TELESCOPIC POLE CHAIN SAW

MODEL:CS015

USER MANUAL

IMPORTANT: Read and understand this manual before assembling

or operating this appliance. Improper use of this appliance can cause

severe injury or death. Keep this manual in a safe place for future

reference.

Any questions or problems-please call the Eckman Helpline on 0845

555 4440 or visit www.eckman.co.uk

1

Contents:

Page 2……………………………………………….Safety symbols explanation

Page 2……………………………………………….Technical data

Page 3-6…………………………………………….Safety instructions

Page 7……………………………………………. Assembly

Page 8……………………………………………….Saw chain tension

Page 9……………………………………………….Saw chain tension adjustment

Page 10…………………………………………..….Pole length adjustment

Page 10-11………………………………………..…Using the machine

Page 11-12………………………………………......Cleaning and maintenance

Page 12-14……………..…………………..………. Sharpening / Replacement

Page 15………………………………………..……. Storage and guarantee

2

Explanation of Symbols on your product

Do not use in the rain.

Read the user manual before using the machine.

Always wear a helmet, goggles and ear protection.

Risk of fatal electric shock. Work at least 10m distance from overhead power

lines..

DANGER Do not operate this equipment when there are children, people or

pets in the immediate work area.

Wear gloves to protect your hands.

Wear rubber-soled safety shoes to protect against short circuits.

Technical data

Voltage

AC 230V-240V

Frequency

50Hz

Input Power

750W

No-load Speed

10.5m/s

Bar Length

255mm Bar Type-Oregon

Chain Type-Oregon

Oil Capacity

150ml

Adjustable Length

1.8m-2.7m

Weight

3.5Kg

Power Cable Length

10m with fitted plug

3

PRODUCT IDENTIFICAT ION

CONTENTS:

1. Guard 2.Saw Chain 3. Guide Bar 4. Power Head 5. Inner adjustable

6. Locking knob 7.Collet. 8.Under pole 9.Grip 10.Strap 11. Buckle 12.Handle

13.Switch Lockout 14.ON/OFF Trigger 15.Mains Power Cable 16.Oil Filler Cap.

SAFETY INSTRUCTIONS

WARNING Read all safety warnings and all instructions. Failure to follow the

warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases or dust. Power tools create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the mains supply outlet. Never modify the plug

in any way. Do not use any adapter plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric shock if

4

your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a residual

current device (RCD) protected supply. Use of an RCD reduces the risk of electric

shock. NOTE: The term “residual current device (RCD)” may be replaced by the term

“ground fault circuit interrupter (GFCI)” or “earth leakage circuit breaker (ELCB)”.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inattention while operating power

tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source, picking up or carrying the tool. Carrying power

tools with your finger on the switch or energising power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection

can reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was

designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power

tool that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug of the power tool from the power source before making

any adjustments, changing accessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the power

tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

5

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could

result in a hazardous situation and invalidate your guarantee

h) Should the mains power head become damaged, have this replaced by a

qualified engineer. Do not attempt to replace by yourself.

5) Service

a) Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power tool is

maintained.

6) Storage

a) use of transport guard during transport and storage

b) cleaning and maintenance before storage

c) securing of the unit during transport to prevent loss of fuel, damage or injury

POLE SAW TRIMMING PRECAUTIONS

Never stand directly under the limb you are trimming. Always position

yourself out of the path of falling debris.

6

Never stand on a ladder or other type of unstable support while using the

Pole saw.

Always use both hands to operate pole saw. Keep a firm, steady pressure

on the pole saw while cutting but do not try to force the saw through

the wood.

Do not use the pole saw to cut limbs larger in diameter than the length of

the guide bar.

Keep other persons away from cutting end of pole saw and at a safe distance

from work area.

Do not use pole saw near electric power cable or telephone lines. Maintain

a minimum clearance of 10 feet from all power lines.

7

POLE SAW INFORMATION

POLE SAW ASSEMBLY

(WARNING: Cutting edges on chain are sharp. Use protective gloves when

handling chain.)

1. Lay chain out flat.

2. Turn adjusting screw counterclockwise (see Figure 1). Continue to turn adjusting

screw until adjusting block is to rear of adjusting plate.

