Page 1

E

clipse

Installation Guide 248

4/10/07

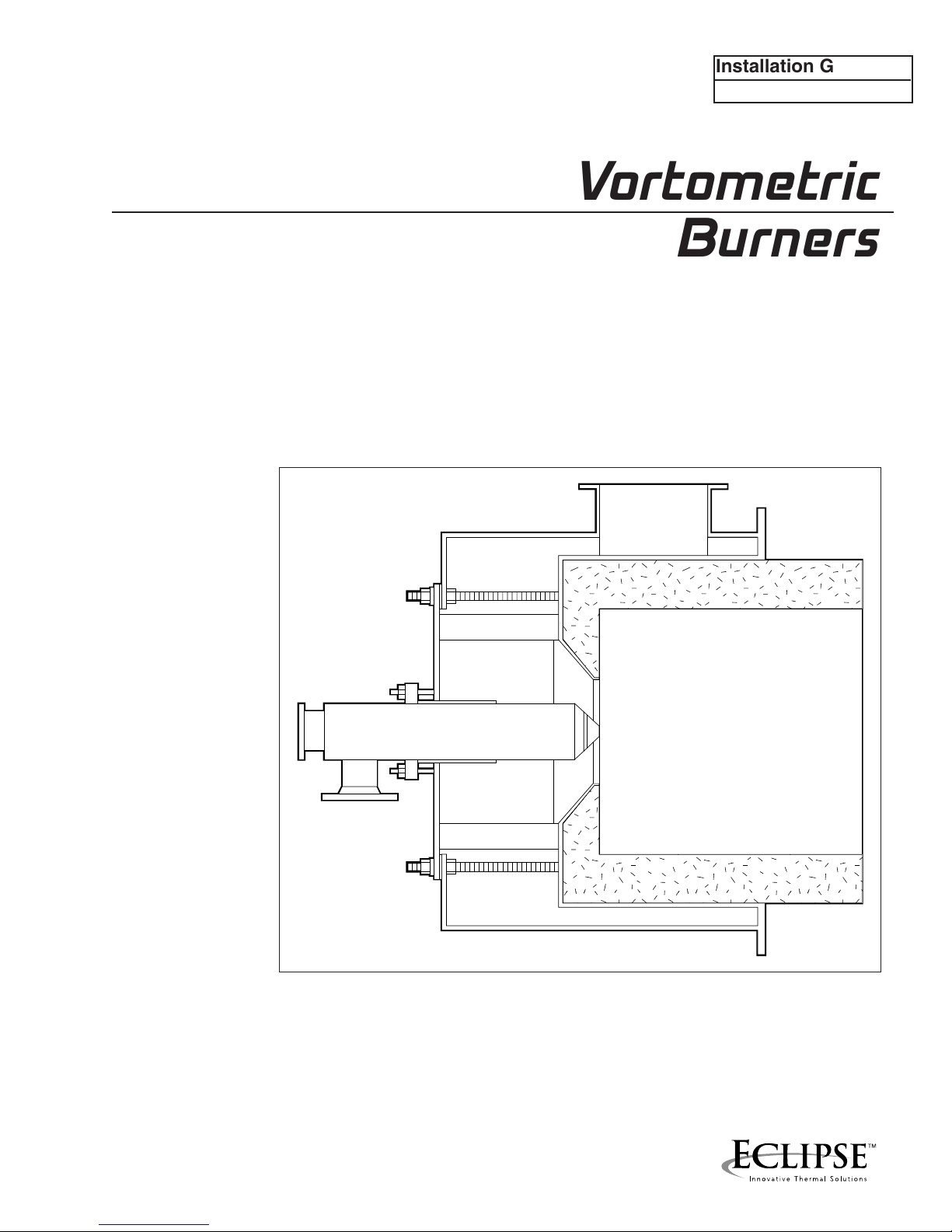

Vortometric

Burners

Page 2

COPYRIGHT

Copyright 1997 by Eclipse Combustion. All rights reserved worldwide.

This publication is protected by federal regulation and shall not be

copied, distributed, transmitted, transcribed or translated into any

human or computer language, in any form or by any means, to any third

parties, without the express written consent of Eclipse Combustion.

DISCLAIMER NOTICE

LIABILITY AND

WARRANTY

In accordance with the manufacturer’s policy of continual product

improvement, the product presented in this brochure is subject to

change without notice or obligation.

The material in this manual is believed adequate for the intended use of

the product. If the product is used for purposes other than those

specified herein, confirmation of validity and suitability must be

obtained. Eclipse Combustion warrants that the product itself does not

infringe upon any United States patents. No further warranty is

expressed or implied.

We have made every effort to make this manual as accurate and

complete as possible. Should you find errors or omissions, please bring

them to our attention so that we may correct them. In this way, we

hope to improve our product documentation for the benefit of our

customers. Please send your corrections and comments to our

Marketing Communications Manager.

It must be understood that Eclipse Combustion’s liability for its

products, whether due to breach of warranty, negligence, strict liability,

or otherwise, is limited to the furnishing of replacement parts and

Eclipse Combustion will not be liable for any other injury, loss, damage

or expenses, whether direct or consequential, including but not limited

to loss of use, income of, or damage to material arising in connection

with the sale, installation, use of, inability to use or the repair or

replacement of Eclipse Combustion’s products.

ii

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 3

About this manual

AUDIENCE

SCOPE

This manual has been written for those persons who are already familiar

with all the aspects of a burner and its add-on components, also referred

to as “the burner system”. These aspects are:

• design/selection

• installation

• use

• maintenance

The audience is expected to have previous experience with this kind

of equipment.

This manual provides information for installing the Vortometric

burner ONLY and does not include the burner control system

(such as fuel/air ratio controls, flame supervision systems, etc.).

When Eclipse Combustion sells the burner as part of a complete

package, then schematic piping and wiring diagrams will be furnished

which explain the control system operation. When Eclipse

Combustion sells only the Vortometric burner, then it is the

purchaser’s responsibility to ensure that:

• the control system is adequate for the application,

• the control system meets all applicable codes and regulations, and

• the operating personnel are fully familiar with safe control system

operation.

VORTOMETRIC

PUBLICATIONS

Installation Guide No. 248

• This publication.

Data Sheets No. 248-1, 248-2

• Lists burner models information including dimensions.

Bulletin No. 248

• Used with Data Sheets to define burner specifications and

available options.

Price Sheet No. 248

• Used to order burners.

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

iii

Page 4

RELATED PUBLICATIONS

• EFE-825 (Combustion Engineering Guide)

• Eclipse Bulletins & Instruction Manuals: 818, 820, 826, 832, 852, 854, 856

IMPORTANT NOTICES

DOCUMENT

CONVENTIONS

• Read this manual carefully. Make sure that you understand the structure

and contents of this manual.

• Obey all the safety instructions.

• Do not deviate from any instructions or application limits in this

manual without written consent from Eclipse Combustion.

• If you do not understand any part of the information in this manual, do

not continue. Contact your Eclipse sales office or Eclipse Combustion.

There are several special symbols in this document. You must know

their meaning and importance.

The explanation of these symbols follows. Please read it thoroughly.

Danger:

Indicates hazards or unsafe practices which WILL

result in severe personal injury or even death.

Only qualified and well trained personnel are

allowed to carry out these instructions or

procedures.

Act with great care and follow the instructions.

Warning:

Indicates hazards or unsafe practices which could

result in severe personal injury or damage.

Act with great care and follow the instructions.

Caution:

Indicates hazards or unsafe practices which could result in

damage to the machine or minor personal injury.

Act carefully.

Note:

Indicates an important part of the text.

Read the text thoroughly.

iv

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 5

Table of Contents

About this manual................................................................ ii

Table of Contents.................................................................. v

1

2

3

Introduction............................................................................... 1-1

Product Description ........................................................................ 1-1

Safety............................................................................................... 2-1

Introduction....................................................................................... 2-1

Safety ................................................................................................... 2-1

Capabilities ......................................................................................... 2-2

Operator Training ............................................................................. 2-2

Replacement Parts ........................................................................... 2-2

Installation .................................................................................. 3-1

Introduction....................................................................................... 3-1

Handling and Storage....................................................................... 3-1

Position of Components................................................................. 3-1

Approval of Components............................................................... 3-2

Limits controls and safety equipment ..................................... 3-2

Electrical wiring ............................................................................ 3-2

Gas piping ...................................................................................... 3-2

Where to get the standards...................................................... 3-2

Checklist before Installation .......................................................... 3-3

Burner Mounting .............................................................................. 3-4

Prepare the Burner .......................................................................... 3-2

Gas, Gas/Oil or Oil Gun Positioning ....................................... 3-2

Install the flame sensor............................................................... 3-7

Pilot ................................................................................................. 3-8

Piping............................................................................................... 3-8

Strainers ......................................................................................... 3-10

Atomizing Control Methods ..................................................... 3-10

Installing and Curing Refractory Block ....................................... 3-11

