Design Guide 205

3/5/07

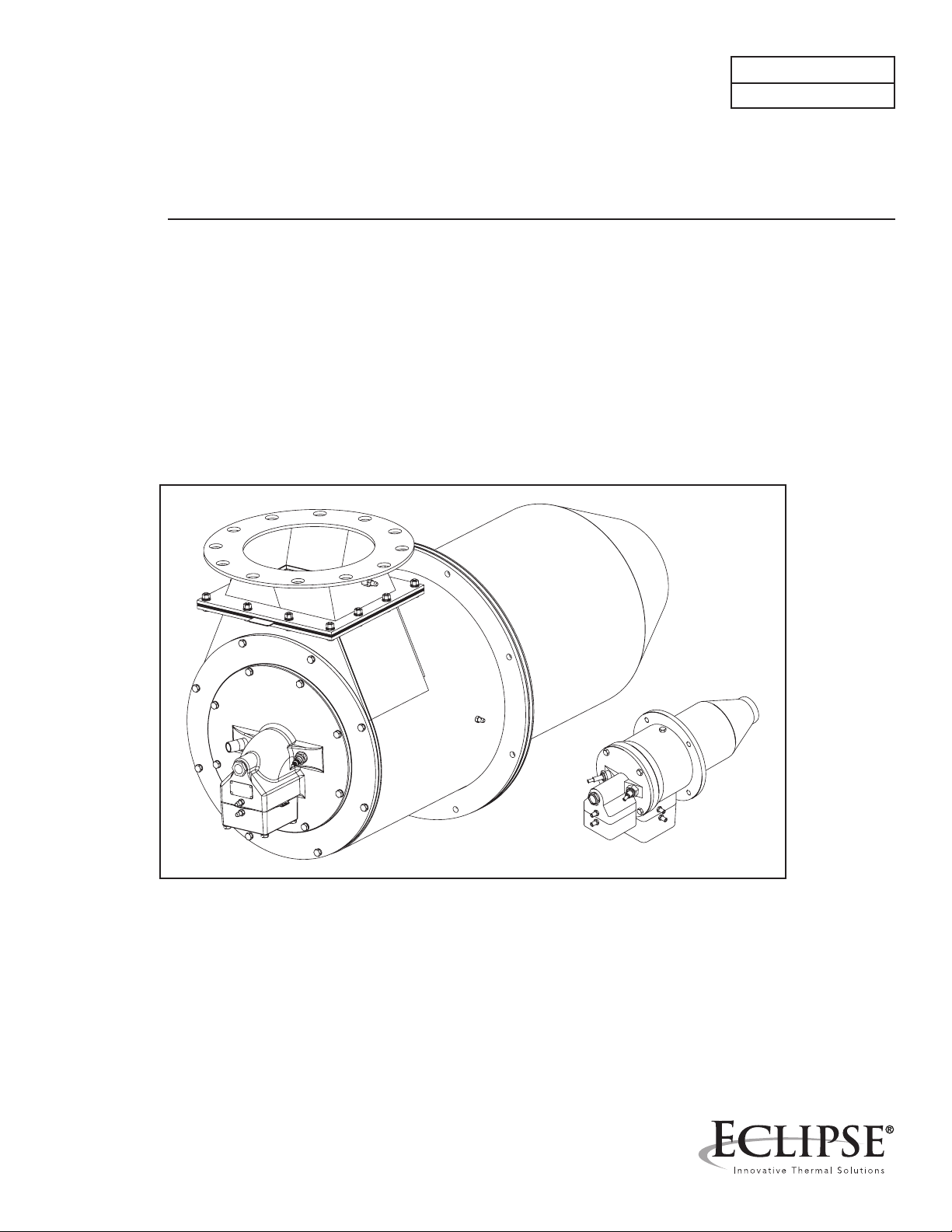

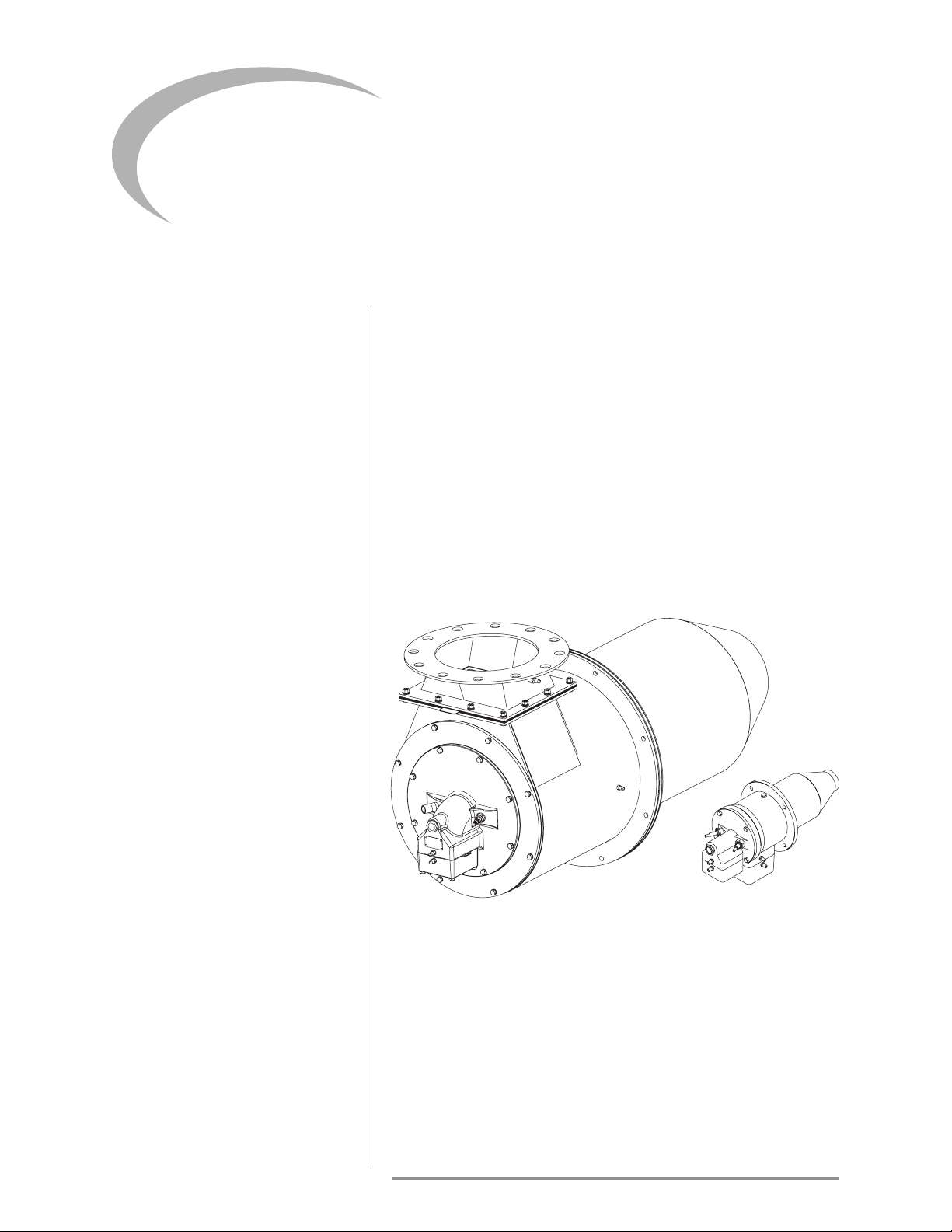

Eclipse ThermJet

Burners

Models TJ0015 – TJ2000

Version 2

Copyright

Copyright 2007 by Eclipse, Inc. All rights reserved worldwide.

This publication is protected by federal regulation and shall not

be copied, distributed, transmitted, transcribed or translated

into any human or computer language, in any form or by any

means, to any third parties, without the express written consent

of Eclipse, Inc.

In accordance with the manufacture’s policy of continual product improvement, the product presented in this brochure is

subject to change without notice or obligation.

DisClaimer NotiCe

liability aND

WarraNty

The material in this manual is believed adequate for the intended use of the product. If the product is used for purposes other

than those specied herein, conrmation of validity and suitability must be obtained. Eclipse warrants that the product itself

does not infringe upon any United States patents. No further

warranty is expressed or implied.

We have made every effort to make this manual as accurate

and complete as possible. Should you nd errors or omissions,

please bring them to our attention so that we may correct

them. In this way we hope to improve our product documentation for the benet of our customers. Please send your corrections and comments to our Marketing Communications

Manager.

It must be understood that Eclipse’s liability for its product,

whether due to breach of warranty, negligence, strict liability,

or otherwise is limited to the furnishing of replacement parts

and Eclipse will not be liable for any other injury, loss, damage

or expenses, whether direct or consequential, including but not

limited to loss of use, income, or damage to material arising in

connection with the sale, installation, use of, inability to use, or

the repair or replacement of Eclipse’s products.

Any operation expressly prohibited in this Guide, any adjustment, or assembly procedures not recommended or authorized

in these instructions shall void the warranty.

Eclipse ThermJet Design Guide No. 205, 3/5/07

About this manual

auDieNCe

thermJet DoCumeNts

This manual has been written for people who are already

familiar with all aspects of a nozzle-mix burner and its add-on

components, also referred to as “the burner system.”

These aspects are:

Design/selection

•

Use

•

Maintenance.

•

The audience is expected to have had experience with this

kind of equipment.

