Eclipse RatioMatic RM Series, RatioMatic RM1000, RatioMatic RM1250, RatioMatic RM2500, RatioMatic RM3000 Installation Manual

...Page 1

Installation Guide 110

12/3/2014

Eclipse RatioMatic

Burners

RM Series

Version 5

Page 2

Copyright

Copyright 2010 by Eclipse, inc. All rights reserved

worldwide. This publication is protected by federal

regulation and shall not be copied, distributed,

transmitted, transcribed or translated into any human or

computer language, in any form or by any means, to any

third parties, without the express written consent of

Eclipse, inc.

Disclaimer Notice

In accordance with the manufacturer’s policy of continual

product improvement, the product presented in this

brochure is subject to change without notice or obligation.

The material in this manual is believed adequate for the

intended use of the product. If the product is used for

purposes other than those specified herein, confirmation

of validity and suitability must be obtained. Eclipse

warrants that the product itself does not infringe upon any

United States patents. No further warranty is expressed or

implied.

Liability & Warranty

We have made every effort to make this manual as

accurate and complete as possible. Should you find errors

or omissions, please bring them to our attention so that we

may correct them. In this way we hope to improve our

product documentation for the benefit of our customers.

Please send your corrections and comments to our

Technical Documentation Specialist.

It must be understood that Eclipse’s liability for its product,

whether due to breach of warranty, negligence, strict

liability, or otherwise is limited to the furnishing of

replacement parts and Eclipse will not be liable for any

other injury, loss, damage or expenses, whether direct or

consequential, including but not limited to loss of use,

income, or damage to material arising in connection with

the sale, installation, use of, inability to use, or the repair

or replacement of Eclipse’s products.

Any operation expressly prohibited in this manual, any

adjustment, or assembly procedures not recommended or

authorized in these instructions shall void the warranty.

Document Conventions

There are several special symbols in this document. You

must know their meaning and importance.

The explanation of these symbols follows below. Please

read it thoroughly.

How To Get Help

If you need help, contact your local Eclipse

representative. You can also contact Eclipse at:

1665 Elmwood Rd.

Rockford, Illinois 61103 U.S.A.

Phone: 815-877-3031

Fax: 815-877-3336

http://www.eclipsenet.com

Please have the information on the product label available

when contacting the factory so we may better serve you.

www.eclipsenet.com

Product Name

Item #

S/N

DD MMM YYYY

This is the safety alert symbol. It is used to alert you to potential personal

injurt hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

Indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING

CAUTION

NOTICE

NOTE

2

Indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

Is used to address practices not related to personal injury.

Indicates an important part of text. Read thoroughly.

Page 3

Table of Contents

Introduction .............................................................................................. 4

Product Description....................................................................... 4

Audience ....................................................................................... 4

RatioMatic Documents .................................................................. 4

Purpose......................................................................................... 4

Safety ........................................................................................................ 5

Safety Warnings............................................................................ 5

Capabilities.................................................................................... 5

Operator Training .......................................................................... 5

Replacement Parts........................................................................ 5

Installation ................................................................................................ 6

Handling & Storage ....................................................................... 6

Approvals of Components............................................................. 6

Checklist Before Installation.......................................................... 7

Installing the Flame Sensor........................................................... 7

Burner Installation ......................................................................... 7

Refractory Block Curing Schedule ................................................ 9

Gas Piping..................................................................................... 9

Setting Ignitor Location (RM1000-RM3000).................................. 11

Checklist After Installation............................................................. 11

Adjustment, Start & Stop......................................................................... 12

Adjustment Procedure................................................................... 12

Step 1: Reset the System ............................................................. 12

Step 2: Set Low Fire Air ................................................................ 13

Step 3: Ignite the Burner (RM0050-RM0700 only)........................ 14

Step 4: Set Low Fire Gas (RM0050-RM0700 only)....................... 17

Step 5: Verify Settings (RM0050-RM0700 only) ........................... 18

Step 3: Ignite the Burner (RM1000-RM3000 only)........................ 19

Step 4: Set Low Fire Gas (RM1000-RM3000 only)....................... 19

Step 5: Verify Settings (RM1000-RM3000 only) ........................... 19

Maintenance & Troubleshooting ............................................................ 20

Monthly Checklist .......................................................................... 20

Yearly Checklist ............................................................................ 20

Troubleshooting ............................................................................ 21

Appendix................................................................................................... i

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

3

Page 4

Introduction

Product Description

The RatioMatic is a nozzle-mix type burner designed for

direct and indirect air heating and oven applications up to

1900°F(1040°C).

The burner package includes a combustion air blower and

an air/gas ratio regulator to fire over a wide gas turndown

range with controlled ratio.

The burner is designed for:

• Efficient Ratio Controlled Combustion

• Reliable Burner Operation

• Simple Burner Adjustment

• Direct Spark Ignition

• Multiple Fuel Capability

A wide variety of options and configurations are available

due to the modular design of the burner.