Checklist after Installation ............................................................. 3-14

vEclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 6

4

Adjustment, Start & Stop .............................................. 4-1

Introduction....................................................................................... 4-1

Adjustment Procedure.................................................................... 4-1

Step 1: Reset the system .......................................................... 4-1

Step 2: Set low fire combustion air pressure drop ........... 4-2

Step 3: Verify air settings .......................................................... 4-2

Step 4: Ignite the pilot............................................................... 4-2

Step 5: Ignite the burner .......................................................... 4-3

Step 6: Adjust low fire ............................................................... 4-4

Step 7: Adjust high fire .............................................................. 4-5

Step 8: Verify settings ................................................................. 4-5

Start Procedure ................................................................................ 4-6

Stop Procedure ................................................................................. 4-7

5

Maintenance & Troubleshooting............................... 5-1

Introduction....................................................................................... 5-1

Maintenance Schedules ................................................................... 5-1

Monthly Checklist........................................................................ 5-1

Yearly Checklist ............................................................................ 5-2

Maintenance Procedures ................................................................ 5-2

Fuel Oil Tip Cleaning ................................................................... 5-2

Dismantling of Atomizer ............................................................ 5-4

Assembly of Atomizer................................................................. 5-6

Troubleshooting ................................................................................ 5-8

Appendix ...................................................................................... A-1

Flow and Input Charts .................................................................... A-1

Table A.1– Combustion Air Pressure Drop vs. Burner Heat Input

for Medium Intensity Burners................................................... A-1

Table A.2– Combustion Air Pressure Drop vs. Burner Heat Input

for High Intensity Burners ......................................................... A-2

Table A.3– Gas Gun Press. Drop vs. Burner Heat Input ..... A-3

Table A.4–Oil Nozzle Press. Drop vs. Burner Heat Input.... A-4

Table A.5– Atomizing Air Press. Drop vs. Air Flow ............... A-4

Table A.6–Atomizing Steam Press. Drop vs. Steam Flow ..... A-5

Recommended Spare Parts ............................................................ A-5

Conversion Factors ......................................................................... A-6

System Summary .............................................................................. A-7

vi

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 7

Introduction

1

PRODUCT

DESCRIPTION

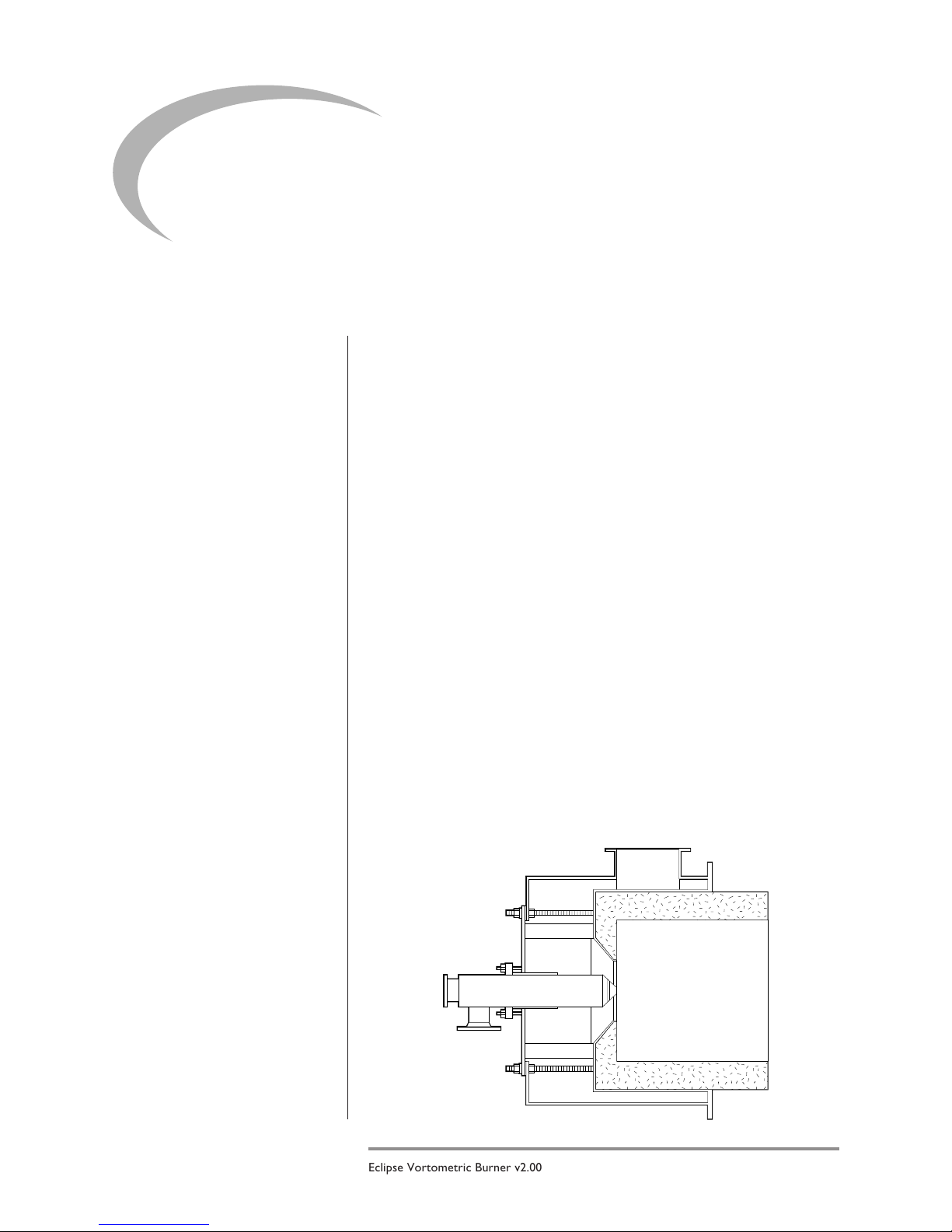

The Eclipse Vortometric v2.00 is a dual-fuel, high intensity burner

which operates at maximum efficiency whether firing fuel oils or

natural, propane, butane, manufactured or other mixed gases.

The Vortometric’s versatility and rugged design make it the right

choice for any heating process, including driers, kilns, thermal fluid

heaters, thermal oxidizers, oil heaters, vaporizers, boilers, liquid and

waste incineration, and many air heating applications.

The high combustion air swirl rate produced by the Vortometric

burner results in a stable flame with high turndown capabilities on a

wide range of fuels. The burner can be operated with low excess air

where maximum efficiency is required or high excess air for high

volume process air heating. The intense and thorough mixing of the

air and gas results in low NOx and CO emissions.

The novel design of the oil atomizer uses shear forces and

acoustical energy created by a “vortex generator” to vaporize the

fuel for clean, smoke-free combustion.

Vortometric v2.00 burners are available with capacities of 6mmBtu/

hr. to 210mmBtu/hr. Low combustion air pressure is used (7.5"w.c.)

with all sizes and atomization of the fuel oil can be by steam, air, or

any gaseous fuel.

Figure 1.1 Vortometric v2.00 Burner

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

1-1

Page 8

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 9

Safety

2

INTRODUCTION

SAFETY

In this section, you will find important notices about safe operation

of a burner system.

Danger:

The burners covered in this manual are designed

to mix fuel with air and burn the resulting

mixture. All fuel burning devices are capable of

producing fires and explosions when improperly

applied, installed adjusted, controlled, or

maintained.

Do not bypass any safety feature.

You can cause fires and explosions.

Never try to light the burner if the burner shows

signs of damage or malfunctioning.

Warning:

The burner and duct sections are likely to have

HOT surfaces. Always wear protective clothing

when approaching the burner.

Note:

This manual gives information for the use of these burners

for their specific limited design purpose. Do not deviate from

any instructions limits in this manual without written advice

from Eclipse Combustion.

Note:

Read this entire manual before you attempt to start the

system. If you do not understand any part of the information

in this manual, then contact your Eclipse representative or

Eclipse Combustion before you continue.

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

2-1

Page 10

CAPABILITIES

Adjustment, maintenance and troubleshooting of the mechanical and the

electrical parts of this system should be done by qualified personnel with

good mechanical aptitude and experience with combustion equipment.

OPERATOR TRAINING

REPLACEMENT PA RT S

The best safety precaution is an alert and competent operator. Thoroughly

instruct new operators so they demonstrate an adequate understanding

of the equipment and its operation. Regular retraining must be scheduled

to maintain a high degree of proficiency.

Order replacement parts from Eclipse only. Any customer-supplied

valves or switches should carry UL, FM, CSA, CGA and/or CE approval

where applicable.

2-2

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 11

Installation

3

INTRODUCTION

HANDLING AND

STORAGE

In this section you will find the information and instructions that you

need to install the burner.

Handling

1. Make sure that the area is clean.

2. Protect the components from the weather, damage, dirt and

moisture.

3. Protect the components from excessive temperatures and humidity.

4. Take care not to drop or hit components.

Storage

1. Make sure that the components are clean and free of damage.

2. Store the components in a cool, clean, dry room.

3. After you have made sure that everything is present and in good

condition, keep the components in the original package as long

as possible.

