Page 1

Design Guide

No. 160, 8/1/05

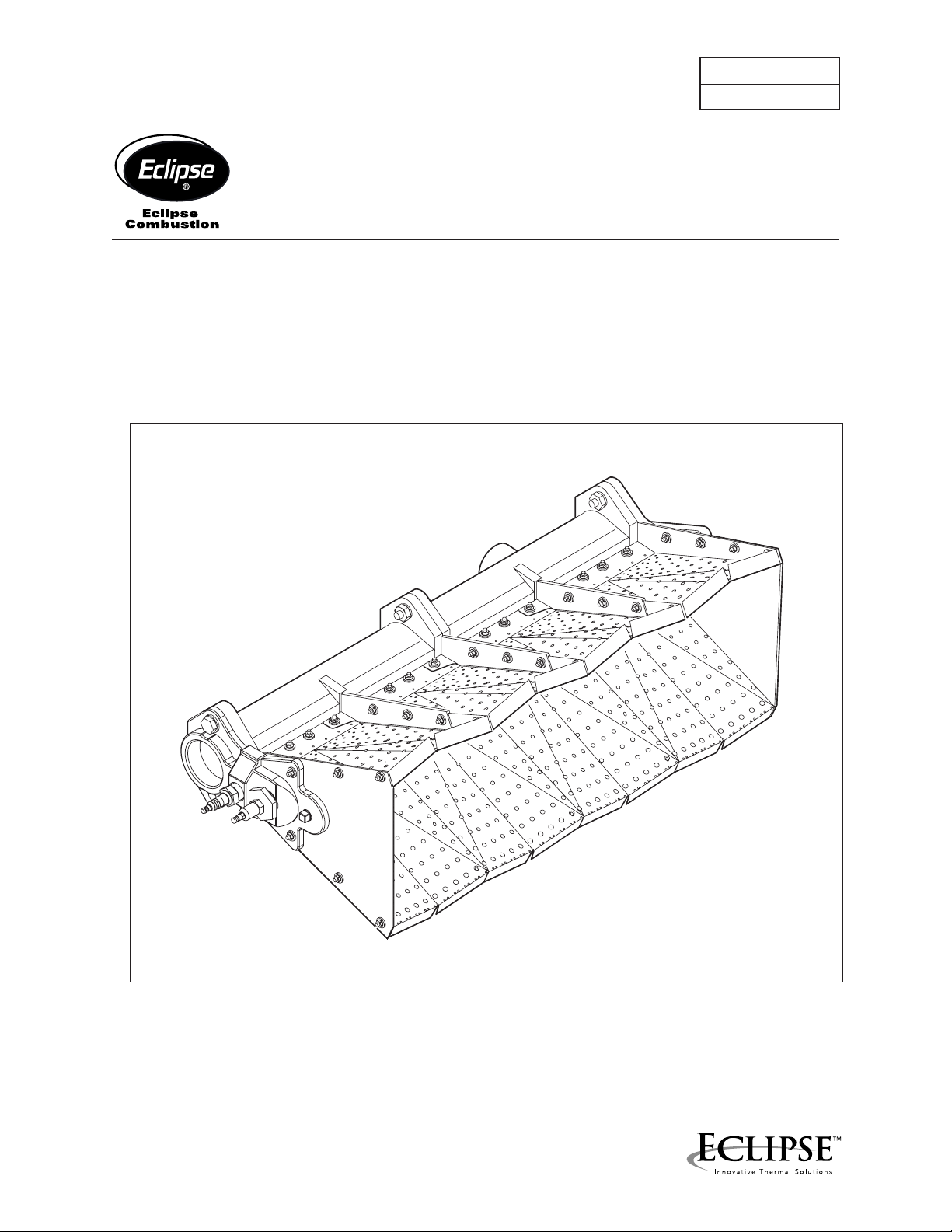

AirHeat

Burners

AH-MA Series

Version 2

Page 2

C

OPYRIGHT

Copyright 2004 by Eclipse, Inc. All rights reserved worldwide.

This publication is protected by federal regulation and shall

not be copied, distributed, transmitted, transcribed or

translated into any human or computer language, in any form

or by any means, to any third parties, without the express

written consent of Eclipse, Inc., Rockford, Illinois, U.S.A.

D

ISCLAIMER NO TICE

L

IABILITY AND

WARRANTY

We reserve the right to change the construction and/or

configuration of our products at any time without being

obliged to adjust earlier supplies accordingly.

The material in this manual is believed adequate for the

intended use of the product. If the product, or its individual

modules or procedures, are used for purposes other than

those specified herein, confirmation of their validity and

suitability must be obtained. Eclipse, Inc. warrants that the

material itself does not infringe any United States patents. No

further warranty is expressed or implied.

We have made every effort to make this manual as accurate

and complete as possible. Should you find errors or omissions,

please bring them to our attention so that we may correct

them. In this way we hope to improve our product

documentation for the benefit of our customers. Please send

your corrections and comments to our Documentation

Manager .

