Page 1

1????

ENGLISH

FRANÇAIS

DEUTSCH

ITALIANO

ESPAÑOL

OPERATOR'S MANUAL

MANUEL D'UTILISATION

BEDIENUNGSANLEITUNG

MANUALE PER L'OPERATORE

MANUAL DE INSTRUCCIONES

RM-520ES

WARNING

READ THE INSTRUCTIONS CAREFULLY AND FOLLOW THE RULES FOR

SAFE OPERATION.

FAILURE TO DO SO COULD RESULT IN SERIOUS INJURY.

AVERTISSEMENT

LIRE ATTENTIVEMENT LES INSTRUCTIONS ET SUIVRE LESRÈGLES DE

SECURITÉ.LE NON-RESPECT DES RÈGLES DE SÉCURITÉ ENTRAÎNE UN

ISQUE DE BLESSURE GRAVE.

WARNUNG

LESEN SIE DIE BEDIENUNGSANLEITUNG SORGFÄLTIG DURCH, UND BE

FOLGEN SIE DIE SICHERHEITSREGELN. ANDERNFALLS BESTEHT DAS

RISIKO SCHWERER VERLETZUNGEN.

AVVERTENZA

LEGGERE E SEGUIRE ATTENTAMENTE LE ISTRUZIONI PER LAVORARE IN

CONDIZIONI DI MASSIMA SICUREZZA. LA MANCATA OSSERVANZA DELLE

ISTRUZIONI POTREBBE PROVOCARE LESIONI GRAVI.

ADVERTENCIA

LEA ATENTAMENTE LAS INSTRUCCIONES Y SIGA LAS INDICACIONES

PARA UN FUNCIONAMIENTO SEGURO. DE NO HACERLO, PODRÍA SUFRIR

LESIONES GRAVES.

Page 2

2

Page 3

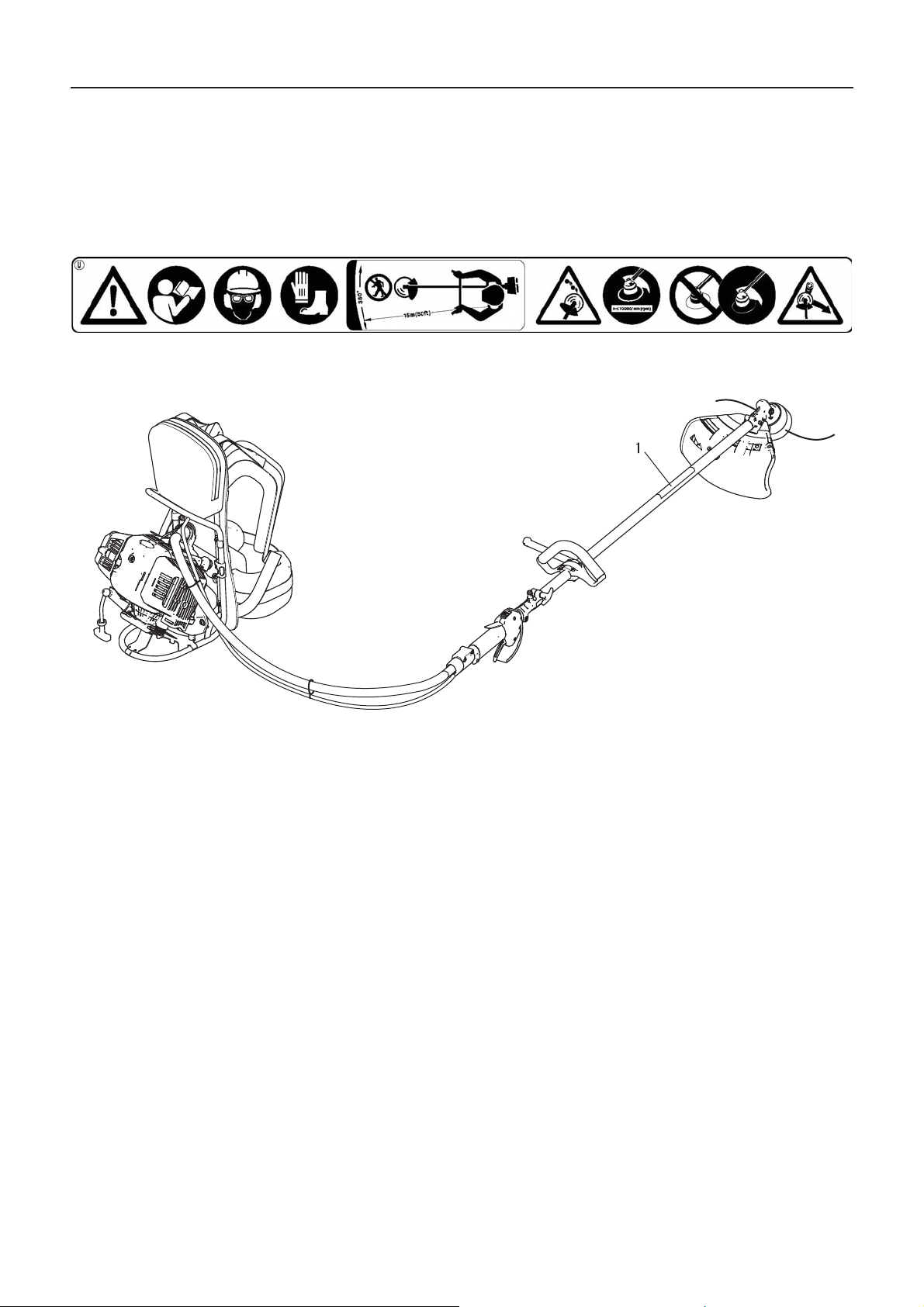

1Cover

ENGLISH

(Original instructions)

OPERATOR'S MANUAL

GRASS-TRIMMER/BRUSHCUTTER

RM-520ES

WARNING

READ THE INSTRUCTIONS CAREFULLY AND FOLLOW THE

RULES FOR SAFE OPERATION.

FAILURE TO DO SO COULD RESULT IN SERIOUS INJURY.

Page 4

Contents

For safe use of your product...................................... ... .... ... ... ............................................3

Description..........................................................................................................................8

Before you start ..................................................................................................................9

Packing list ....................................................................................................................9

Assembly.....................................................................................................................10

Preparing the fuel ........................................................................................................12

Engine operation...............................................................................................................13

Starting the engine ......................................................................................................13

Stopping the engine..................................................................................................... 14

Trimming operation.......................................... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... 15

Basic trimming operation with nylon line cutting head.................................................16

Basic trimming operation with metal blade..................................................................18

Maintenance and care......................................................................................................20

Servicing guidelines.....................................................................................................20

Maintenance and care................................................. ... ... ... .... ... ... ... ... .... ... ... ... .... ......20

Storage........................................................................................................................28

Specifications....................................................................................................................29

Declaration of conformity..................................................................................................30

2

Page 5

For safe use of your product

For safe use of your product

Important information

WARNING

Please ensure that you read the operator's manual before using yo ur product.

About your operator's manual

This manual contains necessary information about the assembly, operation, and maintenance of your product.

Please read it carefully and absorb its contents.

Always keep your manual in a place where it is readily accessible.

If you have lost your manual or it is damaged and no longer readable, please purchase a new one from your dealer.

The units used in this manual are SI units (International System of Units). Figures in parentheses are reference values, and there may be a slight conversion error in some cases.

Failure to do so could lead to an accident or serious injury.

Intended use of this product

This product is lightweight, high-performance, petrol engined unit designed for weed control, grass trimming and

brush cutting in areas difficult to control by any other means.

Do not use this unit for any purpose other than aforementioned.

The content of this manual may be changed without notice for the purpose of upgrades to the product. Some of the

illustrations used may differ from the product itself in order to make the explanations clearer.

Please consult your dealer if anything is unclear or of concern.

Failure to do so could lead to an accident or serious injury.

Do not modify the product

You must not modify the product.

To do so could lead to an accident or serious injury. Any malfunction resulting from a modification to the product will not be

covered by the manufacturer's warranty.

Do not use the product unless it has been checked and maintained

You must not use the product unless it has been checked and maintained. Always ensure that the product is checked

and maintained on a regular basis.

Failure to do so could lead to an accident or serious injury.

Loaning or assigning your product

When loaning your product to another party, ensure that the person borrowing the product receives the operator's

manual along with it.

If you assign your product to another party, please enclose the operator's manual with the product when handing it

over.

Failure to do so could lead to an accident or serious injury.

Users of the product

The product should not be used by:

people who are tired

people who have taken alcohol

people who are on medication

people who are pregnant

people who are in poor physical condition

people who have not read the operator's manua l

children

Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people or their property.

Failure to observe these instructions could lead to an accident.

The ignition system of this product generates electromagnetic fields during operation. Magnetic fields can cause

pacemaker interference or pacemaker failure. To reduce health risks, we recommend that pacemaker users consult

their physician and the pacemaker manufacturer before operating this product.

3

Page 6

For safe use of your product

WARNING

Vibration and cold

It is believed that a condition called Raynaud's Phenomenon which affects the fingers of certain individuals may be

brought about by exposure to vibration and cold. Exposure to vibration and cold may cause tingling and burn ing,

followed by loss of colour and numbness in the fingers. The following precautions are strongly recom mended because the minimum exposure which might trigge r the ai lment is unknown.

Keep your body warm, especially the head and neck, feet and ankles, and hands and wrists.

Maintain good blood circulation by performin g vigoro us arm exercises during frequent work breaks, and also by

not smoking.

Limit the number of hours of operation. Try to fill each day with jobs where operating the trimmer or other hand-

held power equipment is not required.

If you experience discomfort redness and swelling of the fingers, followed by whitening and loss of feeling, con-

sult your physician before exposing you rself further to cold and vibration.

Failure to observe these instructions could result in damage to your health.

Repetitive stress injuries

It is believed that over-using the muscles and tendons of the fingers, hands, arms and shoulders may cause soreness, swelling, numbness, weakness and extreme pain to the areas just mentioned. Certain repetitive hand activities

may put you at a high risk for developing a repetitive stress injury (RSI). To reduce the risk of RSI, do the following:

Avoid using your wrist in a bent, extended or twisted position.

Take periodic breaks to minimize repetition and rest your hands. Reduce the speed and force in which you do the

repetitive movement.

Do exercises to strengthen hand and arm muscles.

See a doctor if you feel tingling, numbness or pain in your fingers, hands, wrists or arms. The sooner RSI is diag-

nosed, the more likely permanent nerve and muscle damage can be prevented.

Failure to observe these instructions could result in damage to your health.

Proper training

Do not permit operation without proper training and protective equipment.

Be thoroughly familiar with the controls and proper use of unit.

Know how to stop the unit and shut off the engine.

Know how to unhook a harnessed unit quickly.

Never allow anyone to use the unit without proper instruction.

Failure to observe these instructions could result in damage to your health.

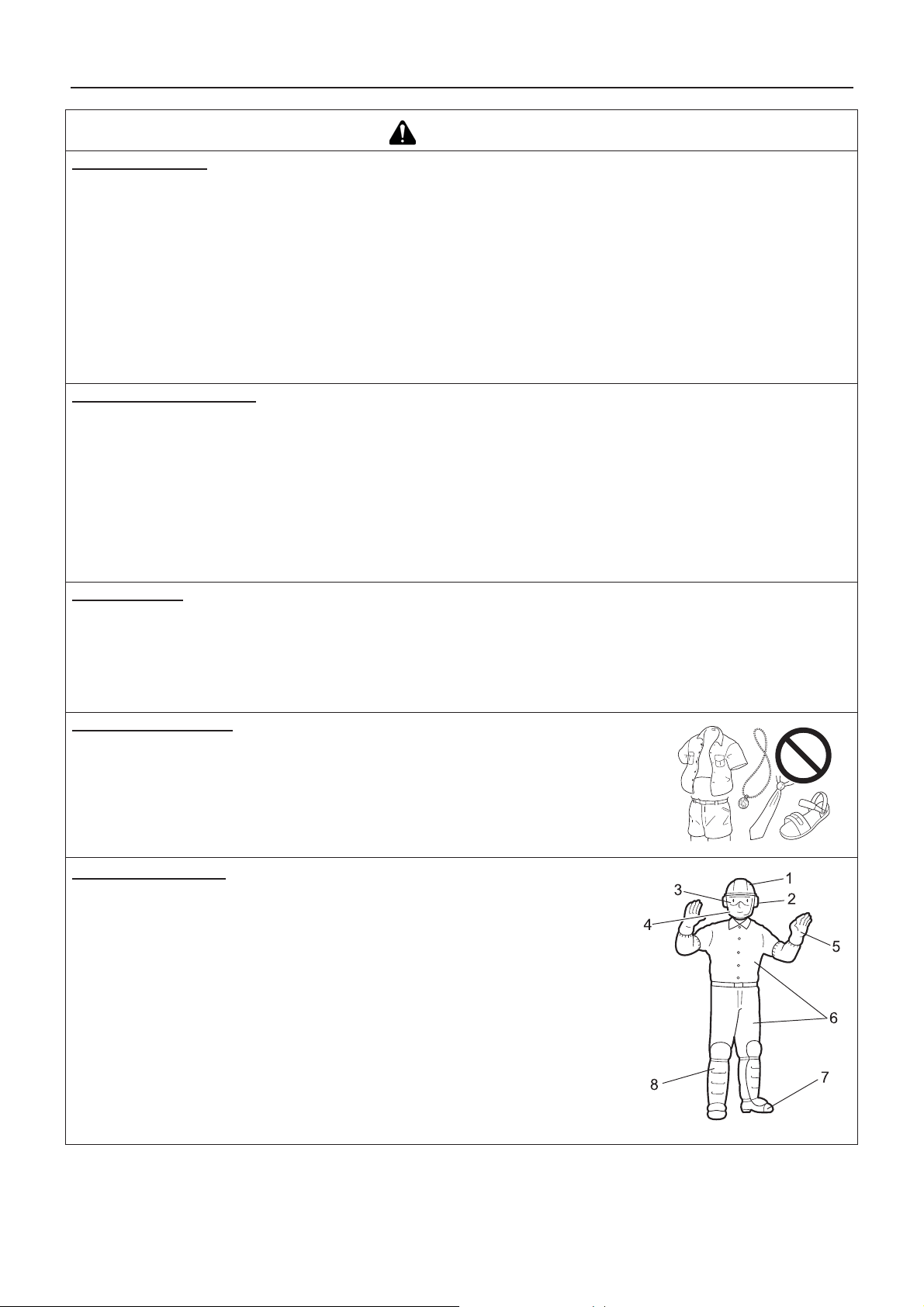

Wear proper clothing.

Secure hair so it is above shoulder length.

Do not wear ties, jewellery, or loose, dangling clothing which could be caught in the

unit.

Do not wear open toed footwear, or go bare-foot or barelegged.

Failure to observe these precautions could result in damage to your sight or hearing, or lead

to a serious injury.

Wear protective gear

Always wear the following protective gear when working with the trimmer.

1. Head protection (helmet): Protects the head

2. Ear muffs or ear plugs: Protect the hearing

3. Safety goggles: Protect the eyes

4. Face shield: Protects the face

5. Safety gloves: Protect the hands from cold and vibration

6. Work clothes that fit (long sleeves, long trousers): Protect the body

7. Heavy duty, non-slip protective boots (with toecaps) or non-slip work shoes

(with toecaps): Protect the feet

8. Shin guards: Protect the legs

Failure to observe these precautions could result in damage to your sight or hearing, or

lead to a serious injury.

When necessary, please use the protective gear below.

Dust mask: Protects the breathing apparatus

Bee net: To deal with attacks by bees

4

Page 7

For safe use of your product

WARNING

Environment of use and operation

Do not use the product:

under poor weather conditions.

on steep slopes or in places which give no secure foothold and are thus slippery.

at night or in dark places with poor visibility.

When using the product on a gentle slope, work in a level, contour-like motion.

A serious injury could result if you fall or slip, or fail to operate the product correctly.

For your own health and your safe and comfortable work, operate the machine within the air temperature range of

í5oC to 40oC.

Failure to observe these instructions could result in damage to your health.

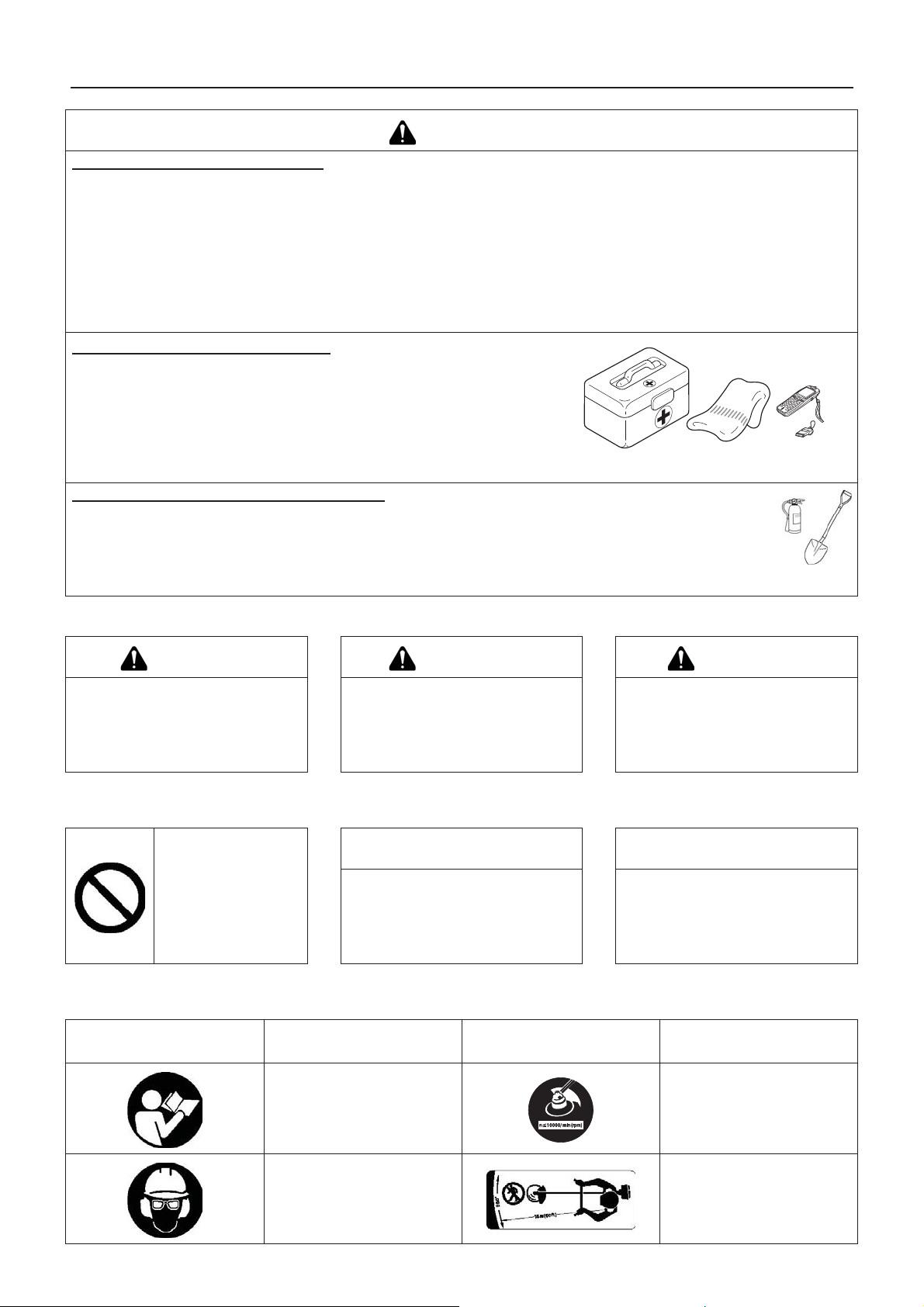

Being prepared in case of an injury

In the unlikely event of an accident or injury, please ensure that you are

prepared.

First aid kit

Towels and wipes (to stop any bleeding)

Whistle or mobile phone (for calling outside help)

If you are unable to perform first aid or call for outside help, the injury could

worsen.

Put safety first in the case of fire or smoke

If fire comes from the engine or smoke appears from any area other than the exhaust vent, first distance

yourself from the product to ensure your physical safety.

