Page 1

ECLIPSE AIR HEAT BURNERS

Series “AH”, “DAH”, “TAH” & “CAH”

U.S. Reissue Pat. No. 26,244 Canadian Pat. No. 743,782

Info 140

11/4/03

AH, Front View

DAH, Blower Down

Data 140-2

Data 140-1

AH, Back View

Data 140-1

TAH

Data 140-3

CAH

Data 140-4

WARNING

The burners covered in this Guide are designed to

mix fuel with air and burn the resulting mixture. All

fuel burning devices are capable of producing explosions and fires when improperly applied, installed,

adjusted, controlled, or maintained. This Guide will

provide information for using these burners for their

limited design purpose. Do not deviate from any in-

structions or application limits in this Guide without

written advice from the Eclipse Combustion Division

in Rockford, Illinois. Read this entire Guide before attempting to light burners. If you do not understand

any part of the information in this Guide, contact your

local Eclipse representative or Eclipse Combustion

before proceeding further.

Page 2

Important Notices About Safe Burner Operation

Storage Store the burner inside. Exposure to the elements can damage the burner.

Qualifications Adjustment, maintenance, and troubleshooting of the mechanical parts of this

unit should be done by people with good mechanical aptitude and experience

with combustion equipment.

Replacement Parts Order replacement parts from Eclipse only. Any customer-supplied valves or

switches should carry UL, FM, CSA, and/or CGA approval where applicable.

Operator Training The best safety precaution is an alert and competent operator. Thoroughly in-

struct new operators so they demonstrate an adequate understanding of the

equipment and its operation. Regular retraining must be scheduled to maintain a

high degree of proficiency. The operator must have easy access to this Information Guide at all times.

1.0 Burner Operating Parameters & Requirements

Applications Eclipse Air Heat Burners are line type burners ideal for generating large vol-

umes of clean, hot air. Applications include ovens, dryers, fume incinerators, and

similar industrial equipment.

The “AH” models feature an integral combustion air blower mounted on the back

of the burner’s steel case. By supplying the correct air volume and pressure to

the burner, the blower allows stable operation over a wide range of duct velocities without installing a profile plate around the burner.

Capacities & Supply Pressures

See Figure 2.

Burner Environment Weather Protection: Protect burners from the weather.

Combustion Air: Must be free of contaminants. Eclipse strongly recommends

use of a combustion air filter to remove airborne particles. If corrosive fumes or

materials are present in the air, supply the blower with fresh, clean air from an

uncontaminated area of the plant.

Room Openings: If the burner is mounted on the side of the duct, provide at

least one square inch of opening to the outdoors for every 4000 Btu/hr (1.2 kW)

of burner firing rate. This will admit fresh combustion air.

Access: Provide access to the burner for inspection and maintenance.