It must be understood that Eclipses liability for its products,

whether due to breach of warranty, negligence, strict liability,

or otherwise, is limited to the furnishing of such replacement

parts and Eclipse will not be liable for any other injury, loss,

damage or expenses, whether direct or consequential,

including but not limited to loss of use, income of or damage

to material arising in connection with the sale, installation, use

of, inability to use or the repair or replacement of Eclipses

products.

Any operation expressly prohibited in this Guide, any

adjustment, or assembly procedures not recommended or

authorized in these instructions shall void the warranty.

2

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

Page 3

A

UDIENCE

About this manual

This manual has been written for those persons who are already

familiar with all the aspects of an air heat burner and its add-on

components, also referred to as the burner system. These aspects

are:

design/selection

installation

use

maintenance

The audience is expected to have pre vious experience with this

kind of equipment.

AH-MA

R

ELA TED PUBLICA TIONS

PUBLICATIONS

Design Guide No. 160

This publication.

Data Sheet No. 160

Required to complete design calculations in this guide.

Installation Guide No. 160

Used with Data Sheet to complete installation.

Price Sheet No. 160

Used to order burners.

EFE-825 (Combustion Engineering Guide)

Eclipse Bulletins & Instruction Manuals: 818, 820, 826, 832, 852, 854, 856

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

3

Page 4

I

MPORTANT NO TICES

D

OCUMENT

CONVENTIONS

Read this manual carefully. Make sure that you understand the

structure and contents of this manual.

Obey all the safety instructions.

Do not deviate from any instructions or application limits in this

manual without written consent from Eclipse Combustion.

If you do not understand an y part of the information in this

manual, do not continue. Contact your Eclipse sales office or

Eclipse Combustion.

There are sev eral special symbols in this document. You must know

their meaning and importance.

The explanation of these symbols follows. Please read it thoroughly.

Danger:

Indicates hazards or unsafe practices which WILL

result in severe personal injury or even death.

Only qualified and well trained personnel are

allowed to carry out these instructions or

procedures.

Act with great care and follow the instructions.

Warning:

Indicates hazards or unsafe practices which could

result in severe personal injury or damage.

Act with great care and follow the instructions.

Caution:

Indicates hazards or unsafe practices which could

result in damage to the machine or minor personal

injury.

Act carefully.

Note:

Indicates an important part of the text.

Read the text thoroughly.

4

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

Page 5

Table of Contents

1

2

3

About this manual

Table of Contents

Introduction

Product Description ....................................................................... 6

Safety

Introduction....................................................................................... 7

Safety .................................................................................................... 7

Capabilities.......................................................................................... 8

Operator Training ............................................................................. 8

Replacement Parts ........................................................................... 8

................................................................................................... 7

.................................................................................... 6

System Design

Design .................................................................................................. 9

Burner Design ................................................................................... 10

Step 1a: Calculating Maximum Input Required ................... 10

Step 1b: Choosing Design Heat Input at High Fire ............ 10

Step 1c: Determining the Length of Burner Needed ........ 10

Step 1d: Calculating Minimum Input Required ................... 10

Step 1e: Layout of the Burner Sections ................................. 11

Figure 3.1.1 Burner Sections .................................................... 12

Figure 3.1.2 End Plate Examples.............................................. 14

Step 1f: Sizing & Layout of Gas Manifold ............................... 15

Step 1g: Sizing Profile Plates ...................................................... 16

System Design................................................................................... 19

Step 2: Control Methodology................................................... 20

Step 3: Ignition System ............................................................... 21

Step 4: Flame Monitoring System ............................................ 22

Step 5: Gas Valv e Train ................................................................. 23

Appendix

Conversion Factors......................................................................... 25

.......................................................................................... 25

....................................................................... 3

........................................................................ 5

............................................................................... 9