3. Install guide bar onto saw body. Place rear of guide bar between adjusting plate and

sprocket support.(IMPORTANT: Make sure to insert adjusting block into adjusting

hole on guide bar.)

Figure 1

4.Place chain around drive sprocket, then along top groove of guide bar and around

guide bar nose. Note: Make sure cutting edges of chain are facing the right direction

(see Figure 16). Position chain so cutting edges on top of guide bar face guide bar

nose (see Figure 1).

5. Adjust saw chain tension. Follow steps under Saw Chain Tension Adjustment.

Figure 2

8

6. Fill with chain oil before use. Always check oil level before use. A full tank of oil

will last approximately 30 minutes. (See Figure 2)

Pole Saw Information

SAW CHAIN TENSION

WARNING:Unplug chain saw from power source before adjusting saw chain

tension. Severe injury or death could occur from body contact with moving

chain.

WARNING: Cutting edges on chain are sharp. Use protective gloves when

handling chain.

WARNING: When cleaning saw body:-

• do not submerge saw in any liquids

• do not use products that contain ammonia, chlorine, or abrasives

• do not use chlorinated cleaning solvents, carbon tetrachloride, kerosene, or

gasoline

(Note: The saw chain tension is properly set at the factory. A new chain will stretch.

Check new chain tension frequently (after disconnecting the plug from the power

source) during the first 2 hours of operation. Allow chain to cool down. Follow steps

below to check saw chain tension.)

1. Unplug chain saw from power source.

2. Place chain saw on a firm surface to check chain tension.

3. Pull chain with light force 1/8" away from bottom of guide bar and release (See

Figure 3). If chain lightly snaps back into place, tension is correct. A slight sag (1/16"

or less) between chain and bottom of guide bar is acceptable.

Figure 3

Saw Chain Tension Adjustment

1. Loosen guide bar screw before adjusting chain. ( See Figure 4)

9

Figure 4

2. Turn adjusting screw on front of power head clockwise until slack is out of chain.

( See Figure 5)

Figure 5

3. Wearing protective gloves, pull down on chain to check chain tension.

4. Do not over-tension chain. Over-tensioning will cause excessive wear and will

reduce the life of the guide bar and chain.

5. After chain tension is correct, tighten guide bar screw firmly.(See Figure 6)

Figure 6

10

Adjusting Pole Length

The Pole Saw has a telescoping pole assembly that will extend from 1.8 meters (fully

retracted) to 2.7 meters (fully extended). The collet with a locking knob is used to

hold the pole in position at any extended length.

1. To extend the pole, loosen the locking knob(see Figure 7). Pole will slide freely.

2. Pull inner pole section out to desired length of extension. Note: Only extend pole to

minimum length required to reach limb that is being cut.

3. To lock pole in position, tighten locking knob (see Figure 7).

Figure 7

CUTTING WITH THE CHAIN SAW

1. Fill the oil tank with chain oil.

2. Connect power cord to power supply.

3. Use both hands to grip pole saw. Use designated grip areas and strap when

operating pole saw. (See Figure 8) Use firm grip. Thumbs and fingers must wrap

around pole saw handle and pole.

4. Make sure your footing is firm. Keep feet apart. Divide your weight evenly on both

feet.

Figure 8

11

5. When ready to make a cut, press in trigger lockout and squeeze trigger(See Figure

9). This will turn pole saw on. Releasing trigger will turn pole saw off. Make sure saw

is running before starting a cut.

Figure 9

6. When starting a cut, place moving chain against wood. Hold pole saw firmly in

place to avoid possible bouncing or skating (sideways movement) of saw.

7. Remove pole saw from a cut with saw running at full speed. Stop pole saw by

releasing trigger. Make sure chain has stopped before setting pole saw down.

CLEANING AND MAINTENANCE

CLEANING SAW BODY

Keep saw body clean. Use a soft cloth dampened with a mild soap and water mixture.

Wipe saw body to clean.

CARE OF GUIDE BAR

Uneven bar wear causes most guide bar problems. Incorrect sharpening of chain

cutter and depth gauge settings often cause this. When bar wears unevenly, it widens

guide bar groove (See Figure 10). This causes chain clatter and rivet popping. Saw

will not cut straight. Replace guide bar if this occurs.