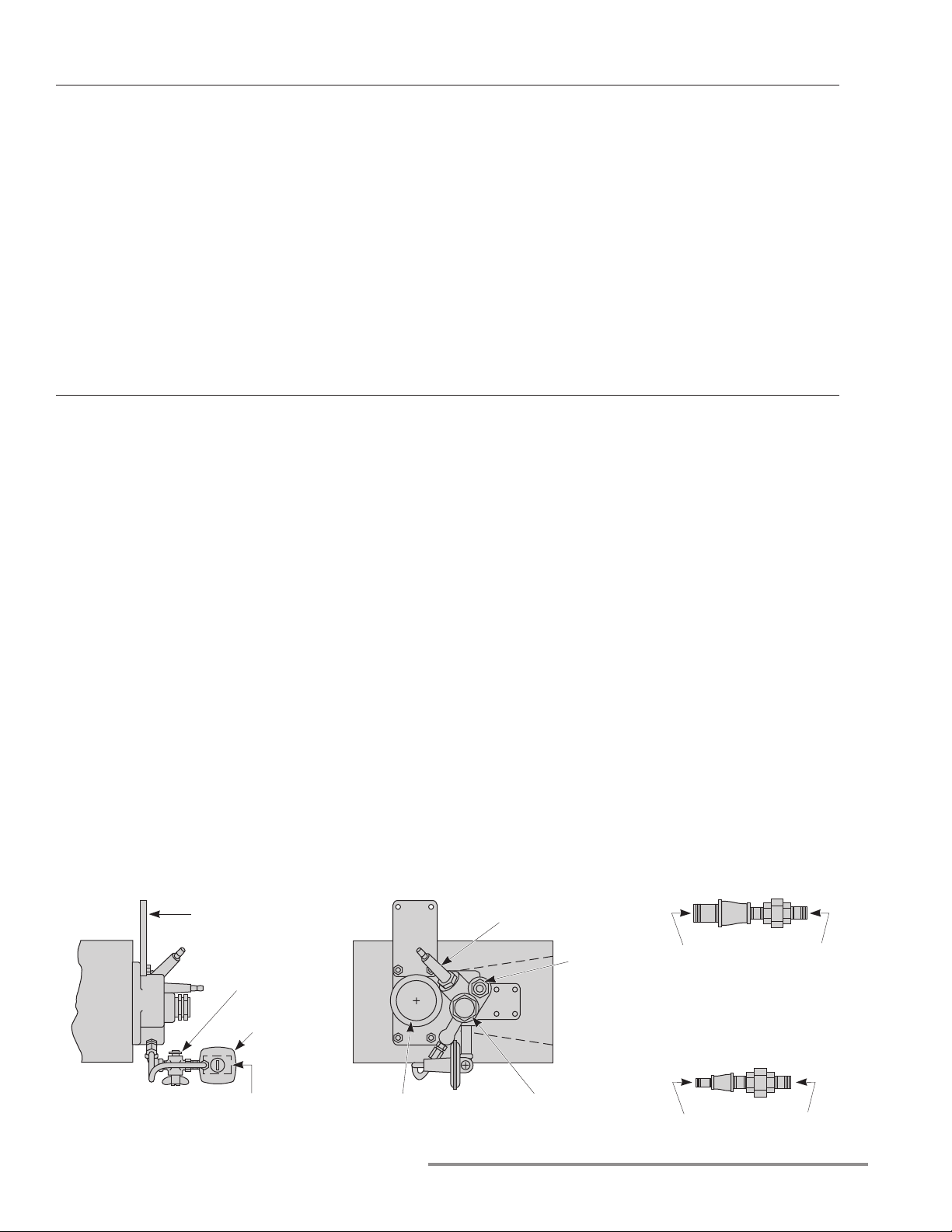

Figure 1–Ignition, Flame Monitoring, and Pilot Components

Mounting

Bracket

Pilot Cock

#12659

Pilot

Regulator

#15027

Flame Rod

#13093-3

Spark

Plug

#13047

Mount In Place

For Sizes 440 through 800 AH

Scanner Adaptor 109000

For Sizes through 400 AH

Scanner

of Peepsight

3/4"N.P.T.

Connection

1/2" N.P.T.

Scanner Adaptor 109559

Pilot Gas Inlet

1/4" N.P.T.

2

Main Gas Inlet

2" N.P.T.

Eclipse AirHeat v1.0 - Installation Guide No. 140, 11/4/03

Peepsight

#10509

3/4" N.P.T.

Mount In Place

of Flame Rod

1/4"N.P.T.

Scanner

Connection

1/2" N.P.T.

Page 3

Specifications

Input: 1,000,000 Btu/hr. per lineal foot (962 kW/m).

Fuels: Natural gas or 100% propane vapor. Call Eclipse for information on using other fu-

els.

Gas Turndown: 40:1

Pilot Input: Approximately 25,000 Btu/hr. (7.3 kW)

Gas Inlet Pressure: 800,000 Btu/hr/ft. (769 kW/m): Nat. Gas: 2.2" w.c. 5.5 mbar

Propane: 0.9" w.c. 2.2 mbar

1,000,000 Btu/hr/ft. (962 kW/m): Nat. Gas: 3.5" w.c. 8.7 mbar

Propane: 1.3" w.c. 3.2 mbar

Gas pressure shown is a differential measured between the gas inlet and a tap on

the duct wall 10" to 20" (254 to 508 mm) downstream of the burner.

Ambient Temp. Limits*: –40° to +104° F –40° to +40° C

Downstream Temp. Limits: 1500° F 815° C

Flame Length**: 800,000 Btu/hr. (769 kW/m): 28" 0.71 m

1,000,000 Btu/hr. (962 kW/m): 46" 1.17 m

Piloting: Integral spark-ignited pilot; ignition plug included.

