up. Then release the button.

EAEA

EAEA

EA’ now appear on the heating control’s LCD.

0

6

12

18

24

MO DI MI DO FR SA SO

Figure 37

31

Page 32

• After a few minutes the heating control is synchronised to the

transmissions from the door/ window contact sensor and the system is

ready for use.

9.11. Deleting door/window contact sensors

Door/window contact sensors that are no longer required or are no longer in

operation should be deleted in order to avoid repeated error messages from

being displayed (‘reception failure’). The power consumption also increases

as attempts are regularly made to receive signals from the door/window

contact sensors.

Proceed as follows to delete a door/window contact sensor:

• Press the ‘PROG’ button until ‘Sond’ appears on the LCD.

• Using the scroller, select the special ‘FEn’ function.

• To confirm your selection, briefly press the ‘PROG’ button.

• Using the scroller, select the door/window contact sensor that you wish

to delete.

• Keep the ‘ ’ button pressed

until the status is displayed as

‘not registered’ (‘nicht

angemeldet’, ‘nA’):

• Briefly press the ‘PROG’ button to

quit the status indicator. The heating control returns to the normal operating

mode.

9.12. Radiator offset (‘OFFS’)

This setting option is only displayed, if you use more than one valve operating

mechanism. If several radiators are controlled by one heating control, it may

be that these radiators do not heat up to the same level.

The reason for this is that the flow rates of the valves differ greatly, depending

on varying or poorly dimensioned radiators. This problem may be solved by

SondSond

SondSond

Sond’ appears on the LCD.

FEnFEn

FEnFEn

FEn’ function.

’ button pressed until the status is displayed as ‘not registered’ (‘nicht

angemeldet’, ‘

nAnA

nAnA

nA’).

0

6

12

18

24

MO DI MI DO FR SA SO

Figure 38

32

Page 33

adjusting the settings of single radiators so that they give off more (positive

offset) or less (negative offset) heat.

• Press the ‘PROG’ button until ‘Sond’ appears in the LCD.

• Use the scroller to select the special ‘OFFS’ function.

• To confirm your selection, briefly press the ‘PROG’ button.

• Use the scroller to select the valve operating mechanism/radiator you

require, and confirm your selection by pressing the ‘PROG’ button.

• Use the scroller to set the offset, and confirm your setting by pressing

the ‘PROG’ button. The heating control then returns to the normal

operating mode.

You may have to repeat this process several times until the heating power

has been optimally distributed.

10. Replacing the batteries

10.1. FHT 80b Wall Thermostat (heating control)

If the ‘

’ symbol appears on the LCD, this means that the batteries are low

and must be replaced.

To replace the batteries, proceed as follows:

• Remove the heating control from the wall holder and open the battery

compartment cover (slide down).

• Remove the batteries from the battery compartment and dispose of

them according to the applicable environmental regulations. See

section 16, page 39.

• Insert two new AA batteries; make sure the polarity is correct. If

possible, use alkaline batteries.

• Close the battery compartment.

33

Page 34

• If a FHZ 1000 central unit is present, the heating control automatically

requests the current time and date and then sets these. Otherwise you

need to set these manually.

The time program settings, the comfort/lowering temperature settings

and so on are maintained.

• As the heating control and the valve operating mechanism are no

longer synchronised with each other, the heating control performs a

synchronisation procedure (‘SYnC Auto’) that lasts approx. 2 minutes.

After this synchronisation the heating control returns to the normal

operating mode.

10.2. FHT 8V Actuator (valve operating mechanism)

The battery symbol appears when the valve operating mechanism’s batteries

are low. In addition, an acoustic signal is generated every 2 minutes for one

hour, three times a day.

To replace the batteries, proceed as follows:

• Remove the battery compartment cover from the valve operating

mechanism by sliding it down.

• Remove the old batteries and dispose of them according to the

applicable environmental regulations. See section 16, page 39.

• Wait until all the segments of the valve operating mechanism’s LCD

have gone out. You can speed up this process by keeping the button on

the valve operating mechanism pressed.

• Insert two new AA batteries into the valve operating mechanism’s

battery compartment, making sure that the polarity is correct. Otherwise

you may destroy the valve operating mechanism’s electronic

components!

• The display shows ‘C1’ followed by a 2-digit number. The display then

shows ‘C2’, followed by another 2-digit number (both numbers are the

currently stored security code of the valve operating mechanism).

• A signal tone is then generated and ‘A1’ is displayed.

• The valve operating mechanism now fully retracts the control pin.

• ‘A2’ is then displayed.

34

Page 35

• Briefly press the button on the valve operating mechanism.

• ‘A3’ is displayed and the valve operating mechanism closes the valve

completely.

• The antenna symbol then blinks and ‘0%’ is displayed.

• The first radio signal that is received is acknowledged by a signal tone,

and the antenna symbol is permanently displayed.

• Replace the battery compartment cover.

10.3. FHT 80TF Door / Window Contact Sensor

When the batteries in the door/window contact sensor are low, the device

sends this information to the heating control. The corresponding error

message (the window icon blinks) is shown on the heating control’s display.

You can use the ‘FEn’ special function menu to identify the door/window

contact sensor whose batteries are low.

To replace the batteries, proceed as follows:

• Open the casing by pushing the two catches on the left side of the

casing approx. one millimeter inwards using a flat screwdriver while

simultaneously pulling the lid forwards.

