Page 1

Instruction Manual 904

7/24/06

Eclipse Programmable

Rotary Actuator

Series PRA6

Version 1

Page 2

Copyright

DisClaimer notiCe

liability anD

warranty

Copyright 2006 by Eclipse, Inc. All rights reserved

worldwide. This publication is protected by federal

regulation and shall not be copied, distributed,

transmitted, transcribed or translated into any

human or computer language, in any form or

by any means, to any third parties, without the

express written consent of Eclipse, Inc.

In accordance with the manufacturer’s policy of

continual product improvement, the product

presented in this brochure is subject to change

without notice or obligation.

The material in this manual is believed adequate for

the intended use of the product. If the product is

used for purposes other than those specied herein,

conrmation of validity and suitability must be

obtained. Eclipse, Inc. warrants that the product itself

does not infringe upon any United States patents.

No further warranty is expressed or implied.

We have made every effort to make this manual

as accurate and complete as possible. Should

you nd errors or omissions, please bring them

to our attention so that we may correct them.

In this way we hope to improve our product

documentation for the benet of our customers.

Please send your corrections and comments to

our Marketing Communications Manager.

It must be understood that Eclipse's liability for

its products, whether due to breach of warranty,

negligence, strict liability, or otherwise, is limited

to the furnishing of rotary actuator replacement

parts and Eclipse will not be liable for any other

injury, loss, damage or expenses, whether direct

or consequential, including but not limited to loss

of use, income of, or damage to material arising

in connection with the sale, installation, use of,

inability to use or the repair or replacement of

our products.

2

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

Page 3

About this manual

auDienCe

sCope

aCtuator

publiCations

important notiCes

This manual has been written for the people who

will install the product and the technicians who

work on it. They are expected to have previous

experience with this kind of equipment.

This manual contains essential information for the

proper installation and operation of an Eclipse

Programmable Rotary Actuator.

Instruction Manual No. 904

• This publication.

Data Sheet No. 904

• Lists actuator information including dimensions.

Price Sheet No. 904

• Used to order actuators.

• Read this manual carefully. Make sure that you

understand the structure and contents of this

manual.

• Obey all the safety instructions.

• Do not deviate from any instructions or application limits in this manual without written consent

from Eclipse, Inc.

• If you do not understand any part of the information in this manual, do not continue. Con-

tact your Eclipse sales ofce or Eclipse, Inc.

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

3

Page 4

DoCument

Conventions

There are several special symbols in this document.

You must know their meaning and importance.

The explanation of these symbols follows. Please

read it thoroughly.

Warning:

Indicates hazards or unsafe practices

which could result in severe personal

injury or damage.

Act with great care and follow the instructions.

Caution:

Indicates hazards or unsafe practices which could

result in damage to the machine or minor personal injury.

Act carefully.

Note:

Indicates an important part of the text.

Read the text thoroughly.