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

5

Page 6

Introduction

P

RODUCT

DESCRIPTION

1

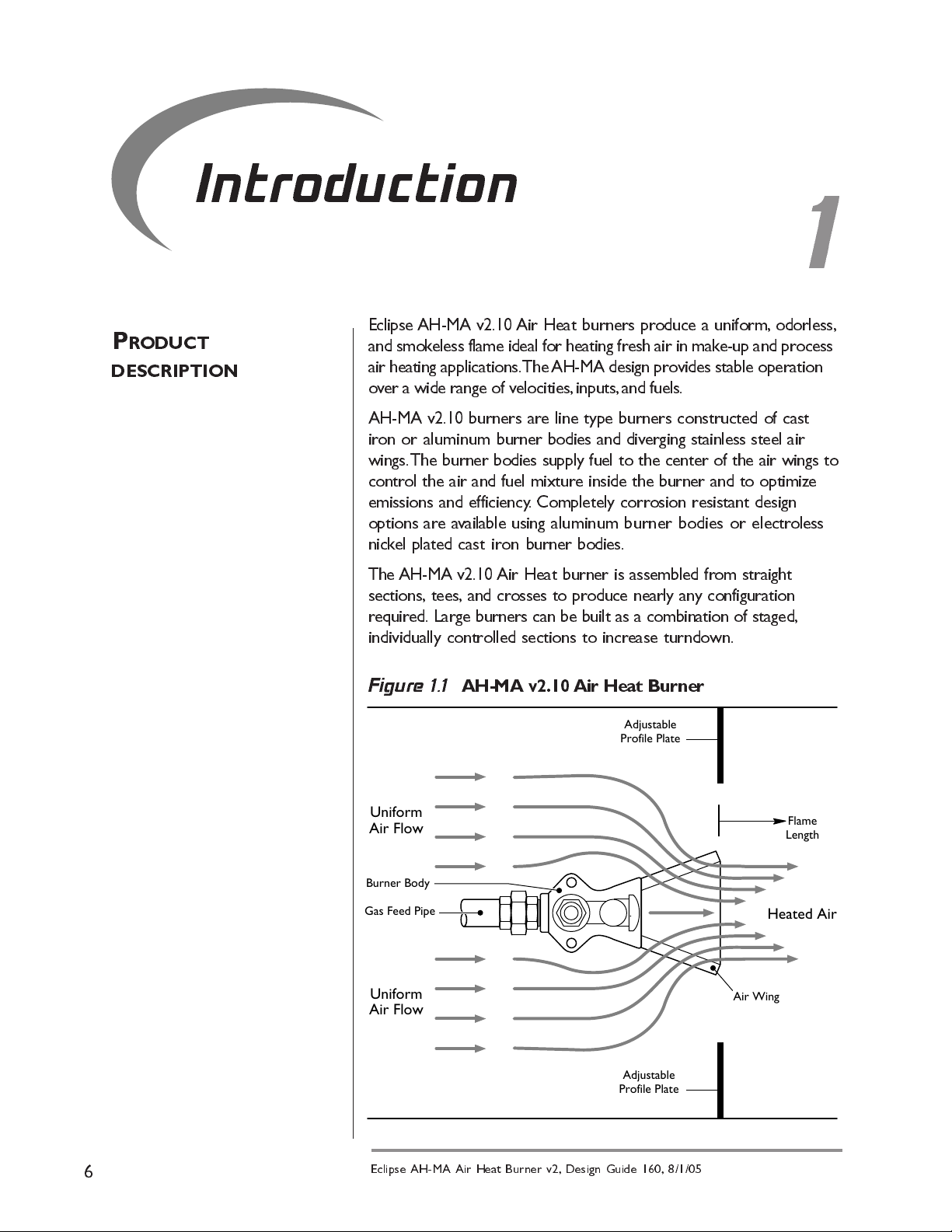

Eclipse AH-MA v2.10 Air Heat burners produce a uniform, odorless,

and smokeless flame ideal for heating fresh air in mak e-up and process

air heating applications. The AH-MA design provides stable operation

over a wide range of velocities, inputs, and fuels.

AH-MA v2.10 burners are line type burners constructed of cast

iron or aluminum burner bodies and diverging stainless steel air

wings. The burner bodies supply fuel to the center of the air wings to

control the air and fuel mixture inside the burner and to optimize

emissions and efficiency. Completely corrosion resistant design

options are a vailable using aluminum burner bodies or elec troless

nickel plated cast iron burner bodies.

The AH-MA v2.10 Air Heat burner is assembled from straight

sections, tees, and crosses to produce nearly any configuration

required. Large burners can be built as a combination of staged,

individually controlled sections to increase turndown.

Figure 1.1 AH-MA v2.10 Air Heat Burner

Adjustable

Profile Plate

Uniform

Air Flow

Burner Body

Gas Feed Pipe

Uniform

Air Flow

Adjustable

Profile Plate

Flame

Length

Heated Air

Air Wing

6

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

Page 7

Safety

I

NTRODUCTION

S

AFETY

2

In this section, you will find important notices about safe

operation of a burner system.

Danger:

The burners covered in this manual are designed

to mix fuel with air and burn the resulting

mixture. All fuel burn-ing devices are capable of

producing fires and explosions when improperly

applied, installed adjusted, controlled, or

maintained.

Do not bypass any safety feature.

You can cause fires and explosions.

Never try to light the burner if the burner shows

signs of damage or malfunctioning.

Warning:

The burner and duct sections are likely to have

HOT surfaces. Always wear protective clothing

when approaching the burner.

Note:

This manual gives information for the use of these burners

for their specific limited design purpose. Do not deviate from

any instructions limits in this manual without written advice

from Eclipse Combustion.

Note:

Read this entire manual before you attempt to start the

system. If you do not understand any part of the information

in this manual, then contact your Eclipse representative or

Eclipse Combustion before you continue .

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

7

Page 8

C

APABILITIES

O

PERA TOR TRAINING

R

EPLACEMENT PARTS

Adjustment, maintenance and troubleshooting of the

mechanical and the electrical parts of this system should be

done by qualified personnel with good mechanical aptitude

and experience with combustion equipment.

The best safety precaution is an alert and competent operator.

Thoroughly instruct new operators so they demonstrate an

adequate understanding of the equipment and its operation. Regular

retraining must be scheduled to maintain a high degree of

proficiency.

Order replacement parts from Eclipse only. Any customer

supplied valves or switches should carry UL, FM, CSA, CGA and/or

CE approval where applicable.

8

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

Page 9

D

ESIGN

System Design

Design structure

Designing a burner system is a straight-forward exercise of

combining modules that add up to a reliable and safe system.

