Page 1

Instruction Manual

No. 826, 05/03

Bi-Flame

Dual Burner Monitoring System

Model 6500

Version 1.8

Page 2

COPYRIGHT

Copyright 2003 by Eclipse Combustion. All rights reserved

worldwide. This publication is protected by federal regulation and

shall not be copied, distributed, transmitted, transcribed or

translated into any human or computer language, in any form or

by any means, to any third parties, without the express written

consent of Eclipse Combustion.

DISCLAIMER NOTICE

LIABILITY AND

WARRANTY

In accordance with the manufacturer’s policy of continual product

improvement, the product presented in this brochure is subject

to change without notice or obligation.

The material in this manual is believed adequate for the intended

use of the product. If the product is used for purposes other than

those specified herein, confirmation of validity and suitability must

be obtained. Eclipse Combustion warrants that the product itself

does not infringe upon any United States patents. No further

warranty is expressed or implied.

We have made every effort to make this manual as accurate and

complete as possible. Should you find errors or omissions, please

bring them to our attention so that we may correct them. In this

way we hope to improve our product documentation for the benefit

of our customers. Please send your corrections and comments to

our Marketing Communications Manager.

It must be understood that Eclipse Combustion’s liability for its

products, whether due to breach of warranty, negligence, strict

liability, or otherwise, is limited to the furnishing of burner

monitoring system replacement parts and Eclipse Combustion will

not be liable for any other injury, loss, damage or expenses, whether

direct or consequential, including but not limited to loss of use,

income of, or damage to material arising in connection with the sale,

installation, use of, inability to use or the repair or replacement of

Eclipse Combustion’s products.

Eclipse Combustion, for a period of one year fr om shipment, warrants

each Bi-Flame burner monitoring system to the original purchaser to

be free from defects in material and workmanship under normal use

as defined hereafter. Any operation expressly prohibited in this Guide,

any adjustment or assembly procedures not recommended or

authorized in these instructions, shall void the warranty.

2

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

Page 3

About this manual

AUDIENCE

IMPORTANT NOTICES

DOCUMENT

CONVENTIONS

This manual has been written for the people who select and install

the product and the technicians who work on it. They are expected

to have previous experience with this kind of equipment.

• Read this manual carefully. Make sure that you understand the

structure and contents of this manual.

• Obey all the safety instructions.

• Do not deviate from any instructions or application limits in this

manual without written consent from Eclipse Combustion.

• If you do not understand any part of the information in this

manual, do not continue. Contact your Eclipse sales office or

Eclipse Combustion.

There are several special symbols in this document. You must know

their meaning and importance.

The explanation of these symbols follows. Please read it thoroughly.

Danger:

Indicates hazards or unsafe practices which WILL

result in severe personal injury or even death.

Only qualified and well trained personnel are

allowed to carry out these instructions or

procedures.

Act with great care and follow the instructions.

Warning:

Indicates hazards or unsafe practices which could

result in severe personal injur y or damage.

Act with great care and follow the instructions.

Caution:

Indicates hazards or unsafe practices which could result in

damage to the machine or minor personal injury.

Act carefully.

Note:

Indicates an important part of the text.

Read the text thoroughly.

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

3

Page 4

Table of Contents

2

3

1

About this manual....................................................................

Table of contents.......................................................................

Introduction...................................................................................

Product Description..........................................................................

Specifications ..............................................................................

Introduction...........................................................................................

Specifications .........................................................................................

Dimensions ............................................................................................

Modules Description ..............................................................

Introduction...........................................................................................

Module Description and Identification ...........................................

Relay Module.........................................................................................

Logic Module.........................................................................................

Power Module.......................................................................................

Sensor Module......................................................................................

Remote Display ....................................................................................

3

4

7

7

8

8

8

9

10

10

10

10

10

10

11

11

4

4

DIP Switch Selection .............................................................

Introduction...........................................................................................

DIP Switch Location............................................................................

DIP Switch Access................................................................................

S2 DIP Switch Settings........................................................................

S4 DIP Switch Settings........................................................................

S6 DIP Switch Settings........................................................................

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

12

12

12

12

13

13

13

Page 5

5

6

Function Summary..................................................................

Introduction...........................................................................................

Standard Features.................................................................................

Combustion Air Flow Check Terminal............................................

Main Fuel Valve Proof-of-Closure Terminal....................................

Low Fire Start T erminal ......................................................................

High Fire/High Fire Purge Check Terminal.....................................

Recycle Mode........................................................................................

Pilot Test Mode .....................................................................................

Interrupted or Intermittent Pilot.....................................................

Spark, Pilot Flame & Main Flame Separation .................................

Auxiliary Inputs.....................................................................................

History Log............................................................................................

Modulation Contacts...........................................................................

Valve Leak Sensing Device .................................................................

Remote Display Unit...........................................................................

RS232/RS485 Communication Interfaces ......................................

Logic Module Status Lights & Push-buttons ..................................

Limits.......................................................................................................

Air ............................................................................................................

Purge .......................................................................................................

Burner On..............................................................................................

Fault .........................................................................................................

Alarm.......................................................................................................

Low Fire..................................................................................................

High Fire.................................................................................................

Scan..........................................................................................................

Enter........................................................................................................

Reset........................................................................................................

System Faults.........................................................................................

System Lockout Conditions ..............................................................

14

14

14

14

14

14

14

15

15

15

15

16

16

17

18

19

19

19

19

20

20

20

20

20

20

20

20

20

20

21

21

System Installation..................................................................

Introduction...........................................................................................

Interlocks and Limit Switch Input ....................................................

Combustion Air Switch Input............................................................

Ignition Wiring.......................................................................................

Communication Wiring ......................................................................

Power Supply.........................................................................................

Low Fire Input.......................................................................................

Main Valv e Proof-of-Closure..............................................................

High Fire Input ......................................................................................

Auxiliary Inputs.....................................................................................

Remote Reset .......................................................................................

Remote Display ....................................................................................

Terminal Strips Identification & Location (Figure 6.1) ................

Wiring Diagram & Connections–Main Chassis (Figure 6.2) ........

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

22

22

22

22

23

23

23

23

23

23

23

23

24

25

26

5

Page 6

7

Sensor Installation ...................................................................

Introduction...........................................................................................

Sensor Wiring........................................................................................

Flame Rods ............................................................................................

Scanners..................................................................................................

Scanner Sighting Considerations......................................................

27

27

27

28

28

29

8

9

10

Test Procedures ...............................................................................

Introduction...........................................................................................

Flame Signal Strength ..........................................................................

Minimum Pilot Test...............................................................................

Pilot Flame Failure Test .......................................................................

Main Flame Failure Test.......................................................................

Spark Sighting Test................................................................................

Limits & Interlock Tests ......................................................................

Maintenance & Troubleshooting ..............................................

Introduction...........................................................................................

Maintenance...........................................................................................

Monthly Checklist ................................................................................

Yearly Checklist ....................................................................................

Troubleshooting....................................................................................

Remote Display Messages...........................................................

Introduction...........................................................................................

Bi-Flame Operating Sequence (Table 10.1) ...................................

Remote Display Diagnostic Messages (Table 10.2)......................

30

30

30

30

31

31

31

31

32

32

32

32

33

34

35

35

36

40

Appendix .............................................................................................

Conversion Factors .............................................................................

Illustrated Parts List.............................................................................

6

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

43

43

44

Page 7

Introduction

1

PRODUCT

DESCRIPTION

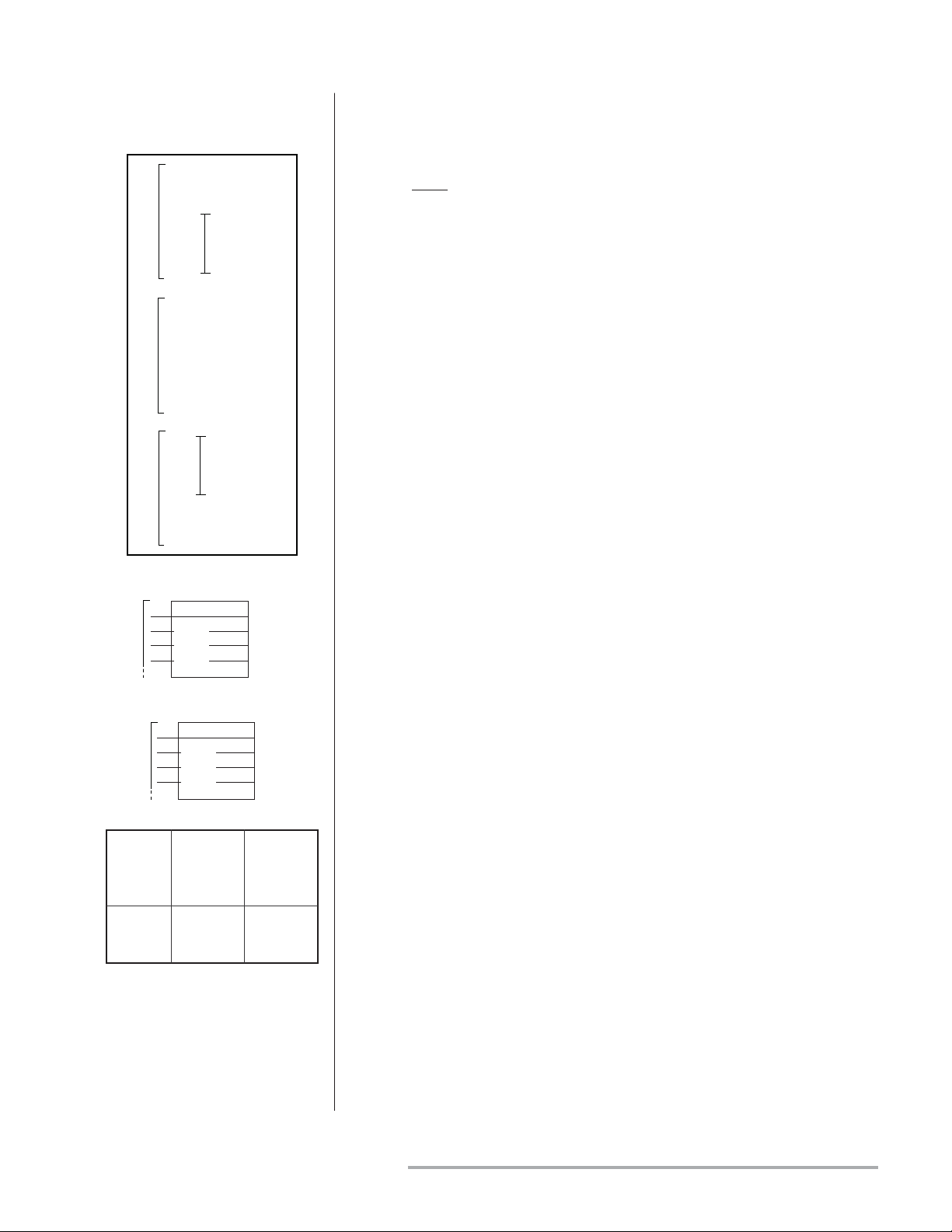

The Eclipse Combustion Bi-Flame Burner Monitoring System

controls the start-up sequence and monitors the flame of two

individual gas, oil, or combination gas/oil burners connected to a

common valve train. Its dynamic on-board testing checks for

faulty relays, proof of valve closure, high and low fire switch

interlocks, and shorted air switch.