4

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

Page 5

Table of Contents

About this manual ................................. 3

Audience ................................................................ 3

Scope ...................................................................... 3

Actuator Publications .......................................... 3

Important Notices ............................................... 3

Document Conventions ..................................... 4

Table of Contents ................................... 5

1

Introduction ................................................ 7

Product Description ............................................ 7

Installation .................................................... 8

2

Introduction .......................................................... 8

Handling and Storage .......................................... 8

Approval of Components ................................... 9

Electrical wiring ................................................ 9

Where to get the standards .......................... 9

Checklist Before Installation .............................. 9

A Note on Safety.................................................. 10

Actuator Mounting .............................................. 11

Mount Actuator to Buttery Valve .................. 12

Actuator Wiring ................................................... 15

Power supply ..................................................... 16

Auxiliary contacts ............................................ 16

Low re wiring ................................................. 16

High re wiring ................................................. 17

Control signal wiring ....................................... 17

Disable settings wiring .................................... 17

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

5

Page 6

Parameter Selection ........................... 21

3

Introduction .......................................................... 21

Low Fire Stop (LF) ............................................... 21

High Fire Stop (HF) ............................................. 22

Control Signal Loss (LO).................................... 22

Low Fire Contact Release (LL) ......................... 23

Low Fire Contact Sense (LS) ............................. 23

High Fire Contact Sense (HS) ........................... 25

High Fire Contact Release (HH) ...................... 26

Manual Position Select ........................................ 26

Signal Input Select ................................................ 27

Auxiliary Contact Select–Normally Closed ...... 27

Auxiliary Contact Select–Normally Open ......... 27

Clockwise Rotation Select ................................. 28

Counterclockwise Rotation Select .................. 28

Examine Setpoints ................................................ 28

Default Setpoints .................................................. 29

Stalled Motor ........................................................ 29

Specications ............................................. 30

4

Dimensions ............................................................ 31

Keypad orientations ............................................. 32

Maintenance & Troubleshooting 33

5

Introduction .......................................................... 33

Maintenance .......................................................... 33

Monthly Checklist ............................................ 33

Yearly Checklist ................................................ 33

Troubleshooting .................................................... 34

Appendix ........................................................ 35

Table 1: Actuator Parameter Record ............. 35

Table 2: Model Number Conguration ......... 35

6

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

Page 7

Introduction

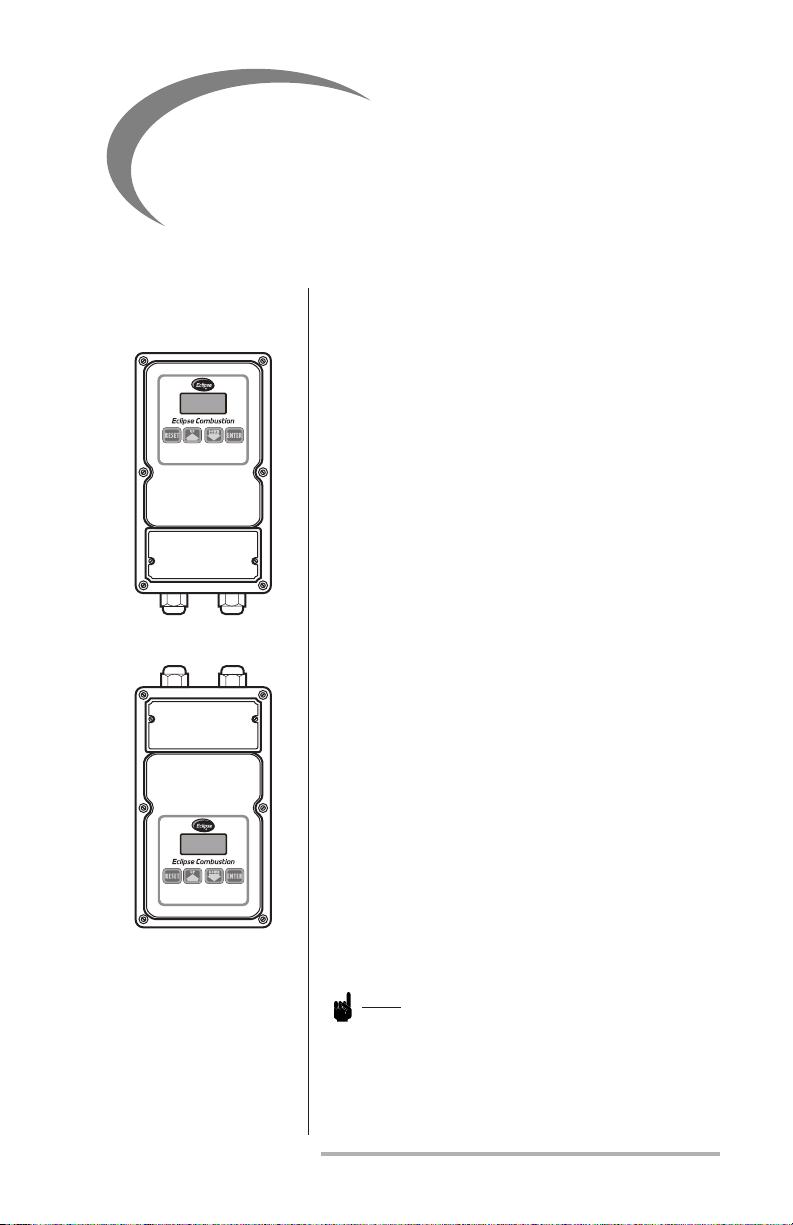

Upright (Standard) Orientation

Inverted Orientation

1

proDuCt

DesCription

The Eclipse Programmable Rotary Actuator is a

keypad-programmable, direct-coupled modulating

motor for use in burner and valve control systems.

It is typically used with an electronic control to regulate a process temperature. The drive shaft of the

actuator connects to a buttery valve stem, which

rotates 90 degrees from minimum to maximum

position.

Actuator features include: solid state electronics;

LED display with membrane keys; 4-20mA, 0-10Vdc

and switch inputs for positioning; and two auxiliary

contacts for position feedback.

The display keypad provides indication of position

and direction of travel, and allows local manual

positioning control. It also provides access to set

the following parameters: minimum and maximum

travel positions; actuation position for the auxiliary contacts; and direction of rotation.

The display keypad can be ordered in four positions: upright (standard) for vertical mounting

with the wiring connections at the bottom; 90

degrees (RH) for horizontal mounting with the

wiring connections to the right; 270 degrees (LH)

for horizontal mounting with the wiring connections to the left; or inverted for mounting with

the wiring connections at the top. (See page 32

for additional keypad orientation illustrations.)

The keypad orientation cannot be changed in the

eld.

Note:

These instructions apply to heating applications

where a maximum output from the tempera-

ture controler drives a buttery valve up to its

maximum ow position.

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

7

Page 8

Installation

2

introDuCtion

hanDling anD

storage

In this section you will nd the information and

instructions that you need to install the actuator.

Caution:

Installation and maintenance must conform

with the National Electrical Code and all other

national and local codes and authorities having

jurisdiction. The actuator must be installed by a

qualied, licensed technician.

Handling

1. Make sure that the area is clean.

2. Protect the actuator from the weather, dam-

age, dirt and moisture.

3. Protect the actuator from excessive temperatures and humidity.

4. Take care not to hit or drop the actuator.

Storage

1. Make sure that the actuator is clean and in

good condition.

2. After you have made sure that everything is

present and in good condition, keep the actuator in the original package as long as possible.

3. Store the actuator in a cool, clean, dry room.

8

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

Page 9

approval of

Components

Electrical Wiring

All of the electrical wiring must comply with one

of the following standards:

• NFPA Standards 70

• EN60204-1

• the electrical wiring must be acceptable to the

local authority having jurisdiction.

Where to get the

standards

CheCklist before

installation

The NFPA Standards are available from:

National Fire Protection Agency

Batterymarch Park

Quincy, MA 02269

Information on the EN standards, and where to

get the standards is available from:

European Committee for Electrotechnical

Standardization

4, Galerie Ravenstein

B-1000 Brussels, Belgium

Access

Make sure that you install the actuator in such a

way that you have easy access to it for inspection

and maintenance.

