FLIGHT TRAINING

AND STANDARDS MANUAL

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL 1

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

2

LOG OF REVISIONS

Original Issue……………………………………………………………December XX, 2006

Revision Number Revision Date

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

3

4

Table of Contents

1. INTRODUCTION................................................................................................................. 6

2. SINGLE PILOT RESOURCE MANAGEMENT AND OPERATIONS......................... 8

Risk Management Definitions.......................................................................................... 8

Risk Management Tools.................................................................................................... 9

Risk Management Procedures ........................................................................................ 9

Resource Management .................................................................................................... 12

Automation Management............................................................................................12

Task Management......................................................................................................... 14

Available Resources .................................................................................................... 20

Situational Awareness................................................................................................. 20

3. NORMAL OPERATIONS................................................................................................. 23

a. Flight Planning........................................................................................................... 23

b. Normal Checklists..................................................................................................... 24

c. SELF BRIEFINGS ............................................................................................. 51

d. PROFILES....................................................................................................................... 52

Taxi.................................................................................................................................... 53

Takeoff............................................................................................................................. 55

Traffic Pattern Ops (closed patterns)...................................................................... 56

Departure and Climb....................................................................................................56

Cruise............................................................................................................................... 57

Descent............................................................................................................................ 58

Approach......................................................................................................................... 59

Missed approach / rejected landing......................................................................... 66

Holding............................................................................................................................. 68

Landing............................................................................................................................ 68

4. ABNORMAL OPERATIONS............................................................................................70

Emergency management................................................................................................70

Go No-Go Decision........................................................................................................... 70

Rejected takeoff................................................................................................................. 71

Single engine operations................................................................................................ 71

Landing with flap malfunctions..................................................................................... 80

In-flight cabin smoke........................................................................................................ 80

Emergency descent/rapid decompression................................................................ 81

Single and dual generator failure................................................................................. 82

Emergency evacuation.................................................................................................... 82

Unusual Attitude/Upset Recovery................................................................................82

5. FLIGHT TRAINING OPERATIONS................................................................................. 84

Introduction........................................................................................................................ 84

Maneuvers........................................................................................................................... 84

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

5

1. INTRODUCTION

The material in this Flight Training and Standards Manual is provided as a

reference document for use by all Eclipse 500 pilots. It provides guidance for

Eclipse 500 normal flight operations, abnormal flight operations, and flight training

operations. Additionally, it provides specific material intended to give each pilot the

higher order pilot skills required to become proficient in single pilot resource

management and flight operations. The intent of this manual is to promote

standardization in all Eclipse 500 flight procedures with the ultimate goal of safe

flight operations in today’s National Airspace System (NAS).

This manual is organized into four sections that cover the following topics:

• Single Pilot Resource Management and Operations

• Normal Operations

• Abnormal Operations

• Flight Training Operations

Single Pilot Resource Management and Operations

This section encompasses a broad spectrum of procedures and techniques for

the single pilot in both preflight planning and in-flight operations. The material

contained in this section will help the pilot understand what key elements must

be integrated in order to be an effective single pilot manager and operator.

These elements include airplane control, flight automation, PFDs / MFD,

standard operating procedures, airplane systems, resource management, risk

management, and decision making. At the end of this section is a list of safe

practices that every pilot should embrace to uphold a commitment to safety.

Normal Operations

This section covers all operations that would be encountered during normal

preflight and flight. This section includes an expanded explanation of all the

normal checklists, and the techniques to accomplish those checklists in an

organized and standardized pattern. This section also gives the procedures and

profiles for all the normal maneuvers performed from takeoffs to approaches

and landings in both VMC and IMC. Included are guides for single pilot “self

briefings” in order to instill the self-discipline of situational awareness and safety

consciousness.

Abnormal Operations

This portion provides standards and procedures for selected events that would

not be seen in normal operations. The events cover topics such as rejected

takeoffs, single engine operations, flap malfunctions, cabin smoke and fires,

emergency descents, rapid decompressions, upset recoveries, and emergency

evacuations. This section also includes a discussion on emergency procedures

management and standards to follow in any abnormal situation.

6

Revisions

Flight Training Operations

This section provides guidance as to how the airplane should be configured

and flown during initial and recurrent type rating training. These training

maneuvers include but are not limited to the maneuvers required in the Airline

Transport Pilot and Type Rating Practical Test Standards (PTS) for the Eclipse

500 FAA type rating. It provides specific guidance concerning the conduct of

each maneuver, tolerances and safeguards when conducting flight training in

the actual airplane or simulator.

Revisions are issued by Eclipse Aviation as necessary to keep the Flight

Training and Standards Manual current. It is the responsibility of the owner of

this Flight Training and Standards Manual to maintain its currency. With each

revision to this manual, the owner of the manual must annotate the revision

number along with the date of the revision on the Log of Revisions page. The

Log of Revisions Page must be retained at all times in this manual.

Immediately following the Log of Revisions page is a List of Effective Pages. A

re-issue of the Flight Training and Standards Manual or the revision of any

portion thereof will include a new List of Effective Pages. The List of Effective

Pages enables the user to determine the currency of each page.

The revised portion of text on a given page is indicated by a solid revision bar

located adjacent to the area of change.

If the holder of this Flight Training and Standards Manual would like to

recommend a change to any of this material, it should be made in writing to:

Flight.training@eclipseaviation.com

Or mail to;

Eclipse Aviation, Flight Training

2506 Clark Carr Loop SE

Albuquerque, NM 87106

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

7

2. SINGLE PILOT RESOURCE MANAGEMENT AND OPERATIONS

The Eclipse 500 pilot must employ higher order piloting skills to safely operate the

aircraft through its full range of capabilities. In addition to physical and motor skills

associated with normal and abnormal operations, pilots must be competent in risk

management and single pilot resource management (SRM) procedures.

Risk Management Definitions

Risk is present in all human activity. Risk can be managed effectively through

use of simple procedures and tools. The Eclipse 500 pilot can effectively

employ risk identification, risk assessment, and risk mitigation procedures to

minimize risk during pre-flight planning and in-flight operations. The following

guidance regarding this process assumes that the pilot has a basic knowledge

of risk management obtained through the Eclipse 500 type rating training or

through some other source.

Risk Identification

During pre-flight planning, the Eclipse 500 pilot should consider all potential

hazards that may affect the flight. The pilot must then determine which of

those hazards will become risks as a result of some triggering event.

Example:

A mountain next to an airport is a hazard but may not become a risk until

the pilot attempts to complete a night circling approach to that airport

during IMC conditions.

Once risk identification is complete, the pilot should conduct a risk

assessment.

Risk Assessment

The Eclipse 500 pilot should fully assess all identified risks by determining

risk severity and risk likelihood. Risk severity describes the potential

consequences of a given risk while risk likelihood refers to the probability of

a given event occurring.

It is then possible to classify each identified risk since each combination of

risk severity and risk likelihood results in a cumulative level of risk that may

be identified as high, medium, or low.

Example:

An engine out on takeoff may be a high risk at gross weight at high density

altitude with inhospitable terrain. At sea level and light weight with flat

terrain, the overall risk may be low. In both cases, the low risk likelihood

of an engine out on takeoff makes this risk manageable.

8

Once risk assessment is complete, the pilot must address all high risk areas

and most medium risk areas through risk mitigation.

Risk Mitigation

Through effective use of technology and procedures, most risks can be

effectively mitigated. Eclipse 500 pilots can use the aircraft’s advanced

technology to their advantage during risk mitigation.

Example:

Pilots may take on a reduced fuel load to reduce takeoff weight, and

potential engine out risk, during a takeoff from a high density altitude

airport.

The objective should be to reduce risk likelihood and/or severity from high

or moderate levels to low or moderate levels. Moderate risks can be

accepted, providing the pilot is willing to accept them on behalf of him/her

and his/her passengers. However, the pilot should ensure that all available

steps have been taken to reduce risk likelihood and or severity, regardless

of the risk level.

In rare cases, if risks can not be mitigated or accepted, the pilot may need

to cancel or delay a flight, or shift to another transportation mode.

Advanced risk planning is therefore essential.