The microcomputer based system features a plug-in modular

design so any of the circuit board modules attached to the

motherboard can be replaced when power is removed. Its DIP

switches allow sequence and timing functions, as well as system

configuration. It is also capable of modulation (high and low fire

purging) and monitoring up to four auxiliary inputs, history

logging, and interfacing to valve leakage detection devices. It is UL

recognized, FM approved and CSA certified.

Figure 1.1

Bi-Flame Burner Monitoring System

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

7

Page 8

Specifications

2

INTRODUCTION

Specifications

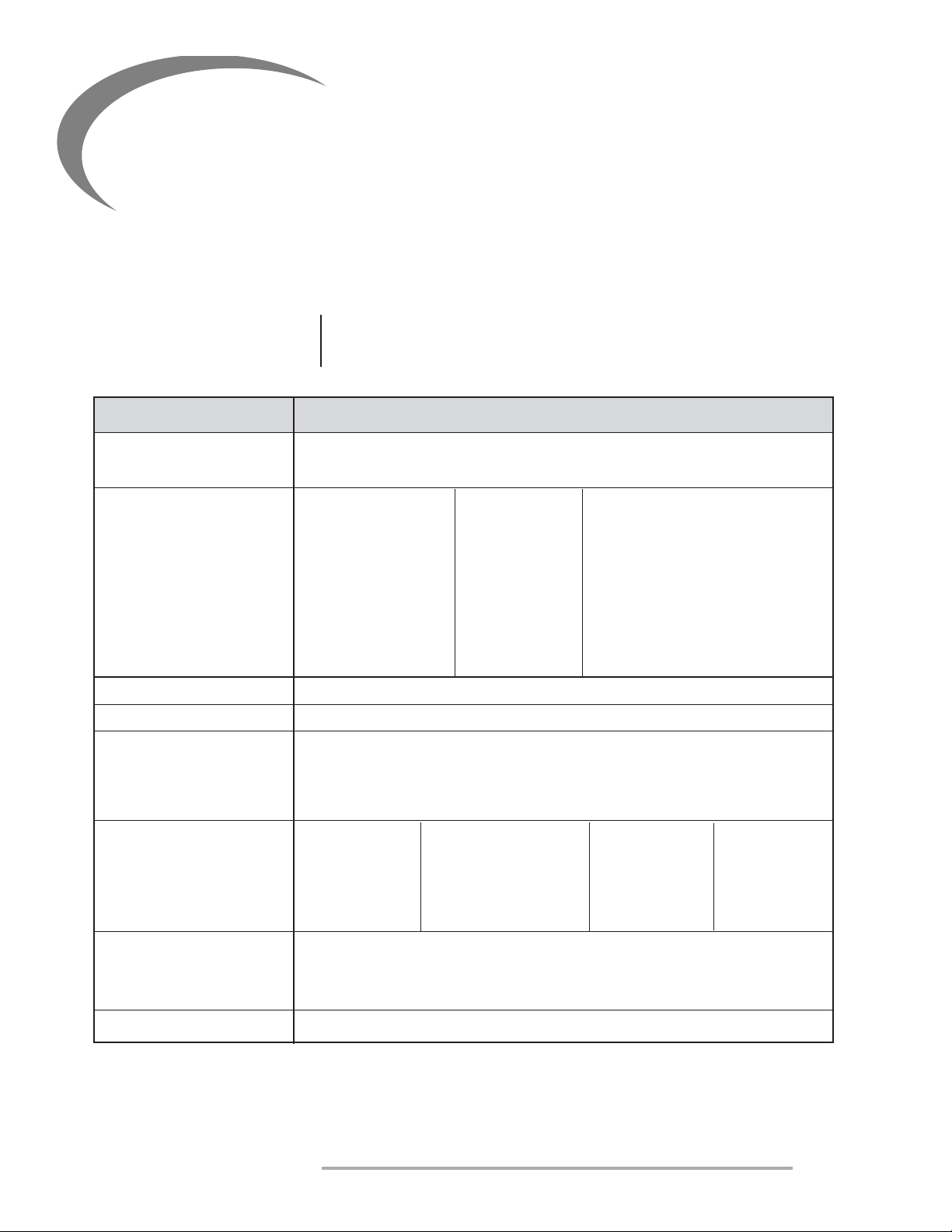

Parameter Description

Supply •120 VAC (+10%, -15%), 50/60 Hz standard.

Internal power consumption: 24VA

Temperature Ranges Unit Model Nos. Temperature Range

Bi-Flame 6500 -40˚ to +60˚C (-40˚ to +140˚F)

90˚ U.V. Scanner 5600-90A -20˚ to +60˚C (0˚ to 140˚F)

U.V. Scanner 5600-91 -40˚ to +125˚C (-40˚ to +257˚F)

NEMA4 UV Scanner 5600-91N4 -20˚ to +125˚C (0˚ to 257˚F)

Self-Check U.V. 5602-91 -40˚ to +60˚C (-40˚ to +140˚F)

Remote Display 6000D 0˚ to 50˚C (32˚ to 122˚F)

Flame Failure Response • 3 seconds ±0.5 seconds.

TFI/Pilot Interrupt • 5, 10 or 15 seconds selectable.

Purge Time • Modulating: selectable from 0-225 seconds in 15 second increments,

or 0-15 minutes in 1 minute increments

• Process: selectable from 0-15 minutes in 1 minute increments,

or 0-60 minutes in 4 minute increments.

This section gives a detailed overview of Bi-Flame specifications and

dimensions.

Contact Ratings @ 120 VAC Function Affected Terminals Inductive Load Resistive Load

(maximum total connected Output Relay J2-4 through J2-8 1/3 HP 10 amps

load not to exceed 15 amps) Output Relay J2-3 1/2 HP 15 amps

Modulation J3-1 through J3-4 1/3 HP 10 amps

Approvals • UL Recognized; File MP1537 (category MCCZ2)

• FM Approved; J.I. 2Y3A5.AF (class 7610)

• CSA Certified; File 007989-0-000 (class 2632-01, 2642-01)

Shipping Weight • 2.7 kilograms (6 lbs.)

8

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

Page 9

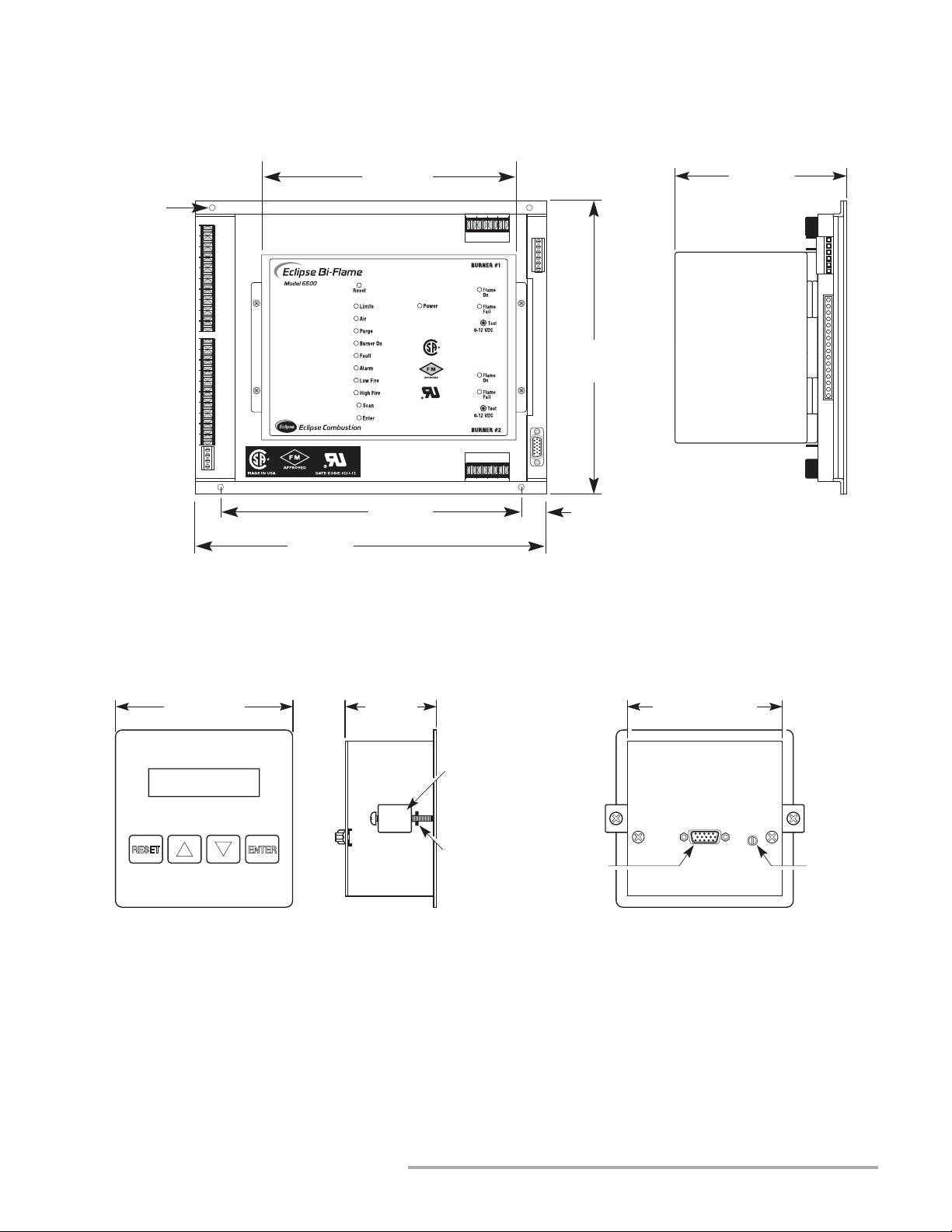

DIMENSIONS

Main Chassis

Mounting

Holes (4)

5 mm

(3/16") Dia.