1

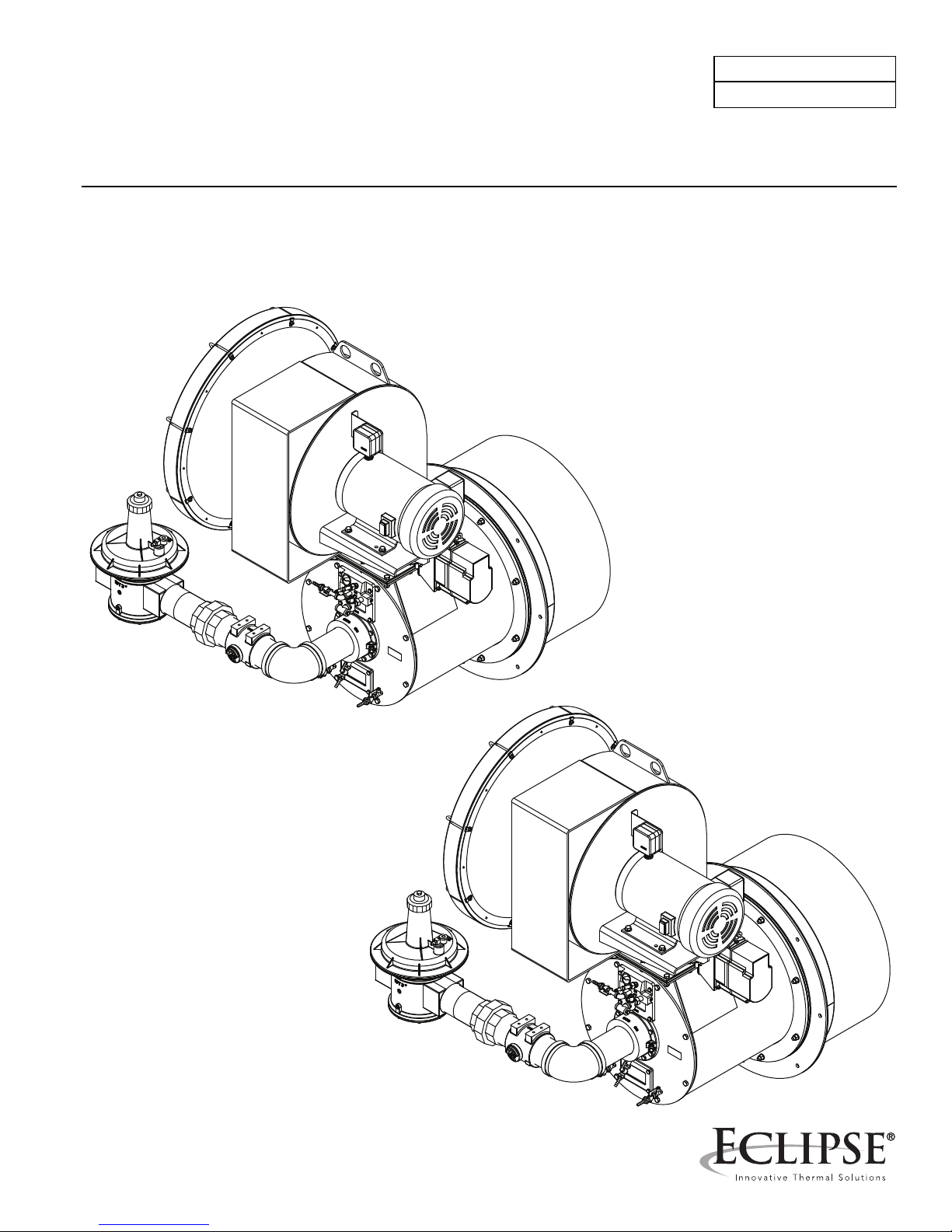

Figure 1.2. RatioMatic Burner (RM1000 - RM3000)

RatioMatic Documents

Installation Guide No. 110

• This document

Audience

This manual has been written for people who are already

familiar with all aspects of a nozzle-mix burner and its addon components, also referred to as “the burner system”.

These aspects are:

• Installation

• Use

• Maintenance

The audience is expected to have previous experience

with this type of equipment.

Datasheet, Series 110

• Available for individual RM models

• Required to complete design and selection

Design Guide No. 110

• Used with Datasheet to complete installation

Related Documents

• EFE 825 (Combustion Engineering Guide)

• Eclipse Bulletins and Info Guides: 710, 732, 760,

818, 830, 832, 852, 854, 856, 610, 820, 902, 930

Purpose

The purpose of this manual is to ensure the installation

and adjustment of a safe, effective and trouble-free

combustion system.

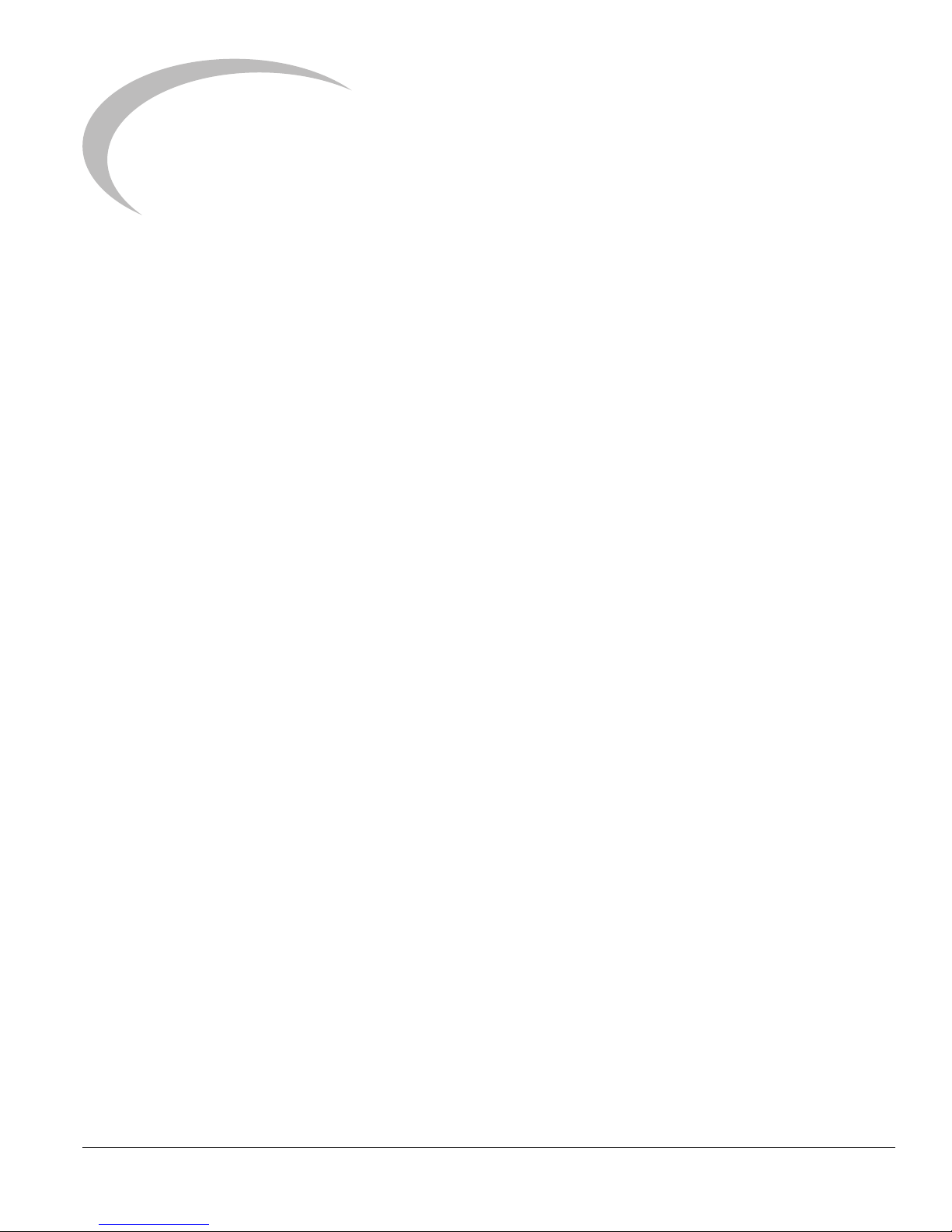

Figure 1.1. RatioMatic Burner (RM0050 - RM0700)

4

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

Page 5

Safety

Important notices which help provide safe burner

operation will be found in this section. To avoid personal

injury and damage to the property or facility, the following

warnings must be observed. All involved personnel should

read this entire manual carefully before attempting to start

or operate this system. If any part of the information in this

manual is not understood, contact Eclipse before

continuing.

Safety Warnings

DANGER

■ The burners, described herein, are designed to mix

fuel with air and burn the resulting mixture. All fuel

burning devices are capable of producing fires and

explosions if improperly applied, installed,

adjusted, controlled or maintained.

■ Do not bypass any safety feature; fire or explosion

could result.

■ Never try to light a burner if it shows signs of

damage or malfunction.

WARNING

■ The burner and duct sections are likely to have

HOT surfaces. Always wear the appropriate

protective equipment when approaching the

burner.

2

NOTICE

■ This manual provides information regarding the

use of these burners for their specific design

purpose. Do not deviate from any instructions or

application limits described herein without written

approval from Eclipse.

Capabilities

Only qualified personnel, with sufficient mechanical

aptitude and experience with combustion equipment,

should adjust, maintain or troubleshoot any mechanical or

electrical part of this system. Contact Eclipse for any

needed commissioning assistance.

Operator Training

The best safety precaution is an alert and trained

operator. Train new operators thoroughly and have them

demonstrate an adequate understanding of the

equipment and its operation. A regular retraining schedule

should be administered to ensure operators maintain a

high degree of proficiency. Contact Eclipse for any needed

site-specific training.

Replacement Parts

Order replacement parts from Eclipse only. All Eclipse

approved valves or switches should carry UL, FM, CSA,

CGA and/or CE approval where applicable.

■ Eclipse products are designed to minimize the use

of materials that contain crystalline silica.