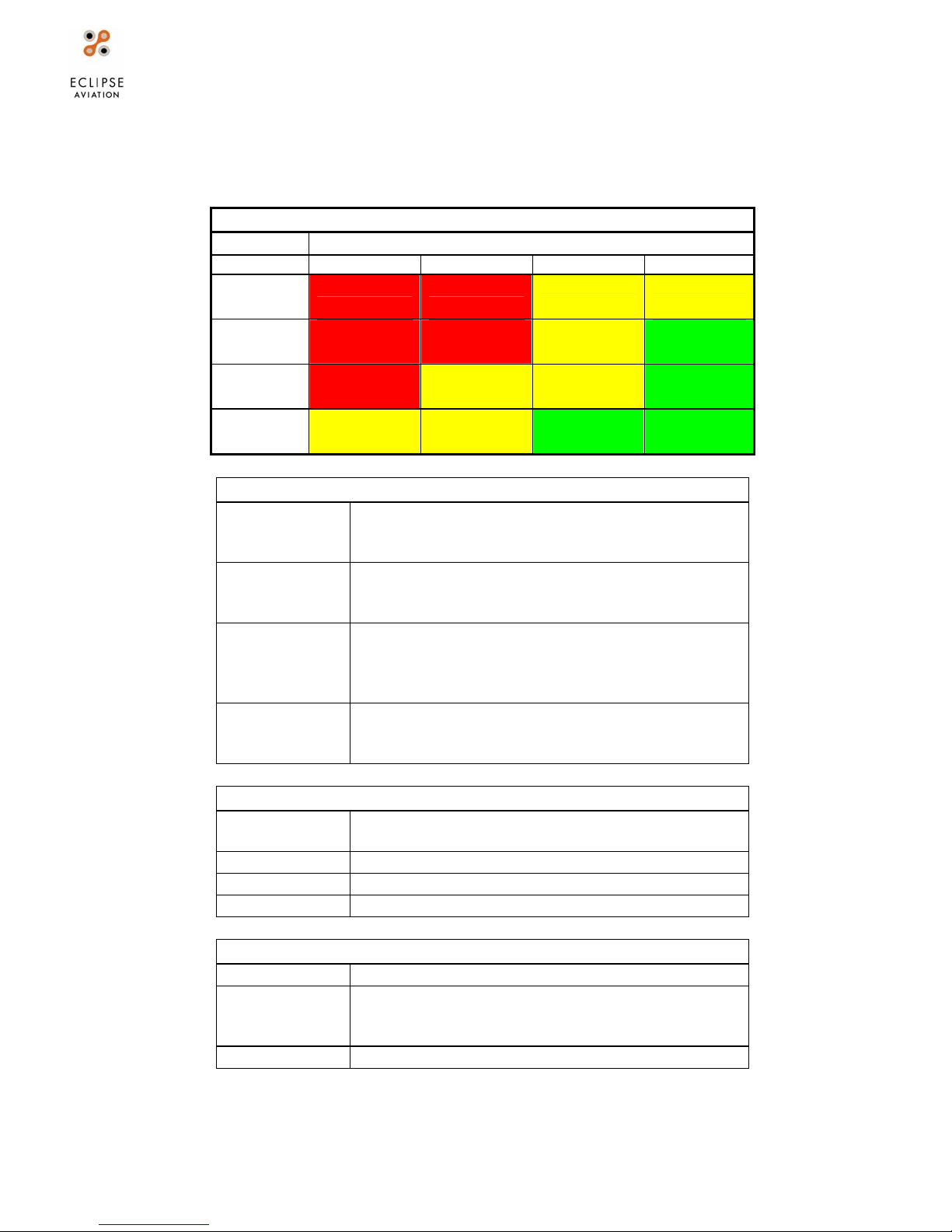

Risk Management Tools

The risk management process can be simplified through use of a risk

management tool and a risk assessment matrix. Eclipse Aviation has

developed a risk management tool (Figure 1 on pg. 9) for Eclipse 500 pilots to

use in identifying, assessing and mitigating risk. The tool is accompanied by a

risk assessment matrix developed by the FAA to classify risk severity and

likelihood to arrive at an overall level of risk for each risk factor identified.

The risk management tool uses the well known industry/FAA PAVE (P

A

ircraft, EnVironment, External Factors) model to identify risks. Using the tool

and the risk assessment matrix, the pilot can then assess and classify risks for

each PAVE category and element. The tool (second page) then uses the less

well known FAA developed TEAM (T

to mitigate risk.

Risk Management Procedures

1. Eclipse 500 pilots will use the risk management tool and assessment

matrix and the following procedures on all training and mentoring flights.

ilot,

ransfer, Eliminate, Accept, Mitigate) model

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

9

Eclipse Aviation strongly recommends that pilots continue to use these

tools and procedures during normal operations until they are comfortable

with their use and can effectively identify, assess, and mitigate risk

without reference to them.

2. Pilots should conduct preliminary pre-flight planning procedures prior to

a proposed flight so that applicable data can be gathered for risk

management purposes. For example, weather, weight and balance,

performance data, and other information will be needed to accurately

identify, assess, and mitigate risks. Final preparation and planning

(route planning, fueling, filing flight plan, etc.) should be deferred until the

risk identification and risk assessment process is completed.

3. Following pre-flight planning, the pilot should use the risk management

tool to identify and record potential hazards for the proposed flight and

then identify and record the risks of those hazards.

4. Following risk identification, the pilot should use the risk management

tool to assess identified risks by determining their potential severity and

likelihood, using the categories on the risk assessment matrix. The pilot

will then classify risks as high, medium, or low, using the matrix.

5. Following risk assessment, the pilot should review all aspects of the

proposed flight to determine options with regard to risk mitigation. For

example, the pilot could select a different route, change departure times,

change the fuel load or take other steps.

6. The pilot should then complete the risk mitigation portion of the risk

management tool to execute decisions regarding mitigation. All risks

classified as high must be mitigated to reduce the severity and/or

likelihood of the risks. Medium risk areas should also be mitigated to the

extent possible and pilots must be willing to accept any residual risks.

Low risk areas do not require mitigation but any risk which can be readily

mitigated should be.

7. Following completion of the risk management tool, remaining pre-flight

preparation should be accomplished.

8. In flight, Eclipse 500 pilots must continue active risk management

procedures. New hazards and risks may be identified, requiring the pilot

to assess them and potentially take action to mitigate them. The

advanced technology in the Eclipse 500 will be useful in mitigating risk

and the pilots should employ effective SRM procedures as outlined in

the next section.

10

RISK ASSESSMENT MATRIX HANDOUT

HO-1-RA

RISK ASSESSMENT MATRIX

Likelihood

Frequent

Severity

Catastrophic Critical Marginal Negligible

Probable

Occasional

Remote

Catastrophic Accident with serious injuries and/or fatalities.

Critical Accident or Serious Incident with injuries and/or

Marginal Accident or Incident with minor injury and/or minor

Negligible Less than minor injury and/or less than minor

Severity Scale Definitions

Loss (or breakdown) of an entire system or subsystem.

moderate damage to aircraft. Partial breakdown of

a system or subsystem.

aircraft damage. System Deficiencies leading to

poor air carrier performance or disruption to the air

carrier schedules.

system damage. Little or no effect on system or

subsystem.

Frequent Will be continuously experienced unless action is

Probable Will occur often if events follow normal pattern.

Occasional Potential for infrequent occurrence.

Remote Not likely to happen (but could).

Likelihood Scale Definitions

taken to change events.

Red High Risk - Unacceptable; requires action.

Yellow Medium Risk - May be acceptable with review by

Green Low Risk - Acceptable without further action.

Risk Classification

appropriate authority; requires tracking and

probable action.

Figure 1

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

11

Resource Management

Single pilot resource management (SRM) was developed as a doctrine by the

FAA under the FAA/Industry Training Standards (FITS) program. It builds on

the concepts of crew resource management (CRM) pioneered by the airline

community and is tailored for single pilot operation of technically advanced

aircraft (TAA). SRM integrates risk management (described in the previous

section), automation management, task management, and situational

awareness.

SRM also balances two important elements: workload drivers and pilot

resources available. The Eclipse 500 pilot’s task is to use SRM techniques and

procedures to ensure that resources always exceed the work load imposed on

the pilot.

Automation Management

The autopilot, auto-throttle, flight management system (FMS), and cockpit

displays and sensors are important tools for SRM as well as for precise

navigation. The pilot must clearly understand the flight automation modes and

be able to select confidently from among the various modes.

Autopilot

The autopilot can provide workload relief and precise lateral and vertical

navigation. To be effective, it must be properly managed.

