Page 1

1Top cover(composite volume)

ENGLISH

FRANÇAIS

DEUTSCH

ITALIANO

ESPAÑOL

OPERATOR'S MANUAL

MANUEL D'UTILISATION

BEDIENUNGSANLEITUNG

MANUALE PER L'OPERATORE

MANUAL DE INSTRUCCIONES

PB-770

WARNING

READ THE INSTRUCTIONS CAREFULLY AND FOLLOW THE RULES FOR

SAFE OPERATION.

FAILURE TO DO SO COULD RESULT IN SERIOUS INJURY.

AVERTISSEMENT

LIRE ATTENTIVEMENT LES INSTRUCTIONS ET SUIVRE LES RE-GLES DE

SECURITE. LE NON-RESPECT DES REGLES DE SECU-RITE ENTRAINE UN

RISQUE DE BLESSURE GRAVE.

WARNUNG

LESEN SIE DIE BEDIENUNGSANLEITUNG SORGFÄLTIG DURCH, UND BEFOLGEN SIE DIE SICHERHEITSREGELN. ANDERNFALLS BESTEHT DAS

RISIKO SCHWERER VERLETZUNGEN.

AVVERTENZA

LEGGERE E SEGUIRE ATTENTAMENTE LE ISTRUZIONI PER LA-VORARE

IN CONDIZIONI DI MASSIMA SICUREZZA. LA MANCA-TA OSSERVANZA

DELLE ISTRUZIONI POTREBBE PROVOCARE LESIONI GRAVI.

ADVERTENCIA

LEA ATENTAMENTE LAS INSTRUCCIONES Y SIGA LAS INDICA-CIONES

PARA UN FUNCIONAMIENTO SEGURO. DE NO HACER-LO, PODRÍA SUFRIR

LESIONES GRAVES.

Page 2

Packing list

Packing list

3

Page 3

1Top cover

ENGLISH

(Original instructions)

OPERATOR'S MANUAL

PB-770

WARNING

READ THE INSTRUCTIONS CAREFULLY AND FOLLOW THE

RULES FOR SAFE OPERATION.

FAILURE TO DO SO COULD RESULT IN SERIOUS INJURY.

Page 4

Important information

2Important information

Please ensure that you read the operator's manual before using your product.

Intended use of this product

ECHO Power Blowers are designed for blowing away dust of various sorts, including fallen leaves.

Do not use this unit for any purpose other than aforementioned.

Users of the product

You should not use this product until you have read the operator's manual carefully and fully absorbed its content.

This product should not be used by anyone who has failed to read the operator's manual properly, is suffering from a

cold, tiredness or otherwise in poor physical condition, or children.

Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people or their prop-

erty.

About your operator's manual

This manual contains necessary information about the assembly, operation, and maintenance of your product. Please

read it carefully and absorb its contents.

Always keep your manual in a place where it is readily accessible.

If you have lost your manual or it is damaged and no longer readable, please purchase a new one from your ECHO

DEALER.

The units used in this manual are SI units (International System of Units). Figures in parentheses are reference values,

and there may be a slight conversion error in some cases.

Loaning or assigning your product

When loaning the product described in this manual to another party, ensure that the person borrowing and working with

the product receives the operator's manual along with the product. If you assign your product to another party, please

enclose the operator's manual with the product when handing it over.

Enquiries

Please contact your ECHO DEALER for requests regarding information about your product, the purchase of consum-

ables, repairs, and other such enquiries.

Notices

The content of this manual may be changed without notice for the purpose of upgrades to the product. Some of the

illustrations used may differ from the product itself in order to make the explanations clearer.

This product requires the assembly of some parts.

Please consult your ECHO DEALER if anything is unclear or of concern.

Manufacturer

YAMABIKO CORPORATION

7-2 SUEHIROCHO 1-CHOME, OHME, TOKYO 198-8760, JAPAN

Authorized Representative in Europe

Atlantic Bridge Limited

Atlantic House, PO Box 4800, Earley, Reading RG5 4GB, United Kingdom

2

Page 5

Contents

For safe use of your product ............................................................................................... 4

Warning notices ............................................................................................................. 4

Other indicators ............................................................................................................. 4

Symbols.........................................................................................................................4

Location in which the safety decal is attached............................................................... 6

Handling fuel.................................................................................................................. 7

Handling the engine....................................................................................................... 8

Handling the product ..................................................................................................... 9

Packing list........................................................................................................................ 12

Description........................................................................................................................13

Before you start ................................................................................................................14

Assembly ..................................................................................................................... 14

Preparing the fuel ........................................................................................................ 15

Engine operation............................................................................................................... 16

Starting the engine ...................................................................................................... 16

Stopping the engine..................................................................................................... 18

Operation ..........................................................................................................................19

Operating blower ......................................................................................................... 19

Maintenance and care ...................................................................................................... 20

Servicing guidelines..................................................................................................... 20

Maintenance and care ................................................................................................. 20

Troubleshooting table .................................................................................................. 24

Long-term storage(30 days or more)........................................................................... 25

Specifications.................................................................................................................... 26

Declaration of conformity .................................................................................................. 27

3

Page 6

For safe use of your product

Be careful to read this section before using your product.

For safe use of your product

The precautions described in this section contain important safety information. Please observe them carefully.

You must also read the precautions that appear in the body of the manual itself.

Text following a [diamond mark] mark describes the potential consequences of failing to observe the precaution.

Warning notices

Situations where there is a risk of physical injury to the operator and other people are indicated in this manual and on the product

itself by the following warning notices. Always read and observe them carefully in order to ensure safe operation.

DANGER WARNING CAUTION

This symbol accompanied by the

word "DANGER" calls attentions to

an act or a condition which will lead to

serious personal injury or death of operators and bystanders.

Other indicators

As well as warning notices, this manual uses the following explanatory symbols:

This symbol accompanied by the

word "WARNING" calls attentions to

an act or a condition which can lead to

serious personal injury or death of operators and bystanders.

"CAUTION" indicates a potentially

hazardous situation which, if not

avoided, may result in minor or moderate injury.

NOTE IMPORTANT

Circle and slash symbol means whatever is

shown is prohibited.

This enclosed message provides tips

for use, care and maintenance of the

product.

Framed text featuring the word "IM-

PORTANT" contains important information about the use, checking,

maintenance and storage of the product described in this manual.

Symbols

In this manual and on the product itself, a series of explanatory symbols is used. Please make sure that you fully understand what

each symbol means.

Symbol form/shape Symbol description/applica-

tion

Carefully read the operator's

manual

Wear eyes, ears and head

protection

Safety / Alert

Emergency stop

Symbol form/shape Symbol description/applica-

tion

Petrol and oil mixture

Purge bulb (Primer)

Carburettor adjustment

- Low speed mixture

Carburettor adjustment

- High speed mixture

Finger Severing

Carburettor adjustment

- Idle speed

4

Page 7

For safe use of your product

Symbol form/shape Symbol description/applica-

tion

Do not use the product in places with poor ventilation

Beware of fire

Beware of electric shocks Idle speed

Guaranteed sound power level

Ignition

ON / OFF

Symbol form/shape Symbol description/applica-

tion

Choke Control

"Cold Start"

Position

(Choke Closed)

Choke Control

"Run"

Position

(Choke Open)

