Page 1

INSTALLATION INSTRUCTIONS

TM

REPOWER

PART

NUMBER 90094

FOR MODELS: PP-600, 800, PPF-2100, 2110, PPSR-2122, 2433,

PPF-210, 211, PPF-265

CUTTING ATTACHMENT TO SHAFT TUBE INSTALLATION

Tools Required: 10 mm hex socket wrench, screwdriver, 4 mm hex key

wrench. Drill, 7 mm (1/4 in.) drill bit.

W ARNING DANGER

Saw Chain is sharp! Always wear gloves when handling assembly,

otherwise serious personal injury may result.

1 . Follow Guide Bar and Saw Chain Replacement Instructions in

your Operator’s Manual to remove guide bar and saw chain from

existing cutting attachment.

GEAR CASE

NOTE

If standard guide bar with front-access chain tensioner will be

used, remove chain tensioner and install parts on new gear case.

Follow guide bar and saw chain installation, adjustment, and

replacement instructions in your original operator’s manual. If

mounting the side access IntenzTM guide bar, follow instructions

provided here.

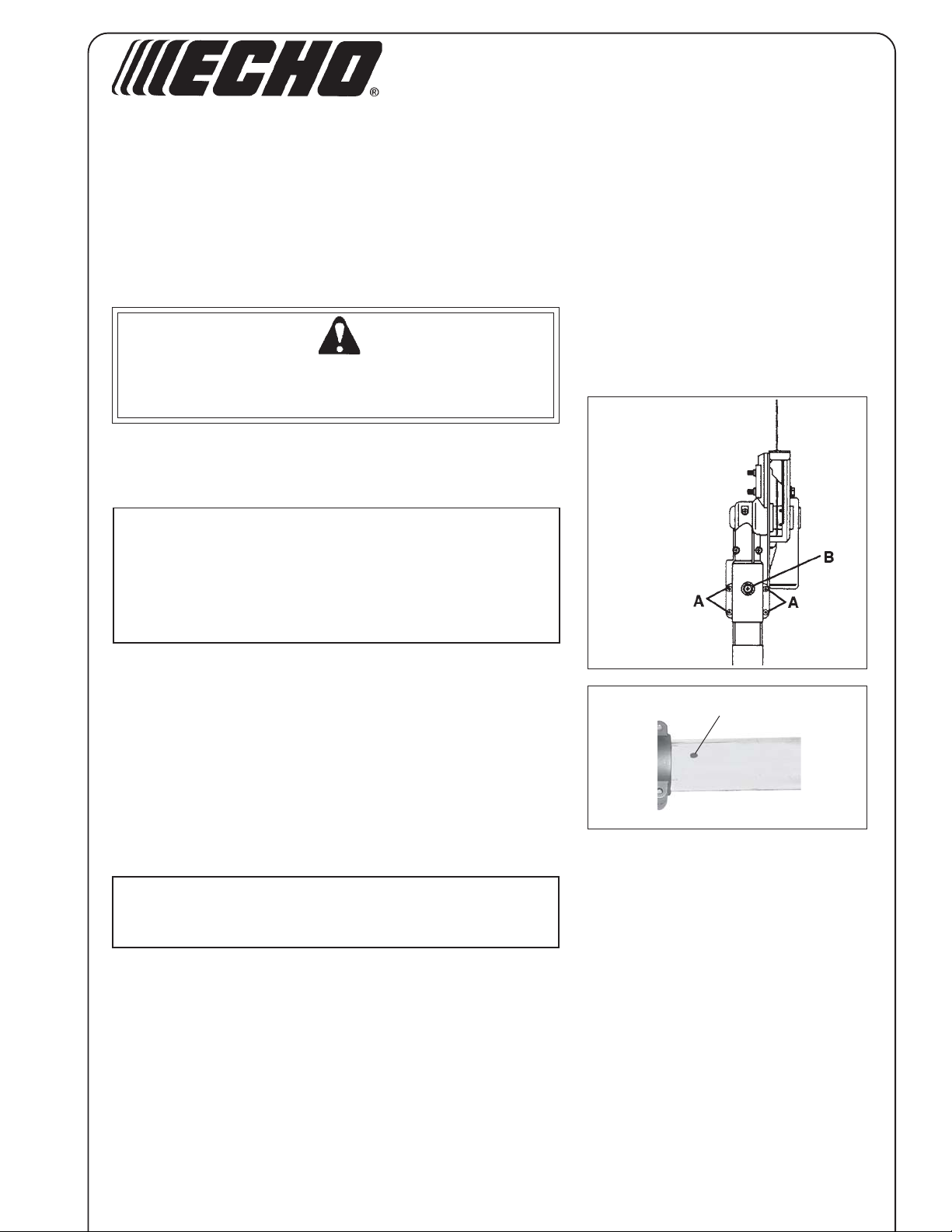

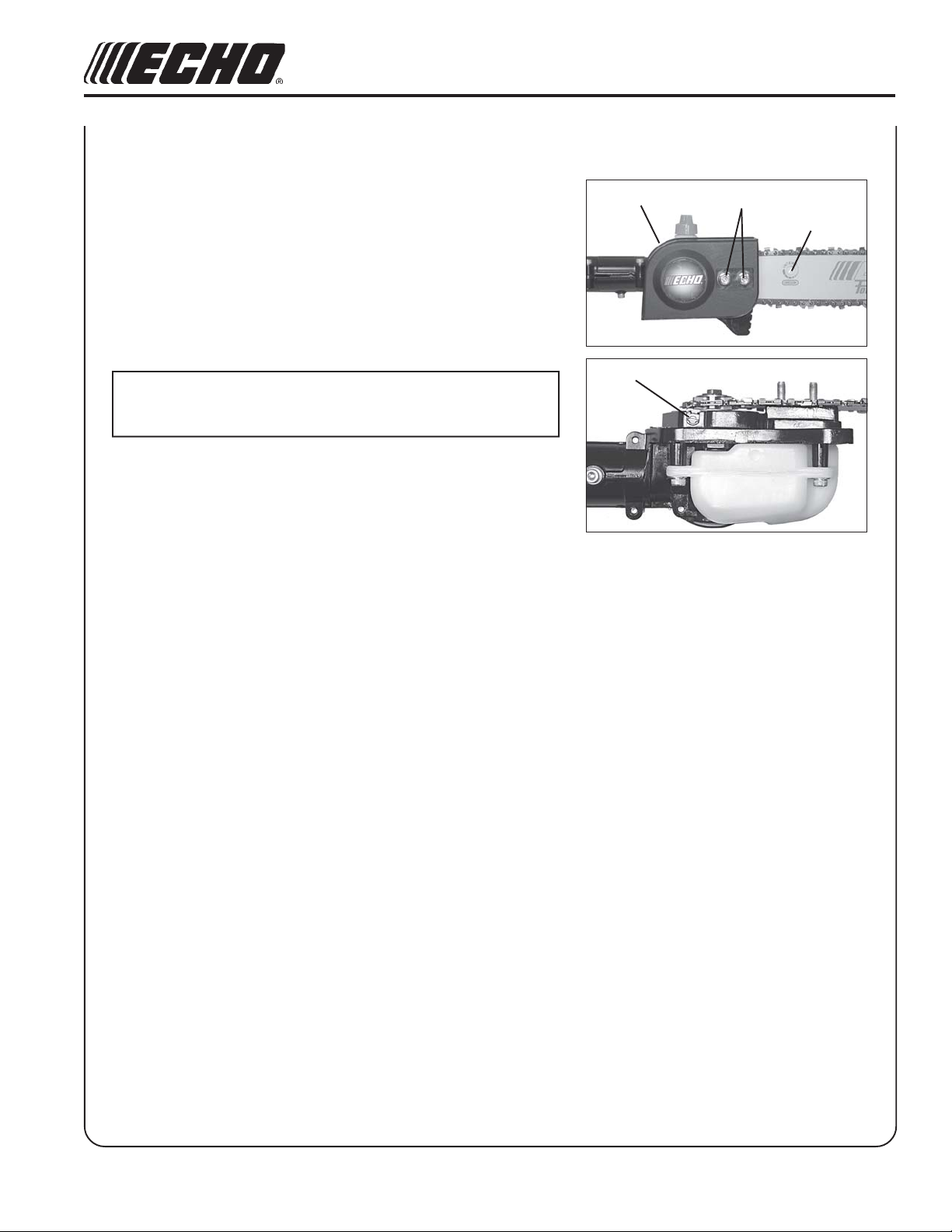

2 . Loosen four (4) screws (A) and locator screw (B), and remove

existing cutting attachment from aluminum shaft tube.

3. OLDER POWER PRUNER MODELS ONLY:

Loosen 4 clamp screws and remove locator screw from Gear

Case. Slide Gear Case on driveshaft tube and align with power

head. Be certain square inner drive shaft engages into square

socket of gear case. If driveshaft and gear case locator holes do

not match, drill a 7 mm (1/4 in. ) hole through one side of shaft

tube, using locator hole in Gear Case as a guide. Remove burrs

from hole, and clear all debris from tube after drilling.

NOTE

Do not allow drill bit to contact inner driveshaft, otherwise

driveshaft may be damaged.