The pilot should use the autopilot in high workload situations such as high

traffic density in terminal areas where communications and navigation

demands are most likely to be high. It also should be used for instrument

approaches at or near minimums. Using the autopilot enables the pilot to

devote more time to other aspects of flight management, such as situational

awareness and traffic surveillance. However, when pilot workload is light,

hand flying helps to maintain proficient flying skills.

Autopilot Mode Awareness

The pilot should remain aware of what the autopilot is doing and about to

do. The only reliable indications of autopilot active and armed pitch and roll

modes and mode changes are displayed on the Flight Mode Annunciator

(FMA) at the top of the Primary Flight Display (PFD). Make a practice of

scanning the FMA as you would scan any other instrument or synoptic

page.

It is good practice to monitor the FMA for proper response to mode selection

every time a different autopilot mode is selected. Autopilot mode changes

are a two-step process:

1. Select the action on the ACP

12

2. Verify that the action has occurred on the FMA

Some modes changes occur automatically as the flight progresses. These

changes should be monitored as well. This provides confidence that the

autopilot will perform as expected. On an approach with the autopilot

engaged, FMA changes should be called out as they are annunciated.

Automation Distraction

Although flight automation has been shown to decrease human error, it has

introduced new types of human error:

1. Lack of vigilance. People generally do not make good systems

monitors. People may neglect active monitoring tasks.

Automation also provides a very high potential for distraction

from more important activities. For example, if the pilot’s

autopilot, PFD and / or MFD proficiency is marginal, there is a

natural tendency to spend too much time head down trying to

“sort it out”.

2. Complacency. This is related to lack of vigilance. People tend to

neglect automated systems in favor of other tasks by shifting

their attention. They may place too much trust in the automation

and take themselves “out of the loop.”

3. Slower manual reversion. People who are complacent or

placing too much trust in the automation will take longer to reorient themselves to their present situation after automation

failure. The farther “out of the loop” the person is, the longer it

will probably take to get back “in the loop.”

4. Lack of trust in automation. This is the flip-side of over-trust and

complacency. Automation cannot be used to its best advantage

if it is not trusted. Some of this lack of trust may also come from

lack of proficiency in the use of automation.

PFD / MFD Management

Apart from the flight controls, the primary interfaces between the pilot and

the Eclipse 500 are the airplane computer systems. The primary flight

display and the multi-function displays provide capacities for display and

functionality that do not exist in older airplanes. This requires that the pilot

develop and maintain the ability to recall displays and functionality with ease

and confidence.

Automation Policy

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

13

Automation is a tool to be mastered and used by the pilot. It is always the

pilot’s responsibility to manage workload, set priorities, and use automation

as a tool to improve situational awareness. It is important for the pilot to

manage the automation and to be continuously aware of automation modes,

the potential for input or programming errors, and the possibility of

automation failure. Eclipse recommends adoption of the following

automation policies:

1. Use automation appropriate for your circumstances and

conditions of flight. Differing circumstances may require different

levels of automation.

2. If any autopilot function is not operating as expected, disconnect

it.

3. If the automation does something unexpected, revert to manual

flight or to a lower level of automation.

4. If you do not fully understand what the automation is doing,

revert to manual flight or to a lower level of automation.

5. When conducting a self-briefing, briefing another pilot, or

transferring the controls to another pilot, include the current or

intended level of automation in the briefing. Plan ahead for how

you intend to use automation.

6. Be aware of too much heads-down time.

Task Management

Although the Eclipse 500 provides the pilot with advanced technology important

for effective SRM, the pilot will also find that the use of effective procedures will

lower workload and assist with task management.

Sterile Cockpit

Eclipse encourages the use of the “sterile cockpit” concept in ground and

flight operations in order to minimize distractions. Air carriers are required

by law to regulate the performance of pilot duties during critical phases of

flight. This rule prohibits crew members from engaging in any activities other

than those required for the safe operation of the aircraft during taxi, takeoff,

landing, and all flight operations below 10,000 feet except cruise flight.

This “sterile cockpit” rule prohibits such activities as calling for ground

transportation, eating meals, filling out paperwork or reading publications

that are not required for the safe operation of the aircraft, engaging in nonessential conversation with passengers or other pilots, etc.

Standard Operating Procedures (SOP)

14

The Eclipse 500 pilot will find work load drivers (weather, ATC, automation,

etc.) easier to manage if proper SRM procedures are used. These

procedures include a number of techniques, including:

1. Using an orderly cockpit flow to accomplish key tasks, using the

normal checklist to verify accomplishment, rather than as a “do

list”.

2. Use emergency checklists as “do lists.”

3. If you interrupt a checklist and cannot recall where it was

interrupted, start over at the beginning of that checklist.

4. Using standard avionics and systems setups to minimize time

required for changing radio frequencies, and other tasks.

5. Using any change in phase of flight as a cue to begin

accomplishing required tasks for the next phase. For example,

use the Before Start checklist to program the FMS with the

entire flight plan; use the Before Descent checklist as a cue to

prepare for arrival into the terminal area.

6. In high-workload times, consider leaving the keyboard out and

using it for direct data entry.

7. In low workload times, consider using the knobs for data entry.

Routine use of both keyboard and knobs will improve

proficiency in both modes of input.

8. Perform data entry as much as possible with the autopilot

engaged.

9. At every opportunity, fly an instrument approach at your

destination.

Task Management by Phase of Flight

Pre-flight

1. Obtain a thorough weather briefing.

2. Plan your route and alternates accordingly.

3. Always have an alternative plan.

4. Plan fuel burn carefully and realistically. If your mission pushes

the limits of range or may result in encountering ATC or weather

challenges while in a low fuel state, plan a fuel stop enroute.

5. Self-brief (“chair-fly”) the flight in advance.

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

15

6. Do your homework. You should be able to fly the mission with

no surprises caused by inadequate planning, and you will be

more prepared to handle any real-time surprises that come your

way during flight.

Before taxi

1. Obtain ATIS/AWOS/ASOS and ATC clearance.

2. Set up ACP:

• HDG SEL – first assigned heading; otherwise

runway heading

• ALT SEL – initial cleared altitude

• SPD SEL – as planned

• BARO – set

3. Set up PFD:

• COM 2 – all ground, including ATIS, clearance,

ground control

• COM 1 – all flight, including tower and departure

control

• XPDR – set code

• NAV – tune all four frequencies in the order you

intend to use them

4. Set the CDI (L1) to initial course.

5. Set the bearing pointer (L2) to navaid that will offer the most SA.

6. Have taxi diagram out and available in the cockpit.

7. Self-brief the taxi plan before contacting ground control.

8. Perform taxi check before moving, or wait until runway end.

9. Perform departure briefing – expected runway, taxi route,

takeoff flap position, departure procedure (SID, obstacle

departure), weather/radar/anti-ice/MEL considerations, noise

abatement, rejected takeoff procedure, engine failure after

takeoff plan, immediate return to airport plan.

Taxi

1. Maintain the sterile cockpit rule.

2. Do not perform checklists while moving.

3. If CDI course guidance is not needed immediately after takeoff,

consider setting the CDI to the takeoff runway alignment.

4. Stop all extraneous activities when approaching a taxiway or

runway intersection.

Before Takeoff

1. Conduct a takeoff briefing prior to entering the active runway –

flap position, speeds, initial heading/altitude as a minimum.

16

Takeoff

1. Set HDG SEL to assigned heading. Leave at runway heading if

no heading is assigned.

2. After takeoff and cleanup, at or above 1000 feet AGL, engage

autopilot, engage HDG. Check FMA for:

• HDG (green engaged)

• PITCH (green engaged)

• ALT (white armed)

3. Complete After Takeoff checklist.

4. Use pitch wheel to maintain desired vertical path.

Climb

1. Use autopilot in HDG and PITCH mode.

2. Use pitch wheel to maintain desired vertical path.

3. Autopilot will capture pre-selected altitude if in PITCH mode with

ALT armed.

4. Initiate climbs from ALT HOLD mode by setting cleared altitude

using ALT SEL, pressing ALT to toggle to PITCH mode, then

verifying FMA for:

• HDG (green engaged)

• PITCH (green engaged)

• ALT (white armed)

5. Use pitch wheel to maintain desired vertical path.

Cruise

1. Use autopilot in HDG and ALT mode.

2. Frequently scan FMA.

3. Frequently scan CAS messages and synoptic pages.

4. Continually monitor flight progress and fuel consumption against

targets – watch for trends.

5. Continually monitor and evaluate enroute, destination, and

alternate weather.