Fast speed

Beware of high-temperature

areas

Engine start

5

Page 8

For safe use of your product

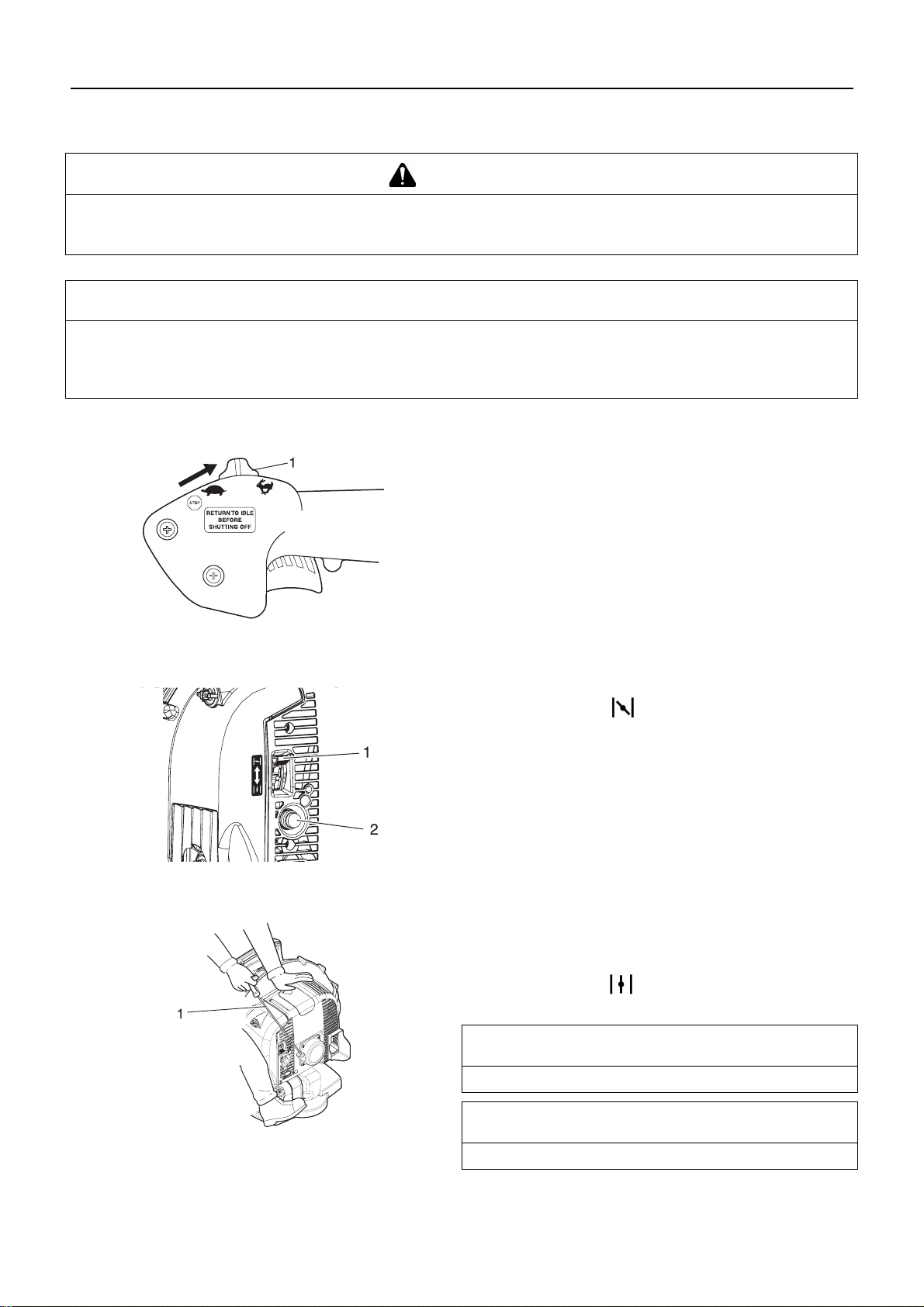

Location in which the safety decal is attached

The safety decal shown below has been attached to the product described in this manual. Ensure that you understand what the

decal means before using your product.

If the decal becomes unreadable due to wear and tear or damage, or peels off and is lost, please purchase a replacement decal

from your ECHO DEALER and attach it in the location shown in the illustrations below. Ensure that the decal is readable at all

times.

1. Safety decal (Part number X505002310)

2. Safety decal (Part number 89016009461)

6

Page 9

For safe use of your product

Handling fuel

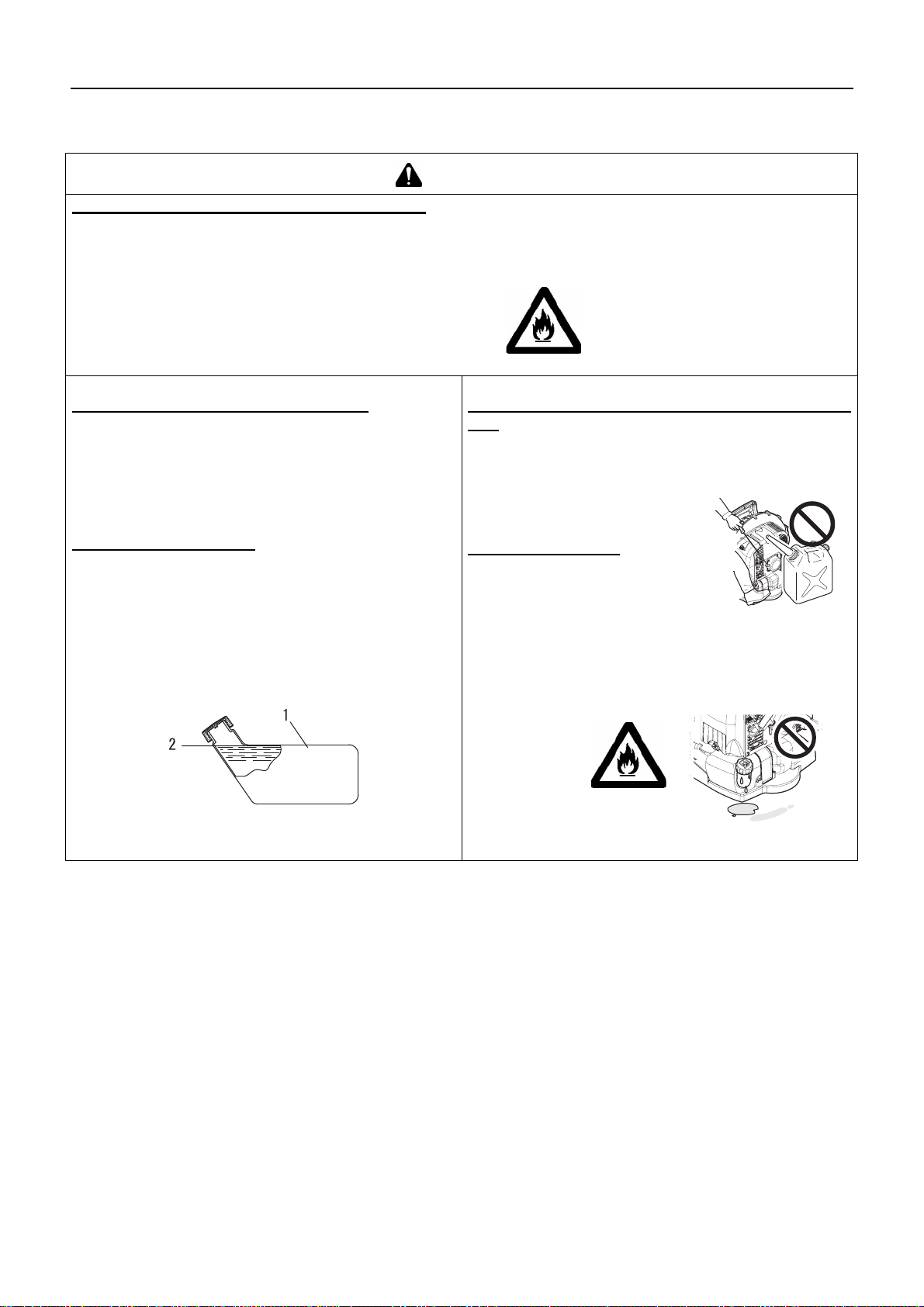

DANGER

Always keep well away from fire when refuelling

Fuel is highly inflammable and leads to a risk of fire if mishandled. Use extreme care when mixing, storing or handling

or serious personal injury may result. Be careful to observe the following instructions.

Do not smoke or hold a flame near when refuelling.

Do not fuel up while the engine is hot or in operation.

If you do so, the fuel could ignite and cause fire, leading to burns.

About the container and refuelling place

Use an approved fuel container.

Fuel tanks/cans may be under pressure.

Always loosen fuel caps slowly allowing pressure to

equalize.

DO NOT fill fuel tanks indoors.

ALWAYS fill fuel tanks outdoors over bare ground.

Fuel spills can cause fire

Observe the following precautions when refuelling:

Do not add so much fuel that it reaches the mouth of the

fuel tank. Keep the fuel within the prescribed level (up to

the shoulder level of the fuel tank).

Mop up any fuel that overflows or spills out due to overfilling.

Tighten the fuel tank cap securely after refuelling.

Fuel spills can cause fire and burns when ignited.

1. Fuel tank

2. Shoulder level

Do not start the engine in the area where you refueled

You must not start the engine in the place where you

carried out the refuelling. Move at least 3m from the

place where you refueled before starting the engine.

Fuel leaks that occur while refuel-

ling can cause fire if ignited.

Fuel leaks cause fire

After refuelling, always check

that there are no leaks or discharges of fuel from the fuel

pipe, fuel system grommets, or

around the fuel tank cap.

If you do find fuel leaks or discharges, stop using the

product immediately and contact your ECHO DEALER

to have it repaired.

Any fuel leaks could cause fire.

7

Page 10

For safe use of your product

Handling the engine

WARNING

Starting the engine

Be particularly careful to observe the following precautions when starting the engine:

Check that none of the nuts and bolts are loose

Check that there are no fuel leaks

Do not try to start the engine with the product shouldered

Place the product in a flat, well ventilated place

Leave plenty of space around the product and do not allow people or animals near it

Remove obstructions, if any

Start the engine with the throttle lever in the start/operation position

Hold the product firmly to the ground when starting the

engine

Failure to observe the precautions could cause an accident

or injury, or even lead to a fatality.

Once the engine has started, check for abnormal vibrations and sounds

Check that there are no abnormal vibrations or sounds

once the engine starts. Do not use the product if there

are abnormal vibrations or sounds. Contact your ECHO

DEALER to have it repaired.

Accidents involving parts that fall or shatter off can cause

wounds or serious injury.

Do not touch high temperature or high voltage components while the product is running

Do not touch the following high temperature or high voltage components while the product is running or for some

time after it stops.

Silencer, cylinder, and other high temperature components

You could burn yourself if you touch a high

temperature component.

Spark plug, spark plug wire, and other

high voltage components

You could receive an electric shock if you

touch a high voltage component while the

product is running.

Exhaust fumes are toxic

The exhaust fumes from the engine contain toxic gases.

Do not operate the product indoors or in a plastic greenhouse or in other ill ventilated places.

The exhaust fumes could cause poisoning.

Turn off the engine when checking or maintaining

the product

Observe the following precautions when checking and

maintaining your product after use:

Turn the engine off and do not attempt to check or maintain the product until the engine has cooled

You could burn yourself.