Use a shovel to throw sand or other such material on the fire to prevent it from spreading, or put it out

with a fire extinguisher.

A panicked reaction could result in the fire and other damage becoming more extensive.

Warning notices

DANGER WARNING CAUTION

This symbol accompanied by the

word "DANGER" calls attentions to

an act or a condition which will lead to

serious personal injury or death of operators and bystanders.

Other indicators

Circle and slash symbol means whatever is

shown is prohibited.

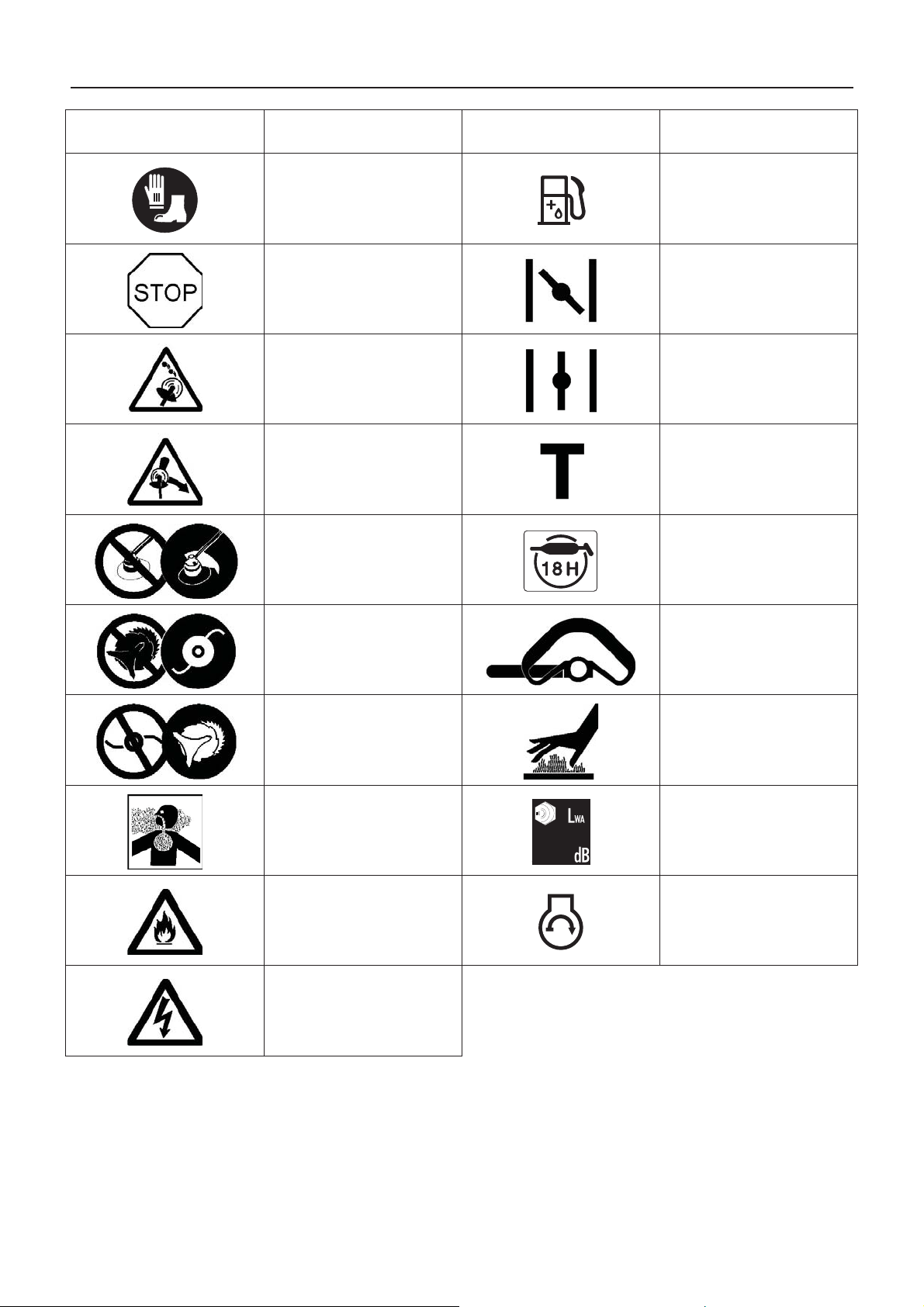

Symbols

Symbol form/shape Symbol description/applica-

This symbol accompanied by the

word "WARNING" calls attentions to

an act or a condition which can lead to

serious personal injury or death of operators and bystanders.

This enclosed message provides tips

for use, care and maintenance of the

product.

tion

"CAUTION" indicates a potentially

hazardous situation which, if not

avoided, may result in minor or moderate injury.

NOTE IMPORTANT

Framed text featuring the word "IMPORTANT" contains important infor-

mation about the use, checking,

maintenance and storage of the product described in this manual.

Symbol form/shape Symbol description/applica-

tion

Carefully read the operator's

manual

Wear eyes, ears and head

protection

The maximum speed of the

cutting attachment shaft in

r/min

Keep bystanders away 15 m

5

Page 8

For safe use of your product

Symbol form/shape Symbol description/applica-

tion

Wear foot protection and

gloves

Emergency stop

Warning!

Thrown objects!

Warning, side thrust

Usage without shield not permitted

Symbol form/shape Symbol description/applica-

tion

Petrol and oil mixture

Choke Control "Cold Start"

Position (Choke Closed)

Choke Control "Run" Position

(Choke Open)

Carburettor adjustment

- Idle speed

Lubricate in every 18 hours

Usage of metal blades not

permitted

Usage of nylon line cutting

head not permitted

Do not use the product in places with poor ventilation

Beware of fire Engine start

Beware of electric shocks

-

Loop handle

Beware of high-temperature

areas

Guaranteed sound power level

6

Page 9

For safe use of your product

Safety decal(s)

The safety decal shown below has been attached to the products described in this manual. Ensure that you understand what

the decal means before using your product.

If the decal becomes unreadable due to wear and tear or damage, or peels off and is lost, please purchase a replacement decal

from your dealer and attach it in the location shown in the illustrations below. Ensure that the decal is readable at all times.

1. Safety decal (Part number 890617-43130)

7

Page 10

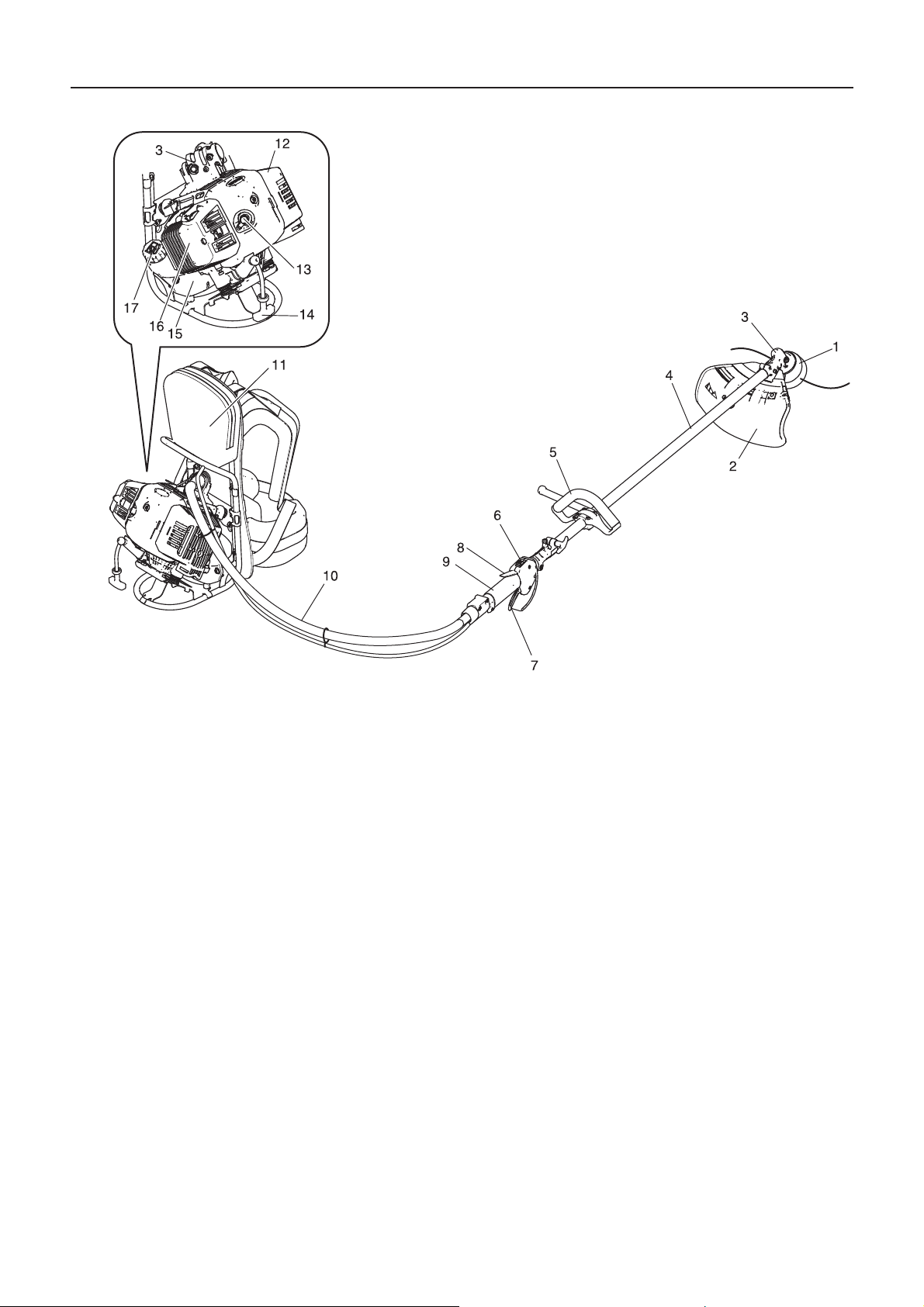

Description

Description

1. Cutting attachment - Nylon line cutting head for cutting

grass and weed.

2. Shield - Device to protect the operator from accidental

contact with the cutting head and thrown objects.

3. Angle transmission - Having two gears to change to

angle of rotating axis.

4. Shaft tube - Part of the unit that provides a casing for

power transmission shaft.

5. Front handle - Handle located towards the cutting device.

6. Ignition switch - "Slide switch" mounted on top of the

throttle trigger housing, move switch upward to RUN,

downward to STOP position.

7. Throttle trigger - Activated by the operator's finger for

controlling the engine speed.

8. Throttle trigger lockout - Locks throttle trigger in the

idling position until you have a proper grip with your right

hand around the handle.

9. Rear handle - Handle located towards the knapsack

power unit.

10. Flexible shaft assembly - Flexible tube for the power

transmission shaft.

11. Tool bag - Removable bag for tool and accessories.

12. Silencer cover - Cover the silencer not to make operator touch to hot surface of silencer.

13. Spark plug

14. Starter handle - Pull handle to start the engine.

15. Fuel tank - Contains fuel and fuel filter.

16. Air cleaner cover - Covers air filter.

17. Fuel tank cap - For closing the fuel tank.

8

Page 11

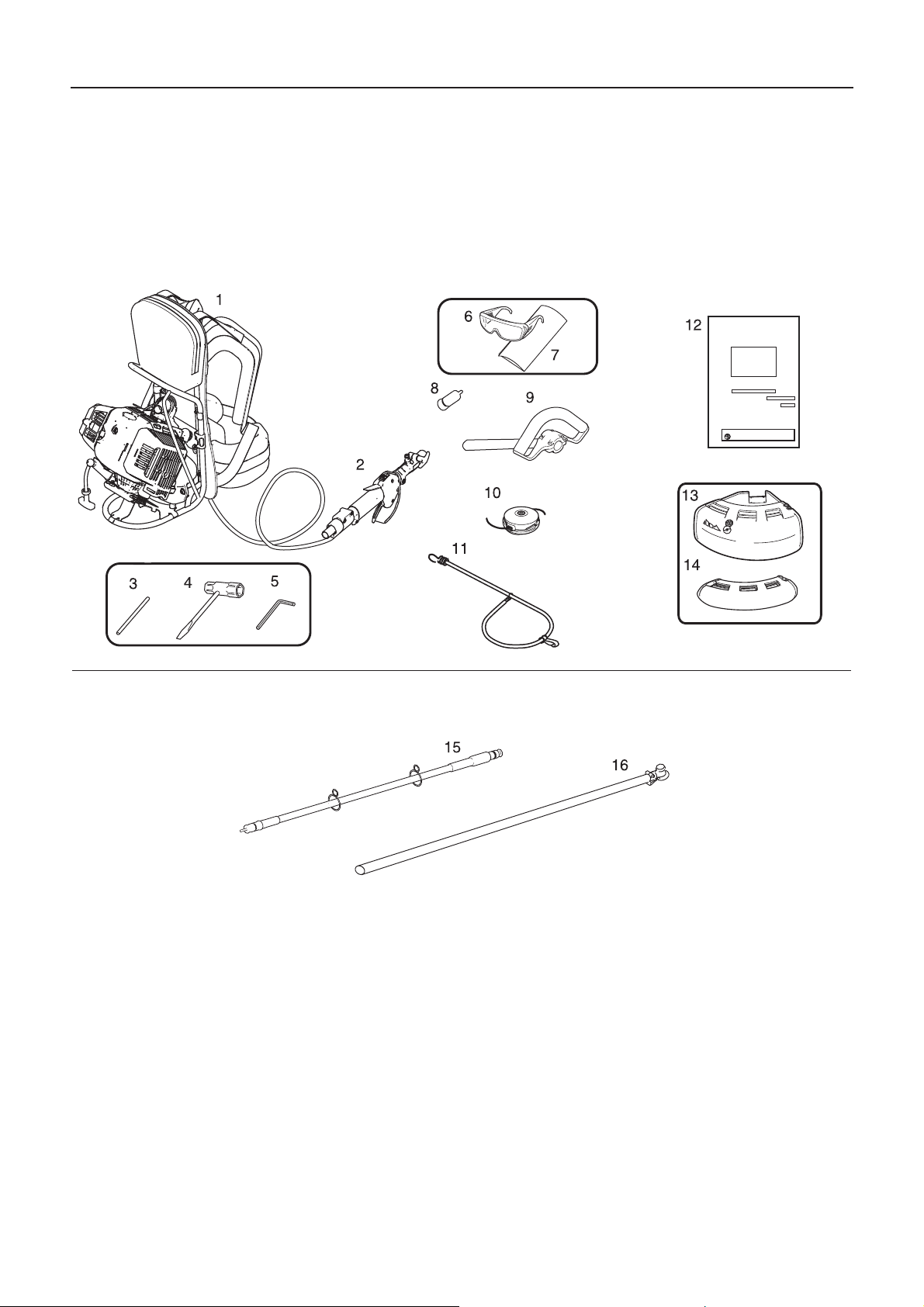

Before you start

Packing list

The following parts are packed separately in the packing box.

When you have unpacked the box, please check the parts that it contains.

Contact your dealer if anything is missing or broken.

Engine

Before you start

Operation Shaft

1. Engine

2. Throttle trigger

3. Locking tool

4. Socket wrench

5. L-wrench

6. Safety goggles

7. Caution tag

8. Plastic cap

9. Front handle

10. Nylon line cutting head

11. Strap

12. Operator's manual

13. Shield (for nylon line cutting head)

14. Shield (for metal blade)

15. Flexible shaft assembly

16. Shaft tube

9

Page 12

Before you start

Assembly

WARNING

Read the operator's manual carefully to ensure that you assemble the product correctly.

Using a product that has been incorrectly assembled could lead to an accident or serious injury.

