Page 1

99 Washington Street Melrose, MA 02176

Phone 781-665-1400 Toll Free 1-800-517-8431

MT-2017

Protective Function Analog Multimeter

User’s Manual

1st Edition, 2015

©2015 Copyright by Prokit’s Industries Co., Ltd.

Page 2

INTRODUCTION

This Multi-meter is an accurate, safe handheld meter that comes

with robust protective holster alongside, built-in stand and hook-up

design. MT-2017 is powered by batteries, offers accurate, reliable

measurement of DC/AC Voltage, +/-DCV, DC Current, Resistance

and Diode, LED, Transistor, Decibels, Continuity test and

Capacitance with very high sensitivity quality movement.

This meter is designed with double-sided glass-epoxy PCB, full

overload & misused protection via two Fuses, Oxide Varactor &

Diodes, as well as mirrored Aluminum dial plate. Ideal for indoor

use in the laboratory, school, workshop, hobby and home

applications.

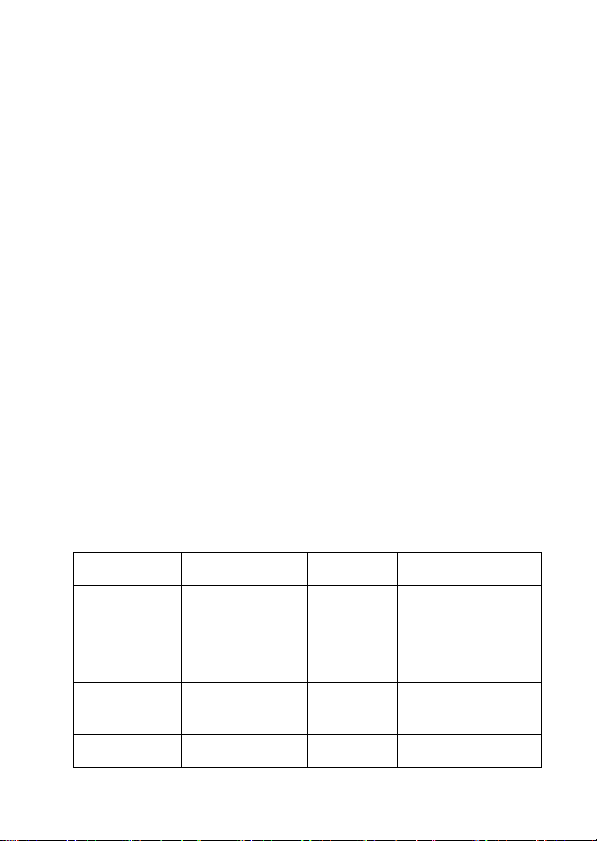

SPECIFICATION

Safety Category: IEC61010-1, CAT II 1000V, CAT III 500V and

Pollution Degree 2.

Common Environment: 23C5C, less than 75% RH.

Operating temperature: 0C to 40C, 32 F to 104 F

Storage temperature: -10 C to 50C, 14 F to 122F

Operating Humidity Scope: less than 90% RH.

Storage Humidity Scope: less than 80% RH.

Dimensione: 171(W) x 108(D) x 37(H) MM

Weight: 390g approx. (including batteries 3pcs)

Accessories: One pair of test leads;

Two Spare Fuses: 0.5A/250V & 10A/250V, Φ5x20mm

Test

Functions

DC V 0-0.1-2.5-10-50-

Null DCV ±-5V, ±25V 5% FSD.

AC V 0-10-50-250V

Range Accuracy Remarks

250 V-1000V

-1000V

3% FSD.

4% FSD.

For 1000V

4% FSD.

5% FSD.

1

Input Impedance:

20KΩ /V Overload

Protection: Max.

1000V AC/DC

BUT 0.1V/2.5V/10V

250V Max.

Input Impedance:

40KΩ /V Overload

1000V Max.

Input Impedance:

9KΩ /V Overload

Page 3

For 1000V Protection: Max.

DC mA 0-0.05-2.5-25-25

Ω X 1: 0.2 ~ 2KΩ

Capacitance

(uF)

BATT Check 0 ~ 1.5V: GOOD

Transistor

Check

LED, Diode via special hFE Approx. At Ω X 10 Range

0 mA, 10A

Midscale at 20Ω

X 10: 2 ~ 20KΩ

Midscale at

200Ω

X 100: 20 ~

200KΩ

Midscale at

2000Ω

X1K: 200~ 2MΩ

Midscale at

0KΩ

X10K: 2K

~20MΩ

Midscale at

200KΩ

C: 2,000uF Max.. Approx.

- ? – BAD

0 ~ 9V: GOOD

- ? – BAD

hFE: 0-1000 via

special hFE

socket

3% FSD.

4% FSD.

For 10A

4% of

ARC of

Scale

Length

Value

5% of

ARC of

Scale

Length

Approx.

Value

1000V AC/DC

But 10V/50V only

250V Max. Band

width: 40 ~10K Hz

Drop Voltage: 250

mV Overload

protected by Fuses

0.5A/250V & 10A /

250V at 10A range,

and Oxide

Varactor.<250V

AC/ DC(5s). Max.

test time 15sec. for

10A.

Overload protected

by the Oxide

Varactor & Fuse

<250V AC/DC (5s).

Use the R x 1K

range

Load Current:

270mA for 1.5V

25mA for 9V

Overload protected

by Fuse & Oxide

Varactor .<250V

AC/DC(5s).

At Ω X 10 Range

2

Page 4

Check socket Value

Decibel -22 dB ~ + 62

Continuity

Check

POWER

Source

dB (0dB=1mW

at 600Ω )

Beeper

sounding under

200 Ohm

Internal Battery:

R3P, AAA, 1.5V

2pcs, 6F22,

NEDA1604, 9V

1pc

Approx.

Value

Overload protected

At ACV ranges

Via Test Leads

by Fuse & Oxide

Varactor .<250V

AC/DC(5s).

CALIBRATION

Ohms Zero Adjustor located at the right side of the panel.

Adjust the meter pointer to the Zero mark on the right side of

Ohm scale of the meter dial when the test leads are touched

together.

Mechanical Adjustor Screw: located right side below the center

of the meter dial to set pointer to Zero mark at the left side of

the scale.

(-) Jack: Plug-in connector at the lower left on the panel for

black, negative test lead.

(+) Jack: Plug-in connector at the lower right on the panel for

Red, positive test lead.