Environment

Make sure that the local environment matches

the original operating specications. Check the

following items:

• voltage, frequency and stability of the

electrical power

• humidity, altitude and temperature of air

• presence of damaging corrosive gases in the

air.

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

9

Page 10

PRA6 controlling

Fuel Butterfly Valve

Blower

Burner

Safety Shut-off valves

controlled by

Flame Safeguard

Ratio Regulator

Fuel Flow

Control Valve

Burner

PRA6 Controlling

Air Butterfly Valve

Safety Shut-off Valves

controlled by

Flame Safeguard

Blower

Sensing Line

A Note on Safety

The Eclipse Programmable Rotary Actuator must

be used with an approved listed combustion con-

trol system consisting of a ame safeguard and

safety shut-off valves. The diagrams below illustrate the general arrangement of the typical control schemes. These diagrams do not show all of

the devices that may be required for a complete

control system and are not meant to be used for

construction.

Fixed Air Burner

Ratio Burner

10

Caution:

Use of this product in the European community

shall only be deployed in a manner that meets

the applicable EC directives and laws.

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

Page 11

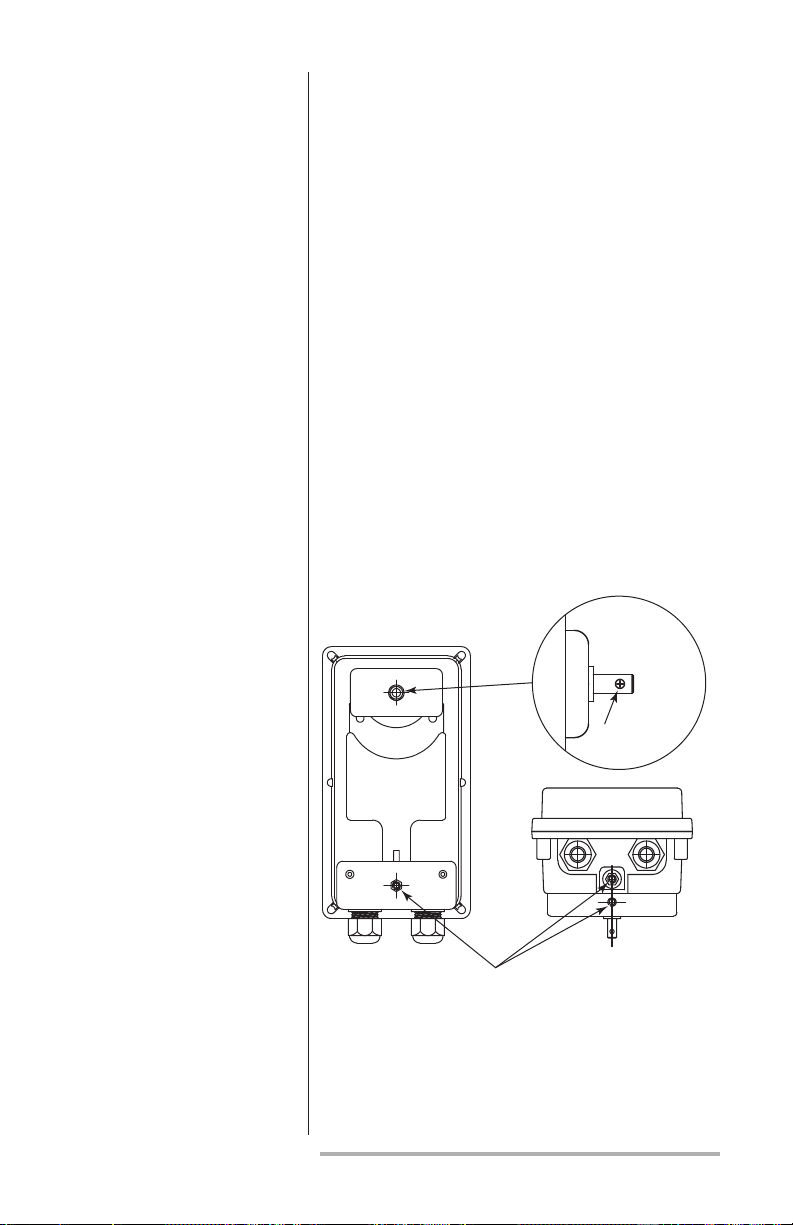

aCtuator

Bottom End View

Mounting

Holes

Shaft Detail

3mm

(0.12”) Dia.

mounting

Depending on your application, please keep the

following in mind when mounting the actuator:

• The actuator housing has three mounting holes,

as shown in Figure 1. The holes are threaded and

use M6 metric screws.

• Mounting this actuator depends on the application; See Data 904 and contact Eclipse, Inc. for

available mounting kits.

• When mounting the actuator, be certain that the

actuator’s drive shaft is properly aligned with the

other shaft to which it will be coupled to avoid

undue lateral stress.

• The actuator’s drive shaft has a 3mm through

hole for a coupler, as shown in Figure 1.

• Provide support for the weight of conduit or

cables into the actuator.

Figure 1 Coupler & Mounting Holes Location

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

11

Page 12

Caution:

Electrical ttings are factory installed to maintain seal and must not be altered. Use only

factory supplied ttings assembled as shown

on Data 904.