Examples of these chemicals are: respirable

crystalline silica from bricks, cement or other

masonry products and respirable refractory

ceramic fibers from insulating blankets, boards, or

gaskets. Despite these efforts, dust created by

sanding, sawing, grinding, cutting and other

construction activities could release crystalline

silica. Crystalline silica is known to cause cancer,

and health risks from the exposure to these

chemicals vary depending on the frequency and

length of exposure to these chemicals. To reduce

the risk, limit exposure to these chemicals, work in

a well-ventilated area and wear approved personal

protective safety equipment for these chemicals.

5

Page 6

Installation

3

In this section you will find information and instructions

needed to install the burner and system components.

Handling & Storage

Handling

• Make sure that the area is clean.

• Protect all components from weather, damage, dirt

and moisture.

• Protect the components from excessive

temperatures and humidity.

• Take care not to drop or damage components.

Storage

• Make sure the components are clean and free of

damage.

• Store the components in a cool, clean, dry room.

• After you have made sure everything is present and

in good condition, keep the components in their

original packaging as long as possible

Approval of Components

Limit Controls & Safety Equipment

All limit controls and safety equipment must comply with

all applicable local codes and/or standards and must be

listed for combustion safety by an independent testing

agency. Typical application examples include:

• American: NFPA 86 with listing marks from UL, FM,

CSA

• European: EN 746-2 with CE mark from TuV,

Gastec, Advantica

Electrical Wiring

All the electrical wiring must comply with all applicable

local codes and/or standards such as:

• NFPA Standard 70

• IEC60364

• CSA C22

• BS7671

Gas Piping

All the gas piping must comply with all applicable local

codes and/or standards such as:

• NFPA Standard 54

• ANSI Z223

• EN 746-2

Where to Get the Standards:

The NFPA Standards are available from:

National Fire Protection Agency

Batterymarch Park

Quincy, MA 02269

www.nfpa.org

The ANSI Standards are available from:

American National Standard Institute

1430 Broadway

New York, NY 10018

www.ansi.org

The UL Standards are available from:

333 Pfingsten Road

Northbrook, IL 60062

www.ul.com

The FM Standards are available from:

1151 Boston-Providence Turnpike

PO Box 9102

Norwood, MA 02062

www.fmglobal.com/approvals

Information on the EN standards and where to get them is

available from:

Comité Européen de Normalisation

Stassartstraat 36

B-1050 Brussels

Phone: +32-25196811

Fax: +32-25196819

www.cen.eu

Comité Européen de Normalisation Electronique

Stassartstraat 36

B-1050 Brussels

Phone: +32-25196871

Fax: +32-25196919

www.cenelec.org

6

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

Page 7

Checklist Before Installation

Air Supply

Provide an opening in the burner room of at least one

square inch per 4000 BTU/hr (6 cm

the burner intake with fresh, outdoor, combustion air.

If there are corrosive fumes or materials in the

surrounding air, find an uncontaminated source to supply

air to the burner, or provide a sufficient air filtering system.

Exhaust

2

per 1 kW) to supply

Flame Rod

NOTE: Only specific burner sizes with alloy or silicon

carbide combustors can use a flamerod (see specific

burner datasheets).

For detailed information on how to install and connect a

flamerod, refer to Bulletin/Info guide 832.

Installing the Spark Plug

Install the spark plug into the opening in the rear cover.

Do not allow exhaust fumes to accumulate in the work

area. Provide some positive means for exhausting from

the furnace and the building.

Access

Make sure the burner is installed in such a way to allow

easy access for inspection and maintenance.

Environment

Make sure the local environment matches the original

operating specifications. Check the following items:

• Voltage, frequency and stability of the electrical

power

• Fuel type and supply pressure of the fuel

• Availability of enough fresh, clean combustion air

• Humidity, altitude and temperature of air

• Presence of damaging corrosive gases in the air

• Prevent direct exposure to water

Installing the Flame Sensor

1. Install the flame sensor into the 1/2" NPT opening in the

rear cover.

NOTE: Do not apply any grease to the threads of the

spark plug or bad grounding of the spark plug may occur,

resulting in a weak spark.

NOTICE

■ Adjustments may vary from Eclipse published

values if the flame controls other than those

recommended in the Design Guide are used.

Consult with the engineer who specified the

alternate control for limitations.

Burner Installation

Chamber Opening

Minimum 1/4" (6mm)

space per side

Combustor

2. Make sure the flame sensor of a burner is connected to

the electrical circuit for that burner.

DANGER

■ If you connect the flame sensor of a burner to the

electrical circuit of the wrong burner, you can

cause fires and explosions.

There are two different types of flame sensors; UV

scanner and flamerod.

UV Scanner

The UV Scanner must be compatible to the flame

monitoring control that is used. Refer to the manual of

your selected control for proper selection of the scanner.

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

Chamber Wall

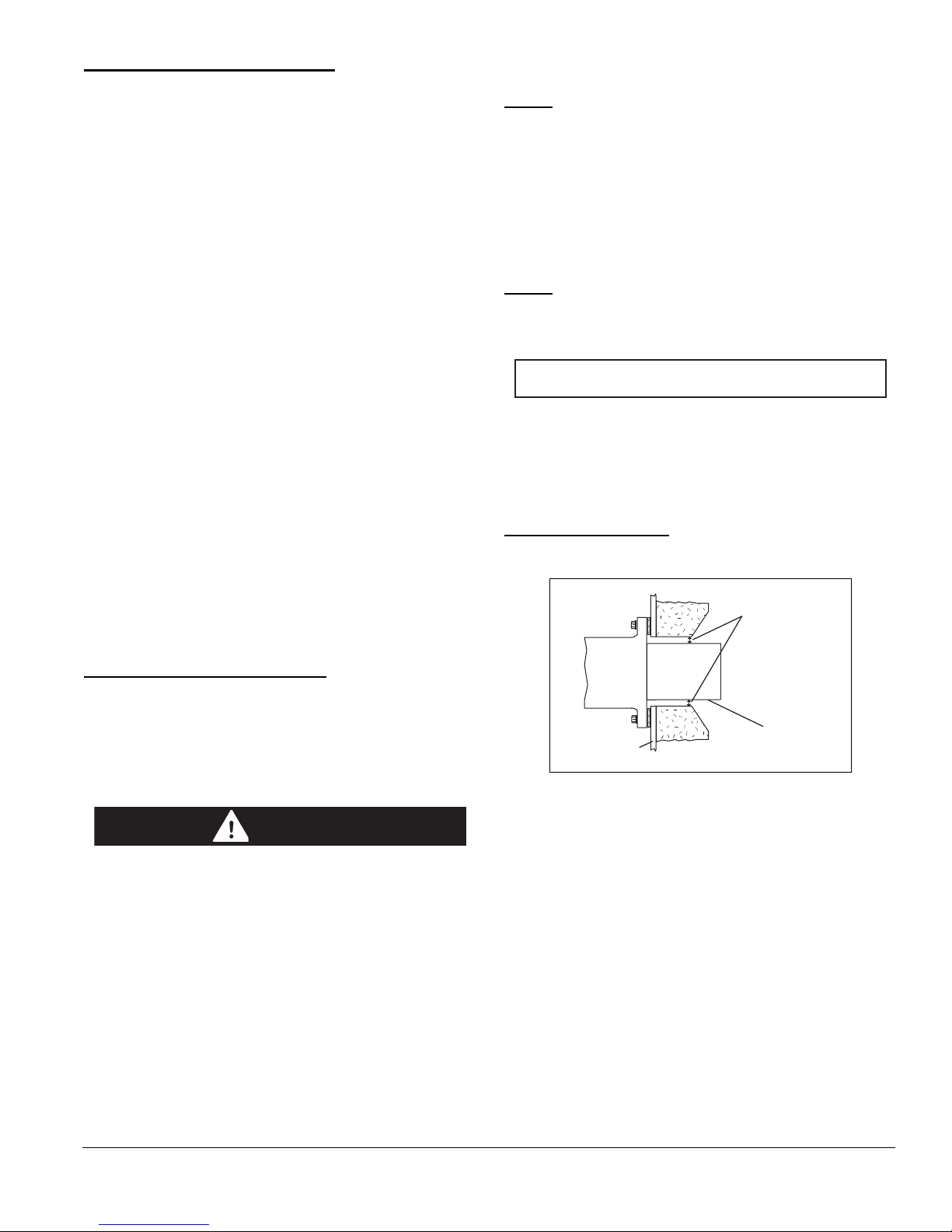

Figure 3.1.