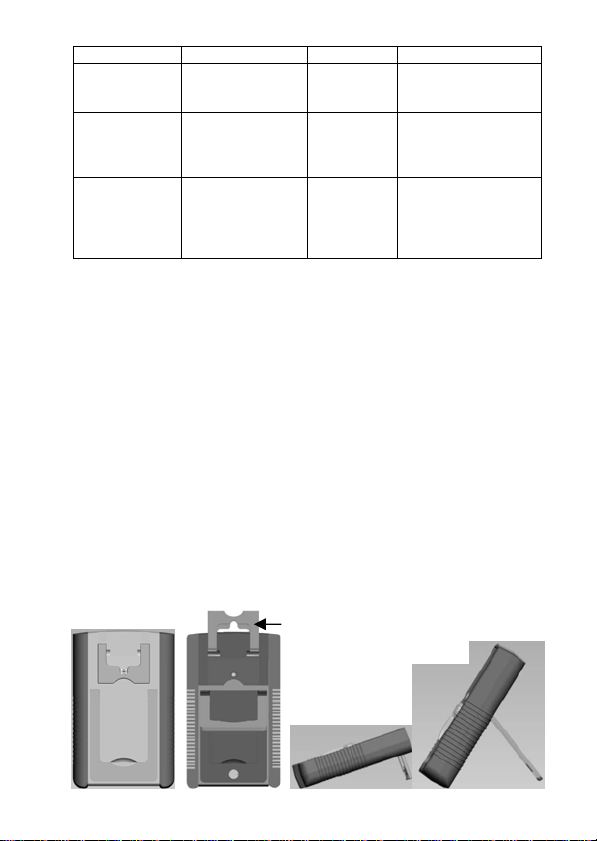

STAND & HOOK-UP

This meter can be used in any operating position. It has two rear

support devices, i.e. the upper small bracket and the lower big tilt

device. The upper one not only performs the light slanted position,

but also hook-up the tester which makes it easier to place the

tester and read the display when measuring.

And the lower big tilt device can provide the steeper slant degree

position easy for user’s reading too.

Hook-up

Upper Tilt

Device

Big Lower

Tilt Device

3

Page 5

OPERATING INSTRUCTIONS

CAUTION!

When making voltage or current measurements, develop the

habit of turning off all power to the circuit under test. Connect the

test leads at the desired points in the circuit, and then turn on

the power while taking readings. Turn off the power before

disconnecting the test leads from the circuit.

INTERNAL BATTERY CHECK

To check the battery condition, insert the black test lead into the

(-) jack. Set the range switch to the R X1 range position and

short the ends of the two sides of the test leads. If the pointer

can not be brought to the zero mark, replace the 1.5V cells or 9V

cell. (See battery replacement.)

BEFORE OPERATING

1. Set the range switch to the proper position before making any

measurement.

2. Never apply more voltage or current than the rated value in

every position.

When the voltage or current to be measured it not known,

3.

always start with the highest range.

4. If meter indication is in the lower half of the scale and falls

w

ithin the range

lower range for greatest accuracy.

5. If the meter won’t work at all, check the fuse located on the

PCB. If it’s blown, replace it. (See fuse replacement.)

6. Avoid placing the meter where extreme shock or continuous

vibration is enco

damp places. Although very rugged, the meter is a sensitive

measuring device and should be handled carefully & properly.

7. Do not check resistance, transistor, diode, LED, or

capacitance when live voltage or current input across the

circuit.

8. When the meter is not in use, keep the selector switch to the

of a lower scale, reset selector switch to the

untered and do not store in excessively

hot or

4

Page 6

“OFF” range position, this provides direct short across meter

movement for minimum needle bounce when transporting

meter.

9. If you should accidentally apply excessive voltage or current

on a certain range, disconnect the leads from the circuit as

quickly as possible, check instrument operation on that range

by applying peoper input. If the meter does not operate

properly, check fuse. If it is blown replace it. (See fuse

replacement.)

OPERATION PROCEDURES

DC Voltage Measurement

WARNING: USE EXTREME CARE WHEN MAKING

MEASUREMENTS FOR HIGH VOLTAGE. DO NOT TOUCH

TERMINAL OR PROBE ENDS.

1. Set the selector switch to the appropriate DCV range to be

used.

2. Connect the BLACK test lead to the “-COM” jack and the RED

test lead to the “+” jack.

3.

If you know the polarity of the circ

black probe to the negative side.

4. If you don’t know the polarity, connect the probes to opposite

sides of the circuit and watch the pointer. If it goes to the left,

reverse the probes. The RED probe will be connected to the

positive.

5. Check the needle position and the get the reading on V.A scale.

uit to be tested, connect the

Null DCV (Central Zero) Measurement

At these two ranges, it can automatically judge the polarity of

circuit as the pointer can move to the center line and become a

Null meter.

1. Set the selector switch to the DCV ±5V or 25V range.

Connect the B

2.

test lead to the Red “+” jack.

LACK test lead to the “-

5

COM” jack and the RED

Page 7

3. Set the Zero Ω adjustor to place the pointer exactly to the

Central Zero position

4. Connect the test leads across the circuit or load under

measurement.

Take the readings on the Red dial Null DCV scale.

5.

NOTE: If the needle failed to be set at Central Zero position

power of 9V battery may be weak and should be replaced by

new one for normal working.

AC Voltage Measurement

WARNING: USE EXTREME CARE WHEN MAKING

MEASUREMENTS FOR HIGH VOLTAGE. DO NOT TOUCH

TERMINAL OR PROBE ENDS!

1. Set the selector switch to the appropriate ACV range to be used

and connect the test leads across the circuit or load under

measurement. (Polarity of the test probes is unimportant on ACV

test.)

Connect the BLACK test lead to the “-COM” jack and the RED

2.

test lead to the“+” jack.

3. Check the needle position and the get the reading on V.A

DC Current Measurement

WARNING: DO NOT APPLY VOLTAGE TO MEASURING

TERMINAL WHILE RANGE SWITCH IS IN CURRENT POSITION.

DO NOT ATTEMPT TO MEASURE AC CURRENT.

1. Set the selector switch to the appropriate DC mA range to be

used and connect the test leads in series with the circuit or the

load under measurement. If the pointer deflects to the lef

reverse the probes.

2. Connect the BLACK test lead to the “-COM” jack and the RED

test lead to the Red “+” jack for Current at/less than 0.25A. For

large current max. 10A, move the red test lead to the Red “10A”

jack.

if need.

, the

scale.

t,

6

Page 8

3. Check the needle position and the get the reading on V.A scale.

Note:

Excessive current input across mA range will blow the fuse

that must be replaced by a same fuse rating 0.5A/250V or

10A/250V. The max. testing time once must be not more than

15sec. and pause 5min. for next time at big current load.