183 mm

(7-3/16")

140 mm

(5-1/2")

237 mm

(9-5/16")

Remote Display

102 mm

(4") Square

229 mm

(9")

270 mm

(10-5/8")

(Shown with remote keypad and reset)

54 mm

(2-1/8")

Mounting

Bracket &

Screw (2)

Mounting

Bracket

Slot (4)

21 mm

(13/16")

15-pin

Port

Terminal

89 mm

(3-1/2") Square

Contrast

Adjustment

Slot

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

9

Page 10

Modules Descr iption

3

INTRODUCTION

MODULE DESCRIPTION

AND

IDENTIFICATION

Relay Module Location

In this section, you will find descriptions of the various modules

which comprise the Bi-Flame dual burner flame monitoring system,

whether standard or optional items.

Relay Module

The relay module contains the output relays which provide power

for operating the ignition coil, pilot valve, main valve, combustion

fan and alarm. This module is mounted in the first position on the

left of the motherboard closest to the output terminals.

Logic Module

The logic module houses the microcomputer which provides all

the sequential logic and safety start-up and shutdown circuitry. On

the front of this module is the reset, scan and enter push-buttons,

and status lights. This module is mounted in the second position

from the left of the motherboard next to the relay module.

Power Module

10

The power module supplies the power required for the electronic

circuitry. It is mounted in the motherboard to the right of the logic

module. The green LED on the front indicates that power is on to

the Bi-Flame.

Logic Module Location

Power Module Location

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

Page 11

Sensor Module Location

Sensor Module

The sensor module is the flame sensing module of the Bi-Flame. It is

mounted in the furthest right position of the mother board.

On the front of the sensor module are two “Flame On” LED’s, which

illuminate when a flame is detected at the corresponding burner.

Directly below the “Flame ON” LED are “Flame Fail” LED’s, which

energize to show the first burner to lose its signal.

The sensor module incorporates test point connection jacks in the

front of the unit. Using these, the flame signal strength of each burner

can be measured using a 0-15 VDC, one meg ohm/v olt meter as

explained and shown in “Flame Signal Strength” on page 30.

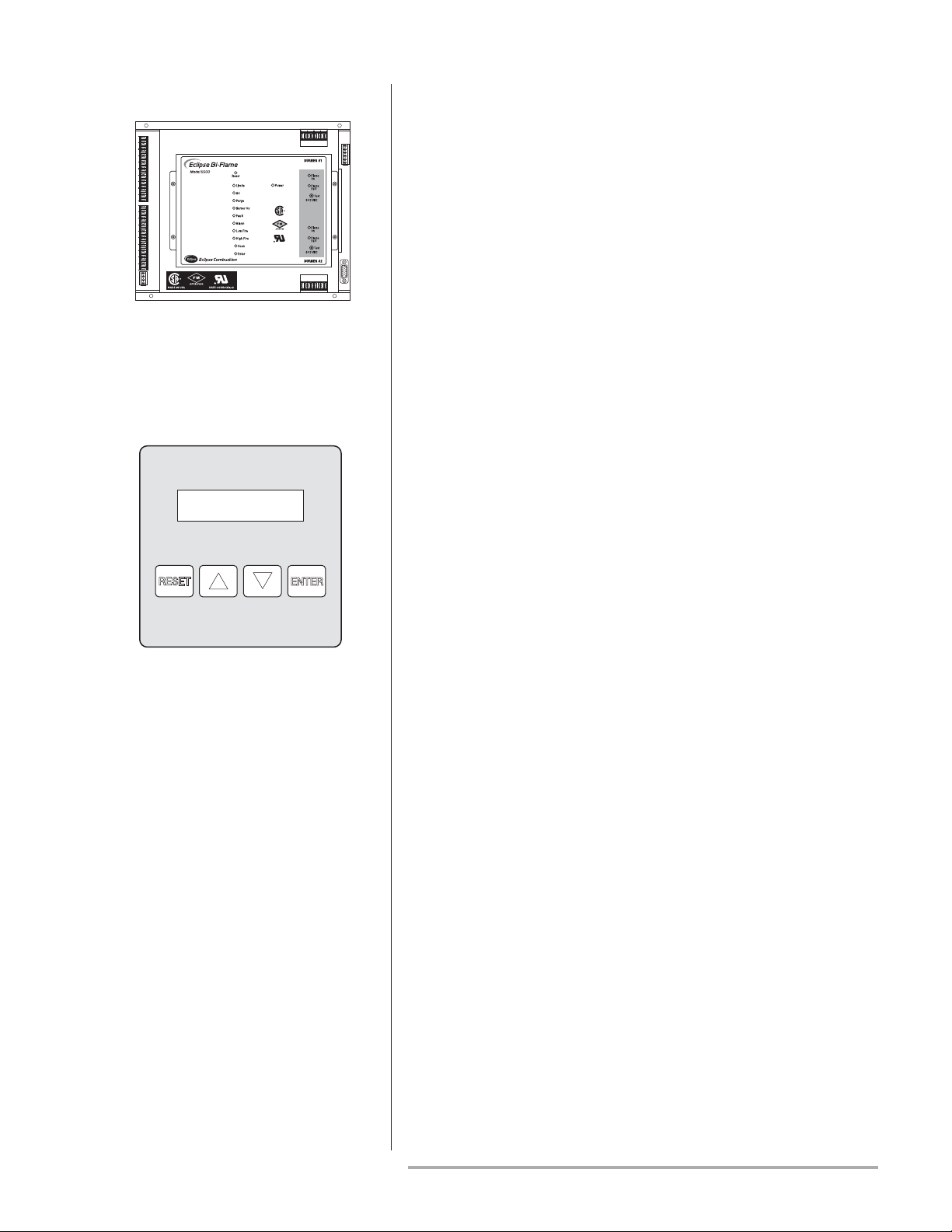

Remote Display

The remote display provides alphanumeric messages which indicate

burner status as well as annunciate lockout condition in the Bi-Flame

system. It also provides remote reset, a keypad and history logging

capability.

A cable connects the remote display to the motherboard; this cable is

available in six and 10 feet lengths.

Remote Display

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

11

Page 12

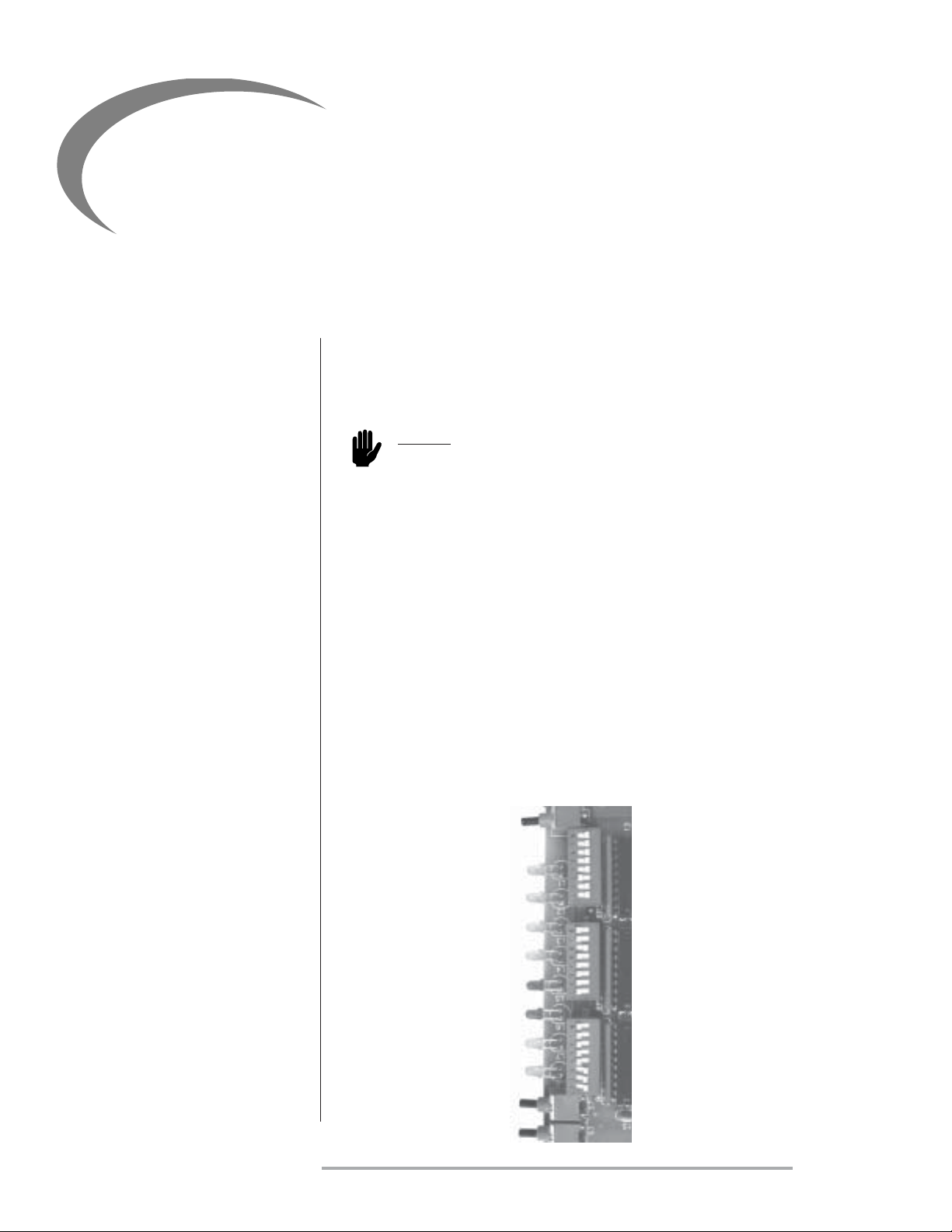

DIP Switch Selection

INTRODUCTION This section details the location, selection and description of the

Bi-Flame DIP switches, which allow for sequence and timing functions as well as system configuration.

