Page 1

ECLIPSE

EC-11-xxx40

Advanced Line Scan Cameras

Camera User’s Manual

03-32-00418

rev 05

Printed 4/20/2005 9:26:00 AM

Page 2

2 EC-11User’s Manual

© 2005 DALSA. All information provided in this manual is believed to be accurate and reliable. No

responsibility is assumed by DALSA for its use. DALSA reserves the right to make changes to this

information without notice. Reproduction of this manual in whole or in part, by any means, is prohibited

without prior permission having been obtained from DALSA.

About DALSA

DALSA is an international high performance semiconductor and electronics company that designs,

develops, manufactures, and markets digital imaging products and solutions, in addition to providing

wafer foundry services. DALSA’s core competencies are in specialized integrated circuit and electronics

technology, and highly engineered semiconductor wafer processing. Products include image sensor

components; electronic digital cameras; and semiconductor wafer foundry services for use in MEMS,

power semiconductors, image sensors and mixed signal CMOS chips.

DALSA is a public company listed on the Toronto Stock Exchange under the symbol “DSA”. Based in

Waterloo, ON. Canada, the company has operations in Bromont, PQ; Colorado Springs, CO; Eindhoven,

NL; Munich, Germany and Tokyo, Japan.

All DALSA products are manufactured using the latest state-of-the-art equipment to ensure product

reliability.

For further information not included in this manual, or for information on DALSA’s extensive line of

image sensing products, please call:

DALSA Sales Offices

Waterloo Europe Asia Pacific

605 McMurray Rd

Waterloo, ON N2V 2E9

Canada

Tel: 519 886 6000

Fax: 519 886 8023

www.dalsa.com

sales.americas@dalsa.com

Breslauer Str. 34

D-82194 Gröbenzell (Munich)

Germany

Tel: +49 - 8142 – 46770

Fax: +49 - 8142 – 467746

www.dalsa.com

sales.europe@dalsa.com

Space G1 Building, 4F

2-40-2 Ikebukuro

Toshima-ku, Tokyo 171-0014

Japan

+81 3 5960 6353 (phone)

+81 3 5960 6354 (fax)

www.dalsa.com

sales.asia@dalsa.com

DALSA Worldwide Operations

Waterloo Colorado Springs Europe Asia Pacific

605 McMurray Rd

Waterloo, ON N2V 2E9

Canada

Tel: 519 886 6000

Fax: 519 886 8023

www.dalsa.com

sales.americas@dalsa.com

Camera Link is a trademark registered by the Automated Imaging Association, as chair of a committee of

industry members including DALSA.

4820 Centennial Blvd., Suite 115

Colorado Springs, CO 80919

USA

Tel: 719 599 7700

Fax: 719 599 7775

www.dalsa.com

sales.americas@dalsa.com

Breslauer Str. 34

D-82194 Gröbenzell (Munich)

Germany

Tel: +49 - 8142 – 46770

Fax: +49 - 8142 – 467746

www.dalsa.com

sales.europe@dalsa.com

Space G1 Building, 4F

2-40-2 Ikebukuro

Toshima-ku, Tokyo 171-0014

Japan

+81 3 5960 6353 (phone)

+81 3 5960 6354 (fax)

www.dalsa.com

sales.asia@dalsa.com

03-32-00418-05 DALSA Corp.

Page 3

EC-11 User’s Manual 3

Contents

Introduction___________________________________________________________ 5

1.1 Camera Highlights.......................................................................................................................................................5

1.2 Image Sensors .............................................................................................................................................................6

1.3 Camera Performance Specifications ............................................................................................................................7

1.4 CCD Camera Primer.....................................................................................................................................................9

Camera Hardware Interface________________________________________________ 11

2.1 Installation Overview...................................................................................................................................................11

2.1 Input/Output................................................................................................................................................................12

2.3 Connectors, Pinouts, and Cables..................................................................................................................................12

2.4 Power Supplies............................................................................................................................................................13

2.5 Control Inputs..............................................................................................................................................................13

2.6 Data Bus ......................................................................................................................................................................14

2.7 Timing .........................................................................................................................................................................15

2.8 Multi-Camera Operation .............................................................................................................................................16

2.9 Serial Interface ............................................................................................................................................................17

Optical and Mechanical Considerations ________________________________________ 19

3.1 Mechanical Interface....................................................................................................................................................19

3.2 Optical Interface ..........................................................................................................................................................22

Troubleshooting________________________________________________________ 25

4.1 Common Solutions.......................................................................................................................................................25

4.2 Troubleshooting Using the Serial Interface.................................................................................................................26

4.3 Specific Solutions.........................................................................................................................................................27

4.4 Product Support...........................................................................................................................................................30

EMC Declaration of Conformity______________________________________________ 35

Software Interface: How to Control the Camera __________________________________ 37

C1 Overview.......................................................................................................................................................................37

C2 Processing Chain...........................................................................................................................................................37

C3 Startup..........................................................................................................................................................................38

C4 Saving and Restoring Settings......................................................................................................................................38

C5 Setting Direction...........................................................................................................................................................39

C6 Setting Line Rate (EXSYNC)..........................................................................................................................................39

C7 Setting Data Rate (EXRCLK).........................................................................................................................................40

DALSA Corp. 03-32-00418-05

Page 4

4 EC-11User’s Manual

C8 Setting Gains ................................................................................................................................................................40

C9 Calibrating the Camera: Overview...............................................................................................................................41

C10 Increasing Sensitivity with Binning.............................................................................................................................44

C11 Generating Test Patterns............................................................................................................................................44

C12 Returning Video Information .....................................................................................................................................44

C13 Monitoring the Camera ..............................................................................................................................................45

C14 Rebooting the Camera................................................................................................................................................45

C15 Setting the Pre-trigger ...............................................................................................................................................45

C16 Setting and Reading FPN Coefficients........................................................................................................................45

C17 Setting and Reading PRNU Coefficients.....................................................................................................................46

Communications Protocol _________________________________________________ 47

D1 Protocol Overview ........................................................................................................................................................47

D2 Protocol Features.........................................................................................................................................................47

D3 Command Format........................................................................................................................................................47

D4 Networking Mode.........................................................................................................................................................48

D5 Examples......................................................................................................................................................................48

D6 Error Handling.............................................................................................................................................................48

D7 Commands ...................................................................................................................................................................49

Revision History ________________________________________________________ 53

Index _______________________________________________________________ 55

03-32-00418-05 DALSA Corp.

Page 5

EC-11 User’s Manual 5

1

Introduction

1.1 Camera Highlights

Responsivity

• 1950 DN/(nJ/cm

• 100x more responsive than standard line scan cameras

• Ideal for applications with low-intensity, low-cost lighting

2

) nominal responsivity

Size

• Small form factor: 50mm x 50mm x 88mm, <350g

• C-mount optics for 512 & 1024; F-mount for 2048

Performance

• 40MHz single output data rate

• 8-bit output from 10-bit digitization

• 512, 1024 and 2048 pixels, 13µm x 13µm, 100% fill factor

• Line rates up to 64kHz

• 96 TDI stages

• Bidirectional

• RS-644 (LVDS) data format

Programmability

• Simple ASCII protocol controls binning, gain, offset, line and data rates, trigger mode,

direction, pixel correction, test pattern output, and camera diagnostics.

• RS-232 interface (ASCII, 9600 baud)

Usability

• Programmable gains, offsets, and camera controls

DALSA Corp. 03-32-00418-05

Page 6

6 EC-11User’s Manual

• End-of-line sequence and test pattern output for debugging

• Single input supply (+12V to +15V)

• Compliant with CE and MIL-STD-810E (shock and vibration)

• Multiple camera synchronization

The EC-11 cameras use DALSA’s newest compact modular architecture. Within the

camera, driver circuits provide bias voltages and clocks to the CCD image sensor, timing

circuits generate internal timing, and A/D circuits process the video and digitize it for

output.

Description

The EC-11 is an incredibly responsive—100 times greater responsivity than standard line

scan cameras, fast—up to 64.1kHz, easy-to-use—programmable pixel-to-pixel correction,

line rate, gain and more, and compact—50mm x 50mm x 88mm, <350g., advanced line

scan camera.

With unmatched sensitivity, performance, size, and an unprecedented array of

programmable diagnostic and signal processing features, the EC-11-xxx40 is a truly

remarkable camera.

The camera’s simple ASCII communications protocol allows you to configure and

program virtually all camera functions through an RS232 serial interface.

To speed setup and system debugging, the camera can output a test pattern and end-ofline sequence to help track the path of data through an acquisition system.

Applications

The EC-11 is ideal for space-constrained applications demanding low-light or costeffective lighting.

1.2 Image Sensors

The EC-11-xxx40 uses the IT-F7 family of image sensors, and is available in 512, 1024 and

2048 pixel models with 13µm square pixels and 100% fill factor.

03-32-00418-05 DALSA Corp.