Provide an opening in the chamber wall at least 1/2"

(12mm) larger in diameter than the outside diameter of the

combustor, or 1/2" (12mm) larger in height and width than

the square refractory block. (1/4" - 6mm per side).

Provide an accessible pressure tap on the chamber wall

to measure the pressure inside the firing chamber. The

pressure tap should be located near the burner.

Mounting Pattern

Attach mounting bolts to the chamber wall. Position these

bolts to match the clearance holes “C” on the burner

mounting flange. Refer to the appropriate RatioMatic

datasheet.

7

Page 8

“C”

“C”

1

4

RM0050 - RM0700

RM1000 - RM3000

Figure 3.2. Mounting Pattern

Chamber Wall

Make sure the chamber wall is strong enough to

support the weight of the burner . If necessary, reinforce

the mounting area.

If the chamber insulation extends beyond the nozzle

position of the burner, taper the insulation around the

combustor at a minimum 45° angle. Refer to Datasheets

to determine the position of the nozzle relative to the

chamber wall.

4

45° Minimum

NOZZLE

POSITION

Chamber

2

Insulation

NOZZLE

POSITION

Fiber insulation

Chamber

2

insulation

Figure 3.4. Alloy Combustor

CAUTION

■ Placing insulation around the combustor beyond

the burner nozzle position will decrease

combustor life.

3. No gasket is supplied or required between the burner

and combustor.

Silicon Carbide (SiC) Combustor Only

CAUTION

■ SiC combustor is fragile. Handle with care.

Figure 3.3. Chamber Wall

Burner Mounting

Mount burner to chamber wall using four (4 or 8) customer

supplied nuts and lock washers, as required.

Both Alloy and Silicon Carbide (SiC) Combustor

1. Be sure gasket is installed between burner and

chamber wall .

2. Pack fiber insulation around the combustor to a depth

not beyond the nozzle position, as illustrated.

If the SiC combustor is not already attached to the burner,

be sure gasket is installed between the SiC combustor

and flange . Tighten the screws which hold the flange

to the burner evenly. Do not over tighten.

1

4

3

6

2

5

POSITION

Fiber insulation

Chamber

insulation

Figure 3.5. Silicon Carbide (SiC) Combustor

CAUTION

■ When replacing SiC combustor be sure gasket

is installed, tighten screws evenly, and do not use

excessive force.

8

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

Page 9

Refractory Block

1. Ensure gasket is installed between burner and

block holder .

2. Ensure gasket is installed between block holder

and chamber wall .

• Cool or raise the operating temperature at a rate of

100°F (55°C) per hour.

NOTE: The correct insulation of burner combustion blocks

in furnaces results in longer block life and adds value by

reducing downtime and maintenance.

Block Holder Temperature

3. Support the weight of refractory block with hard brick

work anchored to the furnace shell . Fill the 1/2"

space between block and the three unsupported

sides with soft gasket material .

7

1

4

NOZZLE

8

2

9

3

POSITION

10

Figure 3.6. Refractory Block

Large Refractory Blocks

On sizes RM0300 through RM3000; the block must be

tightly surrounded by a collar made of brick, plastic

refractory, or a castable refractory of at least 4" (10 cm)

minimum thickness on all sides of the block. If the collar is

cast around the block, a thin plastic film (i.e. Saran Wrap

or Glad Wrap®) should be wrapped around the block to

keep moisture from leaching into it. The collar should be

anchored to the furnace shell with suitable anchors and

must be constructed to rest on a surface capable of

supporting its weight, such as a hearth or a solid refractory

or brick wall. For furnaces that are unable to support the

weight of the refractory block, a stainless steel shelf can be

welded to the shell to support the collar.

Excessive block holder temperatures can cause

problems. Overheating can be reduced by carefully

sealing the burner blocks in the wall to prevent the

leakage of hot gases back to the furnace shell.

In high temperature (>1,400°F, 760°C) fiber-wall furnace

installations, the length of the metallic wrapper should

extend no farther than the point in the wall where the

interface temperature is higher than 1800°F (760°C).

Vertical Down Firing Blocks (Figure 3.6)

1. Down firing blocks may be suspended by customer

supplied hangers attached to the burner body mounting

bolts.

2. Hangers should be attached to structural support.

Gas Piping

Burner Piping

The burner is factory assembled and shipped as ordered.

NOTE: If it is necessary to redirect piping, be sure the:

• ratio regulator spring column is pointing up.

• arrow on the ratio regulator points in the direction of

gas flow.

®

• integral fuel orifice and o-rings are re-installed in

the same orientation with respect to the fuel flow.

• same straight run of pipe remains between the

ratio regulator and the burner.

Refractory Block Curing Schedule

The refractory block was cured at the factory up to a

temperature of 650°F (345°C). Final curing should be

done after installation.

The recommended curing schedule is:

• Ambient to 600°F (315°C) at 100°F (55°C) per hour.

• 600 °F (315°C) to 1000°F (540°C) at 25°F (14°C) per

hour.

• Hold the refractory block at 1000°F (540°C) for 12

hours.

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

Figure 3.7. Burner Piping

9

Page 10

Supply Piping

Pilot Valve Trains (RM1000-RM3000)

Inlet pressure to the ratio regulator must stay within

specified limits. Refer to the appropriate RatioMatic

datasheet.

• Locate the valve train close to the burner. The gas

must reach the burner during the fixed trial for

ignition.

• Appropriately size shut off valves in the valve train.

• Make sure piping is large enough to accommodate

flow required to meet burner input.

• Minimize piping elbows.

• If a reducing nipple is necessary, install it at the inlet

to the burner proportionator. Do not use a reducing

bushing in the proportionator inlet.

Bypass Start Gas Piping (Optional for RM0050RM0700 Only)

Install the piping as shown in the schematics using the

following guidelines:

• Locate the bypass start gas solenoids close to the

burner. The gas must reach the burner during the

trial for ignition period.

• Minimize piping elbows.

• Install an adjustable limiting orifice (ALO) for start

gas adjustment. Refer to Bulletin 728 and 730 for

further information.

• Include a straight run of pipe at least 8" (192mm)

long before (upstream from) the start gas orifice

(optional) and at least 4" (96mm) long after

(downstream from) the start gas orifice.

The pilot gas valve train should be connected as close as

possible to the pilot adjusting cock.

Pipe Connections

• Installation of a pipe union in the gas line is

recommended to simplify burner removal.

• Use of flexible pipe is optional.

NOTE: Flexible pipe causes higher pressure drops than

standard pipe. Consider this when sizing your gas lines.