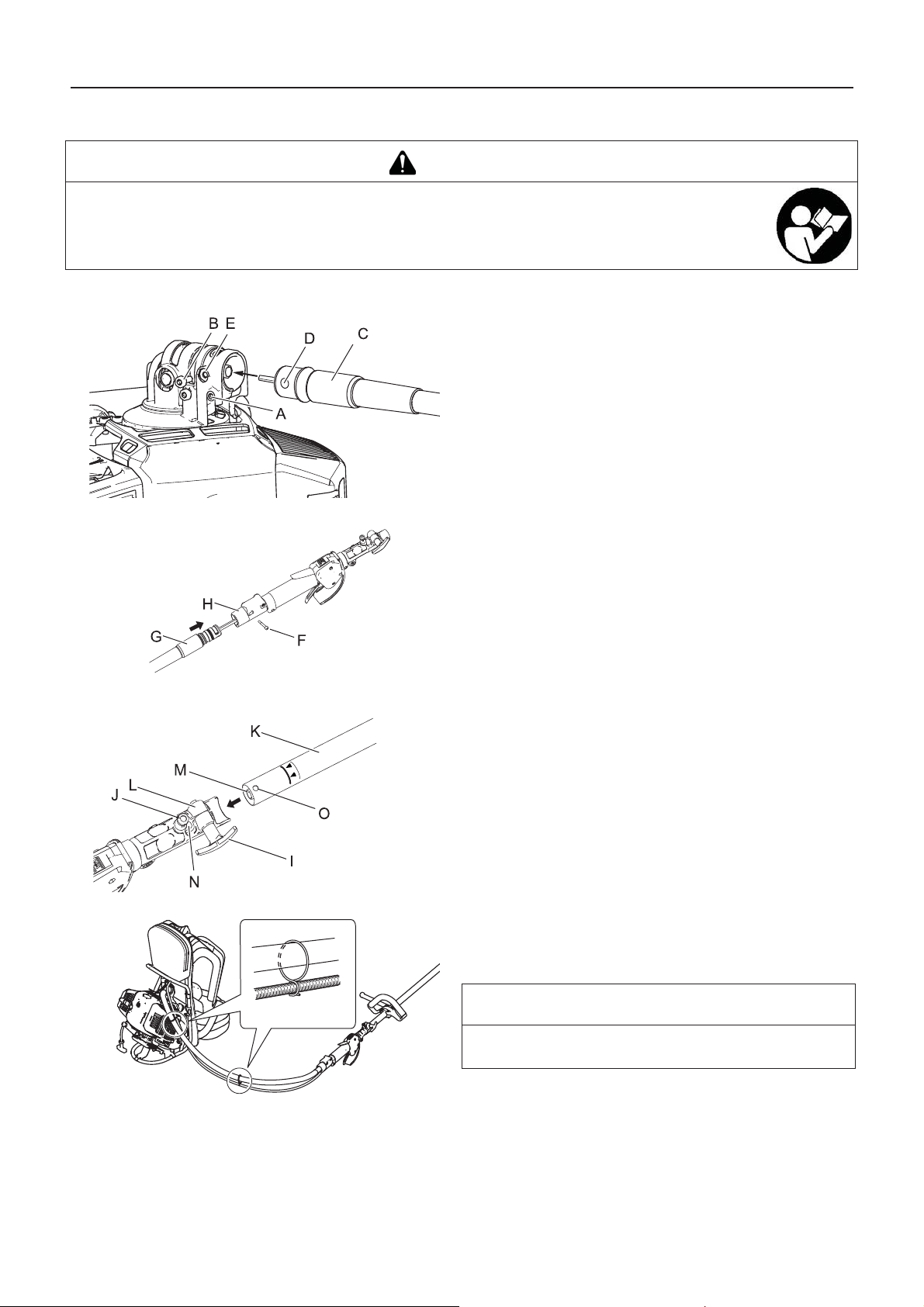

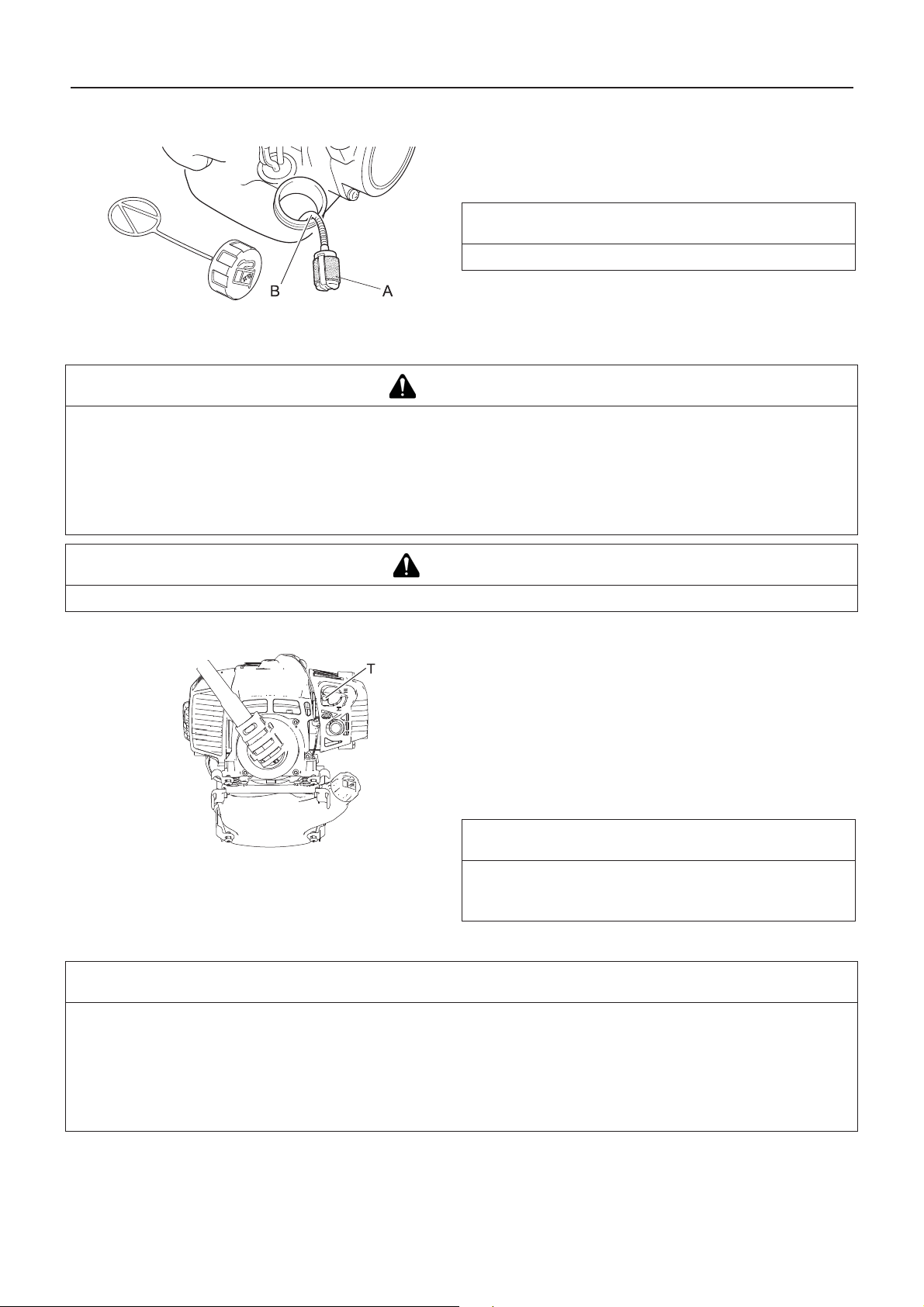

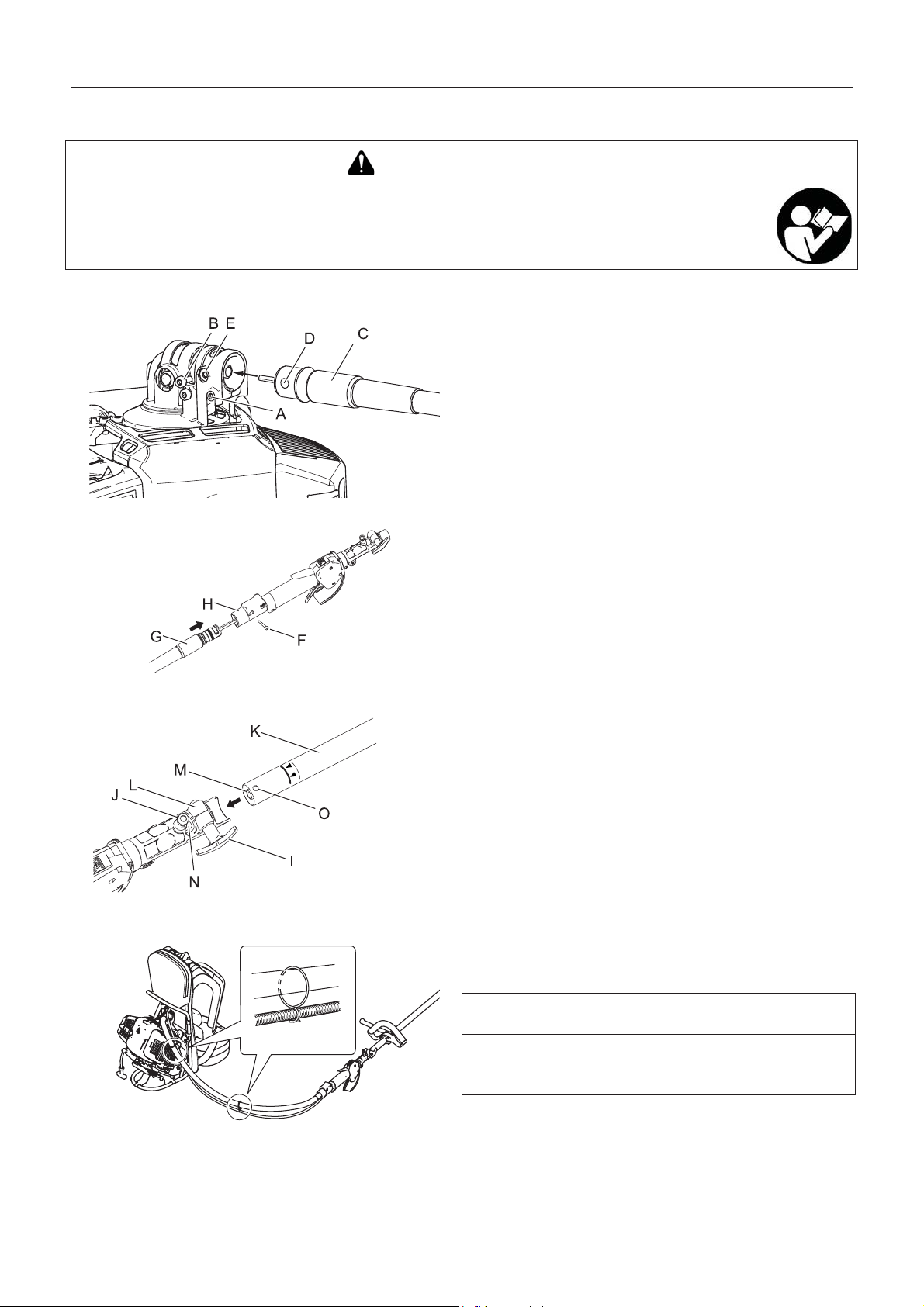

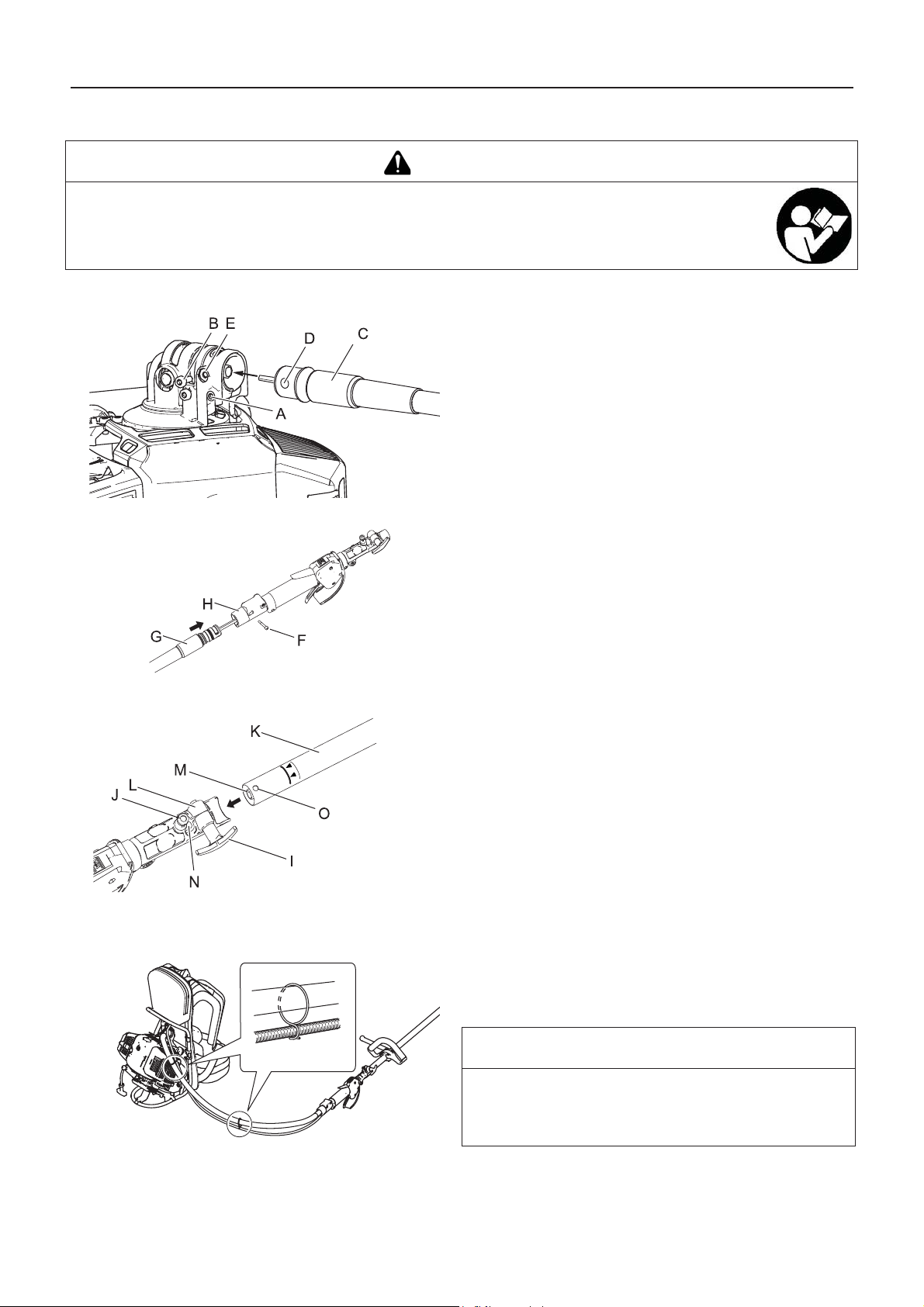

Operation shaft assembly

1. Loosen the bolt (A).

2. Remove the lock bolt (B).

3. Insert the flexible shaft assembly (C) into the angle transmission.

4. Align the hole of the flexible shaft assembly (D) with the hole

of the angle transmission (E).

5. Tighten the lock bolt and bolt.

6. Remove the lock bolt (F).

7. Insert the flexible shaft assembly (G) into the trigger tube.

8. Tighten the lock bolt.

9. Loosen the clamping knob (I).

10. Pull locator pin (J) out, and turn anticlockwise 1/4 turn to

lockout position.

11. Insert the operation shaft assembly (K) into the coupler (L)

as aligning the socket (M) with the flexible shaft (N).

12. Rotate locator pin 1/4 turn clockwise to engage operation

shaft hole. Insure locator pin is fully engaged by twisting operation shaft. Locator pin should snap flush in coupler. Full

engagement will prevent further shaft rotation.

13. Tighten the lock bolt.

14. The two pieces of clip attached to flexible shaft assembly

must be set to appropriate positions on the throttle cable (at

equal distance on the whole length of the flexible shaft assembly).

NOTE

To disassemble, reverse assembly instructions. Insert the

plastic cap to the coupler in order to prevent grease leakage

10

Page 13

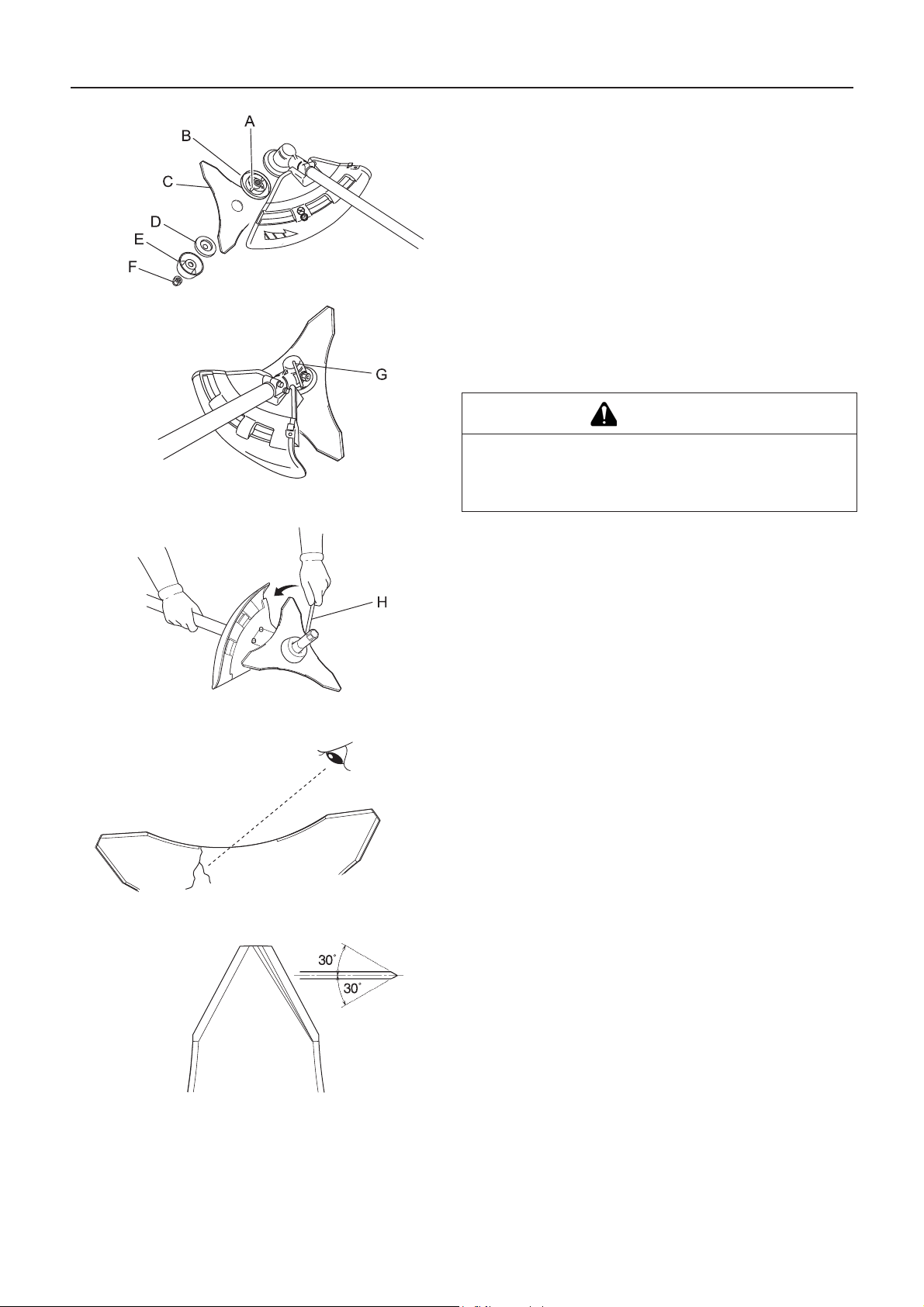

Loop handle assembly

Shoulder harness

Before you start

1. Assemble the front handle (A) and bracket (B) on the shaft

tube (C) loosely.

2. Adjust the location of the front handle to a convenient position.

3. Tighten the screws (M5×35) (D) and nuts (E) securely. - One

of the 4 screws must be tighten together with the hanger (F)

as illustrated.

1. Suit the length of knapsack band to comfort.

2. As the strap is elastic and adjustable, it is preferable to connect the strap (A) to the hangers (B) located on the front handle (C) and the left or right knapsack band to maintain a

fatigueless and comfortable operation.