Caution:

To avoid electric shock, shut off the power supply when installing

any control device. Flame monitoring systems must be installed

by a qualified, licensed technician.

4

DIP SWITCH LOCA TION

DIP SWITCH ACCESS

All of the DIP switches are located in the logic module, which is

mounted in the second position from the left of the motherboard

next to the relay module (see page 10 for logic module location).

To gain access to the DIP switches, remove the circuit board

cover. To do this, remove the four screws which hold the cover to

the motherboard. Remove the cover by lifting up and off of the circuit boards. The logic module is the second board from the left.

Gently pull the logic module with a rocking motion to disengage

the terminal pins at the module base. The photo below sh ows

the DIP switch locations.

ON/OFF

S6

S4

12

S2

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

Page 13

DIP SWITCH SETTINGS

S2 DIP Switches

ON/OFF

8

50/60Hz

7

—

6

—

5

S6

S4

S2

8

7

6

S2

5

4

S2 Modulation Purge Time, S4 - 8 = ON

8

7

6

S2

5

4

S2 Process Purge Time, S4 - 8 = OFF

Number

4

3

2

1

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

of

PAF

MOD/PROC

TFI

—

LEAK 110/40

—

—

—

BLOWER

P

U

R

G

E

PILOT IMIT/IRPT

RECYCLE

DIP Switch Functions

ON

OFF

—

X4

120 sec.

Time

60 sec.

Not

30 sec.

Added

15 sec.

ON

OFF

—

X4

8 min.

Time

4 min.

Not

2 min.

Added

1 min.

X4

120/8

60/4

30/2

15/1

TFI

The S2 DIP switches permit programming of timing and sequence

functions of the Bi-Flame.

Note:

The S2 DIP switch settings at left are for illustrative purposes

only; the actual settings of any of these switches will be

determined by your system conditions.

SW1: Recycling mode selection (On=Recycling; Off=Non-recycling)

SW2: Pilot selection (On=Intermittent, where pilot remains on during

burner cycle; Off =Interrupted, where pilot valve closes after main

burner is established).

SW3: T rial-for -ignition (TFI) range selection; used with SW7 of the S4

DIP switch. See the table at left for proper selection.

SW4 through 8: Purge time selection; switch in off position selects

indicated purge time. Selected purge times are additive. See

illustration at left for exact times.

S4 DIP Switches

SW1: Fan operation on flame failure (on = fan turns off; off = fan stays

on).

SW5: Leak test time (on=110 seconds; off=40 seconds).

SW7: T rial-for -ignition (TFI) range selection; used with SW3 of the S2

DIP switches. See the table at left for proper selection.

SW8: Purge mode; (on = modulation, off = process).

S6 DIP Switches

The S6 DIP switches are factory set for two burners. DO NOT

CHANGE. Any other setting will result in an “UNMATCH#” fault

condition.

SW6: Off, Not used.

SW7: Off, Not used.

SW8: Frequency Selection; (On = 50Hz, Off = 60 Hz)

THEN

SW3 of S2

If the

TFI

needed is:

5 seconds

10 seconds

15 seconds

DIP switch

must be

turned:

Off

Off

On

Trial-for-Ignition (TFI) Settings

AND

SW7 of S4

DIP Switch

must be

turned:

Off

On

Off or On

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

13

Page 14

Function Summar y

5

INTRODUCTION This section describes the function features of the Bi-Flame that can

be found on the various terminal strips and the modules of the BiFlame.

Combustion Air Flo w Check Terminal

The Bi-Flame checks that the combustion air flow switch is open before start-up, closed during operation and open again at burner shutdown, thus preventing operation with an air switch that is defective,

maladjusted or jumpered.

Main Fuel Valve Proof-of-Closur e T erminal

The Bi-Flame checks that the main fuel valve is closed before startup and after burner shutdown. This ar rangement requir es a closed

position switch on the main fuel valve.

Low Fire Start Terminal

The system checks for the low fire start position prior to light-off. If

voltage is not present on this terminal within 15 minutes, the Bi-Flame

goes to lockout and alarm.

High Fire Purge Check Terminal

The system checks that the air modulation motor reached the high

fire position during high fire purge. The modulation motor or air

valve must be fitted with a high fire position switch, which is then

connected to the high fire check terminal. An air flow or pressure

switch that is set to prove sufficient purge air may be used instead

of the high fire position switch. If v oltage is not pr esent on this terminal within 15 minutes, the Bi-Flame goes to lockout and alarm.

14

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

Page 15

Recycle Mode

When selected, the Bi-Flame will restart the sequence after flame or

air failure. The recycle mode allows the system to re-initiate the

start-up sequence automatically, once the main burners have been

operating for at least 20 seconds. If the pilot flame fails to light during recycling, the system will lock out and annunciate a pilot flame

fail. If the recycle is successful and the main burners are operational

for at least 20 seconds, the system is ready for another recycle. At

no time will the system recycle in the event of pilot flame fail.

Pilot T est Mode

This mode is entered by pressing the “Reset” and the “Enter” buttons simultaneously then releasing the “Reset” button but holding

the “Enter” button for another 10 seconds. The limits light will

flash off and on, indicating that the system is in the test mode.

In the pilot test mode, the Bi-Flame operates normally with the exception that the main valves are not energized, preventing the main burners from igniting.

To exit the pilot test mode, simply press the “Reset” button and the

Bi-Flame will exit the pilot test mode and restart the sequence. Entering the pilot test mode erases the history log.

Interrupted or Intermittent Pilot

Pilot mode is selected using the DIP switch (see “S2 DIP Switch

Settings” on page 13). An interrupted pilot shuts off after the main

flame is established. An intermittent pilot continues during the entire main flame firing cycle.

Spark, Pilot Flame and Main Flame Separation

During the trial for ignition period (TFI), the pilot and ignition outputs remain energized. At the end of the TFI, the pilot output remains on and the ignition output is de-energized. After a five second delay to prove the pilot flame, the main output is energized.

Note:

Both pilots must light within the specified TFI or a pilot flame

failure will occur. If one burner experiences either a pilot or

main flame failure, then both burners will shut down. The failed

burner will be indicated by the red “Flame Fail” light.

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

15

Page 16

Auxiliary Inputs

This feature provides four auxiliary inputs which are monitored by

the Bi-Flame as alarm interlocks. This means that when the input

voltage is interrupted, the system locks out and will annunciate on

the optional remote display unit.

A voltage of 120 VAC must be present at the input for the Bi-Flame

system to operate. If an auxiliary input loses its voltage for more

than one second while the interlocks and limits input is powered, a

lockout condition will occur. If the Bi-Flame is equipped with a remote display unit, the following message will occur:

Aux. Input #1 Aux. Input #2 Aux. Input #3 Aux. Input #4

AUX.LIM. #1 FAIL AUX.LIM. #2 FAIL AUX.LIM. #3 FAIL AUX.LIM. #4 FAIL

LKOUT HHHH:MM:SS LKOUT HHHH:MM:SS LKOUT HHHH:MM:SS LKOUT HHHH:MM:SS

Note:

Unused auxiliary inputs should be connected to 120 VAC.

History Log

The history log is only accessible through the remote display unit

with remote reset, and when the Bi-Flame is in a “LOCKOUT” or

“LIMITS OPEN” condition. The history log records the total number of operating cycles, total recycles, cause of last recycle and t h e

last lockout messages up to a maximum of 10.

With a remote display available and the Bi-Flame in one of the two

conditions described above, the history log can be accessed as follows:

1) P ress and hold the ENTER key on the remote display unit until

the following message appears:

TOTAL OPERATING CYCLES = XXXXXX (where X is a

digit between 1 and 9).

The record number will display as long as the ENTER key is

pressed. The scan button on the logic board also scrolls the history log.

2) If there has been a recycle, release and press the ENTER key to

see: RECYCLES TOTAL = XXXXXX then release and press

the ENTER key to see:

LAST RECYCLE BY AIR=XXXXXX or

LAST RECYCLE BY FLAME=XXXXXX

3) Release and press the ENTER key a second time. The record

number of the lockout message will be displayed:

RECORD #X (where X is the number of the most recent

lockout)

(continued on next page)

16

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

Page 17

History Log (continued)

4) Release the ENTER key and the most recent lockout message

will display for seven seconds.

5) If you wish to see the next lockout message, press and release

the ENTER key before the seven second time duration ends of

the most recent lockout message display. This will prompt the

next lockout message. If desired, continue this procedure until

the maximum of ten lockout messages has been displayed (remember that the highest record number is the most recent

lockout message).