Remove the spark plug cap before performing checks

and maintenance

An accident could occur if the product starts unexpectedly.

Checking the spark plug

Observe the following precautions when checking the

spark plug.

If the electrodes or terminals are worn, or if there are

cracks in the ceramics, replace them with new parts.

The spark test (for checking whether the spark plug is

sparking) must be carried out by a professional. Please

ask your ECHO DEALER.

The spark test must not be carried out in proximity of

the spark plug hole.

The spark test must not be performed in places where

there are fuel spills or inflammable gases

You must not touch the

metal parts of the spark

plug

The spark plug could ig-

nite a fire or give you an

electric shock.

Put safety first in the case of fire or smoke

If fire comes from the engine or smoke appears from

any area other than the exhaust vent, first distance

yourself from the product to ensure your physical safety.

Use a shovel to throw sand or other such

material on the fire to prevent it from

spreading, or put it out with a fire extinguisher.

A panicked reaction could result in the fire and

other damage becoming more extensive.

8

Page 11

For safe use of your product

Handling the product

General precautions

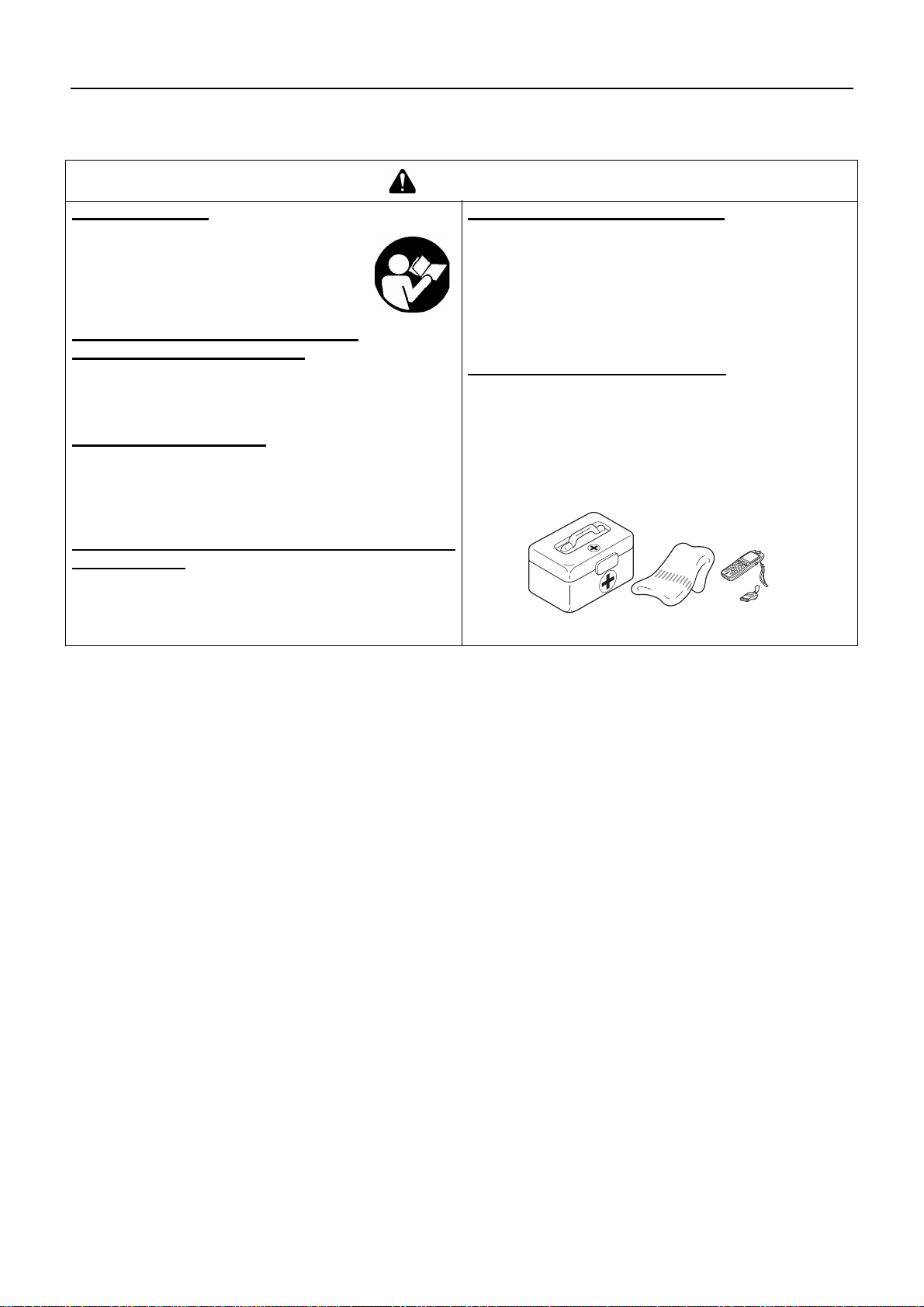

Operator's manual

Be careful to read the operator's manual

properly before using your product in order to ensure correct operation.

Failure to do so could lead to an accident or

serious injury.

Do not use the product for anything

other than its intended purpose

You must not use the product for any purpose other

than those described in the operator's manual.

To do so could lead to an accident or serious injury.

Do not modify the product

You must not modify the product.

To do so could lead to an accident or serious injury. Any

malfunction resulting from a modification to the product will

not be covered by the manufacturer's warranty.

WARNING

Loaning or assigning your product

When loaning your product to another party, ensure

that the person borrowing the product receives the operator's manual along with it.

If you assign your product to another party, please enclose the operator's manual with the product when

handing it over.

Failure to do so could lead to an accident or serious injury.

Being prepared in case of an injury

In the unlikely event of an accident or injury, please ensure

that you are prepared.

First aid kit

Towels and wipes (to stop any bleeding)

Whistle or mobile phone (for calling outside help)

If you are unable to perform first aid or call for outside help,

the injury could worsen.

Do not use the product unless it has been checked

and maintained

You must not use the product unless it has been

checked and maintained. Always ensure that the product is checked and maintained on a regular basis.

Failure to do so could lead to an accident or serious injury.

9

Page 12

For safe use of your product

Precautions for use

WARNING

Users of the product

The product should not be used by:

people who are tired

people who have taken alcohol

people who are on medication

people who are pregnant

people who are in poor physical

condition

people who have not read the operator's manual

children

Failure to observe these instruc-

tions could lead to an accident.

Environment of use and operation

Do not use the product:

when it is raining, thundering, or lightning strikes are

likely to occur.

on steep slopes or in place which give no secure foothold and are thus slippery.

at night or in places with poor visibility.

A serious injury could result if you fall or slip, or fail to oper-

ate the product correctly.

Using the product

When using the product, pay special attention to observe

the following precautions.

Do not allow people who are irrelevant to the work conducted or animals to be in the worksite.

Do not point the blower pipe at people or animals.

Do not use the product in places where there is no sure

foothold.

Hold the arm tightly.

Avoid using the product late at night or early in the

morning so that the neighbors will not be disturbed by

noise.

Failure to observe these instructions could lead to an acci-

dent or injury.

Turn off the engine when moving around

When moving around in the situations described below,

turn off the engine and move with the product shouldered.

Failure to observe these precautions could cause burns or

Travelling by car with fuel in the fuel tank could lead to a fire.

Be careful not to get caught in the fan

The wind pressure from the fan could make your hand get

Vibration and cold

It is believed that a condition called Raynaud's Phenomenon which affects the fingers of certain individuals may be

brought about by exposure to vibration and cold. Exposure to vibration and cold may cause tingling and burning,

followed by loss of colour and numbness in the fingers.

The following precautions are strongly recommended because the minimum exposure which might trigger the ailment is unknown.

Failure to observe these instructions could result in damage

Moving to the place where you are working

Moving to another area while you are working

Leaving the place where you have been working

serious injury.

When transporting the product by car, empty the fuel

tank, put the product in the upright position, and secure

it firmly in place to prevent it from moving around.

Be careful not to get your hair caught in the fan.

Never put your hand in between the engine and the

backpack frame when the product is in operation.

caught in the fan, resulting in a serious injury.

Keep your body warm, especially the head and neck,

feet and ankles, and hands and wrists.

Maintain good blood circulation by performing vigorous

arm exercises during frequent work breaks, and also by

not smoking.

Limit the number of hours of operation.

Try to fill each day with jobs where operating the blower

or other hand-held power equipment is not required.

If you experience discomfort redness and swelling of

the fingers, followed by whitening and loss of feeling,

consult your physician before exposing yourself further

to cold and vibration.

to your health.

10

Page 13

For safe use of your product

WARNING

Repetitive stress injuries

It is believed that over-using the muscles and tendons of

the fingers, hands, arms and shoulders may cause soreness, swelling, numbness, weakness and extreme pain to

the areas just mentioned. Certain repetitive hand activities

may put you at a high risk for developing a repetitive

stress injury (RSI).

To reduce the risk of RSI, do the following:

Avoid using your wrist in a bent, extended or twisted

position.

Take periodic breaks to minimize repetition and rest

your hands. Reduce the speed and force in which you

do the repetitive movement.

Do exercises to strengthen hand and arm muscles.

See a doctor if you feel tingling, numbness or pain in

your fingers, hands, wrists or arms. The sooner RSI is

diagnosed, the more likely permanent nerve and muscle

damage can be prevented.