Caution:

When the refractory combustion block is supplied with the

burner, it is critical that the instructions for handling and storage

are followed. The refractory should be considered fragile;

improper handling and storage will cause premature failure.

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

3-1

Page 12

APPROVAL OF COMPONENTS

Limit controls and safety

equipment

Electrical wiring

All limit controls and safety equipment must comply with the following

current standards:

• NFPA Standard 86

• NFPA Standard 86C

•UL

•FM

• CGA

• CSA

• EN 746-2

• all applicable local codes and/or standards.

All of electrical wiring must comply with the one of the following

standards:

• NFPA Standard 70

• ANSI-C11981

• CSA

• EN 746-2

• the electrical wiring must be acceptable to the local authority having

jurisdiction.

Gas piping

Where to get the standards

All of the gas piping must comply with the one of the following

standards:

• NFPA Standard 54

• ANSI Z223

• EN 746-2

• the gas piping must be acceptable to the local authority having

jurisdiction.

The NFPA Standards are available from:

National Fire Protection Agency

Batterymarch Park

Quincy, MA 02269

The ANSI Standards are available from:

American National Standard Institute

1430 Broadway

New York, NY 10018

The UL Standards are available from:

United Laboratories

333 Pfingsten Road

Northbrook, IL 60062

3-2

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 13

The FM Standards are available from:

Factory Mutual

1151 Boston-Providence Turnpike

P.O. Box 9102

Norwood, MA 02062

The CGA Standards are available from:

Canadian Gas Association

55 Scarsdale Road

Toronto, Ontario

Canada M3B 2R3

The CSA Standards are available from:

Canadian Standards Association

178 Rexdale Boulevard

Etobicoke, Ontario

Canada M9W 1R3

Information on the EN standards, and where to get the standards is

available from:

Comité Européen de Normalisation

Stassartstraat 36

B-1050 Brussels

Phone: +32-25196811

Fax: +32-25196819

CHECKLIST BEFORE

INSTALLATION

Comité Européen de Normalisation Electronique

Stassartstraat 36

B-1050 Brussels

Phone: +32-25196871

Fax: +32-25196919

Access

Make sure that you install the system in such a way that you can get

easy access to the burner for inspection and maintenance.

Environment

Make sure that the local environment matches the original operating

specifications. Check the following items:

• voltage, frequency and stability of the electrical power

• type and supply pressure of the fuel

• availability of enough fresh, clean combustion air

• humidity, altitude and temperature of air

• presence of damaging corrosive gases in the air.

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

3-3

Page 14

BURNER MOUNTING

Depending on your application, please keep the following in mind

when mounting a burner:

• Ensure that the burner is level and that the furnace or burner

casing has sufficient rigidity to support the burner. If necessary,

provide stiffeners on the casing or supports under the burner.

• Remember to compensate for the burner’s combustor liner

extension for the refractory combustion block.

• Use gasketing between the burner mounting flange and the

furnace casing and ensure that you have a gas-tight joint between

these two surfaces. This tightness is especially critical for systems

operating under positive pressures.

PREPARE THE BURNER

Gas, Gas/Oil or Oil Gun

Positioning

There are several components that must be installed to a burner

systems before it can operate. Instructions to do that follow below.

Prior to starting the burner, the gun position in relation to the

burner throat cone must be checked.

Note:

Burners are not necessarily shipped with guns in the correct

position; it is also possible that the gun could shift during shipment.

Note:

All of the following adjustments provide a relative position for

safe operation for all applications; occasionally, adjustments in or

out from the relative positions may be necessary depending on

your application.

For Gas Only Burners (see Figure 3.1):

1. To adjust the gas gun, loosen the gland.

2. Using the chart in Figure 3.1, determine the “X” dimension

based on your burner size.

3-4 Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

3. Once the “X” dimension is verified and the gas gun is centered

in relation to the throat cone, tighten the gland.

Note:

Failure to center the gun in the burner throat will cause uneven

air flow and flame instability. The gun should be centered with

+/- 1/8".

Page 15

Figure 3.1 Vortometric Gas Gun Position

4

Gland

To Adjust

Gun Position

3

2

1

Gas Inlet

2

Gas Gun

3

Throat Cone

4

Air Inlet

5

Refractory Block Walls

1

Figure 3.2 Vortometric Gas/Oil Gun Position

Gland “B”

Used to adjust the position

of entire gun assembly

within burner throat

2

31

Gland “A”

Used to adjust the position

of oil gun within gas gun.

5

4

6

throat cone ring

“X”

Dim.

7

End of

oil atomizer

is flush with

5

5

Burner “X”

Size (Inches)

6V 11/16

8V 1-3/8

10V 1-5/16

12V 1-1/2

14V 1-11/16

16V 2-1/16

18V 2

22V 2-5/16

24V 2-1/4

28V 3-3/16

32V 3-1/16

36V 3-7/8

8

1

Oil Inlet

2

Oil Gun

3

Steam/Air Inlet

4

Gas Inlet

5

Gas Gun

6

Throat Cone

7

Air Inlet

8

Refractory Block Walls

8

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

3-5

Page 16

For Combination Gas/Oil Burners–Initial Adjustment (see

Figure 3.2):

1. Adjust the oil gun position by loosening gland “A”.

2. Align the conical faces of the oil and gas guns.

3. Once both guns are aligned, tighten gland “A” on the oil gun.

Note:

After this initial adjustment, all subsequent adjustments for

combination gas/oil burners require that both guns be moved as

a single unit.

For Combination Gas/Oil Burners–Subsequent Adjustments

(see Figure 3.2):

1. Adjust the entire gas/oil gun assembly by loosening gland “B”.

2. Move the entire gun assembly until the oil nose cone aligns with

the small diameter of the throat cone.

3. Once both cones are aligned and the gas gun is centered in

relation to the throat cone, tighten gland “B”.

For Oil Only Burners (see Figure 3.2):

1. Adjust the oil gun position so that the end of the oil nose cone

aligns with the small diameter of the throat cone as shown at left.

2. Verify that the oil gun is centered in relation to the throat cone;

once verified, tighten the large gland nuts.

Note:

Failure to center the gun in the burner throat will cause uneven

air flow and flame instability. The gun should be centered with

+/- 1/8".

3-6

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 17

Install the flame sensor

U.V. Scanner

(Model 5600-91)

An ultraviolet flame sensing device, or U.V. scanner, must be used

with a 3/4" N.P.T. swivel connector. The scanner and connector can

be used in three possible locations: two mounting ports are located

near the gun assembly adjacent to the pilot which sight both pilot

and main flames, while a third mounting port on the side of the

combustor sights only the main flame. Flame detection methods

are affected by fuels and applications:

• For gas, light oil, or heavy oil with air atomization, locate a U.V.

scanner in one of the two mounting ports near the pilot to prove

pilot and main flames.

90° U.V.

Scanner

(Model 5600-90A)

Self-Check

U.V. Scanner

(Model 5602-91)

• For heavy oil with steam atomization, two scanners must be used.

Because atomizing steam absorbs ultraviolet light, a scanner

mounted near the pilot will only prove the pilot flame. Therefore,

a second scanner mounted on the combustor side is needed to

prove the main flame.

Note:

Due to the low U.V. content of oil flames, some U.V. scanner/

flame safety systems may have difficulty sighting oil flames at

high inputs. In these cases, a more sensitive U.V. detector may

be required or an infrared (I.R.) detector may be used.

Make sure that you connect the flame sensor of a burner to the

electrical circuit of the burner.

Danger:

If you connect the flame sensor of a burner to the

electrical circuit of the wrong burner, then you can

cause fires and explosion.

For detailed information on how to install and connect a U.V. scanner,

refer to:

• straight U.V. scanner; Bulletin/Instruction Manual 854

• 90° U.V. scanner; Bulletin/Instruction Manual 852

• self-check U.V. scanner; Bulletin/Instruction Manual 856.

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

3-7

Page 18

Pilot Pilot ignition

The standard Vortometric spark-ignition pilot requires an ignition

transformer with a minimum of 6000 volt secondary. Mount the

transformer in a location where it will not overheat while allowing

as short an ignition lead as possible.

Pilot assembly positioning

The relation of the pilot assembly to the main burner gun affects air

flow through the throat cone. Therefore, it is important that the pilot

be as far away as possible from the throat cone while maintaining

reliable ignition. For initial start-up, the pilot assembly should be

between 6" and 8" away from throat cone; if necessary, adjust the

pilot assembly gland to achieve this distance.

Piping

Support the piping and ductwork

Use brackets or hangers to support the piping and ductwork to

avoid placing undue loads on the burner. If you have questions,

consult your local gas company.

Pipe connections

The use of flexible pipe in gas, oil and atomizing air lines to the

burner is recommended. Adjustments of the main gas, pilot gas and

oil guns may be required during burner setup.

Avoid large pressure drops

Note:

The pressure drop of the gas in the piping is a critical

parameter. Make sure that the size of all the piping is large

enough to prevent excessive pressure losses.