Design Guide No. 205

This document

•

Data Sheet No. 205-1 through 205-13

Available for individual TJ models

•

Required to complete design calculations in this guide

•

Installation Guide No. 205

Used with Data Sheet to complete installation

•

Price List No. 205

Used to order burners

•

relateD DoCumeNts

EFE 825 (Combustion Engineering Guide)

•

Eclipse bulletins and Info Guides:

•

610, 710, 720, 730, 742, 744, 760, 930

Purpose

The purpose of this manual is to make sure that the design of a

safe, effective and trouble-free combustion system is carried out.

Eclipse ThermJet Design Guide No. 205, 3/5/07

3

DoCumeNt

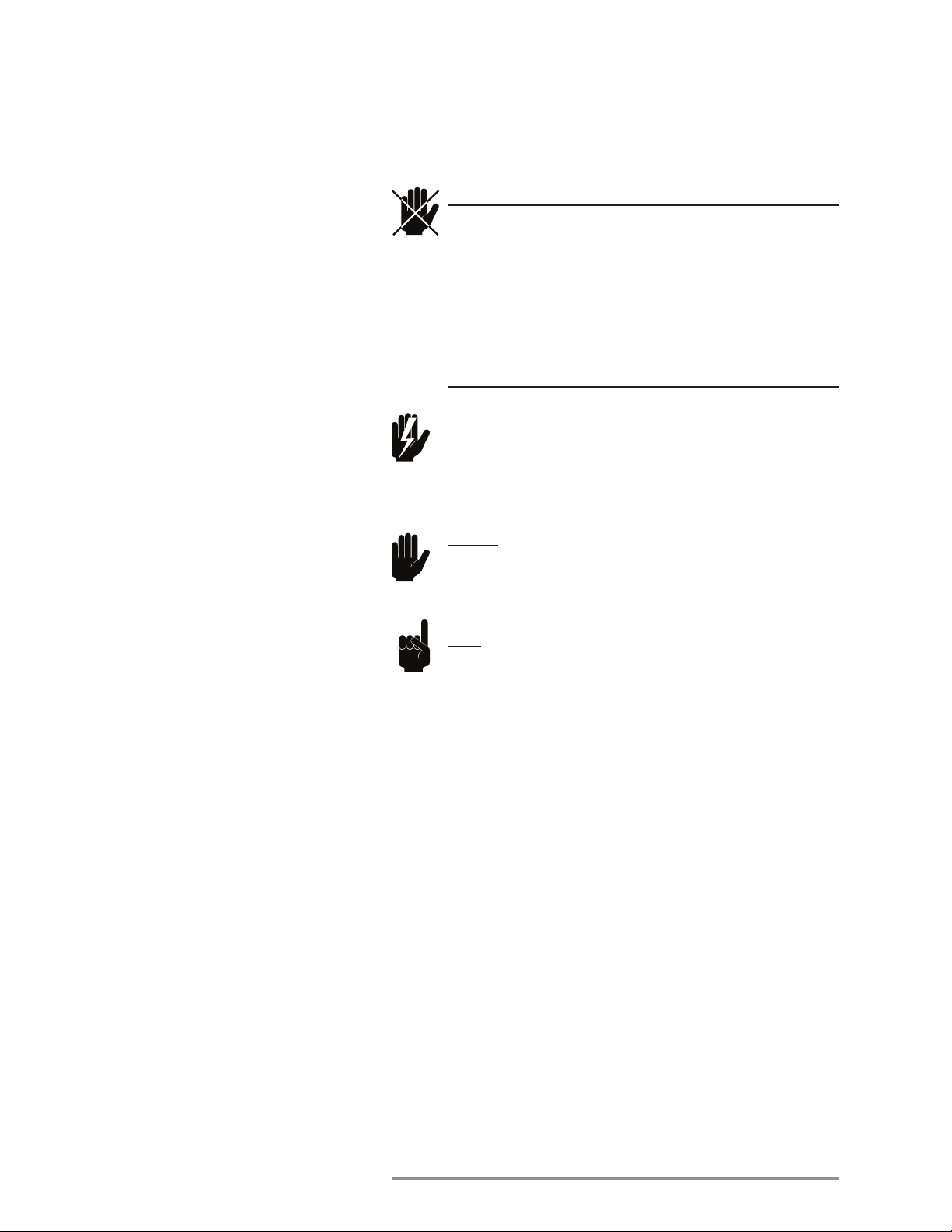

CoNveNtioNs

There are several special symbols in this document. You must

know their meaning and importance.

The explanation of these symbols follows below. Please read it

thoroughly.

Danger:

Indicates hazards or unsafe practices which

WILL result in severe personal injury or even

death.

Only qualied and well trained personnel are

allowed to carry out these instructions or procedures.

Act with great care and follow the instructions.

Warning:

Indicates hazards or unsafe practices which could

result in severe personal injury or damage.