Caution:

Prevent water from condensation owing into

the actuator housing through the wiring conduits. Keep conduits oriented such that gravity

will cause water to ow away from the actuator or provide a watertight seal in the conduit

near the actuator.

Warning

Local regulations may require guards

and/or warnings when connecting the

actuator to a component with linkage

that could cause nger pinching. The

actuator stall torque is at least 3.9 n-m

(35 lb-in).

mount aCtuator

to butterfly

valve

12

Warning

Do not attempt to mechanically force

the PRA6 shaft to rotate

Determine if the buttery valve (BV) has

1.

unrestricted full rotation or if it has physical

stops that limit rotation to a specic angle.

Also determine the minimum position, rotation direction to open, and maximum open

position for the BV. The Programmable Rotary

Actuator (PRA) is shipped in its minimum position, clockwise to open, and the part number

shows whether the stroke has been factory

set to either 90 degrees or 75 degrees (see

Table 2 of the Appendix). These settings can

be changed through the keypad. Compare the

BV requirements to the PRA.

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

Page 13

Butterfly Valve

Shutter

Shaft

Slot is in

line with

the shutter

Bolt is

perpendicular

to shutter

Coupling

Note:

The buttery valve rotation direction is viewed

from the shaft end connected to the actuator,

the same view as facing the actuator’s keypad.

The slot at the end of the buttery valve shaft is

parallel to the shutter. When the shaft is rotated

to align the slot to the pipe direction, the valve is

at maximum ow. Eclipse BVs with the beveled

shutter option have a 75-degree stroke. The

minimum positions of these valves physically stop

at about a 15-degree angle when the buttery

shaft is turned fully counter-clockwise. Therefore

the PRA must have its low position set to about

15 to prevent trying to rotate against the physical

stop. Final ne-tuning adjustments to the

minimum position can be made after mounting

the PRA to the BV.

2. If the stroke or rotation comparison does

not match or if you suspect the PRA has

been set differently from the part number,

then provide temporary power to the PRA

before mounting. Refer to the “Power

Supply” heading on page 16. Then refer to

Section 3 (“Parameter Selection,” page 21)

and adjust the settings as follows:

a. Refer to “Clockwise or

Counterclockwise Rotation Select”

to set the rotation direction to

match the BV.

b. Refer to “Low Fire Stop (LF)” to

set the minimum position. Also

reference the note for “Control

Signal Loss (LO)”.

c. Refer to “High Fire Stop (HF)” to set

the maximum position.

d. Check your settings by putting

the PRA in the manual mode (see

Section 3, “Parameter Selection” and

“Manual Position Select”). Drive

the PRA up to the full open position

and note the display and shaft. Then

drive back down to the full closed

position and note the display and

shaft.

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

13

Page 14

3a.

3b.

3c.

4.

5.

6.

7.

3. Install the coupling to the PRA shaft. For

the standard solid coupling with a 3mm

slotted spring pin:

a. Insert the spring pin partially into

the coupling. Insertion may be

easier by rst squeezing the tip

slightly with pliers.

b. Slide the coupling onto the PRA

shaft and align the spring pin hole

in the coupling with the through

hole in the shaft. A view from the

opposite side open hole of the

coupling will assist alignment.

c. Use slip-lock pliers to press the

spring pin through the coupling

and shaft. Make sure the actuator

body is supported and be careful

not to apply excessive stress on

the shaft.

4. Loosely attach the mounting bracket to the

BV. The Eclipse mounting kits include M8

bolts, at washers, and lock washers for

this purpose. Do not tighten at this time to

allow alignment in the next steps.

5. Rotate the BV to its minimum position to

match the position of the PRA. Slide the

PRA with coupling onto the BV shaft and

align to the bracket.

6. Insert the M4 bolt and lock washer through

the coupling hole and thread about 4 turns

into the BV shaft.

7. Adjust the bracket along its slots to bring

the bracket mounting surface up to the

PRA. Also check and keep the alignment of

the BV and PRA shafts. Attach the M6 bolt

and washer through the bracket into the

mounting hole of the PRA (Figure 1), nger

tight only. Also nger tighten the M8 bolts

holding the bracket to the BV.

8. Remove the M4 bolt from the coupling.

Grab the BV shaft with your ngers and see

if the shaft can be turned within the coupling.

If the shaft is very difcult to turn,

14

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

Page 15

8.

9.

then the bracket must be re-aligned as follows:

a. Partially reinsert the M4 bolt

through the coupling.

b. Loosen the M6 and M8 bolts as

required to make small adjustments

to the bracket alignment until the

BV shaft can be turned by nger

within the coupling when the M4

bolt is removed.

c. Finger-tighten the bolts and repeat

step 8.

9. Tighten the M8 bolts to 5 Nm (45 lb-in) and

check if the alignment has shifted as in step

8. Tighten the M6 bolt to 2 Nm (19 lb-in).

Insert and tighten the M4 bolt to 1 Nm (9

lb-in).

10. Make the electrical connections either

temporary or as required by the application

and apply power. Verify for proper and

smooth motion over the full stroke range,

see step 2-d. Correct any abnormalities

before placing the equipment into operation.

Place the PRA into the correct operating

mode (manual or automatic) as required

by the application, Section 3 “Parameter

Selection” and “Manual Position Select” or

“Automatic Signal Input Select.”

aCtuator wiring

Access is through the two electrical connectors at the

end of the actuator. Remove the front coverplate to

access the terminal strips, as shown in Figure 2.

Warning:

Risk of electric shock. Removal of the

cover plate allows access to conductors

carrying hazardous voltages.