Page 7

EC-11 User’s Manual 7

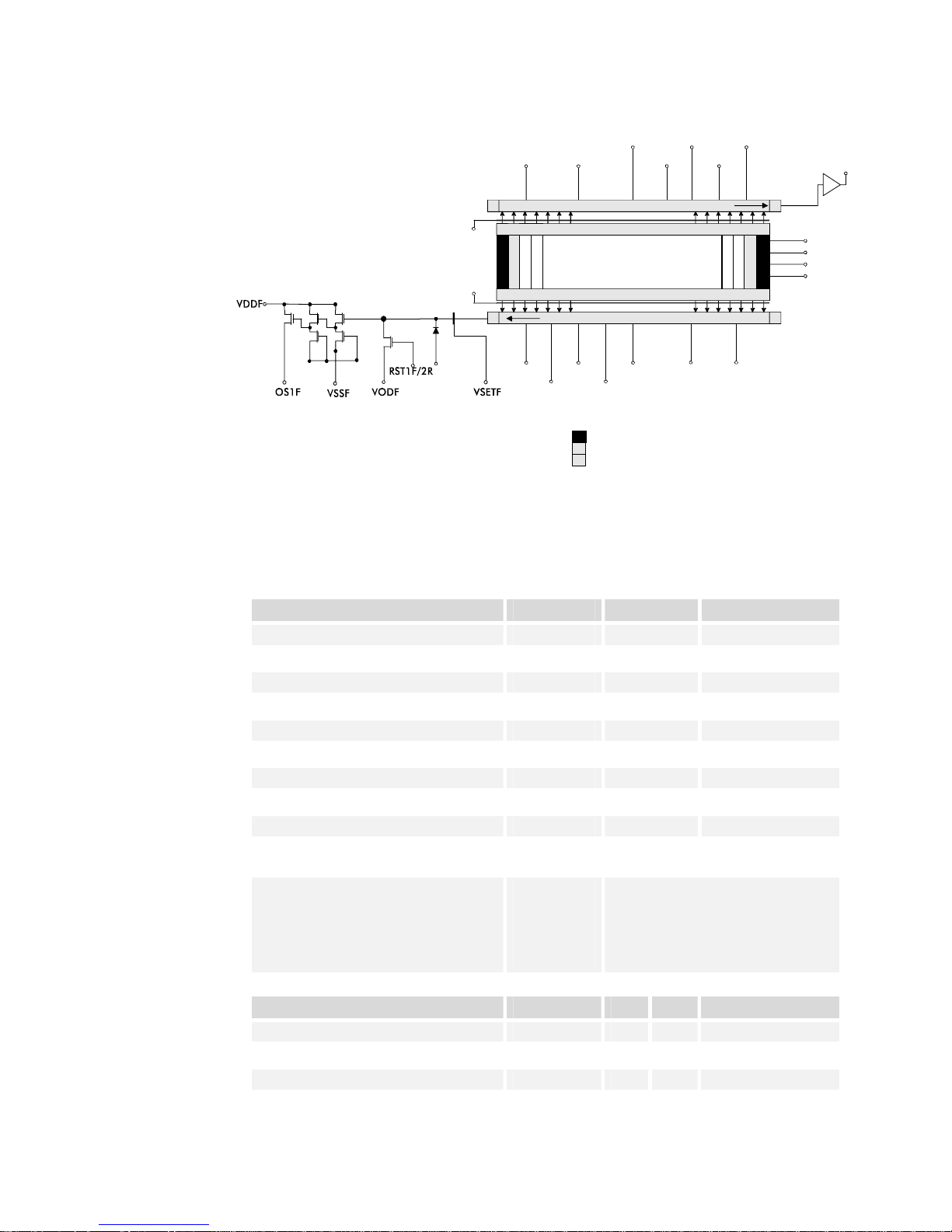

Figure 1: IT-F7 Image Sensor

CR1S-1R

CR1B-1R

CR2B-2F

VBB

TCKR

TCKF

CR2B-2R

I

4 S

I

4 I

TDI Col. 1

TDI Col. 2

CR2S-1F

CR2B-1F

CR1B-2R

CR1S-1F

4S 4 Light Shielded Columns (Dark Reference)

4 I

CRLast-R

Reverse CCD Readout Shift Register

1.25 Isolation Rows

TDI Imaging Regio n

13µm x 13µm Pixels

96 TDI Rows

1.5 Isolation Rows

Forwar d CCD Readou t Shift Re gister

CRLast-F

CR1B-1F

4 Isolation Columns (2.5 light shielded +1.5 non-shielded)

9 Dummy Pixels & 1 White Reference

I

N = 512, 1024 or 2048

1.3 Camera Performance Specifications

CR2B-1R

TDI C ol. N-1

CR1B-2F

CR2S-1R

4 I

TDI Col. N

OS1R

I

CI1

CI2

CI3

4 S

CI4

I

Table 1: EC-11-xxx40 Performance Specifications

Physical Characteristics Units Notes

Power Dissipation W Typ

512 5

1024 5.2

2048 5.4

Time to calibrate sec. Typ

512 10

1024 17

2048 30

Time to power up, typ sec. >10

Forward/Reverse Switching Time,

ms 150

typ

Sensor Alignment x, y

z-axis

Θz

Parallelism/Tilt

mm

mm

mm

“

µm

±0.18

17.52 ±0.18 C-mount

46.50 ±0.18 F-mount

±0.6

<100

Operating Ranges Units Min Max Notes

Data Rate MHz 10 40 3

Line Rate 512 kHz 3.5 64.1

1024 kHz 3.5 34.8

2048 kHz 3.5 17.4

DALSA Corp. 03-32-00418-05

Page 8

8 EC-11User’s Manual

Operating Ranges Units Min Max Notes

Temperature °C 0 50

Temperature drift before

recalibration, recommendation

RS232 Data Rate kbps 9.6

Photoresponse Variation across field

of view (combining light source

variation and lens vignetting)

°C 10

(onl

y)

DN 128

(7

bits)

2

Electro-Optic Specifications Units Min Typ Max Notes

Average Broadband Responsivity,

typ

Dynamic Range Ratio 1

Minimum Gain 272:1 500:1

0dB Gain 174:1 350:1

Maximum Gain 63:1 120:1

Pk-Pk Noise, max DN 4 8 24 1

RMS Noise, max DN 0.9 1.4 3.8 1

FPN uncorrected, max DN 6 15 46 1

FPN corrected, max DN 2 4 10 1,4

PRNU uncorrected, max DN 14 23 54 1

PRNU corrected, max DN 4 6 12 1,4

DC Offset, max DN 3 5 7 1,5

Power Supply Current - Vin @ 12V mA 1

512 420 480

1024 430 500

2048 450 540

DN/(nJ/cm

)

2

730 1950 5850

Notes:

DN = Digital Numbers (0-255); also known as gray levels.

1. Min, Typ, and Max are maximum values at the minimum, 0dB, and maximum gain

levels. Tungsten halogen light source, 3200K bulb temp., and 750nm cutoff filter.

2. This specification represents the amount of variance across the field of view that the

camera can compensate for with its FPN and PRNU correction algorithms.

3. Internal clock: Camera is selectable between 40, 20 and 10MHz data rates. External

clock (EXRCLK): Range between 10-40MHz.

4. This is the value the specification can meet when the camera is calibrated and

remains at the calibrated temperature. It is recommended that after a >10°C

temperature change the camera is re-calibrated because DC Offset, FPN and PRNU

vary with temperature.

03-32-00418-05 DALSA Corp.

Page 9

EC-11 User’s Manual 9

5. DC Offset needs to be set at calibrated gain setting. Digital gain correction may be

required to achieve maximum values.

Figure 2: EC-11 Spectral Responsivity

EC-11 Typical Spectral Responsivity

2500

2000

1500

1000

Responsivity DN/(nJ/cm²)

500

0

450 550 650 750 850 950 1050

Wavelength (nm)

1.4 CCD Camera Primer

How CCD Image Sensors Work

A CCD image sensor converts photons (light) into electrons (charge). When photons hit

an image sensor, the sensor accumulates electrons. This is called charge integration. The

brighter your light source, the more photons available for the sensor to integrate, and the

smaller the amount of time required to collect a given amount of light energy.

The way photosensitive

elements (pixels) on CCD

image sensors collect

charge has often been

compared to wells or

buckets filling with

water. From this analogy

comes the term "full-well

capacity," meaning the

maximum charge (number of electrons) a pixel well can hold without "spilling" charge

onto adjacent pixels.

As an image sweeps over a line of pixels, the pixels collect charge. At certain intervals, the

sensor transfers its collected charge to one or more readout registers, which feed each

pixel’s charge from the image sensor into an output node that converts the charges into

voltages.

DALSA Corp. 03-32-00418-05

Page 10

10 EC-11User’s Manual

After this transfer

and conversion, the

voltages are

amplified to become

the camera’s analog

output. In digital

output cameras, the

camera’s analog-todigital (A/D) board

converts voltages to

digital numbers (0255 for 8-bit

cameras, 0-4095 for

12-bit cameras). These digital numbers are what the camera outputs as data to a frame

grabber.

For more information on terms and concepts from the digital imaging industry, see DALSA’s

current Databook Glossary, CCD Technology Primer, and Application Notes.

03-32-00418-05 DALSA Corp.

Page 11

EC-11 User’s Manual 11

2

Camera Hardware

Interface

2.1 Installation Overview

In order to set up your camera, you should take these steps:

1. Data

2. STROBE

3. LVAL

4. R232 port

5. Power connect

You must also set up the other components of your system, including light sources, frame

grabbers, camera mounts, heat sinks, host computers, optics, encoders, and so on.

8 BIT Data

STRO BE

EXSYNC (optional)

EXRCLK (optional)

FORWARD (optional)

RS232 Serial

+12V to +15V and Ground

DALSA Corp. 03-32-00418-05

Page 12

12 EC-11User’s Manual

2.1 Input/Output

!

WARNING: It is extremely important that you apply the appropriate voltages to your camera. Incorrect

voltages will damage the camera. See section 2.4 for more details.