Bracket

Pipe Union

Figure 3.9. Piping Connections

Piping Support

Use brackets or hangers to support the gas piping. If you

have questions, consult your local gas company.

Main gas

shut-off

NC

Figure 3.8. Bypass Start Gas Piping

valve train

NC

NOTICE

■ Please verify that piping complies with all

applicable codes and/or standards.

Packaged Blower Motor Support (RM1000 RM3000)

Install a control motor to modulate the air butterfly valve if

not previously installed on the burner.

For RatioMatic models RM1000 through RM3000, the

packaged blower motor requires additional support, which

must be supplied by the customer.

NOTE: Be sure the control motor shaft and air butterfly

valve shaft are aligned properly. In some cases washers

may be used as shims (stacked 0, 1, or 2 high) to ensure

proper alignment. Additionally, a flexible coupling can be

used to handle minor misalignment.

10

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

Page 11

Motor

BV

Shaft

Shaft

Set

Screws

Control

Motor

Coupling

Figure 3.10. Control Motor Mounting

Checklist After Installation

To verify the system was properly installed, perform the

following checks:

1. Be sure there are no leaks in the gas lines.

2. Be sure all the components contained in the flame

monitoring and control system are properly installed.

This includes verifying that:

• all the switches are installed in the correct locations.

• all wiring, pressure, and impulse lines are properly

connected.

3. Be sure all components of the spark ignition system are

installed and functioning properly.

Setting Ignitor Location (RM1000-RM3000)

For RatioMatic models RM1000 through RM3000, set the

ignitor location using the self-tightening compression

fitting. The distance required is shown in Figure 3.11.

A

4. Be sure the blower rotates in the proper direction. If the

rotation is incorrect, have a qualified electrician rewire

the blower to rotate in the proper direction.

5. Be sure all valves are installed in the proper location

and correctly oriented relative to the flow direction.

Figure 3.11. Spark Rod Distance

RM Model

Dimension A,

mm (inches)

RM1000 82 (3.2)

RM1250 82 (3.2)

RM1500 95 (3.7)

RM2000 95 (3.7)

RM2500 95 (3.7)

RM3000 95 (3.7)

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

11

Page 12

Adjustment, Start &

Stop

4

In this chapter, you will find instructions on how to adjust,

start, and stop the burner system. Become familiar with

burner control methods before attempting to make

adjustments.

DANGER

■ The RatioMatic burners, described herein, are

designed to mix fuel with air and burn the resulting

mixture. All fuel burning devices are capable of

producing fires and explosions if improperly

applied, installed, adjusted, controlled, or

maintained.

■ Do not bypass any safety features. This can cause

fires and explosions.

■ Never try to light a burner if it shows signs of

damage or malfunction.

Adjustment Procedure

If you are adjusting the burner system for the first time,

then you must follow these steps:

Step 1: Reset the System

1. Set the low gas pressure switch to 20% below the

“Main Gas Inlet Pressure” range as specified in the

appropriate datasheet.

2. Set the high gas pressure switch to 20% above the

“Main Gas Inlet Pressure” range as specified in the

appropriate datasheet.

3. Close all the burner gas valves, manual and

automatic.

4. Try to ignite the burner; be sure the flame monitoring

system indicates a flame failure.

5. Activate the pressure switches and other limit

interlocks. Be sure the switches fail as intended in the

event of a power failure.

DANGER

6. If the burner is firing into a duct or chamber with a

circulating fan, start the fan to produce a full process

air flow past the burner.

7. Adjust main gas inlet pressure to the ratio regulator

within the range specified in the appropriate

datasheet.

WARNING

■ Gas inlet pressures must stay within the specified

range. Pressure above the specified range can

damage the ratio regulator.

■ Pressure below the specified range can impair the

ability of the ratio regulator to control the gas flow.

■ Operating the system outside the specified range

can cause excess fuel consumption and the

possible accumulation of unburned fuel in the

chamber. In extreme cases, this accumulation of

unburned fuel may cause fires or explosions.

8. Verify that the actuator opens the air BV towards the

back of the burner as shown in Figure 4.1. If it doesn’t,

refer to the actuator’s literature for instructions on how

to reverse the direction.

Back

Closed

Open in this

direction only

■ If simulated limits or simulated flame failure do not

shut down the fuel system within the required

failure response time, immediately correct the

problem before proceeding.

12

Open

Figure 4.1. Air Butterfly Valve

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

Page 13

Step 2: Set Low Fire Air

1. Start combustion air blower.

2. Drive control motor to low fire position.

3. Measure air differential pressure between tap “C” and

combustion chamber. See the appropriate series 110,

datasheet.

To Chamber

When firing into a positive chamber pressure,

rotate the air butterfly valve from the closed position

in the direction of actuator travel to obtain a

minimum

0.3" w.c. (0,8 mbar) air differential pressure.

d. For air control actuators that have a coupling with

set screws, as shown in Figure 4.3, hold the

butterfly valve firmly in place and tighten the set

screw .

For air control actuators that have a keyed or

pinned coupling, as shown in Figure 4.4, hold the

butterfly valve firmly in place and re-engage the

cam’s low or off starting position.

• For T500 series Trilogy Actuators, see Instruction

Manual 902 or Quick Guide 902.

e. High fire air adjustment is not required if the burner

is firing into a neutral pressure chamber and a 90°

travel control motor is used. It may be necessary to

limit control motor stroke to less than 90° if firing

into a large negative chamber. Contact Eclipse for

further information.

Figure 4.2.

NOTE (RM0050-RM0700): The pressure tap is in the

open position when the screw inside the tap is unscrewed

approximately 1/2 turn. Do not remove screw. Be sure to

tighten pressure tap screw clockwise to the closed

position after pressure measurements have been taken.

4. Set low fire air.

a. For air control actuators that have a coupling with

set screws, as shown in Figure 4.3, loosen the set

screw on the burner side of the coupling .

For air controlled actuators that have a keyed or

pinned coupling, as shown in Figure 4.4, please

refer to the cam adjustment section of the

actuator’s installation literature for instructions on

releasing the cam’s low or off start position.

• For T500 series Trilogy Actuators, see Instruction

Manual 902 or Quick Guide 902.

b. There is a slot in the end of the butterfly valve shaft

that is parallel to the air damper. This slot is used

for visual indication of the butterfly valve position.

The butterfly valve is closed when the shaft slot is

perpendicular to the direction of air flow through

the butterfly valve. See Figure 4.5

c. Rotate the air butterfly valve shaft to a fully closed

position. (Holes in the butterfly valve will supply

low fire air.)

Figure 4.3. Actuator with Flexible Coupling

Figure 4.4. Actuator with Keyed Coupling

5. Verify high fire air:

a. Drive control motor to high fire, full open.

b. Compare the high fire air differential pressure

between Tap C and the combustion chamber to

the approximate datasheet chart “Air p vs. Input”.

If high fire air is insufficient, refer to section 5,

“Troubleshooting & Maintenance”, in this

document.

6. Return the control motor to the low fire position.

7. Close the pressure taps.

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

13

Page 14

BV shaft shown in

closed position

Figure 4.5. Air Butterfly Valve Shaft

NOTE: Steps 3-5 RM0050-RM0700 Only (see page 20 for

RM1000-RM3000)

Step 3: Ignite the Burner (RM0050-RM0700

only)

WARNING

■ This procedure is written with the assumption the

burner has a flame monitoring control system

installed and operating. A proper purge cycle must

be part of the system and purge timing should not

be bypassed.