Inspect guide bar before sharpening chain. A worn or damaged guide bar is unsafe. A

worn or damaged guide bar will damage chain. It will also make cutting harder.

Figure 10

12

Normal Guide Bar Maintenance

1. Remove guide bar from chain saw.

2. Remove sawdust from guide bar groove periodically. Use putty knife or wire (See

Figure 11).

3. Clean oil slots after each day of use.

4. Remove burrs from sides of guide bar. Use flat file to make side edges square.

Replace guide bar when

• bar is bent or cracked

• inside groove of bar is badly worn

(Note: When replacing guide bar, see Replacement Parts and Accessories for

replacement information. See Parts List for correct bar.)

Figure 11

SHARPENING SAW CHAIN

Keep chain sharp. Your saw will cut faster and more safely. A dull chain will cause

undue sprocket, guide bar, chain, and motor wear. If you must force chain into wood

and cutting creates only sawdust with few large chips, chain is dull and must either be

sharpened or replaced.

Items Needed to Sharpen Chain

Purchase these items from your local dealer, hardware store, or pole saw supplies

outlet.

• 5/32" round file

• Depth gauge tool

• File guide

• Vice

• Medium sized flat file

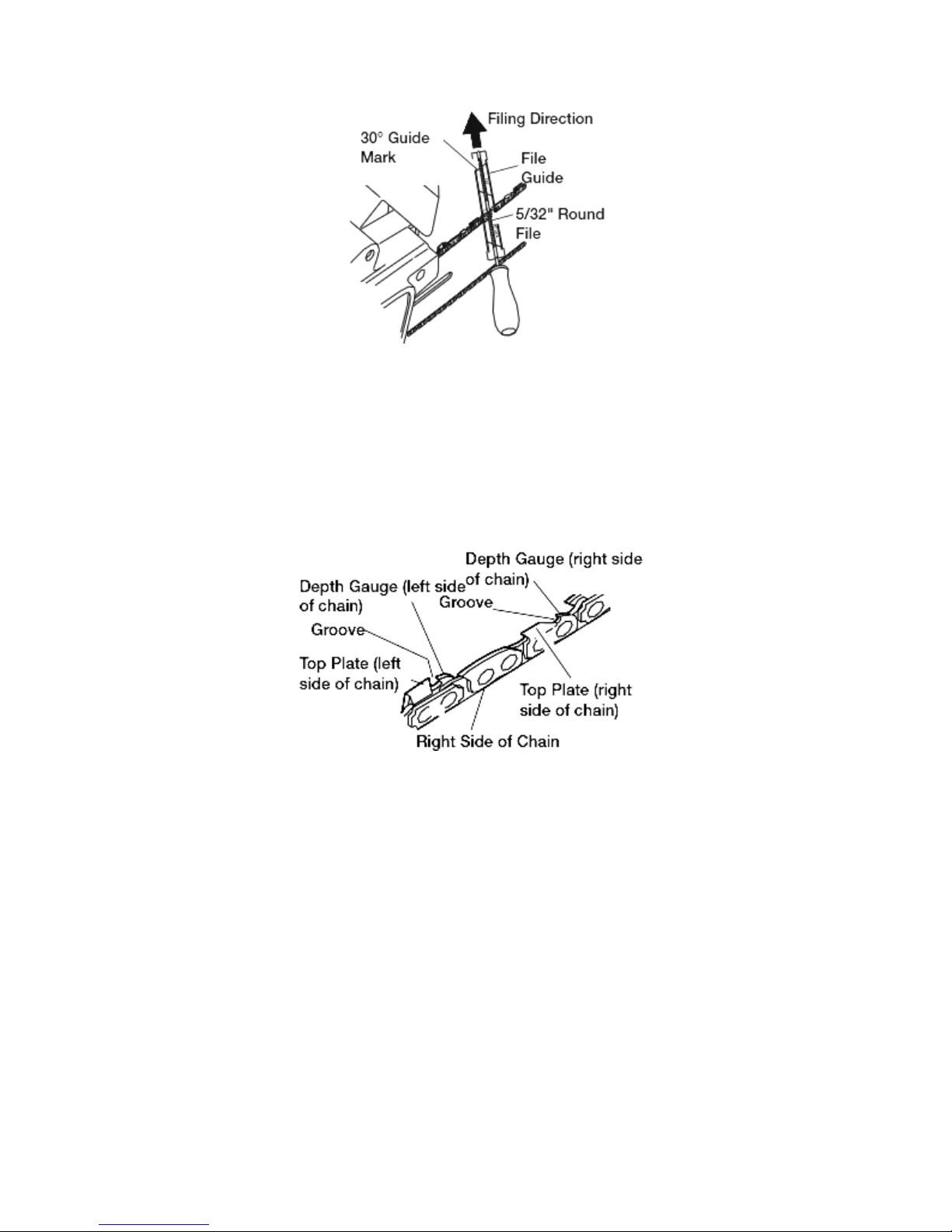

Sharpening Cutters

Use file guide for 30° filing.

1. Adjust chain for proper tension.

2. Clamp guide bar in vise to hold saw steady. (Note: Do not clamp chain.)

3. Press 5/32" round file (attached to file guide) into groove between top plate and

depth gauge on chain. File guide should rest on both top plate and depth gauge (see

13

Figure 12). (Note: File at midpoint of guide bar.)

Figure 12

Note: This illustration shows file guide placement and filing direction for sharpening

cutters on left side of chain.

4. Hold file guide level. Make sure 30° mark on file guide is parallel to center of

guide bar (see Figure 13). This will insure that you file cutters at 30° angle.

5. File from inside towards outside of cutter until sharp. Only file in this one direction

(see Figure 13). (Note: Two or three strokes with file should sharpen cutter.)

Figure 13

Filing Cutter Depth Gauges

The cutter depth gauge clearance is reduced as cutters are sharpened. After every

second or third sharpening, reset cutter depth gauges.

1. Place depth gauge tool (.025") firmly across top of two cutters. Make sure depth

gauge enters slot in depth gauge tool (see Figure 14).