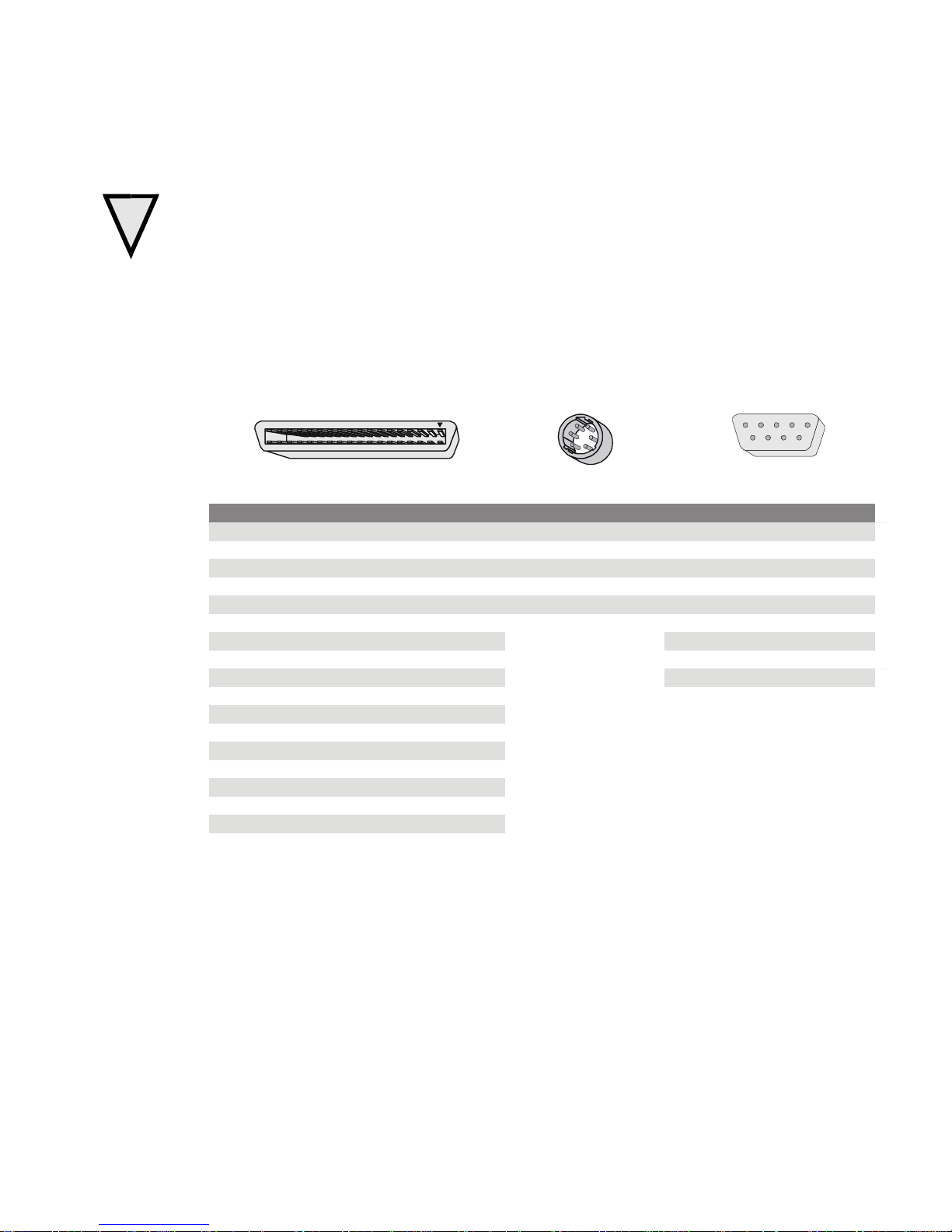

2.3 Connectors, Pinouts, and Cables

The camera uses a high-density 36-pin MDR36 connector for control, and data signals, a

6-pin Hirose connector for power, and a DB9 connector for serial communications.

18

36

Mating Part

Cable:

Pin Description Pin Description Pin Description Pin Description

1 N/U 19 N/U 1 +12V to +15V 1 Data Carrier Detect, N/U

2 N/U 20 N/U 2 +12V to +15V 2

3 Future Use 21 Future Use 3 +12V to +15V 3

Future Use 22 Future Use 4 GND 4 D ata Term in al R eady, N /U

4

5 EXRCLK 23 EXRCLKB 5 GND 5 GND

6 FORWARD 24 FORWAR D B 6 GND 6 Data Set Ready, N /U

7 EXSYNC 25 EXSYNCB 7 Ready To Send, N/U

Future Use 26 Future Use 8 Clear To Send, N/U

8

9 D7 27 D7B 9 Ring Indicator, N/U

10 D6 28 D6B

11 D5 29 D5B

D4 30 D4B

12

13 D3 31 D3B

14 D2 32 D2B

15 D1 33 D1B

D0 34 D0B

16

17 STROBE 35 STROBEB

18 LVAL 36 LVALB

MDR36 Female

: 3M 10136-6000EC series

26AWG 100 W shielded twisted pair

1

19

Hirose 6-pin Circular Male

1

2

3

Mating Part: HIROSE

HR10A-7P-6S

6

5

4

DB9 Female

9

"straight-through"

9-pin serial cable

Tra n sm i t t e d D ata

Received D ata

15

6

03-32-00418-05 DALSA Corp.

Page 13

EC-11 User’s Manual 13

2.4 Power Supplies

The camera requires a single input (+12V to +15V). The camera meets all performance

specifications using standard switching power supplies, although well-regulated linear

supplies provide optimum performance. See the Performance Specifications for current

requirements.

When setting up the camera’s power supplies follow these guidelines:

• Protect the camera with a fast-blow fuse between power supply and camera.

• Do not use the shield on a multi-conductor cable for ground.

• Keep leads as short as possible to reduce voltage drop.

See section 1.3 for power requirements.

WARNING: It is extremely important that you apply the appropriate voltages to your

!

camera. Incorrect voltages will damage the camera. Protect the camera with a fast-blow

fuse between power supply and camera.

The companies listed below make power supplies that meet the camera’s requirements,

but they should not be considered the only choices. Many high quality supplies are

available from other vendors. DALSA assumes no responsibility for the use of these

supplies.

• Uniforce, 408-946-3864 (CA, USA) • Power-One, 805-987-8741 (CA, USA)

• Vision 1, 406-585-7225 (MT, USA) • Tectrol Inc., 416-630-4026 (ON, CAN)

• Xantrex, 206-671-2966 (WA, USA)

2.5 Control Inputs

The camera accepts control inputs through an MDR36F connector. All inputs are

optional. The camera ships in default, logic HIGH. The camera defaults (no external

input required) to maximum data rate, forward direction, maximum line rate, and

internal sync to trigger readout. Line rate can be set internally using the RS232 interface.

External control signals, EXSYNC, EXRCLK, and FORWARD, are optional and enabled

through the RS232 interface.

Control signals use EIA-644 (LVDS) format, which requires twisted pair cable. DALSA

recommends shielded cables. Maximum cable length depends on environmental factors

and EIA-644 limitations. See Appendix A. Control signals are differential, requiring

complements denoted with a “B” suffix (e.g. BIN, BINB).

DALSA Corp. 03-32-00418-05

Page 14

14 EC-11User’s Manual

EXRCLK

EXRCLK is an optional input signal used to control readout timing. EXRCLK is applied to

the read portion of a FIFO and directly drives STROBE and LVAL. EXRCLK is required

for multisync operations.

EXSYNC (Triggers Line Readout)

EXSYNC is an optional input signal that can be used to trigger the line readout rate. This

camera uses the falling edge of EXSYNC to trigger line readout.

IMPORTANT:

This camera uses the

falling edge of EXSYNC

to trigger line readout,

unlike previous DALSA

cameras, which used the

rising edge.

Note: EXSYNC must not be clocked faster than the camera’s specified maximum line rate.

Notes on Free Run Mode

When the camera is powered on for the first time, it defaults (no external input required)

to free run mode (maximum data rate, forward direction, maximum line rate, and internal

Sync to trigger readout). Subsequently it will load user settings.

FORWARD

FORWARD is an optional input signal supporting bidirectional camera functionality.

“Logic high” for forward direction. “Logic low” for reverse. Eclipse defaults to “logic

high”, forward.

2.6 Data Bus

See section 2.3 for

pinouts.

These signals indicate when data is valid, allowing you to clock the data from the camera

to your acquisition system:

Clocking Signal Indicates

LVAL (high) Outputting valid line

STROBE (rising edge) Valid data

IMPORTANT: This camera’s data should be sampled on the rising edge of STROBE.

Digital Data

The camera digitizes to 10-bit ADCs and outputs the most significant 8 bits in LVDS

format. To clock digital data into a frame grabber, the camera outputs clocking signals

STROBE and LVAL.

The camera digitizes internally to 10 bits and outputs the most significant 8 bits in LVDS

format on a MDR36F connector.

Test Pattern Pixels and End-of-line Sequence

To facilitate system-level debugging and verification of data path integrity, the camera

can generate both a test pattern and an end-of-line sequence.

03-32-00418-05 DALSA Corp.

Page 15

EC-11 User’s Manual 15

The test pattern is a ramp from 0 to 255DN, then starts at 0 again. Use the test pattern to

verify the proper timing and connections between the camera and the frame grabber.

The end-of-line sequence outputs “aa”, “55”, “line counter”, “line average”, “pixels above

threshold”, “pixels below threshold”.

