Page 1

Instruction Manual 742

5/1/2009

Eclipse

Ratio Regulators

ES Series

Version 1

Page 2

Copyright

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

Indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

Indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

Is used to address practices not related to personal injury.

Indicates an important part of text. Read thoroughly.

NOTE

NOTICE

WARNING

CAUTION

Copyright 1997 by Eclipse, Inc. All rights reserved

worldwide. This publication is protected by federal

regulation and shall not be copied, distributed,

transmitted, transcribed or translated into any human or

computer language, in any form or by any means, to any

third parties, without the express written consent of

Eclipse, Inc.

It must be understood that Eclipse’s liability for its product,

whether due to breach of warranty, negligence, strict

liability, or otherwise is limited to the furnishing of

replacement parts and Eclipse will not be liable for any

other injury, loss, damage or expenses, whether direct or

consequential, including but not limited to loss of use,

income, or damage to material arising in connection with

the sale, installation, use of, inability to use, or the repair

or replacement of Eclipse’s products.

Disclaimer Notice

In accordance with the manufacture’s policy of continual

product improvement, the product presented in this

brochure is subject to change without notice or obligation.

The material in this manual is believed adequate for the

intended use of the product. If the product is used for

purposes other than those specified herein, confirmation

of validity and suitability must be obtained. Eclipse

warrants that the product itself does not infringe upon any

United States patents. No further warranty is expressed or

implied.

Liability and Warranty

We have made every effort to make this manual as

accurate and complete as possible. Should you find errors

or omissions, please bring them to our attention so that we

may correct them. In this way we hope to improve our

product documentation for the benefit of our customers.

Please send your corrections and comments to our

Marketing Communications Manager.

Any operation expressly prohibited in this manual, any

adjustment, or assembly procedures not recommended or

authorized in these instructions shall void the warranty.

Document Conventions

There are several special symbols in this document. You

must know their meaning and importance.

The explanation of these symbols follows below. Please

read it thoroughly.

How To Get Help

If you need help, contact your local Eclipse representative.

You can also contact Eclipse at:

1665 Elmwood Rd.

Rockford, Illinois 61103 U.S.A.

Phone: 815-877-3031

Fax: 815-877-3336

http://www.eclipsenet.com

2

Eclipse Ratio Regulator, V1, Instruction Manual 742, 5/1/2009

Page 3

Table of Contents

Introduction............................................................................................................................... 4

Product Description.............................................................................................................. 4

Safety......................................................................................................................................... 5

Safety Warnings................................................................................................................... 5

Capabilities .......................................................................................................................... 5

Operator Training................................................................................................................. 5

Replacement Parts .............................................................................................................. 5

Specifications ........................................................................................................................... 6

Compatability/Temperature Specifications .......................................................................... 6

Model Specifications ............................................................................................................6

Flow vs Pressure Drop......................................................................................................... 6

Dimensions .......................................................................................................................... 7

Design & Installation ................................................................................................................ 9

General Information .............................................................................................................9

Ratio Regulator/Pipe Connections....................................................................................... 9

Gas Bias Adjustment ........................................................................................................... 10