6. Continually evaluate diversionary airports should problems

arise.

7. Perform descent planning in cruise – stay ahead of the game:

• Obtain destination weather through FSS or ATIS

• Review all STARs for familiarization. Brief a

particular STAR if expecting it

• Review all approaches for familiarization. Brief a

particular approach if expecting it

• Set up the approach as much as possible, before

or as you brief it

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

17

• If planning a visual approach to an ILS runway,

brief and set up the ILS

• Review airport diagram and brief a taxi plan

• Brief the passengers as necessary

• Perform descent checklist at or before start of

descent

Descent

1. Initiate descent by setting cleared altitude using ALT SEL,

pressing ALT to toggle to PITCH mode, then verifying FMA for:

• HDG (green engaged)

• PITCH (green engaged)

• ALT (white armed)

2. Use pitch wheel to maintain desired vertical path.

3. Autopilot will capture pre-selected altitude if in PITCH mode with

ALT armed.

4. Use throttles to maintain target airspeed.

5. Monitor and correct your descent plan to arrive 30 NM from

airport at 10000 feet AGL or as cleared by ATC.

Approach and landing

1. Use autopilot in HDG and ALT modes while maneuvering.

2. Use pitch wheel for vertical adjustments after toggling from ALT

to PITCH mode.

3. Verify FMA ALT (white armed) annunciation during every

altitude change.

4. Verify approach briefing and cockpit setup are complete. Rebrief if there are any changes.

5. Use autopilot in HDG to intercept and track final approach

course.

6. Set the approach navaid and inbound course on the CDI when

issued your first radar vector.

7. If navigating direct to a fix, such as a VOR or FMS waypoint,

consider tracking to the fix using the bearing pointer (L2) so the

approach navaid and course can be set on the CDI (L1).

8. Frequently scan FMA.

9. Apply sterile cockpit rule at 10,000 feet, or any time workload is

heavy or increasing.

10. If in VMC and not needing the CDI for navigation, set CDI

course to runway alignment for orientation.

11. Fly a stabilized approach. Stabilize by 1000 feet HAT in IMC,

500 feet HAT in VMC, and be wings level on final at 500 feet

HAT (straight in) or 300 feet HAT (circling):

• Only small heading or pitch changes are required

to stay on desired flight path

• Aircraft is properly configured for the type of

approach

18

• Speed is no greater than Vref + 20 and no less

than Vref

• Sink rate does not exceed 1000 feet per minute

• All checklists are complete

12. Disconnect autopilot no lower than 400 feet.

Taxi

1. Maintain the sterile cockpit rule.

2. Taxi completely clear of the active runway before performing

extra duties.

3. Have taxi diagram out and available in cockpit.

4. Have a taxi plan before contacting ground control.

5. Ask for progressive taxi if you are unfamiliar or uncomfortable.

6. Do not perform checklists while moving.

7. Stop all extraneous activities when approaching a runway or

taxiway intersection.

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

19

Available Resources

Managing work load drivers is the more reactive part of task management. The

Eclipse 500 pilot will find that SRM will be more effective by proactively

managing all available resources.

The major resources to be managed and used in preflight planning and while

en route include:

Internal

Pilot knowledge

Fuel/range/endurance

PFD/MFD

External sensors (weather data link, etc.)

FMS

Auto flight

Checklists

Charts

Standard Operating Procedures (SOP’s)

Cockpit organization

Passengers

External

Air Traffic Control

FAA Flight Service Stations

Dispatch services such as JetComplete

Other airplanes

Fixed Base Operators (FBO’s)

The quality of operational decisions and therefore the ongoing safety of the

flight is the result of how well these resources are managed.

Two pilot crews have the advantage of workload sharing, and monitoring

and cross checking critical activities. The single pilot must compensate with

training, currency, proficiency and the habit of planning ahead.

The anthem is, “Do things when they can be done; don’t wait until they must

be done.” Do as much as possible before takeoff. Prepare for the approach

at altitude rather than during descent when the workload is increasing. Use

flight automation for workload relief and precision.

Situational Awareness

The other crucial element of SRM is maintaining situational awareness (SA).

SA may be defined as knowing where one is, in four dimensions, relative to

weather, terrain, traffic, airspace, route, fuel remaining, aircraft status, and

external events.

20

The Eclipse 500 pilot has advanced automation available to assist with SA. The

MFD is especially useful in maintaining SA for aircraft status, weather, terrain,

traffic, airspace, and route.

For some Eclipse 500 pilots, this may be the first turbine powered aircraft they

have operated. Accordingly, maintaining SA of fuel status is a crucial element

of SRM. Like all turbine aircraft, the Eclipse 500 has range and endurance

characteristics which change significantly with altitude. As a result, pilots need

to constantly be considering the impact that ATC driven altitude changes will

have on range and endurance remaining.

SRM Procedures

Eclipse 500 pilots will find that SRM proficiency will improve steadily as

experience is gained. The following inventory of procedures will provide a

starting point for pilots to use in obtaining SRM mastery.

General Procedures and Good Practices

1. Fly only when physically, mentally and emotionally fit.

2. Acknowledge one’s current limitations and operate within them.

3. Operate with the well-being and comfort of the passengers

foremost in mind.

4. Never knowingly operate in violation of an FAR unless the

situation dictates and an emergency has been declared.

5. Maintain a thorough knowledge of airplane systems and

procedures.

6. Accomplish pre-flight planning thoroughly, using all appropriate

resources.

7. Seek advice and support when approaching the limit of one’s

personal comfort zone.

8. Develop a target for every parameter of flight and strive to

achieve it. (e.g., airspeed, altitude, heading, runway centerline

etc.)

9. Maintain proficiency in both manual flight and auto flight.

10. Avoid distractions during climb and descent.

11. Maintain a sterile cockpit below 10,000 feet AGL during

departure, arrival, and ground operations.

12. Conduct thorough takeoff and approach briefings appropriate to

the circumstances, even when alone.

13. Fly a stabilized approach

14. Practice good checklist discipline.

15. Use Normal checklists every time without skipping items.

16. When called for, use Emergency checklists to completion.

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

21

17. Autopilot:

• Use the autopilot when other operational tasks could

distract from positive airplane control and for precise

navigation.

• Use the flight director as desired for precise manual

airplane control and to monitor autopilot performance.

• When flying manually using the flight director, keep it

zeroed or turn it off.

18. In flight, continuously ask yourself these questions:

• Where am I now?

• Where am I going?

• What should I be doing now?

• What should I be doing next?

19. At every opportunity, fly an instrument approach at the

destination.

• Alternate precision and non-precision approaches.

• Alternate autopilot coupled and manually flown

approaches.

Indications of loss of SA

Several sources identify a number of indicators of loss of situational

awareness or links in a developing error chain. The existence of any one of

these indicators does not necessarily indicate an impending problem, but

taken individually or in combination these indicators may indicate a need to

re-assess your situation and take action to improve your situational

awareness and develop alternative courses of action. Be alert for any of the

following indications:

• Failure to meet targets

• Using an undocumented procedure

• Deviating from SOP

• Violating limitations or minimums

• No one flying the airplane

• No one looking out the window

• Communications

• Ambiguity of information

• Unresolved discrepancies

• Preoccupation or distractions

• Confusion or empty feeling

22

3. NORMAL OPERATIONS

a. Flight Planning

In preparation for any flight the Eclipse pilot should have the following

information available before the briefing. Reference materials, at minimum,

include the AIM and the AFM. The AFM section 5 (Performance) contains

data for each phase of flight. Frequent reference to this section is

encouraged until the pilot develops known parameters and rules of thumb

within which he/she is confident that the airplane can operate safely (e.g.,

density altitude and runway length for takeoff and landing).

Weather/ NOTAMS (reference AIM)

Refer to any authorized source you are comfortable with. In addition to the

many web sites available, you can simply call a flight service station (1-800WXBRIEF).

At a minimum, gather FA, METAR, TAF, winds aloft, AIRMETS/SIGMETS,

as well as local, distant and FDC NOTAMS

Weather and NOTAMS should cover origin, destination, enroute, and any

potential alternate airport.

Airport information (reference A/FD)

Be familiar with planned and potential airports you may use.

At a minimum know runway, length, width, pattern altitude and direction,

lighting, comm/nav frequencies, servicing facilities (fuel, O2, maintenance,

etc).

Airspace (reference Sectional or WAC VFR chart, Hi/Low IFR Enroute

charts)

Know types of airspace you may use.