2.7 Timing

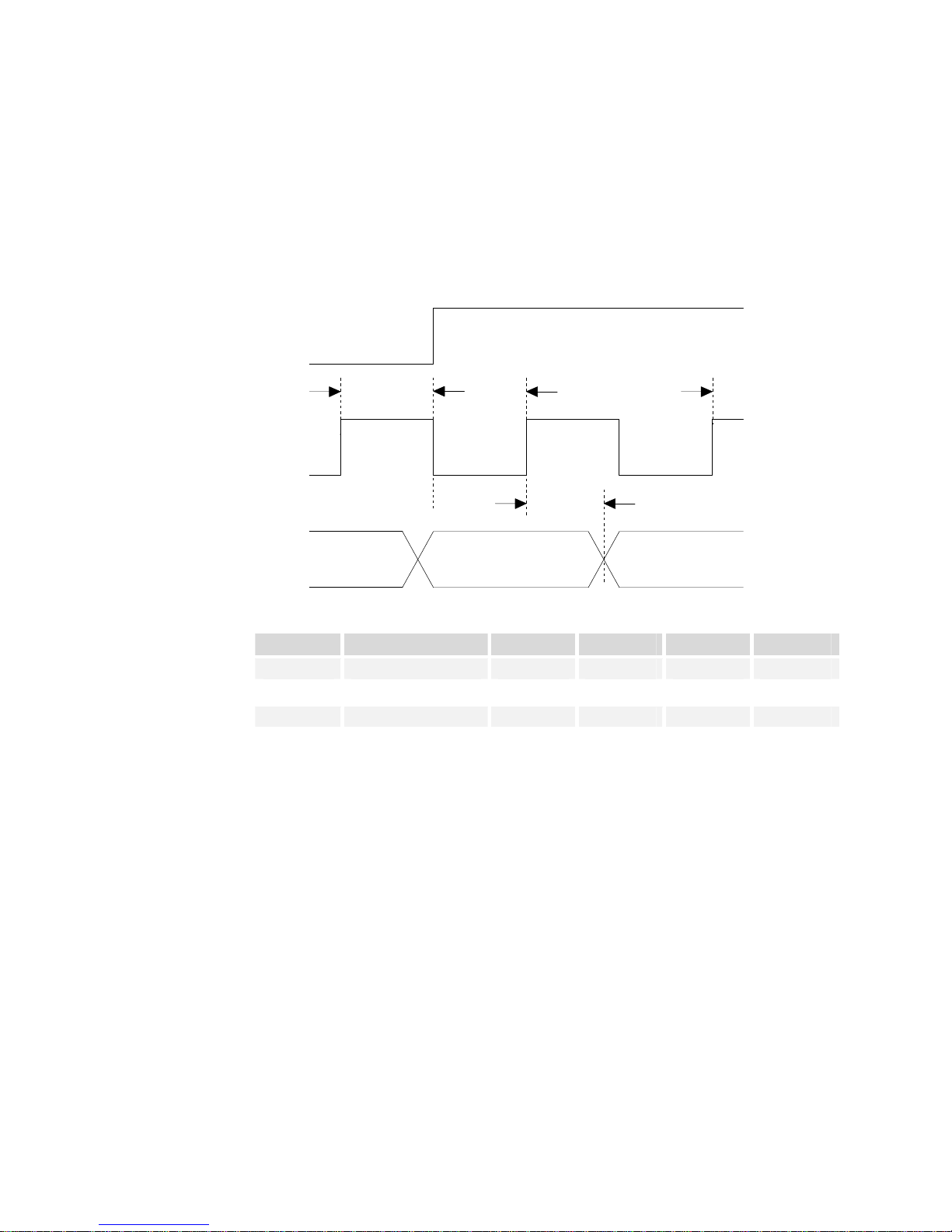

Figure 3. EC-11-xxx40 Timing

LVAL

STROBE

Data

T

LVAL

T

DATA

T

STROBE

Table 2: Timing Definition

Symbol Parameter Unit Min. Nom. Max.

T

Strobe to LVAL ns 12 15 18

LVAL

T

Strobe to Data ns 5 10 20

DATA

T

Strobe period ns 25 25 100

STROBE

Notes:

• T

LVAL

and T

measured at 40MHz.

DATA

DALSA Corp. 03-32-00418-05

Page 16

16 EC-11User’s Manual

2.8 Multi-Camera Operation

Multisync is used to connect two or more cameras to the frame grabber and receive all of

the camera’s output synchronously. The camera switches to multisync mode when both

EXSYNC and EXRCLK are applied. You may need to compensate for cable lengths and

nominal delays.

Multi-Camera Sync

If your frame grabber is capable of receiving 16 or more bits, you can connect two or more

cameras to the frame grabber and receive all of the cameras’ output synchronously to

image a wider web. However, since most frame grabbers accept only one set of clocking

signals, you must synchronize the outputs by configuring your system to meet these

requirements:

1. All cameras must receive identical, synchronous EXRCLK and EXSYNC signals (max.

external EXRCLK = 40 MHz. EXRCLK:Pixel Clock ratio is 1:1). Compensate for

different cable lengths and nominal delays.

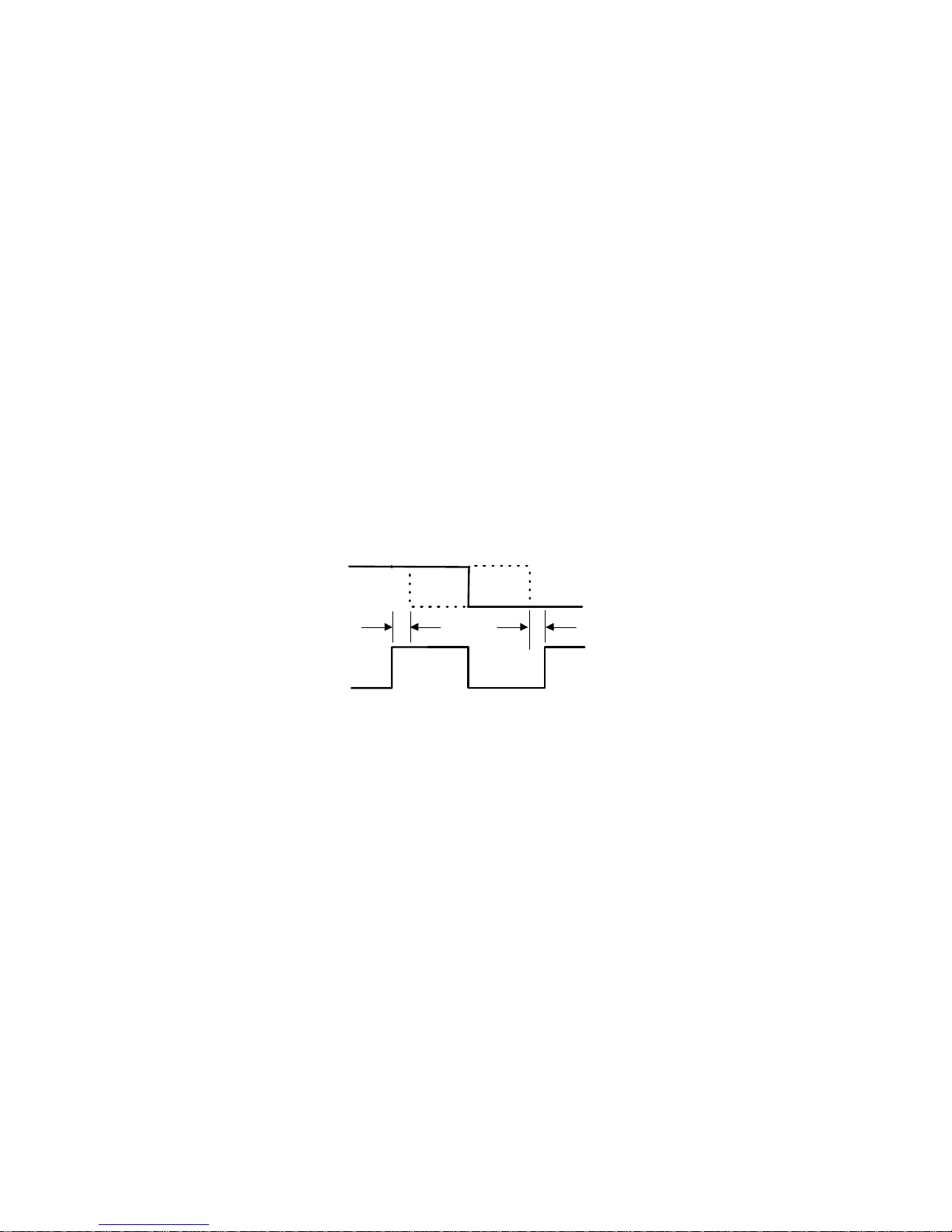

2. The timing relationship between the rising edge of EXSYNC and the rising edge of

MCLK must meet the requirements in the diagram below:

EXSYNC

T

hold

EXRCLK

3. Data and control cabling must be separate for each camera. Although each camera will

get the same EXRCLK and EXSYNC signals, the control signals must come from

separate differential pairs of a LVDS line driver.

Because the cameras’ output will be synchronized, use the data clocking signals (LVAL,

STROBE) from just one of the cameras to clock all the others.

T

setup

T

min 2ns

hold

min 6ns

T

setup

03-32-00418-05 DALSA Corp.

Page 17

EC-11 User’s Manual 17

2.9 Serial Interface

Camera features can be controlled through the serial interface (RS232, 9600 baud). The

serial interface uses simple ASCII-based protocol and the camera does not require any

custom software. The complete protocol is described later in the manual (Appendix C and

D). Functions available include:

• Controlling basic camera functions such as binning (horizontal and vertical), gain,

offset, line and data rate, and direction

• Pixel-by-pixel FPN and PRNU correction and balancing

• Measuring sensor temperature, supply voltages

• Capturing video and line statistics

• Generating end-of-line sequencing (line counter, line average, pixels above/below

threshold) and test patterns for debugging

For quick help, the camera can return all available commands and parameters through

the serial interface.