Flame Monitoring: Flame rod supplied. UV scanner adaptors are available. For UV scanners, Eclipse

recommends a flame monitoring system that terminates the ignition spark and

proves the pilot flame without spark prior to opening the main gas valves.

CGA requires two flame rods on burners over 36" long (914 mm). Use a flame

monitoring endplate (see Data 140-6) to mount a second flame rod on the end opposite the gas inlet.

Motor: Standard: 230/460/3/60 TEFC. Other motors can be supplied.

Materials: All portions of the burner exposed to flame are cast iron or #321 stainless steel.

Emissions:

Emissions performance depends not only on the burner,

but also other factors such as chamber temperature, chamber design, and heat loading. For estimates of emissions performance in your application, call Eclipse.

Packaging Options: Available with complete valve trains and control systems. AH burners and systems

can be supplied mounted on duct sections as specified by the customer. Call Eclipse

for information on custom packaged systems.

Models: Model Description Data Sheet

AH Line-shape, blower mounted on rear Data 140-1

DAH Line-shape, blower mounted on bottom Data 140-2

TAH “I”-shape, blower mounted on rear Data 140-3

CAH Cross-shape, blower mounted on rear Data 140-4

Related Information: Blower and motor specifications Data 140-5

* Based on blower motor limitations.

** Based on parallel air flow. If mounted in a cross flow, then flame will be shorter.

CAUTION: It is dangerous to use any fuel burning equipment unless it is equipped with suitable flame sensing devices and automatic fuel shut-off valves. Eclipse can supply such equipment or information on alternate sources.

Eclipse AirHeat v1.0 - Installation Guide No. 140, 11/4/03

3

Page 4

2.0 Control System Requirements

p

Turndown Method Input is normally controlled by a motorized butterfly valve in the gas line to the

burner.

Regulator Loading Lines Connect the top diaphragm chambers of the main gas and pilot gas regulators to the

duct approximately 10" downstream of the burner. This will allow the regulators to

maintain a constant supply pressure to the burner regardless of varying pressures in

the duct.

Piloting Pilot gas flow is adjusted as shown in Figure 6.

Ignition Ignition voltage should be 6000 VAC.

Check Valve

See Figure 3. At high fire, the gas pressure at the burner inlet is higher than the air pressure, and

the check valve is closed. At low fire, gas pressure falls below the air pressure, and the check

valve opens, permitting a small amount of air to mix with the gas. This premix at low fire stabilizes

the flame and helps distribute the flame evenly down the length of the burner.

w

Warning

Do not install any valve or controlling device in the gas line between the

burner and the check valve tee, Figure 3. Because this section of the gas

line carries a partial pemix at low fire, it is possible under unusual conditions for the flame to travel back through the pipe to the tee. Devices installed in this section may be damaged and may melt, releasing gas to the

atmosphere and causing fires or explosions.

Pressure Switch Connection See Figure 4 for typical connection of combustion air and circulating fan limit

switches.

Limit Controls &Safety Equipment

Limit controls and safety equipment should comply with current NFPA Standards* 86 and 86C, and all applicable local codes and/or standards.

*Available from:

National Fire Protection Association American National Standard Inst.