Determine system layout and use the applicable ignition

procedure.

Low fire start without high turndown option Procedure “A”.

Main gas

shut-off

valve train

NOTE: The ratio regulator is factory set. Use Procedure “A”

only if burner does not ignite or requires further adjustment.

Bypass start gas without fuel orifice meter Procedure “C”.

Low fire start with high turndown option Procedure “B”.

Ratio regulator

with bypass

adjusting screw

Main gas

shut-off

valve train

NOTE: The RatioMatic burner with high turn down option

includes a ratio regulator with internal bypass adjustment.

Bypass start gas with fuel orifice meter Procedure “D”.

Main gas

shut-o

valve train

NC

NC

14

Main gas

shut-o

valve train

NC

NC

Figure 4.6.

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

Page 15

Procedure A: Low fire start without high turndown

option

Main gas

shut-off

valve train

Figure 4.7. Procedure A

1. Drive control motor to low fire.

2. Be sure combustion air blower is running.

3. Verify bias adjusting screw on ratio-regulator spring

column is six full clockwise turns (360° x 6) down from

the top (initial setting).

8. Flame signal strength: Adjust gas flow with bias

adjusting screw for lowest gas flow that maintains

a stable flame signal:

• clockwise, for more fuel

• counterclockwise, for less fuel

9. Verify low fire flame:

a. Shut off gas. When chamber temperature is below

250°F (121°C), shut off combustion air blower.

b. Restart combustion air blower and ignite burner.

c. Verify repeatability of ignition and low fire flame

signal.

Procedure B: Low fire start with high turndown option

Ratio regulator

with bypass

adjusting screw

Main gas

shut-off

valve train

&:IRU

PRUHJDV

%LDV

$GMXVWLQJ

6FUHZ

Figure 4.8. Ratio Regulator

4. Open main gas manual shut off valves.

5. Set system control to stay at low fire during and after

ignition sequence.

6. Attempt to ignite burner.

7. If burner does not ignite:

a. Attempt to ignite burner again to purge air from the

gas piping.

b. If burner still does not ignite, turn bias adjusting

screw a half turn clockwise to increase gas flow.

c. Attempt to ignite burner.

d. Repeat steps b and c until burner ignites. If

necessary, refer to Chapter 5 for troubleshooting

tips.

Figure 4.9. Procedure B

NOTE: The RatioMatic burner with high turndown option

includes a ratio regulator with internal bypass adjustment.

1. Drive control motor to low fire.

2. Be sure combustion air blower is running.

3. Verify bias adjusting screw on ratio-regulator spring

column is six full clockwise turns (360° x 6) down from

top (initial setting).

4. Open main gas manual shut off valves.

CW for

more gas

1

Bias

adjusting

screw

CCW for

more gas

2

Internal bypass

adjusting screw

Figure 4.10. Ratio Regulator with Internal

Bypass Adjusting Screw

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

15

Page 16

5. Close internal bypass adjusting screw by turning it

A

clockwise to closed position.

6. Set system control to stay at low fire during and after

1. Drive control motor to low fire.

2. Be sure combustion air blower is running.

3. Be sure main gas manual shut off valves are closed.

ignition sequence.

4. Open main gas manual shut off valve in the bypass.

7. Attempt to ignite burner.

8. If burner does not ignite:

a. Attempt to ignite burner again to purge air from the

gas piping.

b. If burner still does not ignite, turn bias adjusting

screw a half turn clockwise to increase gas flow.

c. Attempt to ignite burner.

d. Repeat steps b and c until burner ignites. If

ALO

djusting

Screw

CCW for

more gas

necessary, refer to Chapter 5 for troubleshooting

tips.

9. After burner ignites, slowly decrease gas flow with

Cap

bias adjusting screw . Decrease gas flow until the

flame signal becomes erratic. (Refer to flame

monitoring relay literature for a description of an

erratic flame signal.)

10. If burner has gone out: Repeat ignition sequence.

Turn internal bypass adjusting screw a half turn

counterclockwise to increase gas flow at each attempt

until burner lights.

11. Flame signal strength: Adjust gas flow with internal

bypass adjusting screw for lowest gas flow that

maintains a stable flame signal:

• clockwise, for more fuel

• counterclockwise, for less fuel

12. Verify low fire flame:

a. Shut off gas. When chamber temperature is below

250°F (121°C), shut off combustion air blower.

b. Restart combustion air blower and ignite burner.

c. Verify repeatability of ignition and low fire flame

signal.

Procedure C: Bypass start gas without fuel orifice

meter

Figure 4.12. Adjusting Limiting Orifice (ALO)

5. Set the system to operate on bypass gas only.

6. Attempt to ignite burner by energizing spark and

bypass gas solenoid valves .

7. If burner does not ignite:

a. Attempt to ignite burner again to purge air from the

gas piping.

b. If burner still does not ignite, turn ALO adjusting

screw a half turn counterclockwise to increase

gas flow.

c. Attempt to ignite burner.

d. Repeat steps b and c until burner ignites. If

necessary, refer to Chapter 5 for troubleshooting

tips.

8. Flame signal strength: Adjust gas flow ALO adjusting

screw for lowest gas flow that maintains a stable

flame signal:

• counterclockwise, for more fuel

• clockwise, for less fuel

9. Verify low fire flame:

a. Shut off gas. When chamber temperature is below

250°F (121°C), shut off combustion air blower.

b. Restart combustion air blower and ignite burner.

c. Verify repeatability of ignition and low fire flame

Main gas

shut-o

valve train

NC

NC

signal.

Figure 4.11. Procedure C

16

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

Page 17

Procedure D: Bypass start gas with fuel orifice meter

Main gas

shut-o

valve train

NC

NC

1. Drive control motor to low fire.

2. Be sure combustion air blower is running.

3. Be sure main gas manual shut off valves are closed.

4. Prepare to measure bypass gas flow at the fuel orifice

meter .

5. Open manual shut off valve in the bypass.

6. Set the system to operate on bypass gas only.

7. Attempt to ignite burner by energizing spark and

bypass gas solenoid valves .

Figure 4.13. Procedure D

NOTE: When firing into negative or fluctuating chamber

pressures, a higher bypass gas flow may be necessary.

10. Verify the bypass gas flame:

a. Shut off gas. When chamber temperature is below

250°F (121°C), shut off combustion air blower.

b. Restart combustion air blower and ignite burner.

c. Verify repeatability of ignition and low fire flame

signal.

Step 4: Set Low Fire Gas (RM0050-RM0700

only)

(Only required if Bypass Start is Used)

WARNING

■ This procedure is written with the assumption the

burner has a flame monitoring control system

installed and operating. A proper purge cycle must

be part of the system control and purge timing

should not be bypassed.

This step is only necessary when bypass start gas is used.

Determine the piping method (low fire or bypass) and ratio

regulator installed (standard or high turndown), and

proceed with the applicable procedure:

Bypass Start Gas with Standard Turndown Ratio

Regulator

Figure 4.14. Adjusting Limiting Orifice (ALO)

8. If burner does not ignite:

a. Attempt to ignite burner again to purge air from the

gas piping.

b. If burner still does not ignite, turn ALO adjusting

screw a half turn counterclockwise to increase

gas flow.

c. Attempt to ignite burner.

d. Repeat steps b and c until burner ignites. If

necessary, refer to Chapter 5 for troubleshooting

tips.

9. Adjust bypass gas flow with ALO adjusting screw to

achieve the low fire gas flow indicated on datasheet.

Refer to the fuel orifice meter literature for instructions

on flow measurement.