Failure to observe these instructions could result in damage

to your health.

Turn off the engine immediately if anything goes

wrong

Turn off the engine immediately if the product suddenly

starts to emit abnormal sounds or vibrate abnormally.

The product cannot be used when it suffers from abnormal vibration or sounds.

Contact your ECHO DEALER for repair.

Continuing to use parts when they are damaged could lead

to an accident or serious injury.

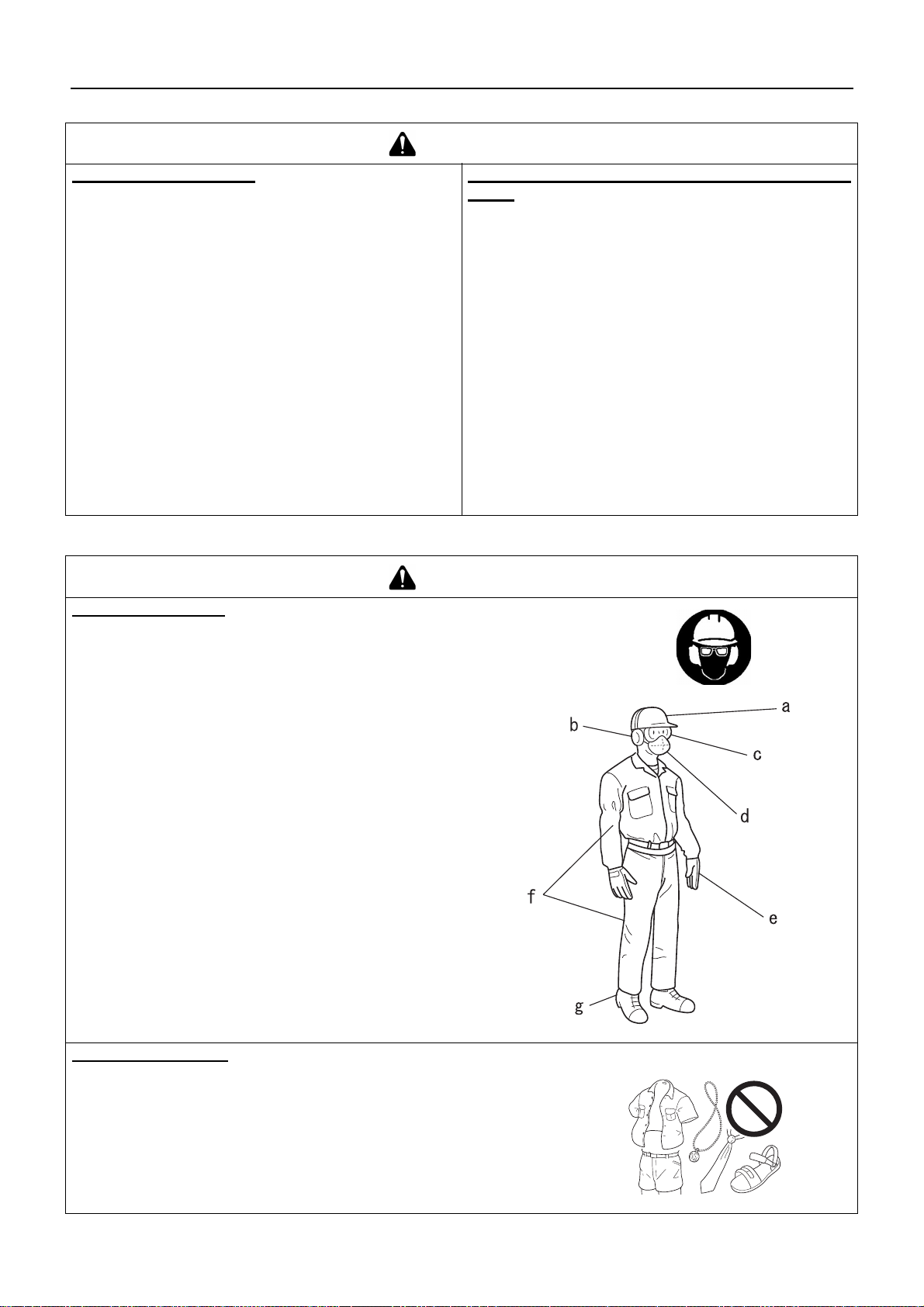

Protective gear

WARNING

Wear protective gear

Wear appropriate work clothes and protective gear

when working with the power blower. Above all, make

sure to wear safety goggles, a dust mask, and ear muffs

at all times while working.

Without the protective gear, you could inhale the debris or

dust blown away or get them in your eyes, which could lead

to an accident or injury.

a Head protection (helmet): Protects the head

b Ear muffs or ear plugs: Protect the hearing

c Safety goggles: Protect the eyes

d Dust mask

e Safety gloves: Protect the hands from cold and vibration

f Work clothes that fit (long sleeves, long trousers): Pro-

tect the body

g Heavy duty, non-slip protective boots (with toecaps) or

non-slip work shoes (with toecaps): Protect the feet

Failure to observe these precautions could result in damage

to your sight or hearing, or lead to a serious injury.

Wear proper clothing

Do not wear ties, jewellery, or loose, dangling clothing which could be

caught in the unit. Do not wear open toed footwear, or go bare-foot or

barelegged. In certain situations, total face and head protection may be required.

Failure to observe these precautions could result in damage to your sight or

hearing, or lead to a serious injury.

11

Page 14

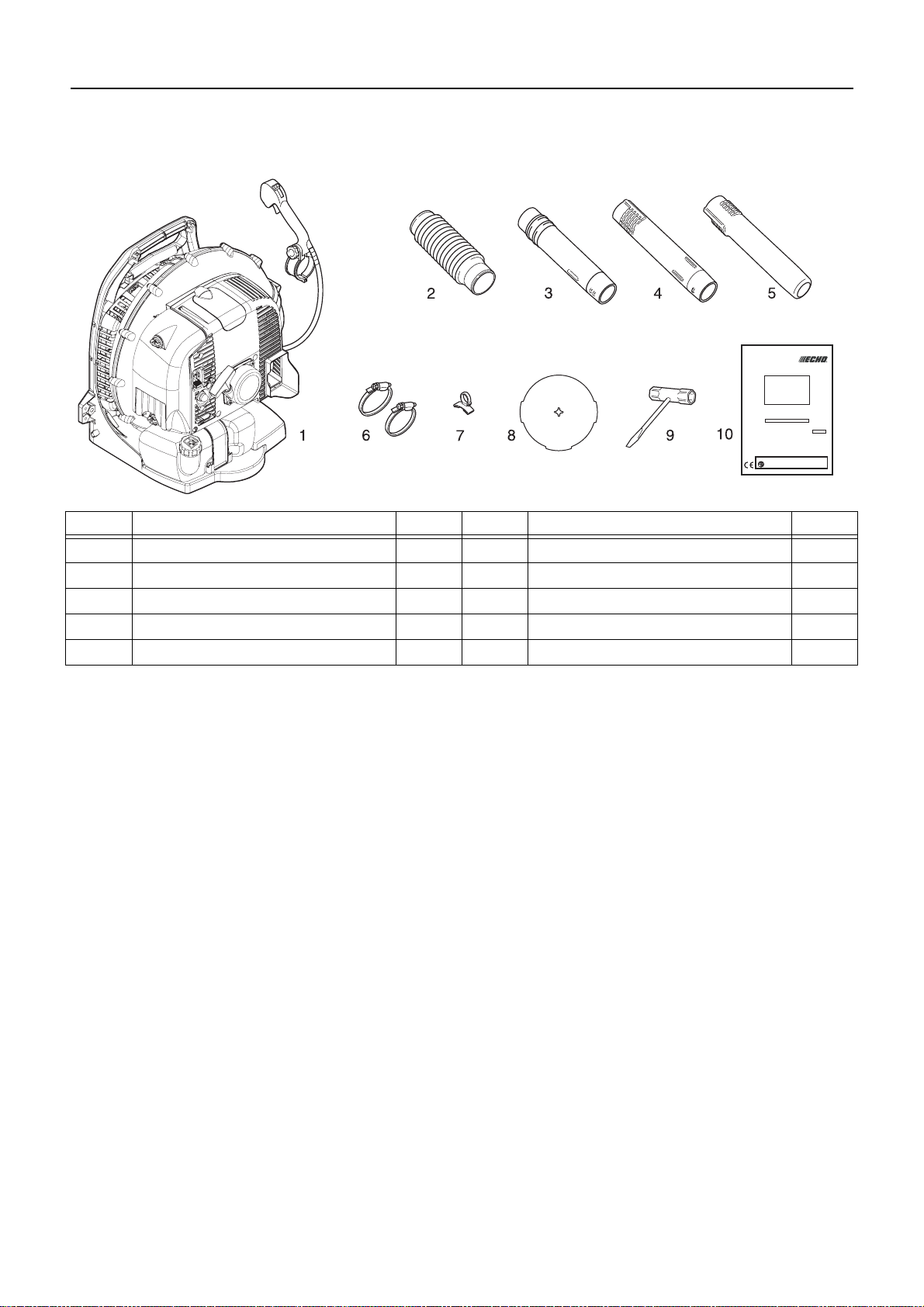

Packing list

The following parts are packed separately in the packing box.

When you have unpacked the box, please check the parts that it contains.

Contact your ECHO DEALER if anything is missing or broken.