Eclipse Ratio Regulator, V1, Instruction Manual 742, 5/1/2009

3

Page 4

Introduction

WARNING

1

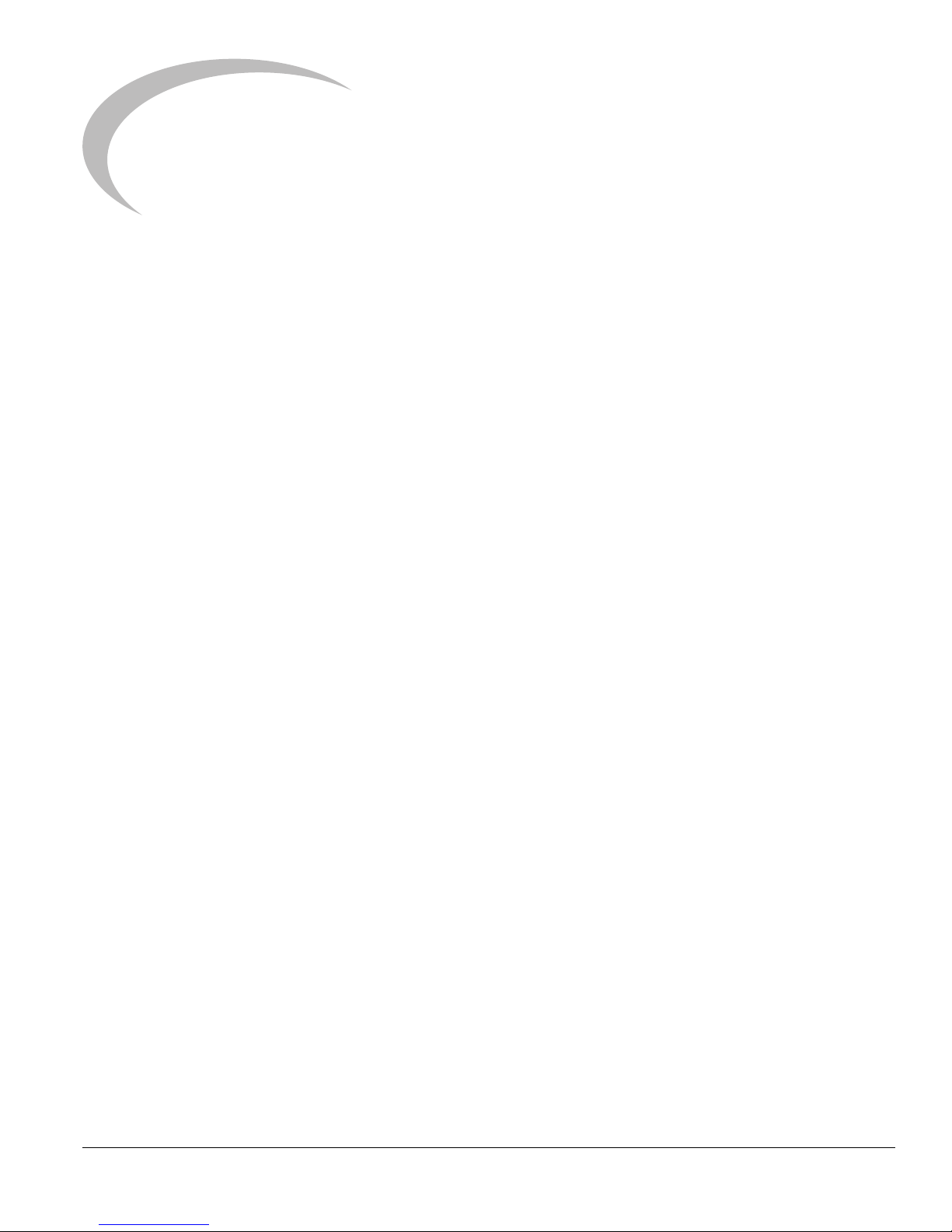

Product Description

The ES-Series Ratio Regulators are used in applications

where gas to air proportional flow is required. The gas flow

is controlled as a function of the air pressure through a

loading line which connects into the top of the regulator.

As the system air pressure increases, it forces the ratio

regulator valve to open causing the outlet pressure to

increase until the two pressures balance. As the load line

pressure increases, the ratio of the outlet pressure to the

load line pressure will be slightly less than 1:1.

The ratio regulators have a bias adjustment for varying the

gas flow when setting the burner at low fire. It can be used

to increase or decrease the gas flow resulting in gas rich

or lean combustion. The adjustment is restricted in the

gas rich direction therefore limiting the gas flow at zero air

pressure.

■ The ratio regulators are control valves only and

cannot be used as gas shut-off valves.