BOTTOM

VIEW

B

X7502307401

X750008571

09/05

Page 2

2

POWER PRUNER

TM

INSTALLATION INSTRUCTIONS

GUIDE

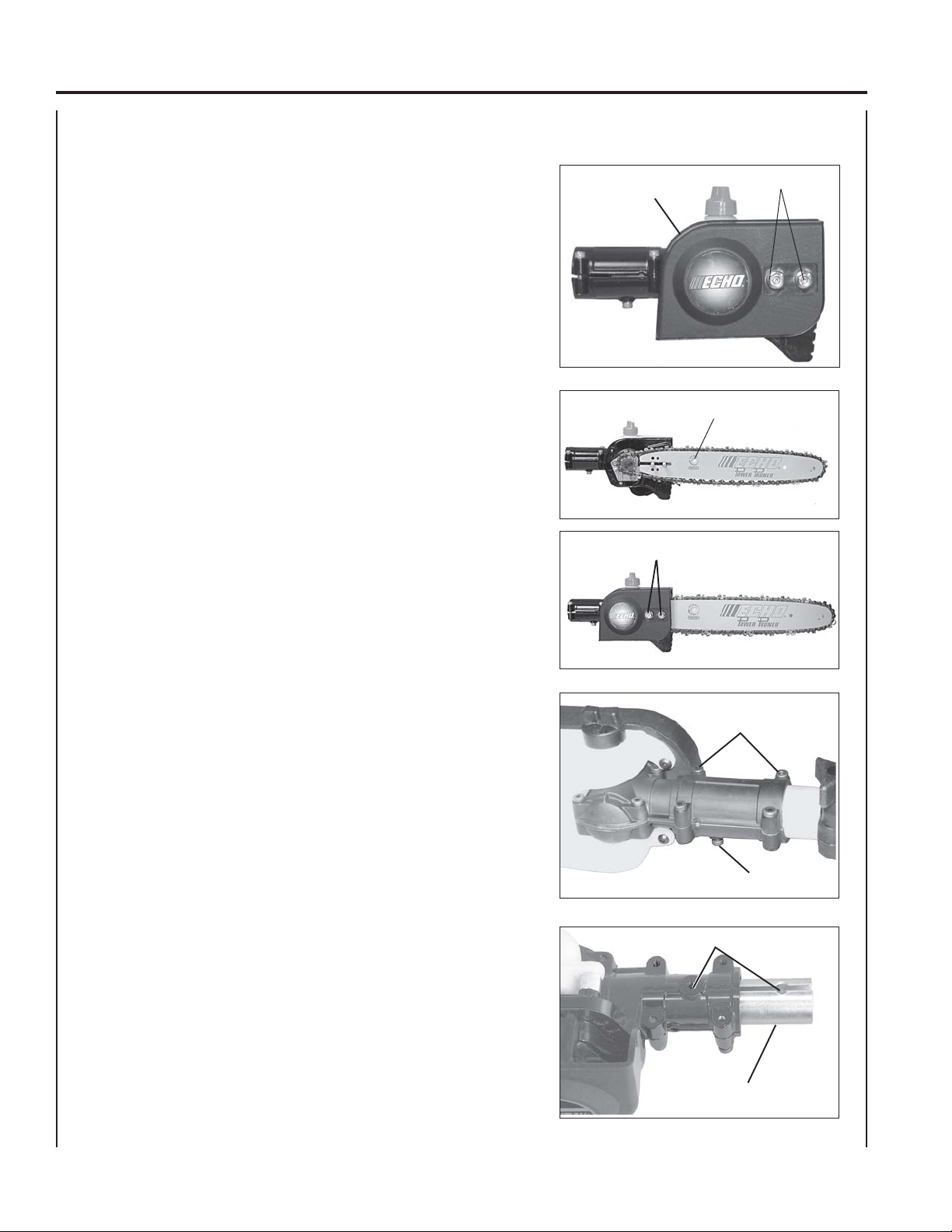

4 . Remove two (2) 6 mm guide bar nuts (C) and remove sprocket

5 . Turn saw chain tension adjuster slot (E) counterclockwise until it

6 . Install chain on guide bar, with cutters on top of bar facing toward

7. Install guide bar and chain on gear case, engaging chain with

8 . Turn tension adjustment slot clockwise to take up slack in saw

BAR AND SAW CHAIN INSTALLATION

cover (D).

stops.

bar tip.

drive sprocket.

chain.

D

E

C

C

9 . Install sprocket guard, and tighten guide bar nuts (C) finger tight.

10. Adjust chain tension. See Saw Chain Tension Adjustment

Instructions on Page 5 of this manual.

11. Loosen the four (4) screws (A) and remove locator screw (B) from

cutting attachment.

12 . (PPSR-2122/2433 Only) Insert collar (G) into cutting attachment

(long end of collar first) until locator holes (B) are aligned.

A

B

B

G

Page 3

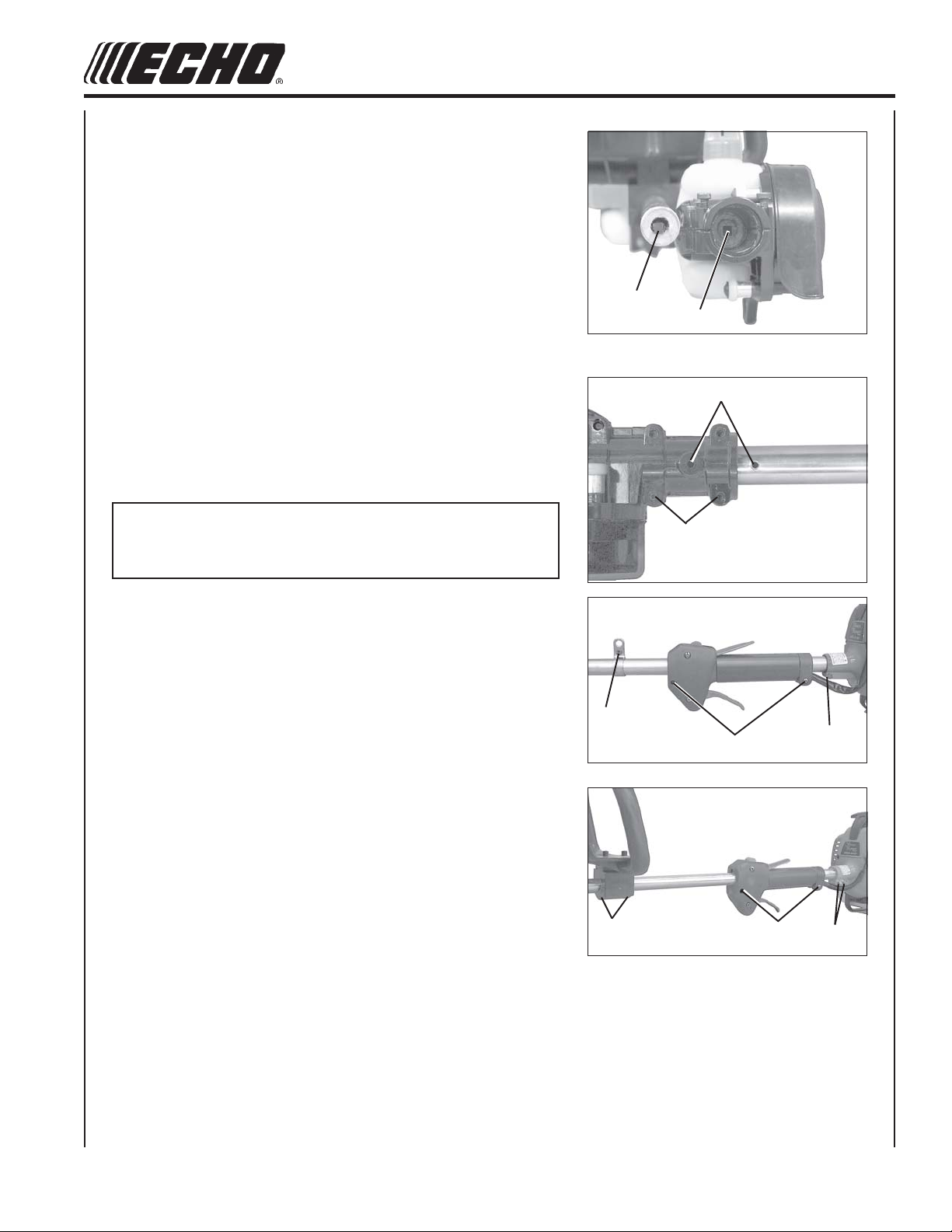

13. Slide cutting attachment onto aluminum shaft tube. Be certain

inner drive shaft (H) engages into square socket (I) of cutting

attachment.