6) Continued pressing and releasing of the ENTER k ey in less than

seven seconds keeps the history log active and repeats the lockout message list; waiting longer than seven seconds deactivates

the history log mode and the next display is the last sequence

message before the history log was activated. For example, if the

message “LIMITS OPEN” was displayed when the history log was

activated, then that message will appear again after seven seconds.

7) If you wish to erase all of the lockout messages from the history log, press the RESET and ENTER keys simultaneously

while the history log is active. Release the RESET key, but hold

the ENTER key for another five seconds. Wait five seconds and

press and release the RESET key.

Modulation Contacts

The modulation feature incorporates “drive high”, “drive low”, and

“automatic” contacts into the purge sequence. This feature allows

the Bi-Flame to sequence internal dry contacts which can be used

by the customer requiring a high fire purge of the combustion

chamber before ignition.

The high fire purge time is selectable by means of S2 DIP switches

on the logic board (see “S2 DIP Switch Settings” on page 13)

With this option, the modulation terminals on J3 terminal strip will

sequence as follows:

Sequence Step Internal Contact Connections

High Fire Purge Terminal 1 (COMMON) to Terminal 3 (HI FIRE)

Low Fire Start Terminal 1 (COMMON) to Terminal 4 (LOW FIRE)

Automatic Terminal 1 (COMMON) to Terminal 2 (AUTO)

Post Purge Terminal 1 (COMMON) to Terminal 4 (LOW FIRE)

Power Off Terminal 1 (COMMON) to Terminal 2 (AUTO)

Power On/Limits Off Terminal 1 (COMMON) to Terminal 4 (LOW FIRE)

Alarm Terminal 1 (COMMON) to Terminal 4 (LOW FIRE)

The Automatic step occurs 20 seconds after the main output has

energized (see Table 10.1 beginning on page 36) and allows the

burner firing rate to be controlled by an automatic temperature

controller.

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

17

Page 18

Valve Leak Sensing Device (VLSD) Interface

The Bi-Flame Valve Leak Sensing Device (VLSD or VDK) interface

provides a 120 VAC output which triggers the start of the test pe-

riod. An input is also provided which receives a 120 VAC signal

from the VLSD. If the signal is received within the selected test pe-

riod (40 or 110 seconds, see page 13), then the test has been suc-

cessfully completed. This option includes the required sequential

software to initiate the valve leak test on start-up and shutdown of

the burners.

When the limits close to the Bi-Flame, the 120 VAC output to the

VLSD is activated. If an optional remote display is connected, the fol-

lowing message will appear:

VALVE LEAKAGE

UNDER TEST XX (where X is the remaining seconds of the

test).

If the VLSD does not activate the VLSD 120 VAC input within the

test period, an alarm lockout will occur, and the following message

will appear on the optional remote display:

VALVE LEAK FAIL

LKOUT HHHH:MM:SS

If a valve leak occurs, the fan output on the Bi-Flame will be acti-

vated to purge the combustion chamber of gases.

Note:

If the VLSD input is not used, then it should be connected to

120 VA C.

18

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

Page 19

Remote Display Unit

The remote display with keypad allows remote reset and activation

of the history log option. It is panel mountable and features a backlit liquid crystal display in a 1/4 DIN housing. It connects to the BiFlame by a six or ten foot cable. The display incorporates the following features:

1) P rovides status messages for the Bi-Flame sequence. (See Section 10)

2) Indicates lockout conditions when they occur, as well as the

amount of time into the sequence when the lockout occurred

and the amount of time elapsed from lockout.

3) P rovides continuous monitoring of each burner’s flame signal

strength during main burner operation. (Pressing ENTER once

will lock on a particular burner’s status; pressing ENTER a second time will resume scrolling).

4) Incorporates a remote reset key.

5) P rovides the interface required for the History Log.

6) Incorporates keys for pilot test mode.

L

OGIC MODULE ST A TUS

L

IGHTS

& P

USH-BUTT ONS

RS232 Communication Interfaces (RS485 optional)

Terminals 1, 5, and 6 on Bi-Flame terminal strip J7 provide a serial

ASCII output communication interface for remotely monitoring the

system sequence and status using a terminal or a modem; refer to

Section 10 for the types of messages sent by the Bi-Flame.

The communications protocol is 8 bit, no parity , 1 stop bit and1200

baud. This feature is pr o vided standar d as a RS232 interface.The RS485

interface is optional.

Sending a carriage return (<CR> = ASCII Hex 0D) from the terminal

causes the Bi-Flame to retransmit the last message. Sending a CTRLE (<ENQ> = ASCII Hex 05) accesses the optional history log.

The logic module provides all the sequential logic, and safety startup and shutdown circuitry. On the front of the module is the reset,

scan and enter push-buttons, and status lights. This section describes the their respective functions.

Limits

This LED illuminates when the operation limits are made. These limits

are wired in series to terminal J1-1. This input becomes energized to

begin the burner sequence. When in the test mode, this LED flashes

(see “Pilot Test Mode” on page 15).

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

19

Page 20

Air

This LED illuminates when the air switch is closed and power is

thereby applied to the air switch input. The Bi-Flame also checks this

input for an air switch short (see “Combustion Air Flow Check Terminal” on page 14).

Purge

This LED illuminates whenever the combustion blower is energized,

including the purge period and the main burner period of the sequence. It blinks on and off while the purge is in process and remains

constant when the purge process is complete.

Burner On

This LED illuminates when the main gas valve is energized, permitting

gas flow to all the burners.

Fault

This LED illuminates when a system fault is detected (see “System

Faults” on page 21).

Alarm

This LED illuminates when an alarm condition causes a system lockout (see “System Lockout Conditions” on page 21).

Low Fire

This LED illuminates during the low fire period of the purge cycle.

High Fire

This LED illuminates during the high fire period of the purge cycle.

Scan

This push-button can be used to scroll the history log.

Enter

This push-button is used with the RESET button to enable the pilot

test mode.

Reset

This push-button resets the control. It is also used with the ENTER

button to enable the pilot test mode.

20

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

Page 21

System Faults

A system fault (illuminated by the fault LED on the logic cards) prevents gas ignition but does not lock out the system. System fault conditions are as follows:

1) If a flame is detected out of sequence, which may be caused by:

a) a faulty scanner

b) electrical interference on the sensor leads

c) a flame exists in the burner due to a gas leak or other condition.

2) Air flow switch closed before start-up.

System Lockout Conditions

A system lockout will occur (illuminated by the alarm LED on the

logic card) for any of the following conditions:

1) Air failure–loss of combustion anytime during the operational

cycle.

2) Pilot flame fail–loss of flame during the trial for pilot ignition

period.

3) Main flame fail–loss of flame during the main burner trial for ig-

nition.

4) Main fuel valve–open after cycle shutdown or before start-up

with interlocks closed.

5) Unmatched burners–the S6 DIP switch is not set correctly (see

“S6 DIP Switch Settings” on page 13).

6) Relay fail–failure of Bi-Flame internal relays.

7) Low fire fail–low fire switch open for more than 15 minutes

prior to trial for ignition.

8) High fire fail–high fire switch has not closed within 15 minutes

of high fire purge.

9) Flame fail–loss of flame after main flame has been established.

10) Auxiliary input fail–loss of input voltage to any of the four

“Aux” terminals after the limit input is made.

11) Valve leak fail–valve leak sensing device has detected a leak.

12) Wiring error which puts external voltage on any of the output

terminals.

13) W elded internal contacts or other malfunctions in the Bi-Flame.

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

21

Page 22

System Installation

6

INTRODUCTION

INTERLOCKS AND

LIMIT

SWITCH INPUT

In this section, the necessary procedures are detailed to integrate a

Bi-Flame into a burner system; Figure 6.1 (page 25) illustrates the

various terminal strips mentioned.

Note:

Shut off the power supply before any module is removed or

replaced from the unit, including the remote display.

Caution:

Installation and maintenance must conform with the National

Electrical Code and all other national and local codes and authorities having jurisdiction.

Interlocks are generally pressure or temperature switches which,

when activated, start the burner. Limit switches are generally

pressure, temperature and other switches which, when activated,

stop the burner. The interlocks and limit switches are wired in

series. A break in this circuit will shut the burner down, but will not

produce an alarm. This input is considered the normal operation

control input to the Bi-Flame system.

22

COMBUSTION AIR

SWITCH

INPUT

This input is for monitoring the combustion air switch separately

from other interlocks and limits. When wired to this input, the air

switch will be proven open before start-up and after shutdown. It

will also be proven closed 10 seconds after the combustion air

blower is energized.

If the air switch opens during the main firing cycle, the system will

either lockout or recycle, depending on the DIP switch selection.

If this terminal is not used, place a jumper between the combustion

blower output (terminal 3 on terminal strip J2) and the air switch

input (terminal 2 on terminal strip J1). This jumper must not be

used in place of a required air flow switch interlock.

If the combustion air blower is controlled outside of the Bi-Flame

system, then the air switch must be wired between the combustion

blower output and the air switch input. Connecting the air switch

in this manner will prevent the open contact (air short) check on

the switch.

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

Page 23

IGNITION WIRING

Route ignition wiring a sufficient distance from all sensors and other

low voltage wiring to avoid electrical interference, which may cause

erratic operation of the Bi-Flame system.

Caution:

Do not connect multiple ignition coils in excess of output relay

contact rating

COMMUNICATION

WIRING

POWER SUPPLY

LOW FIRE POSITION

INPUT

MAIN VALVE

PROOF

-OF-CLOSURE

Route communication wiring, using shielded cable, a sufficient

distance from ignition and other high voltage wiring to avoid

electrical interference.

All input power must be single phase 120 VAC, 60/50 Hz selectable,

see page 13. All circuits must have a common 15 amp fuse and

disconnect. The neutral must be grounded. Do not use solid-state

triac output devices in any of the input circuits. 120 VAC wiring

must be at least 90°C 16 AWG minimum and satisfy all applicable

codes.