3-8

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 19

Oil fuel considerations

1. In heavy oil (#5 or #6) applications, the oil temperature at the

burner inlet should be 220° to 270°F for good viscosity

(maximum 150 SSU). Depending on burner location, steam or

electric tracing AND pipe insulation are usually needed to

ensure this oil temperature range. Other oils (wastes, residues,

etc.), may also require similar provisions to ensure good

viscosity.

2. Foreign material can easily clog the small injection holes in the oil

nozzle tip. Therefore, ensure that all inside surfaces of assembled

piping to the burner are free of dirt, grit, shavings or any other

foreign material. To avoid contamination, use thread sealants such

as Teflon paste only on pipe threads that will not come in contact

with the oil flow.

3. A purge of the oil nozzle should be conducted after burner

shutdown. To do so, connect a line between the atomizing

medium and the oil piping just upstream of the oil nozzle, and

install check valves in this line and the oil piping.

Atomizing steam considerations

Atomizing steam must be dry and superheated to at least 20° F

1.

above saturated at the burner inlet. Therefore, this piping line must

be insulated up to the burner inlet. Provisions must also be made

for continuous condensate disposal via a steam trap and drain.

Compressed air considerations

1. When compressed air is used for atomization, it is possible for

water and oil vapor from the air compressor to contaminate the

atomizer. Therefore, include preventative measures against this

possibility when designing the air distribution system.

2. ALL compressors should be equipped with a suitable aftercooler,

oil separator, and automatic traps or drain valves.

3. When compressed air is used for atomization of heavy oils (#5

or #6), preheat the air to a temperature between 220° and

270°F and insulate the air lines.

Pilot gas considerations

1. ALL supplied gas pilot piping (natural, propane, etc.) MUST be

fitted with a pilot gas pressure regulator.

2. ALL supplied gas pilot piping (natural, propane, etc.) SHOULD BE

fitted with an adjustable orifice valve for pilot gas flow adjustment.

3-9Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 20

Strainers

No matter what fuel is used, it is essential that the valve train

components, the atomizer and the fuel oil tip be protected from

foreign material damage. Therefore, it is suggested that strainers be

used as follows:

Oil valve trains

1. It is recommended that an edgeplate type filter with 0.0035"

separations (170 mesh) be used UPSTREAM of all valve train

components.

2. It is recommended that a strainer with 100 mesh screen be used

ADJACENT to the oil gun inlet.

Atomizing valve trains

It is recommended that a strainer with 1/32" diameter perforated or

20 mesh screen be used UPSTREAM of all valve train components

for steam or compressed air applications.

Fuel gas valve trains

It is recommended that a strainer with 1/32" diameter perforated or

20 mesh screen be used UPSTREAM of all valve train components.

Atomizing control methods

There are two possible control methods for atomizing air and steam:

1. Fixed: If the burner’s turndown ratio requirement does not

exceed 5:1, then the atomizing pressure at the burner may be

set to run constantly at 50/55 psig, eliminating the need for a

differential pressure regulator.

2. Modulating: Use a differential pressure regulator which is “top

loaded” with the oil pressure at the nozzle, which allows the

atomizing pressure to increase proportionally with the oil

pressure. To do so, set the atomizing pressure approximately 20

psig above the oil pressure, but not exceeding 50/55 psig. To

ensure this maximum pressure is not exceeded, adjust the

pressure regulator for the incoming atomizing supply to not

exceed 50/55 psig.

3-10

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 21

INSTALLING AND

CURING

BLOCK

REFRACTORY

It is the customer’s choice whether the combustion refractory

block is factory or field installed. The following provisions deal with

installing either choice. The standard, general purpose refractory

for Vortometric combustor blocks is Plibrico 80 Air Bond with an

80% alumina plastic ramming mix.

Factory installed refractory

The Eclipse factory installed refractory has been oven cured at

relatively low temperatures to remove most of the water content.

However, some residual water may still be present and must be

removed at the initial start-up.

After the burner and refractory have been installed, the following

steps will ensure proper curing and maximum strength to reduce

chances of cracking or spalling:

1. Set the combustion air at its minimum input.

2. Light only the pilot and leave on for approximately three hours.

3. After three hours, light the main burner at the minimum input.

4. Increase the heat input by 150°F per hour.

5. Water evaporation (steam) is usually heaviest and most

prominent around 1,000°F. If steam is still prevalent after the

hour at 1,000°F, hold at that temperature for two to three more

hours or until the steam stops.

Caution:

If at anytime during the curing process visible steam rises from

the refractory, hold the temperature until it dissipates.

6. Once steam stops coming from the refractory, assume the 150°F

temperature rise per hour until you reach 2,000°F.

7. Hold at 2,000°F for three to four hours to ensure proper curing.

3-11Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 22

Field installed refractory

The customer is responsible for supplying all refractory materials

for field installation as follows:

1. Cover the inside surfaces of the combustor shell with an 1/8"

layer of Plibrico “Plisulate” fibrefax paper or equivalent.

2. Install alloy anchors in the combustor shell according to the

refractory supplier’s recommendations. The alloy anchors should

be coated with bitumastic wherever they protrude through the

layer of Plibric Plisulate.

3. Install the chosen refractory, realizing it is essential that:

• the combustion block dimensions are held as given on Eclipse

drawings

• the inside diameter of the combustion block be concentric

with the air cone in the burner.

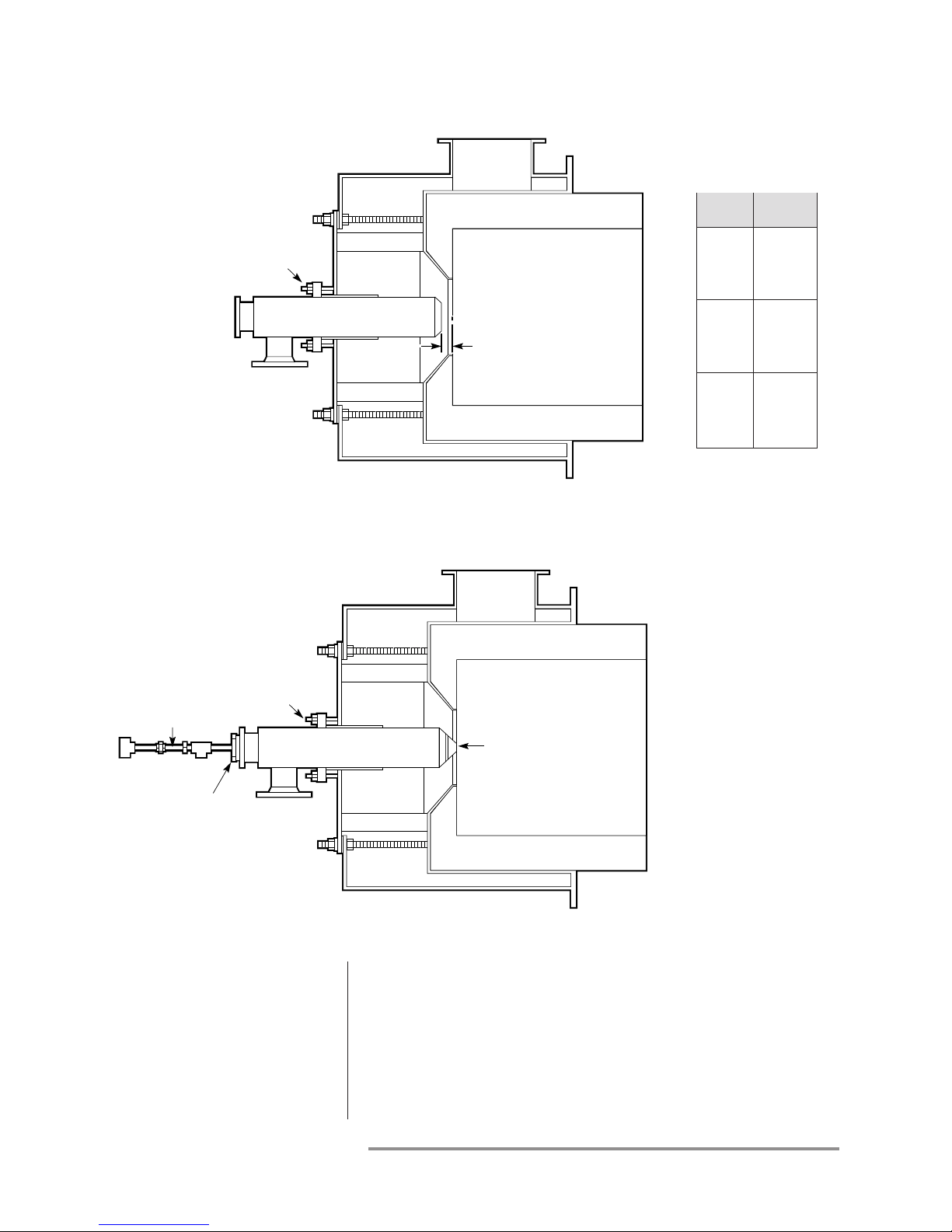

Refer to Figure 3.3 for wall interface, and typical refractory

installation details and recommendations.