The design process is divided into the following steps:

1.

Burner design

a.

calculating the maximum input requirements

b.

choosing design heat input at high fire

c.

determining the length of burner needed

d.

calculating the minimum input requirements

e.

layout of the burner sections

f.

sizing and layout of the gas manifold

g.

sizing the profile plates

h.

burner staging

2.

Control methodology

3.

Ignition system

4.

Flame monitoring system

5.

Gas valve train selection

3

Note:

Information in Data Sheet No. 160 is necessary to complete

some of the procedures.

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

9

Page 10

Step 1:

Burner design

Calculating the maximum input requirements

To calculate the total burner maximum input required, solve:

∆

Max. Input (Btu/hr) = 1.3 x SCFM x

Caution:

This is an approximation based on the gross heating value of the

fuel. For mo r e accurate heat balance calculations, refer to the

Eclipse Combustion Engineering Guide (EFE-825).

Choosing design heat input at high fire

See Data Sheet No. 160 for the following:

1) Use the Operating Range chart to determine the maximum and

minimum heat inputs per foot of burner based on the known air

pressure drop.

2) Use the Flame Length chart to check flame length v ersus available

distance downstream of the burner for uniform temperature

distribution.

Determining the length of burner needed

Burner length, feet =

max. heat input, total burner (Btu/hr)

heat input per foot (Btu/hr/ft)

T (max)

Note:

Round fractional lengths (in ft.) up to the next half-foot.

Calculating minimum input required

1)

Minimum Input (Btu/hr) = 1.3 x SCFM x T (min)

2)

Min. Heat Input per foot, Btu/hr/ft =

3) With the minimum heat input per foot, go to the Operating

Range chart in Data Sheet No. 160 and confirm that the burner

can operate at the input for the air pressure drop the burner will

see. If the minimum input required is too low, there are two

options to obtain this operating condition:

a. Use a staged burner control (see burner staging and contr o l

methods in this section).

b. Modulate the air flow to a lower pressure drop, thus lowering

the minimum input capability of the burner.

Example

60,000 SCFM air from 0°F to 80°F maximum; and, from 75°F to

80°F minimum. Air

0.7"w.c. at high fire. The fuel is natural gas.

: A make-up air heat burner will be used to heat

∆

P across the burner is designed to be

min. heat input, total burner, Btu/hr.

D

burner length, feet

10

1) Max. Input Required: Btu/hr = 1.3 X 60,000 X 80 = 6,240,000

Btu/hr.

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

Page 11

2) From the Operating Range chart in Data Sheet No. 160, the maximum

heat input at 0.7"w.c. air pressure drop is 800,000 Btu/hr/ft. The flame

length from the Flame Length chart in Data Sheet No. 160 is 30".

Burner length, feet =

6,240,000 Btu/hr

= 7.8 feet; round up to 8 feet.

800,000 Btu/hr/ft

3) Minimum: Btu/hr = 1.3 X 60,000 X 5 = 390,000 Btu/hr.

4) Minimum per foot =

390,000 Btu/hr

= 48,750 Btu/hr/ft.

8 ft.

5) From the Operating Range chart in Data Sheet No. 160, the

minimum input at 0.7 w .c. is 20,000 Btu/hr/ft. Ther efore, the

burner can operate over the desired input range.

Layout of the burner sections

Once the lineal feet of burner has been determined, use Figure 3.2

and the criteria below to define the burner geometry.

For optimum burner performance and a uniform temperature profile,

even gas and air flow throughout the burner is essential. The following

guidelines should be used to lay out a burner:

1) Every leg of a Tee or Cross section must be separated from another

Tee or Cross section by at least 150mm (6") of burner.

2) Include the proper number of gas feed inlet sections. Use Table 3.1

as a guide to the number and size of gas feed inlets required based

on the length of the burner .

Table 3.1 Gas Feed Inlet Capacities

Gas Inlet

Pipe Size

1-1/2"

1-1/2"

1-1/2"

1-1/2"

* Number of feet or 300mm sections

Directon

1"

2"

2"

2"

1"

2"

2"

2"

Side

Rear

Side

Rear

Rear

Side

Side

Rear

Side

Rear

Rear

Side

300mm straight section

300mm straight section, Cast Iron

300mm straight section

300mm straight section, Aluminum

300mm x 300mm cross section

300mm straight section

300mm straight section

300mm straight section, Cast Iron

300mm straight section

300mm straight section, Aluminum

300mm x 300mm cross section

300mm straight section

Section Type

Gas

Pressure

standard

standard

standard

standard

standard

standard

Low

Low

Low

Low

Low

Low

Max. Burner

Length Per

Inlet*

1

4

3

4

6

4

.5

2

1.5

2

6

2

Example: A six-foot burner for standard gas pressure will use 2"

N.P.T. rear inlets to supply gas. How man y gas inlets are required?

Solution:

Therefore,

Each 2" back inlet can supply 4 feet of burner.

6/4

= 1.5, or 2 inlets are required

3) Space gas inlets equally to assure uniform gas distribution.

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

11

Page 12

10.6"

1.6"

5.9"

11.8"

5.9"

150mm x 300mm Tee Section

7

(LBS.)