&:IRU

PRUHJDV

Figure 4.15. Ratio Regulator

1. Verify bias adjusting screw on ratio regulator spring

column in six full clockwise turns (360° x 6) down from

the top (initial setting).

2. Open all manual gas shut off valves.

3. Set system control to stay at low fire during and after

ignition sequence.

4. Ignite the burner.

%LDV

$GMXVWLQJ

6FUHZ

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

17

Page 18

5. If burner goes out due to main gas flame failure, turn

r

bias adjusting screw a half turn clockwise to

increase gas flow. Repeat ignition sequence until

burner lights.

6. Flame signal strength: adjust gas flow with bias

adjusting screw for lowest gas flow that maintains

a stable flame signal:

• clockwise, for more fuel

• counterclockwise, for less fuel

7. Verify low fire flame:

a. Drive control motor from low fire and back. Verify

low fire and stable flame signal are repeated.

b. Turn the burner off and repeat the ignition

sequence. Verify low flow and stable flame signal

are repeated.

Bypass Start Gas with High Turndown Option

CW for

more gas

8. If burner has gone out, repeat ignition sequence. Turn

internal bypass adjusting screw a half turn

counterclockwise to increase gas flow at each attempt

until burner lights.

9. Flame signal strength, adjust gas flow with internal

bypass adjusting screw for lowest gas flow that

maintains a stable flame signal:

• counterclockwise, for more fuel

• clockwise, for less fuel

10. Verify low fire flame:

a. Drive the control motor from low fire and back.

Verify low fire and stable flame signal are

repeated.

b. Turn the burner off and repeat the ignition

sequence. Verify low fire and stable flame signal

are repeated.

Step 5: Verify Air Settings (RM0050-RM0700

only)

NOTE: There are no high fire gas adjustments or air

adjustments when firing into a neutral chamber. However,

air and gas pressures can be used to verify the burner

system is properly adjusted.

1

Bias

adjusting

screw

CCW for

more gas

2

Internal bypass

adjusting screw

Figure 4.16. Ratio Regulator with

Internal Bypass Adjusting Screw

1. Verify bias adjusting screw on ratio regulator spring

column in six full clockwise turns (360° x 6) down from

the top (initial setting).

2. Open all manual shut off valves.

3. Close internal bypass adjusting screw by turning it

clockwise to closed position.

4. Set system control to stay at low fire during and after

ignition sequence.

5. Ignite the burner.

6. If burner goes out due to main gas flame failure, turn

bias adjusting screw a half turn clockwise to

increase gas flow. Repeat ignition sequence until

burner lights.

7. Slowly decrease gas flow with bias adjusting screw .

Decrease gas flow until the flame signal becomes

erratic. (Refer to flame monitoring relay literature for a

description of an erratic flame signal.)

Tap C

Chambe

Tap D

Tap B

Figure 4.17. Setting Verification

1. With burner lit, drive control motor to high fire.

2. Wait for the chamber to reach normal operating

conditions (e.g. chamber temperature, process flows,

etc.).

3. Measure high fire fuel differential pressure between

tap “B” and tap “D”. this to the “Fuel Orifice P vs.

Input” graph on the datasheet.

4. Measure high fire air differential pressure between tap

“C” and the chamber. Compare this pressure to the

“Air P vs. Air Flow” graph on the datasheet.

5. Drive the control motor to low fire and verify low fire

flame signal and flame appearance (if viewing).

18

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

Page 19

NOTE: Gas pressure at low fire will be too low to measure

and verify the fuel settings.

6. Cycle burner from high to low several times to check

repeatability of settings.

7. Readjust burner if the settings do not repeat as

expected. If necessary refer to Chapter 5,

Maintenance & Troubleshooting.

8. Record all setup data as an aid for future

troubleshooting and setup operations.

9. Stop the burner.

NOTE: Steps 3-5 RM1000-RM3000 Only (see page 15 for

RM0050-RM0700)

Step 3: Adjust Pilot (RM1000-RM3000 only)

1. Drive the control motor to low fire and set the system

to operate on pilot only

2. Turn the handle of the pilot adjusting cock open to

light the pilot.

3. Turn the internal screw (Figure 4.18)

counterclockwise to increase flow, clockwise to

decrease flow, until the pilot gives reliable ignition and

a steady flame signal with minimum pilot gas flow.

CAUTION

■ Do not turn the blower off until the chamber

temperature is below 250°F (121°C). This will

prevent hot gases from flowing back through the

burner and blower and damaging them.

Pilot

Valve

Figure 4.18. Pilot Valve Adjustment

t

Step 4: Set High Fire Gas (RM1000-RM3000

only)

1. With the pilot lit and the control motor in the low fire

position, open the main gas shut-off valve. The main

flame should light.

2. Drive the control motor to its high fire position.

3. Measure the gas differential pressure as shown in

Figure 4.19.

4. If necessary, adjust the gas flow with the butterfly

valve. The flame should be clear blue. If the flame is

yellow, see Troubleshooting, page 22.

Step 5: Adjust Low Fire Flame (RM1000RM3000 only)

1. Return the control motor to the low fire position.

2. Check the combustion air differential pressure as

discussed in Step 2.

3. Gas pressure drop across the burner will be too low to

read reliably, but the flame should be clear blue,

entirely within the firing tube, and tight on the burner

head.

4. If necessary, adjust the ratio regulator bias screw as

shown in Figure 4.20 to obtain the proper low fire

flame. If the flame cannot be viewed, adjust the bias

screw to produce the minimum gas flow that will

generate a steady flame detector signal of sufficient

strength.

5. After adjusting the low fire flame, return to high fire

and check gas differential pressure as described in

Step 4.

Measure differential

pressure between here

and tap in chamber wall

Figure 4.19. High Fire Differential

Gas Pressure

&:IRU

PRUHJDV

Figure 4.20. Ratio Regulator

%LDV

$GMXVWLQJ

6FUHZ

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

19

Page 20

Maintenance &

Troubleshooting

5

This section is divided into two parts. The first part

describes the maintenance procedures, and the second

part helps you to identify problems that may occur and

gives advice on how to solve these problems.

Preventative maintenance is the key to a reliable, safe

and efficient system. The following are suggested

guidelines for periodic maintenance. Burners in severe

environments or operational conditions should be

checked more frequently.

NOTE: The monthly and yearly lists are an average

interval. If your environment is dirty, then the intervals may

be shorter. Check with local authorities having jurisdiction

on their recommended maintenance schedules.

Monthly Checklist

1. Inspect flame-sensing devices for good condition and

cleanliness.

2. Check for proper air/gas pressures (refer to the

RatioMatic Datasheets, Series 110).

3. Test all the system alarms for proper response signals.

4. Check and clean igniter electrodes.

5. Check the air control valve for smooth, trouble free

operation and adjustment.

6. Check for the proper operation of ventilating

equipment.

7. Test the interlock sequence on all safety equipment.

Manually force each interlock to intentionally fail while

at the same time noting if related equipment closes or

stops as specified by the manufacturer. Test the flame

safeguard by manually shutting off the gas to the

burner.

3. Visually check ignition cable and connectors.

4. Inspect impulse piping for leaks.

5. Clean and inspect all burners.

6. Remove and clean the orifice plate , see Figure 5.1.

7. Be sure the following components are not damaged or

distorted:

• the burner nozzle

• the igniter

• the flame sensors

• the combustion tube or block

The nozzle and combustion tube/block can be inspected

without removing the burner from the chamber wall or

entering the chamber. See Figure 5.1. Perform the

following:

a. Shut the burner off and manually close the main

gas shut off cocks.

b. Allow the chamber temperature to cool down to

250°F (121°C).

c. Disconnect the gas piping at a union or the gas

inlet flange provided on the burner.

d. Remove the rear cover bolts .

e. Remove the rear cover from the burner

housing .

f. To re-assemble, follow this sequence in the

reverse order.