It is possible to wire the system for checking low fire start position

prior to pilot ignition. To use this feature, the low fire start switch

must be connected to the low fire start input (terminal 4 on

terminal strip J1). If this feature is not used, a jumper must be

placed between terminals 1 and 4 on terminal strip J1.

The system can be wired to check for the proof of valve closure

(POVC) switch on the main gas valve prior to start-up and after

the end of the burner cycle.

To use this feature the POVC switch must be connected to the

POVC switch input (terminal 3 on terminal strip J1). If this feature

is not used, a jumper must be placed between terminals 2 on

terminal strip J2 and 3 on terminal strip J1.

HIGH FIRE POSITION

INPUT

AUXILIARY INPUTS

The system can be wired to check for high fire position during the

high fire purge portion of the sequence. To use this feature, the

high fire position switch must be connected to the high fire input

(terminal 5 on terminal strip J1). If this feature is not used, a jumper

must be placed between terminals 1 and 5 on terminal strip J1.

The system can be wired to check auxiliary status conditions with

the four auxiliary inputs. To use this feature, the auxiliary input

switches must be wired to the auxiliary inputs (terminals 7,8,9 and

10 on terminal strip J1). If this feature is not used, these inputs

must be connected to 120 VAC.

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

23

Page 24

REMOTE RESET

This feature permits remote mounting of a switch to reset the BiFlame. To use this feature, a normally closed remote reset switch

must be wired between terminals 1 and 4 on terminal strip J7. When

it is depressed or actuated, the connection between the terminals is

momentarily interrupted and resets the Bi-Flame. This is a low

voltage signal circuit that must be routed separately from other

control voltage wiring. Use two-conductor shielded cable with the

shield connected on one end only to terminal 1 of J7.

Note:

If reset is required from both the dispaly and the J7 terminals, use

a normally open switch.

REMOTE DISPLAY

When installed, the remote display must be grounded. Panel

mounting is through a 1/4 DIN cutout (see page 9). Use either the

six or ten foot cable to connect it to the motherboard.

Warning:

Power must be off when inserting or removing

the cable.

24

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

Page 25

Figure 6.1

Terminal Strips Identification & Location

Main Chassis

J1

J2

J3

J4

J7

J6

Remote

Display

Connection

J5

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

25

Page 26

Figure 6.2

Wiring Diagram & Connection s–Main Chassis

VDK/VLSD

J4

Terminals

Flame Rod

1

2

3

4

On/Off

Interlocks & Limits

Leak Detect

Aux. Input #1

Aux. Input #2

Aux. Input #3

Aux. Input #4

2

Yellow

Blue

Shield

Air Flow

POVC

Low Fire

High Fire

5600-90A

or 5600-91

U.V. Scanner

15 A. Fuse

Terminals

1

1

1

1

J1

1

2

3

4

5

6

7

8

9

10

Burner #1

J3

Terminals

1

2

3

4

GND (Return)

120 VAC

Common

Auto

High Fire

Low Fire

Terminals

120 VAC

Neutral

Signal (UV)

Neutral

Customer Supplied (if used)

ACT004

P1-1

P1-2

P1-4

Temperature

Controller

4 to 20 mA

J7

Rx

6

5

RS 232

Tx

4

3

2

1

Remote

Reset

Pushbutton

(if required)

B

A

C

D

5602-91

U.V.

Self-Check

Scanner

+

Terminals

Terminals

J5

1

2

Flame Rod

3

4

J2

1

2

3

4

5

6

7

8

2

Blue

Yellow

Shield

Neutral

Fan Motor

Main

Pilot

Ignition

Leak Detect

Alarm

MS

Pilot Gas Valve

VDK/VLSD

5600-90A

or 5600-91

U.V. Scanner

Main Gas Valve

Block Valve

Ignition Coil

Ignition Coil

Burner #2

J1 (Input) Terminals

1 – Limits Input

2 – Air Switch Input

3 – POVC Switch Input

4 – Low Fire Switch Input

5 – High Fire Switch Input

6 – VDK/VLDS Input

7 – Aux. #1

8 – Aux. #2

9 – Aux. #3

10 – Aux. #4

1

1

1

1

J2 (Output) Terminals

1 – Neutral

2 – 120 VAC

3 – Fan

4 – Main Gas Valve

5 – Pilot Gas Valve

6 – Ignition Transformer

7 – VDK/VLSD

8 – Alarm

1

When not used, must be tied into 120 VAC.

2

Using both sensors isn’t mandatory; you may use a flame rod, or a UV scanner, or both.

Auxiliary

Inputs

J3 (Modulation) Terminals

1 – Common

2 – Auto

3 – Hi Fire

4 – Low Fire

Modulation

Motor

Connections

for High Fire &

Low Fire Start

J4 (Sensors/Burners 1 & 3) Terminals

1 – Flame Rod

2 – Ground (Yellow)

3 – U.V. (Blue)

Burner #1

J5 (Sensors/Burners 2 & 4) Terminals

1 – U.V. (Blue)

2 – Ground (Yellow)

3 – Flame Rod

4 – Shield Connection

2

4 – Shield Connection

J7 (Interface) Terminals

Bi-Flame

Power Inputs

Outputs

6 – RS 232/RS 485 Interface

5 – RS 232/RS 485 Interface

4 – Reset

3 – Scan

2 – Enter

1 – Ground

2

Burner #2

26

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

Page 27

Sensor Installation

7

INTRODUCTION

SENSOR WIRING

This section describes the proper wiring, installation and sighting considerations for all sensors that can be used with a Bi-Flame.

Warning

Incorrect sensor installation may cause the sensor

to generate a false flame signal, causing unburned

fuel to collect in the combustion chamber. The result can be explosions, injuries and property damage. Be cer tain that the flame sensor detects only

pilot and main flames, not glowing refractory,

burner or ignition parts.

Route sensor wiring a sufficient distance from ignition and other

high voltage or high current wiring to avoid electrical interference.

Interference from ground currents, nearby conductors, radio-frequency emitters (wireless divices), and inv erter drives can induce false

flame signals. Shielded cables can help reduce interference with the

shield connected to ground at the control end only. The wire type

and its capacitance (picofarads or microfarads) to ground may cause

low signal problems, so a gr ounded shield may decr ease the signal due

to the cable’s internal capacitance. Multiple U.V. tube-type sensor

leads run together without shielding may interfere or “cross talk”, so

the shield or flexible armor must be grounded to prevent this situation. For flame rod sensor runs approximately 100 feet (30 meters)

or greater, use Eclipse part number 21741 coax cable. To achieve the

maximum wiring distance, the shield should not be grounded (keep

in mind that an ungrounded shield provides less protection against

electrical interference).

Do not ground the shield to terminal GND.

Note:

Unshielded sensor wiring must not be run in common with other

wires; it must be run in separate conduit. Multiple unshielded

flame sensor wiring must not be run together in a common

conduit or wireway. Use #14 to #18 AWG wire suitable for 90°C

(194°F) and 600 volt insulation, or better grade if required by

the application. Multiple shielded cables can be run in a common

conduit.

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

27

Page 28

FLAME RODS

Flame Rod

WRONG

Rod Detects

Weak Pilot

PILOT

Flame Rod Position

CORRECT

Rod Detects

Only Strong

Pilot Flame

Flame rods should be used only on gas burners. They accumulate

soot on oil burners, causing nuisance shutdowns and unsafe operating conditions.

See the burner manufacturer’s literature for flame rod mounting

location. When installing flame rods, please consider the following:

1) Keep the flame rod as short as possible and at least 13 mm (1/2")

away from any refractory .

2) Position the rod into the side of both the pilot and main flames,

preferably at a descending angle to minimize drooping of the

flame rod against burner parts. Flame rod position must adequately detect the pilot flame at all burner draft conditions. Extend the rod 13 mm (1/2") into nonluminous flames, such as blue

flames from burning an air/gas mixture. For partially luminous

flames, such as atmospheric air/gas mixtures, place the rod at the

edge of the flame.

3) Provide a burner/flame grounding area that is at least four times

greater than the flame rod area contacting the flame. The flame

rod/burner ground ratio and position of the rod in the flame

may need adjustment to yield maximum flame signal strength.

4) Ignition interference from the spark plug may increase or decrease

the flame signal strength. Reversing the ignition transformer primary leads may reverse this effect. Reducing the spark gap or adding grounding area between the flame rod and spark plug may

eliminate the interference.

SCANNERS

U.V . Scanner

(Model 5600-91)

90° U.V .

Scanner

(Model 5600-90A)

Self-Check

U.V . Scanner

(Model 5602-91)

Use only Eclipse model 5600-90A, 5600-91, 5602-91or 5600-91N4

scanners. Consult the burner manufacturer’s instructions for mounting

location. When installing scanners, please consider the following:

1) Position the scanner within 457 mm (18") of the flame.

2) Bushing threads are 1/2 inch F.N.P.T. for scanner models

5600-90A, 5600-91 and 5600-91N4; model 5602-91 has 1

inch F.N.P.T. bushing threads.

3) The ambient temperature limits of each scanner varies, (see specifications). For higher temperatures, use Eclipse heat insulator

49099 or the Heat Block Seal, Model 23HBS, that has a purge fitting.

4) An optional magnifying lens (Eclipse #49600-98) may also be used

to increase the flame signal strength in difficult sighting situations.

28

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

Page 29

SCANNER SIGHTING

CONDITIONS

MAIN

BURNER

Scanner

Sight

Line

SCANNER

U.V. Scanner Sighting

1/3 of

Flame Length

Aim scanners at the third of the flame closest to the burner nozzle, as

shown at left. This is especially true for oil flames which typically have

less UV radiation in the outer flame. The scanner should view the intersection of the pilot and main flames. When sighting scanners, please

consider the following:

1) Sight the scanner away from the ignition spark. Sighting the spark

or its reflections from burner internals can be misinterpreted as a

flame signal.

2) Do not allow the scanner to detect a pilot flame that is too small

to ignite the main burner.