WEIGHT

102250-2

CAST IRON

LOW PRESSURE

BURNER BODIES

14

16

16

102238-2

102240-2

102239-2

19

30

30

102251-2

102255-2

102254-2

Cast Iron Burner Sections

10.6"

10.6"

10.6"

1.6"

1.6"

1.6"

5.9"

1.5" I.D.

11.8"

2.2"

11.8"

9.6"

9.6"

9.6"

ASSEMBLY NUMBERS

with Back Inlet

300mm Straight Section

300mm Straight Section

Burner Sections Assembly Numbers, Dimensions & Weights

10.6"

102250-1

RESISTANT

CORROSION

BURNER BODIES

102250

BODIES

BURNER

CAST IRON

DESCRIPTION

150mm Straight Section

102238-1

102240-1

102239-1

102251-1

102255-1

102254-1

102238

102240

102239

102251

102255

102254

300mm Straight Section

300mm Straight Section w/Back Inlet, BSP

300mm Straight Section w/Back Inlet, NPT

300mm x 150mm Tee Section

300mm x 300mm Cross Section, BSP

300mm x 300mm Cross Section, NPT

1.9"

5.9"

11.8"

5.9"

I.D.

2.0"

150mm Straight Section

300mm x 300mm Cross

Figure 3.1

1

2

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

Page 13

10.6"

1.6"

5.9"

11.8"

5.9"

150mm x 300mm Tee Section

3.5

(LBS.)

WEIGHT

7.0

8.0

8.0

9.0

14.0

14.0

Aluminum Burner Sections

10.6"

10.6"

1.6"

1.6"

5.9"

2.0" I.D.

11.8"

2.0"

11.8"

9.6"

9.6"

ALUMINUM

LOW PRESSURE

with Back Inlet

300mm Straight Section

300mm Straight Section

ASSEMBLY NUMBERS

ALUMINUM

Burner Sections Assembly Numbers, Dimensions & Weights

10.6"

BURNER

102250-4

102238-4

102240-4

102239-4

BURNER BODIES

102250-3

102238-3

102240-3

BODIES

DESCRIPTION

150mm Straight Section

102239-3

300mm Straight Section

300mm Straight Section w/Back Inlet, BSP

300mm Straight Section w/Back Inlet, NPT

1.9"

102251-4

102255-4

102254-4

102251-3

102255-3

102254-3

300mm x 150mm Tee Section

300mm x 300mm Cross Section, BSP

300mm x 300mm Cross Section, NPT

11.8"

Figure 3.1 (Continued)

10.6"

1.6"

5.9"

2.0"

5.9"

I.D.

9.6"

150mm Straight Section

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

300mm x 300mm Cross

1

3

Page 14

3.1"

5.2"

3.9"

Plug

Rod

Flame

Plug

Rod

Flame

Main Gas

Connection

Plug

Ignition

1/4" npt

Pilot Gas

Connection

Plug

Ignition

U.V. Scanner

Adaptor

U.V. Scanner

Main Gas

Connection

(shown with optional UV scanner, flame rod & spark plug installed)

with

Flame Rod

Flame Monitoring End

PA RT

with

Pilot End

Flame Rod

Accessories

with

Pilot End

U.V. Scanner

Ø0.5"

21509

13093

76506

13047-1

NUMBER

DESCRIPTION

Mtg. Brkt. for Hanger Rods

Ignition Plug

Flame Rod

Divider Plate for Staging

444444444 4 4 4 4 4 4

(LBS.)

WEIGHT

—

BC

—

DIMENSIONS

A

—

for Staging

Divider Plate

18767

202010

UV Scanner Adapter – 1/2" NPT

1" NPT

14mm

—

12659

202011

UV Scanner Adapter – 3/4" NPT

UV Scanner Adapter – 1" NPT

Pilot Gas Cock

1" BSP

1" NPT

14mm

14mm

1" BSP

1.5"NPT

1" BSP

14mm

1.5" BSP

1" NPT

14mm

1" NPT

Flame rod ordered with burner includes adapter to pilot or flame monitoring

endplate.

Adapter fits Eclipse straight, Eclipse 90 and Honeywell C7027A U.V. scanners.

Adapter fits Eclipse self-check and Honeywell C7035A U.V. scanners.

1" BSP

1" NPT

14mm

14mm

2" BSP

2" NPT

1" BSP

1" NPT

14mm

14mm

———

1" BSP

1" NPT

—

—

—

—

1" BSP

1" NPT

**

**

—

1-1/2" BSP

1-1/2" BSP

1-1/2" NPT

4

—

—

1-1/2" NPT

Figure 3.1 (Continued)

1

4

8.7"

2"

8.7"

C (pipe thread)

B (straight thread)

End Plate Assemblies End Plate Examples

102257-1

10010970-1

RESISTANT

END PLATES

CORROSION

3.9" 0.8"

Plain End Plate Assembly

1.3"

2.6"

3.9"

0.8"

A (pipe thread)