14A.(PPF-210/211/251/2100/2110 Only) Align locator hole (B) in cutting

attachment with locator hole in aluminum shaft tube.

14 B . (PPSR-2122/2433 Only) Align locator hole (B) in cutting attach-

ment and collar with locator hole in aluminum shaft tube.

15. Install and tighten locator screw (B). Tighten four (4) cutting

attachment screws (A).

NOTE

Cutting Attachment Assembly is complete for models PPF-210, 211,

265. All other models follow steps 16 - 19.

3

H

I

B

A

16A.(PPF-2100/2110 Only) Loosen harness clamp screw (J), two (2)

throttle grip clamping screws (K) and engine fan housing clamp

bolt (L).

16 B . (PPSR-2122/2433 Only) Loosen four (4) front handle screws (M),

two (2) throttle grip clamping screws (N) and two (2) engine fan

housing clamp bolts (O).

17A. (PPF-2100/2110 Only) Position cutting attachment upright and

rotate harness clamp, throttle grip, and engine upright on drive

shaft and in-line with cutting attachment.

17B. (PPSR-2122/2433 Only) Position cutting attachment upright and

rotate front handle, throttle grip and engine upright on drive shaft

and in-line with cutting attachment.

18. (All Models) Tighten engine and throttle grip fasteners securely.

19A. (PPF-2100/2110 Only) Install harness and position harness clamp

for comfortable operation. Tighten harness clamp screw securely.

J

L

O

M

K

N

19B. (PPSR-2122/2433 Only) Position front handle for comfortable

operation. Tighten four (4) screws securely.

Page 4

4

POWER PRUNER

TM

INSTALLATION INSTRUCTIONS

GUIDE

BAR AND SAW CHAIN REPLACEMENT

Guide Bar Replacement / Installation

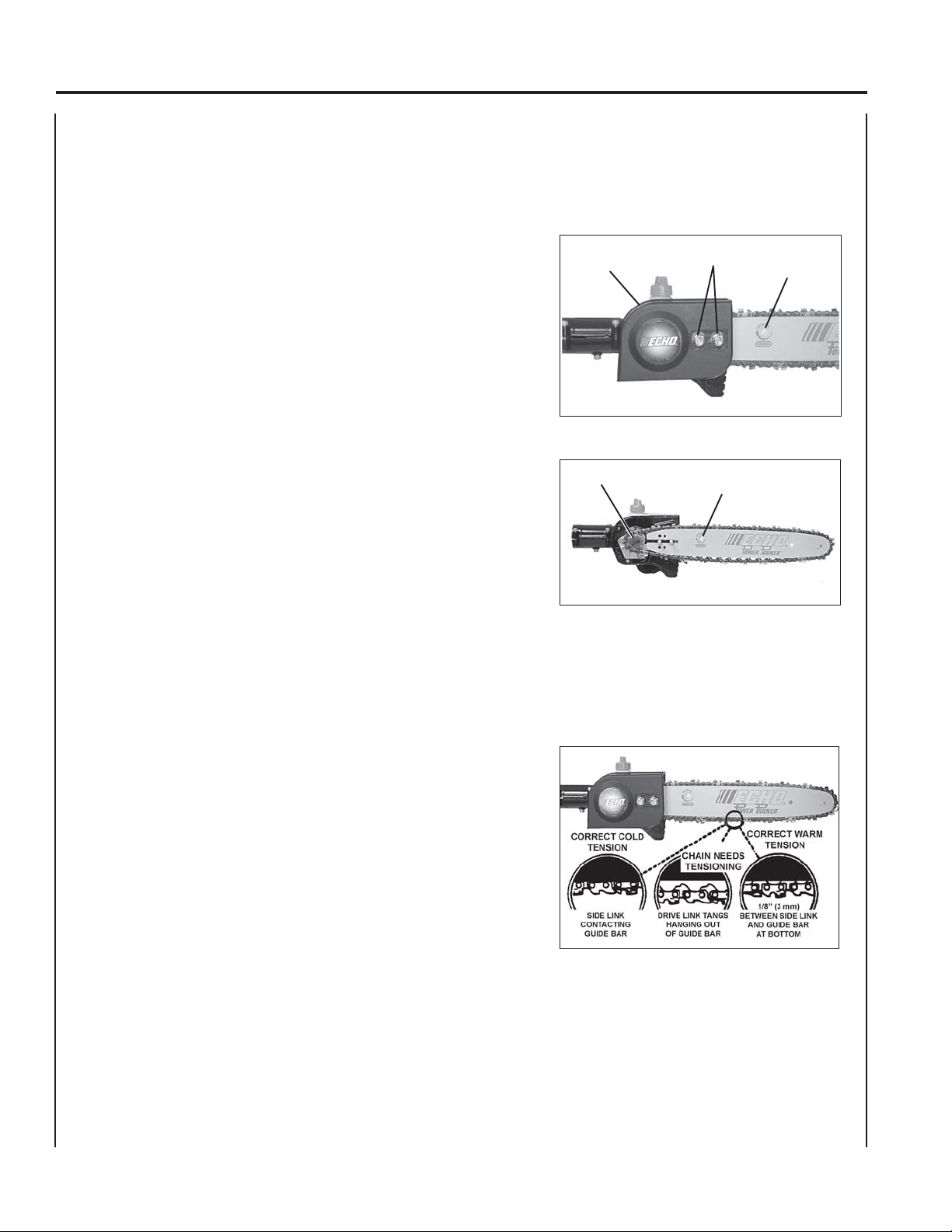

1 . Remove two (2) 6 mm guide bar nuts (C), and turn saw chain

tension adjustment slot (E) counterclockwise to release tension.