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

15

Page 16

Once the front coverplate is removed, the terminal

strip on the left side (P2) is used for the power supply,

and low and high re auxiliary contacts. The terminal

strip on the right side (P1) is used for the control

signal inputs (4-20mA, 0-10V, etc.).

To install a wire into a terminal, rst be sure the ter-

minal is full open. Strip the wire insulation back 1/4"

(6mm), and insert the wire. Hold the wire in place

while tightening the terminal screw. Inspect the

wire for loose strands and gently pull it to ensure a

secure connection. Use only one wire per terminal.

Figure 3 on page 18 shows the wiring diagram for

the actuator, while Figure 4 on page 19 shows a typical application.

Warning:

After wiring, inspect the seal and install

the cover carefully. Make sure cover is

seated properly to seal out water.

Power Supply

Auxiliary Contacts

Low Fire Wiring

Connect the ground wire to P2-G, the neutral

conductor to P2-1, and the “hot” or line voltage

conductor to P2-2. Provide proper circuit protection (fuse or circuit breaker).

The internal contacts are isolated and voltage-free.

Take care not to exceed the contact ratings listed in

the specications table on page 30. These contacts can

be used for position detection. Connect an external

supply to the common terminals, P2-3 and P2-5.

Connect the external low position load to P2-6, and

the external high position load to P2-4.

A switch or voltage-free contact can be wired

between P1-5 (Low Fire) and P1-1 (COM) to

move the actuator to the low re position.

16

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

Page 17

Figure 2 Coverplate & Terminal Connections

Remove these

two screws to

expose terminal

connections at right

High Fire Wiring

Control Signal

Wiring

Disable Settings

Wiring

A switch or voltage-free contact can be wired

between P1-4 (High FIRE) and P1-1 (COM) to

move the actuator to the high re position.

Note:

These digital signals override the 4-20mA and

0-10Vdc analog positioning signals.

Connect a 4-20mA signal positive (+) to P1-2 and

negative (–) to P1-1 (COM). Or alternately connect

a 0-10 Vdc signal positive (+) to P1-3 and negative

(–) to P1-1 (COM). If both signals are connected,

the greater value signal will determine the actuator’s

position.

After setting the parameters according to

Section 3, connect P1-6 (LC) to P1-1 (COM) to

prevent inadvertent parameter changes through

the keypad. With this jumper installed, pressing

the ENTER key will display "LC" and not allow

parameter changes.

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

17

Page 18

Figure 3 Wiring Diagram for Actuator

Com (-)

Input

Contact Outputs

120 or 230 VAC

Power Supply

HF LF

+

–

+

–

4-20mA

0-10V

High Fire

Low Fire

LC

Shield

P1

P2

Earth

Neutral

Line

HF Com

HF Switch

LF Com

LF Switch

G 1 2 3 4 5 6 1 2 3 4 5 6 G

Note:

1. Separate low voltage signal wiring from high voltage signal wiring.

2. Control circuit wires must:

a) meet 90°C (194°F) specication minimum;

b) recommended range from 22 to 16 AWG (.5 to 1.5mm2), and

c) be in accordance with all applicable codes.

3. Insert only one wire per terminal.

4. Provide power supply circuit protection.

5. P2-G and P1-G are internally connected

18

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

Page 19

Figure 4 Typical Application

Sensor

Start

These components relate to burner sequence (not shown);

See “Control Signal Loss (LO)” on page 22.

High Fire

Low Fire

Temperature

Controller

Actuator

L1 GND L2

Power

OnOff

5A Fuse

L1

L2

GND

T/C

+

–

4-20mA

+

–

1

2

1

2

1

1

1

1

P1-2

P1-1

P1-4

P1-5

P2-G

P2-2

P2-1

P2-3

Coil

P2-4

P2-5

P2-6

shaft at

Coil

high position

shaft at

low position

Note:

The following diagram is an example of how to use the actuator’s various inputs and outputs. Some devices shown may be

omitted or changed, depending on your application.

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

19

Page 20

CheCklist after

installation

1. Conrm the alignment and tightness of all

mechanical connections.

2. Inspect the terminal wiring for stray wire

strands that might cause a short circuit. Check

that the wires are properly inserted into the

terminals and are not loose. Reinstall the

terminal cover.

3. Apply power and verify that the stroke motion is smooth over its entire range. Refer

to Section 3, “Parameter Selections,” for any

adjustments.

4. Record the parameter settings for future

reference in Table 1, Actuator Parameter Con-

guration Record, on page 35.

20

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

Page 21

Parameter Selection

1 2

3

4

5 6

3

introDuCtion

low fire stop

(lf)

In this section you will nd the information about the

actuators various selectable parameters, and how they

can be programmed through the keypad.

This parameter sets the minimum shaft travel position:

1. Press the ENTER key; the message “SC” will appear on the display.

2. Press either the UP or DOWN key until the

number “15” appears on the display.

3. Press the RESET key; the message “PG” will appear on the display.

4. Press the DOWN key; the message “LF” will appear on the display.

5. Press either the UP or DOWN key until your

desired number (the desired degree of shaft rotation) appears on the display.

6. Press the RESET key to complete the sequence.

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

21

Page 22

high fire stop

1 2

3

4

5 6

1

2

3

4

5

6

(hf)

This parameter sets the highest shaft travel position:

1. Press the ENTER key; the message “SC” will appear on the display.

2. Press either the UP or DOWN key until the number “15” appears on the display.

3. Press the RESET key; the message “PG” will appear on the display.

4. Press the UP key; the message “HF” will appear on

the display.