DALSA Corp. 03-32-00418-05

Page 18

18 EC-11User’s Manual

03-32-00418-05 DALSA Corp.

Page 19

EC-11 User’s Manual 19

3

Optical and Mechanical

Considerations

3.1 Mechanical Interface

The camera’s electronics are housed in a ruggedized lightweight aluminum case. See

Figure 4.

Mounting

The camera can be mounted using the M3 holes (metric-threaded) on its base or top.

!

IMPORTANT: The mounting of the camera is critical. Improper mounting may affect alignment. All sensor

measurements are based on alignment with the front plate of the camera. Refer to Figure 3. Mechanical

Interface.

Environment

The camera and cables should be shielded from environmental noise sources for best

operation. The camera should also be kept as cool as possible. Specified operating

temperature is 0-50° C. Mounting holes (see above) allow you to attach heat sinking.

Periscope Configuration

To give users more mechanical flexibility, this camera is available in a periscope

configuration that reduces the z-axis space required to mount the camera, allowing you to

regain up to several inches of working space by channeling the camera body and cabling

perpendicular to the optical axis.

DALSA Corp. 03-32-00418-05

Page 20

20 EC-11User’s Manual

Figure 4. Mechanical Interface

512, 1024

2048

Relative

position of

pixel 1 (forward)

25 ±0.18mm

25 ±0.18mm

8.1

12.1

14.5

15.5

2048 Lens

Mount Detail

Relat ive

position of

pixel 1 (forward)

03-32-00418-05 DALSA Corp.

Page 21

EC-11 User’s Manual 21

“Periscope”

Configuration

32 (2x)

Relative

position of

pixel 1

25 ±0.18mm

25 ±0.18mm

512, 1024

137 (2x)

25 ±0.18mm

25 ±0.18mm

Relative

position of

pixel 1

2048

M3.0 – 0.5 7 DEEP TYP

32

22 (2x)

148

143

25

35

50

55

M3x0.5

81

TYP 7 DEEP

33

32

64

81 (2x)

32 (2x)

137

32

148

143

50

32

22

DALSA Corp. 03-32-00418-05

Page 22

22 EC-11User’s Manual

3.2 Optical Interface

The cameras come with a built in C-mount lens adapter for the 512 and 1024 models. A

built in F-mount adapter is provided on the 2048 model. Both adapters have the

appropriate back focal distance for the lens types being used. Ensure that the image circle

diameter of the lens to be used is as great as the length of the imaging region of the image

sensor.

Illumination

The amount and wavelengths of light required to capture useful images depend on the

particular application. Factors include the nature, speed, and spectral characteristics of

objects being imaged, exposure times, light source characteristics, environmental and

acquisition system specifics, and more. DALSA’s current Databook provides an

introduction to this potentially complicated issue. See “Radiometry and Photo

Responsivity” and "Sensitivities in Photometric Units" in the CCD Technology Primer

chapter.

It is often more important to consider exposure than illumination. The total amount of

energy (which is related to the total number of photons reaching the sensor) is more

important than the rate at which it arrives. For example, 5µJ/cm

exposing 5mW/cm

2

for 1ms just the same as exposing an intensity of 5W/cm2 for 1µs.

2

can be achieved by

Light Sources

Keep these guidelines in mind when setting up your light source.

• LED light sources are relatively inexpensive, provide a uniform field, and longer

lifespan compared to other light sources. However, they also require a camera with

excellent sensitivity, such as DALSA’s Eclipse camera.

• Halogen light sources generally provide very little blue relative to IR.

• Fiber-optic light distribution systems generally transmit very little blue relative to IR.

• Some light sources age; over their lifespan they produce less light. This aging may not

be uniform—a light source may produce progressively less light in some areas of the

spectrum but not others.

Filters

CCD cameras are extremely responsive to infrared (IR) wavelengths of light. To prevent

infrared from distorting the images you scan, use a “hot mirror” or IR cutoff filter that

transmits visible wavelengths but does not transmit wavelengths over 750nm. Examples

are the Schneider Optics™ B+W 489, which includes a mounting ring, the CORION™ LS750, which does not include a mounting ring, and the CORION™ HR-750 series hot

mirror.

Lens Modeling

Any lens surrounded by air can be modeled for camera purposes using three primary

points: the first and second principal points and the second focal point. The primary

03-32-00418-05 DALSA Corp.

Page 23

EC-11 User’s Manual 23

f

f

m

points for a lens should be available from the lens data sheet or from the lens

manufacturer. Primed quantities denote characteristics of the image side of the lens. That

is, h is the object height and h

The focal point is the point at which the image of an infinitely distant object is brought to

focus. The effective focal length (f

second focal point. The back focal length (BFL) is the distance from the image side of the

lens surface to the second focal point. The object distance (OD) is the distance from the first

principal point to the object.

′

is the image height.

′

) is the distance from the second principal point to the

Figure 5. Primary Points in a Lens System

Magnification and Resolution

The magnification of a lens is the ratio of the image size to the object size:

h

m

=

h

By similar triangles, the magnification is alternatively given by:

=

m

OD

These equations can be combined to give their most useful form:

h

′

=

h

OD

Example: An acquisition system has a 512 x 512 element, 10µm pixel pitch area scan

camera, a lens with an effective focal length of 45mm, and requires that 100µm in the

object space correspond to each pixel in the image sensor. Using the preceding equation,

the object distance must be 450mm (0.450m).

10

µ

100

µ

where m is the magnification, h’ is the image height (pixel size)

′

and h is the object height (desired object resolution size).

′

This is the governing equation for many object and image plane

′

parameters.

45

mmmOD

450 0 450

OD mm m==(. )

DALSA Corp. 03-32-00418-05

Page 24

24 EC-11User’s Manual

03-32-00418-05 DALSA Corp.

Page 25

EC-11 User’s Manual 25

4

Troubleshooting

The information in this chapter can help you solve problems that may occur during the

setup of your camera. Remember that the camera is part of the entire acquisition system.

You may have to troubleshoot any or all of the following:

• power supplies • cabling

• frame grabber hardware & software • host computer

• light sources • optics

• operating environment • encoder

Your steps in dealing with a technical problem should be:

1. Try the general and specific solutions listed in sections 4.1, 4.2 and 4.3.

2. If these solutions do not resolve your problem, see section 4.4 on getting product

support.

4.1 Common Solutions

Connections

The first step in troubleshooting is to verify that your camera has all the correct

connections.

Power Supply Voltages

Check for the presence of all voltages at the camera power connector. Verify that all

grounds are connected.

EXSYNC

When the camera is powered on for the first time, it defaults (no external input required)

to free run mode (maximum data rate, forward direction, maximum line rate, and internal

Sync to trigger readout). After a user has saved settings, the camera power ups with the

saved settings. Note, a warning appears when switching to external signals (EXSYNC or

EXRCLK) with no preset signals.

DALSA Corp. 03-32-00418-05

Page 26

26 EC-11User’s Manual

EXRCLK

EXRCLK is an optional input signal used to control readout timing. EXRCLK is applied to

the read portion of a FIFO and directly drives STROBE and LVAL.

Data Clocking/Output Signals

Verify the presence of all data clocking and output signals. Trigger the oscilloscope from

the rising edge of LVAL (ch1; DC coupled). Adjust the oscilloscope time base to allow for

a complete cycle of each signal:

• STROBE—Verify the presence of the STROBE and STROBEB signals. There should be

a continuous clock signal present at the same frequency as your data rate. Sample data

on the rising edge of STROBE.

• LVAL—Verify the presence of the LVAL and LVALB signals.

• Digital Output—Do not probe LVDS data signals with a scope probe unless it has less

than 0.5pf of capacitance. If you can probe safely, use LVAL to trigger the scope

sweep. Illuminate the camera target and check each individual digital output signal on

ch2 of the oscilloscope (±D0 - D7 on the digital output connector). The digital output

data signal should change value when light is blocked from the camera lens. Ensure

that the bitpattern, that is output just before the active video pixels, is correct (as

specified in Chapter 2).

If any of the above signals are missing, contact DALSA product support.

4.2 Troubleshooting Using the Serial Interface

The following commands can aid in debugging. (The complete command protocol is

described in Appendix C and D.)

Verify Parameters

To verify the camera setup, send the get_camera_parameters command.

Verify Factory Calibrated Settings

To restore the camera’s factory settings and reset the FPN and PRNU coefficients to 0,

send the

After executing this command send the

the factory settings.

Verify Timing and Digital Video Path

To generate a test pattern, use the command set_video_mode 2. The test pattern is a

ramp from 0 to 255DN, then starts at 0 again. Use the test pattern to verify the proper

timing and connections between the camera and the frame grabber and verify the proper

output along the digital processing chain.

restore_factory_settings command.

get_camera_parameters command to verify

03-32-00418-05 DALSA Corp.

Page 27

EC-11 User’s Manual 27

• No test pattern or bad test pattern — May indicate a problem with the camera (e.g.

missing bit) or a system setup problem (e.g. frame grabber or timing). Verify the

presence of the LVAL and STROBE signals.

• Test pattern successful — Run the

video correction. Then run the

conditions to retrieve a line of raw video (no digital processing). Under dark

conditions, with factory settings, the analog offset value should be within the specified

range (refer to the user specifications). Adjust the analog offset using the

set_analog_offset and calibrate_analog_offset commands. Under light

conditions, you should receive a value.

set_video_mode 0 command to deactivate

get_line command under both dark and light

Verify Voltage

To check the camera’s input voltages and internal voltages, use the verify_voltage

command. If they are within the proper range, the camera returns OK>. Otherwise the

camera returns an error message.

Verify Temperature

To check the internal temperature of the camera, use the verify_temperature

command. For proper operation, this value should not exceed 75°C.