The Maximum terminal voltage drop is 250mV except for the

10A range.

Note: If connected incorrectly with the voltage at these ranges,

quickly remove the test leads from the circuit as to avoid

damage to this tester.

(This tester can afford the voltage <250V DC/AC rms. for the

period of 5 seconds max.)

Resistance Measurement

WARNING: DO NOT APPLY VOLTAGE TO MEASURING

TERMINAL WHILE RANGE SWITCH IS IN OHM POSITION.

1. Set the selector switch to the appropriate Ω range to be used.

Connect the BLACK test lead to the “-COM” jack and the RED

2.

test lead to the Red “+” jack.

Short the leads by touching the probes together. Pointer should

3.

read zero at the right hand end of the upper most scale, if it

doesn’t, use the Ohm adjust knob on the right hand of the panel

to line up the pointer with zero. (If pointer can’t be brought to

zero, replace battery.)

4. Connect the test leads across the resistance to be measured.

5. Take reading on the top “Ω” scale and multiply it by the

multiplication factor indicated by the selector switch.

6. If there is little or no pointer movement from the left side of the

scale, reset the selector switch to higher range. The effective

reading scope on an Ohm meter scale is within the area of

between 25 degree of Arc left side to the Midscale and 25

degree right side to the Midscale.

Note: If connected incorrectly with the voltage, quickly remove

7

Page 9

the test leads from the circuit as to avoid damage to this tester.

(This tester can afford the voltage <250V DC/AC rms. for the

period of 5 seconds max.)

Diode Measurement

1. Set the selector switch to the appropriate Ω range to be used.

NOTE: To test the diode while current below 0.060 mA at X 10K

range; current below 0.15 mA at X 1K range; current below 1.5

mA at X 100 range; current below 15 mA at X 10 range; current

below 150 mA at X 1 range.

2. For IF (forward current) test, put the BLACK test lead to the

“-COM” jack and the RED test lead to the Red “+” jack. And then

connect the Black probe to the Positive terminal of the Diode,

the Red probe to the Negative terminal of the Diode.

For IR (reverse current) test, reverse the connection.

3. Read the value IF or IR of the diode on the LI scale.

4. Read the linear (forward voltage) VF of the diode on the LV

scale.

Continuity Test

WARNING: DO NOT APPLY VOLTAGE TO MEASURING

TERMINAL WHILE RANGE SWITCH IS IN OHM POSITION.

Set the selector switch to the BUZZ range. Connect the test leads

to two points of circuit. If the resistance is lower than 200 Ohm

approx., the Beeper sounds.

Note: Battery voltage is sufficient for Buzzer operation as long as

the Zero Ohm pointer can be adjusted to the Zero scale place.

Note: If connected incorrectly with the voltage, quickly remove

the test leads from the circuit as to avoid damage to this

tester..

(This tester can afford the voltage <250V DC/AC rms. for the

period of 5 seconds max.)

8

Page 10

Transistor hFE and LED Test

1. Set the selector switch to the R X 10 range.

FOR Measuring Transistor hFE

2. Take note the type of transistor “PNP” or “NPN” and then insert

the transistor terminals of the Emitter, Base and Collector

separately into the proper holes of the socket on the front panel.

3. Read the approximate hFE Value directly at the hFE scale.

Note: Current 10μA. VCE 2.8V.

When the Base terminal cut, the value of Leak is Iceo for

4.

Transistor.

FOR Measuring LED: Insert the transistor terminals directly into

the “+” and

And then check if the LED under testing is lighting.

Battery Check

1. This meter comes with two separate battery check ranges to test

either DC 1.5V or 9V batteries.

Set the selector switch to the appropriate BATT range to be

2.

used.

3. Connect the BLACK test lead to the “-COM” jack and the RED

test lead to the Red “+” jack.

4.

Connect the Red test lead to the positive end of battery a

Black one to the negative end of the battery to be measured.

5. Take reading on the “BATT” scale and check it good or bad as

per which portion indicated.

(Note: the mark section of “?” shows that the battery may be

starting to decay.)

Note: If connected incorrectly with the voltage, quickly remove

the test leads from the circuit and can avoid the damage to

this tester.

(This tester can afford the voltage <250V DC/AC rms. for the

period of 5 seconds max.)

“-” holes of the socket on the front pane

l.

nd the

9

Page 11

Decibels Measurement

1. Set the selector switch to AC 10V range.

2. Connect the BLACK test lead to the “-COM” jack and the RED

test lead to the Red “+” jack.

3. Connect the test leads to the measuring circuit specially in

series with a 0.047μF/400V Metalized Polyester Capacitor.

And then read the bottom Red dB scale.

4. For more dB scope, change the selector switch to the others

of ACV ranges and make the same actions. Add the

appropriate number of dB scale reading as noted on the chart

below.

NOTE: For absolute dB measurements, circuit im

must be 600 Ohm. 0 dB = 1mw dissipated in a 600 Ohm

impedance (equivalent to 0.755V across 600 Ohm)

ACV RANGE ADD dB Number

50 14

250 28

1000 40

tance Measurement

Capaci

WARNING: DO NOT APPLY VOLTAGE TO MEASURING

TERMINAL WHILE MAKING ANY CAPACITANCE

MEASUREMENTS.

BEFORE TESTING ANY CAPACITORS, DISCHARGE THE

CAPACITOR COMPLETELY.

1) Set the selector switch to the C (R X1K) ran

2) Connect the BLACK test lead to the “-COM” jack and the

RED test lead to the Red “+” jack.

3) Connect the test leads to the capacitor to be measured

(Note the polarity of capacitor).

4) Watch the needle deflection to the right topside, and read

the Red C2000uF scale on the Dial.

pedance

ge.

10

Page 12

TROUBLESHOOTING

Nevertheless, problems or malfunctions may occur.

For this reason, the following is a description of how you can

eliminate possible malfunctions yourself:

Error Possible cause

The multimeter does

not work.

No measurements

possible via V/mA

socket.

No measurements

possible via 10A

socket.

No change in

measured values.

Faulty measuring

results are displayed.

Are the batteries exhausted?

Check the state of the batteries and

the fuse 0.5A.

Is the fuse defective? Check the fuse

0.5A (fuse replacement)

Is the fuse defective? Check the fuse

10A (fuse replacement)

Have you selected the right

measuring sockets? Is the measuring

range/mode correct (AC/DC)?

Has null balancing of the display or a

0 Ohm calibration for the resistance

measurement been carried out? Is

the batteries not properly assembled

in?