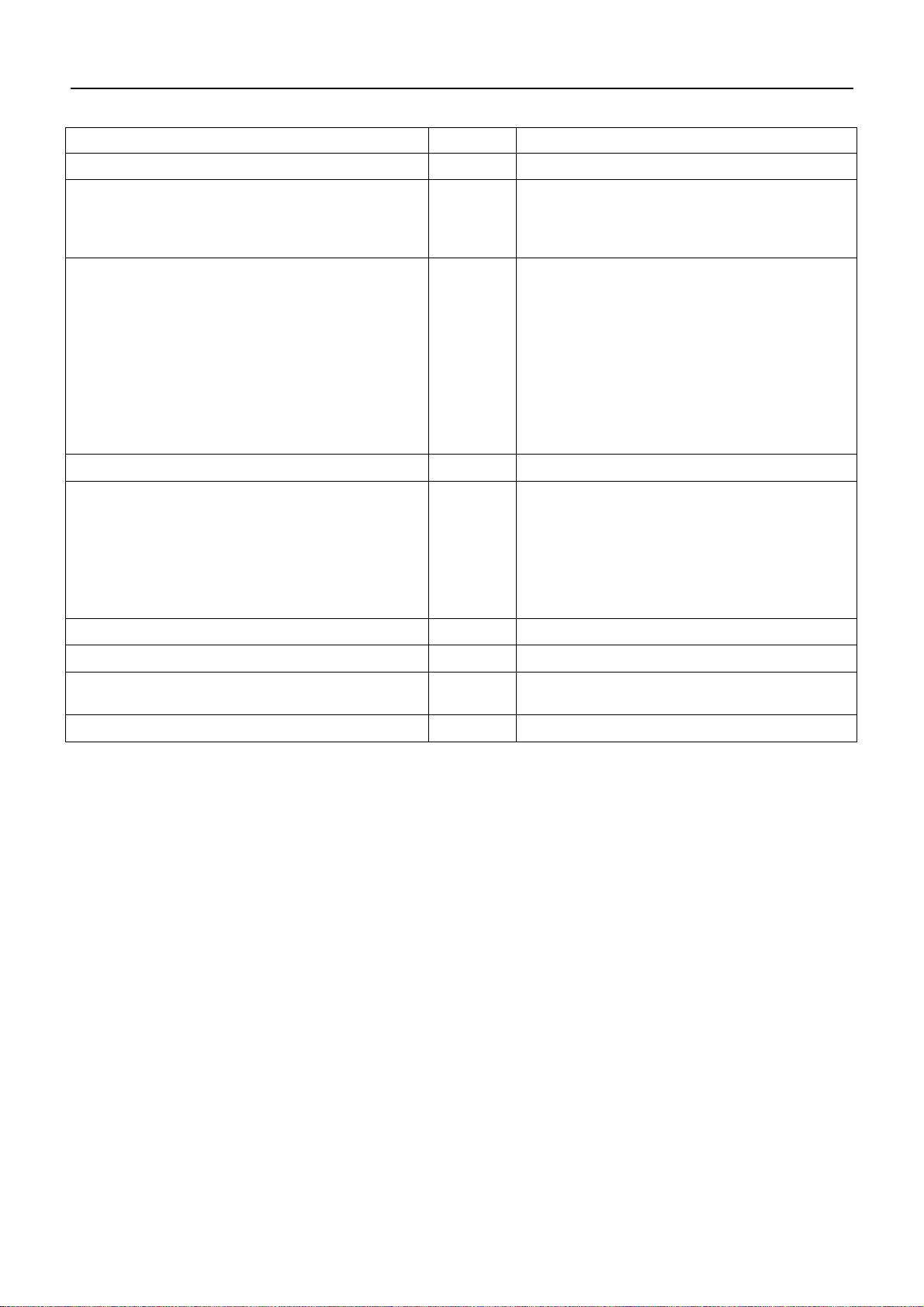

Number Part name Quantity Number Part name Quantity

(1) Power Head 1 (6) Clamps w/screws 2

(2) Flex Pipe 1 (7) Guide Loop 1

(3) Swivel Pipe 1 (8) Intake cover 1

(4) Straight Pipe 1 (9) T-Wrench 1

(5) Straight Pipe 1 (10) Operator's Manual 1

Packing list

12

Page 15

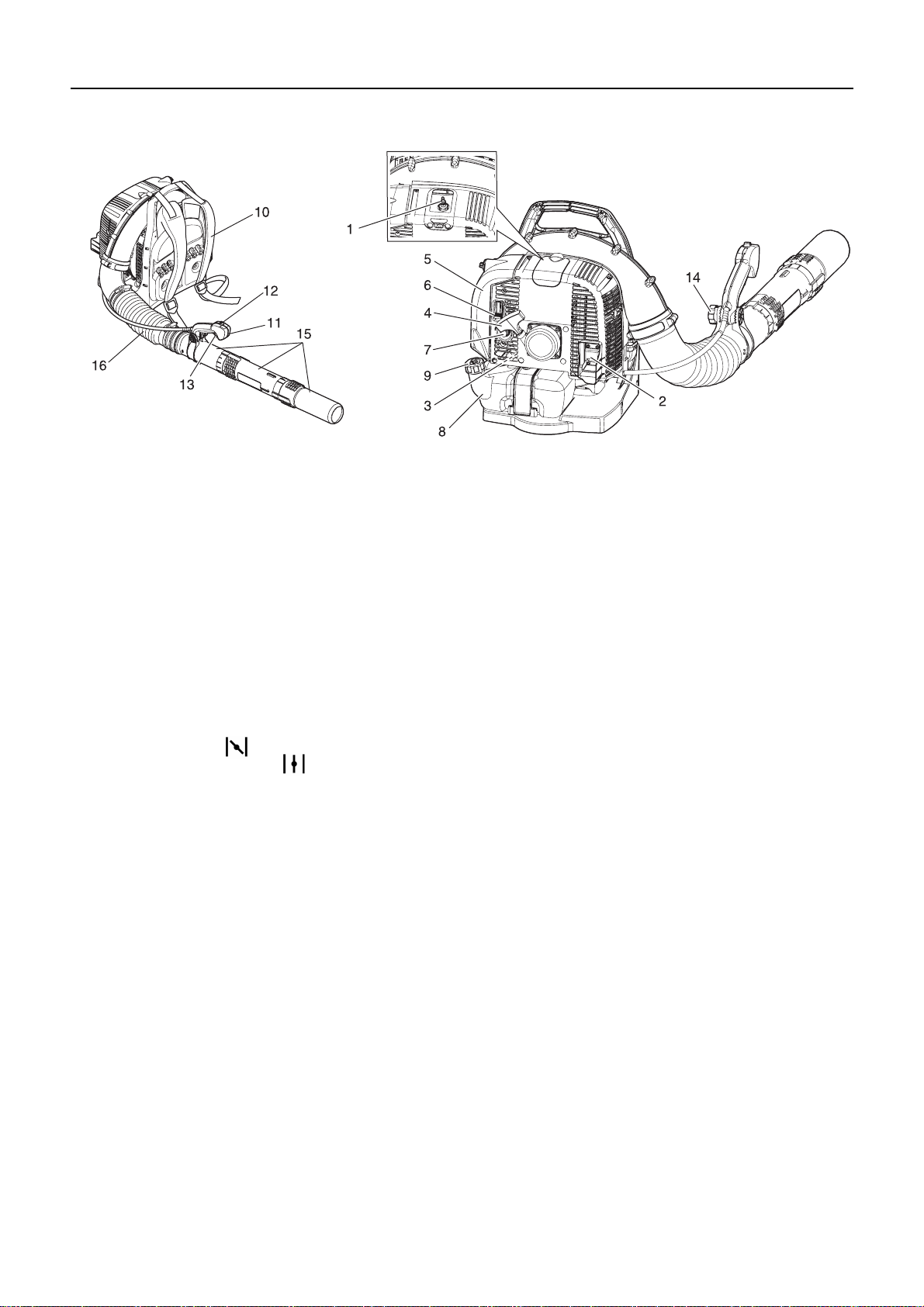

Description

Description

1. Spark plug Provides spark to ignite fuel mixture.

2. Spark arrester - Catalytic silencer / Silencer The si-

lencer or catalytic silencer controls exhaust noise and

emission. The spark arrester screen prevents hot, glowing particles of carbon from leaving the silencer. Keep

exhaust area clear of flammable debris.

3. Serial number label Lists model number and serial

number of unit.

4. Starter handle Pull recoil handle slowly until recoil starter

engages, then quickly and firmly. When engine starts,

return handle slowly. DO NOT let handle snap back or

damage to unit will occur.

5. Air cleaner Contains replaceable air filter element.

6. Choke Choke is located on the side of the air cleaner.

Move choke lever to position to close choke for cold

starting. Move choke lever to position to open

choke.

7. Purge bulb Pumping purge bulb before starting engine

draws fresh fuel from the fuel tank, purging air from the

carburettor. Pump purge bulb until fuel is visible. Pump

purge bulb an additional 4 or 5 times.

8. Fuel tank Contains fuel and fuel filter.

9. Fuel tank cap Covers and seals fuel tank.

10. Shoulder harness Used to support unit on operator's

back. The straps are adjustable.