1. Front handle

2. Hanger

3. Strap

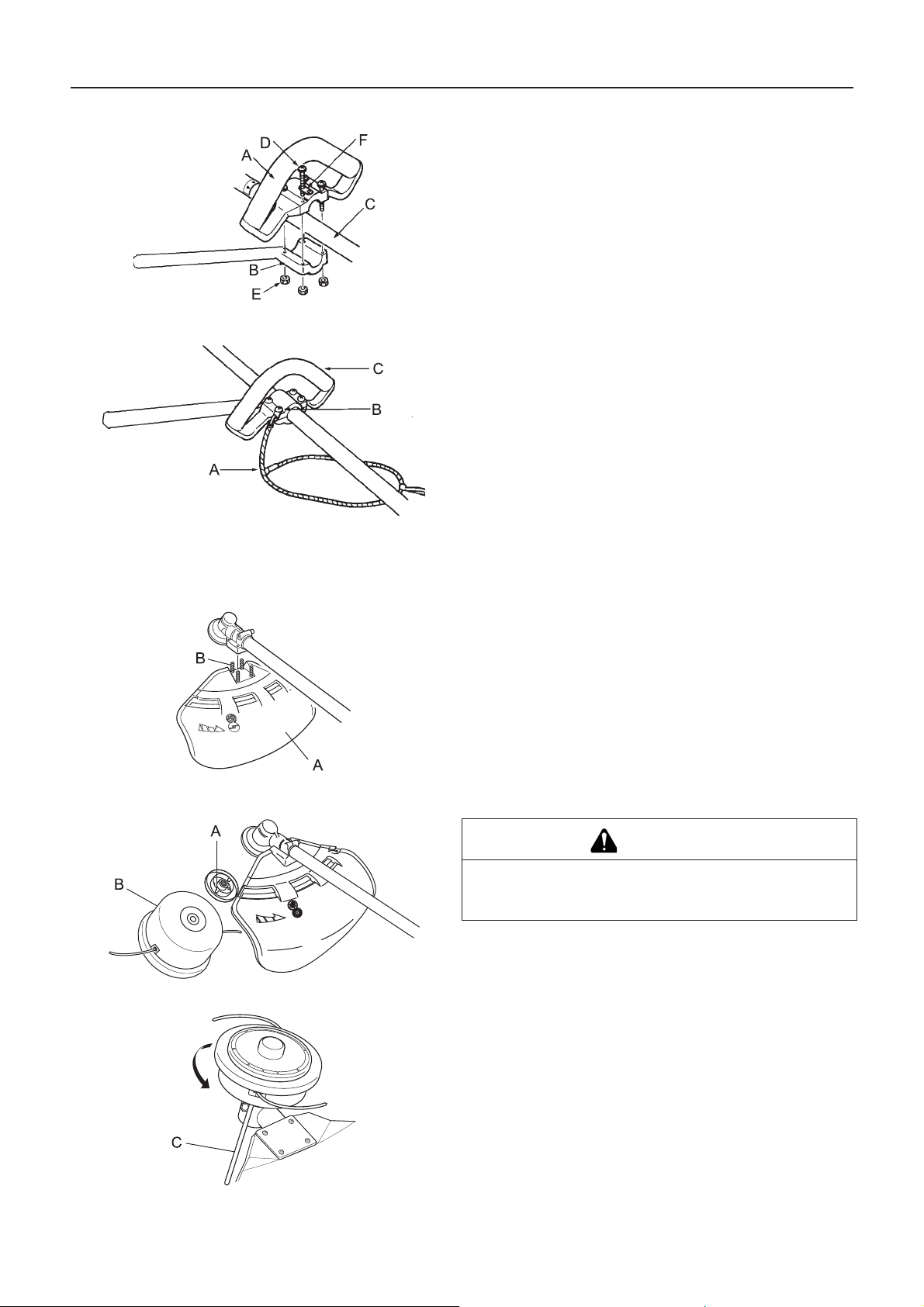

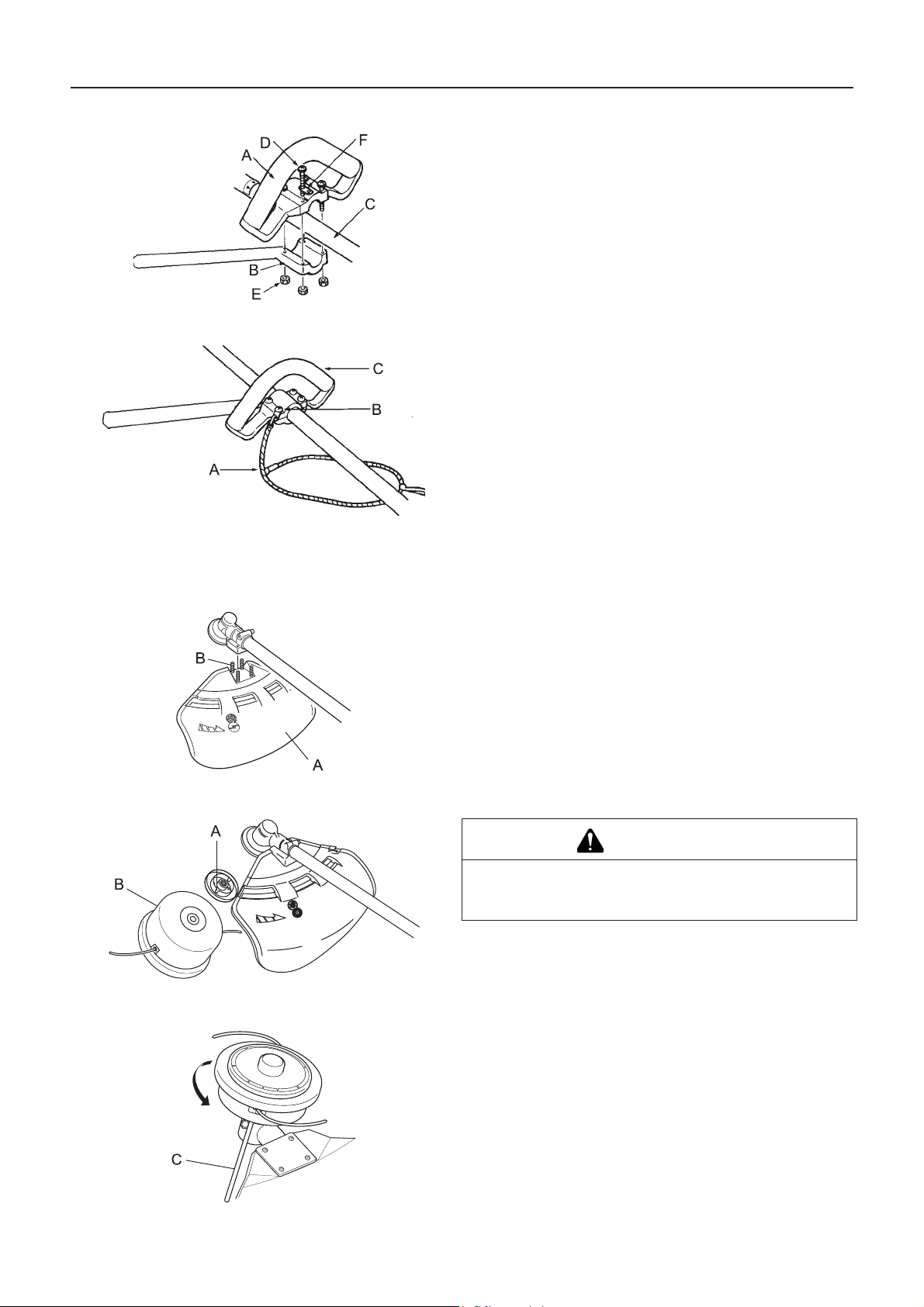

Installation of shield

Installing nylon line cutting head

1. Fit shield (A) to mounting portion of angle transmission and

tighten 4 bolts (B).

CAUTION

Fix output shaft securely using locking tool in order to

prevent it form rotating when nylon cutting head is

mounted.

1. Insert locking tool into a hole located on the right side of angle transmission while forcing retainer spring to the left side.

2. Insert locking tool further into blade retainer fixing slot (A) to

fix output shaft.

3. Thread nylon line cutting head (B) onto shaft (anticlockwise)

until it is tight.

4. Remove locking tool (C).

11

Page 14

Before you start

Preparing the fuel

DANGER

Do not fuel up while the engine is hot or in operation.

Do not smoke or hold a flame near when refuelling.

If you do so, the fuel could ignite and cause fire, leading to burns.

WARNING

Do not fill fuel tanks indoors. Always fill fuel tanks outdoors over bare ground. Do not refuel the product on the loading platform of a truck, or in other such places.

Fuel tanks/cans may be under pressure. Always loosen fuel caps slowly allowing pressure to equalize.

Otherwise, fuel may get spewed.

Mop up any fuel that overflows or spills out due to overfilling.

Fuel spills can cause fire and burns when ignited.

After refuelling, always check that there are no leaks or discharges of fuel from the fuel pipe, fuel system grommets,

or around the fuel tank cap. If you do find fuel leaks or discharges, stop using the product immediately and contact

your dealer to have it repaired.

Any fuel leaks could cause fire.

Keep the refuelling tank in a shaded area away from fire.

Use an approved fuel container.

IMPORTANT

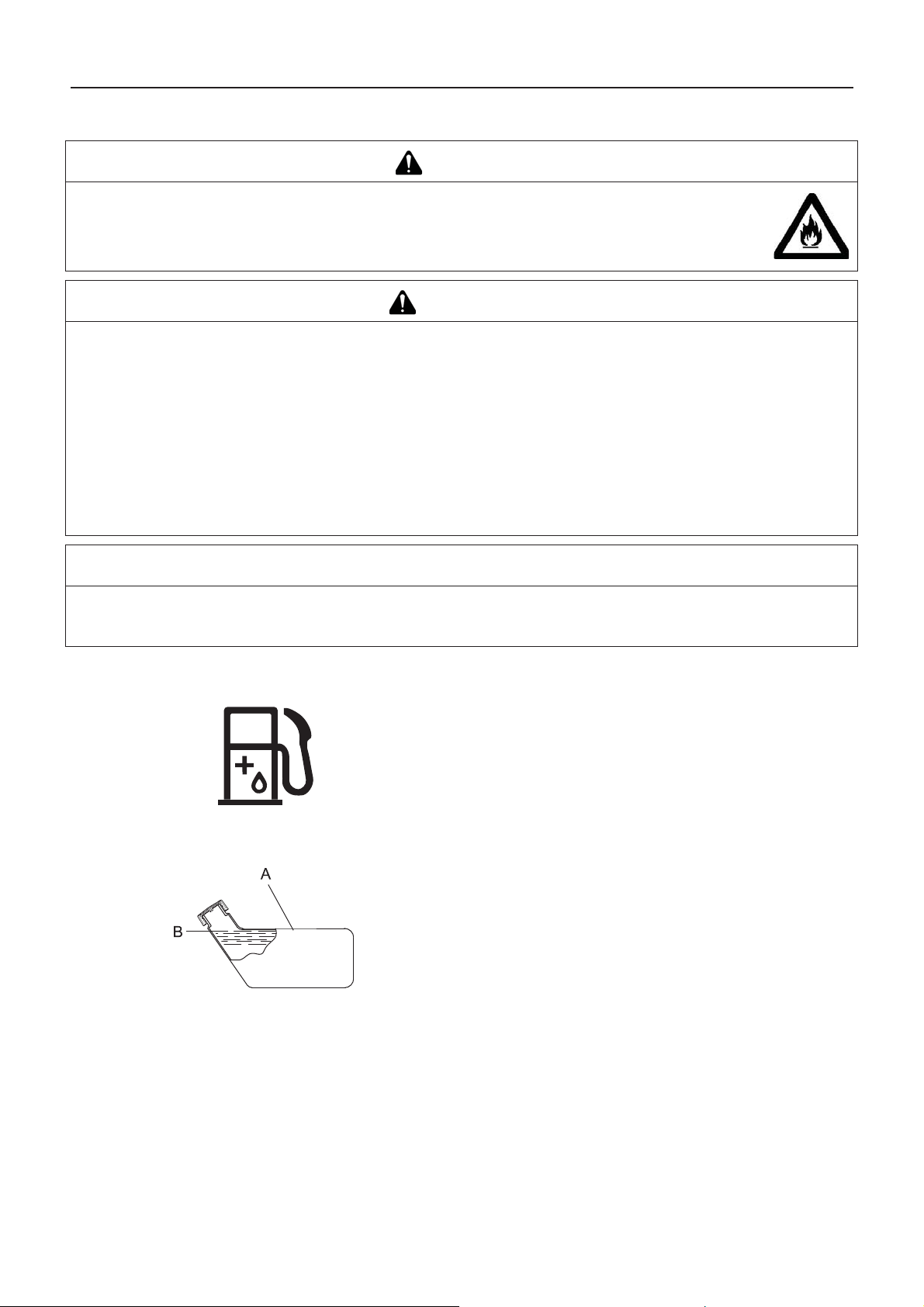

Fuel is a mixture of regular grade petrol and an air-cooled 2-stroke engine oil of reputable brand name. Minimum 89 Octane

unleaded petrol is recommended. Do not use fuel containing methyl alcohol or more than 10 % of ethyl alcohol.

Stored fuel ages. Do not mix more fuel than you expect to use in thirty (30) days.

Fuel

Recommended mixture ratio; 50: 1 (2%) for ISO-L-EGD

Standard (ISO/CD 13738), JASO FC,FD grade and ECHO

Premium 50: 1 oil.

Do not mix directly in engine fuel tank.

Fuel supply

Do not add so much fuel that it reaches the mouth of the fuel

tank (A). Keep the fuel within the prescribed level (up to the

shoulder level (B) of the fuel tank).

Tighten the fuel tank cap securely after refuelling.

12

Page 15

Engine operation

Engine operation

Starting the engine

WARNING

Be particularly careful to observe the following precautions when starting the engine:

Move at least 3m from the place where you refueled.

Place the product in a flat, well ventilated place.

Check that there are no fuel leaks.

Inspect metal blades for cracks.

Check that none of the nuts and bolts are loose.

Leave plenty of space around the product and do not allow people or animals near it.

Start the engine with the throttle trigger in the idle speed position.

Hold the product firmly to the ground when starting the engine.

Failure to observe the precautions could cause an accident or injury, or even lead to a fatality.

Check that there are no abnormal vibrations or sounds once the engine starts. Do not use the product if there are

abnormal vibrations or sounds. Contact your dealer to have it repaired.

Accidents involving parts that fall or shatter off can cause wounds or serious injury.

The exhaust fumes from the engine contain toxic gases. Do not operate the product indoors or in other

ill ventilated places.

The exhaust fumes could cause poisoning.

Do not touch silencer, spark plug, angle transmission, and other high temperature components while

the product is running or for some time after it stops.

You could burn yourself if you touch a high temperature component.

Do not touch spark plug, spark plug wire, and other high voltage components w hile the product is running.

You could receive an electric shock if you touch a high voltage component while the product is running.

If the cutting attachment rotates even though the throttle trigger is in the idle speed position when the engine is started, adjust the carburettor before using the product.

Failure to observe the precautions could cause an accident or injury, or even lead to a fatality.

NOTE

Pull out the starter grip gently at first, and then more rapidly. Do not pull the starter rope out to more than 2/3 of its length.

Do not let go of the starter grip as it returns.

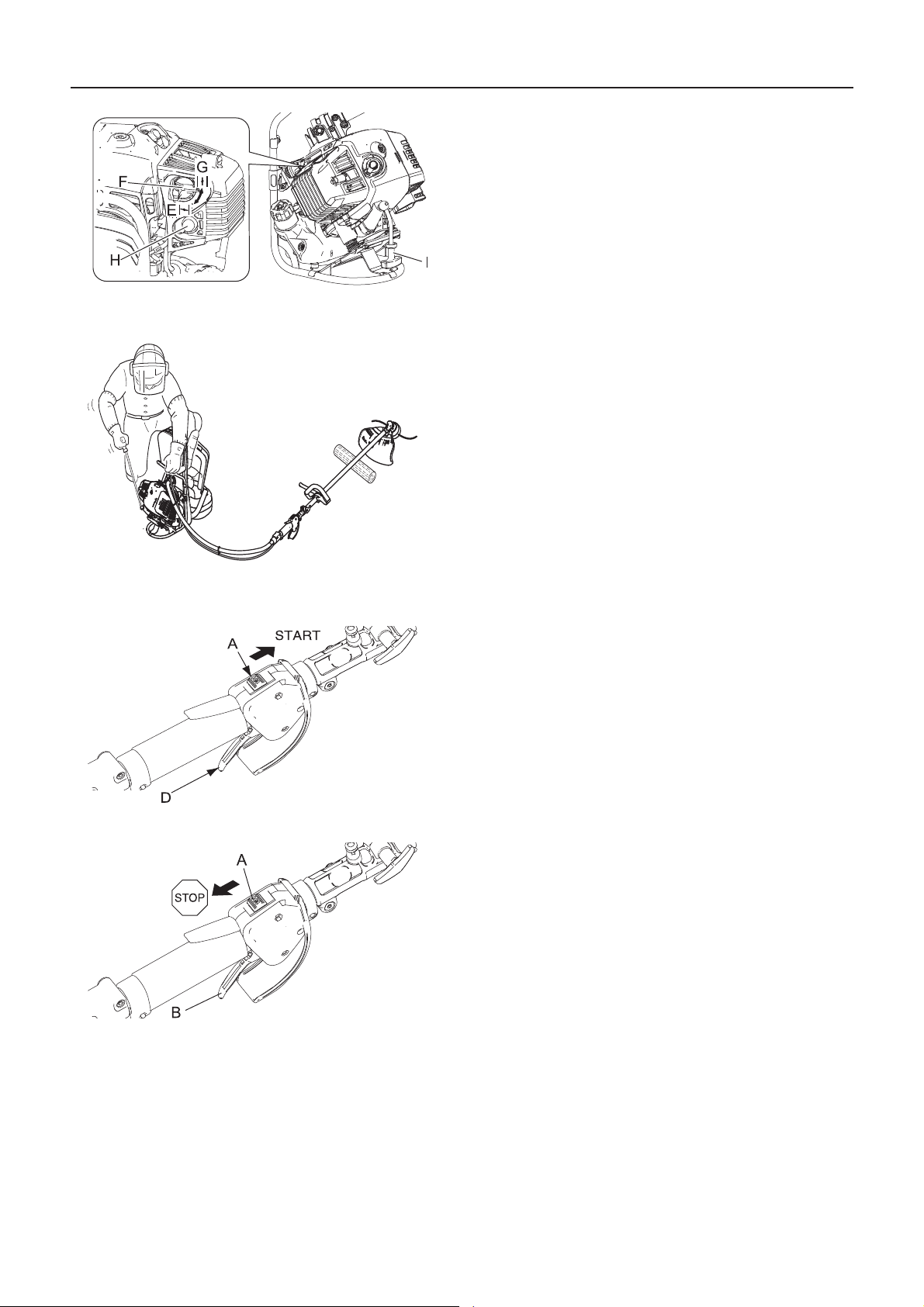

Starting a cold engine

(Connect the spark plug cap if the product has been in storage for

a long period of time.)

1. Remove the blade cover.

2. Placing the product on level ground, check to ensure that the

cutting attachment does not come into contact with the surface of the ground or any other impediment using a beam or

other such implement.

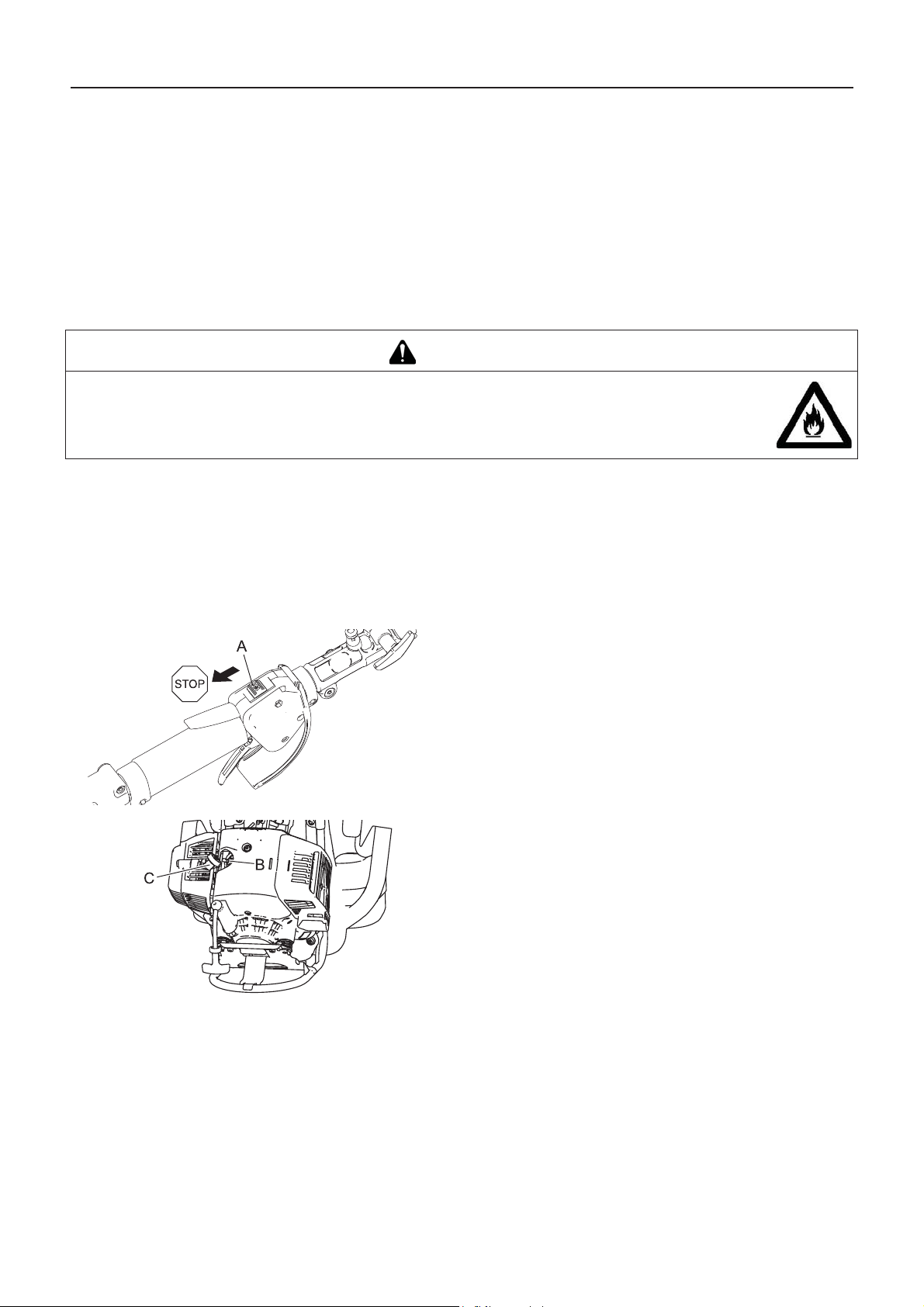

3. Move the ignition switch (A) to the Start position.

4. Make sure that the throttle trigger (D) is at the idle speed position.

13

Page 16

Engine operation

5. Move the choke lever (F) to the "Cold Start" (E) position.

6. Alternately press and release the purge bulb (H) until the fuel

is sucked up into it.

7. Checking that the area around you is safe, hold the position

closest to the engine firmly as shown in the illustration, pulling several times on the starter grip (I).

8. If you hear an explosion-like sound and the engine stops immediately, move the choke lever to the "Run" (G) position

and continue pulling on the starter grip to start the engine.

9. If the engine does not stop, return the choke lever gently to

the "Run" position.