Class A/B/C/D/G, Restricted areas, MOAs, Prohibited areas, Alert areas,

ADIZ

Terrain/Obstacles (reference VFR chart, IFR Enroute chart)

Know the highest terrain/obstacle that may affect you on the flight.

When operating IFR, find MSA, MRA, MOCA, and MEA altitudes. Keep in

mind that adequate terrain clearance can be assured only under the

following conditions:

Operating above charted minimum IFR altitudes (MEA)

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

23

Operating in radar contact at or above the MVA. In extreme cold

weather in the U.S., the MVA may not provide standard terrain

separation. If in doubt, request an altitude above the MVA.

Conducting an instrument approach in compliance with an IAP

Departing an airport in compliance with specific ATC climb instructions

Departing an airport in compliance with a published Obstacle Departure

Procedure (DP)

Performance data (reference AFM, chapters 5 and 6)

Compute the following data using applicable charts/graphs/tables

Weight and CG

Takeoff distance

Rejected takeoff distance

Single engine climb speed, rate and gradient

Single engine service ceiling

Landing distance

V speeds (Vr, Vxse, Vyse, Vref)

Cruise altitude, speed, fuel flow

b. Normal Checklists

The normal checklists for the Eclipse 500 include:

GENERAL

Preflight Inspection

Before Start

Start

After Start

Before Taxi

Taxi

Before Takeoff

After Takeoff

Climb

Descent / Approach

Before Landing

After Landing

Shutdown

24

This section provides the normal operating procedures for the aircraft. Included are all

the procedures required by regulation, as well as those procedures determined to be

necessary for the safe operation of the aircraft.

Normal checklists are designed to be a memory aid in performing tasks that, if not

completed, would effect the normal operation of the flight. They are not designed to be

‘do’ lists, but rather the pilot does the normal preflight and in-flight tasks from memory

using logical and organized patterns then references the checklist to confirm all the

proper tasks have been accomplished. The pilot should refer to the checklists only

when conditions permit its safe use (i.e. not while taxing nor during times of high

workload).

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

25

PREFLIGHT INSPECTION

Cockpit/Cabin Inspection

1. Engine Start Selector Switches OFF

• Ensure both switches are OFF. If power is applied to the aircraft with an engine

selector switch in the ON/START position, the engine may start.

2. Gear Handle DOWN

• Before applying power to the aircraft verify that the landing gear handle is in the

down position.

3 .Control Gust Lock REMOVE AND STOW

• Remove gust lock straps and stow in a secure location.

4. START BATT Switch ON

• The START BATT switch will supply power for the rest of the interior and exterior

lighting preflight check. If ground power is connected, the pilot should select both

the START BATT and SYS BATT switches to ON to keep both batteries charged. If

ground power is available it should be used to maintain battery life as well as aid in

the exterior lighting check.

• Without ground power connected, only the START BATT switch should be

selected on. This will limit battery power depletion during the exterior preflight

check.

5. DC Voltage CHECK 23 VDC MINIMUM

FOR BATTERY START, 25 DC

MINIMUM FOR GPU START

• If battery voltage is too low, external power will be necessary to start first engine.

6. External Lights CHECKED

• position

• landing

• strobe/beacon

• ice prot insp

• TAXI/RECOGNITION

26

• Verify operation of the exterior lights during walk around. Only the left landing light

will operate when operating on battery power only. Taxi lights are also load shed in

this situation. To verify operation of all aircraft lighting, external power must be

connected with both battery switches selected ON.

7. Parking Brake SET

• Depress toe brakes prior to pulling parking brake handle. If power is applied to the

aircraft a PARKING BRAKE status message will appear on the MFD. This

message is displayed as a function of the position of the parking brake handle. If

the toe brakes have not been depressed prior to pulling the parking brake handle a

PARKING BRAKE status message will appear but the parking brake is NOT set.

8. Portable Fire Extinguisher ABOARD

• Check to assure pin is present and properly installed with a plastic retaining strap.

Check for inspection/expiration date.

9. Emergency Gear Release Handle STOWED, COVER CLOSED

• The emergency gear release handle cover should be stowed flush with the aircraft

floor panel. Assure that the carpet will not interfere with the operation of the

release handle door.

10. Fuel Quantity and Balance CHECKED

• Verify by selecting the FUEL system synoptic page on the MFD.

• The aircraft should be parked on a level surface prior to fueling and fuel quantity &

balance check.

11. START BATT switch OFF

• Before executing the exterior preflight check, turn off the battery switches.

However, if ground power is connected, both battery switches may be left on for

the remainder of the exterior preflight check at the option of the pilot.

• Do not leave aircraft unattended with battery switches on.

12. Emergency Exit Pin REMOVE

• Stow the pin in a location where it will not be bent.

13. Emergency Exit CLEAR AND SECURE

• A clear path to the emergency exit should ALWAYS be maintained for ALL persons

on board the aircraft while on the ground and in flight. Items on the aircraft shall be

stored in a manner as to not interfere with the operation of the emergency exit.

14. Documents ABOARD

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

27

• Airworthiness certificate, Registration, AFM containing weight and Balance and all

applicable supplements, radio station license (international operations). RVSM

documentation and Minimum Equipment List, if applicable.

28

EXTERIOR INSPECTION

During the exterior inspection, make a general check for the condition, security and

cleanliness of the aircraft and components.

Pay special attention to:

٠ any damage to and the condition of tires and flight controls

٠ any evidence of fuel, oil and brake fluid leakage

٠security of access panels and doors

٠any blockage of ventilation inlets, exhausts and drain ports.

Ensure all covers, tie downs, and chocks are removed and stowed.

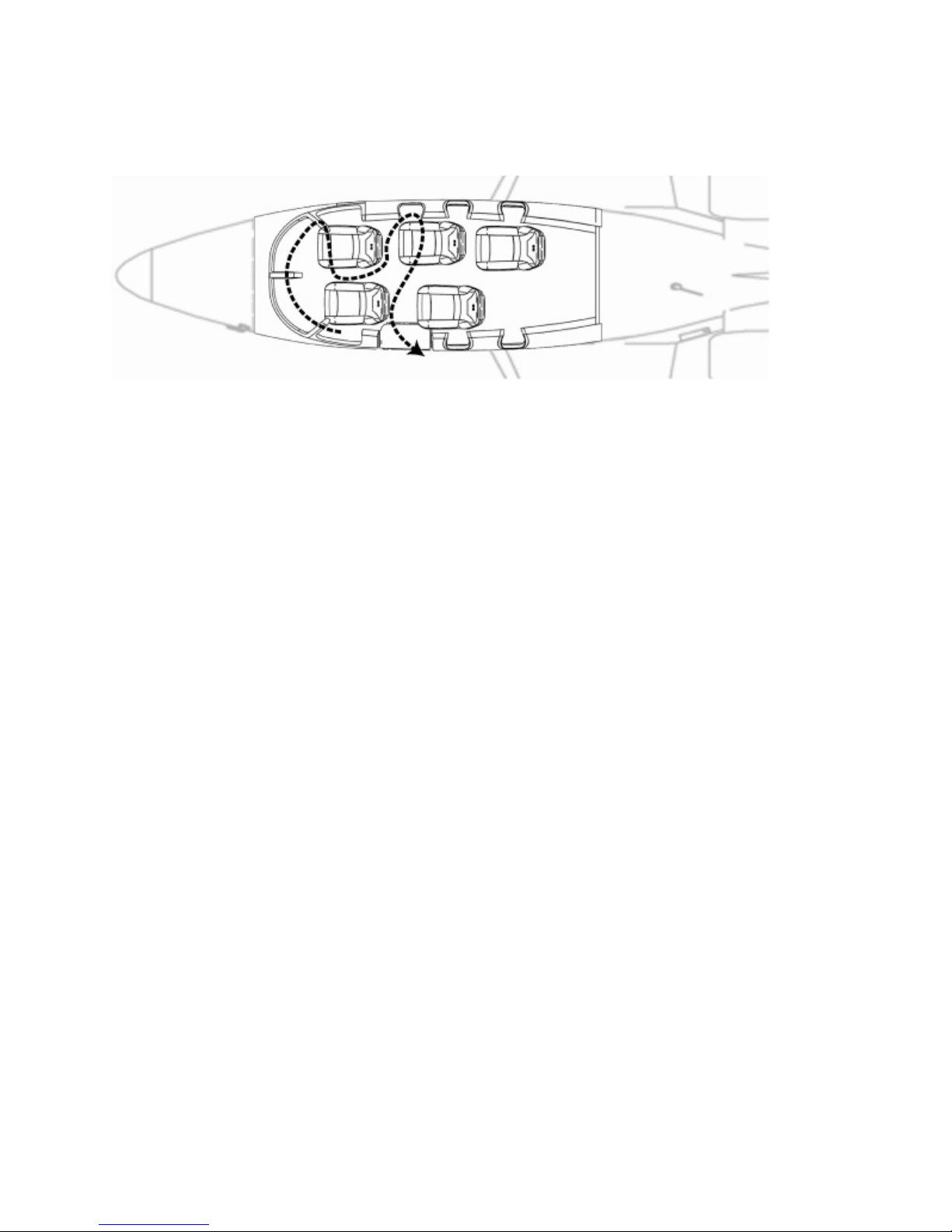

The Exterior Inspection is designed so that the walk-around inspection begins at the

crew door and transits around the aircraft in a clockwise direction.