11

Page 13

MAINTENANCE

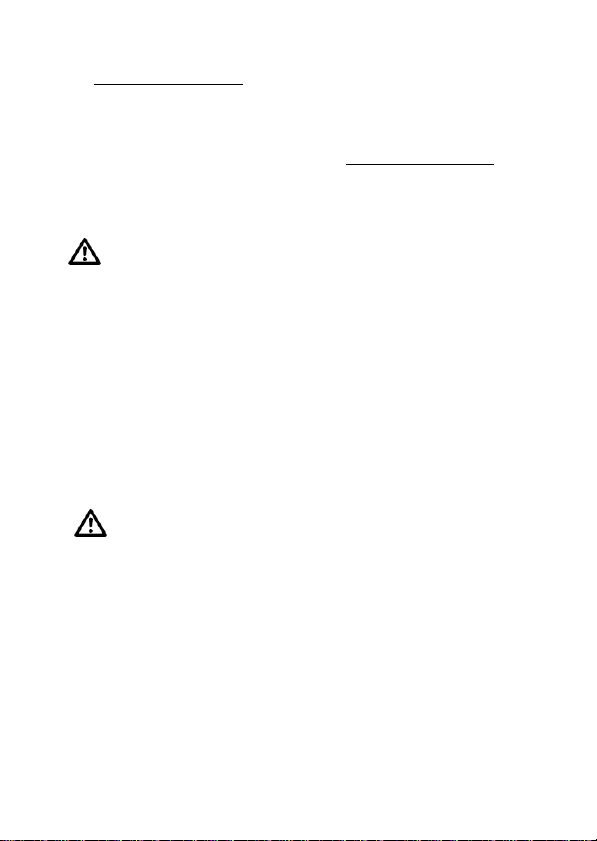

Replacement for Battery and/or Fuse should only be done

after the test leads have been disconnected and POWER OFF.

1. Battery Replacement

- 1.5V Battery (Pls. see the Picture below for reference)

1). This tester uses 2pcs AAA size 1.5V batteries which are

located under the lower battery cover together with the big

tilt device on the lower part of the rear case.

2).Note the condition of the batteries using the procedure

described above, if the battery needs to be replaced, turn

the lock by 90°degree and take off the cover of the battery

cabinet together with the big tilt device on the rear case.

3). Remove the spent batteries and replace them with a battery

of the same type. Observing polarity as indicated battery

polarity marking on the bottom of the battery compartments.

4). Replace the battery cover and turn the lock by 90°degree

again to tighten the battery cover.

- 9V Battery (Pls. see the Picture below for reference)

1). This tester uses One 9V battery which is located under the

upper battery cover together with the tilt-Hookup device on

the upper part of the rear case.

2).Note the condition of the battery using the procedure

described above, if the battery needs to be replaced, remove

the screw and open the upper cover of the battery cabinet

on the rear case.

3). Take off the spent 9V battery and replace them with a battery

of the same type. Observing polarity as indicated battery

polarity marking on the bottom of the battery compartment.

4). Replace the battery cabinet cover and tighten the screw.

2. Fuse Replacement(Pls. see the Picture below for reference)

1). When the fuse needs replacement, use only UL-Listed

0.5A/250V fuse or 10A/250V fuse identical in physical size to

the original type Φ5 x 20 mm.

12

Page 14

2). Open the big lower tilt device on the rear case and then turn

the lock by 90°degree and take off the cover of the battery

cabinet together with the big tilt device.

3). The old fuses inside their holders located on the PCB can be

visible and access to be removed. Then take off the melt

fuses and install the new fuses into their original places.

The 0.5A/250V fuse is at the left side and 10A/250V fuse at

the right side.

4). Replace the battery cover and turn the lock by 90°degree

again to tighten the lower battery cover.

NOTE: 2pcs stand-by fuses are provided and located beside the

batteries under the lower battery cover with rating marked below

the fuses.

Lock for lower 1.5V

Battery Cover

Lower 1.5V Battery Cabinet

inside and Fuses Layout

9V

Screw

Hole

Battery

13

Page 15

MT-2017 指針型防誤測三用電錶

操作使用說明書

特點:

本機是指針式,防誤測全保護,斜立型三用電錶(附晶體 LED 座,短

路蜂鳴及 10A 檔,及鍍金表筆)。具有以下基本特點和參數如下:

- 斜立型,兩個可調後蓋支撐架。上部支架可拉出後,向上轉動 90 度,

壓下可固定; 並附帶掛鈎設計(支撐架向上轉動 180 度伸出後蓋,

以便懸掛)。下部大支撐架可拉出以更大角度斜立。

- 後蓋下部特別設置了 1.5V 電池倉和用鎖扣固定的電池蓋,以非常

方便用戶拆卸和更換電池及保險管。

- 配置玻璃釺維環氧樹脂鍍金盤雙面電路板,日系電池,通過 CE 認證。

- 檔位切換簧片採用彈簧寶石軸承及二極體雙向限幅電路

- 具有全面的防誤測超載保護電路及速斷型保險絲多重保護

- 具有緊湊的兩側軟性防滑減振保護套

- 可測直流電壓和中間零位正負直流電壓,直流電流(最大 10A),交

流電壓,電阻,電晶體,二極體,LED,電池,短路蜂鳴, 和電容

(2000uF Max.) 等.

- 輸入阻抗:DC20Kohm /V,AC 9Kohm/V

- 直流電壓:0.1/2.5/10/50/250/1000V 六檔

- 中間零位正負直流電壓:±5V/25V 兩檔

- 直流電流:50μA/2.5m/25m/250mA/10A 五檔

- 交流電壓:10/50/250/1000V 四檔

- 電 阻:1/10/100/1K/10K 四檔

- 電 池:1.5/9V

- 電 容:C(RX1K),Max. 2,000 uF;

- 標準環境條件:23C5C, 濕度< 75% RH。

- 工作環境範圍:0C ~ 40C, 濕度< 90% RH。

- 儲存條件:-10C ~ 50C, 濕度< 80% RH。

- 電錶外形尺寸:171(長)x 108(寬)x 37(高)mm

- 電錶重量:390 克(包括電池)

二檔

14

Page 16

規格表:

測試功能 檔位 準確度 說明

直流電壓

DCV

正負直流電壓

Null DCV

交流電壓 ACV

直流電流

DCA

電阻 Ω

電 容

0-0.1-2.5-10-50-25

0-1000V

DC ±5V/±25V ±5% FSD.(滿刻度)

0-10-50-250V-100

0V

0-0.05-2.5-25-250

mA, 10A

X1:0.2~2KΩ

(中值:20Ω)

X10:2~20KΩ

(中值:200Ω)

X100:20~200KΩ

(中值:2000Ω)

X1K:200~2MΩ

(中值:20KΩ)

X10K:2K~20MΩ

(中值:200KΩ)

C:2,000uF 最大值 參考值 使用 Rx1K 檔

±3%FSD(滿刻度)

±4%FSD(1000V

檔)

±4%FSD(滿刻度)

±5%FSD(1000V

檔)

頻率範圍:

40~10KHz

±3%FSD(滿刻度)

±4%FSD(10A 檔 )

±4%ofARC(弧長)

Capacitance

電池測量

BATT Check

0~1.5V:GOOD

-?-BAD

0~9V:GOOD-?-BA

D

參考值

三極管檢測 hFE: 0-1000 參考值 使用 Ω×10 檔

LED,

Diode Check

參考值 使用 Ω×10 檔

輸入阻抗:20KΩ/V

超載:Max 1000V

但在 0.1V/2.5V/10V 各

檔,250V Max.