11. Handle Used by operator to direct and control air flow.

12. Combination Throttle Position / Stop Switch Button

Controls engine speed and turns ignition on or off. Forward position - STOP. First detent position - IDLE. Move

button back to increase speed, forward to decrease

speed. Use throttle position button to set and hold blower speed for continuous operation.

13. Throttle trigger Spring-loaded throttle trigger controls

engine speed. Releasing trigger returns engine to

speed set by Throttle Position / Stop Switch Button. Always release trigger and allow engine to return to idle

before shutting off with Throttle Position / Stop Switch

Button. Use throttle trigger to vary blower speed settings

for intermittent operation.

14. Locking knob Allows operator to adjust handle position

for optimum comfort and control.

15. Blower pipes Exclusive positive locking system.

16. Flexible pipe Allows for full range of movement.

13

Page 16

Before you start

Before you start

Assembly

WARNING

Read the operator's manual carefully to ensure that you assemble the product correctly.

Never perform maintenance or assembly procedures with engine running.

Using a product that has been incorrectly assembled could lead to an accident or serious injury.

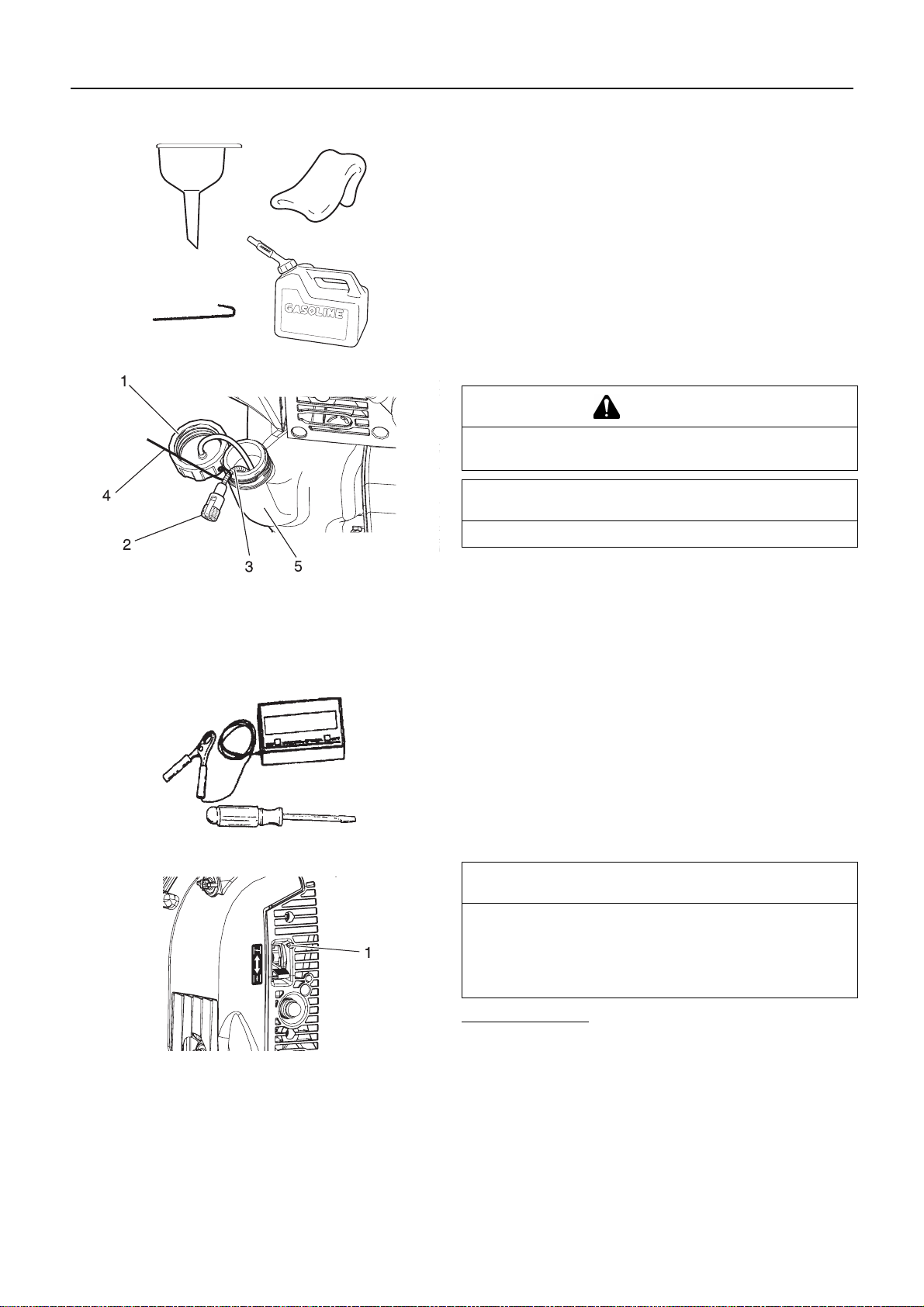

Install blower pipes

1. Place guide loop across elbow clamp, and turn until clip fully

engages clamp band.

2. Assemble clamps onto both ends of flexible pipe.

NOTE

Clamp with cable guide loop fits elbow end of flexible pipe.

1. Guide loop

3. Flexible pipe

1. Handle

3. Swivel pipe

5. Anti-static wire

1. Throttle cable

3. Knob

2. Two clamps

4. Swivel pipe

2. Knob

4. Clamp

6. Elbow

2. Guide loop

3. Assemble swivel pipe into flexible pipe and tighten clamp.

4. Loosen knob on handle. AIign notch in handle with tabs. Install onto swivel pipe past long ridges in pipe.

5. Insert anti-static wire through flexible pipe.

6. Assemble flexible pipe to elbow on blower. Position guide

loop on outside of flexible pipe (away from blower) and tighten clamp.

NOTE

A light lubricant may be used to ease assembly of flexible pipe

to blower elbow.

NOTE

Hang handle freely from blower to assure throttle cable is not

twisted before installing handle.

7. Clip throttle cable into throttle cable guide loop.

8. Position handle for comfortable operation, and tighten knob

hand tight.

9. Assemble straight pipe onto swivel pipe, until you feel light

resistance. Do not force connection. Hold swivel pipe and

turn straight pipe clockwise, engaging positive locking channels,until connection is firm. Do not force connection.

10. Assemble straight pipe with decal to straight pipe as in step

9.

1. Swivel pipe

3. Straight pipe

NOTE

Blower use will eventually loosen pipe connections. Exclusive

positive locking system allows pipes to be tightened. If loosening occurs, remove two straight pipes and install according to

instructions 9 & 10.

2. Straight pipe

14

Page 17

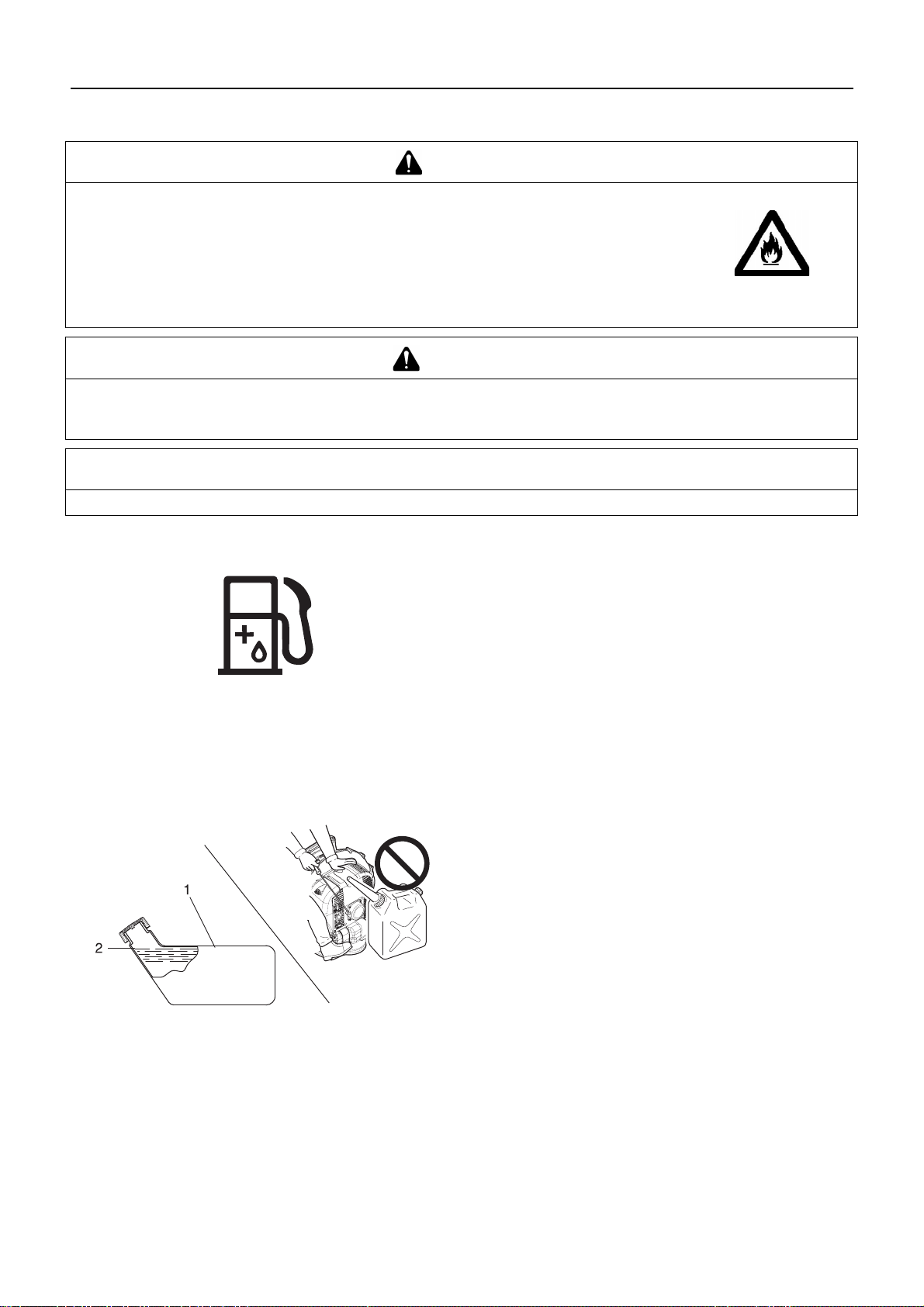

Before you start

Preparing the fuel

DANGER

Fuel is highly inflammable and there is a risk of fire if it is handled incorrectly. Carefully read

and observe the precautions in the section of this manual titled "For safe use of your product".