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

29

CABIN DOOR

1. Door Seal CONDITION

• Ensure the seal is intact. The door seal is an essential component and is directly

responsible for maintaining cabin pressurization. If a door seal becomes worn,

cracked or broken, have it replaced prior to flight.

• Ensure that the lower cabin door cables are fully extended before stepping on the

steps. Failure to do so may cause damage to the door mechanism.

2. Exterior Handle STOWED

• Check condition of locking pins. Visually inspect each pin to assure that it is not

bent or damaged.

LEFT NOSE

1. Windshield and Cockpit Side Window CHECK

• Ensure windshield is free of bugs, grime and deformities.

NOTE

The windshield should not be cleaned with any petroleum-based substance. A 50/50

mixture of isopropyl alcohol and de-mineralized water is the only approved cleaning

agent.

2. Left Static Port CHECK

• No blockage. Verify left static port is free of bugs and other debris.

NOTE

DO NOT touch any port; oil from your finger will provide an adhesive surface for dirt to

collect around port openings.

3.Nose Access Panel CONDITION, SECURITY

• Ensure all fasteners are present and panel is mounted flush with aircraft surface.

4. Pitot/Static Probe CHECK

• No blockage. Verify Pitot/Static probe is free of bugs and other debris.

NOTE

DO NOT touch any probe; oil from your finger will provide an adhesive surface for dirt

to collect around port openings.

5. Pitot/AOA Probe CHECK

• No blockage. Verify Pitot/AOA probe is free of bugs and other debris

NOTE

30

DO NOT touch any probe; oil from your finger will provide an adhesive surface for dirt

to collect around port openings.

6. Oxygen Servicing Port Door SECURED

• Verify oxygen level is sufficient for the flight. Oxygen bottle pressure may also be

verified in the cockpit. The service port door should be tightly secure and flush with

the skin of the aircraft.

NOTE

The red line on the oxygen service gauge is displayed differently from the red line on

the oxygen pressure gauge in the cockpit. The service port gauge has a red line at the

high pressure end to define the maximum pressure capacity of the oxygen bottle. The

interior gauge has a redline to indicate the lowest usable pressure.

7. Oxygen High Pressure Burst Disk CONDITION

• Verify blowout disc is visible and is intact. A blown disk indicates that the oxygen

system has been improperly serviced and the aircraft’s oxygen system must be

inspected before flight.

NOTE

It is advisable that during the filling operation all servicing personnel should maintain a

clear area immediately in front of the indicator disk.

8. Nose Gear, Doors and Tire CONDITION, SECURITY

• Verify tire has sufficient tread depth. If tire pressure is low fill the tire to the

appropriate pressure. The nose gear actuator should be retracted and the

downlock proximity sensor should be firmly attached to its mounting surface.

9. Nose Gear Hard Landing Indicator CONDITION

• Verify hard landing indicator tab is not bent.

NOTE

A bent tab indicates a hard landing and the aircraft’s landing gear requires inspection

prior to flight.

RIGHT NOSE

1. Radome CONDITION, SECURITY

• The radome should be free of cracks, chips, and scratches. A damaged radome

will impair radar signal quality.

2. VCS Inlet door CONDITION, SECURITY

• Verify air conditioning door hinges allow free and unobstructed operation of the

door. If the air conditioning system is running the door will be open.

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

31

3. VCS Outlet Door CONDITION, SECURITY

• Verify air conditioning door hinges allow free and unobstructed operation of the

door. If the air conditioning system is running the door will be open

4. Pitot/AOA Probe CHECK

• No blockage. Verify Pitot/AOA probe is free of bugs and other debris

NOTE

DO NOT touch any probe, oil from your finger will provide an adhesive surface for dirt

to collect around port openings.

5. Right Static Port CHECK

• No blockage. Verify right static port is free of bugs and other debris.

NOTE

DO NOT touch any port; oil from your finger will provide an adhesive surface for dirt to

collect around port openings.

6. Windshield and Cockpit Side Window CHECK

• Ensure windshield is clean and free of scratches, bugs, grime and deformities.

NOTE

The windshield should not be cleaned with any petroleum-based substance. A 50/50

mixture of isopropyl alcohol and de-mineralized water is the only approved cleaning

agent.

RIGHT WING

1. Emergency Exit and Handle CONDITION, SECURITY

• Verify emergency exit is tightly sealed with the airframe. The handle should be

stowed flush with the airframe.

2. Landing/Taxi Light CONDITION

• Inspect Landing/Taxi Light lens scratches, cracks, and interior moisture.

3. Wing De-Ice Boot CONDITION

• Inspect boot for cracks, holes, chips, and wear. A damaged boot may not

inflate/deflate properly which could result in the inability to shed ice. In addition, a

damaged boot may not be held tight against the wing which could result in a

significant loss in aircraft performance.

4. Main Gear (Front) CHECK

a. No External Damage

b. Actuator Condition

c. Tire Condition

d. Wheel Condition

e. Brake Condition (wear indicator)

f. Sensors (WOW and downlock)

32

g. Side Brace Condition

h. Strut Extension / Hard Landing Indicator

i. Gear Door

• All landing gear components should be free of damage and should be inspected

thoroughly prior to flight. The gear wells should be inspected for anything that

would restrict free landing gear operation. The tire should have sufficient tread

depth and if necessary be filled to the proper pressure. Brake wear indicator pins

should be inspected and should not be flush with their mounting surface. Brake

lines should be firmly attached in a manner that will not cause any pinching during

gear cycles. Brake line fittings should show no evidence of leakage. A leak will be

indicated by yellowish brake fluid dripping from brake line fittings. Both WOW and

Downlock sensors should be firmly mounted to their mounting surface. The hard

landing indicator should be properly seated in its grove. The landing gear overcenter brace should be fully extended and the landing gear door should be

inspected for signs of damage.

NOTE

A displaced landing gear ring (red groove visible) indicates a hard landing and the

aircraft’s landing gear requires inspection prior to flight.

5. Under Wing CONDITION

• Ensure lower wing surface is free of dents and deformities. Inspect for ice and

other contaminants adhering to the wing. These contaminants must be removed

prior to flight as they can significantly reduce aircraft performance.

6. Fuel Drains (3) CHECK

• Inspect fuel drains for obstructions and fuel leaks prior to flight.

7. Fuel Vents (2) CHECK

• Inspect fuel vents for obstructions.

8. Wing Tip CONDITION

a. Taxi / Recognition and Anti-Collision / Position Lights

b. Fuel Filler Cap

c. Static Wick

• Inspect wing tip condition with emphasis on the light fixtures, fuel filler cap and

seal, as well as the condition of the static wick. Note that fuel may not be visible if

tank is less than full.

9. Over Wing CONDITION

• Ensure over wing surface is free of dents and deformities. Inspect for ice and other

contaminants adhering to the wing. These containments must be removed prior to

flight as they can significantly reduce aircraft performance.

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

33

10. Aileron CHECK

• Inspect aileron surfaces for damage, deformities and contamination which can

cause loss of aileron effectiveness.

11. Flap CHECK

a. No External Damage

b. Actuator Condition

c. Fairings

d. Tracks

• Inspect flap surface for damage, deformities and contamination. All flap actuators

should be free of debris.