輸入阻抗:40KΩ/V;

超載:Max.250V

輸入阻抗:9KΩ/V

超載:Max.1000V

但 10V/50V 檔,250V Max.

壓降:250mV

超載保護:0.5A/250V

保險絲管;在 10A 檔,超

載保護:F10A/250V, 大電

流測試時間最多 15 秒。

超載:最高 AC/DC250V,

最低 DC/AC50V

超載最大測試時間 5 秒。

負載電流:270mA(1.5V 電

池), 25mA(9V 電池)

超載:最高 AC/DV250V,

最低 DC/AC 50V,

超載最大測試時間 5 秒。

15

Page 17

Continuity

Check

內部電源

200 歐姆左右以

內,蜂鳴器會響。

1.5V5 號電池:2

節,

6F22.9V 矩形電

池:1 節

超載:最 高 AC/DC 250V,

最低 DC/AC 50V 超載最

大測試時間 5 秒。

指針防誤測斜立型三用電錶指針閱讀參考表

測試

Te st

電阻(歐姆)

Resistance(Ω)

直流電壓

(伏特)

DC Volt(V)

正負直流電壓(伏特)

Null DC Volt(V)

直流電流

(安培)

DC Current(A)

交流電壓

(伏特)

AC Volt(V)

hFE Ω×10 IC/IB ×1

量程檔位

Range Position

×1

×10

×100

×1K

×10K

DC 0.1V

2.5V

10V

50V

250V

1000V

DC ±5V

±25V

DC 50μA

2.5mA

25mA

250mA

10A

AC 10V

50V

250V

1000V

指標刻度讀數

Scale to read

Ω ×1

10

250

10

50

250

10

-5-0-+5

-25-0-+25

50

250

250

250

10

10V

50

250

10

倍數

Multiplied

×10

×100

×1000

×10000

×0.01

×0.01

×1

×1

×1

×100

×1

×1

×1

×0.01

×0.1

×1

×1

×1

×1

×1

×100

16

Page 18

二極體 Diode

Ω×10K

×1K

×100

×10

×1

μA×1

μA×10

μA×100

mA×1

mA×10

測量注意事項:

1. 指針調零

調整零位調整器,使指針和左側的零位對齊,不必每次測量前都

調,但是在開始測量之前,指標都必須確認指標在零位上。

2. 測試棒的連接

紅色棒插“+”插孔,黑色棒插入“-COM”插孔。

3. 電錶內部電池檢查

將表棒按以上規定方式接入好,再將檔位旋鈕轉到 Rx10 檔位。

然後,將表棒的兩端短路連接。這時,檢查指針是否正常回歸零

位。若不能,則電池電力不足,應要更換新電池。

4. 量程的選擇

選擇測量檔位時,旋鈕上的“三角形”記號對準規定的適當量程。

測量工作程式:

1. 直流電壓:

用於測量電池、放大器電路、通訊設備電源、電子管和電晶體電

路偏 壓的直流電壓。6 個檔位元中的每一個檔位元標記,分別表

示該檔的最大電壓示值。

(※不確定之直流電壓,應從最大值依序向下調整量測)

2. 中值零位正負直流電壓:(不可測量任何交流電壓!)

本功能專用檢測電子電路的正負電平。通過表棒接入電路,可直

接查看刻度讀數。

注意:在此檔位時,可用歐姆電調零將指針設置在中間位置。若

無法調到中值零位,則有可能是 9V 電池電量不足。請檢查

電池。

3. 交流電壓:

用於測量商業交流電壓、交流電源電路、交流放大信號級等。4 個

檔位元中的每一個檔位元標記,分別表示該檔的最大電壓示值.(※

不確定之交流電壓,應從最大值依序向下調整量測)

17

Page 19

4. 直流電流:(不可測量任何交流電流或電壓!)

用於測量直流電源控制裝置的電流消耗、電晶體電路的工作電流

等。5 個檔位元中的每一個檔位元標記,分別表示該檔的最大電流

示值。

(※不確定之直流電流,應從最大值依序向下調整量測)

注意:當在 10A 檔測試大電流時,單次測試時間不能超過 15 秒。

而且兩次測試間隔時間不少於 5 分鐘。

本機具有防誤測保護電路。可短時(5 秒內)承受低於 AC/DC 250V

的電壓衝擊,僅爆保險絲。

5. 電阻:(※此功能不能測試帶電壓電路)

測量電阻值和測試線路和線路間的連通性。5 個檔中的每一個檔

位元標記,分別表示該檔乘數。(K 即 X1000)

注意:本機在電阻檔具有防誤測保護電路。可短時(5 秒內)承

受低於 AC/DC 250V 的電壓衝擊,僅爆保險絲。

6. 連通性測試(Buzz) (※此功能不能測試帶電壓電路)

將量程選擇旋鈕置於 Buzz 檔, 當被測電路<200ohm, 蜂鳴器鳴叫。

注意:本機在檔位元具有防誤測保護電路。可短時(5 秒內)承

受低於 AC/DC 250V 的電壓衝擊,僅爆保險絲。

7. 電池測試:(※電池能用於小的晶體管收音機,但不能用作裝的電

源。)

好電池:指針停留在綠色(GOOD)範 圍 內。電 量 不 足:指 針 停 在 “?”