2. Use medium flat file. File depth gauge level with depth gauge tool.

3. Remove depth gauge tool. With flat file, round off front corner of cutter depth

gauge (see Figure 15).

After several hand filings, have authorized service center or sharpening service

machine sharpen chain. This will insure even filing.

14

Figure.14

Figure.15

REPLACING SAW CHAIN

Replace chain when cutters are too worn to sharpen or when chain breaks. Only use

replacement chain noted in this manual. Check drive sprocket for wear when

replacing chain. This will maintain proper driving of chain. (Note: For proper chain

and drive sprocket, see Parts List.)

Refer to Figure 1 while completing the following steps.

1. Loosen and remove guide bar screw.

2. Remove sprocket cover.

3. Remove saw chain.

4. Place new chain around drive sprocket, along top groove of guide bar, and around

guide bar nose. Note: Make sure cutting edges of chain are facing in right direction.

Position chain so cutting edges on top of guide bar face guide bar nose (see Figure 16

and indicator on side cover of saw).

5. Before placing sprocket cover into Positioning groove, verify that the adjusting nib

is in the adjusting hole on the guide bar.

6. Place sprocket cover into Positioning groove.

7.Locking the sprocket cover with guide bar screw. (IMPORTANT: Finger tighten

only.)

8. Adjust chain tension.

9. Securely tighten guide bar screw with Hexagon wrench.

15

Figure 16

CAUTION: Do not place chain on saw backwards. If chain is backwards, saw

will vibrate badly and will not cut.

STORAGE

If storing saw for more than 30 days, follow steps below.1. Drain oil tank after each

use.

2. Remove and clean guide bar and chain. Clean guide bar and chain by soaking in

petroleum based solvent or mild soap and water mixture.

3. Dry guide bar and chain.

4. Place chain in container filled with oil. This will prevent rust.

5. Wipe a thin coating of oil over surface of guide bar.

6. Wipe off outside of saw body. Do this with soft cloth dampened with a mild soap

and water mixture.

7. Store chain saw

• in a high or locked place, out of children's reach

• in a dry place

GUARANTEE:

This product is guaranteed for a period of 12 months from date of purchase. Any

modification or misuse of this machine will invalidate your guarantee. Your statutory

rights remain unaffected.

Imported by T2 Direct Ltd - London

Loading...

Loading...