12. Main Landing Gear (Rear) CHECK

a. No External Damage

b. Actuator Condition

c. Tire Condition

d. Wheel Condition

e. Sensors (WOW and downlock)

f. Side Brace Condition

g. Gear Door

• All landing gear components should be free of damage and should be inspected

thoroughly prior to flight. The landing gear wells should be inspected for anything

that would restrict free landing gear operation. The tire should have sufficient tread

depth and if necessary be filled to the proper pressure. Brake wear indicator pins

should be inspected and should not be flush with their mounting surface. Brake

lines should be firmly attached in a manner that will not cause any pinching during

gear cycles. Brake line fittings should show no evidence of leakage. A leak will be

indicated by yellowish brake fluid dripping from brake line fittings. Both WOW and

downlock sensors should be firmly mounted to their mounting surface. The hard

landing indicator should be properly seated in its grove. The landing gear overcenter brace should be fully extended and the landing gear door should be

inspected for signs of damage.

NOTE

A displaced landing gear ring (red groove visible) indicates a hard landing and the

aircraft’s landing gear requires inspection prior to flight.

13. Right OAT Probe CONDITION

• Inspect OAT probe for signs of damage.

14. Rotating Beacon (Upper) CHECK

• Inspect lens/mounting rotating beacon fixture for signs of damage.

RIGHT ENGINE AND NACELLE

1. Ram Air Flapper Door (RAFD) CONDITION

• Inspect ram air flapper door for signs of damage.

2. Fire Extinguisher Pressure Indicator GREEN

34

• Check PhostrEx canister pressure by viewing the pressure gauge on the top of the

engine pylon. The pressure should be in the green arc (see note for cold weather

operations)

NOTE

If the outside air temperature is -10°C or lower and the aircraft has been soaked at

or near that temperature, the fire canister pressure reading may be at or below

the green band on the canister pressure gauge. For outside

air temperatures below -10°C refer to AFM Figure 4-2

3. Engine Inlet CONDITION

• Inspect engine inlet for damage. Ensure all surfaces of the engine inlet are free of

dents and other deformities that would diminish airflow and anti ice capability.

4. Engine Fan CONDITION

• Inspect fan hub/blades for damage. Fan should rotate freely via the hub.

NOTE

Do not touch the fan blades as oil from the fingertips will contaminate the blades. The

pilot should only rotate the fan by placing their hand on the hub and rotating.

5. Nacelle Skin CONDITION

• Inspect engine nacelle for damage. All surfaces at fasteners should be secure and

flush with the surface of the nacelle.

6. Oil Level and Servicing Door CHECK, SECURITY

• Check that engine oil levels are between MIN and MAX on the sight gauge.

Significant ramp slope may affect oil level indications. If additional oil is required,

use the same brand Type II oil previously used. If necessary, refer to the engine

log for the brand name.

NOTE

Use only approved turbine engine oils; do not mix brands or types.

7. Drain Lines (4) CLEAR

• Inspect all drain lines for obstructions and signs of damage.

8. Engine Exhaust and Bypass Duct CONDITION

• Inspect engine exhaust and bypass duct for blockage and damage. Care should be

taken when inspecting these components after engine operation as they will

remain hot.

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

35

9. Variable Outlet Ram Exhaust (VORE) CONDITION

• Inspect the variable outlet ram exhaust for damage/blockage.

10. Pylon Panels CONDITION

• Inspect both upper and lower surface of the pylon panels for damage. All pylon

surfaces should be smooth and free of deformities.

FUSELAGE

LOWER FUSELAGE

1. VCS Drain FWD CLEAR

• Inspect forward VCS drain for blockage and damage.

2. Antennas CONDITION

• Inspect all antennas for damage.

3. VCS Drain AFT CLEAR

• Inspect aft VCS drain for blockage and damage.

4. Pressurization Outflow Static Ports L/R CLEAR

• Inspect pressurization outflow ports damage which could result in a reduction of

proper airflow.

UPPER FUSELAGE

1. Antennas CONDITION

• Inspect all antennas for damage.

EMPENNAGE

1. Tailstrike Fitting and Bumper Block CONDITION

• Inspect tailstrike fitting and bumper block for wear or structural damage.

2. Right VOR Antenna CONDITION

• Inspect VOR antenna for damage to the antenna and mounting surface.

3. Right Horizontal Boot CONDITION

• Inspect boot for cracks, holes, chips, and wear. A damaged boot may not

inflate/deflate properly which could result in the inability to shed ice. In addition, a

damaged boot may not be held tight against the stabilizer which could result in a

significant loss in aircraft performance.

4. Tail Cone and Anti-Collision Lights CONDITION

• Inspect anti-collision light/tail cone light for damage to lens and internal

components.

36

5. Rudder, Trim Tab CONDITION

• Inspect rudder and trim tab and their hinge points for damage. All surface edges

should be inspected for signs of binding.

6. Aft Position Lights CONDITION

• Inspect aft position lights for damage to lens and internal components.

7. Right Elevator, Trim Tab and Static Wicks (2) CONDITION

• Inspect static wicks; replace before flight if broken or missing.

8. Left Elevator, Trim Tab and Static Wicks (2) CONDITION

• Inspect static wicks; replace before flight if broken or missing.

9. Left Horizontal Boot CONDITION

• Inspect boot for cracks, holes, chips, and wear. A damaged boot may not

inflate/deflate properly which could result in the inability to shed ice. In addition, a

damaged boot may not be held tight against the stabilizer which could result in a

significant loss in aircraft performance.

10. Left VOR Antenna CONDITION

• Inspect VOR antenna for damage to antenna and antenna surface.

11. Identification Plate CONDITION

• The identification plate should be firmly attached to the aircraft. The data on the

identification plate should be consistent with the aircraft’s documentation.

LEFT ENGINE AND NACELLE

1. Pylon Panels CONDITION

• Inspect both upper and lower surface of the pylon panels for damage. All pylon

surfaces should be smooth and free of deformities.

2. Variable Outlet Ram Exhaust (VORE) CONDITION

• Inspect variable outlet ram exhaust for damage/blockage.

3. Engine Exhaust and Bypass Duct CONDITION

• Inspect engine exhaust and bypass duct for blockage and signs of damage. Care

should be taken when inspecting these components after engine operation as they

will remain hot.

4. Drain Lines (4) CLEAR

• Inspect all drain lines for obstructions and signs damage.

5. Oil Level and Servicing Door CHECK, SECURITY

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

37

• Check that engine oil levels are between MIN and MAX on the sight gauge.

Significant ramp slope may affect oil level indications. If additional oil is required,

use the same brand Type II oil previously used. If necessary, refer to the engine

log for the brand name.

NOTE

Use only approved turbine engine oils; do not mix brands or types.

6. Nacelle Skin CONDITION

• Inspect engine nacelle for damage. All surfaces at fasteners should be secure and

flush with the surface of the nacelle.

7. Engine Fan CONDITION

• Inspect fan blades for damage. Fan should rotate freely via the hub.

NOTE

Do not touch the fan blades as oil from the fingertips will contaminate the blades. The

pilot should only rotate the fan by placing their hand on the hub and rotating.

8. Engine Inlet CONDITION

• Inspect engine inlet for damage. Ensure surfaces of the engine inlet are smooth

and free of dents and other deformities that would diminish airflow and anti ice

capability.

9. Engine Cover Stowage Door SECURITY

10. Fire Extinguisher Pressure Indicator GREEN

• Check Phostrex canister pressure by viewing the pressure gauge on the top of the

engine pylon. The pressure should be in the green arc (see note for cold weather

operations)

NOTE

If the outside air temperature is -10°C or lower and the aircraft has been soaked at or

near that temperature, the fire canister pressure reading may be at or below the green

band on the canister pressure gauge. For outside air temperatures below -10°C refer

to AFM Figure 4-2

11. Ram Air Flapper Door (RAFD) CONDITION

• Inspect the ram air flapper door for damage.

LEFT WING

1. Left OAT Probe CONDITION

• Inspect OAT probe for damage.

2. Over Wing Condition CHECK

38

• Inspect over wing surface for dents and deformities. Inspect for ice and other

contaminants adhering to the wing. These contaminants must be removed prior to

flight as they can significantly reduce aircraft performance.

3. Flap CHECK

a. No External Damage

b. Actuator Condition

c. Fairings

d. Tracks

• Inspect flap surface for damage, deformities and contamination. All flap actuators

should be free of debris.