4. The refractory should then be pounded into place with a

pneumatic rammer, starting around the air cone. Use care in

ensuring that the specified contours and dimensions on the

aforementioned Eclipse drawing are maintained. Provide vent

holes so moisture can escape during dry-out.

Note:

The corner angle between the cone and the sidewall must be

90° or slightly less, but NOT MORE.

After the burner and refractory have been installed, the following

steps will ensure proper curing and maximum strength to reduce

chances of cracking or spalling:

1. Set the combustion air at its minimum input.

2. Light only the pilot and leave on for approximately three hours.

3. After three hours, light the main burner at the minimum input.

4. Increase the heat input by 100°F per hour.

5. Water evaporation (steam) is usually heaviest and most

prominent around 1,000°F. If steam is still prevalent after the

hour at 1,000°F, hold at that temperature for two to three

more hours or until the steam stops.

Caution:

If at anytime during the curing process visible steam rises from

the refractory, hold the temperature until it dissipates.

6. Once steam stops coming from the refractory, assume the 100°F

temperature rise per hour until you reach 2,000°F.

3-12 Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

7. Hold at 2,000°F for three to four hours to ensure proper curing.

Page 23

Figure 3.3 Vortometric Burner Mounting Arrangements

Suggested Mounting Arrangement

For Standard Burner

Provide adequate

shell stiffeners

Furnace backstay

229mm (9")*

Flange position on standard burner allows correct shell dimension above

*178mm (7") for 6V and 8V medium intensity burner sizes.

Furnace shell plate

Weld heads of mounting bolts inside furnace shell plate.

Allow for 3mm (1/8") thick, high temperature gasket

between the burner flange and shell plate.

90 hold

Ring

Smooth refractory

flush with throat

3mm (1/8") high temp. gasket

(Customer supplied)

To allow for thermal expansion of combustion liner extension,

the main wall should be constructed with an opening 25mm (1") greater

in diameter than diameter of combustion liner.

The outside of combustion liner should be covered with 1/8" thick

insulating paper. The remaining gap between the burner and main wall

should be densely packed with ceramic fiber or wool blanket insulation.

General Notes:

1. Mounting illustrations show typical Vortometric combustor blocks of high alumina

plastic refractory as used by Eclipse for normal duty.

2. The dimensions given must be held as specified, and the inner diameter of the

combustor must be round and concentric with the throat cone.

3. Alloy rod-type anchors welded inside the combustor block are the customer’s

responsibility if the refractory is field installed rather than factory installed.

4. All mounting arrangements are meant for vertically or horizontally fired burners.

Regardless of orientation, the refractory block MUST be protected from thermal

expansion of the furnace wall.

Alternate Mounting Arrangement

For Thick Walls

229mm to 457mm

2

5

431

(9" to 18")

229mm (9") minimum

6

7

Alternate Mounting Arrangement

For Thin Walls

152mm (6")

minimum

for standard

burner mounting

76mm (3")

maximum

projection

Main flame

scanner

Burner mounting

box by customer

Cup angle or special anchor

fitting welded to shell plate

1

Furnace Backstay

2

Furnace Shell Plate

3

Block Insulation

30

4

Insulated Fire Brick

5

Fire Brick

6

Castable Refractory Ring (Alternate Plastic)

7

Refractory or Alloy Anchor

(305mm to 457mm or 12" to 18" apart)

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

3-13

Page 24

CHECKLIST AFTER

INSTALLATION

To make sure that the system is installed correctly, do the steps that

follow:

1. Make sure that there are no leaks in the gas lines.

2. Make sure that the blower rotates in the correct direction. If

incorrect, then have a qualified electrician rewire the blower to

reverse its rotation.

3. Set the air proving switch.

4. Set the low gas pressure switch.

5. Set the high gas pressure switch.

6. Close all the burner gas cocks.

7. Trip out pressure switches and other limit interlocks. Make sure

that the main gas valves close.

Danger:

If simulated limits or simulated flame failures do

not shut down the fuel system within the required

failure response time, then immediately correct the

problem.

3-14

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 25

Adjustment, Start & Stop

4

INTRODUCTION

ADJUSTMENT

PROCEDURE

In this chapter you will find instructions on how to adjust a system

and how to start and stop a system.

Danger:

Do not bypass any safety features. You can cause fires

and explosions.

Obey the safety precautions in the Safety chapter.

Read all of this chapter before starting your system.

If you are adjusting the burner system for the first time, then you

must follow these steps:

1. Reset the system

2. Set combustion air pressure drop

3. Verify the air settings

4. Ignite the pilot

5. Ignite the burner

6. Set low fire fuel flow

Step 1: Reset the system

7. Set high fire fuel flow

8. Verify the settings

Close the automatic gas valves and the gas cocks.

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

4-1

Page 26

Step 2: Set low fire

combustion air pressure

drop

1. Start the combustion air fan.

2. Set the air control damper to produce the desired pressure

drop across the burner. Air pressure drop should be read as a

differential pressure between the windbox pressure test port

and the chamber. See the combustion air pressure drop versus

air flow curves (Tables A.1 and A.2 in the Appendix).

Step 3: Verify air settings

Step 4: Ignite the pilot

Table 4.1 Pilot Capacities

Burner

Size Main Burner Pilot

6V 6,000,000 60,000

8V 10,500,000 105,000

10V 17,000,000 170,000

12V 23,000,000 230,000

14V 32,000,000 320,000

16V 42,000,000 420,000

18V 55,000,000 550,000

22V 78,000,000 780,000

24V 90,000,000 900,000

28V 125,000,000 1,250,000

32V 160,000,000 1,600,000

36V 210,000,000 2,1000,000

Input (Btu/hr.)

Make sure that all the settings are still the same after you cycle the

system several times between high fire and low fire. Check air

proving switch and adjust if necessary.

Note:

Test spark ignitor with a visual or audible check before

attempting ignition.

1. Set system to operate on pilot only. See the literature included

with the flame monitoring relay.

2. Set pilot regulator to 6"w.c. outlet pressure.

3. Open the pilot adjusting valve two turns.

4. Initiate start sequence and ignite the pilot.

Note:

Initially it may be necessary to repeat step 4 two or three times

to purge air out of the gas pipework.

5. Trim pilot with adjustable gas cock to obtain pressure drops of:

• 1.5" to 2.0"w.c. for natural gas

• 0.6" to 0.9"w.c. for propane, butane

Refer to Table 4.1 at left for pilot input capacities. Pressure drop

is differential between pilot gun inlet and chamber.

Note:

The pilot flame should be a bushy, blue flame which curls

around the main gas/oil gun nozzle. This flame should provide a

stable pilot with good flame signal readings sufficient to

energize the main gas valve.

4-2

6. If necessary, adjust the position of the U.V. scanner to ensure

good pilot flame detection.

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 27

Step 5: Ignite the burner

Note:

This procedure assumes that automatic flame safety is installed

and is serviceable.

For Gas Burners

1. Make sure the supply air fan is running.

2. Adjust the main gas regulator to supply the minimum pressure

required; see the Appendix for gas pressure drop information.

3. Verify that the main gas control valve is at its minimum open

position.

4. Light the pilot.

5. Open all manual fuel shut-off valves.

6. Initiate the ignition sequence through the flame safety.

7. Check that the pilot and main burner flames have ignited.

8. The gas flame should be a pale blue color set inside the

refractory combustion block.

Note:

Combination gas/oil burners may be operated on gas with the

oil gun in place provided that the atomizing medium is left on

at a minimum pressure of 5 to 10 psig. When shutting down,

leave the atomizing medium on until the block and combustion

chamber are cool.

Combination gas/oil burners may also be operated with the oil

gun and oil gun gland removed; see Figure 3.2 on page 3-5 for

gland “A” identification and location. When doing so, a blanking

plate must be substituted for gland “A” at the rear of the gas gun.

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

4-3

Page 28

For Oil Burners

1. Make sure the supply air fan is running.

2. Adjust the main oil regulator to supply the minimum pressure

required; see the Appendix for oil nozzle pressure drop information.

3. Turn on the atomizing medium and adjust atomizing pressure

to approximately 20 to 30 psig.

Note:

If using heavy oil as the fuel with either steam or preheated air

for atomization, then warm up the oil feed pipe and fuel oil

nozzle by running the atomizing medium through the burner

bypass valve. Leave this bypass valve open for 5 to 10 minutes.

4. If steam is being used for atomization, allow plenty of time to

drain the system of accumulated condensate and ensure steam

traps are working.

5. Verify that the main oil control valve is at its minimum open

position.

6. Light the pilot.

Step 6: Adjust low fire

Step 7: Adjust high fire

7. Open all manual fuel shut-off valves.

8. Initiate the ignition sequence through the flame safety.

9. Check that the pilot and main burner flames have ignited.

10. The oil flame should be a bright yellow color set inside the

refractory combustion block.