Batterymarch Park 1430 Broadway

Quincy, MA 02269 New York, New York 10018

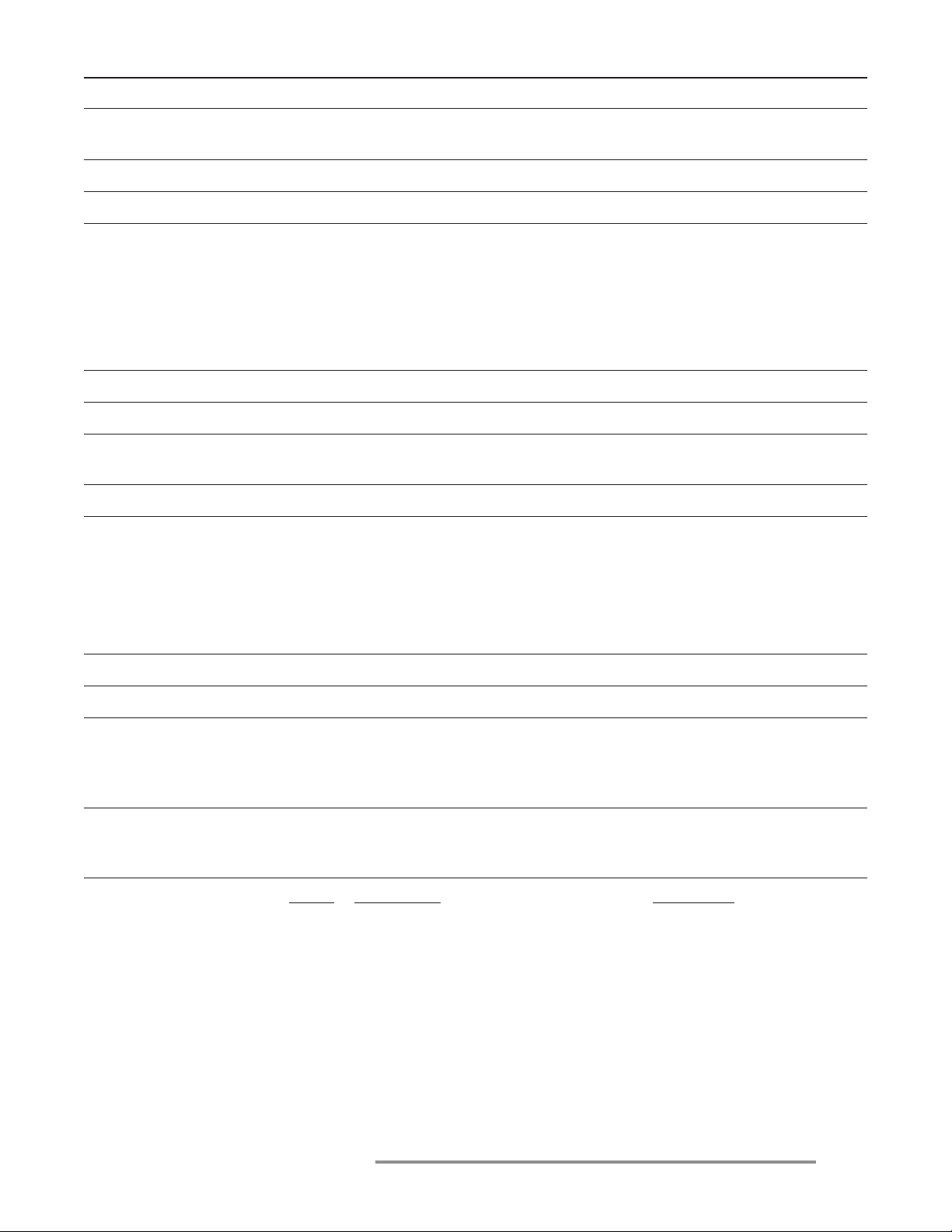

Figure 3–Check Valve Operation Figure 4—Pressure Switch Location

Blower

Pressure Switch

P

HiLo

P

LoHi

4

Do Not Install Any Valves Here!

WARNING!

See Section 2.0

Process Air

Check Valve Opens When

Gas Inlet Pressure Is at Low Fire

Tee

Tube at

Blower Inlet

Gas Inlet

Manifold

Tube Points

Upstream

Eclipse AirHeat v1.0 - Installation Guide No. 140, 11/4/03

Circulating Air

Pressure Switch

Burner Air Ta

See Figure 7

Tube Points

Downstream

Page 5

Figure 5–Mounting & Duct Lengths

Min./Max. Velocity: 500 to 6000 fpm

2.54 to 30.48 m/s

1000 to 4000 fpm

5.08 to 20.32 m/s

Optimum Velocity:

In-Duct Sealed

Min./Max. Velocity: 500 to 6000 fpm

2.54 to 30.48 m/s

Optimum Velocity:

• Provide at least 3" (76 mm) clearance between burner and top, bottom and sides of the duct.

• Profile plates are not required for

good burner operation, but uniform velocity must be maintained

for full length of burner. If velocity

is not uniform, profile plates can

be used to correct this condition.

1000 to 4000 fpm

5.08 to 20.32 m/s

Duct Press: +0.2" to –0.5" w.c.

+0.5 to –1.2 mbar

Min./Max. Velocity: 500 to 1200 fpm

2.54 to 6.10 m/s

Min./Max. Velocity: 500 to 1200 fpm

2.54 to 6.10 m/s

Slot-Fired

Duct Press: 0" to –0.5" w.c.