2 . Remove sprocket cover (D).

3 . Remove guide bar and saw chain from gear case and sprocket.

4 . Remove chain from guide bar and check guide bar for damage and

excessive or uneven wear. Replace guide bar if necessary.

5 . Turn saw chain tension adjuster slot (E) counterclockwise until it

stops.

6. Install chain on guide bar with cutters on top of bar facing toward

bar tip.

7. Install guide bar and chain on gear case, engaging chain with

drive sprocket (F).

8 . Turn tension adjustment slot clockwise to take up slack in saw

chain.

D

F

C

E

E

9. Install sprocket guard (D), and tighten guide bar nuts finger tight.

10. Adjust chain tension.

To Adjust Saw Chain Tension.

1. Loosen two guide bar nuts (C), if necessary.

2 . Turn saw chain adjuster slot (E) clockwise to tighten saw chain on

guide bar. Turning slot counter clockwise will loosen saw chain on

guide bar.

3 . Tighten guide bar nuts (C) firmly. Pull the saw chain around the

guide bar by hand. Saw chain should move freely on guide bar. If

saw chain is difficult to rotate or binds on guide bar, it is too tight.

4. Keep the saw chain lubricated and properly adjusted and the

guide bar nuts tightened firmly at all times.

Page 5

ADJUSTING AUTOMATIC OILER

5

1 . Remove two (2) 6 mm guide bar retaining nuts (C) and sprocket

cover (D).

2 . From bottom of gear case, turn adjustment screw (P) clockwise to

decrease oil volume - counter clockwise to increase oil volume.

3 . Install sprocket guard (D) and secure with two (2) guide bar

retaining nuts (C).

NOTE

Very little visible oil on the saw chain will provide sufficient

lubrication.

D

P

C

E

Page 6

INSTRUCCIONES DE INSTALACIÓN

CAJA

PARA LOS MODELOS: PP-600, 800, PPF-2100, 2110, PPSR-2122, 2433

PPF-210, 211, PPF-265

INSTALACIÓN DEL ACCESORIO DE CORTE EN EL TUBO DEL EJE

Herramientas necesarias: Llave de boca hexagonal de 10 mm, destornillador,

llave Allen de 4 mm, taladro, taladro de7 mm

(1/4 pulg)

ADVERTENCIA PELIGRO

¡La cadena de la sierra está afilada! Tenga mucho cuidado al mezclar,

guardar o manipular combustible, ya que se pueden producir lesiones

personales graves.

1 . Siga la página las instrucciones de reemplazo de la barra guía y cadena

de la sierra en el manual del operador para quitar la barra guía y la

cadena de la sierra del accesorio de corte existente.

NOTA

Si se va a usar una barra guía estándar con tensor de cadena de acceso

delantero, quite el tensor de la cadena e instale las piezas en la nueva

caja de engranajes. Siga las instrucciones de instalación, ajuste y

reemplazo de la barra guía y de la cadena de la sierra indicadas en el

manual original del operador. En caso de montar la barra guía Intenz™

de acceso lateral, siga las instrucciones aquí indicadas.

2 . Afloje los cuatro (4) tornillos (A) y el tornillo posicionador (B) y quite el

accesorio de corte existente del tubo del eje de aluminio.

3. MODELOS DE PODADERAS ANTERIORES SOLAMENTE: Afloje 4

tornillos de fijación y quite el tornillo ubicador de la caja de engranajes

Deslice la caja de engranajes por el tubo del eje de impulsión y alinéela

con la cabeza de impulsión. Asegúrese de que el eje de impulsión

interior de sección cuadrada se conecte en el adaptador cuadrado de la

caja de engranajes. Si los orificios del eje de impulsión y del ubicador

de la caja de engranajes no corresponden, perfore un orificio de ¼” (7

mm) por un lado del tubo del eje, usando el orificio ubicador de la caja

de engranajes como guía. Quite las rebabas del orificio, y retire todos

los residuos del tubo después de taladrar.

DE ENGRANAJES REPOWER

NÚMERO DE PIEZA 90094

VISTA

DESDE

ABAJO

TM

B

NOTA

No deje que la broca del taladro haga contacto con el eje de impulsión

interno, de lo contrario el eje de impulsión se puede dañar.

X7502307401

X750008571

09/05

Page 7

INSTALACIÓN DE LA BARRA GUÍA Y CADENA DE LA SIERRA

7

4 . Afloje las dos (2) tuerca de 6 mm de la barra guía (C) y quite la tapa

de la rueda dentada (D).

5 . Gire la ranura (E) del tensor de la cadena de la sierra hacia la

izquierda hasta que se pare.

6 . Instale la cadena en la barra de guía, con los cortadores encima de

la barra apuntando hacia la punta de la barra.

7 . Instale la barra guía y la cadena en la caja de engranajes,

enganchando la cadena con la rueda de impulsión.

8 . Gire la ranura de ajuste de tensión hacia la derecha para tensar la

cadena de la sierra.

9 . Instale el protector de la rueda de impulsión, y apriete las tuercas

de la barra de guía (C) con la mano.

D

E

C

C

10. Ajuste la tensión de la cadena. Vea las Instrucciones de ajuste de

tensión de la cadena de la sierra en la página 4 de este manual.

11. Afloje los cuatro (4) pernos (A) y quite el perno posicionador (B)

del accesorio de corte.