Note:

The first time that the burner is started, allow the refractory

combustion block to warm up slowly to reduce thermal shock.

Refer to “Installing and Curing Refractory Block” in Chapter 3

for details.

If necessary, adjust the main control valve’s minimum open position

to obtain the desired low fire setting.

For Gas Burners

1. Drive the main gas control valve to high fire.

2. Measure the gas pressure drop at high fire and compare to the

appropriate chart in the Appendix. If the maximum input is not

4-4

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 29

achieved or is too high while the main gas control valve is fully open,

two adjustments can be made:

a. the main gas control valve can be adjusted open or closed, or

b. the main gas pressure regulator can be adjusted higher or lower.

3. The main gas flame should have a slightly blue periphery and a

somewhat yellowish center at high fire; refer to Table 4.2 below

for flame length estimates.

For Oil Burners

1. Drive the main oil control valve to high fire.

2. Measure the oil pressure drop at high fire and compare to the

appropriate chart in the Appendix. If the maximum input is not

achieved or is too high while the main oil control valve is fully open,

two adjustments can be made:

a. the main oil control valve can be adjusted open or closed, or

b. the main oil pressure regulator can be adjusted higher or lower.

3. Note the atomizing air pressure. If modulating control is used,

the atomizing pressure should be approximately 20 psig above

the oil pressure without exceeding 50/55 psig.; refer to

“Modulating Control” on page 3-10 for further details.

Step 8: Verify settings

4. The high fire oil flame should be bright yellow; refer to Table 4.2

below for flame length estimates.

1. Once the high and low fire conditions have been set, cycle the burner

from high to low fire several times to check repeatability of settings.

2. Shut down the burner and relight to ensure automated pilot and

main flame ignition operates correctly.

3. Check all safety interlocks and limits to ensure proper operation.

Table 4.2 Flame Sizes

Burner Input Flame MI* HI*

Burner MI or HI*

Size (MMBtu/hr.) Dia. (in.) Burner Burner

6V 6.0 30 6.0 5.0

8V 10.5 32 7.0 6.0

10V 17.0 36 8.0 7.0

12V 23.0 40 9.0 8.0

14V 32.0 46 10.5 9.0

16V 42.0 52 12.0 10.0

18V 55.0 58 13.0 11.0

22V 78.0 64 15.0 13.0

24V 90.0 68 16.0 14.0

28V 125.0 78 18.0 16.0

32V 160.0 86 20.0 17.0

36V 210.0 96 24.0 20.0

* MI means Medium Intensity and HI means High Intensity.

Flame Length (ft.)

Note:

Flame lengths are measured

from the open end of the

combustor.

Flame lengths are estimates

based on general operating

conditions and are useful for

design purposes. Actual flame

lengths will depend on

chamber size and presence of

secondary air.

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

4-5

Page 30

STA RT PROCEDURE

1. Start the air supply fan.

2. Open all the gas or oil cocks.

3. Start the automatic ignition sequence.

Danger:

If a burner does not light, and the system does not

shut down automatically, then you must close the

main gas cock on gas burner systems. An uncontrolled

flow of gas can cause fires and explosions.

Do not touch the ignition plug or the ignition wire

when the ignition is on. You will get a shock.

4. Make sure that you can see the flame in the burner system.

If the burner system does not light and

– the system does not shut down automatically:

then close the main gas or oil cock manually. DO NOT

operate the system. Go to “Checklist after Installation” on

page 3-8 and verify the steps. After that, repeat the start

procedure.

– the system shut downs automatically:

then see the “Trouble-shooting” Tables in the next chapter.

4-6

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 31

STOP PROCEDURE

For Gas Burners

1. Drive combustion air and gas valves to low fire position.

2. Shut off main gas supply valves and pilot.

3. Leave combustion air at low fire until combustion chamber and

block are cooled; once cooled, shut off combustion air fan.

4. Shut off all manual valves as required.

For Oil Burners

1. Drive combustion air and fuel valves to low fire position; shut

down the oil supply.

2. Turn on the pilot.

3. Purge the oil nozzle with the atomizing medium through the

bypass connection valves.

4. When the oil nozzle is clear of oil, then turn off the pilot.

5. Leave combustion air and atomizing medium on until the

combustion chamber and block are cooled; once cooled, shut off

the combustion air and atomizing medium supplies.

6. Shut off all manual valves as required.

4-7Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 32

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 33

Maintenance &

Trouble-shooting

5

INTRODUCTION

MAINTENANCE

SCHEDULES

This section is divided into two parts:

• The first part describes the maintenance procedures.

• The second part helps you to identify problems that may occur,

and gives advice on how to solve these problems.

Preventative maintenance is the key to a reliable, safe and efficient

system. The following are sugested guidelines for periodic

maintenance. Burners in severe environments or operational

conditions should be checked more frequently.

Note:

The monthly and yearly lists are an average interval. If your

environment is dirty, then the intervals may be shorter. Check

with local authorities having jurisdiction on their recommended

maintenance schedules.

Caution:

Turn off power to burner and controls before proceeding with

burner inspection.

Monthly Checklist

1. Inspect flame-sensing devices for good condition and cleanliness.

2. Test all alarms for proper signals.

3. Check ignition spark electrode operatin and check proper gap.

4. Check all valve motors and control valves for free, smooth

action and adjustment.

5. Test interlock sequence of all safety equipment and manually

make each interlock fail, noting that related equipment closes

or stops as specified by the manufacturer. Test flame safeguard

by manually shutting off gas to burner.

6. Test all manual fuel valves for operation.

7. Check filters on main air fan for cleanliness.

8. Check gas filter or strainers.

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

5-1

Page 34

Yearly Checklist

1. Test (leak test) safety shut-off valves for tightness of closure.

2. Test pressure switch settings by checking switch movements

against pressure settings.

3. Visually check ignition cable and connectors.

4. Check the refractory combustion block to ensure that it is not

badly cracked or spalled. Minor hairline cracks are of no

consequence and should be considered normal. Examine the

refractory around the throat cone, since this area is where

breakage can easily occur. If repairs are needed to this area,

ensure that any new refractory is installed to the original

contours and surface texture.

5. Remove the pilot assembly and examine the ceramic insulators

on the spark rods. Clean the spark rod end with a fine emery

cloth. Adjust the spark gap to no more than 1/8".

6. Remove the gas gun assembly and clean the gas orifices. Use

compressed air to blow all scale or dust out of the ports.

7. Remove the oil gun assembly, and clean the oil injection orifices

and atomizing air nozzles according to the instructions that

follow in this chapter.

MAINTENANCE

PROCEDURES

Fuel Oil Tip Cleaning

Vortometric burner sizes 6V through 12V use an oil nozzle held by

a retaining ring. With these sizes, the nose cone assembly must be

unscrewed from the body to remove or replace the entire tip.

Vortometric burner sizes 14V and larger use an oil nozzle which is

made in two pieces, which allows the outer end of the tip to be re-

moved from the nozzle body. Therefore, the tip head containing the

oil orifices can be removed for cleaning without dismantling the en-

tire atomizer.

Note:

On a burner with CLOCKWISE air rotation, the tip head has LEFT

HAND threading. On a burner with COUNTERCLOCKWISE air

rotation, the tip head has RIGHT HAND threading.

5-2

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 35

Table 5.1 Fuel Oil Tip Data

Burner No. of Hole Drill

Size Holes Dia. (in.) Size

6V 4 .0400 60

8V 6 .0400 60

10V 6 .0469 3/64

12V 9 .0430 57

14V 10 .0469 3/64

16V 10 .0550 54

18V 12 .0595 53

22V 12 .0670 51

24V 12 .0730 49

28V 12 .0860 44

32V 12 .0980 40

36V 16 .0980 40

When inspecting and cleaning the fuel oil tips, please observe

the following:

• Vortometric oil nozzles are manufactured of stainless steel, with

all surfaces manufactured to close tolerances and highly polished.

Therefore, avoid marring the nozzle’s machined surfaces in any

way when the atomizer is dismantled.

• Never use abrasive cleanser or emery cloth on the internal sur-

faces of the nose cone. However, a wire brush may be used on the

outside surfaces of the nose cone where carbon has accumulated.

If the oil tip holes become blocked, you cannot clear the blockage by

forcing the atomizing medium through them. Instead, the tip must be

removed and cleaned out. Care should be taken when dismantling

and cleaning the oil tip to avoid burring or other damage. After removing the tip, the recommended cleaning procedure is as follows:

1. Soak the tip in a solvent such as Varsol, especially if the atomizer

has been used with heavy oil.

2. Blow out the tip with compressed air in the reverse direction to

the oil flow.

3. Wash the tip again in solvent.

4. Select the correct drill size needed from Table 5.1. Use a new bit

to avoid potential marring. Insert the drill bit by hand into each

hole in the oil tip to clear any hard carbon or other residue.

Caution:

Forcing an oversized drill bit into the oil tip holes will ruin the tip.