Product Features

The ratio regulators are designed to optimize performance

as ambient temperature and inlet pressure vary. Features

include:

• UL recognized and CE approved for natural gas,

propane, and butane.

• Valve seat design for consistent low fire

repeatability.

• Balanced double diaphragm design allows regulator

to operate over a wide range of inlet pressures while

minimally affecting outlet pressure.

• Rugged die cast aluminum housing.

• Corrosion resistant internal components.

• Synthetic rubber diaphragms for excellent low

temperature performance.

• Inlet pressure tap with connector (1-1/2", 2" & 3"

NPT (Rp) models only).

Audience

This manual has been written for people who are already

familiar with all aspects of a combustion system and its

add-on components, also referred to as “the burner

system”.

The audience is expected to have had experience with the

ratio regulator component of a burner system.

Purpose

The purpose of this manual is to make sure that the ratio

regulator component of a burner system is used in a safe,

effective and trouble free manner.

Figure 1.1. Ratio Regulators

4

Eclipse Ratio Regulator, V1, Instruction Manual 742, 5/1/2009

Page 5

Safety

DANGER

NOTICE

2

Important notices about safe ratio regulator operation will

be found in this section. Read this entire manual before

attempting to start the system. If any part of the

information in this manual is not understood, contact

Eclipse before continuing

Safety Warnings

■ Do not bypass any safety feature. Fires and

explosions can be caused.

■ Never try to use a ratio regulator that shows signs

of damage or appears to be malfunctioning.

■ This manual gives information for the use of these

ratio regulators within their specific design

purpose. Do not deviate from any instructions or

application limits in this manual without written

advice from Eclipse.

Capabilities

Adjustment, maintenance and troubleshooting of the

mechanical parts of this system should be done by

qualified personnel with good mechanical aptitude and

experience with combustion equipment.

Operator Training

The best safety precaution is an alert and competent

operator. Thoroughly instruct operators so they

demonstrate an understanding of the equipment and its

operation.

Replacement Parts

Order replacement ratio regulators from Eclipse only.

Eclipse Ratio Regulator, V1, Instruction Manual 742, 5/1/2009

5

Page 6

CAUTION

Specifications

3

Compatibility/Temperature Specifications

Tab le 3.1

Ambient Temperature

Compatible Gases

Natural

Manufactured

Mixed

Vaporized Liquified Petroleum

LP Gas-Air Mixture

■ Below 32°F (0°C), the gas must be free of water

vapor which could condense and freeze within the

valve.

Range

-40°F to 205°F

(-40°C to 96.1°C)

Model Specifications

Table 3.2

Model Part No. Pipe Thread

ES365 19997 3/4" NPT 1.0 psi 1,245 scfh

ES365M 19998 Rp 3/4 69.2 mbar 35.27 Nm3/hr

ES366 15939 1" NPT

ES366M 19999 Rp 1 69.2 mbar 39.09 Nm3/hr

ES363 20312 1-1/2" NPT

ES363M 20311 Rp 1-1/2 346.2 mbar 179.9 Nm3/hr

ES368 10315 2" NPT

ES368M 19990 Rp 2 346.2 mbar 328.6 Nm3/hr

ES369 10316 3" NPT

ES369M 19989 Rp 3 346.2 mbar 736.5 Nm3/hr

1

Gas inlet pressure must be greater than the total of the outlet pressure plus the pressure drop across the regulator at the required

flow.

2

Capacity for natural gas (0.60 sg). When using propane or butane, divide capacity by conversion factors listed in Table 3.3.