• Remove both of the old batteries and dispose of them according to the

applicable environmental regulations. See section 16, page 39.

• Insert 2 new AAA batteries into the battery compartment, observing the

correct polarity.

• Close the casing cover.

• If necessary, the door/window contact sensor now conducts a

synchronisation procedure that lasts approx. 1 minute (the LED blinks

every second).

35

Page 36

11. Troubleshooting

15. Troubleshooting

Problem

Permanent signal tone and ‘F1’

is displayed on the valve operating mechanism

Permanent signal tone and ‘F2’

is displayed on the valve operating mechanism

Permanent signal tone and ‘F3’

is displayed on the valve operating mechanism

No radio symbol displayed on

the valve operating mechanism.

The valve operating mechanism

generates a tone sequence

every hour. The valve is 30%

opened.

‘Low battery’ symbol is displayed. The valve operating

mechanism generates a tone

sequence every 2 minutes for

one hour.

‘LOC’ is displayed when a button is pressed

The window symbol ‘ ’ blinks

Possible cause

•The valve is too tight or the

valve operating mechanism

is blocked

•Control range is too large

•Valve operating mechanism

is not mounted to the heat

ventilator

•Control range is too small

•Radio connection failure due

to interference

•Heating control’s batteries

are low

•Heating control’s code is not

right (or has been

misadjusted)

•The valve operating mechanism’s batteries are almost

empty

Button lock is activated

•Radio connection failure to a

door/window contact sensor

•Empty batteries

Solution

•Remove the valve operating mechanism

•Manually check valve operation

•Mount the valve operating mechanism again

•If necessary, consult a heating technician

•Mount the valve operating mechanism again

•Unsuitable valve

•Insert a spacer that is 1mm thick (a

washer, for example) between the

heat ventilator and the actuator

•Mount the valve operating mechanism again

•Unsuitable valve

•Install the heating control in a different location

•Replace the heating control’s batteries

•Transmit the current security code

to the valve operating mechanism

•Replace the batteries

•Deactivate the button lock

•Identify and rectify the fault

•Replace the batteries

36

Page 37

12. Handling

Protect the product against humidity, cold, heat, dust, and direct sunlight.

Do not disassemble the product. Have any repairs per- formed by experts,

otherwise the license (CE) of the product will lapse!

Do not drop the product, it will be damaged even if it falls from a low height.

13. Maintenance and cleaning

The product does not require any maintenance apart from replacing of

batteries. Clean the product with a soft, clean, dry and fuzz free cloth. To

achieve a better cleaning action the cloth can be dampened with lukewarm

water.

Take care not to let any moisture get into the product!

Do not use cleaning agents containing solvents, since these may damage the

plastic housing and labeling.

14. Information about radio operation

Transmission of data between heating control and valve operating

mechanism is performed wirelessly per radio transmission.

The transmitting power is less than 10mW, i.e. much below the transmitting

power of a mobile phone which may have a transmitting power that is 200

times as great. Therefore, negative effects on sensitive people or animals are

not to be expected.

The radio heating thermostat system works in the 868MHz range which is

also used by other radio services. There- fore restrictions in the operation and

the range can occur through the devices which work on the same or

neighboring frequency.

The range stated of up to 100m is the free-field range, i.e. the range at sight

contact between the transmitter and the receiver.

37

Page 38

15. Technical Data

15.1. FHT 80b heating control

Typical range in open field....................................................................... 100m

Max. no of valve operating mechanisms per unit: ...................................... 8

Radio frequency: .............................................................................868.35MHz

Power supply:......................................................................2 LR6 (Mignon/AA)

Battery service life: .................................................................. approx. 2 years

Temperature range when in operation:...........................................6°C to 30°C

Number of switching times:.................................................................4 per day

Safety code consisting of two parts, up to 10,000 different codes possible

After a battery replacement only date and time have to be reset, all other data

are maintained

15.2. FHT 8V valve operating mechanism

Power supply:..................................................................... 2 LR6 (Mignon/AA)

(if possible use alkaline batteries)

Battery service life:...................................................................approx. 2 years

(depending on the number of valve movements)

38

Page 39

16. Disposal

¬$ISPOSAL

a) General

Dispose of the unusable product according

to valid legal regulations

B¬$ISPOSING¬OF¬USED¬BATTERIES¬AND¬ACCUMULATORS

You, as ultimate consumer, are required by law (battery

regulations) to return all used batteries. Disposing of used

batteries with domestic waste is prohibited!

Batteries / accumulators containing toxins are

marked by appropriate symbols which refer to the

prohibition of disposal with domestic waste.

The designations for the decisive heavy metals

ARE¬#D¬¬CADMIUM¬(G¬¬MERCURY¬0B¬¬LEAD¬4HE¬

designation can be found on the battery under the

dustbin symbol illustrated on the left).

You may return used batteries/accumulators

free of charge to collecting stations, our outlets

or anywhere else where batteries/accumulators

are sold.

By doing so, you fulfil the legal requirements and contribute to the conservation of our environment.

4HE¬#%¬SIGN¬IS¬A¬FREE¬TRADE¬SIGN¬ADDRESSED¬

exclusively to the authorities and does not

warrant any properties.

39

Loading...

Loading...