5. Repeat Step 2.

6. Repeat Step 3.

7. Before reassembling the oil tip in the atomizer assembly, clean

out the oil feed pipe with either compressed air or solvent as

necessary.

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

5-3

Page 36

Dismantling of Atomizer

Note:

Refer to Figure 5.1 for oil nozzle component identification and

location.

1. Remove the complete oil gun from the burner by removing the

bolts on the rear flange of the gun assembly.

2. Place the oil gun in a pipe vise.

3. Loosen the bolts on the packing gland at the rear (outer) end of

the oil gun.

4. Using a spanner wrench, loosen the nose cone assembly, which

has a standard right hand thread.

5. After freeing the nose cone assembly from the threaded portion

of the body, pull the nose cone foward enough to expose the

base and tip retaining ring.

6. Using two adjustable wrenches, loosen the retaining ring from

the base, then slide the retaining ring back on the fuel pipe to

expose the wrench flats on the end of the oil tip.

7. Using an adjustable wrench on the flats of the oil tip, grasp the

nose cone assembly and rotate it while pulling it foward. This

action separates the nose cone inlet ring and base assembly from

the tip. Be careful not to lose or damage the spacer washers.

8. Remove the oil tip by using a pipe wrench on the fuel oil feed

pipe and an adjustable wrench on the oil tip flats.

9. Refer to the previous section, “Fuel Oil Tip”, for the proper oil

tip cleaning procedure.

10. If you need to dismantle the atomizer further, then remove the cap

screws and carefully separate the nose cone, inlet ring and base.

11. Wash all parts with a solvent such as Varsol. Wipe all parts

clean of any foreign material.

Note:

Due to the tight fit between the oil tip and base, no foreign

material can be left on the tip’s outside surface OR the base’s

inside surfaces. Foreign material such as grit can cause scoring

of these surfaces and possible binding of the two surfaces. If

necessary, a very fine emery cloth may be used to restore them.

5-4

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 37

12. Referring to Table 5.2, select the correct drill size. Use this drill

bit to check the hole diameters of the venturi inlets in the

tangential inlet ring. If the holes are worn beyond the

corresponding maximum throat diameter number shown in

Table 5.2, then replacing the venturi insert should be

considered.

13. Examine the flat faces of the base and nose cone, which form

the front and rear of the vortex chamber, respectively. Although

slight “dimpling” of the surfaces adjacent to the inlet holes is

normal, pitting and scoring is not. Clean these surfaces with

solvent if they appear oily or sooty.

14. Clean any accumulated carbon from the internal bore of the

nose cone, but do not scratch or mar these surfaces.

Figure 5.1 Atomizer Assembly Components

1

Atomizing Medium Inlet

2

Oil Inlet

3

Oil Nozzle Retaining Ring

4

Body

5

Spacers

6

Base

7

Inlet Ring

8

Nose Cone

9

Oil Nozzle

12

3

5

4

68

9

7

Table 5.2 Atomizing Inlet Ring Data

Orig. Max. Max.

Insert Orig. Worn Worn

Burner No. of Throat Drill Throat Drill

Size Inserts Dia. (in.) Size Dia. (in.) Size

6V 6 .0760 48 .0820 45

8V 6 .0995 39 .1093 7/64

10V 6 .1250 1/8 .1360 29

12V 6 .1440 27 .1570 22

14V 6 .1695 18 .1875 3/16

16V 6 .1935 10 .2130 3

18V 6 .2130 3 .2340 A

22V 10 .1960 9 .2130 3

24V 10 .2090 4 .2280 1

28V 10 .2420 C .2656 17/64

32V 10 .2720 I .2968 19/64

36V 10 .3020 N .3320 Q

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

5-5

Page 38

Assembly of Atomizer

1. With all of the parts clean of foreign material, put a smear of

anti-seize compound or similar lubricant on all mating surfaces

and on all threads.

2. Slide the retainer ring onto the fuel pipe.

3. Screw the fuel pipe into the oil tip and tighten securely.

4. Assemble the base and inlet ring onto the nose cone using the

provided cap screws. Tighten all cap screws securely and evenly.

The tangential inlet ring can provide either clockwise or

counterclockwise rotation to the steam. However, the steam’s

rotation direction (as viewed through the rear of the atomizer)

MUST match the rotation direction of the air flow through the

burner assembly’s vanes.

5. Install a new oil tip spacer (standard size of 0.030") on the oil tip,

and insert the tip into the atomizer base. Step 7 details what size

of spacers should be used to properly locate the oil tip.

6. Tighten the retainer ring securely, using the wrench flats on the

ring and on the base.

7. Check the relationship of the oil holes to the nose cone by

inserting the specified drill from Table 5.1 into the oil holes as

shown at left. The drill’s sides should JUST TOUCH the nose

cone’s lip. If you have trouble inserting the drill into the oil holes,

there are two probable causes:

a. if the drill cannot be inserted easily, then the oil tip is too far

back in the nose cone; a thinner spacer is needed so the oil

tip can come further forward, or

b. if there is an obvious space between the drill and the nose

cone lip, then the oil tip is too far forward; more spacers are

needed to move the tip further back.

5-6 Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Each atomizer assembly is provided with three spacers of nominal

thickness from 0.010" to 0.030"; the 0.030" spacer is the one

generally used on the assembly. Depending on your situation, any

one or combination of these spacers may be necessary to

correctly locate the oil jets.

8. Once the oil tip is correctly located, loosen the packing gland

at the outer end of the atomizing steam pipe. Insert the entire

atomizer assembly, including the fuel pipe, into the body and

atomizing steam pipe.

9. Screw the nose cone assembly into the body threads, being

careful not to get it cross-threaded. Tighten the assembly

securely with a spanner wrench.

Page 39

10. Tighten the packing gland at the outer end of the atomizing

steam pipe. A final check on the location of the oil holes in

relation to the nose cone lip can be done as follows:

a. Connect the oil feed line to a water supply line and spray

water out of the nozzle at 5 PSIG.

b. If properly located, then the water streams emerging out of

the oil holes should be separate, distinct and uniform; the

water streams should also clear the inside lip of the nose

cone or just barely touch the lip’s edge.

11. Reinstall the oil gun into the burner and connect all hoses securely.

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

5-7

Page 40

TROUBLE-SHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Table 5.1 Trouble-shooting

Cannot initiate start-up sequence.

Air pressure switch has not made contact:

• Air flow too low.

• Air pressure switch incorrectly set.

• Air pressure drop measured incorrectly.

High gas pressure switch has tripped:

• Gas pressure too high.

• Gas pressure switch set too low.

Low gas pressure switch has tripped:

• Gas pressure too low.

• Gas pressure switch set too high.

Purge cycle not completed.

Main power is off.

Check air flow and investigate any changes.

Check air pressure switch adjustment.

Move pressure taps on chamber to a

better location.

Check incoming gas pressure against

initial settings; adjust as required.

Adjust setting to be approximately

4" w.c. above gas pressure.

Check incoming gas pressure against

initial settings; adjust as required.

Adjust setting to be approximately

4" w.c. below gas pressure.

Check flame safeguard system or purge timer.

Make sure power is on to control system.

No power to control unit.

Malfunction of flame safeguard system:

• Flame sensor shorted out.

• Electrical noise in sensor line.

• Unit is broken.

Call qualified electrician to investigate.

Check UV sensor and wiring.

Shield or separate sensor lines from

high voltage.

Call qualified electrician to investigate.

5-8

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 41

TROUBLE-SHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Table 5.1 Trouble-shooting

Start-up sequence runs but pilot does

not light.

No spark:

• No power to ignition transformer.

• Open circuit between the ignition

transformer and the spark plug.

• Spark plug has carbon build-up.

• Spark plug not correctly grounded.

• Spark plug gap is incorrect.

• Spark is shorting inside pilot pipe

Not enough pilot gas:

• Pilot gas regulator set too low.

• Gas pressure into pilot regulator too low.

• Pilot gas cock closed.

• Pilot solenoid valve does not open.

• Pilot adjusting valve set too low.

Have electrician investigate.

Repair or replace wiring to spark plug.

Clean or replace spark plug.

Clean spark plug threads. Do not apply

grease or pipe compound to pipe threads.

Set gap to 1/8".

Remove spark plug and clean inside

of pipe and star insulators.

Check incoming gas pressure against

initial settings; increase as necessary.

Check outgoing gas pressure of main

regulator; increase as necessary.

Open pilot gas cock.

Have qualified electrician check

power supply to solenoid.

Adjust gas flows to give pressures/

flows indicated on page 4-2.

• Air in the gas line.

Too much gas.

Repeat start-up several times to

purge air out of gas lines.

Trim pilot gas adjusting valve to give

pressures/flows indicated on page 4-2.

5-9Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 42

TROUBLE-SHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Table 5.1 Trouble-shooting

Start-up sequence runs, pilot lights but

main burner does not light.

Pilot ignites but flame safeguard shuts

down burner.

Burner kicks out shortly after start-up.

No UV signal.

Not enough main fuel:

• Main fuel regulator set too low.

• Fuel pressure into main regulator too low.