Maximum Inlet

Pressure

1.0 psi 1,380 scfh

5.0 psi 6,350 scfh

5.0 psi 11,600 scfh

5.0 psi 26,000 scfh

1

Capacity

2

6

Eclipse Ratio Regulator, V1, Instruction Manual 742, 5/1/2009

Page 7

10.0

8.75

7.5

6.25

5.0

3.75

2.5

1.25

0.0

0200

5.66

400

11.33

600

16.99

800

22.66

1000

28.32

1200

33.99

1400

39.66

1600

45.32

Model ES365 & ES365M

Model ES366 & ES366M

Capacity, scfh

∆P "wc

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

∆P mbar

0.0

Capacity, Nm³/hr

0

87.5

75

Figure 3.1. Flow vs Pressure Drop, 3/4" & 1" NPT (Rp) Models

35

30

62.5

37.5

∆P mbar

12.5

50

25

0

25

20

15

∆P "w.c.

10

5

0

05,000

0

141.6

10,000

Capacity, scfh

283.3

Capacity, Nm3/hr

Figure 3.2. Flow vs Pressure Drop, 1-1/2", 2" & 3" NPT (Rp) Models

NOTE:

Above graphs are for natural gas (0.60 s.q.). For

propane or butane, multiply the gas flow by the factors

listed below, to calculate the equivalent natural gas flow,

then find the pressure drop from the previous graphs.

Propane (1.5 s.g.) 1.58

Butane (2.0 s.q.) 1.82

Table 3.3 Conversion Factors

Gas Conversion Factor

15,000

424.9

Model ES363, ES363M

Model ES368, ES368M

Model ES369, ES369M

20,000

566.5

25,000

708.2

30,000

849.8

Example: Find the pressure drop created by 15,000 scfh

of propane through an ES369 ratio regulator.

1. Convert propane to the equivalent natural gas flow:

15,000 x 1.58 = 23,700 scfh

2. Plot the point where 23,700 scfh crosses the ES369

curve on the above graph.

3. Translate the intersection point back to the pressure

drop axis.

4. The pressure drop at 23,700 scfh natural gas,

equivalent to 15,000 scfh propane, is approximately

23.5" w.c.

Eclipse Ratio Regulator, V1, Instruction Manual 742, 5/1/2009

7

Page 8

Figure 3.3. Dimensions in inches (mm), Models ES365 (M) & ES366 (M)

3-7/8

(98.4)

1-1/2

(38.1)

5-11/16

(144.5)

1/8" NPT

Load Line

2-3/8

(60.3)

Inlet

ES365(M) 3/4" NPT (Rp 3/4)

ES366(M) 1" NPT (Rp 1)

4

(101.6)

Outlet

ES365(M) 3/4" NPT (Rp 3/4)

ES366(M) 1" NPT (Rp 1)

4-7/8

(123.8)

Outlet End View

Swing

Radius

E

A

C

Inlet

B Dia.

D

F

Load Line

Outlet End View

Swing

Radius

Inlet Pressure Tap

1

Inlet Test

Tap Connector

2

1

1/4" taper pipe plug on ES363(M) and ES368(M). No tap this side on ES369(M).

2

1/8" taper test tap connector, 0.34" OD (8.6 mm) for slip-on hose.

Outlet

Figure 3.4. Dimensions in inches (mm), Models ES363 (M), ES368 (M) & ES369 (M)

Table 3.4

Model Swing Radius Inlet/Outlet A B C D E F

ES363 6-3/16" 1-1/2" NPT 9" 7" 5-1/2" 2-3/8" 3-3/4" 1/2" NPT

ES363M 157.1 mm Rp 1-1/2 228.6 mm 177.8 mm 139.7 mm 60.3 mm 92.2 mm Rp 1/2

ES368 9-3/16" 2" NPT 11-1/4" 9-1/8" 7-5/8" 3-1/8" 4-5/16" 3/4" NPT

ES368M 233.4 mm Rp 2 285.7 mm 231.7 mm 193.6 mm 79.3 mm 109.5 mm Rp 3/4

ES369 13-1/4" 3" NPT 16-1/16" 13-7/16" 10-3/8" 4-7/8" 6-1/8" 3/4" NPT

ES369M 336.6 mm Rp 3 407.9 mm 341.3 mm 263.5 mm 123.8 mm 155.5 mm Rp 3/4

8

Eclipse Ratio Regulator, V1, Instruction Manual 742, 5/1/2009

Page 9

WARNING

CAUTION

Design & Installation

4

Design

To select the ratio regulator best suited for a combustion

system, several parameters need to be considered. The

following steps identify those items that need to be

considered when selecting a ratio regulator.