0 to –1.2 mbar

Min./Max. Velocity: 500 to 1200 fpm

2.54 to 6.10 m/s

Min./Max. Velocity: 500 to 1200 fpm

2.54 to 6.10 m/s

Guidelines for All Mounting Arrangements

• Center the burner in the duct.

• Allow a minimum of 46" (1168 mm) from burner to nearest point

of possible flame impingement at an input of 1,000,000 Btu/hr.

(962 kW/m).

• On burners longer than 36" (914 mm), use a hanger or a pedes-

tal to support the blower and motor.

Duct Lengths

Minimum Distance Before Transition

Rectangular Ducts: One Height or Width, Whichever is Greater

Round Ducts: One Diameter

Air Flow

AH

Burner

Possible Flame Impingement = 46"

7.5°

Maximum

Minimum Distance Before

Eclipse AirHeat v1.0 - Installation Guide No. 140, 11/4/03

5

Page 6

3.0 Duct Design and Burner Mounting

Duct Design See Figure 5 for typical mounting arrangements and duct designs.

Support The mounting flange or brackets supplied with an AH burner are capable of sup-

porting the weight of the burner and blower. The AH burner case itself is designed to support the weight of the blower, so the blower does not require independent support.

Valve Train Support Support valve trains independently of the burner.

Gas Piping Use flexible nipples to allow for thermal expansion of the burner.

Check Valve Piping Gas flow through the check valve must be horizontal. See Figure 3.

Gas Piping Standards Gas piping must comply with American National Standard entitled “National Fuel

Gas Code”* (NFPA No. 54 or ANSI Z223.1), or must be acceptable to the authority having jurisdiction.

Wiring Standards Electrical wiring must comply with the National Electric Code*, (NFPA Std. 70 or

ANSI-CI 1981), or must be acceptable to the authority having jurisdiction.

*Available from:

National Fire Protection Association American National Standard Inst.

Batterymarch Park 1430 Broadway

Quincy, MA 02269 New York, New York 10018

4.0 Start-Up And Adjustment

Initial Settings Adjust the linkage of the gas control valve so that when heat is called for, the

valve is 10° from fully open, and when cooling is required, the valve is approximately 5° from fully closed.

Close all manual gas cocks.

With the pilot cock handle in the closed position, remove the top screw and turn

the adjusting screw five turns out from fully closed. See Figure 6.

Start Blower Start the combustion air blower on the burner. Check the rotation to make sure it

is correct. If not, have a qualified electrician rewire the blower for proper rotation.

Start Circulating Fan Start the duct circulating fan.

Figure 6–Pilot Cock

Handle

(Shown in

Open Position)

Top Screw

Figure 7–Pressure Measurement

Air Pressure

Taps (2)

Gas

Pressure

Tap

Duct Tap

10" to 20"

Downstream of Burner

Adjusting Screw

(Clockwise for less pilot gas,

Counterclockwise for more pilot gas)

6

Eclipse AirHeat v1.0 - Installation Guide No. 140, 11/4/03

Page 7

4.0 Start-Up And Adjustment

Set Air Pressure Drop Measure the air pressure drop across the burner as shown in Figure 7.

Turn the disc on the blower air inlet until the air pressure drop is between 0.4"

w.c. minimum and 1.0" w.c. maximum. For a given input, lower air pressure

drops will produce a longer flame, and higher drops will produce a shorter flame.

Large Burners Only: Some models, such as the 640, 680, and 720 TAH burners, contain a butterfly valve in the check valve line as shown in Figure 8. On

these models, after setting the air flow as described in the previous paragraph,

measure the air pressure drop between the gas pressure tap and duct as shown

in Figure 7. Gas flow must be off. Adjust the butterfly valve to produce an air

pressure drop of 0.2" w.c.

Start Spark Energize the ignition spark. Do not touch

the ignition rod, ignition wire, or transformer while the spark is energized, or

you will get a shock.

Set Pilot Flow Open all pilot gas valves, including the

handle of the pilot cock, Figure 6. The pilot

should light.

Turn the pilot adjusting screw to produce a

bushy blue flame that provides a flame

monitoring signal strong enough to reliably

open the gas shut-off valves.

Set Gas Flow Measure the gas differential pressure as

shown in Figure 7.