Pilot, Flame Monitoring and

Burner Feed End Plate Assemblies

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

ASSEMBLY NUMBERS

End Plate Assembly Numbers, Dimensions & Weights

CAST IRON

END PLATES*

DESCRIPTION

10010972-1

102257

10010970

10010972

Plain End Plate

Pilot End Plate, No Gas Feed

Pilot End Plate, 1" Gas Feed NPT

10010974-1

10010975-1

10010976-1

10010974

10010975

10010976

Pilot End Plate, 1" Gas Feed BSP

Pilot End Plate, 1.5" Gas Feed NPT

Pilot End Plate, 1.5" Gas Feed BSP

101237-1

10010977-1

10010978-1

10010979-1

10010977

10010978

10010979

Pilot End Plate, 2" Gas Feed NPT

Pilot End Plate, 2" Gas Feed BSP

Pilot End Plate, Angled Flame Monitor NPT

101238-1

10010980-1

101237

101238

10010980

Pilot End Plate, Angled Flame Monitor BSP

Flame Monitoring End Plate, BSP

Flame Monitoring End Plate, NPT

101233-1

101234-1

101235-1

101233

101234

101235

Burner Feed/Flame Monitoring End Plate, BSP

Burner Feed/Flame Monitoring End Plate, NPT

Burner Feed End Plate, BSP

101236-1

101236

Burner Feed End Plate, NPT

* Standard Cast Iron End Plates with powder coated surface finish are supplied on burners with aluminum gas manifolds.

** 14mm plug may be replaced by ignition plug for direct spark ignition of burners 450mm (18") or less.

Page 15

Sizing and layout of the gas manifold

Choose the gas manifold size to evenly supply gas to each of the

sections, using Table 3.3 and Figure 3.2.

Table 3.3

MAXIMUM MANIFOLD MAXIMUM MAIN GAS

GAS INPUT PIPE SIZE GAS INPUT PIPE SIZE

(MMBTU/HR.) (INCHES) (MMBTU/HR.) (INCHES)

Gas Pipe Sizing & Layout

1.4 1-1/2 0.3 1/2

2.5 2 0.6 3/4

5.2 2-1/2 1.1 1

8.0 3 3.2 1-1/2

14.0 4 6.6 2

45.0 6 13.0 2-1/2

80.0 8 20.0 3

Note:

Maximum inputs shown for natur al gas only. For propane,

multiply inputs by 1.5; for butane, multiply inputs by 1.7.

Figure 3.2 Gas Manifold Sizing & Lay o u t

Main

Gas

Pipe

Union

Gas Manifold

Feed Pipe

Pipe

Union

Burner

Burner Body

Pipe

Union

Pilot End Plate

Spark

Ignitor

Pilot

Gas

Flame

Rod

Example: A gas manifold is supplying gas to two 1-1/2" N.P.T. rear

inlets on a burner. Each of the rear inlets supplies a maximum of

2,000,000 Btu/hr.

Solution: The total fuel supplied is 2 x 2,000,000 = 4,000,000 Btu/hr.

Referring to Table 3.3, the choice for manifold size is 2-1/2"; the

choice for main gas pipe size is 2".

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

1

5

Plain

End Plate

Page 16

Profile plate sizing

Profile plates are required to ensure sufficient air pressure drop across

the burner . An example of pr ofile plate lay out is shown in Figure 3.4 on

the next page.

Caution:

It is essential that even air flow is delivered to the

burner to obtain optim um performance.

To calculate the profile gap sizes, you will need to know the following:

1) SCFM

= Total air flow around and through the burner in cubic feet

per minute.

2) Design pressure drop across the burner .

= Profile gap area required per flow from Figur e 3.3; see Table 3.4

3) G

p

for corrections at higher or low er burner air inlet temperature s.

Profile area, A

g

=

SCFM x G

p

1000

Where:

Ag

= Area in square inches of the gap between the profile plates and

the burner.

The areas on the sides of the burners should first be calculated based

on a fixed gap of 2". Then calculate the gap size required on the top

and bottom to obtain the required profile gap area.

Example: Size a profile plate for a seven-foot long AH-MA v2.00

burner. Air flow around and through the burner will be 60,000 SCFM.

The design pressure drop is 0.7"w.c.

Note:

Use a burner wing width of 8.9 for profile gap sizing on top and

bottom.

From Figure 3.3: G

=

g

60,000 x 48

1,000

A

= 48

p

= 2,880 sq. in.

Calculate gap sizes:

Side Area = 2 x 2" x 8.9" = 36 sq. in.

Area Top & Bottom = 2,880 36 = 2,844 sq. in.

Therefore, Top & Bottom Gap =

2,844 sq. in.

= 16.9 inches

(7 x 12) x 2 gaps

where 7 x 12 = burner length in inches

1

6

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

Page 17

Figure 3.3 Profile Gap Area vs. Air Pr essure Gap

110

100

90

80

70

60

50

(Sq. In. per 1000’s SCFM)

40

Gp, Profile Gap Area Required

30

20

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3 1.4

Table 3.4

AIR T

EMP

. (°F) 0 30 70 150 200 250 300 350 400 450

Burner Air Inlet Temperature @ 70 F

Combustion Air Pressure Drop ("w.c.)