Verify Pixel Coefficients

To activate video correction, send the command set_video_mode 1. Then use the

display_pixel_coeffs command to display the pixel coefficients in the order

PRNU, FPN, PRNU, FPN, …for both directions.

4.3 Specific Solutions

No Output or Erratic Behavior

If your camera provides no output or behaves erratically, it may be picking up random

noise from long cables acting as antennae. Do not attach wires to unused pins. Verify that

the camera is not receiving spurious inputs (e.g. EXSYNC or EXCLK, if camera is in

external mode).

Line Dropout, Bright Lines, or Incorrect Line Rate

Verify that the frequency of the internal sync is set correctly, or when the camera is set to

external sync that the EXSYNC signal supplied to the camera does not exceed the

camera’s maximum specified line rate.

Noisy Output

Check your power supply voltage outputs for noise. Noise present on these lines can

result in poor video quality. Low quality or non-twisted pair cable can also add noise to

the video output.

DALSA Corp. 03-32-00418-05

Page 28

28 EC-11User’s Manual

Dark Patches

If dark patches appear in your output the optics path may have become contaminated.

Clean your lenses and sensor windows with extreme care.

1. Take standard ESD precautions.

2. Wear latex gloves or finger cots

3. Blow off dust using a filtered blow bottle or dry, filtered compressed air.

4. Fold a piece of optical lens cleaning tissue (approx. 3" x 5") to make a square pad that

is approximately one finger-width

5. Moisten the pad on one edge with 2-3 drops of clean solvent—either alcohol or

acetone. Do not saturate the entire pad with solvent.

6. Wipe across the length of the window in one direction with the moistened end first,

followed by the rest of the pad. The dry part of the pad should follow the moistened

end. The goal is to prevent solvent from evaporating from the window surface, as this

will end up leaving residue and streaking behind.

7. Repeat steps 2-4 using a clean tissue until the entire window has been cleaned.

8. Blow off any adhering fibers or particles using dry, filtered compressed air.

Stuck Bits

If data bits seem to be stuck or do not change, check that the camera is not saturated by

preventing light from entering. To verify the data path integrity, check the levels of the 2

test pattern pixels (first 2 pixels following the last End-of-line pixel. You may need to turn

the End-of-line sequence “on” by sending the command

Any deviation from a consistent value of these pixels (170DN/85DN) could be an

indication of the following:

• shorted bits

• stuck bits

• digital noise pickup on the I/O cable

• open connection.

To activate the test pattern, use the command

to verify the proper timing and connections between the camera and frame grabber.

To receive a complete line of raw video data (without digital processing or test pattern)

through the RS232 port, use the command

pixel value after another and the minimum, maximum, and mean value of the sampled

line. Use this command to ensure the proper video input range.

Probe the output lines with an oscilloscope. Disconnect the digital cable from the camera

and check the digital signals at the output of the camera. Ensure that the correct values

are present. Check all cable connections, especially right at the connector; poor

connections or broken wires will cause randomly changing bits or stuck bits.

set_video_mode 2. Use the test pattern

get_line. The returned data displays one

endof_line_sequence 1).

03-32-00418-05 DALSA Corp.

Page 29

EC-11 User’s Manual 29

Horizontal Lines or Patterns in Image

A faulty or irregular encoder signal may result in horizontal lines due to exposure time

fluctuations; ensure that your exposure time is regular. If you have verified that your

exposure time is consistent and patterns of low frequency intensity variations still occur,

ensure that you are using a DC or high frequency light source.

DALSA Corp. 03-32-00418-05

Page 30

30 EC-11User’s Manual

4.4 Product Support

If the troubleshooting flowchart indicates a problem with your camera, collect the

following data about your application and situation and call your DALSA representative.

Note: You may also want to photocopy this page to fax to DALSA.

Customer name

Organization name

Customer phone number

fax number

Complete Product Model Number

(e.g. EC-11-xxx40...)

Complete Serial Number

Your DALSA Agent or Dealer

Acquisition System hardware

(frame grabber, host computer, light

sources, etc.)

Acquisition System software

(version, OS, etc.)

Power supplies and current draw

Data rate used

Control signals used in your

application, and their frequency or

state (if applicable)

Detailed description of problem

encountered.

EXSYNC BIN

MCLK Other _______

PRIN

please attach description with as

much detail as appropriate

In addition to your local DALSA representative, you may need to call DALSA Technical

Sales Support:

Voice:

Fax:

North America

519-886-6000

519-886-8023

Europe

+49-8142-46770

+49-8142-467746

Asia

519-886-6000

519-886-8023

03-32-00418-05 DALSA Corp.

Page 31

EC-11 User’s Manual 31

A PPENDIX A:

EIA-644 Reference

EIA-644 is an electrical specification for the transmission of digital data. The standard is

available from the EIA (Electronic Industries Association). It defines voltage levels,

expected transmission speeds over various cable lengths, common mode voltage

operating requirements for transmitters and receivers, and input impedances and

sensitivities for receivers. The table below gives a quick comparison between EIA-644 and

RS422 (another differential standard).

Table 3: RS422 vs. EIA-644

Parameter RS422 EIA-644

Differential Driver Output Voltage ±2-5V ±250-450mV

Receiver Input Threshold ±200mV ±100mV

Data Rate <30Mbps >400Mbps

Supply Current, Quad Driver (no load, static)* 60mA 3.0mA

Prop. Delay of Driver, max.* 11ns 3ns

Prop. Delay of Receiver, max.* 30ns 5ns

Supply Current, Quad Receiver (no load, static)* 23mA 10mA

* based on National Semiconductor DS90C031/2

The standard requires that two wires (e.g. twisted pair) be used to transmit one signal in a

differential mode. This means that one wire will be logic HIGH while the other wire is

logic LOW. Voltage swing between HIGH and LOW is approximately 350mV, with a

typical offset of approximately 1.25V. The use of differential signal transmission allows

the receiver to reject common mode voltages. This noise rejection improves data integrity

and allows cameras to be installed in an industrial environment.

EIA-644-compatible line receivers and drivers are available from many different IC

manufacturers in a variety of fabrication technologies such as CMOS and GaAs. The EIA644 standard does not define specific voltages, so it can migrate from 5V power supplies

to 3.3V and sub-3V. DALSA recommends the use of 5V CMOS line drivers and receivers

such as National Semiconductor parts DS90C031 quad line driver and DS90C032 quad

line receiver.

To achieve full benefit of the common mode rejection, twisted pair cable should be used

for all EIA-644 signals. The cable impedance should be 100 Ohms and the cable

terminated at the receiving end with a 100 Ohm resistor. All EIA-644 inputs in a DALSA

camera are terminated with 100 Ohms between the (+) and (-) of a signal. Figure A-1 (a)

shows an example of an EIA-644 transmission.

DALSA indicates the (+) signal by the name of the signal; i.e. EXSYNC, while the (-)

signal is indicated by either an overscore over the name or appending the letter B to the

end of the name; i.e.

signal which is sent or received; i.e. when EXSYNC in the TTL domain is HIGH then

EXSYNC in the EIA-644 domain is HIGH. The (-) signal has the opposite sense of the TTL

domain signal and so if EXSYNC TTL is HIGH then EXSYNCB EIA-644 is LOW. Figure 6

shows the relationship.

EXSYNC

or EXSYNCB. The (+) signal has the same sense as the TTL

DALSA Corp. 03-32-00418-05

Page 32

32 EC-11User’s Manual

Figure 6. EIA-644 Example

Unused EIA-644 Inputs and Outputs

Unused outputs should be left unconnected. This will reduce power dissipation within

the camera and reduce radiated emissions.

Unused inputs should also be left unconnected; EIA-644 chips have fail-safe features that

guarantee a known logic state (HIGH) in fault conditions (unconnected, shorted, or

unterminated). Do not connect cables to unused inputs. Cables can act as antennae and

cause erratic camera behavior.

Cable Lengths

Figure 7 shows a graph of ideal communication data rate vs. cable length for the EIA-644

standard.

03-32-00418-05 DALSA Corp.

Page 33

EC-11 User’s Manual 33

Figure 7. EIA-644 Data Rate vs. Cable Length

1000

20% Jitter Measured at 0V Differential

100

20% Jitter Measured at ±0100mV Differential

CAT3 Cable

Typical Data Rate vs. Cable Length

(National DS90C031)

Data Rate (Mbps)

10

1

1

23510

Cable Length (m)

DALSA Corp. 03-32-00418-05

Page 34

34 EC-11User’s Manual

03-32-00418-05 DALSA Corp.

Page 35

EC-11 User’s Manual 35

A PPENDIX B:

EMC Declaration of Conformity

We,

declare under sole responsibility, that the product(s):

fulfill(s) the requirements of the standard(s)

EMC:

This product complies with the requirements of the Low Voltage Directive

73/23/EEC and the EMC Directive 89/336/EEC and carries the CE mark

accordingly.

Place of Issue

Date of Issue

Name and Signature

of authorized person

DALSA Corp.

605 McMurray Rd., Waterloo, ON

CANADA N2V 2E9

EC-11-xxx40

FCC Part 15

ICES-003

EN 55022: 1998

EN 55024: 1998

EN 61000-6-1: 2001

Waterloo, ON, CANADA

08 March 2005

Hank Helmond

Quality Manager, DALSA Corp.

This Declaration corresponds to EN 45 014.

DALSA Corp. 03-32-00418-05

Page 36

36 EC-11User’s Manual

03-32-00418-05 DALSA Corp.

Page 37

EC-11 User’s Manual 37

A PPENDIX C:

Software Interface: How to

Control the Camera

C1 Overview

i

See the Communications

Protocol for the

complete syntax and

command reference

(including command

shortcuts) for the

camera’s serial interface.