3) Perform a minimum pilot test when installing or adjusting any pilot

or main burner system; see “Minim um Pilot Test” on page 30.

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

29

Page 30

Test Procedures

8

INTRODUCTION

FLAME SIGNAL

STRENGTH

MINIMUM PILOT TEST

This section describes the test procedures that must be performed

after installation to insure that the Bi-Flame is operating properly;

these procedures are mandatory.

Insert the positive probe of a 0-15 VDC, one megohm/volt meter into

the test point on the front cover, as sho wn in the photo at left. Connect the negative probe to ground. A good flame signal strength will

read between 6 and 11 VDC; anything below 4 VDC is inadequate.

Run the following test procedures to ensure that the sensor will

not detect a pilot flame too small to reliably light the main flame:

1) Manually shut off the fuel supply to the burner, but not to the pilot.

2) Start the system normally.

3) To enter the pilot test mode, press the RESET and ENTER buttons simultaneously. Then release the RESET button but keep

the ENTER button depressed for another 10 seconds. The Limits

LED will blink, signalling that the system is in the pilot test mode.

4) The control will hold the operating sequence at the pilot flame

step. Measure signal strength as described above.

30

Voltmeter hook-up to the Bi-Flame

5) Reduce pilot fuel until the flame relay drops out. Increase pilot

fuel until the flame signal is greater than 4 VDC, and flame relay

just manages to pull in. This is the minimum pilot. If you don’t

think this flame will be able to safely light the main burner, realign the sensor so that it requires a larger pilot flame and repeat steps 2 through 5.

6) Push the RESET button to exit the test mode and begin the

normal start-up sequence again.

7) When the sequence reaches the main flame trial for ignition,

smoothly restore the fuel supply to the burner. If the main

burner does not light within five seconds, immediately shut off

the burner supply to shut down the system. Realign the sensor

so that it requires a larger pilot flame. Repeat steps 1 through

6 until the main burner lights off smoothly and reliably.

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

Page 31

PILOT FLAME FAILURE

TEST

1) Manually shut off the fuel supply to one individual pilot and

main burner, or all burners if the system has a single fuel supply.

2) Place system in pilot test mode (please refer to page 15).

3) Start the system normally. The controller should lock out*; if it

doesn’t, then the controller is detecting a false flame signal (see

Section 7). Find the problem and correct it before resuming

normal operation.

4) Repeat steps 1 through 4 until all burners have been tested.

MAIN FLAME FAIULRE

TEST

(For Interrupted Pilot Systems)

SPARK SIGHTING TEST

1) Manually shut off the fuel supply to the main burner, or all burners if the system has a single fuel supply, but not to the pilot.

2) Start the system normally. This should ignite the pilot and lock

out* after pilot interruption. If the system does not lock out, the

controller is detecting a false flame signal (see Section 7). Find

the problem and correct it before resuming normal operation.

3) Repeat steps 1 through 3 until all burners have been tested.

1) Ma nually shut off the fuel supply to the pilot and main burner.

2) Start the system normally.

3) Measure the flame signal as described in “Flame Signal Strength”

in this section.

4) If a flame signal greater than 4 VDC is measured for more than

three seconds during the trial for ignition, the sensor is picking

up a signal from the spark plug or the ignition current is interfering with the sensor wiring. If this is an abnormal condition,

correct before resuming normal operation.

LIMITS AND INTERLOCK

TESTS

Periodically check all interlock and limit switches by manually tripping them during burner operation to make sure they cause the

system to shut down.

Warning

Never operate a system that is improperly adjusted or

has faulty interlocks or limit switches. Always replace

faulty equipment with new equipment before resuming operation. Operating a system with defective

safety equipment can cause explosions, injuries, and

property damage .

* The burner at which a flame fails will be identified by the red “Flame Fail-

ure” LED on the cover.

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

31

Page 32

Maintenance and

Troubleshooting

INTRODUCTION This section is divided into two parts:

• The first par t describes the maintenance procedures.

• The second part helps you to identify problems that may occur,

and gives advice on how to solve these problems.

9

MAINTENANCE

Preventative maintenance is the key to a reliable, safe and efficient

system. The core of any preventive maintenance program is a list of

periodic tasks.

In the paragraphs that follow are suggestions for a monthly list and

a yearly list.

Note:

The monthly list and the yearly list are an average interval. If

your environment is dirty, then the intervals may be shorter.

Caution:

Turn off power before disconnecting or installing sensors, controls or modules.

Monthly Checklist

1. Inspect flame-sensing devices for good condition and cleanliness.

Keep the glass lens of scanners clean with a soft, damp cloth,

since small amounts of dust will measurably reduce the flame

signal strength. Wash the flame rod electrode and insulator with

soap and water, then rinse and dry thoroughly.

32

2. Test all the alarm systems for proper signals.

3. Check ignition spark electrodes and check proper gap.

4. Test interlock sequence of all safety equipment as described in

Test Procedures: man ually make each interlock fail, noting what

related equipment closes or stops as specified by the manufacturer.

Test flame safeguard by manually shutting off gas to the burner.

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

Page 33

Yearly Checklist

1. Test (leak test) safety shut-off valves for tightness of closure.

2. Test pressure switch settings by checking switch movements against pressure

setting and comparing with actual impulse pressure.

3. Visually check ignition cable and connectors.

4. Make sure that the following components are not damaged or distorted:

• the burner nozzle

• the spark plugs

• the flame sensors

• the flame tube or combustion block of the burner

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

33

Page 34

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Cannot initiate start sequence

• Main valve is not closed.

• Air pressure switch has not made

contact.

• High gas pressure switch has tripped.

• Low gas pressure switch has tripped.

• Malfunction of flame safeguard system

such as a shorted-out flame sensor

or electrical noise in the sensor line.

• Purge cycle not completed.

Check proof-of-valve-closur e switch.

Check air pressure switch adjustment.

Check air filter .

Check blower r otation.

Check outlet pressure from blower.

Check incoming gas pressure; adjust

gas pressure if necessary .

Check pressure switch setting and

operation.

Check incoming gas pressure; adjust

gas pressure if necessary .

Check pressure switch setting and

operation.

Have qualified electrician in vestigate

and rectify.

Check flame safeguard system, or

purge timer .

Scrambled messages on remote

display.

“UNSAFE AIR SHOR T” message

appears on displa y.

Burner flame fails but no flame

failure indication occurs.

• Main power is off.

• No power to control unit.

• Improper grounding in system.

• Improperly adjusted air switch.

• Air switch either shorted or wir ed

wrong.

• A faulty scanner.

• Improperly connected sensor wires.

• Electrical interference from other

current carrying wires.

Make sure pow er is on to contr ol

system.

Call qualified electrician to

investigate.

Check grounding in system.

Check air switch settings.

Check wiring to air switch.

Check scanner as explained in

checklists in “Maintenance” portion

of this Section.

Check wiring diagram on page 26

as well as appropriate sensor

information in Section 7.

Check Note information on page

27 regarding sensor wiring.

34

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

Page 35

Remote Displa y

Messages

INTRODUCTION This section covers how the optional remote display is used with

the Bi-Flame. The remote display provides LCD messages which

monitor the status of the Bi-Flame’s functions as well as any lockout conditions. This section is divided into two parts or tables:

• The first table describes the start-up and shutdown monitoring sequences of the Bi-Flame and how the progress (or halt) of the sequence can be monitored by the messages on the remote display.

• The second table alphabetically lists and explains the diagnostic

messages which can appear on the remote display.

Note:

Some of the messages which may appear with some of the options

are not shown; refer to Section 5, Function Summary, for details.

10

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

35

Page 36

VERSION VX.X

NORMAL MESSAGE

CHECKSUM = XXXX

ERROR MESSAGE #1

UNSAFE FLAME ON

Table 10.1

Bi-Flame Operating Sequence

PO WER ON

Was internal saf e start check successful?

YES NO

EXTERNAL INTERLOCK CHECKS

Is flame signal present?

YES NO

Various lockout messages

Is proof of closure cir cuit closed?

If signal is eliminated within 30

seconds, sequence continues. If

not, then . . .

ERROR MESSAGE #2 – 30 SECONDS AFTER #1

UNSAFE FLAME ON

LK OUT XXXX:XX:XX

Fan and Alarm energized.

NORMAL MESSAGE

VALVE LEAKAGE

UNDER TEST XX

Countdown of XX based on DIP

switch

Is voltage present at VDK input

before time out?

ERROR MESSAGE #1

UNSAFE AIR SHOR T

If switch is not opened within

30 seconds and the limit input is

present....

ERROR MESSAGE #2 – 30 SECONDS AFTER #1

UNSAFE AIR SHOR T

LK OUT XXXX:XX:XX

Fan and Alarm energized.

Is voltage present at AUX inputs ?

YES

AUX. LIM. # X F AIL

LKOUT XXXX:XX:XX

#X is 1, 2, 3, or 4 to show

absent input

Is voltage present at air flow switch?

YES NO

Is voltage present at interlock switch?

NO

LIMITS OPEN

TIME = XXXX:XX:XX

ERROR MESSAGE

YES NO

ERROR MESSAGE

MAIN VALVE FAIL

LK OUT XXXX:XX:XX

Fan and Alarm energized.

YES NO

ERROR MESSAGE

Holds until answer is yes.

36

YES

NORMAL MESSAGE

SAFE START OK

VX.X CS=XXXX

NORMAL MESSAGE

FAN ENERGIZED

Fan output is energized; modulator is sent to low fire.

BURNER START-UP

(see next page)

NO

V ALVE LEAK FAIL

ERROR MESSAGE

LK OUT XXXX:XX:XX

Fan and alarm energized.

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

Page 37

Table 10.1

Bi-Flame Operating Sequence (continued)

BURNER START-UP

Is voltage pr esent at air flow switch

within ten seconds?

AIR PROVEN

NORMAL MESSAGE

NORMAL MESSAGE

WAIT FOR HI. FIRE

SWITCH XX:XX

Modulator sent to high fire.