10. Leave the engine to warm up at idle speed for a while.

Starting a warm engine

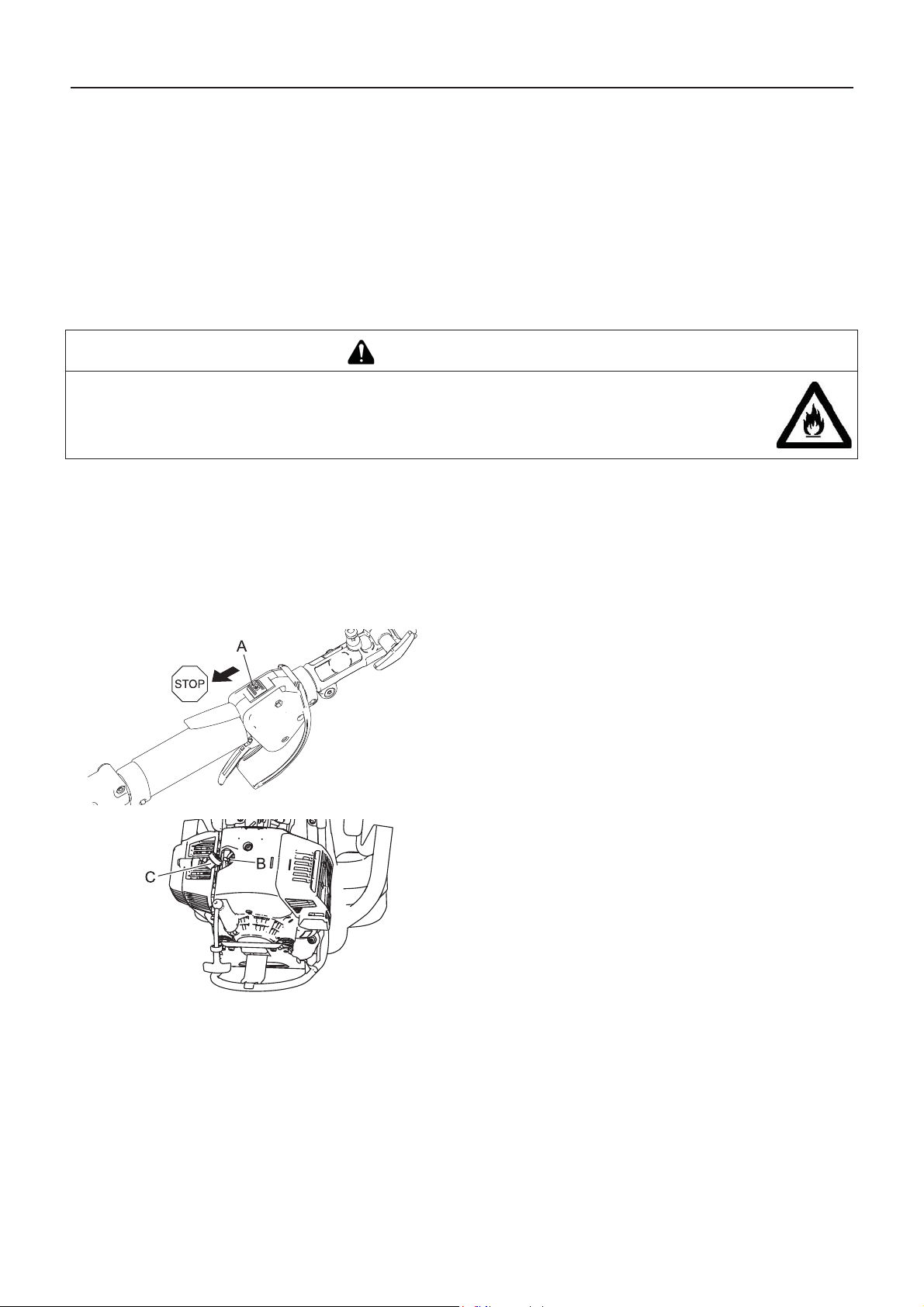

Stopping the engine

1. Move the ignition switch (A) to the Start position.

2. Make sure that the throttle trigger (D) is at the idle speed position.

3. Check that the choke lever is in the "Run" position.

4. If no fuel is visible in the purge bulb, alternately press and release the purge bulb until the fuel is sucked up into it.

5. Checking that the area around you is safe, hold the position

closest to the engine firmly, and pull on the starter grip to

start the engine.

1. Move the throttle trigger (B) to the idle speed position and set

the engine to idling (i.e. low speed).

2. Move the ignition switch (A) to the Stop position.

3. In the event of an emergency, stop the engine immediately

using the ignition switch.

4. If the engine fails to stop, move the choke lever to the "Cold

Start" position. The engine will stall and come to a halt (an

emergency stop).

If the engine fails to stop when the ignition switch is used, have

the ignition switch checked and repaired by your dealer before

you use the product again.

5. Always disconnect the spark plug wire from the spark plug to

ensure the engine cannot be started before you work on the

unit or leave it unattended.

14

Page 17

Trimming operation

Trimming operation

DANGER

Always stop the engine when a cutting attachment jam occurs.

Severe injury can occur if a jam is removed and the cutting attachment suddenly starts.

Do not operate the product without the shield in place.

Any objects that ricochet off the cutting attachment could cause an accident or serious injury.

The area within a 15 m radius of the product is a danger zone. Be careful to observe the following precautions while working with the product.

Do not allow children and other people or pets to enter the danger

zone.

If another person enters the danger zone, turn off the engine to stop

the cutting attachment from rotating.

When approaching the operator, signal to him by, for example,

throwing twigs from outside the danger zone, and then check that

engine has been switched off and the cutting attachment has

stopped turning.

If more than one person is working with the product, identify the way

in which you will signal to each other and work at least 15 m apart.

Any objects that ricochet off the cutting attachment, and any contact with the cutting attachment, could cause blindness or a

fatal accident.

WARNING

Before starting work, check the area where you will be working and remove any small stones

and empty cans likely to ricochet off the cutting attachment, as well as any pieces of string

or wire that might become twisted around the cutting attachment.

An accident or serious injury can occur if foreign objects ricochet off the cutting attachment or wire

and other materials twisted round the product spring off it.

In the following situations, turn off the engine immediately and ensure that the cutting attachments have stopped

before checking each area of the product. Replace any damaged parts.

If the cutting attachment hits a rock, tree, post, or other such obstruction while you work.

If the product suddenly starts to vibrate abnormally.

Continuing to use parts when they are damaged could lead to an accident or serious injury.

Do not hold the cutting attachment up while you work. You must not work with the cutting attachments raised above

knee level.

Raising the cutting attachment above knee level brings the plane of rotation closer to the face, and any objects that fly off the

cutting attachments could cause an accident or serious injury.

Transport of the product

When transporting in the situations described below, turn off the engine and ensure that the trimmer blade has

stopped rotating, then fit the trimmer blade cover and position the silencer away from yourself.

Moving to the place where you are working.

Moving to another area while you are working.

Leaving the place where you have been working.

Failure to observe these precautions could cause burns or serious injury.

When transporting the product by car, empty the fuel tank, fit the blade cover, and secure the product firmly in place

to prevent it from moving around.

Travelling by car with fuel in the fuel tank could lead to a fire.

Never attempt to operate the product with one hand.

Ensure that you hook your thumbs around the grips, wrapping them in your

thumb and remaining fingers.

15

Page 18

Trimming operation

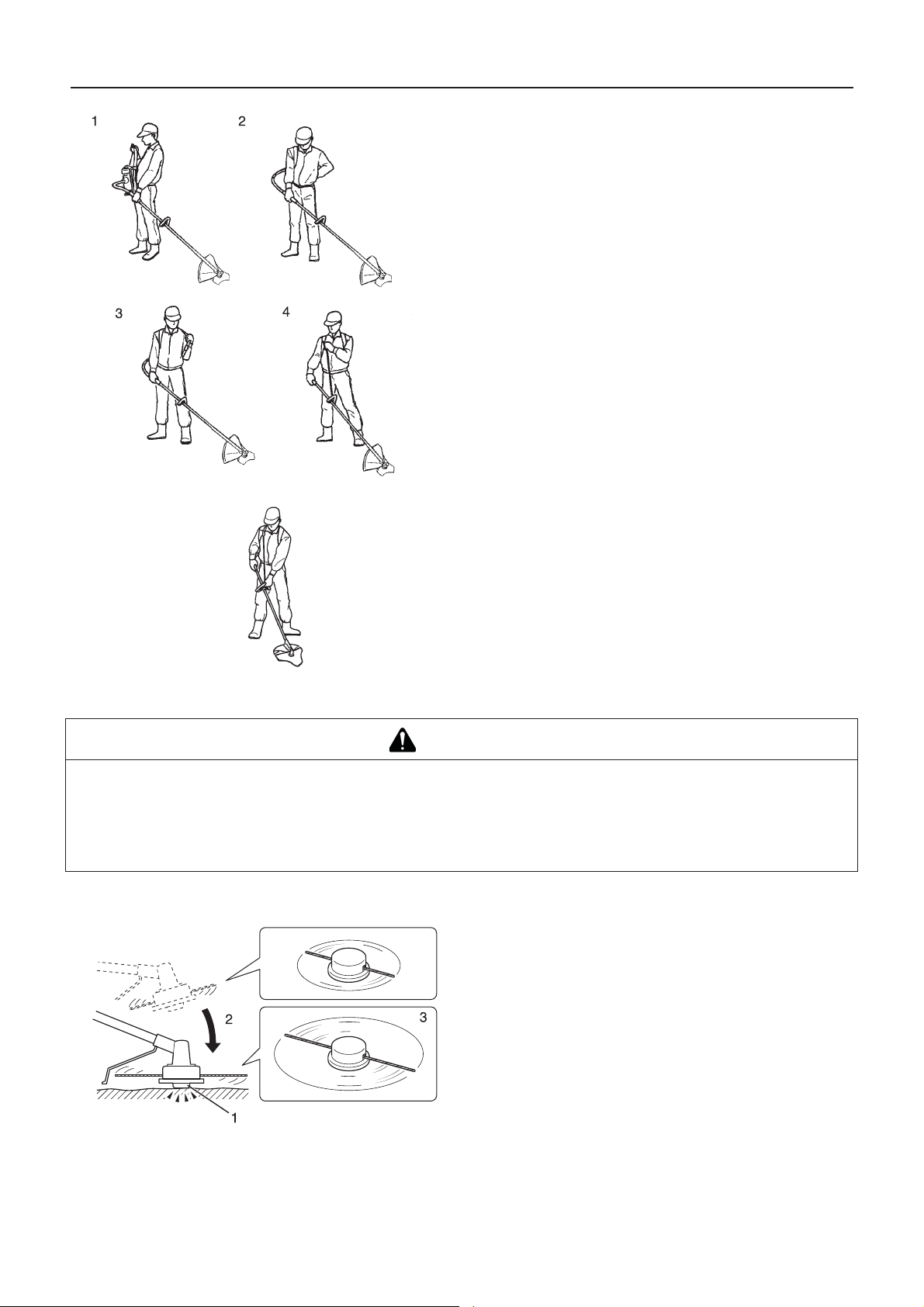

1. Hold the rear handle of shaft tube in left hand and hang the

right knapsack band on the right shoulder.

2. Hold the rear handle of shaft tube in right hand and hang the

left knapsack band on the left shoulder.

3. For even load on both sides of shoulder, joggle the unit on

the shoulder a couple of times.

4. It is preferable to connect the strap to the hangers located on

the loop handle the left or right knapsack band and adjust the

length of the strap to maintain a comfortable operation.

Increase engine speed as necessary, heavy weeds will require

more power than cutting grass.

Hold the front handle (loop handle) and rear handle both hands.

When cutting weeds or grass, swing the blade right and left in

an arc as you move forward.

The blade rotates anticlockwise, so it is necessary to cut the

object from the right to the left.

The manner of walking is as follows: - Place the right foot in

front of the left foot without fail. - Step the right foot forward

firstly and secure your footing. - And then follow the left foot to

the behind of the right foot.

Basic trimming operation with nylon line cutting head

WARNING

Serious injury may result from the improper use of cutti ng attachment. Read and comply with all safety instructions

listed in this manual.

Use only cutting attachments recommended by YAMABIKO CORPORATION.

Excessive nylon line beyond cut off knife could fly off when the nylon line cutting head starts rotating after adjustment of nylon line length.

Failure to do so could lead to an accident or serious injury.

Adjusting nylon line

Do not rotate the nylon line cutting head at more than 10000 r/

min.

When releasing nylon line from spool, hit tap knob of spool

against the ground surface lightly at rotation speed lower than

4500 r/min.

Cut off knife on the shield adjusts cutting swath automatically

by cutting nylon lines evenly when attachment starts rotating.

When operating with less than maximum cutting swath, cut

two nylon lines in equal lengths.

1. Tap knob

2. Hit knob against the ground surface lightly

3. Nylon line comes out

16

Page 19

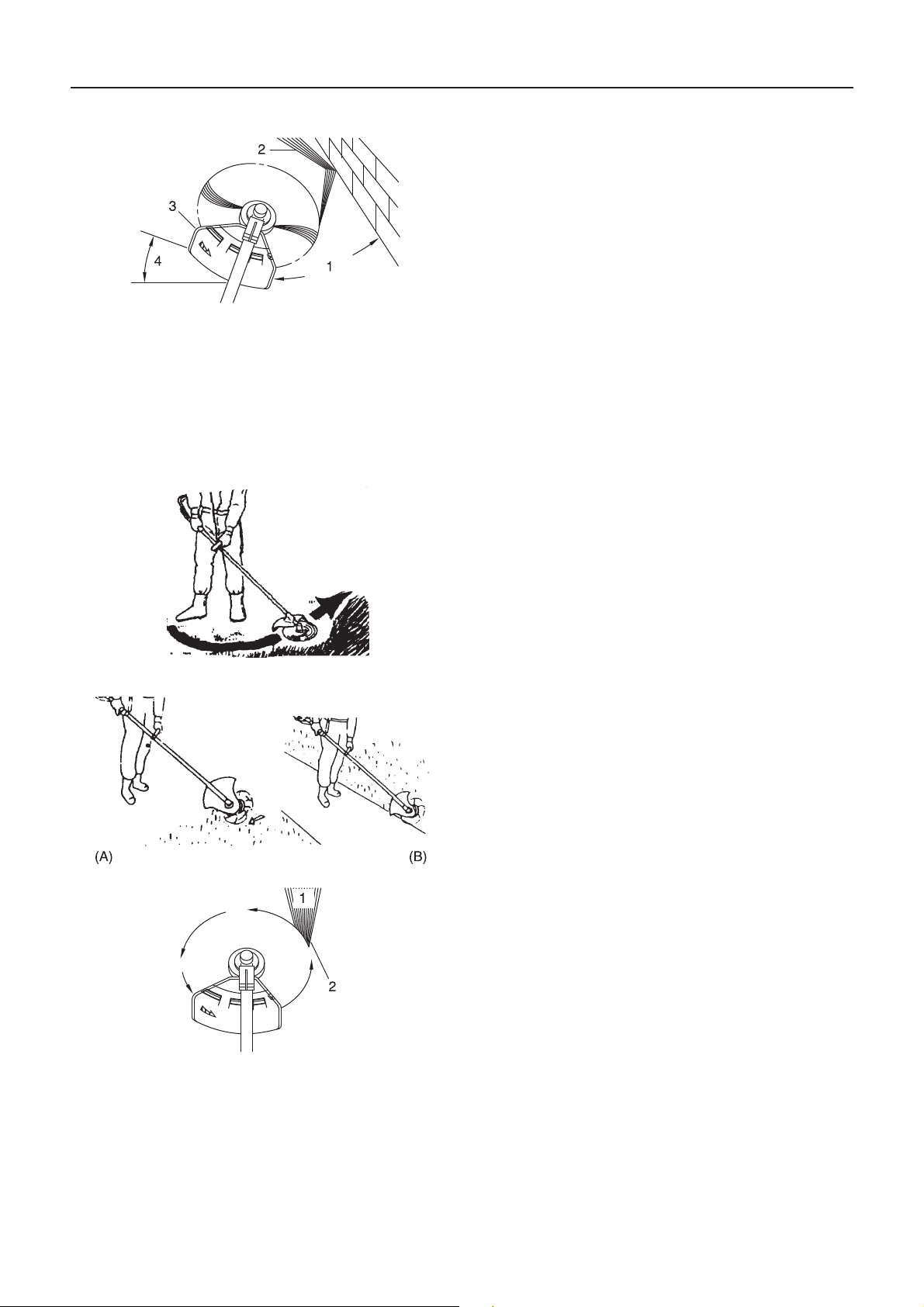

Trimming

Scything

Trimming operation

This is feeding the trimmer carefully into the material you wish

to cut. Tilt the head slightly to direct the debris away from you.

If cutting up to a barrier such as a fence, wall or tree, approach

from an angle where any debris ricocheting off the barrier will

fly away from you.

Move the nylon line cutting head slowly until the grass is cut

right up to the barrier, but do not jam (overfeed) the line into

the barrier. If trimming up wire mesh or chain link fencing, be

careful to feed only up to the wire. If you go too far, the line will

snap off around the wire.

Trimming can be done to cut through weed stems one at a

time. Place the nylon line cutting head near the bottom of the

weed never high up, which could cause the weed to chatter

and catch the line. Rather than cut the weed right through, just

use the very end of the line to wear through the stem slowly.

1. Angle to wall

2. Debris

3. Knife side raised

4. Angle to ground

This is the cutting or mowing of large grassy areas by sweep-

ing or swinging the trimmer in a level arc. Use a smooth, easy

motion. Do not try to hack or chop down the grass. Tilt the nylon line cutting head to direct the debris away from you on the

scything stroke. Then return without cutting grass for another

stroke. If you are well protected and do not care whether some

debris is thrown in your direction, you may scythe in both directions.

Scalping and edging

Both of these are done with the nylon line cutting head tilted at

a steep angle. Scalping (A) is removing top growth, leaving the

earth bare. Edging (B) is trimming the grass back where it has

spread over a pavement or driveway. During both edging and

scalping, hold the unit at a steep angle in a position where the

debris, and any dislodged dirt and stone, will not come back

towards you even if it ricochets off the hard surface.

Although the pictures show how to edge and scalp, every op-

erator must find for himself the angles which suit his body size

and cutting situation.

For nearly all cutting, it is good to tilt the nylon line cutting head

so that contact is made on the part of line circle where the line

is moving away from you and the shield (See appropriate picture). This results in the debris being thrown away from you.

Tilting the head to the wrong side will shoot the debris toward

you. If the nylon line cutting head is held flat to the ground so

that cutting occurs on the whole line circle, debris will be

thrown at you, drag will slow the engine, and you will use up a

lot of line.

Nylon line cutting head rotates anticlockwise. The knife will be

on the left side of the shield.

1. Debris

2. Cut on this side

17

Page 20

Trimming operation

Basic trimming operation with metal blade

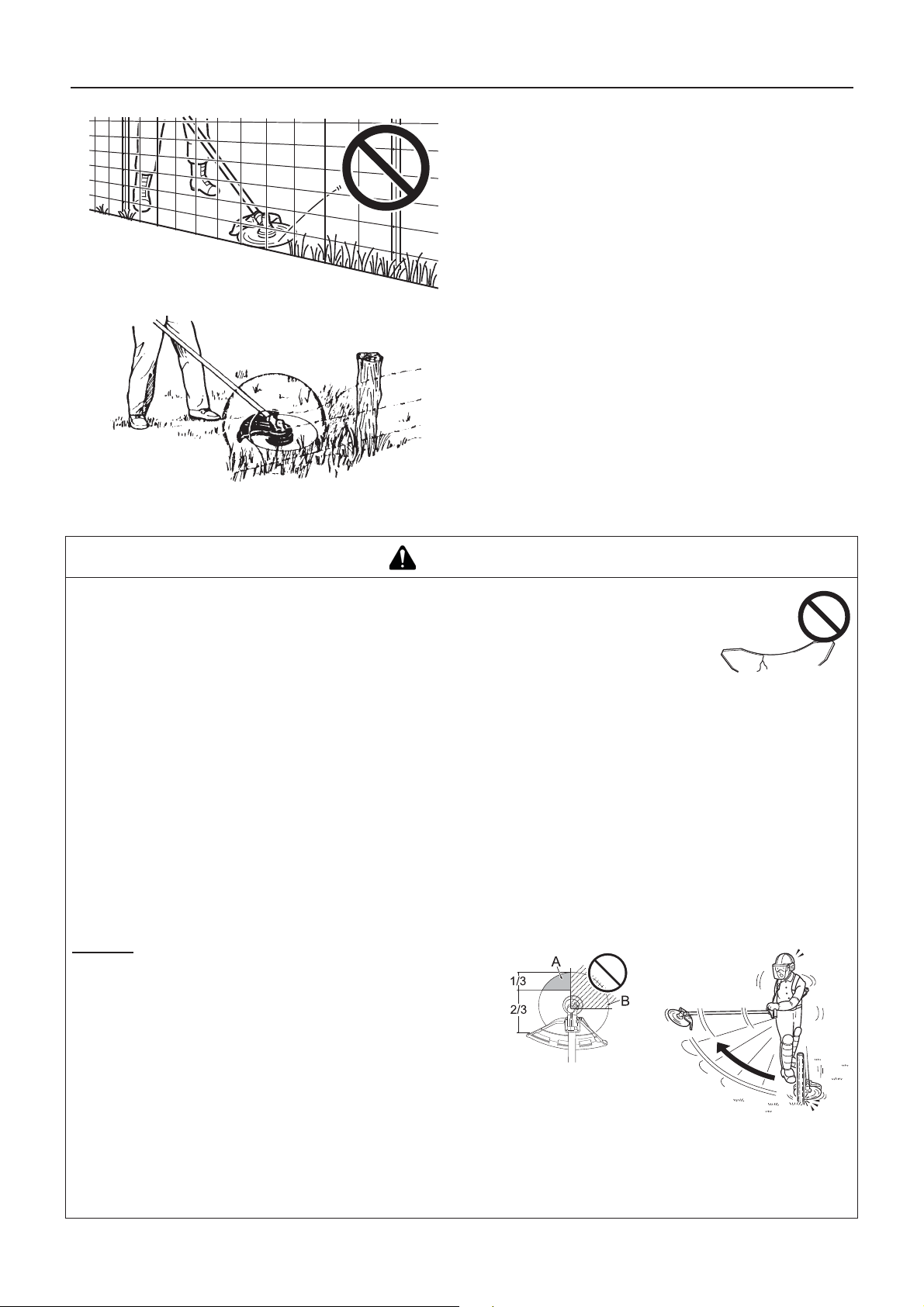

Do not push the line into tough weeds, trees, or wire fences.