Once the refuelling is complete, securely tighten the fuel tank cap and do not forget to

check that there are no leaks or discharges of fuel from the fuel pipe, fuel system grommets,

or around the fuel tank cap. If you do find fuel leaks or discharges, stop using the product

immediately and contact your ECHO DEALER to have it repaired.

If the fuel ignites, it could cause burns and fire.

CAUTION

There is difference in pressure between the fuel tank and the outside air. When refuelling, loosen the fuel tank cap

slightly to eliminate the difference in pressure.

Otherwise, fuel may get spewed.

NOTE

Stored fuel ages. Do not mix more fuel than you expect use in thirty (30) days. Do not mix directly in fuel tank.

Fuel

Fuel supply

1. Fuel tank 2. Shoulder level

Fuel is a mixture of regular grade petrol and an air-cooled 2-

stroke engine oil of reputable brand name.

Minimum 89 Octane unleaded petrol is recommended. Do not

use fuel containing methyl alcohol or more than 10 % of ethyl

alcohol.

Recommended mixture ratio; 50 : 1 (2 %) for ISO-L-EGD

Standard (ISO/CD 13738), JASO FC,FD grade and ECHO

Premium 50 : 1 oil.

- Do not mix directly in engine fuel tank.

- Avoid spilling petrol or oil. Spilled fuel should always be

wiped up.

- Handle petrol with care, it is highly inflammable.

- Always store fuel in approved container.

Always refuel in a well ventilated location. Do not pour fuel in-

doors.

Place the product and the refuelling tank on the ground when

performing the refuelling operation. Do not refuel the product

on the loading platform of a truck, or in other such places.

Always ensure that the fuel level remains below the shoulder

level of the fuel tank when refuelling.

There is a difference in pressure between the fuel tank and the

outside air. When refuelling, loosen the fuel tank cap slightly to

eliminate the difference in pressure.

Always wipe up any fuel spills.

Move at least 3m away from where you refueled before you

start the engine.

Keep the refuelling tank in a shaded area away from fire.

15

Page 18

Engine operation

Engine operation

Starting the engine

WARNING

When starting the engine, observe the precautions described from Page 4 in the section "For safe use of your product" to ensure that you operate the product correctly.

Failure to observe the precautions could cause an accident or injury, or even lead to a fatality.

NOTE

Pull out the starter grip gently at first, and then more rapidly. Do not pull the starter rope out to more than 2/3 of its length.

Do not let go of the starter grip as it returns.

To start the engine, return the choke knob when you hear the first explosion-like sound and pull on the starter grip again. Be

careful not to miss the first explosion-like sound.

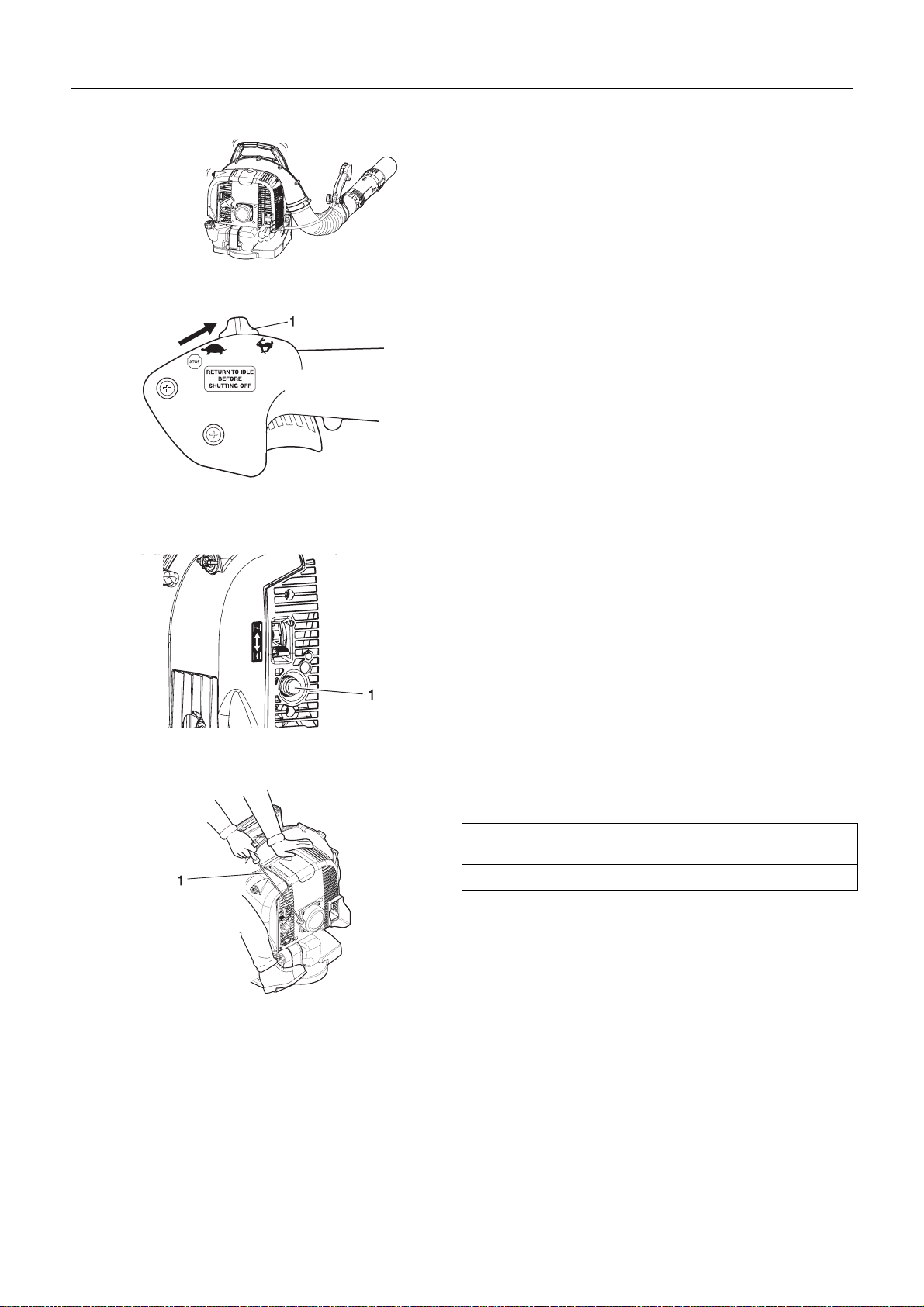

Starting a cold engine

Recoil starter: Use short pulls - only 1/2-2/3 of rope length for

starting. Do not allow the rope to snap back in. Always hold

the unit firmly.

1. Throttle Position / Stop

Switch Button

1. Choke 2. Purge bulb

1. Throttle Position / Stop Switch Button

Slide Throttle Position / Stop Switch Button back to idle position (first detent away from stop position).

2. Choke

Move choke lever to position.

3. Purge Bulb

Pump purge bulb until fuel is visible.

4. Recoil Starter

Pull recoil starter handle until engine fires, or maximum 5

pulls.

5. Choke

Move choke lever to position and if necessary, restart engine.

1. Recoil starter handle

NOTE

If engine does not start after 5 pulls, repeat instructions 2-5.

NOTE

Allow engine to warm up before use.

16

Page 19

Engine warm-up

Starting a warm engine

1. Throttle Position / Stop

Switch Button

Engine operation

1. Once the engine starts, allow it to warm up for 2 to 3 minutes

at idling (i.e. low speed).

2. Warming the engine helps to lubricate its internal workings

more smoothly. Allow the engine to warm up fully, especially

when it is cold.

3. Never run the engine without the blower pipes fitted.

The starting procedure is the same as Cold Start except DO

NOT close the choke.

1. Throttle Position / Stop Switch Button

Slide Throttle Position / Stop Switch Button back to idle position (first detent away from stop position).

1. Purge bulb

2. Purge Bulb

Pump purge bulb until fuel is visible.

3. Recoil Starter

Pull recoil starter handle and engine should start.

NOTE

If engine does not start after 5 pulls, use cold start procedures.