NORMAL MESSAGE

PURGE A T HIGH

FIRE XX

Countdown of “XX” seconds

as set by DIP switch.

YES NO

AIR NOT PR OVEN

ERROR MESSAGE

LK OUT XXXX:XX:XX

Is voltage present

at high fire input?

YES NO

ERROR MESSAGE

HIGH FIRE FAIL

LK OUT XXXX:XX:XX

WAIT FOR LO.FIRE

NORMAL MESSAGE

SWITCH XX:XX

Modulator sent to low fire.

NORMAL MESSAGE

PILOT TRIAL FOR

IGNITION XX

Spark energized until pilot flame

proven; pilot valve energized for

countdown of “XX” seconds

(“XX” equals selected trial for

ignition).

NORMAL MESSAGE

PILOT ON

XX

After “XX” equals zero (0)...

NORMAL MESSAGE

PILOT ON

IGNITION OFF

Delay 5 seconds.

Is voltage present

at low fire input?

YES NO

ERROR MESSAGE

LOW FIRE FAIL

LK OUT XXXX:XX:XX

Is pilot flame signal present?

YES NO

PILOT # (0X) FAILED

ERROR MESSAGE

LK OUT XXXX:XX:XX

X = burner number.

NORMAL MESSAGE

MAIN FLAME ON

Is flame signal present?

YES NO

Is flame signal present?

(see next page)

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

MAIN # (0X) FAILED

ERROR MESSAGE

LK OUT XXXX:XX:XX

X = burner number.

37

Page 38

Table 10.1

Bi-Flame Operating Sequence (continued)

BURNER START-UP (continued)

Is flame signal present ?

YES

MAIN FLAME ON

NORMAL MESSAGE

NO

ERROR MESSAGE

MAIN # (O X) FAILED

X = burner number.

MAIN FLAME ON

NORMAL MESSAGE

PILOT OFF

Pilot will shut off 10 seconds

after main flame is energized.

IF Interrupted Pilot is selected

NORMAL MESSAGE

AUTOMATIC

MODULATION

Modulator sent to automatic 20

seconds after main valve is

energized.

NORMAL MESSAGE

FLAME #(OX) XX.XV

TIME = XXXX:XX:XX

Flame signal = XX.X Volts DC;

(X) = Number of burner being

monitored; the Bi-Flame will

scroll through each burner continuously during the burner-on

cycle.

38

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

Page 39

Table 10.1

Bi-Flame Operating Sequence (continued)

Continued operation.

BURNER SHUTDOWN

Shutdown is started by opening

the operating interlock circuit.

Is voltage pr esent at interlocks?

YES NO

Is proof of closure cir cuit closed?

YES NO

NORMAL MESSAGE

VALVE LEAKAGE

UNDER TEST XX

Countdown of XX based on DIP

switch

POST PURGE

NORMAL MESSAGE

XX

Fuel valves de-energized; fan

energized for 15 seconds.

ERROR MESSAGE

MAIN VALVE FAIL

LK OUT XXXX:XX:XX

Fan and alarm energized.

ERROR MESSAGE #1

UNSAFE AIR SHOR T

If switch is opened within 30

seconds, sequence continues. If

not, then . . .

ERROR MESSAGE #2 – 30 SECONDS AFTER #1

UNSAFE AIR SHOR T

LK OUT XXXX:XX:XX

Alarm energized.

Is voltage present at VDK input

before time out?

YES

NO

V ALVE LEAK FAIL

LK OUT XXXX:XX:XX

Is voltage pr esent at air flow switch?

YES NO

UNSAFE FLAME ON

Fan is energized. If signal is eliminated within 30 seconds, sequence continues. If not, then . .

UNSAFE FLAME ON

LK OUT XXXX:XX:XX

ERROR MESSAGE #1

ERROR MESSAGE #2 – 30 SECONDS AFTER #1

Fan and Alarm energized.

ERROR MESSAGE

Fan and alarm energized.

Is flame signal present?

YES NO

NORMAL MESSAGE

LIMITS OPEN

TIME = XXXX:XX:XX

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

39

Page 40

Table 10.2

MESSAGE TYPE EXPLANATION

Remote Display Diagnostic Messages (Listed Alphabetically)

AIR FAILURE

LKOUT XXXX:XX:XX

AIR FAILURE

RECYCLING

AIR NOT PROVEN

LKOUT XXXX:XX:XX

AIR PROVEN

AUTOMATIC

MODULATION

AUX.LIM.#1 FAIL

LKOUT XXXX:XX:XX

AUX.LIM.#2 FAIL

LKOUT XXXX:XX:XX

AUX.LIM.#3 FAIL

LKOUT XXXX:XX:XX

AUX.LIM.# 4 FAIL

LKOUT XXXX:XX:XX

FAN ENERGIZED

Lockout Combustion air flow limit switch (strip J1, terminal 2) opened for

more than two seconds once initially proven.

Status Combustion air flow limit switch (strip J1, terminal 2) opened;

control will recycle once if “recycle” DIP switch has been selected.

Lockout Combustion air flow limit switch (strip J1, terminal 2) did not

make within ten seconds of fan being energized.

Status Combustion air flow limit switch (strip J1, terminal 2) closed

within ten seconds of fan being energized.

Status Modulating motor is sent to automatic operation. Terminal 1 is

connected to terminal 2 on terminal strip J3.

Lockout Auxiliary input #1 has lost its voltage during system operation,

causing a lockout at the indicated time.

Lockout Auxiliary input #2 has lost its voltage during system operation,

causing a lockout at the indicated time.

Lockout Auxiliary input #3 has lost its voltage during system operation,

causing a lockout at the indicated time.

Lockout Auxiliary input #4 has lost its voltage during system operation,

causing a lockout at the indicated time.

Status Blower motor (strip J2, terminal 3) is energized at the start of pre-purge.

FLAME # ( ) FAIL

RECYCLING

FLAME # (X) FAILED

LKOUT XXXX:XX:XX

FLAME # (Y) XX.XV

TIME=XXXX:XX:XX

HI FIRE FAIL

INTERNAL FAULT

LIMITS OPEN

TIME=XXXX:XX:XX

LOW FIRE FAIL

LKOUT XXXX:XX:XX

Status Main flame lost during automatic modulation; control will recycle

once if “recycle” has been selected.

Lockout Main flame lost during operation in the automatic modulation

mode. Burner number (X) given of failed unit.

Status Main flame of burner number (Y) is proven in the automatic modula-

tion mode; flame strength is XX.XV (volts DC). Elapsed time is

shown in hours:minutes:seconds.

Lockout High damper or high purge rate switch did not make and hold for

high pre-purgee.

Lockout Internal control failure; replace controller.

Status The controller has completed its internal checks and is standing by

for the interlocks (strip J1, terminal 1) to close.

Lockout Low fire switch (strip J1, terminal 4) is open just prior to pilot trial

for ignition.

40

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

Page 41

Table 10.2

MESSAGE TYPE EXPLANATION

Remote Display Diagnostic Messages (continued)

MAIN # ( ) FAILED

MAIN FLAME ON

MAIN FLAME ON

PILOT OFF

MAIN VALVE FAIL

LKOUT XXXX:XX:XX

PILOT FLAME FAIL

LKOUT XXXX:XX:XX

PILOT ON

XX

PILOT TRIAL FOR

IGNITION XX

PLT/MVL ENERGIZ.

XX:XX:XX LOCKOUT

POST PURGE

XX

PROGM SWITCH ERR

LKOUT XXXX:XX:XX

Lockout Main flame was not established during the main burner trial for ignition.

Lockout Main valve has been energized and main flame proven during trial

for ignition.

Status Pilot valve (strip J2, terminal 5) is de-energized and main flame is on.

Lockout Main valve proof-of-closure is open before startup or after burner

shutdown.

Lockout Pilot flame was not established during the pilot trial for ignition.

Status Pilot flame is proven; transformer is de-energized; remaining

countdown for pilot trial for ignition is “XX”.

Status Pilot valve and ignition transformer are energized; countdown for

pilot trial for ignition begins at “XX”.

Lockout An external source of voltage is present on the ignition, pilot or

main output terminals.

Status 15 second post purge is started on burner shutdown; “XX” shows

countdown.

Lockout DIP switch improperly set or changed during cycle.

PURGE AT HIGH

FIRE XX

RECORD #X

RELAY FAIL

LKOUT XXXX:XX:XX

SAFE START OK

UNSAFE AIR SHORT

UNSAFE AIR SHORT

LKOUT XXXX:XX:XX

Status Modulating motor is sent to high fire; “XX” shows purge countdown.

Status Part of the optional history log which records the total number of

operating cycles and the last lockout messages up to a maximum

of 10.

Lockout Internal relay(s) fail initial check. Check ratings. If lockout still oc-

curs after overload is eliminated, replace control.

Status Control has completed internal safe-start check.

Status Combustion air switch is closed before start-up or after shut-

down; control holds start-up until switch re-opens; if interlocks

close before switch opens, alarm will energize in 30 seconds.

Lockout Same conditions as above, except the interlocks closed for 30 sec-

onds before the switch re-opened, causing a lockout and the alarm.

Eclipse Bi-Flame v1.8, Instruction Manual 826, 05/03

41

Page 42

Table 10.2

Remote Display Diagnostic Messages (continued)

MESSAGE TYPE EXPLANATION

UNSAFE FLAME ON

UNSAFE FLAME ON

LKOUT XXXX:XX:XX

UNSAFE–FLM–PURGE

UNSAFE–FLM–PURGE

LKOUT XXXX:XX:XX

VALVE LEAKAGE

UNDER TEST XX

VALVE LEAK FAIL

LKOUT XXXX:XX:XX

WATCHDOG FAIL

LKOUT XXXX:XX:XX

XXXXXXX

XXXXXTESTXX

Hold Flame signal—actual, induced, or faulty scanner—is detected be-