4. Main Gear (Rear) CHECK

a. No External Damage

b. Actuator Condition

c. Tire Condition

d. Wheel Condition

e. Sensors (WOW and downlock)

f. Side Brace Condition

g. Gear Door

• All landing gear components should be free of damage and should be inspected

thoroughly prior to flight. The landing gear wells should be inspected for anything

that would restrict free landing gear operation. The tire should have sufficient tread

depth and if necessary be filled to the proper pressure. Brake wear indicator pins

should be inspected and should not be flush with their mounting surface. Brake

lines should be firmly attached in a manner that will not cause any pinching during

gear cycles. Brake line fittings should show no evidence of leakage. A leak will be

indicated by yellowish brake fluid dripping from brake line fittings. Both WOW and

Downlock sensors should be firmly mounted to their mounting surface. The hard

landing indicator should be properly seated in its grove. The landing gear overcenter brace should be fully extended and the landing gear door should be

inspected for signs of damage.

NOTE

A displaced landing gear ring (red groove visible) indicates a hard landing and the

aircraft’s landing gear requires inspection prior to flight.

5. Aileron CHECK

• Inspect aileron surfaces for damage, deformities and contamination which can

cause loss of aileron effectiveness. Additionally, inspect the aileron hinges and

edges for signs of control binding.

6. Under Wing CONDITION

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

39

• Inspect lower wing surface for dents and deformities. Inspect for ice and other

contaminants adhering to the wing. These containments must be removed prior to

flight as they can significantly reduce aircraft performance.

7. Fuel Drains (3) CHECK

• Inspect fuel drains for obstructions and fuel leaks.

8. Fuel Vents (2) CHECK

• Inspect fuel vents for obstructions.

9. Wing Tip CONDITION

a. Static Wick

b. Fuel Filler Cap

c. Position and Recognition / Anti-Collision Lights

• Inspect wing tip condition with emphasis on the light fixtures, fuel filler cap and

seal, as well as the condition of the static wick. Note that fuel may not be visible if

tank is less than full.

10. Wing De-Ice Boot CONDITION

• Inspect boot for cracks, holes, chips, and wear. A damaged boot may not

inflate/deflate properly which could result in the inability to shed ice. In addition, a

damaged boot may not be held tight against the wing which could result in a

significant loss in aircraft performance.

11. Main Landing Gear (Front) CHECK

a. No External Damage

b. Actuator Condition

c. Tire Condition

d. Wheel Condition

e. Brake Condition

f. Sensors (WOW and downlock)

g. Side Brace Condition

h. Strut Extension / Hard Landing Indicator

i. Gear Door

• All landing gear components should be free of damage and should be inspected

thoroughly prior to flight. The gear wells should be inspected for anything that

would restrict free landing gear operation. The tire should have sufficient tread

depth and if necessary be filled to the proper pressure. Brake wear indicator pins

should be inspected and should not be flush with their mounting surface. Brake

lines should be firmly attached in a manner that will not cause any pinching during

gear cycles. Brake line fittings should show no evidence of leakage. A leak will be

indicated by yellowish brake fluid dripping from brake line fittings. Both WOW and

Downlock sensors should be firmly mounted to their mounting surface. The hard

landing indicator should be properly seated in its grove. The landing gear overcenter brace should be fully extended and the landing gear door should be

inspected for signs of damage.

NOTE

40

A displaced landing gear ring (red groove visible) indicates a hard landing and the

aircraft’s landing gear requires inspection prior to flight.

12. Landing Light CONDITION

• Inspect landing Light lens for scratches, cracks, and interior moisture.

13. Ice Inspection Light CONDITION

• Check the ice inspection light lens for scratches, cracks, and interior moisture.

BEFORE STARTING CHECK

Before Start Flow Pattern

Before Starting Check (Expanded)

1. Passenger Briefing.............................................. COMPLETE

• As a minimum, the passengers should be briefed on the following:

o Use of the cabin door and emergency exit for emergency egress

o Use of the passenger O

system

2

o Location of the first aid kit and portable fire bottle

o Use of the seat belt / shoulder harness

o Sterile cockpit after takeoff and before landing

• Additional items that may be of interest to the passengers are:

o Flight time

o Weather (en route and destination)

o Rout of flight

2. GPU (If Required) ...............................CONNECT

• Ensure both engine selector switches are OFF

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

41

• Both battery switches must be ON in order for the Electrical Power contactor to

close, allowing external power to the aircraft.

3. Door ……………………………………………CLOSED, VERIFY FLAGS GREEN

4. Seat Belts, Shoulder Harnesses, Headrests………FASTEN / ADJUST

• Adjust headrest so that the oxygen mask holder is situated higher than the pilot’s

shoulder. This will allow expeditious donning of the mask (less than 5 seconds) in

an emergency.

5. Seat Rail Stop Assembly DOWN / LOCKED

6. Oxygen Control…………………………………….. PULL ON

• When pulling the oxygen control knob out, there should be an audible rush of air.

7. Crew Mask……………………………………………CHECK, SELECT 100%

• The crew oxygen mask should be checked for proper operation (harness inflation,

breathing capability, and microphone operation). To check, remove mask from the

stowage cup, inspect the face cone for rips/tears, inflate the harness, feel and

listen for leaks, don the mask. Move the MASK HEADSET switch to MASK and

activate the right side speaker via the AUDIO synoptic page or keyboard. You

should hear your voice from the right speaker. Note that aircraft power must be on

to accomplish this check. To check the right pilot’s mask (if installed) repeat this

procedure except select the left speaker to check for proper audio. Remove the

mask and fold properly ensuring 100% setting selection before stowing. NOTE: If

battery power only, the right pilot’s mask cannot be tested at this point; test prior to

“Before Taxi” checklist. A through-flight check of the mask does not require

removal of the mask from the cup. Ensure a proper connection of the microphone

cable and oxygen hose under the armrest, check for a green in-line indicator, and

test the mask by momentarily selecting the “Emergency” setting on the mask

regulator ensuring oxygen flow to the mask and returning the switch back to the

100% setting.

8. Flight Controls………………………………………………..CHECK

• Move sidestick full forward, full left, full aft, full right, then full forward again,

verifying complete freedom of movement of flight controls.

9. MASK HEADSET Switch(es)………………………………...HEADSET

• Ensure MASK HEADSET switches are selected to the HEADSET position.

10. COM System Select………………………………………….L PFD

• Verify left com select switch set to the left PFD position and right com select switch

(if installed) set to the right PFD position.

NOTE

During normal operations (both PFDs functioning) the com select switched(s) should

be set to their respective PFD. Improper selection during normal operations can cause

confusion regarding active frequency assignment.

42

11. L PFD Circuit Breaker SET

• Verify circuit breaker pressed in

12. L ACS Circuit Breaker SET

• Verify circuit breaker pressed in

13. R GEN Switch AUTO

14. BUS TIE Switch AUTO

15. SYSTEM BATT Switch ................................... ON

16. L GEN Switch……………...………………………………………….AUTO

17. ELT Switch…………………………………………………………..ARM

18. Passenger Mask……………………………………………………AUTO

19. AIR SOURCE Switch…………………………………………………OFF

20. External Lights…………………………………………….AS REQUIRED

• Turn Beacon light on.

21. Gear Indication……………………………………………THREE GREEN

22. Parking Brake………………...............................................................SET

• Pulling the parking brake handle without simultaneously depressing the brake

pedals will not

engage the parking brake, even though the PARKING BRAKE

status message is illuminated.

23. COMM / NAV…………………………………………………………….SET

• Set tower and departure frequencies in comm. #1. Use comm. #2 for all ground

frequencies (ATIS, clearance delivery, ground control, etc). This will allow a simple

change to comm. #1 when ready to talk to tower.

• Set the two navaids likely to be initially used in both nav #1 and nav #2.

24. Altimeter………………………………………………………………SET

• Use ATIS/ASOS/AWOS altimeter setting. If no weather source available, set

airport elevation.

12/8/2006 FLIGHT TRAINING AND STANDARDS MANUAL

ECLIPSE 500

© Eclipse Aviation Corporation, 2006

43

25. Ops Page……………………………………………………………..CHECK

a. Weights…….ENTER

• Enter each pilot/passenger weight and any baggage.

b OAT…………ENTER

• Use ATIS temperature, if available. If the OAT is not immediately accepted,

re-enter the OAT after taxi and prior to takeoff. Takeoff performance data is

NOT assured unless the OAT is properly entered.

c. Vr Speed………ENTER

• Enter Vr speed computed from performance data.

26. Trims (3)……………………………………………………………….SET