5. Press either the UP or DOWN key until your

desired number (the desired degree of shaft rotation) appears on the display.

6. Press the RESET key to complete the sequence.

Control signal

loss (lo)

This parameter sets the position when the analog control signal is zero. It can be used to set a control valve

at some intermediate position above LF for burner

start-up (see Figure 4 on page 19):

Note:

Set LO to the same value as LF if you want the

actuator to drive to the Low Fire Stop position (LF)

when the control signal is zero.

1. Press the ENTER key; the message “SC” will appear on the display.

2. Press either the UP or DOWN key until the number “12” appears on the display.

3. Press the RESET key; the message “PG” will appear on the display.

4. Press the DOWN key; the message “LO” will appear on the display.

5. Press either the UP or DOWN key until your

desired number (the desired degree of shaft rotation) appears on the display.

6. Press the RESET key to complete the sequence.

22

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

Page 23

low fire ContaCt

1 2

3

4

5 6

1 2

3

4

5 6

release (ll)

Note:

Please refer to Figure 5 on page 24 for an

illustration of the next two parameters.

This description of the contact state is for the normally open mode. As the shaft travels from high

to low, the LL parameter sets where the low re

contact opens back up after having closed at the

LS setting. For most applications this value should

be kept at zero (0). Set LF to 0 rst if you need to

set LL to 0. Do not view LL through code 17 after

it is set. Instead, press the RESET key twice to see

all parameters (See p. 28, "Examine Setpoints.")

1. Press the ENTER key; the message “SC” will

appear on the display.

2. Press either the UP or DOWN key until the

number “17” appears on the display.

3. Press the RESET key; the message “PG” will appear on the display.

4. Press the DOWN key; the message “LL” will

appear on the display.

5. Press either the UP or DOWN key until your

desired number (the desired degree of shaft

rotation) appears on the display; this number

must be of lesser value than the desired low

re contact sense (LS) number.

6. Press the RESET key to complete the sequence.

low fire ContaCt

sense (ls)

This description of the contact state is for the normally open mode. As the shaft travels from high

to low, the LS parameter sets where the low re

contact closes. For most applications this value

should be kept at least ve degrees above LF or

LO, whichever is higher.

1. Press the ENTER key; the message “SC” will

appear on the display.

2. Press either the UP or DOWN key until the

number “16” appears on the display.

3. Press the RESET key; the message “PG” will appear on the display. (Continued on page 25)

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

23

Page 24

Figure 5 Auxiliary Contact Positions in Relation to Shaft Rotation

0

o

0

o

90o

LL=10

o

LL

HS HH

LS

CLOSED

OPEN

Low Auxiliary Contact (P2-5 & 6)

Angular Diagram

Angular Diagram

Linear Diagram

Linear Diagram

10o 20

o

30o40o 50o 60o 70o80o 90

o

0o

CLOSED

Actuator Shaft’s Degree of Rotation

OPEN

High Auxiliary Contact (P2-3 & 4)

10

o

20o 30o 40o

Actuator Shaft’s Degree of Rotation

50o60o 70o 80o 90o

A

c

t

u

a

t

o

r

S

h

a

f

t

LS=20

o

Key

Contact Closed

Contact Open

For the settings of note 2,

the low contact is closed

when the shaft is between

10 and 20 degrees.

0

o

90o

HS=75

o

A

c

t

u

a

t

o

r

S

h

a

f

t

HH=85

o

Key

Contact Closed

Contact Open

For the settings of note 2,

the high contact is closed

when the shaft is between

75 and 85 degrees.

Note:

In the following examples:

1) 0°and 90° represent the actuator shaft’s range of travel rather than the

shaft’s alignment (therefore, 0° does not equal vertical and 90° does not

equal horizontal).

2) The operating mode is normally open, but the values LL, LS, HS and HH

have been changed from the default setpoints shown on page 29. The set

values are: LL=10, LS=20, HS=75 and HH=85

24

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

Page 25

4. Press the DOWN key; the message “LS” will

1 2

3

4

5 6

appear on the display.

5. Press either the UP or DOWN key until your

desired number (the desired degree of shaft

rotation) appears on the display; this number

must be of greater value than the desired low

re contact release (LL) number.

6. Press the RESET key to complete the sequence.

Note:

Please refer to Figure 5 on page 24 for an illustration of the next two parameters.

high fire ContaCt

sense (hs)

This description of the contact state is for the

normally open mode. As the shaft travels from

low to high, the HS parameter sets where the

high re contact closes. For most applications this

value should be kept at least 5 degrees below HF.

1. Press the ENTER key; the message “SC” will

appear on the display.

2. Press either the UP or DOWN key until the

number “16” appears on the display.

3. Press the RESET key; the message “PG” will appear on the display.

4. Press the UP key; the message “HS” will appear

on the display.

5. Press either the UP or DOWN key until your

desired number (the desired degree of shaft

rotation) appears on the display; this number

must be of lesser value than the desired high

re contact release (HH) number.

6. Press the RESET key to complete the sequence.

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

25

Page 26

1 2

3

high fire ContaCt

1 2

3

4

5 6

release (hh)

This description of the contact state is for the normally

open mode. As the shaft travels from low to high, the

HH parameter sets where the high re contact opens

back up after having closed at the HS setting. For most

applications this value should be kept at 90. Set HF

to 90 rst if you need to set HH to 90. Do not view

HH through code 17 after it is set. Instead, press the

RESET key twice to see all parameters.