All Eclipse camera features can be controlled through the serial interface. The camera can

also be used without the serial interface after it has been set up correctly. Functions

available include:

• Controlling basic camera functions such as gain and sync signal source

• Camera calibration

• Measuring temperature and supply voltages

• Capturing video

• Generating a test pattern for debugging

The serial interface uses a simple ASCII-based protocol and the camera does not require

any custom software. The complete protocol is described in the Communications

Protocol.

For quick help, the camera can return all available commands and parameters through

the serial interface. To generate this list, send the command

help to the camera.

Serial Protocol Defaults

• 8 data bits

• 1 stop bit

• No parity

• No flow control

• 9.6Kbps

• Camera does not echo characters

C2 Processing Chain

The figure below is a simplified block diagram of the camera's processing chain. The

analog processing chain contains two elements–a gain stage and an offset stage. The

digital processing chain contains the FPN correction, PRNU correction, background

subtract, and a system gain stage. The command set, detailed in the Communications

Protocol, allows the user to set and change all the elements of the processing chain

separately for the forward and reverse direction. This enables maximum processing

flexibility and optimized forward/reverse matching depending on the user requirements.

DALSA Corp. 03-32-00418-05

Page 38

38 EC-11User’s Manual

In addition, the two elements of the analog processing chain can be adjusted separately in

calibrated and uncalibrated mode. When changing analog processing values between the

two video mode settings, the camera automatically adjusts the settings according to the

video mode as well as the direction the camera is operating in.

Digital Processing

C3 Startup

When the camera is first started, it must perform several actions before it is ready for

imaging. This startup routine takes approximately 10 seconds, and follows this sequence:

1. Initializes the camera and all internal hardware.

2. Loads the last settings saved to non-volatile memory, including the last set of video

correction coefficients, if previously saved.

3. Restores user settings if previously saved, otherwise factory settings.

4. Performs a memory test and voltage test and reports an error if any occurred.

After this startup sequence is complete, the camera will return either the prompt "OK>" if

no error occurred, or an error code if a problem has been discovered.

C4 Saving and Restoring Settings

i

All commands have short

forms. See the

Communications Protocol

for the complete syntax

and command reference.

The camera provides a number of commands for restoring, storing, and saving settings.

To restore the original factory settings, use the command

restore_factory_settings. The FPN and PRNU coefficients are reset to 0.

To save all current user settings to EEROM, use the command

write_user_settings. The camera will automatically restore the saved user settings

when powered up.

03-32-00418-05 DALSA Corp.

Page 39

EC-11 User’s Manual 39

To save all current pixel coefficients to EEROM, use the command

write_pixel_coeffs.

To restore the last saved user settings and the FPN and PRNU coefficients, use the

command

restore_user_settings.

C5 Setting Direction

The camera's readout direction can be set to forward, reverse, or external input (forward).

To set the direction internal forward, use the command

To set the direction internal reverse, use the command

To set the direction external forward/reverse, use the command

2;

high is forward, low is reverse, and the default direction is forward.

This command also updates all parameters that are forward/reverse dependent.

C6 Setting Line Rate (EXSYNC)

The camera’s line rate (synchronization) is generated internally or input from a frame

grabber/host system. The source is selected using the

command through the serial port.

To set line rate internally, use the command

To set line rate externally, use the command

When using internally generated sync, the frequency can be programmed using the

command

between 3500 and the specified maximum line rate. Use the command

set_sync_counter value, to set the line rate from 3500Hz to the camera's

maximum line rate by applying a counter value. Counter values are from 0 to 65535. Line

rate can be calculated as follows:

set_sync_frequency frequency, where frequency is a number in Hz

set_sync_mode 0.

set_syn_mode 1.

set_ccd_direction 0.

set_ccd_direction 1.

set_ccd_direction

set_sync_mode mode

Line rate = 1/(minimum line time + counter value * 50ns), where minimum line time is =

1/maximum line rate at applied EXRCLK.

Minimum Line

Times

512 15.575µs 28.8µs 57.5µs

1024 29.725µs 55.1µs 110.1µs

2048 57.275µs 110.2µs 220.0µs

For external sync, the control signal EXSYNC determines line rate. The internal

commands

EXSYNC has been selected.

When setting the camera to external sync, EXSYNC must be supplied.

DALSA Corp. 03-32-00418-05

40MHz 20MHz 10MHz

set_sync_frequency and set_sync_counter are disabled when

Page 40

40 EC-11User’s Manual

C7 Setting Data Rate (EXRCLK)

The camera's data rate can be set to one of three internal data rates or to the external read

clock (EXRCLK).

To set the data rate to internal 40MHz, use the command

To set the data rate to internal 20MHz, use the command

To set the data rate to internal 10MHz, use the command

To set the data rate to external read clock, use the command

set_rclk_select 3.

When setting the camera to its external clock, EXRCLK must be supplied.

The internal command

selected. The command

set_sync_frequency is disabled when EXRCLK has been

set_sync_counter can be used to set line rate internally.

set_rclk_select 0.

set_rclk_select 1.

set_rclk_select 2.

Optimizing Offset Performance

To set the analog offset of the camera, use the command set_analog_offset. Offset

values range from 0 to 1023. The offset increases with higher values. The resulting analog

offset value depends on other camera parameters such as temperature, line rate, and gain.

The offset for the forward and reverse direction and for calibrated and uncalibrated video

is set and saved separately.

To subtract the offset or any other background from the output video signal, use the

set_subtract_background command. Subtracted values range from 0 to 511. The

values for the forward and reverse direction are set and saved separately. Note, when

subtracting a digital value from the digital video signal the output can no longer reach its

maximum. Use the system gain function to correct for this.

To subtract the offset from the video signal in the calibrated mode only, prior to the

PRNU correction, use the

from 0 to 511. The values for the forward and reverse direction are set and saved

separately.

Calibrating Offset

To calibrate the analog offset, use the calibrate_analog_offset command. Values

range from 0 to 100DN. This command sets offset in uncalibrated mode.

C8 Setting Gains

To set the analog gain portion of the camera in forward and reverse direction, use the

set_gain command and specify the gain setting. A gain value of 0 sets the camera to its

nominal gain (0dB). The specified gain value range is from –8.5 to 9.5.

To set the digital gain, following a background subtraction, use the

command and specify the gain setting. The gain ranges are 0 to 511 (equal to a gain from

1 to 1.999).

set_digital_offset command. Subtracted values range

set_system_gain

03-32-00418-05 DALSA Corp.

Page 41

EC-11 User’s Manual 41

Note: Parameters need to be specified for both forward and reverse direction in calibrated and uncalibrated

modes.

Calibrating Gains

To calibrate the analog gain, use the calibrate_analog_gain command. Values

range from 128 to 250DN and this function requires constant light input while executing.

This command sets gain in uncalibrated mode.

C9 Calibrating the Camera: Overview

This camera has the ability to calibrate itself in order to improve the FPN and PRNU

performance. This video correction operates on a pixel-by-pixel basis and implements a

two point correction for each pixel. This correction can reduce or eliminate image

distortion caused by the following factors:

• Fixed Pattern Noise (FPN)

• Photo Response Non Uniformity (PRNU)

• Lens and light source non-uniformity

The two point correction is implemented such that for each pixel:

= (V

V

output

where V

V

PRNU( pixel) = PRNU correction coefficient for this pixel

FPN( pixel ) = FPN correction coefficient for this pixel

The calibration algorithm is performed in two steps. The fixed offset (FPN) is determined

first by performing a calibration without any light. This calibration determines exactly

how much offset to subtract per pixel in order to obtain flat output when the CCD is not

exposed.

The white light calibration is performed next to determine the multiplication factors

required to bring each pixel to the required value (balance target) for flat, white output.

Video output is set slightly above the brightest pixel (depending on offset subtracted).

For FPN (dark light) the value must be between 1DN and 127DN, for PRNU (white light)

the value must be between 128DN and 254DN. Use the

the proper input to the digital processing, V

White light calibration will gain up to maximum white light pixel plus the maximum FPN

subtract pixel.

When performing any camera calibration, random noise must be averaged out to ensure

proper sampling. Sample size is fixed at 128.

- FPN( pixel ) ) * PRNU(pixel)

input

= digital output pixel value

output

= digital input pixel value from the CCD

input

input

get_line command to ensure

.

Dark Calibration

Dark calibration is used to remove the fixed analog offset from the video path. It is

recommended you repeat the calibration when a temperature change greater than 10°C

occurs.

DALSA Corp. 03-32-00418-05

Page 42

42 EC-11User’s Manual

To perform dark calibration:

1. Stop all light from entering the camera.

2. Issue the command

OK> if no error occurs. V

correction will be stopped. Use the

Choose low FPN coefficient values to achieve optimum FPN calibration performance.

3. Dark calibration automatically calibrates FPN coefficients and digital offset. This

procedure needs to be repeated for forward and reverse directions, if direction control

is used.

4. After the calibration is complete, you can save these settings, and the PRNU

coefficients, to non-volatile memory so they will be remembered after power-down.

To do so, issue the command

correction_calibrate_fpn. The camera will respond with

needs to be between 1DN and 127DN, otherwise the

input

get_line command to determine input level.

write_pixel_coeffs.

To perform a dark calibration with an analog offset value:

Use the correction_calibrate_fpn value command. Where value is the analog

offset DN. This command sets the analog offset first to value before calculating the FPN

coefficients range from 1 to 100. Use this command in calibrated mode only. If value is left

blank, current offset values are used.