Act with great care and follow the instructions.

hoW to get help

Caution:

Indicates hazards or unsafe practices which could result in

damage to the machine or minor personal injury, act carefully.

Note:

Indicates an important part of the text. Read thoroughly.

If you need help, contact your local Eclipse representative. You

can also contact Eclipse at:

1665 Elmwood Rd.

Rockford, Illinois 61103 U.S.A.

Phone: 815-877-3031

Fax: 815-877-3336

http://www.eclipsenet.com

Eclipse ThermJet Design Guide No. 205, 3/5/07

Table of contents

1

2

3

Introduction

Product Description .......................................................................... 6

Figure 1.1 The ThermJet Burner ..................................................... 6

Safety

Introduction ........................................................................................ 7

Safety ..................................................................................................... 7

Capabilities ......................................................................................... 8

Operator Training ............................................................................... 8

Replacement Parts ............................................................................. 8

System Design

Design ................................................................................................... 9

Step 1: Burner model selection ....................................................... 9

Step 2: Control Methodology .......................................................... 10

Figure 3.1: Modulating gas & air:

On-ratio control or excess air @ low re ............................ 12

Figure 3.2: Modulating gas with xed-air control ...................... 13

Figure 3.4: High/Low gas with xed-air control ........................ 15

Step 3: Ignition System ..................................................................... 16

Figure 3.5: Bypass start gas circuit schematics ........................... 17

Step 5: Combustion Air System: Blower

and air pressure switch ............................................................. 19

Table 3.1: Required calculation information ................................ 20

Table 3.2: Fuel gas heating values ................................................... 20

Example blower calculation ............................................................. 21

Step 6: Main gas shut-off valve train .............................................. 22

Step 7: Process Temperature Control System ............................ 22

Appendix

Conversion Factors ........................................................................... 23

Key to System Schematics ............................................................... 24

Eclipse ThermJet Design Guide No. 205, 3/5/07

5

Introduction

1

proDuCt

DesCriptioN

The ThermJet is a nozzle-mix burner that is designed to re an

intense stream of hot gases through a combustor using ambient

combustion air.

The high velocity of the gases improves temperature uniformity,

product quality and system efciency.

The ThermJet burner comes in two types:

High Velocity (HV)

•

Medium Velocity (MV)

•

The gas velocity can be as high as 500 ft/s for the High Velocity

burner, and 250 ft/s for the Medium Velocity burner.

Figure 1.1 The ThermJet Burner

Eclipse ThermJet Design Guide No. 205, 3/5/07

Safety

2

iNtroDuCtioN

safety

Important notices about safe burner operation will be found in

this section. Read this entire manual before attempting to start

the system. If any part of the information in this manual is not

understood, then contact your local Eclipse representative or

Eclipse, Inc. before continuing.

Danger:

The burners covered in this manual are designed

to mix fuel with air and burn the resulting mixture. All fuel burning devices are capable of

producing res and explosions when improperly

applied, installed, adjusted, controlled or maintained.

Do not bypass any safety feature. Fires and explosions can be caused.

Never try to light the burner if the burner shows

signs of damage or malfunctioning.

Warning:

The burner is likely to have HOT surfaces. Always wear protective clothing when approaching

the burner.

Note:

This manual gives information for the use of these burners

for their specic design purpose. Do not deviate from any instructions or application limits in this manual without written

advice from Eclipse, Inc.

Eclipse ThermJet Design Guide No. 205, 3/5/07

7

safety (CoNtiNueD)

Warning:

Eclipse products are designed to minimize the

use of materials that contain crystalline silica.

Examples of these chemicals are: respirable

crystalline silica from bricks, cement or other

masonry products and respirable refractory

ceramic bers from insulating blankets, boards,

or gaskets. Despite these efforts, dust created by

sanding, sawing, grinding, cutting, and other construction activities could release crystalline silica.

Crystalline silica is known to cause cancer, and

health risks from the exposure to these chemicals vary depending on the frequency and length

of exposure to these chemicals. To reduce this

risk, limit exposure to these chemicals, work in a

well-ventilated area and wear approved personal

protective safety equipment for these chemicals.

Capabilities

operator traiNiNg

replaCemeNt parts

Adjustment, maintenance and troubleshooting of the mechanical

and the electrical parts of this system should be done by qualied personnel with good mechanical aptitude and experience

with combustion equipment.

The best safety precaution is an alert and competent operator. Thoroughly instruct new operators so they demonstrate

an adequate understanding of the equipment and its operation.

Regular retraining must be scheduled to maintain a high degree

of prociency.

Order replacement parts from Eclipse only. Any customer-supplied valves or switches should carry UL, FM, CSA,CGA and/or

CE approval where applicable.

Eclipse ThermJet Design Guide No. 205, 3/5/07

Loading...

Loading...