Ratio Regulator selection based on flow:

• Define the maximum gas flow required for the

system.

• Identify the ratio regulator for that flow based on the

capacities listed in Table 3.2 of the “Specifications”

section.

Minimum inlet pressure calculation:

• Define the pressure drop through the ratio regulator

based on the Flow vs. Pressure Drop curves

(Figures 3.1 and 3.2) and conversion factors listed

in the “Specifications” section.

• Calculate the pressure losses through components

mounted between the ratio regulator and the burner.

• Define the gas pressure required at the burner.

• Calculate the minimum inlet pressure to ratio

regulator by taking 125% of the sum between the

ratio regulator drop, component drops and burner

pressure.

• Verify that the inlet pressure is within the ratio

regulator limit. If not, make the necessary changes

to the ratio regulator or the upstream pressure

control.

■ Shut off gas supply before installing or removing

the ratio regulator

General Installation Information

• Gas flow through the ratio regulator must be in the

direction of the arrow on the body.

• Make sure the gas is compatible per Table 3.1.

• Ambient temperature at the valve location must

remain between 40°F and 205°F (-40°C and

96.1°C).

• The ratio regulator must be mounted with the spring

tower in the vertical upright position.

• Allow clearance above the ratio regulator to allow

access to the bias adjustment.

• Pipe ends are to be free of foreign material

(excluding pipe dope) before connecting into the

ratio regulator body.

• Do not use the ratio regulator to support adjacent

piping.

Regulator/Pipe Connections

1. Remove the protective caps from the ends of the ratio

regulator.

2. Apply a moderate amount of pipe dope to the male

pipe threads only.

NOTE:

set thus affecting pressure regulation.

■ Regulator must be installed with spring tower

3. Install the ratio regulator with the flow in the direction

Excessive pipe dope could contaminate the valve

pointing upward, with flow in the direction of the

cast arrow on regulator body.

of the flow arrow on the body.

Eclipse Ratio Regulator, V1, Instruction Manual 742, 5/1/2009

4. When tightening the pipe into the valve body, hold the

end of the regulator adjacent to that pipe.

9

Page 10

5. Connect the air pressure loading line into the vent on

the top of the ratio regulator. The ratio regulators can

be adjusted to bias the gas outlet pressure relative to

the combustion air pressure when setting low fire

flows. Adjust the regulator as described below.

Gas Bias Adjustment

NOTE: Gas-rich adjustment is limited. If the spring

adjustment will not produce the desired outlet pressure,

make sure that the supply pressure is at least equal to the

desired outlet pressure plus the pressure drop across the

regulator at the required flow.

1. Set the burner air flow to low fire according to the

instructions furnished with the burner.

2. Open the gas shut-off valves to allow gas flow to the

burner. Ignite the burner.

3. Measure the fuel/air ratio using a flue gas analyzer,

metering orifices or estimate the ratio from flame

appearance. Use a screw driver to turn the adjusting

screw clockwise to increase the outlet pressure or

counterclockwise to decrease to outlet pressure.

Figure 5.1. Adjustment of Outlet Pressure

4. Turn the combustion air to high fire and make sure the

burners stay lit.

NOTE:

Some models are equipped with a pressure tap on

the upstream side. It is open when the screw inside the tap

is unscrewed approximately 1/2 a turn.

10

Eclipse Ratio Regulator, V1, Instruction Manual 742, 5/1/2009

Page 11

NOTES

Eclipse Ratio Regulator, V1, Instruction Manual 742, 5/1/2009

11

Page 12

Instruction Manual 742, 5/1/2009

Loading...

Loading...