1. Press the ENTER key; the message “SC” will appear

on the display.

2. Press either the UP or DOWN key until the number “17” appears on the display.

3. Press the RESET key; the message “PG” will appear

on the display.

4. Press the UP key; the message “HH” will appear on

the display.

5. Press either the UP or DOWN key until your

desired number (the desired degree of shaft rotation) appears on the display; this number must be

of greater value than the desired high re contact

sense (HS) number.

6. Press the RESET key to complete the sequence.

manual position

seleCt

26

This parameter puts the actuator in the manual positioning

mode. It allows the operator to manually position the shaft

anywhere between low and high re stop settings with the

UP and DOWN keys:

1. Press the ENTER key; the message “SC” will appear

on the display.

2. Press either the UP or DOWN key until the number “05” appears on the display.

3. Press the RESET key to complete the sequence.

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

Page 27

1 2

3

1 2

3

1 2

3

automatiC signal

input seleCt

This parameter takes the actuator out of the manual

positioning mode. The shaft automatically positions

at a point between low and high res according to

4-20mA, 0-10Vdc or LF/HF inputs on the connec-

tor:

1. Press the ENTER key; the message “SC” will

appear on the display.

2. Press either the UP or DOWN key until the

number “06” appears on the display.

3. Press the RESET key to complete the sequence.

auxiliary ContaCt

seleCt–

normally CloseD

auxiliary ContaCt

seleCt–

normally open

This parameter allows the operator to change the

auxiliary contact from the normally open (NO)

default to normally closed (NC):

1. Press the ENTER key; the message “SC” will

appear on the display.

2. Press either the UP or DOWN key until the

number “07” appears on the display.

3. Press the RESET key to complete the sequence.

This parameter allows the operator to return the

auxiliary contact’s default setting to normally open

(NO) if ever changed:

1. Press the ENTER key; the message “SC” will

appear on the display.

2. Press either the UP or DOWN key until the

number “08” appears on the display.

3. Press the RESET key to complete the sequence.

Note:

The next two parameters describe shaft rotation

when facing the keypad.

Warning:

Disconnect shaft coupling before

changing. The shaft will reposition as

such that 0 becomes 90 degrees.

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

27

Page 28

1 2

3

1 2

3

CloCkwise

1 2

3

rotation seleCt

This parameter allows the shaft to travel clockwise when the input signal increases:

1. Press the ENTER key; the message “SC” will

appear on the display.

2. Press either the UP or DOWN key until the

number “10” appears on the display.

3. Press the RESET key to complete the sequence.

CounterCloCkwise

rotation seleCt

examine setpoints

This parameter allows the shaft to travel counterclockwise when the input signal increases:

1. Press the ENTER key; the message “SC” will

appear on the display.

2. Press either the UP or DOWN key until the

number “11” appears on the display.

3. Press the RESET key to complete the sequence.

Pushing the RESET key twice allows the various

setpoints to be examined. Once activated, the

display will indicate a two-letter parameter code

followed by its value in the following sequence:

a. software version;

b. low re stop position (LF);

c. high re stop position (HF);

d. contact signal loss position (LO);

e. low re contact release position (LL);

f. low re contact sense position (LS);

g. high re contact sense position (HS);

h. high re contact release position (HH);

i. manual (C5) or automatic (C6):

j. aux. contact mode N.O. (C8) or N.C. (C7);

k. rotation CW (CO) or CCW (C1)

The display will show each function's setpoint for

two seconds before scrolling to the next one.

28

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

Page 29

Default setpoints

This parameter resets the actuator to the default

setpoints. The default setpoints are as follows:

• Automatic input signal;

• Normally open (NO) contact;

• Clockwise (CW) rotation;

• 0° for LO, or control signal loss position;

• 0° for LF, or low re contact stop;

• 0° for LL, or low re contact release;

• 5° for LS, or low re contact sense;

• 85° for HS, or high re contact sense;

• 90° for HH, or high re contact release, and

• 90° for HF, or high re contact stop.

To reset the parameters to the default setting:

1. Press the ENTER key; the message “SC” will

appear on the display.

2. Press either the UP or DOWN key until the

number “20” appears on the display.

3. Press the RESET key to complete the sequence.

stalleD motor

If the motor is stalled for more than 30 seconds,

the motor will stop and the display will indicate

the percentage (%) sign.

Normal display and operation will resume automatically when the actuator is commanded to

move in the opposite direction from the stall. To

reverse direction while in the automatic mode,

change either the analog input signal, apply a digital

low re or high re input, or change to the manual

mode. In some cases it may be necessary to disconnect the mechanical coupling to the valve.

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

29

Page 30

Specifications

PARAMETER DESCRIPTION

Power Supply 120VAC (+10%, -15%), 50/60 Hz or 230VAC (+10%, -15%), 50/60 Hz

Internal power consumption: 5VA

Operating Temperature

-

20 to +60 °C (0 to 140 °F)

Storage Temperature

-

25 to +65 °C (-10 to 150 °F)

Humidity 5-95% RH noncondensing

Inputs, Analog 4-20mA @ 250Ω impedance; 0-10Vdc @ 200KΩ Impedance

Inputs, Digital (Isolated contacts) Force to high position; force to low position; disable setting codes

Shaft Rotation Adjustable, 0 to 90º maximum.