8. Test the manual gas shut off cocks for proper operation.

9. Clean and/or replace the combustion air blower filter.

10.Inspect and clean the combustion air blower rotor.

Yearly Checklist

1. Test (leak test) safety shut-off valves for tightness of

closure.

2. Test pressure switch settings by checking switch

movements against pressure settings and comparing

these with the actual impulse pressure.

20

Figure 5.1.

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

Page 21

Troubleshooting

Problem Possible Cause Solution

Start-up sequence runs but

burner does not light.

The low fire flame is weak or

unstable.

No ignition: There is no power to the ignition

transformer.

No ignition: Open circuit between the

ignition transformer and the igniter.

Restore the power to the ignition

transformer.

Repair or replace the wiring of the igniter.

No ignition: The igniter needs cleaning. Clean the igniter.

Clean the threads on the igniter and the

No ignition: The igniter is not correctly

grounded to the burner.

burner.

NOTE: Do not apply grease to the threads

on the igniter.

No ignition: Igniter insulation is broken.

Igniter is grounding out.

Inspect the igniter, replace if broken.

Not enough gas: The gas pressure going

into the ratio regulator (RM0050-RM0700)

or pilot regulator (RM1000-RM3000) is too

Check the start-up settings. Measure the

gas pressures and adjust where necessary.

low.

Not enough gas: The impulse line to the

ratio regulator is leaking.

Not enough gas: The pilot adjusting valve or

bypass valve is not open far enough.

Not enough gas: Start gas solenoid valve

does not open.

Repair any leaks.

Adjust bypass or low fire gas.

Check the solenoid valve coil for proper

operation. Replace it if necessary.

Check the wiring to the automatic gas shutoff valve.

Not enough gas: Gas valve does not open.

Check the output from the flame safeguard.

Open manual gas cock.

Not enough gas: Ratio regulator is

incorrectly set.

No flame signal: Broken flamerod or dirty

UV scanner lens.

No flame signal: Spark plug and flamerod

reversed.

Too much gas: Wrong or missing burner

fuel orifice.

Not enough gas flowing to the burner.

Adjust the ratio regulator to the proper

setting.

Inspect and clean sensor. Replace if

necessary.

Exchange spark plug / flamerod or their

wiring.

Check RatioMatic Datasheets, Series 110

for fuel orifice and given fuel.

Adjust the ratio regulator to increase the

gas flow.

Check for proper blower rotation.

Not enough air.

Check air filter for blockage.

Compensate for chamber by opening the

low fire air butterfly valve position.

Flamerod is directly beneath the

combustion air inlet.

Swap the flamerod with the spark rod so

that the flamerod is 180° from the

combustion air inlet.

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

21

Page 22

Problem Possible Cause Solution

The burner goes out when it

cycles to high fire.

The burner is erratic and

does not respond to

adjustment.

The burner is unstable or

produces soot, smoke, or

excessive carbon monoxide.

The burner cannot achieve

full capacity.

Cannot initiate a start

sequence.

Main flame too long and

yellow at high fire.

Main flame too short at high

fire.

Low fire (pilot) flame is too

long, soft or yellow.

Check the start-up settings.

Not enough gas pressure into the ratio

regulator.

Measure the gas pressures and adjust

them where necessary.

Check for valve train pressure loss.

Loading line to the ratio regulator is leaking. Repair the leak in the loading line.

Pilot set too lean, becoming unstable as air

increases.

Increase pressure into the pilot regulator.

Main gas adjusting valve not open enough. Increase valve opening.

Suction or back pressure in chamber

fluctuates, upsetting pilot stability.

Cross-connect pilot regulator vent to the

combustion chamber, but not via the burner

air pressure tap.

Internal damage to the burner: Some parts

inside the burner are loose, dirty, or burned

Contact Eclipse for further information.

out.

Measure all the gas pressures and air

The air/gas ratio is out of adjustment.

pressures. Compare these pressures to the

documented initial start-up settings and

adjust them where necessary.

Air filter is blocked. Clean or replace the air filter.

Gas pressure going into the ratio regulator

is too low.

Adjust the gas pressure.

Check air pressure switch adjustment.

Check air filter.

Air pressure switch has not made contact.

Check blower rotation.

Check outlet pressure from blower.

Check incoming gas pressure.

High gas pressure switch has activated.

Adjust gas pressure if necessary.

Check pressure switch setting and

operation.

Check incoming gas pressure.

Low gas pressure switch has activated.

Adjust gas pressure if necessary.

Check pressure switch setting and

operation.

Malfunction of the flame safeguard system

(e.g. shorted out flame sensor or electrical

noise in the sensor line).

No power to the control unit.

Main power is off.

Gas flame is too high.

Gas flow is too low.

Have a qualified electrician troubleshoot

and correct the problem.

Have a qualified electrician troubleshoot

and correct the problem.

Be sure the main power to the system is

switched to the “on” position.

Gas butterfly valve is open too far or main

gas regulator spring is screwed in too far.

Gas butterfly valve is closed too far, or main

gas regulator spring is screwed out too far.

Main gas proportionator spring is set for too

much flow, or pilot gas cock adjustment is

Too much gas flow.

open too far.

Insufficient air flow due to dirty blow filter or

impeller.

22

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

Page 23

Conversion Factors

Metric to English

Metric to Metric

English to Metric

From To Multiply By

actual cubic meter/h (am³/h) actual cubic foot/h (acfh) 35.31

normal cubic meter/h (Nm³/h) standard cubic foot /h (scfh) 38.04

degrees Celsius (°C) degrees Fahrenheit (°F) (°C x 9/5) + 32

kilogram (kg) pound (lb) 2.205

kilowatt (kW) Btu/h 3415

meter (m) foot (ft) 3.281

millibar (mbar) inches water column (“w.c.) 0.402

millibar (mbar) pounds/sq in (psi)

14.5 x 10

-3

millimeter (mm) inch (in) 3.94 x 10

-2

MJ/Nm³ Btu/ft³ (standard) 26.86

From To Multiply By

kiloPascals (kPa) millibar (mbar) 10

meter (m) millimeter (mm) 1000

millibar (mbar) kiloPascals (kPa) 0.1

millimeter (mm) meter (m) 0.001

From To Multiply By

actual cubic foot/h (acfh) actual cubic meter/h (am³/h) 2.832 x 10

-2

standard cubic foot /h (scfh) normal cubic meter/h (Nm³/h) 2.629 x 10

-2

degrees Fahrenheit (°F) degrees Celsius (°C) (°F - 32) x 5/9

pound (lb) kilogram (kg) 0.454

Btu/h kilowatt (kW) 0.293 x 10

-3

foot (ft) meter (m) 0.3048

inches water column (“w.c.) millibar (mbar) 2.489

pounds/sq in (psi) millibar (mbar) 68.95

inch (in) millimeter (mm) 25.4

Btu/ft³ (standard) MJ/Nm³ 37.2 x 10-3

Appendix

Offered By:

Power Equipment Company

2

011 Williamsburg Road Richmond, Virginia 23231

Tel: 804-236-3800 Fax: 804-236-3882 www.peconet.com

Loading...

Loading...