尚可使用範圍內。

壞電池:指標

注意:本機在檔位元具有防誤測保護電路。可短時(5 秒內)承

8. dB 測試:

本機測量 dB 值時,要接入表棒並串接一個 0.047μF/400V 電解電

容,然後檢視電錶讀數。

測量在 10V 檔上進行,可直接讀取 dB 刻度(-10dB~+22dB)。

測量在 50V 檔上進行時,刻度讀值要加 14dB,才是實際 dB 值。

測量在 250V 檔上進行時,刻度讀值要加 28dB。

測量在 1000V 檔上進行時,刻度讀值要加 40dB。

停在紅色(BAD)區域。

受低於 AC/DC 250V 的電壓衝擊,僅爆保險絲。

18

Page 20

例如,在 1000V 檔上最大可測 dB 值是 22+40=62dB。

9. hFE(直流放大倍數)和發光二極體(LED)測試:

將量程選擇旋鈕置於“OHM”檔上之 X10 檔

hFE 測試:

(1) 調節 0 Ω 調整器使指針和零位對齊-將電晶體的三個管腳直接

插入面板上的 hFE 端座。

(※注意區分電晶體的類別“PNP”和“NPN”)

(2) 在 hFE 刻度讀出顯示值,所讀之值是 IC/IB,即被測體的直流

放大倍數。

LED 測試:

(1) 將 LED 的兩個腳按正負極性直接插入面板上的 LED 的“+”,“-”

兩個端座。

(2) 檢查 LED 是否正常發光。

10. 二極體測試:

(1) 將量程選擇旋鈕置於“Ω”檔上有選擇的量程位置,X10K 用於

0~60μ A 測試,X1K 用於 0~150μ A,X100 用於 0~1.5m A,

X10 於 0~15mA,X1 用於 0~150mA 測試。

(2)

將電錶與二極體連接測 IF(正向電流),將電錶的“COM”端與

二極體陽極相連,“+”端與二極體陰極相連,對於 IR(反向電

流)測試連接方法和 IF 相反。

(3) 在 LI 刻度線讀出 IF 或 IR

(4) 在測試 IF 或 IR 同時在 LV 刻度上,讀出二極體正向(反向)電壓。

11. 電容測試:

注意:檢測前,須將電容放電並將電錶調零。(※此功能不能測

試帶電壓電路)

a.將電錶量程選擇旋鈕置於“Ωx1k”檔。

b.用表棒連接電容,並注意“+”,“-”極性。

c.觀察指標偏轉最大時,電錶刻度板上紅色 C 刻度。

19

Page 21

常見問題故障及處理

若用戶在使用中,發現本機出現一些普通常見問題故障,可參照下表

自行進行分析處理:

問題和故障 原因和處置

指針無反應,不動 表棒是否接觸良好? 內部保險管是否

燒斷?

內部電池是否正確裝好,並接觸到位?

(參閱有關電池和保險管更換說明)

指針指示異常 檔位量程是否選擇正確? 交流和直流

模式是否使用正確?

內部電池是否電量不足?(參閱有關電

錶內部電池檢查說明)

指針無法正常歸零位 內部電池是否接觸良好?是否電量不

足?(參閱有關電錶內部電池檢查說明)

內部機芯處的遊絲是否並圈?可試用力

將本機甩動幾下或在手中拍擊幾下後,

看是否恢復正常。

DC10A 檔不能工作 表棒是否接觸良好,正確接入?

內部 10A 保險管是否裝好或燒斷?

(參閱有關保險管更換說明)

日常維修

維修更換電錶內部電池和保險絲管時,必須將表棒從電錶上移調,並

切斷電源。

1). 1.5V 電池更換:(參閱下圖)

打開電錶後面的下部大支撐架,將下部的電池倉後蓋的鎖扣旋轉 90

度,既可將電池倉後蓋連支撐架卸下,然後從電池座中拿出不好的

電池。再將新的同規格電池放入原位,並注意電池的正負極性。然

後,蓋上後蓋並將鎖扣旋轉 90 度而鎖住。

2). 9V 電池更換:(參閱下圖)

打開電錶的上部電池倉後蓋,從電池座中拿出不好的電池。再將新的

20

Page 22

同規格電池放入原位,並注意電池的正負極性,然後,蓋上後蓋並擰

緊螺釘。

3). 保險絲管更換:(參閱下圖)

打開電錶後面的下部大支撐架,將下部的電池倉後蓋的鎖扣旋轉 90

度,既可將電池倉後蓋連支撐架卸下。 即可看到電路板上的兩個並

列保險管(左邊的為 0.5A/250V, 右邊為 10A/250V), 從保險絲座中拿

出不好的保險絲管。再將新保險絲管(0.5A/250V 或 10A/250V,

Φ5*20mm)換上 。必須用同規格 UL 認證的保險絲管。 然後,蓋上

後蓋並將鎖扣旋轉 90 度而鎖住。

(本電錶的下部電池倉的左右兩邊一般各設有 1 個備用保險絲管)。

9V 電池

螺絲孔

1.5V 電池蓋鎖扣

1.5V 電池倉和保險管位置

位置

21

Page 23

MT-2017 指针型防误测三用电表

操作使用说明书

特点:

本机是指针式,防误测全保护,斜立型三用电表(附晶体 LED 座,短

路蜂鸣及 10A 档,及镀金表笔)。具有以下基本特点和参数如下:

- 斜立型,两个可调后盖支撑架。上部支架可拉出后,向上转动 90 度,

压下可固定; 并附带挂钩设计(支撑架向上转动 180 度伸出后盖,

以便悬挂)。下部大支撑架可拉出以更大角度斜立。

- 后盖下部特别设置了 1.5V 电池仓和用锁扣固定的电池盖,以非常

方便用户拆卸和更换电池及保险管。

- 配置玻璃钎维环氧树脂镀金盘双面电路板

- 档位切换簧片采用弹簧宝石轴承及二极管双向限幅电路

- 具有全面的防误测超载保护电路及速断型保险丝多重保护

- 具有紧凑的两侧软性防滑减振保护套

- 可测直流电压和中间零位正负直流电压,直流 电流( 最 大 10A),交

流电压,电阻,晶体管,二极管,LED,电池,短路蜂鸣, 和电容

(2000uF Max.) 等.