Minimum Step 1°

Shaft Rotation Direction Selectable: clockwise or counterclockwise

Keypad Orientation Four positions

Display Accuracy ± 1.5°

Position Indicator 9/16" high LED, 0 to 90°

Speed 13 seconds nominal for 90° @ 60Hz

2.3 N-m (20 lb-in)

3.9 N-m (35 lb-in) @ stall

Auxiliary Contact Ratings

Resistive Load: 8A

Inductive Load: 2A

Wiring Connectors Flexible cord connector: 5.8 to 10 mm ( 0.231to 0.394 in.) OD cable

3/8 in. liquid tight conduit

1/2 in. Female NPT adapter

Terminal Connections 0.5 - 1.5 mm2(22 - 16 AWG)

Shipping Weight

1.1 kg (2.5 lb.)

Environment NEMA 4

Torque (Stall Protected)

4

30

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

Page 31

Dimensions

19mm

(0.75")

Front View

Side View

35mm

(1.38”)

146mm

(5.75”)

25mm

(0.98”)

56mm

(2.20”)

6.35mm

(0.25”)

Diameter Shaft

Back View

M6

Threaded

Mounting Hole

12mm Deep

17.47mm

(0.69”)

31.2mm

(1.23”)

164mm

(6.46”)

112mm (4.41")

206mm

(8.11")

74mm

(2.91)

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

31

Page 32

Dimensions (continued)

Keypad Orientation

Upright (Standard) Inverted

RH- 90 degrees LH- 270 degrees

Shaft Detail

4.6mm (0.18”)

36.53mm

(1.44”)

6.35mm

(0.25”)

3mm

(0.12”) Dia.

26.5mm

(1.045”)

Bottom End View

2x M6

Threaded

Mounting Hole

12mm Deep

Holes (2)

19mm (0.75")

each

11mm

(0.43")

27mm

(1.06")

56mm

(2.20")

32mm

(1.26")

10mm

(0.39”)

32

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

Page 33

Maintenance &

Troubleshooting

introDuCtion

This section is divided into two parts:

• The rst part describes maintenance procedures.

• The second part describes troubleshooting

procedures.

5

maintenanCe

Monthly Checklist

Yearly Checklist

Preventative maintenance is the key to a reliable,

safe and efcient actuator. The core of any preventative maintenance program is a list of periodic tasks.

Note:

The monthly and yearly lists are for average

intervals. If your environment is dirty, then the

intervals may be shorter.

1. Inspect the actuator for physical damage to

the housing or display.

2. Inspect the coupling for loose connections.

3. Observe the shaft while moving for smooth

operation.

1. Inspect the actuator for physical damage to

the housing or display.

2. Inspect the coupling for loose connections.

3. Conrm the parameters settings are identical

to those originally selected.

4. Drive the actuator to its full clockwise and

counterclockwise positions and observe the

shaft while moving for smooth operation.

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

33

Page 34

troubleshooting

problem possible Cause solution

No display messages. • No voltage at P2-1 & P2-2. Check power supply.

Actuator will not move • Stalled motor; “oo” message Correct the mechanical

with signal. on display. problem; see “Stalled

Motor” on page 29.

• Actuator is in manual mode. Deselect manual mode;

see “Automatic Signal

Input Select”

on page 27.

• Actuator at low or high re Refer to “Actuator

stop. Mounting” on page 11;

check parameter settings

for low and high res.

• Signal reversed or no signal Check wiring and refer to

connection. Figure 3 on page 18.

Actuator will not move • Manual mode not selected Select manual mode;

with keypad. see “Manual Position

Select” on page 26.

• Defective keypad Call your Eclipse sales

rep.

• External connection to high Check wiring and remove

re input (P1-5 to P1-1) or external connection.

low re input (P1-4 to P1-1).

• Stalled motor; “oo” message Correct the mechanical

on display. problem; see “Stalled

Motor” on page 29.

Displays "LC" • Setting mode disabled. See "Disable Settings

Wiring" on page 17.

34

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

Page 35

Appendix

P R A 6

A- PG11 liquidtite flexible cord connector

B- 3/8" straight liquidtite conduit connecto

r

C- 1/2" Female NPT adapter

1- Standard .... 0

o

o

2- Inverted ...... 180

o

3- RH .............. 90

o

4- LH .............. 270

o

A - 90 stroke

o

D - 75 stroke

A- 120 VAC

B- 230 VAC

Table 1 Actuator Parameter Conguration Record

Code FaCtory your

Parameter SeleCtion abbrev. Setting deFault Setting

Low Fire Stop LF 15 Down 0°

High Fire Stop HF 15 Up 90°

Control Signal Loss LO 12 Down 0°

Low Fire Contact Release LL 17 Down 0°

Low Fire Contact Sense LS 16 Down 5°

High Fire Contact Sense HS 16 Up 85°

High Fire Contact Release HH 17 Up 90°

Manual Position Select [C5] 05 No

Signal Input Select [C6] 06 Yes

Auxiliary Contact Select–

Normally Closed (NC) [C7] 07 No

Auxiliary Contact Select–

Normally Open (NO) [C8] 08 Yes

Clockwise (CW) Rotation Select [C0] 10 Yes

Counterclockwise (CCW)

Rotation Select

Examine Setpoints Reset —

twice

Default Setpoints 20 —

[C1]

11

No

Table 2 Model Number Conguration

Eclipse Rotary Actuator Instruction Manual 904-7/24/06

35

Page 36

904 Instruction Manual 7/24/06

Litho in U.S.A.

Loading...

Loading...