Profile Gap Area Inlet Air Temperature Correction

GP @ AIR T

EMP. =

G

P

FROM FIG

. 3.4 X C

ORRECTION FACTOR

Correction Factor 0.87 0.92 1.00 1.15 1.25 1.34 1.43 1.53 1.62 1.72

Figure 3.4

6" Min.

Duct

Height

(244mm)

6" Min.

Single Burner Profile Plates

9.6"

Duct Width

6" Min.

AH-MA Burner

Profile Plate

2"2"

Gap, As

Required

Gap, As

Required

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

1

7

Page 18

Figure 3.5 Two-Stage Burner Profile Plates

First

Stage

Burner

Profile

Plate

6" Min. 3" Min.

2"

2"

6" Min.

2"

Second

Stage

Burner

Profile

Plate

2"

XXXX

Note:

Make all profile gaps equal (shown as “X” above); profile

plate width between the burners should be at least 3".

Duct Wall

Steel channel of the correct width can be used as the center profile

plate. Install with the legs pointing toward the incoming air flow.

Air Flow Air Flow

Staged Burners

Duct Wall

6" Min.

1

8

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

Page 19

Note:

To compensate for changes in actual air flo w versus calculated,

provide adjustable profile plates so that f inal settings can be

made in the field. Figure 3.6 shows an example of an adjustable

profile plate design.

Figure 3.6 Adjustable Profile Plates

AH-MA

Burner

Adjustable

Profile Plate

Fixed

Profile Plate

Duct

Wall

Figure 3.7 Profile Plate Positioning

Profile

Plate

¼ to 1"

Caution:

Profiles plate should be positioned

upstream of the firing end of the

burner. If necessary, the plates can be

AH-MA

Burner

Profile

Plate

located up to 1" back from the firing

end, but under no circumstances should

they be in front of the burner.

Elongated Screw Slots

Front ViewSide View

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

1

9

Page 20

Step 2:

Control

Methodology

The simplest control method is fuel modulation at fixed air flow. If

required turndown is greater than the burners capabilities, there

are two options:

1.

Air Modulation

To lower the minimum input of the burner, the air flow can be

decreased as long as the pressure drop across the burner does not

go outside of the operating limits given in the Operating Ranges

chart in Data Sheet No. 160. The air flow can be changed with a

two-speed air handling system or a modulated system. As an

example, the air flow could be turned down from a pressure drop

of 1"w .c. to 0.25"w .c., giving a total air turndown of 2:1. This could

extend the minimum input level from 20,000 to 13,000 Btu/hr/ft.

Figure 3.8 Staged Burners

Stage 2

Main

Gas

Pipe

Union

Pipe

Union

Stage 1

Main

Gas

Pipe

Union

Pipe

Union

Staging

Divider Plate

Part No. 76506

Pipe

Union

Stage 1

Pilot Gas

2

0

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

Page 21

2.

Burner Fuel Staging

To further increase the burner turndown, AH-MA v2.10 burners

can be fuel staged. This can be done by installing two or more

separate burners in a duct, each with its own gas control valve, or

by dividing a single burner assembl y into separate zoned sections.

For example, to double the effectiv e turndown, two burner

sections may be staged as shown in Figure 3.8 on the pre vious

page. If more heat is required, stage 2 is lit by simply supplying gas

to it. It will pilot from the adjacent stage.

Warning:

Lockouts must be provided to shut off gas flow to

stage 2 unless flame is pro ven on stage 1.

A spacer (part #76506) must be installed between the burner

bodies to separate the different gas feed sections.

Note:

Ignition performance is enhanced if the gas inlet to stage 2 is as

close to the piloting section as possible.

Step 3:

Ignition System

A

H-MA v2.10 Air Heat burners have an integral spark-ignited gas

pilot for lighting the burner . The pilot fuel is fed into the pilot end

casting which is separate from the main fuel. A pilot adjusting valve

is required to adjust the pilot gas flow (Eclipse part number

12659 is recommended). The needed pilot capacity is 20,000 Btu/

hr, but the pilot will operate equally well at higher or lower inputs.

The pilot is shut off after successfully igniting the main burner to

protect the ignitor .

Local safety and insurance requirements demand that you limit the

maximum time that a burner takes to ignite. These time limits vary

from country to country. For the USA, the time limit is 15 seconds;

for Europe, it is typically 3 seconds. Local requirements may

require shorter time limits. Verify local regulation and insurance

requirements with the authority having jurisdiction.

The time that a burner takes to ignite depends on:

the distance between the gas shut-off valve and the burner

the air pressure drop across the burner

the gas flow at start conditions.

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

2

1

Page 22

Step 4:

system

Flame monitoring

90° U.V. scanner

flame rod

A

flame monitoring system consists of two main parts:

a flame sensor

a flame safeguard.

Flame Sensor

There are two types that you can use for an AH-MA v2.10 Air

Heat burner:

U.V. scanner

flame rod.

You can find information on U.V. scanners in:

Instruction Manual No. 852; 90° U.V. scanner

Instruction Manual No. 854; straight U.V. scanner

Instruction Manual No. 855; solid state U.V./IR scanner

Instruction Manual No. 856; self-check U.V. scanner.

You can find information on flame rods in:

Bulletin/Info Guide No. 832.