Pushing the line into chicken wire, chain link fencing or thick

brush can result in snapped-off line ends being hurled back at

the operator. The proper way is to cut right up to a barrier, such

as any of those mentioned, but never run the line into or

through the obstruction. Do not cut closely to obstruction or

barrier.

Avoid nylon line contact with broken wire fencing. Pieces of

wire broken off by the trimmer can be hurled at high speeds.

WARNING

Please observe the following instructions when trimming.

Check to ensure that the trimmer blade has been tightened securely in place.

Replace the shield if it is damaged or cracked.

Replace the trimmer blade nut when it becomes worn.

Do not cut into the ground with the blade.

Do not operate with a dull, bent, fractured or discoloured blade and worn or damaged nut.

Do not run engine at full throttle without a load.

Failure to do so could lead to an accident or serious injury.

Use only cutting attachments recommended by YAMABIKO CORPORATION.

The type of blade used must be matched to the type and size of material cut. An improper or dull blade can cause

serious personal injury. Blades must be sharp. Dull blades increase the chance of kick-out and injury to yourself and

bystanders.

Plastic/Nylon Grass/Weed Blades may be used where ever the nylon line head is used. Do not use this blade for

heavy weeds or brush.

The 3 cutter blade is designed especially to cut weeds and grass. To avoid injury due to kickback or blade fracture,

do not use the 3 cutter blade to cut brush or trees.

8 Tooth Weed/Grass Blade is designed for grass, garden debris and thick weeds. Do not use this blade for brush

or heavy woody growth, 19 mm diameter or larger.

22 Tooth Clearing Blade is designed for dense thickets and saplings up to 64 mm diameter.

80 Tooth Brush Blade is designed for cutting brush and woody growth up to 13 mm diameter.

Damaged or shattered blades can cause accidents and serious injury.

Kickback

The phenomenon that occurs if the trimmer blade comes into

contact with a tree, post, rock or other hard object while rotating at high speed and reacts by recoiling powerfully and

instantaneously is known as kickback.

Causing kickback can result in a loss of control over the

product and is highly dangerous.

In particular, if the front-right quadrant of the trimmer blade

(B) strikes a shrub or other such object, the trimmer blade

will cause the product to recoil sharply backwards to the

right.

To prevent kickback, do not trim from left to right. Be careful to ensure that the trimmer blade does not strike any

hard objects.

When trimming, ensure that the object you are cutting meets the portion of the blade 1/3 in from the front edge on

the left-hand side (A).

Failure to do so could cause an injury or fatal accident.

18

Page 21

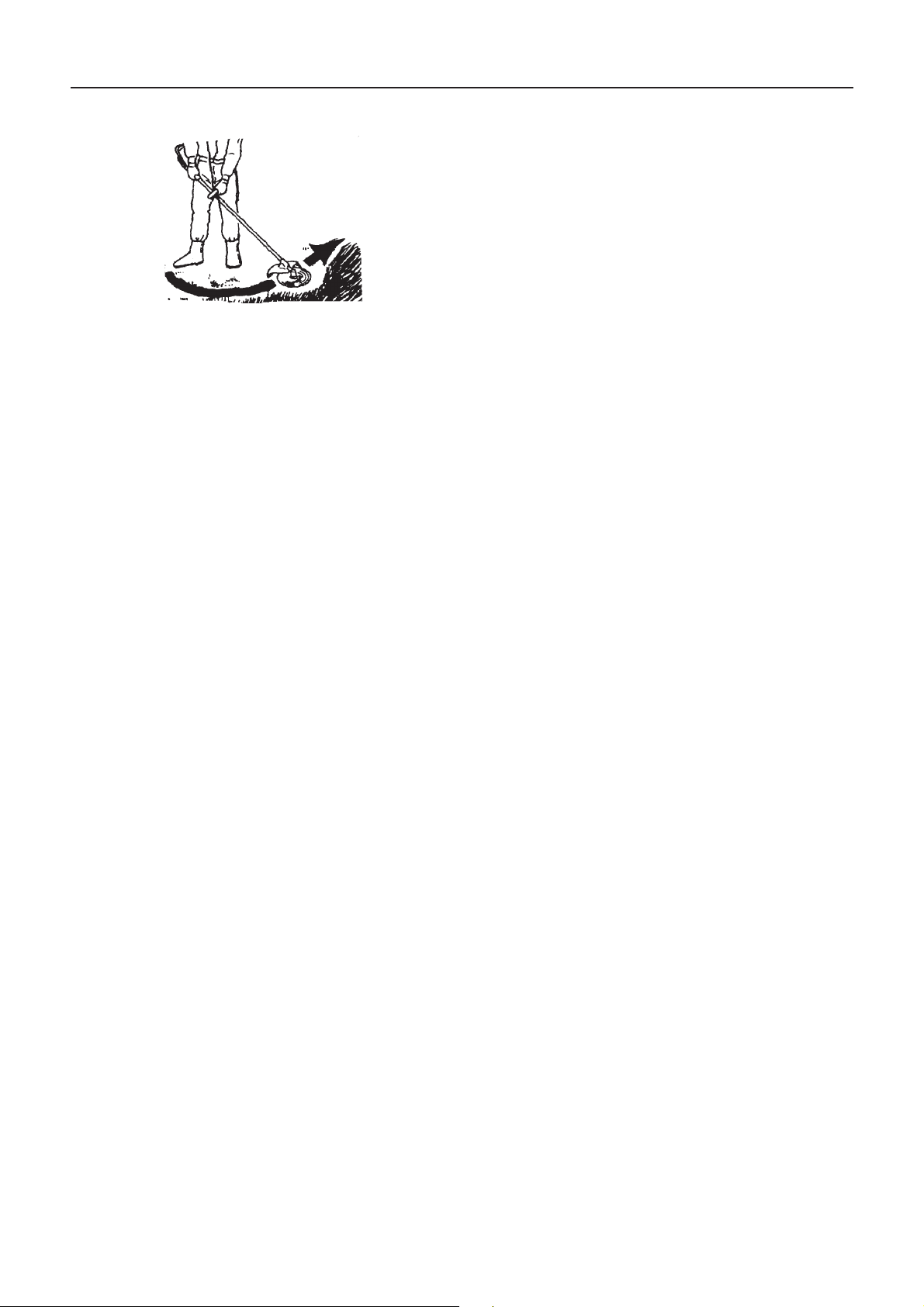

Scything weeds

Trimming operation

This is cutting by swinging the cutting attachment in a level

arc. It can quickly clear areas of field grass and weeds. Scything should not be used to cut large, tough weeds or woody

growths.

If a sapling or shrub binds the cutting attachment, do not use

the cutting attachment as a lever to free the bind, because this

will cause cutting attachment failure.

Instead, shut off the engine and push the sapling or shrub to

free the blades.

19

Page 22

Maintenance and care

Maintenance and care

WARNING

Observe the following precautions when checking and maintaining your product after use:

Turn the engine off and do not attempt to check or maintain the product until the engine has cooled.

You could burn yourself.

Remove the spark plug cap before performing checks and main tenance.

An accident could occur if the product starts unexpectedly.

IMPORTANT

Checking and maintenance requires specialist knowledge. If you are unable to check and maintain the product or deal with a

fault yourself, consult your dealer. Do not attempt to dismantle the product.

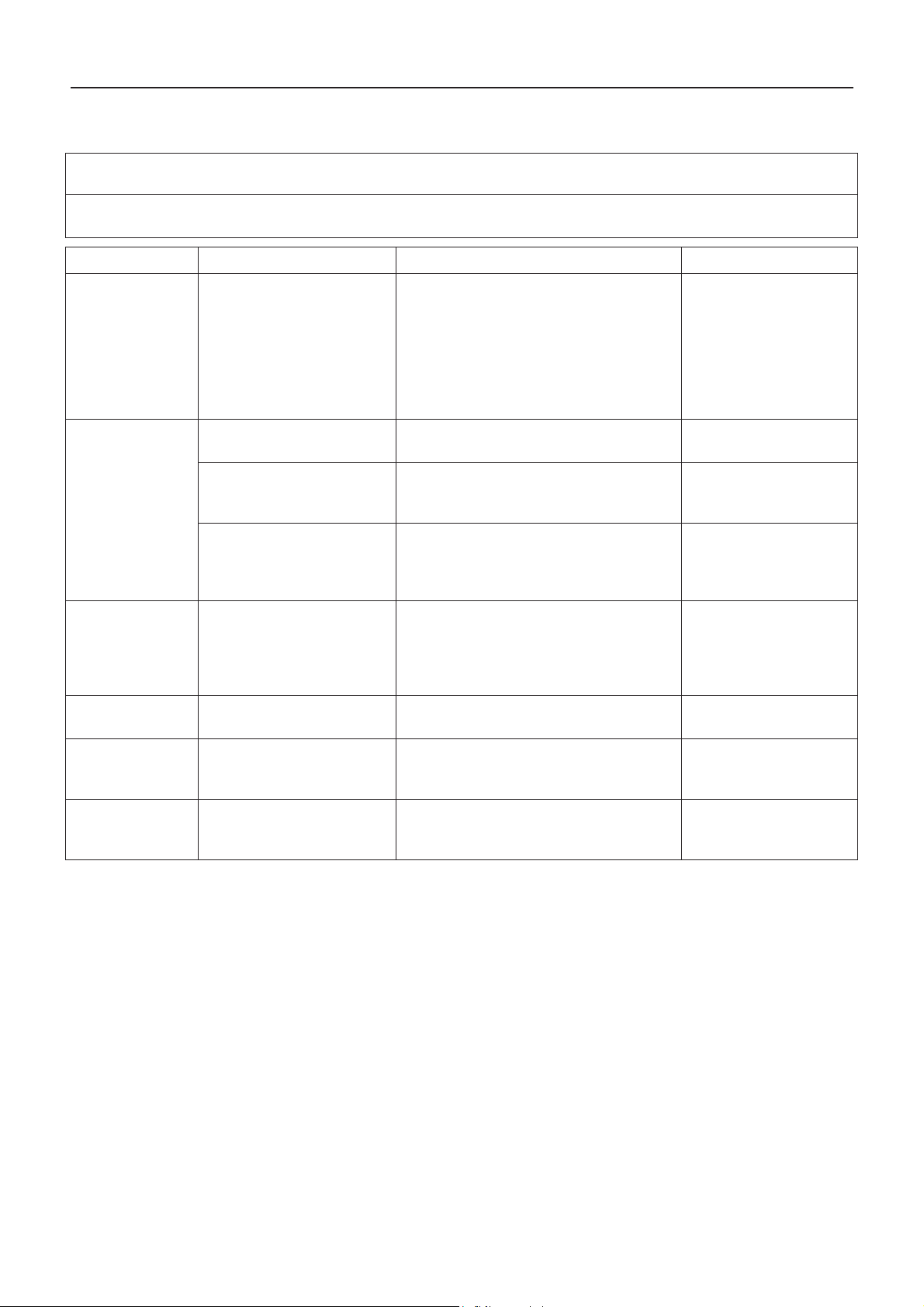

Servicing guidelines

Area Maintenance Page Before use Monthly

Air filter Clean/Replace 20 •

Fuel filter Inspect/Clean/Replace 21 •

Spark plug Inspect/Clean/Adjust/Replace 22 •

Carburettor Adjust/Replace and adjust 21 •

Cooling system Inspect/Clean 21 •

Silencer Inspect/Tighten 22 •

Silencer Clean 22 •***

Flexible shaft Grease 22 •*

Angle transmission Grease 23 •**

Starter Inspect - •

Cut off knife Inspect/Clean - •

Fuel system Inspect 21 •

Screws, bolts and nuts Inspect, Tighten/Replace - •

* Or 18 hours, whichever occurs first. ** Or 50 hours, whichever occurs first. *** Or 100 hours, whichever occurs first.

IMPORTANT

Time intervals are maximum. Actual use and your experience will determine the frequency of required maintenance.

Maintenance and care

If you have any questions or problems, please contact your dealer.

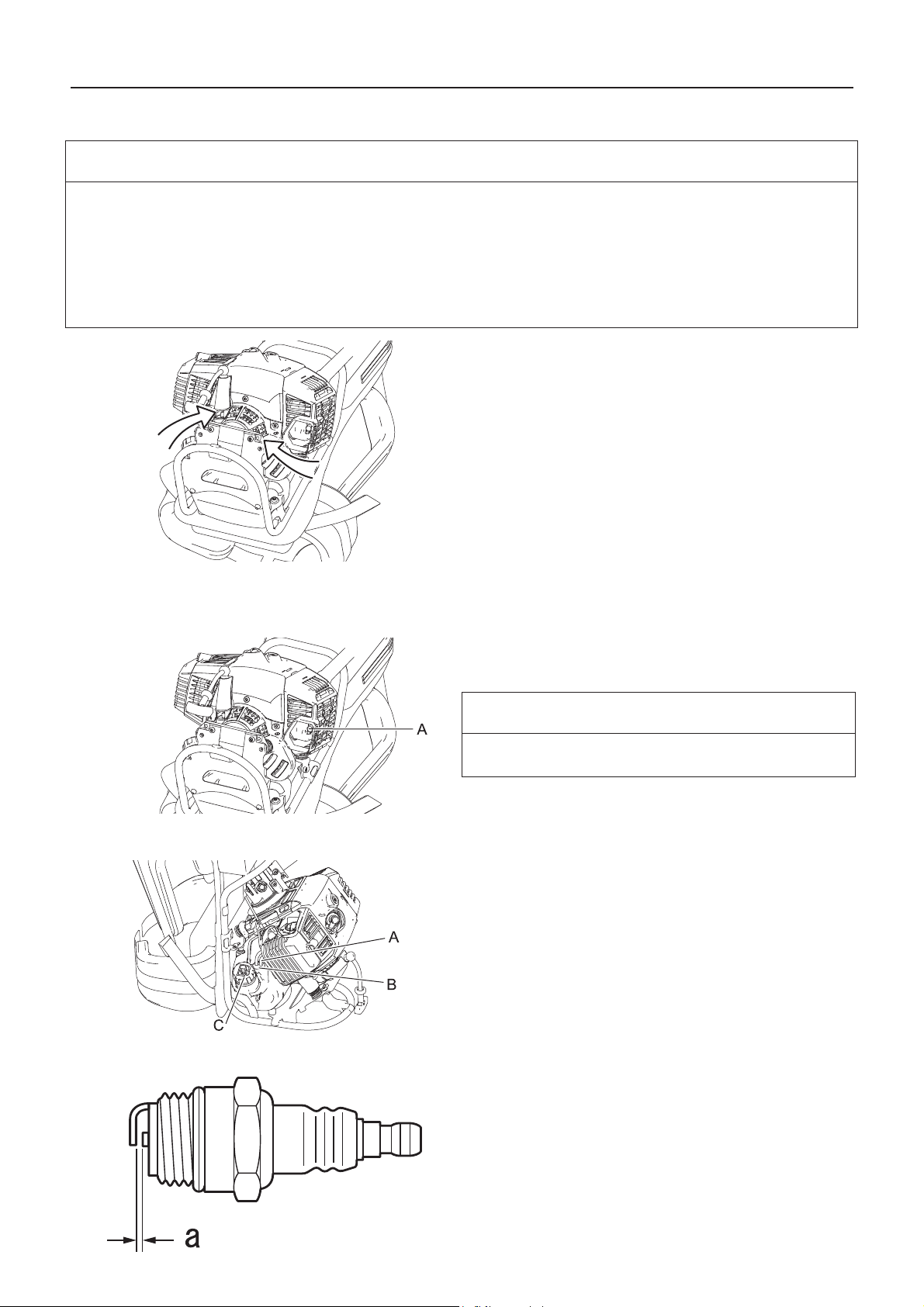

Cleaning air filter

1. Close choke. Loosen screw and remove air cleaner cover

(A).

2. Remove air filter (B) (air filter is located inside air cleaner

cover).

3. Brush dirt from filter or clean with compressed air.

4. Reinstall filter.

5. Reinstall cover and tighten screw.

20

Page 23

Maintenance and care

Replacing fuel filter

1. Use a piece of metal wire or the like to pick up fuel filter (A)

through fuel tank opening.

2. Pull old filter from fuel line (B).

3. Install new fuel filter.

NOTE

If filter is excessive dirty or no longer fits properly, replace it.

Carburettor adjustment

WARNING

YOU MAY ADJUST THE IDLE SPEED ONLY by turning the idle speed adjustment screw (T).

During carburettor adjustment, the cutting attachment may move. Pay utmost attention and care to the cutting attachment so as not to get injured by the moving cutter.

When carburettor adjustment is completed, the cutting attachment should not move at idle speed, otherwise serious

personal injury may result.

You must NOT carry out any Carburettor adjustment, other than the idle speed. All other adjustments MUST be performed by an authorized service dea ler, or serious personal injury may re sult due to malfunction of the engine.

CAUTION

When there is trouble with the carburettor, contact an authorized service dealer.

Every unit is test run at the factory and the carburettor is fine

tuned for maximum performance.

Before adjusting carburettor, clean or replace air filter, start engine and run several minutes to bring it to operating temperature.

To adjust the carburettor proceed as follow:

Turn "idle" speed adjustment screw (T) clockwise until cutting

attachment begins to turn, then turn screw(T) out anticlockwise until cutting attachment stops turning. Turn screw (T) out,

anticlockwise, and additional 1 turn.

NOTE

When the carburettor cannot be adjusted properly with the idle

speed adjustment screw (T), you must contact an authorized

service dealer.

Cooling system maintenance

IMPORTANT

To maintain proper engine operating temperature, cooling air must pass freely through the cylinder fin area. This

flow of air carries combustion heat away from the engine. Overheating and engine seizure can occur when:

Air intakes are blocked, preventing cooling air from reaching the cylinder,

Dust and grass build up on the outside of the cylinder. This build-up insulates the engine and prevents the heat

from leaving.

Removal of cooling passage blockages or cleaning of cylinder fins is considered "Normal Maintenance". Any resultant failure

attributed to lack of maintenance is not warranted.

21

Page 24

Maintenance and care

Air intake

Cleaning silencer

Keep dirt away from engine and air intake grid.

Carbon deposits in silencer (A) will cause a drop in engine out-

put and overheating. Clean deposits from silencer.

IMPORTANT

Do not remove the silencer cover. If necessary, Please consult

your dealer.

Check fuel system

Check spark plug

DPP

Lubricating flexible shaft

Check before every use.

After refuelling, make sure fuel does not leak or exude from

around fuel pipe (A), fuel grommet (B) or fuel tank cap (C).