12 . (PPSR-2122/2433 solamente) Inserte el collar (G) en el accesorio de

corte (extremo largo del collar primero) hasta que los agujeros

posicionadores (B) estén alineados.

A

B

B

G

Page 8

8

13. Deslice el accesorio de corte por el tubo del eje de aluminio.

Asegúrese de que el eje de mando interior (H) se enganche en el

adaptador cuadrado (I) del accesorio de corte.

14A. (PPF-210/211/251/2100/2110 solamente) Alinee el agujero

posicionador (F) del accesorio de corte con el agujero

posicionador del tubo del eje de aluminio.

14B. (PPSR-2122/2433 solamente) Alinee el agujero posicionador (F) del

accesorio de corte y el collar con el agujero posicionador del tubo

del eje de aluminio.

POWER PRUNER

TM

INSTALLATION INSTRUCTIONS

H

I

B

15. Instale y apriete el perno posicionador (F). Apriete los cuatro (4)

pernos del accesorio de corte (E).

NOTA

El accesorio del corte es completo para los modelos PPF-210, 211,

265. El resto de los modelos siguen los pasos 16 - 19.

16A. (PPF-2100/2110 solamente) Afloje el tornillo de la abrazadera del

arnés (J), dos (2) tornillos de sujeción de la empuñadura del

acelerador (K) y el perno de la abrazadera de la caja del ventilador

del motor (L).

16B. (PPSR-2122/2433 solamente) Afloje los cuatro (4) tornillos de la

empuñadura delantera (M), dos (2) tornillos de sujeción de la

empuñadura del acelerador (N) y dos (2) pernos de la abrazadera

de la caja del ventilador del motor (O).

17A. (PPF-2100/2110 solamente) Coloque el accesorio de corte en

posición vertical y gire la abrazadera del arnés, empuñadura del

acelerador y motor hasta ponerlos en posición vertical en el eje de

impulsión y alineados con el accesorio de corte.

17B. (PPSR-2122/2433 solamente) Coloque el accesorio de corte en

posición vertical y gire la empuñadura delantera, empuñadura del

acelerador y motor en posición vertical en el eje de impulsión y

alineados con el accesorio de corte.

18. (Todos los modelos) Apriete bien los sujetadores del motor y de la

empuñadura del acelerador.

A

J

L

O

M

K

N

19A. (PPF-2100/2110 solamente) Instale el arnés y coloque la abrazadera

del arnés para una operación cómoda. Apriete bien el tornillo de la

abrazadera del arnés.

19B. (PPSR-2122/2433 solamente) Coloque la empuñadura delantera

para una operación cómoda. Apriete bien los cuatro (4) tornillos.

Page 9

REEMPLAZO DE LA BARRA DE GUÍA Y CADENA DE LA SIERRA

Reemplazo/Instalación de la barra guía

1 . Quite las dos (2) tuercas de 6 mm de la barra guía (C), y gire la

ranura de ajuste de tensión de la cadena de la sierra hacia la

izquierda para destensar.

2 . Quite la tapa de la rueda de impulsión (D).

3 . Quite la barra guía y la cadena de la sierra de la caja de engranajes

y de la rueda de impulsión.

4 . Quite la cadena de la barra guía y compruebe la barra guía para ver

si está dañada y desgastada excesivamente o de forma desigual.

Reemplace la barra guía si es necesario, e instale una cadena nueva

o afilada.

5 . Gire la ranura (E) del tensor de la cadena de la sierra hacia la

izquierda hasta que se pare.

D

9

C

E

6 . Instale la cadena en la barra guía, con los cortadores encima de la

barra apuntando hacia la punta de la barra (F).

7 . Instale la barra guía y la cadena en la caja de engranajes,

enganchando la cadena con la rueda de impulsión.

8 . Gire la ranura de ajuste de tensión hacia la derecha para tensar la

cadena de la sierra.

9 . Instale el protector de la rueda de impulsión (D), y apriete las

tuercas de la barra guía con la mano.

10. Ajuste la tensión de la cadena.

Ajuste de la tensión de la cadena de la sierra.

1 . Afloje dos de la tuerca de la barra de guía (C), se es necesario.

2 . Gire hacia la derecha el tornillo tensor de la cadena de la sierra (E)

(ubicado junto a la barra guía) para apretar la cadena de la sierra en

la barra guía. El giro del tornillo hacia la izquierda aflojará la cadena

de la sierra en la barra guía.

3 . Apriete bien las tuercas de la barra guía (C). Tire de la cadena de la

sierra con la mano alrededor de la barra de guía. La cadena de la

sierra debe moverse libremente en la barra guía. Si es difícil hacer

girar la barra guía o se atasca en la barra guía, está demasiado

apretada.

F

Corregir la

tensión en frio

Coloque el lado

que contacta la

barra

E

La cadena

necesita

tensionamiento

Lleve la unión del

extremo aplastado

de la espiga de una

broca colgando hacia

afuera de la barra

Corregir la tensión

cuando esta

calentando

Tiene que haber una

distancia de 1/8"

(3mm) en medio de

la unión de la barra

y la parte inferior

4. Mantenga la cadena de la sierra lubricada y bien ajustada y las

tuercas de la barra guía bien apretadas en todo momento.

Page 10

10

POWER PRUNER

TM

INSTALLATION INSTRUCTIONS

AJUSTE

1 . Quite las dos (2) tuercas de retención de la barra guía (C) de 6 mm

2 . En la parte inferior de la caja de engranajes, gire el tornillo de ajuste

3 . Instale la tapa de la barra guía (D) y sujétela con dos (2) tuercas de

NOTA

La presencia de muy poco aceite visible en la cadena de la sierra

proporcionará una lubricación suficiente.

DEL ENGRASADOR AUTOMÁTICO

y la tapa de la rueda dentada (D).