White Light Calibration

White light calibration is more complex than dark calibration because the camera

attempts to create a flat white image. This calibration corrects PRNU effects as well as

non-uniform lighting and lens vignetting affects.

Note: If your

illumination or white

reference does not extend

the full field of view of the

camera, calibration will not

be successful. The camera

will send a warning.

White light calibration requires a clean, white reference. The quality of this reference is

important for proper calibration. White paper is often not sufficient because the grain in

the white paper will distort the correction. A more uniform source such as white plastic

will lead to better balancing.

The camera adjusts to the brightest pixel plus largest FPN pixel subtraction value.

There are several restrictions that must be met in order for the calibration to succeed:

1. The camera is sufficiently sensitive to detect 60 Hz ambient light flicker which may

affect camera performance and calibration results.

2. The light level must be set so that input to the digital processing chain is between

128DN and 254DN, otherwise calibration will stop. Use the

determine input level.

3. The variance in light intensity across the target must not be more than 2 to 1. Since the

maximum per-pixel digital gain is 2x, the camera will not be able to compensate for

extremely non-uniform light.

These restrictions are all tested within the calibration algorithm and the camera will

report an error if any of these conditions could not be met. In this case, the calibration will

stop.

get_line command to

To perform a white light calibration:

1. Place a white reference in front of the camera.

03-32-00418-05 DALSA Corp.

Page 43

EC-11 User’s Manual 43

2. Ensure that the light intensity is characteristic of the final imaging environment.

Choose a light level between 200 and 220DN for optimum calibrated PRNU

performance.

3. Instruct the camera to perform a white light calibration using the command

correction_calibrate_prnu. The camera will respond with OK> if no error

occurs.

4. Repeat the first three steps for forward and reverse directions if required.

5. After the calibration is complete, you can save these settings to non-volatile memory

so they will be remembered after power-down. To do so, issue the command

write_pixel_coeffs.

If pixel coefficients (FPN or PRNU) exceed the maximum limit (511), they will be clipped

and a warning will be sent.

If an error occurs, adjust the light intensity into the correct range for calibration. The

get_line command will help to determine how much to increment or decrement the

light intensity. Or, change the gain value using the

set_gain command.

To perform a white light calibration with an analog gain value:

Use the correction_calibrate_prnu value command. Where value is the analog

gain DN. This command sets the analog gain first to value before calculating the PRNU

coefficients range from 128 to 250. Use this command in calibrated mode only. If value is

left blank, current gain values are used.

Returning Calibration Results and Errors

After calibration, you can retrieve the results using the command

display_pixel_coeffs. This function returns all the pixel coefficients in the order

PRNU, FPN, PRNU, FPN…

The command

get_camera_parameters returns all other settings.

Activating / Deactivating Video Correction

To switch between calibrated and uncalibrated modes, use the following

set_video_mode commands:

• To deactivate video correction (uncalibrated video), use the command

set_video_mode 0.

• To activate video correction (calibrated video), use the command

1

.

• The command

set_video_mode 2, generates a test pattern.

set_video_mode

DALSA Corp. 03-32-00418-05

Page 44

44 EC-11User’s Manual

C10 Increasing Sensitivity with Binning

Binning increases the camera’s light sensitivity by decreasing horizontal and vertical

resolution—the charge collected by adjacent pixels is added together.

More charge

=

brighter pixel

q3

q4

q1

q2

2

Charge in

4 adjacent pixels

q1

+

q2

+

q3

+

q4

1

Charge binned:

1 pixel output

a

a

Normal image Binned image

To enable 2x2 binning, use the command

set_binning_vertical 1. To disable binning, use the command

set_binning_horizontal 0, and set_binning_vertical 0. Horizontal (2x1) and

vertical (1x2) binning can also be used independently.

set_binning_horizontal 1, and

C11 Generating Test Patterns

The camera can generate a test pattern to aid in system debugging. Use the command

set_video_mode 2 to activate the test pattern. The test pattern is a ramp from 0 to

255DN, then starts at 0 again. Use the test pattern to verify the proper timing and

connections between the camera and the frame grabber.

End-of-line Sequence

To further aid debugging, the camera can generate an end-of-line sequence. The end-ofline-sequence outputs "aa", "55", "line counter", "line average", "pixels above threshold",

"pixels below threshold". To activate the end-of-line sequence, use the command

endof_line_sequence 1. To disable the end-of-line sequence, use the command

endof_line_sequence 0.

Use the

threshold values between 0 and 255.

set_upper_threshold and set_lower_threshold commands to set

C12 Returning Video Information

The camera’s microcontroller has the ability to read V

to verify camera operation and to perform basic testing without having to connect the

camera to a frame grabber.

03-32-00418-05 DALSA Corp.

. This functionality can be used

input

Page 45

EC-11 User’s Manual 45

This video information can be sampled through the serial port by issuing the following

command:

get_line

This command returns a complete line of video (without digital processing or test

pattern) displaying one pixel value after another. It also displays the minimum,

maximum, and mean value of the line sampled.

Use this command to ensure the proper video input range into the processing chain

before executing any pixel calibration commands.

C13 Monitoring the Camera

Temperature Measurement

The temperature of the camera can be determined by using the verify_temperature

command. This command will return the temperature inside the cover in degrees Celsius.

For proper operation, this value should not exceed 75°C.

Voltage Measurement

The command verify_voltage checks the camera’s input voltage and internal

voltages during power-up. If they are within the proper range, the camera returns OK>.

Otherwise the camera returns an error message. Note that the voltage measurement

feature of the camera provides only approximate results (typically within 10%). They

should not be used to set the applied voltage to the camera. The purpose of this test is to

isolate gross problems with the supply voltages.

C14 Rebooting the Camera

The command reset_camera reboots the camera. The camera starts up with the last

saved settings. Previously saved pixel coefficients are also restored.

C15 Setting the Pre-trigger

The command set_pretrigger sets the pre-trigger to a specified integer value in the

range of 0 to 15. A pre-trigger may be required for some frame grabbers.

C16 Setting and Reading FPN Coefficients

The command set_fpn_coeff integer integer sets the FPN coefficient. The first

integer is the pixel number, the second integer is a specified value within a range (see

table).

Number of

Pixels

512 0 to 511 0 to 511

1024 0 to 1023 0 to 511

DALSA Corp. 03-32-00418-05

Value 1 (pixel #) Value 2 (FPN coeff)

Page 46

46 EC-11User’s Manual

Number of

Pixels

2048 0 to 2047 0 to 511

The command get_fpn_coeff integer, where integer is the pixel number, reads the

FPN coefficient.

Value 1 (pixel #) Value 2 (FPN coeff)

C17 Setting and Reading PRNU Coefficients

The command set_prnu_coeff integer integer sets the PRNU coefficient. The

first integer is the pixel number, the second integer is a specified value within a range (see

table).

Number of

Pixels

512 0 to 511 0 to 511

1024 0 to 1023 0 to 511

2048 0 to 2047 0 to 511

The command get_prnu_coeff integer, where integer is the pixel number, reads

the PRNU coefficient.

Value 1 (pixel #) Value 2 (PRNU coeff)

03-32-00418-05 DALSA Corp.

Page 47

EC-11 User’s Manual 47

A PPENDIX D:

Communications Protocol

D1 Protocol Overview

This protocol defines the method used to control the camera via an RS232 serial interface.

The communication protocol defines the command format used and error messages

provided.

Note: This document is preliminary. Additional commands and functionality will

continue to be implemented. Backward compatibility is planned for future cameras.

D2 Protocol Features

• ASCII-based

Camera Serial Port Defaults

• 8 data bits

• 1 stop bit

• No parity

• No flow control

• 9.6Kbps

• Camera does not echo characters

D3 Command Format

There are two methods for entering the commands: In long form each command is

written in its entirety. In short form, only a predefined abbreviation is required.

Table 4: Command Format

Short Form

Long Form

When entering commands, remember that:

• Carriage return (CR) Ends each command. The linefeed character is ignored.

• All values are assumed to be in decimal.

• Values in square brackets are optional.

• Command terms uniquely specify each command

• The camera will answer each command with either "OK >" or "Error x: Error Message

>". The ">" is always the last character sent by the camera.

command_short_form [parameters...] CR

command_long_form [parameters...] CR

DALSA Corp. 03-32-00418-05

Page 48

48 EC-11User’s Manual

D4 Networking Mode

• Not available at time of shipment. To be included in a later release.

D5 Examples

Example: To set the gain to –3.5

Short Form

Long Form

Example: To return the camera model number

set_gain –3.5 CR

sg –3.5 CR

Short Form

Long Form

Example: to begin a camera calibration (dark

correction)

Short Form

Long Form

D6 Error Handling

• The camera will send ">" to an empty message (i.e. just a CR).

• All non-query functions return "OK >" unless an error occurs.

• If an error occurs, the function returns "Error x: Description >" where x is an error code

• Error codes include:

Code Description

get_camera_model CR

gcm CR

correction_calibrate_fpn CR

or

correction_calibrate_fpn value CR

ccf CR

or

ccf value CR

0 OK

1 Internal camera error. Please report this error code to DALSA Corp.

2 Camera configuration error. Verify camera settings.

3 Invalid command.

4 Command parameters: invalid.

5 Command parameters: incorrect or out of range

6 General timeout error.

7 Unable to program internal FPGAs. Please report this error code to DALSA Inc.

03-32-00418-05 DALSA Corp.

Page 49

EC-11 User’s Manual 49

Code Description

8 One (or more) of the supply voltages is out of specification.

9 The camera temperature is outside the specified operating range.

10 The camera memory check failed. Please report this error code to DALSA Inc.

11 User input under (over) limit. Setting set to high (low) limit.