In case of fuel leakage or exudation, there is a danger of fire.

Stop using the machine immediately and request your dealer

to inspect or replace.

1. Check plug gap. Correct gap is 0.6 mm to 0.7 mm.

2. Inspect electrode for wear.

3. Inspect insulator for oil or other deposits.

4. If the electrodes or terminals are worn, or if there are cracks

in the ceramics, replace them with new parts.

5. Tighten to 15 N·m - 17 N·m (150kgf·cm to 170 kgf·cm).

The spark test (for checking whether the spark plug is spark-

ing) must be carried out by your dealer.

All the surface of the flexible shaft should always be properly

greased.

At the time of delivery from the pl ant, this is greased, so evenly

grease all the surface of the flexible shaft approximately 10 mL

in every 18 hours.

1. Draw out the flexible shaft assembly from the angle transmission.

22

Page 25

Angle transmission

Maintenance and care

2. Draw out the flexible shaft from the flexible shaft assembly.

3. Use the same grease as the angle transmission's.

4. When reassemble, it is preferable to fit the flexible shaft reversely, and the stopper (A) must be fitted on the angle

transmission side of the flexible shaft.

1. Remove the plug (A) and drain screw (B) from the angle

transmission (C).

2. Add grease into the transmission until old grease is pushed

out. If necessary, use a low pressure pump.

3. Reinstall the drain screw and plug.

1. Remove the plug (A) from the angle transmission (C).

2. Add grease, if necessary, use a low pressure pump.

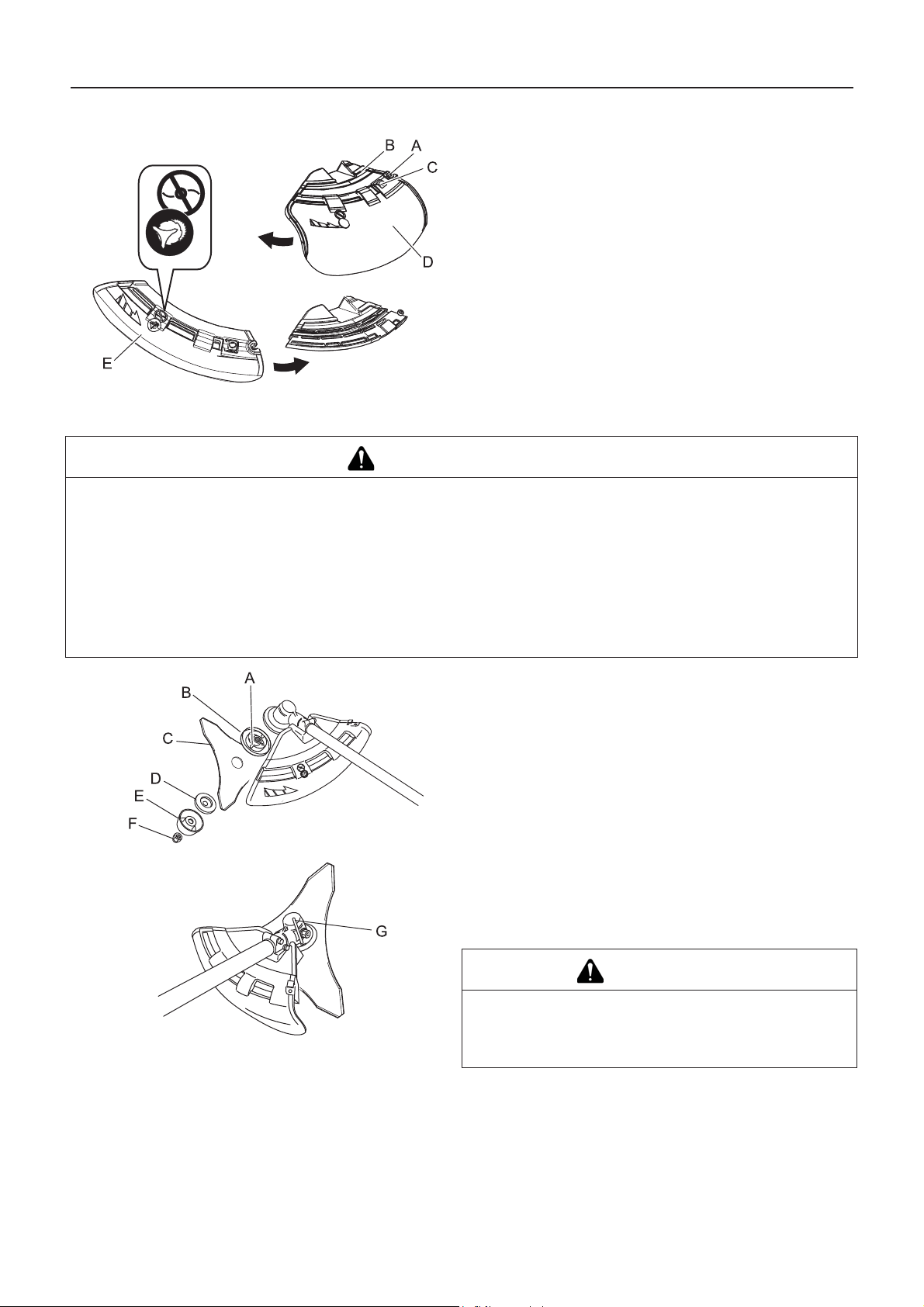

Method to change shield

Installing blade (option)

IMPORTANT

Use the genuine grease from YAMABIKO CORPORATION

(Part number: X695-000010).

3. Reinstall the plug.

There are two types of shields: namely the one used exclu-

sively for nylon line cutting head and the other one used exclusively for metal blade. When metal blade is used, use the

shield for metal blade.

1. Fully loosen the bolt (A) on the right side of the bracket (B)

to slide the shield. The bolt itself cannot be removed from the

bracket.

2. Pushing the button (C), slide the shield (D) to the left and remove it.

3. Put shield of other type (E) into groove and slide it to the right

until it stops. Be sure to tighten the bolt.

WARNING

Wear heavy duty gloves when working with the trimmer blade.

When replacing the trimmer blade during a trimming task, ensure that the engine is switched off and that the blades

have stopped.

When turning the product over to replace the trimmer blade, ensure that the fuel tank cap is securely in place.

Do not attempt to fit the trimmer blade with one hand or without using the socket spanner. Fit the trimmer blade accurately using the supplied socket spanner and tighten firmly in position.

Do not use any tools other than the provided socket spanner to tighten the blade; a pneumatic or electric tool may

tighten the blade more than necessary and cause the nut or the output shaft to break.

If worn nut and cup for blade are used, there is a danger of blade getting loose. Replace them with new one.

Failure to do so could lead to an injury or serious accident, or cause a fire.

23

Page 26

Maintenance and care

1. Inspect blades (C) before installation. Check for sharpness.

Dull blades increase the risk of blade kickback reactions.Small cracks can develop into fractures resulting in a

piece of blade flying off during operation. Discard cracked

blades no matter how small the crack.

2. Securely tighten the blade retainer (B), blade, lower blade

retainer (D), cup (E), and nut (F) by hand.

3. Insert locking tool (G) into a hole located on the right side of

angle transmission while forcing retainer spring to the left

side.

4. Insert locking tool further into blade retainer fixing slot (A) to

fix output shaft.

CAUTION

Fix output shaft securely using locking tool in order to

prevent it form rotating when blade is mounted. Otherwise, the blade fastening nut will not be tightened sufficiently.

Checking the blade

5. Tighten the nut (turn anticlockwise) using a socket wrench

(H). Never fasten while applying your weight. Otherwise the

thread of nut could be broken.

Use only blade designated for this model by the manufacturer.

When a crack is noticed on the blade, do not use it but replace

with a new one.

Ensure that the blade is correctly fitted in accordance with the

instructions.

When the cutting blade becomes dull due to wear reverse it for

further use.

When chip or bend occurs on the blade, vibration will increase.

Replace with new one.

When filing the blade file 3 cutting edges evenly using a flat file

as shown in the illustration. Otherwise, the balance will be lost

and vibration will increase.

24

Page 27

Checking the nylon line cutting head

Maintenance and care

1. Make sure each periphery of the 2 retaining pawls of housing

spreads almost fully up to the outer periphery of the respective cover window.

2. Check mount of cutting head on trimmer and tighten if it is

loose.

3. Check the cutter head for deflection or abnormal noise rotating it by hand. Deflection or abnormal noise can cause abnormal vibration to occur or mount to trimmer to loosen

during rotation which is dangerous.

4. Inspect cover and tap knob for wear. When slot appears on

bottom of the tap knob or when slot appears on cover bottom

close to outlet for nylon line, replace them with new parts

without fail.

5. Check the cutting head for crack or chip. Replace parts that

show any crack or chip with new ones without fail.

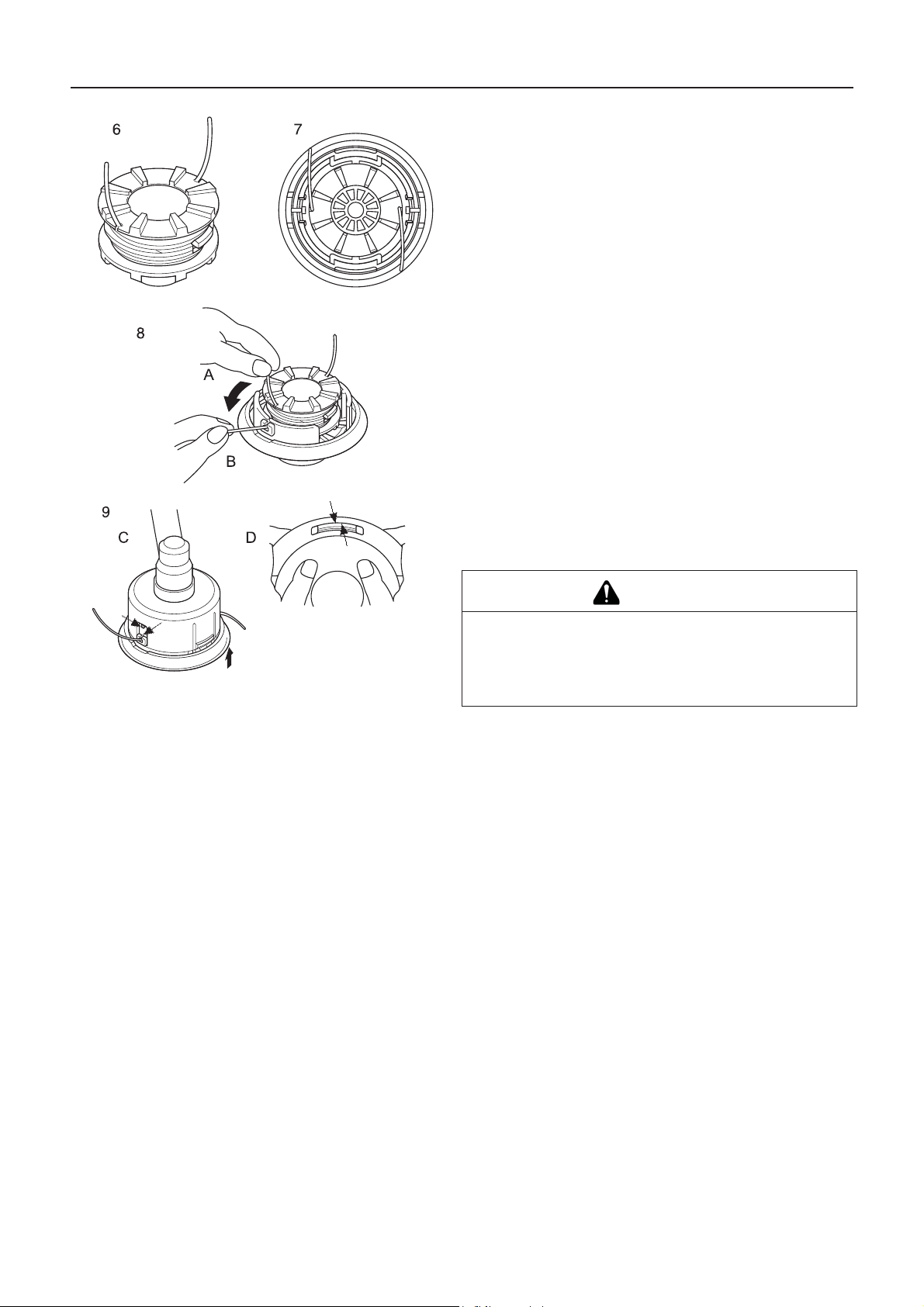

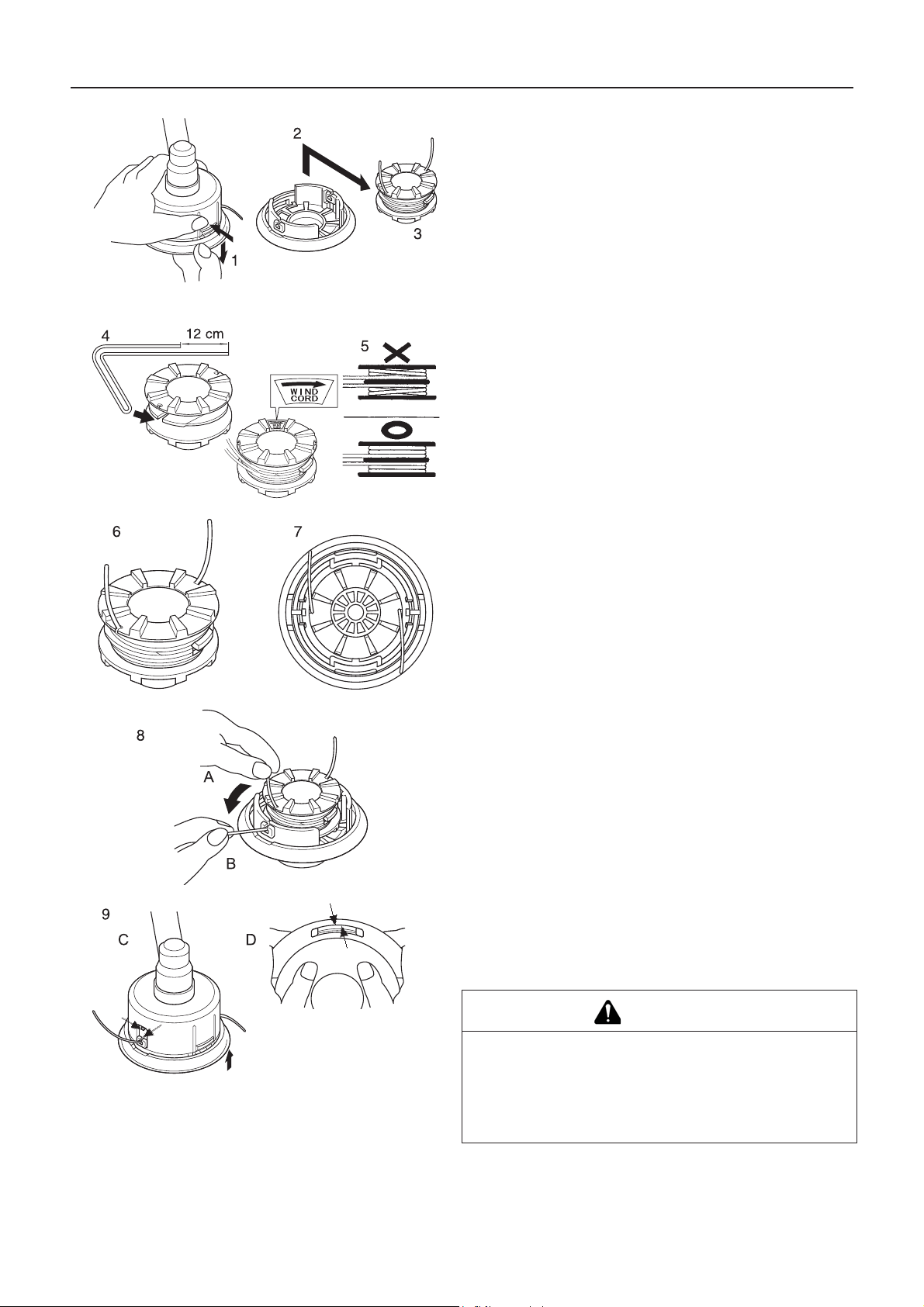

Replacing nylon line

DANGER

Shut down trimmer engine without fail and make sure nylon line cutting head has stopped rotating before starting

replacement procedure.

To do so could lead to an accident or serious injury.

WARNING

Use only flexible, non-metallic line recommended by YAMABIKO CORPORATION.

Failure to do so could lead to an accident or serious injury.

1. Press "retaining pawls" (at two places) inward and remove

cover. It is easier to remove one after another.

2. Remove spool.

3. When nylon line on the spool is almost exhausted, remove

remaining line from spool and wind "new line" according to

the procedures (4) and beyond. When the line on the spool

is "melted and stuck" remove the entire line while peeling off

the "melted and stuck" portion and wind the "removed line"

anew according to procedures (4) and beyond.

4. Bend the line at the point 12 cm away from the middle of

whole length and hook the bent portion into the "notch" of the

intermediate separator.

5. Wind the line firmly into groove of the spool following "winding direction for the arrow".

25

Page 28

Maintenance and care

6. When the line is wound to the end hook both line ends into

respective notch of spool for retaining tentatively the line

while leaving line ends approximately 10 cm beyond notch.

7. Align notches of spool for the line with grooves of eyelets

and fit spool into cover.

8. Pull out the line from cover. (A) Remove the line from "respective notch of spool", and (B) pass it through "groove of

respective eyelet".

9. Fit cover and housing together. (C) Align "eyelets" of cover

with "recesses" of housing, and (D) press pawls of housing

into respective window of cover until the pawls are firmly fitted into the windows.

DANGER

Make sure each outer periphery of pawls of housing

spreads almost fully up to the outer periphery of respective window of cover. If they are loosely fitted and the cutting head is turned, cover or inside components can fly off

which is dangerous.

26

Page 29

Maintenance and care

Troubleshooting table

IMPORTANT

For spare parts and consu mables, please use only genuine parts and designated products and components.

Using parts from other manufacturers or non-designated components may result in a malfunction.

Problem Diagnosis Cause Solution

The engine does

not start

Engine is difficult to

start, fluctuating rotation

Engine starts but

no acceleration is

possible

The engine stops 1. Carburettor adjustment problem

The engine fails to

stop

Cutting attachment

rotates when the

engine is idling

Fuel is entering the overflow

pipe

No fuel is entering the overflow pipe

The spark plug is dirty or

damp

1. There is no fuel in the fuel tank

2. The stop switch is in the Stop position

3. Excess fuel suction

4. Electrical fault

5. Carburettor malfunction or internal sticking

6. Internal engine malfunction

1. Fuel degradation

2. Carburettor problem

1. Fuel filter is clogged

2. Fuel system is clogged

3. Internal carburettor parts sticking

1. Fuel degradation

2. Incorrect electrode gap

3. Carbon deposits

4. Electrical fault

1. Dirty air filter

2. Dirty fuel filter

3. Blocked fuel passage

4. Carburettor adjustment problem

5. Blocked exhaust vent or silencer vent

2. Electrical fault

1. Stop switch malfunction 1. Perform an emergen-

1. Carburettor adjustment problem

2. Damaged clutch spring

1. Fuel supply

2. Move to the Start position

3. Start the engine after

servicing

4. Consult your dealer

5. Consult your dealer

6. Consult your dealer

1. Replace with new fuel

2. Consult your dealer

1. Clean or replace

2. Consult your dealer

3. Consult your dealer

1. Replace

2. Replace

3. Replace

4. Consult your dealer

1. Clean or replace

2. Clean or replace

3. Consult your dealer

4. Adjust

5. Clean

1. Adjust

2. Consult your dealer

cy stop and consult

your dealer

1. Adjust

2. Consult your dealer

Consult your dealer in the event of a problem that is not covered in the table above, or other such concerns.

Please contact your dealer in order to dispose of the product or its parts in compliance with national laws.

27

Page 30

Maintenance and care

Manufacturer:

YAMABIKO CORPORATION

7-2 SUEHIROCHO 1-CHOME, OHME, TOKYO 198-8760, JAPAN

Authorized Representative in Europe:

Atlantic Bridge Limited

Atlantic House, PO Box 4800, Earley, Reading RG5 4GB, United Kingdom

Storage

Long-term storage (30 days or more)

WARNING

Do not store in sealed locations filled with fuel gas, or close to naked flames or sparks.