• Main fuel cock closed.

• Main safety shut-off valve does not open.

• Main fuel control valve set too low.

• Air in the gas line.

• No fuel oil to nozzle.

Too much gas.

No UV signal.

Low main fuel pressure switch is set too

high.

Check wiring and control logic.

Check outgoing fuel pressure of main

regulator; increase as necessary.

Check incoming fuel pressure against

initial settings; increase as necessary.

Open all fuel cocks.

Have qualified electrician check

power supply and safety circuitry.

Adjust fuel flows to give pressures

indicated in Appendix.

Repeat start-up several times to

purge air out of gas lines.

Repeat start-up several times to fill

oil lines and nozzle. Reduce piping

length if necessary.

Trim control valve to give pressure

indicated in Appendix.

Check wiring and control logic.

Adjust position of UV sensor with

swivel mount.

Check and reset low pressure switch

setting.

The low fire flame is weak and

unstable.

Burner does not go to high fire.

Main flame is uneven and not

centered in the refractory block.

Main flame pulsates or is unstable.

5-10

• Not enough fuel.

• Too much air.

• Not enough fuel pressure into main fuel

regulator.

• Fuel pressure drops as input is increased.

• Main fuel control valve is not functioning.

• Incorrectly positioned gas/oil gun.

• Unstable air flow.

• Unstable fuel flow.

• Pilot gun inserted too far.

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Check start-up settings and adjust to

increase fuel flow.

Check combustion air pressure drops/

flow across the burner and adjust.

Adjust pressure regulator so pressure

is provided at burner as specified in

this manual.

Check for clogging of valves and

regulators in fuel line.

Check actuator and linkage.

Ensure gas/oil gun is centered within

the throat cone.

Check blower/air system for

pressure pulsations.

Check pressure regulator and

control valve for pulsations.

Pull back pilot gun.

Page 43

TROUBLE-SHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Table 5.1 Trouble-shooting

Main flame is too large at high fire.

Main flame does not achieve

capacity.

Main flame is yellow and long (in gas

applications)

OR

Main flame appears a dull orange

color (in oil applications).

Main oil flame is white and hard.

Uneven oil flame with stingers

shooting out to one side of the block.

• Fuel pressure too high at burner inlet.

• Combustion air pressure drop/flow is

too low.

• Combustion air pressure drop/flow is

too high.

• Burner is firing below rated input.

• Burner gas holes/oil ports are plugged.

• Air pressure drop/flow is lower than

design.

• Windbox air flow is restricted.

Too much air.

Orifices in the oil tip are plugged.

Check fuel pressure against design.

Adjust main fuel pressure regulator, or

adjust control valve.

Open air damper on main air blower.

Check pressure drop or flow. Check

air damper on main air blower.

Check fuel pressure differential/flow.

Adjust main fuel pressure regulator as

necessary.

Inspect holes/ports for blockage; clean

as needed.

Check pressure drop or flow. Open air

damper on main air blower.

Inspect windbox and blower to ensure

that no foreign material is restricting

the air flow.

Check combustion air pressure drop/

flow. Close control damper as necessary.

Remove oil nozzle and clean as necessary.

Orange or red “sparklers” in the oil

flame.

Flame temporarily becomes black

and smokey, then clears up again

OR

Flame sputters and goes out

momentarily.

Fiery ring of burning oil on the inside

diameter of the combustor surface

OR

Carbon deposits on the inside of the

refractory block.

Carbon accumulation on the oil

nozzle cone.

• The oil is too cold.

• The atomizing medium pressure is too

low.

Moisture (condensate) in the atomizing

medium.

Poor atomization.

Oil nozzle is too far forward into the

throat.

Check oil heating system; increase

temperature as necessary.

Check existing atomizing pressure

versus required (see table in Appendix).

Ensure that the condensate trap is

operating properly for atomizing steam.

Install dryers in the atomizing air line.

Check atomizing pressure and adjust as

necessary.

Check oil nozzle ports for clogging.

Move gun back 1/4" at a time until

carbon no longer accumulates.

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

5-11

Page 44

Appendix

FLOW AND INPUT

CHARTS

7.5

0.8

0.6

0.4

Table A.1 Combustion Air Pressure Drop vs. Burner Heat

Input for Medium Intensity Burners (MI)

•

Operation with 15% excess air on natural gas under standard conditions

(14.7 psia @ 70°F).

• Pressure drop should be taken between the chamber and windbox pressure tap.

8V 10V

6

5

4

3

2

1

6V

12V

16V 22V 28V

14V

18V 24V 32V 36V

0.2

Combustion Air Pressure Drop ("w.c.)*

0.1

0.6 0.8 1 2 4 6 8 10 20 40 60 80 100 200 300

A-1

Burner Gross Heat Input (MMBtu/hr.)

* 7.5"w.c. is the nominal design pressure drop for all models,

except for model 6V of the medium intensity burners.

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 45

Table A.2 Combustion Air Pressure Drop vs. Burner Heat

Input for High Intensity Burners (HI)

• Operation with 15% excess air on natural gas or #2 oil under standard conditions

(14.7 psia @ 70°F).

• Pressure drop should be taken between the chamber and windbox pressure tap.

7.5

6

5

4

3

2

1

0.8

0.6

0.4

0.2

Combustion Air Pressure Drop ("w.c.)

0.1

0.6 0.8 1 2 4 6 8 10 20 40 60 80 100 200 300

6V 8V 10V

12V

16V 22V 28V

14V

18V 24V 32V 36V

Burner Gross Heat Input (MMBtu/hr.)

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

A-2

Page 46

Table A.3 Gas Gun Press. Drop vs. Burner Heat Input

• Pressure drops for natural gas, 1,000 Btu/SCF gross, 0.6 specific gravity.

• Pressure drop should be taken as differential between the chamber and gas gun

pressure tap.

Note:

Fuel pressure drop curves should be used as a guide for setting up

burner. It is recommended to use a direct fuel flow measurement

(orifice plate or flow meter) for calculating actual fuel flows.

24

20

10

8

6

4

2

6V 8V

Gas Gun Pressure Drop ("w.c.)*

1

6421 8 10 20 40 60

Burner Gross Heat Input (MMBtu/hr.)

or Natural Gas Flow (1000’s SCFH)

45

30

20

10V 12V 14V 16V

18V

22V

24V

28V

32V

36V

A-3

10

8

6

4

2

Gas Gun Pressure Drop ("w.c.)*

1

6421 8 10 20 40 60 100 200 300

Burner Gross Heat Input (MMBtu/hr.)

or Natural Gas Flow (1000’s SCFH)

* Nominal pressure drop at maximum capacity is 24"w.c. for

6V through 16V models, and 45" w.c. for all other models.

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10/07

Page 47

Table A.4 Oil Nozzle Press. Drop vs. Burner Heat Input

10

60402010 80 100 1,000200 400 600

20

30

15

40

50

60

Atomizing Air Flow (SCFM)

Atomizing Air

Pressure Drop (psig)

8V6V10V 12V 14V 18V 22V 28V 36V

16V 24V 32V

• Pressure drops for #2 Oil with 137,000 Btu/lb. gross heating value.

Note:

Fuel pressure drop curves should be used as a guide for setting up

burner. It is recommended to use a direct fuel flow measurement

(orifice plate or flow meter) for calculating actual fuel flows.

60

40

6V

20

10

8

6

4

Oil Nozzle Pressure Drop (psig)

2

6421 8 10 20 40 60 80 100 200 300

Burner Gross Heat Input (MMBtu/hr.)

Table A.5 Atomizing Air Pressure Drop vs. Air Flow

• When air is used for atomization of heavy oil, it should be preheated to

approximately the same temperature as the oil.

8V

10V

12V

14V

16V

18V

22V

28V 36V

24V

32V

Eclipse Vortometric Burner v2.00, Installation Guide 248, 4/10///

A-4

Page 48

Table A.6 Atomizing Steam Press. Drop vs. Steam Flow

• Atomizing steam must be dry and superheated a minimum of 20°F above

saturated at the atomizer inlet.

60

50

40

30

20

15

Atomizing Steam

Pressure Drop (psig)

10

8V6V10V 14V 18V 24V 32V

60402010 80 100 4,000200 400 600 1,000 2,000

12V 16V 22V 28V 36V

Atomizing Steam Flow (lb/hr)

RECOMMENDED

SPARE

PA RTS

To make sure that the downtime of the system is as short as possible

in case of a failure, you should keep a stock of spare parts.

Recommended spare parts

PART NAME QTY. PART NO.

Pilot assembly 1 1

Spark rod assembly 1 1

Oil gun assembly 1 1

U.V. scanner (if used) 2 2

1-1/4" N.P.T. peepsight glass 2 13046

1-1/4" N.P.T. peepsight gasket 2 13047

1 Part number varies depending on burner size used.

2 Part number varies depending on U.V. scanner used.

A-5

Eclipse Vortometric Burner v2.00, Installation Guide 248, 6/00

Page 49

CONVERSION

Metric to English.