- 输入阻抗:DC20Kohm /V,AC 9Kohm/V

- 直流电压:0.1/2.5/10/50/250/1000V 六檔

- 中间零位

- 直流电流:50μA/2.5m/25m/250mA/10A 五檔

- 交流电压:10/50/250/1000V 四檔

- 电 阻:1/10/100/1K/10K 四檔

- 电 池:1.5/9V 二檔

- 电 容:C(RX1K),Max. 2,000 uF;

- 标准环境条件:23C5C, 湿度< 75% RH。

- 工作环境范围:0C ~ 40C, 湿度< 90% RH。

- 储存条件:-10C ~ 50C, 湿度< 80% RH。

- 电表外

- 电表重量:390 克(包括电池)

正负直流电压:±5V/25V 两檔

形尺寸:171(长)x 108(宽)x 37(高)mm

,日系电池,通过CE 认证。

22

Page 24

规格表:

测试功能 檔位 准确度 说明

直流电压

DCV

正负直流电压

Null DCV

交流电压 ACV

直流电流

DCA

电阻 Ω

电 容

0-0.1-2.5-10-50-25

0-1000V

DC ±5V/±25V ±5% FSD.(满刻度)

0-10-50-250V-100

0V

0-0.05-2.5-25-250

mA, 10A

X1:0.2~2KΩ

(中值:20Ω)

X10:2~20KΩ

(中值:200Ω)

X100:20~200KΩ

(中值:2000Ω)

X1K:200~2MΩ

(中值:20KΩ)

X10K:2K~20MΩ

(中值:200KΩ)

C:2,000uF 最大值 参考值 使用 Rx1K 檔

±3%FSD(满刻度)

±4%FSD(1000V

檔)

±4%FSD(满刻度)

±5%FSD(1000V

檔)

频率范围:

40~10KHz

±3%FSD(满刻度)

±4%FSD(10A 檔 )

±4%ofARC(弧长)

Capacitance

电池测量

BATT Check

0~1.5V:GOOD

-?-BAD

0~9V:GOOD-?-BA

D

参考值

三极管检测 hFE: 0-1000 参考值 使用 Ω×10 檔

LED,

Diode Check

参考值 使用 Ω×10 檔

输入阻抗:20KΩ/V

超载:Max 1000V

但在 0.1V/2.5V/10V 各檔,

250V Max.

输入阻抗:40KΩ/V;

超载:Max.250V

输入阻抗:9KΩ/V

超载:Max.1000V

但 10V/50V 檔,250V Max.

压降:250mV

超载保护:0.5A/250V

保险丝管;在 10A 檔,超

载保护:F10A/250V, 大电

流测试时间最多 15 秒。

超载:最高 AC/DC250V,

最低 DC/AC50V

超载最大测试时间 5 秒。

负载电流:270mA(1.5V 电

池), 25mA(9V 电池)

超载:最高 AC/DV250V,

最低 DC/AC 50V,

超载最大测试时间 5 秒。

23

Page 25

Continuity

Check

200 歐姆左右以内,

蜂鸣器会响。

超载:最高 AC/DC 250V,

最低 DC/AC 50V 超载最

大测试时间 5 秒。

内部电源

1.5V5 号电池:2 节,

6F22.9V 矩形电池:

1 节

指针防误测斜立型三用电表指针阅读参考表

测试

Te st

电阻(歐姆)

Resistance(Ω)

直流电压

(伏特)

DC Volt(V)

正负直流电压(伏特)

Null DC Volt(V)

直流电流

(安培)

DC Current(A)

交流电压

(伏特)

AC Volt(V)

hFE Ω×10 IC/IB ×1

量程檔位

Range Position

×1

×10

×100

×1K

×10K

DC 0.1V

2.5V

10V

50V

250V

1000V

DC ±5V

±25V

DC 50μA

2.5mA

25mA

250mA

10A

AC 10V

50V

250V

1000V

指标刻度读数

Scale to read

Ω ×1

10

250

10

50

250

10

-5-0-+5

-25-0-+25

50

250

250

250

10

10V

50

250

10

倍数

Multiplied

×10

×100

×1000

×10000

×0.01

×0.01

×1

×1

×1

×100

×1

×1

×1

×0.01

×0.1

×1

×1

×1

×1

×1

×100

24

Page 26

二极管 Diode

Ω×10K

×1K

×100

×10

×1

μA×1

μA×10

μA×100

mA×1

mA×10

测量注意事项:

1. 指针调零

调整零位调整器,使指针和左侧的零位对齐,不必每次测量前都

调,但是在开始测量之前,指标都必须确认指标在零位上。

2. 测试棒的连接

红色棒插“+”插孔,黑色棒插入“-COM”插孔。

5. 电表内部电池检查

将表棒按以上规定方式接入好,再将档位旋钮转到 Rx10 檔位。

然后,将表棒的两端短路连接。这时,检查指针是否正常回归零

位。若不能,则电池电力不足,应要更换新电池。

6. 量程的选择

选择测量档位时,旋钮上的“三角

形”记号对准规定的适当量程。

测量工作程序:

1. 直流电压:

用于测量电池、放大器电路、通讯设备电源、电子管和晶体管电

路偏 压的直流电压。6 个文件位中的每一个文件位标记,分别表

示该文件的最大电压示值。

(※不确定之直流电压,应从最大值依序向下调整量测)

2. 中值零位正负直流电压:(不可测量任何交流电压!)

本功能专用检测电子电路的正负电平。通过表棒接入电路,可直

接查看刻度读数。

注意:在

此档位时,可用歐姆电调零将指针设置在中间位置。若

无法调到中值零位,则有可能是 9V 电池电量不足。请检查

电池。

3. 交流电压:

用于测量商业交流电压、交流电源电路、交流放大信号级等。4 个

文件位中的每一个文件位标记,分别表示该文件的最大电压示

值.(※不确定之交流电压,应从最大值依序向下调整量测)

25

Page 27

4. 直流电流:(不可测量任何交流电流或电压!)

用于测量直流电源控制装置的电流消耗、晶体管电路的工作电流

等。5 个文件位中的每一个文件位标记,分别表示该文件的最大电

流示值。

※

(

不确定之直流电流,应从最大值依序向下调整量测)

注意:当在 10A 档测试大电流时,单次测试时间不能超过 15 秒。

而且两次测试间隔时间不少于 5 分钟。

本机具有防误测保护电路。可短时(5 秒内)承受低于 AC/DC 250V

的电压冲击,仅爆保险丝。

5. 电阻:(

测量电阻值和测试线路和线路间的连通性。5 个文件中的每一个

注意:本机在电阻文件具有防误测保护电路。可短时(5 秒内)

6. 连通性测试(Buzz) (

将量程选择旋钮置于 Buzz 文件,当被测电路<200ohm, 蜂鸣器鸣叫。

注意:本机在文件位具有防误测保护电路。可短时(5 秒内)承

7. 电池测试:(

好电池:指针停留在绿色(GOOD)范围内。电量不足:指针停在“?”