With the gas control valve at low fire, open

all main gas valves. The burner should

light with a stable, blue low fire flame that extends evenly down the burner

length.

Drive the control valve to high fire and adjust the gas adjusting valve to produce

a pressure drop that corresponds to the desired high fire rate, as shown in Fig. 1.

When setting high fire, be sure the flame does not impinge on anything downstream of the burner. To shorten the flame length for a given gas input, increase

the air pressure drop as described above.

Check All Settings Return the burner to low fire and check to be sure that the burner remains lit with

a stable flame that extends down the burner length. Cycle the burner between

low and high fire several times, checking pressure drops and flame lengths.

(cont’d.)

Figure 8–Butterfly

in Check Valve Line

Butterfly Valve On

640, 680 & 720

TAH Burners

Check

Valve

5.0 Routine Maintenance

Motor Lubrication Oil the blower motor according to the manufacturer’s instructions as printed on

the motor label.

Ignition Plug/Flame Rod Ignition plugs and flame rods wear out over long periods of normal burner opera-

tion. Eclipse recommends that the user keep at least one of each in stock at all

times to prevent nuisance shutdowns.

Eclipse AirHeat v1.0 - Installation Guide No. 140, 11/4/03

7

Page 8

6.0 Trouble-Shooting

Symptom Cause Check Remedy

1. Burner does not a) Air pressure switches a) Check pressures in a) Change pressure

start initially. not making. duct at location of connections where

switch connections. a more positive

b) Faulty pressure b) Check electrical pressure is present.

switches. portion of switch.

2. Burner kicks out a) Low gas pressure a) Check low pressure a) Reset

shortly after start-up. switch set too high. switch setting.

3. Pilot will not ignite on a) Raw gas fed into pilot a) Check spark plug for a) Adjust pilot gas cock by

initial light-off. causing carbon hair on carbon hair; also check first screwing needle

spark plug. gap on plug (should be closed, then with trans-

3/64" - 3/32". former powered, open

needle slowly 1/4 turn

at a time.

4. Flame failure when a) Gas pressure to pilot a) Check pilot gas pressure a) Relocate pilot gas line or

burner goes to high fire. regulator too high. to regulator (should be use second pilot

1 PSIG maximum). regulator.

b) Bolts which fasten pilot b) Check tightness of bolts. b) Tighten bolts.

casting to burner are not c) Clean impulse line of any

tight enough. c) Check impulse line for dirt particles and relocate

c) Pilot regulator not react- possible dirt clogging; duct connection to trans-

ing fast enough to duct also check impulse line mit maximum duct

pressure changes. duct connection to pressure.

d) Check valve stuck open. determine if an effective d) Clean check valve.

pressure is being trans-

e) Too much pilot gas. mitted to regulator. e) Reduce pilot gas flow.

5. Flame failure when main a) Gas pressure to pilot a) See Check 4a. a) See Remedy 4a.

burner returns from high regulator.

to low fire. b) Under-gassing pilot. b) Check pilot regulator b) Open needle on pilot

inlet and outlet gas adjusting cock slowly

pressures; also check 1/4 turn at a time.

pilot flame.

c) See Check 4c. c) See Remedy 4c.

6. Main flame too large at a) Gas pressure too high a) Check gas pressures. a) Screw out on main gas

high fire. at burner inlet. pressure regulator.

Adjust linkage on gas

b) Combustion air pressure b) Check air pressure control valve to hold

too low. differential. valve less than full open

when at high fire.

c) Check valve stuck open. b) Open air shutter on

makeup air blower.

c) Clean check valve.

7. Main flame not a) Air pressure a) Check air pressure a) Close air shutter on

extending beyond face differential too high. differential between makeup air blower.

of burner at high fire. b) Burner not firing rated combustion air manifold b) Screw in on main gas

input. and main duct. pressure regulator to

b) Check gas pressure provide more gas.

c) Burner gas holes differential. c) Clean gas holes with #42

plugged. c) Check gas holes for dirt MTD drill. Clean air

or lint. holes with #27 MTD

drill.

8. Main flame long and a) Velocity past burner a) Check velocities and a) Open shutter on

yellow. lower than 500 FPM. rotation of main makeup air blower.

b) Check valve stuck open. circulating fan. b) Clean check valve.

Info 140 11/4/03

Loading...

Loading...