(P) hacia la derecha para disminuir el volumen de aceite y hacia la

izquierda para aumentarlo.

retención de la barra guía (C).

D

P

C

E

Page 11

INSTRUCTIONS D’INSTALLATION

CARTER D’ENGRENAGES REPOWER™

RÉF. 90094

POUR MODÈLES : PP-600, 800, PPF-2100, 2110, PPSR-2122, 2433

PPF-210, 211, PPF-265

INSTALLATION DE L’ACCESSOIRE DE COUPE SUR LE TUBE D’ARBRE

Outils nécessaires : Clé hexagonale de 10 mm, tournevis, clé

hexagonale de 4 mm, Foret de 6,35 mm (1/4 po) de

diamètre

AVERTISSEMENT DANGER

La chaîne est tranchante ! Toujours porter de gants lors de la

manipulation de l’accessoire de coupe pour éviter des risques de

blessures graves.

1 . Suivre les instructions de remplacement du guide-chaîne et de la

chaîne du manuel d’utilisation pour retirer le guide et la chaîne de

l’accessoire de coupe d’origine.

REMARQUE

Si le guide standard à tendeur de chaîne à l’avant est utilisé, retirer

le tendeur de chaîne et installer les pièces sur le nouveau carter

d’engrenages. Suivre les instructions d’installation, de réglage et

de remplacement de la chaîne du manuel d’utilisation original. Pour

le montage du guide Intenz

ci-après.

2 . Desserrer les quatre (4) vis (A) et la vis de guidage (B) puis retirer

l’accessoire de coupe monté sur le tube d’arbre en aluminium.

3. MODÈLES D’ÉLAGUEUSE POWER PRUNER ANCIENS

SEULEMENT : Desserrer les quatre vis de serrage et retirer la vis

de guidage du carter d’engrenages. Glisser le carter d’engrenages

sur l’arbre moteur et l’aligner sur le bloc moteur. Veiller à ce que

l’arbre moteur interne s’engage bien dans le carré d’entraînement

du carter d’engrenages. Si les trous de guidage de l’arbre moteur

et du carter d’engrenages ne correspondent pas, percer un trou de

6,35 mm (1/4 po) dans l’un dés côtés du tube de l’arbre, en utilisant

le trou du carter d’engrenages comme guide. Une fois le trou

percé, l’ébavurer et éliminer tous les débris du tube.

REMARQUE

Ne pas laisser le foret entrer en contact avec l’arbre moteur interne,

car celui-ci pourrait être endommagé.

TM

à accès latéral, suivre les instructions

VEU

DU

DESSOUS

B

X7502307401

X750008571

09/05

Page 12

12

POWER PRUNER

TM

INSTALLATION INSTRUCTIONS

INSTALLATION

4 . Desserrer les deux (2) écrous de 6 mm de la barre-guide (C) et

retirer le couvercle de pignon (D).

5 . Gire la ranura (E) del tensor de la cadena de la sierra hacia la

izquierda hasta que se pare.

6 . Instale la cadena en la barra de guía, con los cortadores encima de

la barra apuntando hacia la punta de la barra.

7 . Instale la barra guía y la cadena en la caja de engranajes,

enganchando la cadena con la rueda de impulsión.

8 . Gire la ranura de ajuste de tensión hacia la derecha para tensar la

cadena de la sierra.

9 . Instale el protector de la rueda de impulsión, y apriete las tuercas

de la barra de guía (C) con la mano.

DU GUIDE-CHAÎNE ET DE LA CHAÎNE

D

E

C

C

10. Ajuste la tensión de la cadena. Vea las Instrucciones de ajuste de

tensión de la cadena de la sierra en la página 5 de este manual.

11. Desserrer les quatre (4) boulons (A) et retirer le boulon (B) de

l’accessoire de coupe.

12 . (PPSR-2122/2433 seulement) Insérer le collier (G) sans l’accessoire

de coupe (extrémité longue en premier) et aligner les trous de

guidage (B).

A

B

B

G

Page 13

13. Glisser l’accessoire de coupe sur le tube d’arbre en aluminium.

Veiller à ce que l’arbre moteur (H) s’engage bien dans le carré

d’entraînement (I) de l’accessoire de coupe.

13

14A. (PPF-210/211/251/2100/2110 seulement) Aligner le trou de guidage

(F) de l’accessoire de coupe sur le trou de guidage du tube d’arbre

en aluminium.

14B. (PPSR-2122/2433 seulement) Aligner les trous de guidage (F) de

l’accessoire de coupe et du collier sur le trou de guidage du tube

d’arbre en aluminium.

15. Installer et serrer le boulon de blocage (F). Serrer les quatre (4)

boulons (E) de l’accessoire de coupe.

REMARQUE

L’attachement de découpage est complet pour les modèles

PPF-210, 211, 265. Tous autres modèles suivent les étapes 16 - 19.

16A. (PPF-2100/2110 seulement) Desserrer la vis (J) du collier de

harnais, les deux (2) vis (K) de fixation de la manette des gaz et le

boulon (L) du carter de ventilateur du moteur.

16B. (PPSR-2122/2433 seulement) Desserrer les quatre (4) vis (M) de

poignée avant les deux (2) vis (N) de la manette des gaz et les deux

(2) boulons (O) du carter de ventilateur du moteur.

17A. (PPF-2100/2110 seulement) Mettre l’accessoire de coupe à la

verticale et tourner le collier de harnais, la poignée de manette des

gaz et le moteur à la verticale sur l’arbre en ligne avec l’accessoire

de coupe.

H

I

B

A

J

K

L

17B. (PPSR-2122/2433 seulement) Mettre l’accessoire de coupe à la

verticale et tourner la poignée avant, la poignée de manette des

gaz et le moteur à la verticale sur l’arbre en ligne avec l’accessoire

de coupe.