坏电池:指针停在红色(BAD)区域。

注意:本机在文件位具有防误测保护电路。可短时(5 秒内)承

8. dB 测试:

※此功能不能测试带电压电路)

文件位标记,分别表示该文件乘数。(K 即 X1000)

承受低于 AC/DC 250V 的电压冲击,仅爆保险丝。

※

此功能不能测试带电压电路)

受低于 AC/DC 250V 的电压冲击,仅爆保险丝。

※电池能用于小的晶体管收音机,但不能用作装的电

源。)

尚可使用范围内。

受低于 AC/DC 250V 的电压冲击,仅爆保险丝。

本机测量 dB 值时,要接入表棒并串接一个 0.047μF/400V 电解电

容,然后检视电表读数。

测量在 10V 档上进行,

测量在 50V 档上进行时,刻度读值要加 14dB,才是实际 dB 值。

测量在 250V 档上进行时,刻度读值要加 28dB。

测量在 1000V 档上进行时,刻度读值要加 40dB。

可直接读取 dB 刻度(-10dB~+22dB)。

26

Page 28

例如,在 1000V 档上最大可测 dB 值是 22+40=62dB。

9. hFE(直流放大倍数)和发光二极管(LED)测试:

将量程选择旋钮置于“OHM”檔上之 X10 檔

hFE 测试:

(3) 调节 0 Ω 调整器使指针和零位对齐-将晶体管的三个管脚直接

插入面板上的 hFE 端座。

(

※注意区分晶体管的类别“PNP”和“NPN”)

(4) 在 hFE 刻度读出显示值,所读之值是 IC/IB,即 被 测体的直流

放大倍数。

LED 测试:

(3) 将 LED 的两个脚按正负极性直接插入面板上的 LED 的“+”,“-”

两个端座。

(4) 检查 LED 是否正常发光。

10. 二极管测试:

(5) 将量程选择旋钮置于“Ω”档上有选择的量程位置,X10K 用于

0~60μ A 测试,X1K 用于 0~150μ A,X100 用于 0~1.5m A,

X10 于 0~15mA,X1 用于 0~150mA 测试。

(6) 将电表与二极管连接测 IF(正向电流),将电表的“COM”端与

二极管阳极相连,“+”端与二极管阴极相连,对于 IR(反向电

流)测试连接方法

(7) 在 LI 刻度线读出 IF 或 IR

(8) 在测试 IF 或IR 同时在 LV 刻度上,读出二极管正向(反向)电压。

11. 电容测试:

注意:检测前,须将电容放电并将电表调零。(

试带电压电路)

a.将电表量程选择旋钮置于“Ωx1k”檔。

b.用表棒连接电容,并注意“+”,“-”极性。

c.观察指标偏转最大时,电表刻度板上红色 C 刻度。

和 IF 相反。

※此功能不能测

27

Page 29

常见问题故障及处理

若用户在使用中,发现本机出现一些普通常见问题故障,可参照下表

自行进行分析处理:

问题和故障 原因和处置

指针无反应,不动 表棒是否接触良好? 内部保险管是否

烧断?

内部电池是否正确装好,并接触到位?

(参阅有关电池和保险管更换说明)

指针指示异常 档位量程是否选择正确? 交流和直流

模式是否使用正确?

内部电池是否电量不足?(参阅有关电

表内部电池检查说明)

指针无法正常归零位内部电池是否接触良好?是否电量不

足?(参阅有关电表内部电池检查说明)

内部机芯处的游丝是否并圈?可试用力

将本机甩动几下或在手中拍击几下后,

看是否恢复正常。

DC10A 檔不能工作 表棒是否接触良好,正确接入?

内部 10A 保险管是否装好或烧断?

(参阅有关保险管更换说明)

日常维修

维修更换电表内部电池和保险丝管时,必 须将表棒从电表上移调,并

切断电源。

1). 1.5V 电池更换:(参阅下图)

打开电表后面的下部大支撑架,将下部的电池仓后盖的锁扣旋转 90

度,既可将电池仓后盖连支撑架卸下,然后从电池座中拿出不好的

电池。再将新的同规格电池放入原位,并注意电池的正负极性。然

后,盖上后盖并将锁扣旋转 90 度而锁住。

2). 9V 电池更换:(参阅下图)

打开电表的上部电池仓后盖,从电池座中拿出不好的电池。再将新的

28

Page 30

同规格电池放入原位,并注意电池的正负极性,然后,盖上后盖并拧

紧螺钉。

3). 保险丝管更换:(参阅下图)

打开电表后面的下部大支撑架,将下部的电池仓后盖的锁扣旋转 90

度,既可将电池仓后盖连支撑架卸下。 即可看到电路板上的两个并

列保险管(左边的为 0.5A/250V, 右边为 10A/250V), 从保险丝座中拿

出不好的保险丝管。再将新保险丝管(0.5A/250V 或 10A/250V,

Φ5*20mm)换上。必须用同规格 UL 认证的保险丝管。 然后,盖上

后盖并将锁扣旋转 90 度而锁住。

(本电表的下部电池仓的左右两边一般各设有 1 个备用保险丝管)。

9V 电池

螺丝孔

位置

1.5V 电池盖锁扣

1.5V 电池仓和保险管位置

29

Page 31

购买日期

公司名称

联络电话

电子邮箱

联络地址

产品型号 □ MT-2017-C

中国地区产品保固卡

店章

※ 在正常使

耗材、消耗品)。

※ 产品保固卡需盖上店章、日期章,其保固效力始生效。

※ 本卡请妥善保存,如需维修服务时,请出示本卡以为证明。

※ 保固期满后,属调整、保养或是维修性质之服务,则酌收检修工

时费用。若有零件需更换,则零件费另计。

产品保固说明

保固期限内,如有下列情况者,维修中心则得酌收材料成本或修

理费(由本公司维修人员判定):

• 对产品表面的损伤,包括外壳裂缝或刮痕

• 因误

• 因事故、火灾、电力变化、其他危害,或自然灾难所造成的

非服务保证内容:

• 机件本体外之消耗品:如电池...等消耗品

• 机件本体之外之附配件:如耳机麦克风,电源供应器,记忆

三.超过保证期限之检修或服务,虽未更换零件,将依公司保固维

修政策酌收服务费。

服务电话: 0755 83692415 / 83692986 /83246594 / 83247554

服务传真: 0755 83692143

用情况下,自原购买日起 12 个月免费维修保证(不含

用、疏忽、不当

修改产品或者任何其他超出预期使用范围的原因所造成的

损害

损害。

卡,CD 等附配件。

安装或测试,未经授权打开产品修理,

30

Page 32

寶工實業股份有限公司

PROKIT’S INDUSTRIES CO., LTD

©2015 Prokit’s Industries Co., LTD. All rights re

2015001(C)

99 Washington Street Melrose, MA 02176

Phone

781-665-1400 Toll Free 1-800-517-8431

31

served

Loading...

Loading...