Flame Monitoring Control

The Flame Monitoring Control processes the signal from the flame

rod or U.V. scanner and controls both the start-up sequence and

the main gas shut-off valve sequence..

For flame safeguard selection there are two options for staged

burners depending on the application requirements:

flame safeguard for each burner: if one burner goes down, only

that burner will be shut off.

multiple burner flame safeguard: if one burner goes down, all

burners will be shut off.

Eclipse Combustion recommends the use of flame monitoring

control systems which maintain a spark for the entire trial for

ignition time when using U.V. scanners. Some of these flame

monitoring models are:

Veri-Flame series; see Bulletin/Instruction Manual No. 818

Bi-Flame series; see Bulletin/Instruction Manual No . 826

Multi-Flame series; see Bulletin/Instruction Manual No. 820.

Burners over 5 lineal feet include flame supervision at the far end.

If pilot ignition is being used, two flame supervision units are

required; one for the pilot and one for the far end. Per NFPA 86,

if using direct spark on the main flame, only flame supervision at

the far end is required providing ignition can be accomplished

within 15 seconds.

22

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

Page 23

Step 5:

Gas Valve Train

Selection

(from shut-off

valve train)

Main

Gas

Pilot

Gas

Main Gas

Control

Valve

Manual

Butterfly

Valve

Pilot

Shut-Off

Valve

Figures 3.9 and 3.10 illustrate gas valve trains for single and staged

burner systems respectively.

The typical main gas valve train for a staged burner has the same valve

layout as a single burner except each burner has an individual sole-

noid valve to independently shut down each section. A common gas

shut-off valve train can be used.

Figure 3.9 Single-Staged Burner Valve L ayout

Pipe

Union

Flexible

Solenoid

Valve

Nipple

Pipe

Union

Adjustable

Gas Cock

Adjustable

Orifice Valve

& Gas Cock

Flexible

Nipple

Duct Wall

OR

Main Burner

Shut-Off Valve

Pilot

Pressure

Regulator

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

2

3

Page 24

Main

Gas

(from shut-off

valve train)

Pilot

Gas

Solenoid

Valve

Solenoid

Valve

Main Gas

Control

Valve

Main Gas

Control

Valve

Pilot

Shut-Off

Valve

Figure 3.10 Staged Burner Valve Layout

Burner 1

Shut-Off Valve

Manual

Butterfly

Valve

Flexible

Nipple

Duct Wall

Pipe

Flexible

Burner 2

Shut-Off Valve

Manual

Butterfly

Valve

Solenoid

Valve

Pilot

Pressure

Regulator

Nipple

Pipe

Union

Adjustable

Gas Cock

OR

Adjustable

Orifice Valve

& Gas Cock

Flexible

Nipple

Note:

A single pilot fuel feed can be used when the stag ed burners are

piloted by the adjacent burners.

Union

Pipe

Union

Consult Eclipse

Eclipse can help you design and obtain a main gas shut-off valve train that

complies with the current safety standards.

The shut-off valve train must comply with local safety standards set by

authorities that hav e jurisdiction.

For details, please contact your local Eclipse representative or Eclipse

Combustion.

Note:

Eclipse supports NFP A r egulations (two shut-off valves) as a

minimum standard for main gas safety shut-off valves.

2

4

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

Page 25

C

ONVERSION

Appendix

Metric to English.

FA CTORS

F

ROM

T

O

M

ULTIPLY BY

cubic meter (m3) cubic foot (ft3) 35.31

3

cubic meter/hour (m

/h) cubic foot/hour (cfh) 35.31

degrees Celsius (°C) degrees Fahrenheit (°F) (°C x 1.8 ) + 32

kilogram (kg) pound (lb) 2.205

kilowatt (kW) Btu/hr 3414

meter (m) foot (ft) 3.28

millibar (mbar) inches water column ("wc) 0.401

millibar (mbar) pounds/sq in (psi) 14.5 x 10

millimeter (mm) inch (in) 3.94 x 10

Metric to Metric.

F

ROM

T

O

M

ULTIPLY BY

kiloPascals (kPa) millibar (mbar) 10

meter (m) millimeter (mm) 1000

millibar (mbar) kiloPascals (kPa) 0.1

millimeter (mm) meter (m) 0.001

-3

-2

English to Metric.

F

ROM

T

O

M

ULTIPLY BY

Btu/hr kilowatt (kW) 0.293 x 10

cubic foot (ft3) cubic meter (m3) 2.832 x 10

cubic foot/hour (cfh) cubic meter/hour (m3/h) 2.832 x 10

degrees Fahrenheit (°F) degrees Celsius (°C) (°F 32) ÷ 1 .8

foot (ft) meter (m) 0.3048

inches (in) millimeter (mm) 25.4

inches water column ("wc) millibar (mbar) 2.49

pound (lb) kilogram (kg) 0.454

pounds/sq in (psi) millibar (mbar) 68.95

Eclipse AH-MA Air Heat Burner v2, Design Guide 160, 8/1/05

-3

-2

-2

2

5

Page 26

Design Guide 160 8/1/05

Litho in U.SA.

Loading...

Loading...