18 . (Tous les modèles) Serrer fermement la boulonnerie du moteur et

de la manette des gaz.

19A. (PPF-2100/2110 seulement) Installer le harnais et régler son collier

sur une position d’utilisation confortable. Serrer fermement la vis

du collier de harnais.

19B. (PPSR-2122/2433 seulement) Placer la poignée avant sur une

position confortable. Serrer fermement les quatre (4) vis.

M

N

O

Page 14

14

REMPLACEMENT DU GUIDE-CHAÎNE ET DE LA CHAÎNE

Remplacement/installation du guide-chaîne

1 . Quite las dos (2) tuercas de 6 mm de la barra guía (C), y gire la

ranura de ajuste de tensión de la cadena de la sierra hacia la

izquierda para destensar.

2 . Quite la tapa de la rueda de impulsión (D).

3 . Quite la barra guía y la cadena de la sierra de la caja de engranajes

y de la rueda de impulsión.

4 . Quite la cadena de la barra guía y compruebe la barra guía para ver

si está dañada y desgastada excesivamente o de forma desigual.

Reemplace la barra guía si es necesario, e instale una cadena

nueva o afilada.

POWER PRUNER

TM

INSTALLATION INSTRUCTIONS

D

C

E

5 . Gire la ranura (E) del tensor de la cadena de la sierra hacia la

izquierda hasta que se pare.

6 . Instale la cadena en la barra guía, con los cortadores encima de la

barra apuntando hacia la punta de la barra.

7 . Instale la barra guía y la cadena en la caja de engranajes,

enganchando la cadena con la rueda de impulsión (F).

8 . Gire la ranura de ajuste de tensión hacia la derecha para tensar la

cadena de la sierra.

9 . Instale el protector de la rueda de impulsión (D), y apriete las

tuercas de la barra guía con la mano.

10. Ajuste la tensión de la cadena.

Réglage de la tension de la chaîne.

1. Desserrer les deux (2) ecrouse (C), au besoin.

2. Tourner la vis (E) du tendeur de chaîne (se trouvant près du

guide-chaîne) dans le sens horaire pour tendre la chaîne sur le

guide. Tourner la vis dans le sens antihoraire pour détendre la

chaîne.

3 . Serrer fermement les écrous (C) de la barre-guide. Engager la

chaîne sur le guide à la main. La chaîne doit tourner librement sur

le guide. Si la chaîne est difficile à tourner ou se coince sur le

guide, elle est trop tendue.

4 . Veiller à ce que la chaîne soit correctement lubrifiée et ajustée et à

ce que les écrous du guide soient bien serrés en tout temps.

F

TENSION CORRECTE

À FROID

Côté du maillon en

contact avec le guide

E

LA CHAÎNE A BESOIN

D’ÊTRE TENDUE

Les crampons d’entraînement

sont écartés du guide

TENSION CORRECTE

À CHAUD

1/8 po (3 mm) entre le côté

du maillon et le bas du guide

Page 15

RÉGLAGE DU GRAISSEUR AUTOMATIQUE

15

1 . Desserrer les deux (2) écrous de 6 mm de retenue de la barre-guide

(C) et retirer le couvercle de pignon (D).

2. Par le dessous du carter d’engrenages, tourner la vis de réglage (P)

dans le sens horaire pour réduire le débit d’huile et dans le sens

antihoraire pour l’augmenter.

3 . Installer le carter de la barre-guide et l’assujettir avec les deux (2)

écrous de retenue (C).

REMARQUE

Une mince couche d’huile visible sur la chaîne assurera une

lubrification suffisante.

D

P

C

E

Page 16

ECHO CONSUMER PRODUCT SUPPORT: If you require assistance or have questions concerning the application,

operation or maintenance of this product you may call the ECHO Consumer Product Support Department at 1-800-6731558 from 8:30 am to 4:30 pm (Central Standard Time) Monday through Friday. Before calling, please know the model and

serial number of your unit to help your Consumer Product Support Representative.

REPLACEMENT MANUALS: Operator's, Parts, and Safety Manuals may be obtained from ECHO, or may be downloaded free from ECHO's website. Make sure you know the model number and serial number of your unit so you can

obtain the correct manual.

ASISTENCIA AL CLIENTE DE ECHO: Si usted requiere asistencia o tiene preguntas concernientes a la aplicación,

operación, o mantenimiento de este producto llame al departamento de asistencia al cliente de ECHO al 1-800-673-1558 de

8:30 am. a 4:30 pm. (Hora del Centro) de Lunes a Viernes Antes de llamar por favor saber el modelo y numero de serie de

su unidad para ayudar a su representante de asistencia al cliente.

MANUALES DE REPUESTO: Se puede obtener los manuales del operador, piezas y seguridad de ECHO, o se puede

descargar gratis del sitio web de ECHO. Asegúrese de que sepa el número de modelo y el número de serie de su unidad

para que pueda obtener el manual correcto.

SERVICE APRÈS-VENTE ECHO: Pour toute assistance ou question concernant l’application, l’utilisation ou l’entretien

de ce produit, appeler le service après-vente ECHO au 1-800-673-1558, de 08:30 à 16:30 heures (heure normale du centre),

du lundi au vendredi. Avant d’appeler, veiller à disposer des numéros de modèle et de série de l’unité afin d’aider votre

représentant du service après-vente.

MANUELS DE REMPLACEMENT : Des manuels d’utilisation, catalogues de pièces et manuels de sécurité peuvent être

achetés chez les concessionnaires ECHO ou commandés directement chez ECHO. Veiller à toujours fournir les numéros

de modèle et de série de la machine pour 6etre sûr d’obtenir le manuel approprié.

ECHO, INCORPORATED

400 OAKWOOD ROAD

LAKE ZURICH, IL 60047-1564

PHONE: 1-800-673-1558

www.echo-usa.com

Loading...

Loading...