You could cause a fire.

When storing the product for long periods of time (30 days or more), ensure that the following preparations for storage are carried

out.

1. Remove any fuel from the fuel tank.

2. Alternately press and release the purge bulb a number of

times to remove the fuel from the purge bulb.

3. Start the engine and run it at idle speed until it comes to a

natural stop.

4. Move the ignition switch (A) to the Stop position.

5. Once the product is sufficiently cool, wipe clean any grease,

oil, dust, dirt and other materials on the outside of the trimmer.

6. Perform the periodic checks prescribed in this manual.

7. Check that the screws and nuts are tightened. Tighten up

any that are loose.

8. Remove the spark plug (B) and add the appropriate quantity

(around 10 mL) of clean, new 2-stroke engine oil to the cylinder via the installation socket.

9. Place a piece of clean cloth over the spark plug installation

socket.

10. Pull 2 or 3 times on the starter grip to distribute the engine oil

into the cylinder.

11. Observe the piston location through the spark plug hole. Pull

the recoil starter handle slowly until the piston reaches the

top of its travel and leave it there.

12. Fit the spark plug. (Do not connect the spark plug cap (C).)

13. Fit the blade cover onto the trimmer bla de and wrap the engine section in a plastic bag or other covering, and store in a

dry, dust-free location out of reach of children.

28

Page 31

Specifications

Specifications

RM-520ES

External dimensions:

Length × Width × Height 2828 × 449 × 564 mm

Mass:

Unit without fuel, cutting attachment and guard (ISO11806)

Unit with fuel, specified cutting attachment, guard and harness

Volume: Fuel tank 1.0 L

Cutting attachment:

Nylon line cutting head

Nylon line head Cutting width (Cutting Swath)

Specified blade diameter (option)

Specified blade thickness (option)

Number of cutting teeth (option)

Blade centre hole diameter

Blade rotational speed at maximum allowable engine speed

Gear ratio: Gear ratio and lubrication 1.33 reduction and high-temperatuire, long-life grease

Rotational direction of output shaft seen from above: Anticlockwise

Engine:Type Air cooled 2-stroke single cylinder

Engine displacement

Maximum shaft brake power, measured in accordance with ISO 8893

Engine speed at maximum engine power

Recommended maximum engine speed (With STD attachment installed)

Recommended engine idling speed

Carburettor

Ignition

Spark plug

Starter

Clutch

12.0 kg

13.7 kg

Z5

430 mm

255 mm

3.0 mm

3

25.4 mm

10000 r/min

3

50.2 mL (cm

2.16 kW

9000 min

10900 min

2800 min

)

-1

-1

-1

Diaphragm type

Flywheel magneto - CDI system

NGK BPMR8A

Recoil starter

Automatic centrifugal clutch

Fuel:

Regular grade petrol. Minimum 89 Octane unleaded

petrol is recommended. Do not use fuel containing methyl alcohol or more than 10% of ethyl alcohol.

Oil

Two stroke, air-cooled engine oil. ISO-L-EGD Standard

(ISO/CD 13738), JASO FC,FD grade and ECHO Premium 50:1 oil.

Ratio

Fuel consumption at maximum engine power

Specific fuel consumption at maximum engine power

Vibration levels: (ISO 22867)a

hv,eq

50:1 (2%)

1.23 L/h

423 g/kW•h

Front handle 5.3 m/s

Rear handle 4.0 m/s

Uncertainty 1.2 m/s

Sound pressure level: (ISO 22868) LpAeq 97.5 dB(A)

Uncertainty 1.5 dB(A)

Guaranteed sound power le v el:(ISO 22868) L

WA

114 dB(A)

These specifications are subject to change without notice.

2

2

2

29

Page 32

Declaration of conformity

The undersigned manufacturer:

YAMABIKO CORPORATION

7-2 SUEHIROCHO 1-CHOME

OHME; TOKYO 198-8760

JAPAN

This declaration of conformity is issued under the sole responsibility of the manufacturer.

declares that the hereunder specified new unit:

GRASS-TRIMMER/BRUSHCUTTER

Brand: ECHO

Type: RM-520ES

complies with:

* the requirements of Directive 2006/42/EC (use of harmonized standard ISO 11806-2: 2011)

Declaration of conformity

* the requirements of Directive 2004/108/EC (use of harmonized standard EN ISO 14982: 2009)

* the requirements of Directive 2000/14/EC

Conformity assessment procedure followed ANNEX V

Measured sound power level: 111 dB(A)

Guaranteed sound power level: 114 dB(A)

Serial Number 37001001 and up

Tokyo, October 1st 2015

YAMABIKO CORPORATION

The authorized representative in Europe who is authorized to

compile the technical file.

Company: Atlantic Bridge Limited

Address: Atlantic House, PO Box 4800, Earley, Reading RG5

4GB, UK

Masayuki Kimura Mr. Philip Wicks

General Manager

Quality Assurance Dept.

30

Page 33

1Notes and rear cover

MEMORANDUM

2015

X750-026430

X750222-7500

31

Page 34

7-2 SUEHIROCHO 1-CHOME, OHME, TOKYO 198-8760, JAPAN

PHONE: 81-428-32-6118. FAX: 81-428-32-6145.

©

2015

X750-026430

X750222-7500

Printed in Japan

0x0xxxx zzzz ES

32

Page 35

1Couverture

FRANÇAIS

(Notice originale)

MANUEL D'UTILISATION

COUPE-HERBE/DÉBROUSSAIL-

LEUSE

RM-520ES

AVERTISSEMENT

LIRE ATTENTIVEMENT LES INSTRUCTIONS ET SUIVRE LES

RÈGLES DE SECURITÉ.

LE NON-RESPECT DES RÈGLES DE SÉCURITÉ ENTRAÎNE UN

RISQUE DE BLESSURE GRAVE.

Page 36

Table des matieres

Pour utiliser l'appareil en toute sécurité..............................................................................3

Description..........................................................................................................................8

Avant de commencer.................................... ... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ...............9

Contenu de l'emballage........ ... ... .... ... ................................................... .... ... ... ... .... ... ... .. 9

Assemblage.................................................................................................................10

Préparation du carburant.............................................................................................12

Fonctionnement du moteur...............................................................................................13

Démarrage du moteur..................................................................................................13

Arrêt du moteur............................................................................................................14

Utilisation de l'appareil......................... ... ... ... ... .... ... ... ... .... ... ... ... .... ... ... ... ..........................15

Utilisation de base de l'appareil avec tête de coupe à fil nylon ...................................16

Utilisation de base de l'appareil avec lame métallique ................................................19

Entretien ...........................................................................................................................20

Instructions d'entretien de l'appareil ........... .... ... ... ... .... ... ... ... .... ... ... .............................20

Entretien ......................................................................................................................20

Remisage ....................................................................................................................29

Caractéristiques................................................................................................................30

Déclaration de conformité.................................................................................................31

2

Page 37

Pour utiliser l'appareil en toute sécurité

Pour utiliser l'appareil en toute sécurité

Information importante

AVERTISSEMENT

Lire attentivement le manuel d'utilisation avant d'utiliser l'appareil pour la première fois.

À propos du manuel d'utilisation

Ce manuel contient les informations nécessaires au montage, à l'utilisation et à l'entretien de l'appareil. L'utilisateur

doit donc le lire attentivement et intégrer les informations qu'il contient.

Toujours conserver le manuel à portée de main.

En cas de perte du manuel ou si ce dernier a été détérioré et n'est plus lisible, s'adresser à un revendeur pour en

obtenir un nouveau.

Les unités utilisées dans ce manuel sont les unités SI (Système international d'unités). Les chiffres indiqués entre

parenthèses sont des valeurs de référence. De légères erreurs de conversion peuvent survenir dans certains cas.

Le non-respect de cette règle de sécurité entraîne un risque d'accident ou de blessure grave.

Utilisation de l'appareil

Ces machines sont légères, très performantes, équipées d'un moteur à essence et conçues pour désherber, tondre

et débroussailler dans des endroits inaccessibles par d'autres moyens.

Ne pas utiliser cet appareil pour d'autres applications que celles mentionnées ci-dessus.

YAMABIKO se réserve le droit de modifier sans préavis le contenu de ce manuel en fonction des améliorations apportées au produit. Il se peut que certains des schémas de ce manuel soient différents de l'appareil. Ces différences

ont pour objectif de rendre les explications plus claires.

En cas de doute, consulter un revendeur.

Le non-respect de cette règle de sécurité entraîne un risque d'accident ou de blessure grave.

Ne pas modifier l'appareil

Aucune modification ne doit être apportée à l'appareil.

Le non-respect de cette règle de sécurité entraîne un risque d'accident ou de blessure grave. Tout dysfonctionnement dû à

une modification de l'appareil n'est pas couvert par la garantie du fabricant.

Ne pas utiliser l'appareil avant d'avoir effectué les opérations de vérification et d'entretien nécessaires

Il ne faut pas utiliser l'appareil avant d'avoir effectué les opérations de vérification et d'entretien nécessaires. Veiller

à ce que l'appareil soit vérifié et entretenu régulièrement.

Le non-respect de cette règle de sécurité entraîne un risque d'accident ou de blessure grave.

Prêt ou cession de l'appareil à un tiers

Si l'appareil est prêté à un tiers, veiller à lui confier également le manuel d'utilisation fourni avec l'appareil.

Si l'appareil est cédé à un tiers, transmettre le manuel d'utilisation fourni avec l'appareil lors de la vente.

Le non-respect de cette règle de sécurité entraîne un risque d'accident ou de blessure grave.

Utilisateurs de l'appareil

L'appareil ne doit pas être utilisé si :

l'utilisateur est fatigué

l'utilisateur a consommé de l'alcool

l'utilisateur prend des médicaments

la personne qui souhaite utiliser l'appareil est enceinte

l'utilisateur est en mauvaise condition physique

l'utilisateur n'a pas lu le manuel d'utilisation

la personne qui souhaite utiliser l'appareil est un enfant

L'utilisateur est tenu pour responsable en cas d'accidents ou de risques pouvant entraîner des accidents corporels

ou des dommages matériels.

Le non-respect de ces règles de sécurité constitue un risque d'accident.

Le système d'allumage de cet appareil produit des champs électromagnétiques lorsqu'il fonctionne. Les champs

magnétiques peuvent provoquer des interférences ou des pannes sur les stimulateurs cardiaques. Pour réduire les

risques pour la santé, nous recommandons aux porteurs d'un stimulateur cardiaque de consulter leur médecin et le

fabricant du stimulateur avant d'utiliser cet appareil.

3

Page 38

Pour utiliser l'appareil en toute sécurité

AVERTISSEMENT

Exposition aux vibrations et au froid

Les personnes exposées aux vibrations et au froid peuvent être victimes du phénomène de Raynaud, une affection

qui touche les doigts. L'exposition à des vibrations et au froid peut provoquer une sensation de picotement et de

brûlure, suivie d'une décoloration et d'un engourdissement des doigts. Il est vivement recommandé de respecter les

mesures de précaution suivantes car le seuil d'exposition minimum pouvant provoquer l'apparition de ce phénomène reste inconnu à ce jour.

Limiter la perte de chaleur corporelle, en protégeant en priorité la tête, le cou, les pieds, les chevilles, les mains

et les poignets.

Stimuler la circulation sanguine en interrompant le travail régulièrement pour remuer énergiquement les bras, et

éviter de fumer.

Limiter le nombre d'heures d'utilisation. Essayer d'intégrer à l'emploi du temps de la journée des tâches ne né-

cessitant pas l'utilisation de l'appareil ou d'une autre machine portative.

En cas d'inconfort, de rougeur et de gonflement au niveau des doigts, suivis d'un blanchissement et d'une perte

de sensibilité, consulter un médecin avant de s'exposer à nouveau au froid et aux vibrations.

Le non-respect de ces instructions peut être dangereux pour la santé.

Lésions attribuables au travail répétitif

Il apparaît que la sollicitation excessive des muscles et des tendons des doigts, des mains, des bras et des épaules

peut provoquer une irritation, un gonflement, un engourdissement, une faiblesse et de fortes douleurs au niveau des

membres mentionnés ci-dessus. L'apparition de lésions attribuables au travail répétitif (LATR) est très fréquente

chez les personnes pratiquant certaines activités manuelles répétitives. Pour réduire le risque d'apparition de LATR,

respecter les mesures de précaution suivantes :

Éviter de plier, d'étirer ou de tordre le poignet pendant le travail.

Faire des pauses régulières pour réduire l'effet répétitif et pour reposer ses mains. Effectuer le mouvement répé-

titif plus lentement et en faisant moins d'effort.

Faire des exercices de musculation des mains et des bras.

En cas de picotements, d'engourdissement ou de douleur dans les doigts, les mains, les poignets ou les bras,

consulter un médecin. Plus les LATR sont diagnostiquées précocement, plus les chances d'empêcher les lésions

nerveuses et musculaires irréversibles sont grandes.

Le non-respect de ces instructions peut être dangereux pour la santé.

Une formation adaptée

Toute personne devant utiliser cet appareil doit obligatoirement avoir reçu une formation et un équipement de protection adaptés.

Vous devez avoir une connaissance parfaite des commandes et du fonctionnement de l'appareil.

Vous devez savoir comment arrêter l'appareil et couper le moteur.

Vous devez savoir comment décrocher la machine du harnais en urgence.

Ne laisser personne utiliser l'appareil sans avoir préalablement reçu une formation adaptée.

Le non-respect de ces instructions peut être dangereux pour la santé.

Port de vêtements adaptés

Attacher les cheveux longs au-dessus du niveau de l'épaule.

Ne pas porter de cravates, bijoux ou vêtements amples qui pourraient se prendre dans

l'appareil.

Ne pas porter de chaussures ouvertes, ne pas travailler pieds nus ou jambes nues.

Le non-respect de ces mesures de précaution peut entraîner une dégradation de la vue ou de

l'ouïe de l'utilisateur, ainsi qu'un risque de blessure grave.

4

Page 39

Pour utiliser l'appareil en toute sécurité

AVERTISSEMENT

Port d'équipements de protection

Toujours porter les équipements de protection suivants pour utiliser un coupeherbe.

1. Protection de la tête (casque) : protège la tête.

2. Casque de protection anti-bruit ou protecteurs d'oreilles : protègent l'ouïe.

3. Lunettes de sécurité : protègent les yeux.

4. Protection du visage : protège le visage.

5. Gants de sécurité : protègent les mains contre le froid et les vibrations.

6. Vêtements de travail adaptés (manches longues, pantalons longs) : pro-

tègent le corps.

7. Bottes résistantes avec semelles anti-dérapantes (à bouts renforcés) ou

chaussures de travail avec semelles anti-dérapantes (à bouts renforcés) : pro-

tègent les pieds.

8. Protège-tibias : protègent les jambes.

Le non-respect de ces mesures de précaution peut entraîner une dégradation de la vue

ou de l'ouïe de l'utilisateur, ainsi qu'un risque de blessure grave.

Si nécessaire, utiliser les équipements de protection ci-dessous.

Masque anti-poussière : protège les voies respiratoires

Voilette de protection : protège contre les piqûres d'abeilles

Environnement d'utilisation et fonctionnement de l'appareil

Ne pas utiliser l'appareil :

en cas de mauvaises conditions météo.

sur des pentes raides ou sur des surfaces instables et glissantes ;

la nuit ou dans des endroits sombres mal éclairés.

Lorsque vous utilisez l'appareil sur un terrain en pente douce, employez un mouvement régulier et gardez la tête de

coupe parallèle au sol.

Toute chute, glissade ou utilisation incorrecte de l'appareil constitue un risque de blessures graves pour l'utilisate ur.

Afin de préserver votre santé et de travailler dans des conditions de sécurité et de confort optimales, utiliser l'appareil uniquement par des températures comprises en tre -5

Le non-respect de ces instructions peut être dangereux pour la santé.

o

C et 40 oC.

Savoir réagir en cas de blessure

Même si les cas de blessure ou d'accident restent exceptionnels, l'utilisateur doit savoir réagir à ces situations.

Kit de premiers secours

Serviettes et lingettes (pour arrêter les saignements)

Sifflet ou téléphone portable (pour appeler de l'aide)

Si l'utilisateur n'est pas capable de prodiguer les premiers soins ou d'appeler à

l'aide, la blessure peut s'aggraver.

Le bon réflexe en cas d'incendie ou de fumée

Si le moteur prend feu ou si de la fumée s'échappe de l'appareil à un autre endroit que la sortie d'échappement, la première chose à faire est de s'éloigner de l'appareil pour éviter tout risque d'accident.

À l'aide d'une pelle, jeter du sable ou un autre matériau équivalent sur les flammes pour éviter que l'incendie ne se propage, ou éteindre les flammes avec un extincteur.

Ne pas céder à la panique permet d'éviter que l'incendie ne se propage et donc de limiter l'étendue des dégâts.

Etiquettes et symboles d'avertissement

DANGER AVERTISSEMENT ATTENTION

Ce symbole associé au mot

« DANGER » signale une action ou

une situation présentant un risque de

blessure corporelle grave ou d'accident mortel pour l'utilisateur et les

personnes à proximité.

Ce symbole associé au mot

« AVERTISSEMENT » signale une

action ou une situation présentant un

risque de blessure corporelle grave

ou d'accident mortel pour l'utilisateur

et les personnes à proximité.

« ATTENTION » signale une situation potentiellement dangereuse qui,

si elle n'est pas évitée, peut entraîner

une blessure légère à modérée.

5

Page 40

Pour utiliser l'appareil en toute sécurité

Autres indications

REMARQUE IMPORTANT

Le cercle barré indique

une interdiction.

Symboles

Ce type de message fournit des

conseils relatifs à l'utilisation et à l'entretien de l'appareil.

Le texte dans l'encadré où figure le

mot «IMPORTANT» donne des in-

formations importantes concernant

l'utilisation, la vérification, l'entretien

et le remisage de l'appareil décrit

dans ce manuel.

Forme des symboles Description/application des

symboles

Lire attentivement le manuel

d'utilisation

Port obligatoire de protections

pour les yeux, les oreilles et la

tête

Port obligatoire de chaussures

et de gants de protection

Arrêt d'urgence

Avertissement !

Projections !

Forme des symboles Description/application des

symboles

Vitesse maximale de l'arbre

de l'outil de coupe en

tr/min

Ne laisser personne s'approcher à moins de 15 mètres

Mélange d'essence et d'huile

Commande de starter en position « Démarrage à froid »

(starter fermé)

Commande de starter en position « Marche » (starter ouvert)

Attention, poussée latérale

Ne pas utiliser sans protecteur

d'outil

Interdiction d'utiliser des

lames métalliques

Interdiction d'utiliser une tête

de coupe à fil nylon

Réglage du carburateur

- Régime de ralenti

Lubrifier toutes les 18 heures

Poignée semi-circulaire

Attention aux températures

élevées

6

Page 41

Pour utiliser l'appareil en toute sécurité

Forme des symboles Description/application des

symboles

Ne pas utiliser l'appareil dans

des endroits mal aérés

Attention aux risques d'incendie

Attention aux risques de choc

électrique

Forme des symboles Description/application des

symboles

Niveau de puissance sonore

garanti

Démarrage du moteur

-

Étiquette(s) de sécurité

L'étiquette de sécurité ci-dessous figure sur les appareils décrits dans ce manuel. S'assurer de bien comprendre la signification

de l'étiquette avant d'utiliser l'appareil.

Si l'étiquette devient illisible avec le temps ou si elle s'est décollée ou a été déchirée, contacter un revendeur pour obtenir une

nouvelle étiquette et la coller à l'emplacement indiqué sur les illustrations ci-dessous. Veiller à ce que l'étiquette soit toujours

lisible.

1. Etiquette de sécurité (numéro de pièce 890617-43130)

7

Page 42

Description

Description

1. Outil de coupe. - Tête de coupe à fil nylon pour couper

l'herbe et les mauvaises herbes.

2. Protecteur d'outil. - Protège l'utilisateur contre les projections et empêche tout contact accidentel avec la tête

de coupe.

3. Renvoi d'angle. - Avec deux engrenages pour changer

l'angle de l'axe de rotation.