1. Recoil starter handle

17

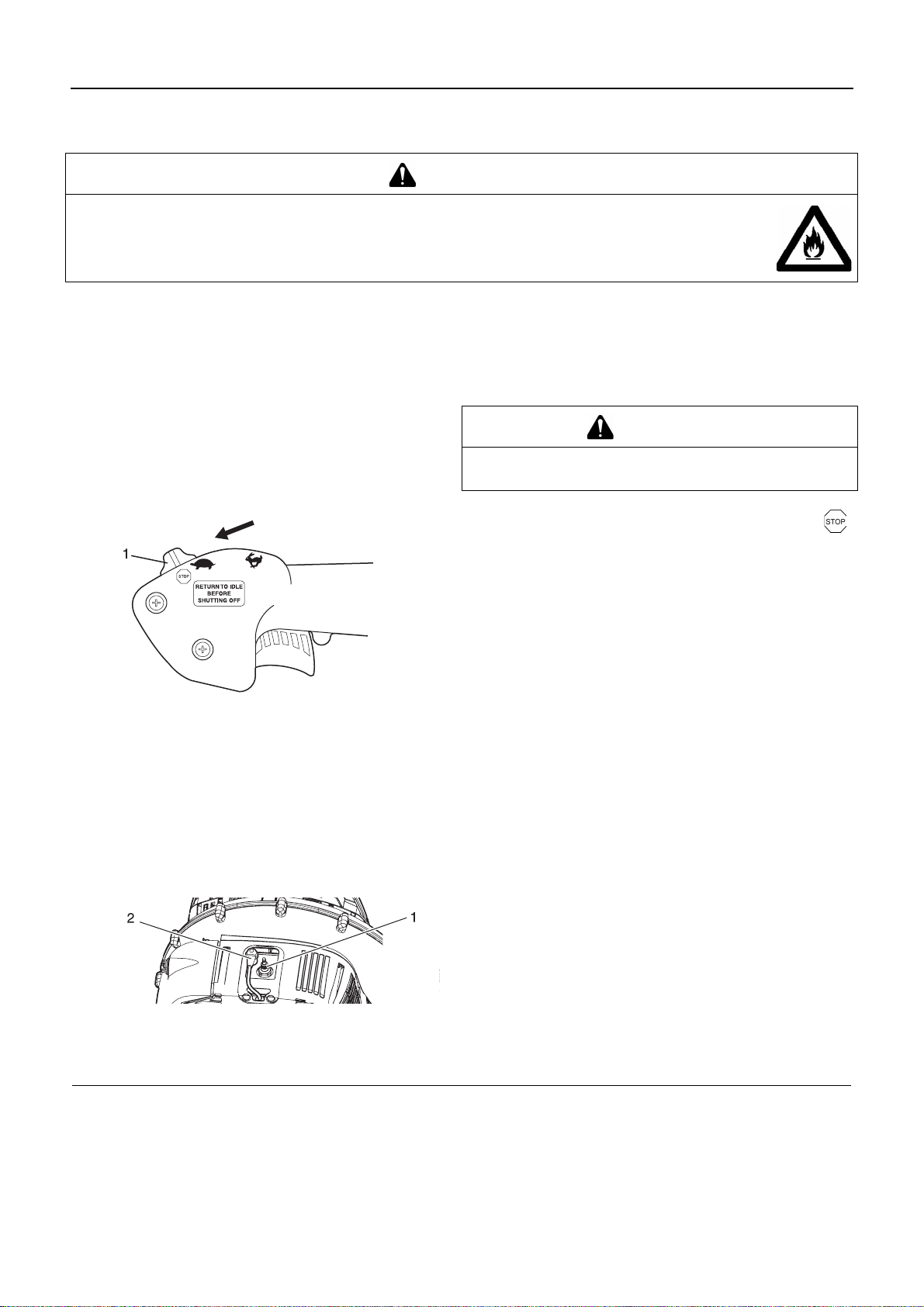

Page 20

Engine operation

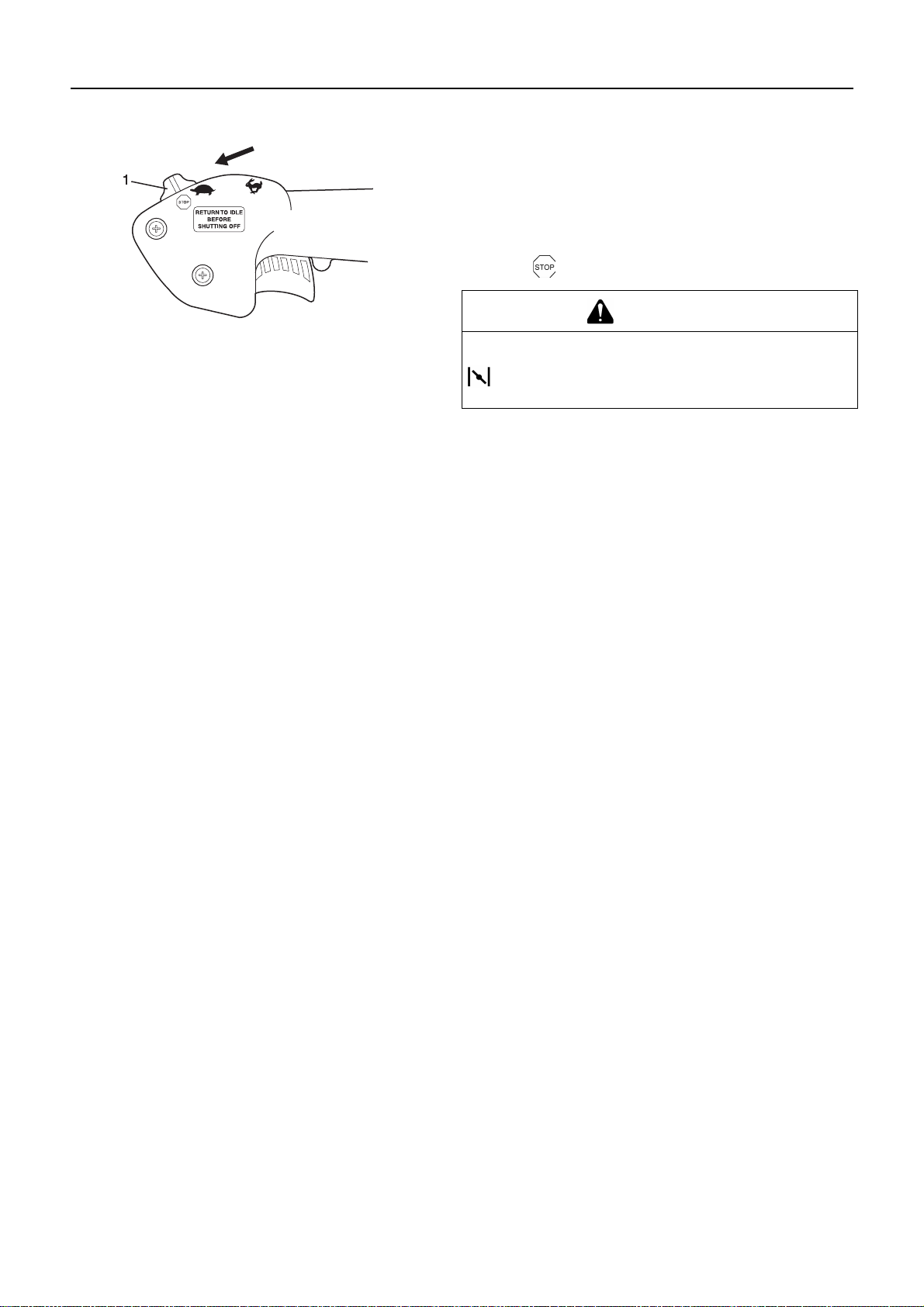

Stopping the engine

1. Throttle Position / Stop

Switch Button

1. Throttle Position / Stop Switch Button

Release throttle trigger. Move Throttle Position / Stop Switch

Button forward to idle position (first detent away from stop position) and allow engine to return to idle before shutting off engine.

2. Throttle Position / Stop Switch Button

Move Throttle Position / Stop Switch Button all the way forward to (Stop) position.

WARNING

If engine does not stop when Throttle Position / Stop

Switch Button is moved to STOP position, close choke -

position- to stall engine. Have your ECHO dealer repair

stop switch before using blower again.

18

Page 21

Operation

Operation

Operating blower

WARNING

Always wear safety glasses, hearing protection, face filter mask and take all safety precautions or serious personal injury may result. Do not point the blower pipe in the direction of people or pets.

IMPORTANT

To avoid engine damage due to over revving, do not block blower pipe opening.

NOTE

Never use a higher speed setting than necessary to perform a task. Remember, the higher the engine speed, the louder the

blower noise. Minimize dust by using blower at lower speeds and by dampening material with water/mist when necessary. Keep

debris on your property. Be Smart - be a good neighbor.

Read the Safety Section carefully.

1. Use only during appropriate hours.

2. Allow the engine to warm up at a fast idle for a few minutes.

3. Control engine speed with throttle trigger, or for continuous

use, set engine speed with Throttle Position / Stop Switch

Button.

4. Use lower speed to blow dry grass and leaves from walks,

patios and drives.

5. Additional speed may be necessary to clean leaves from a

lawn or flowerbed.

1. Throttle Position / Stop

Switch Button

2. Throttle trigger

6. Higher speed may be necessary to move gravel, dirt, snow,

bottles or cans from a driveway, street, parking lot or stadium.

7. Always stop unit using stop engine procedure.

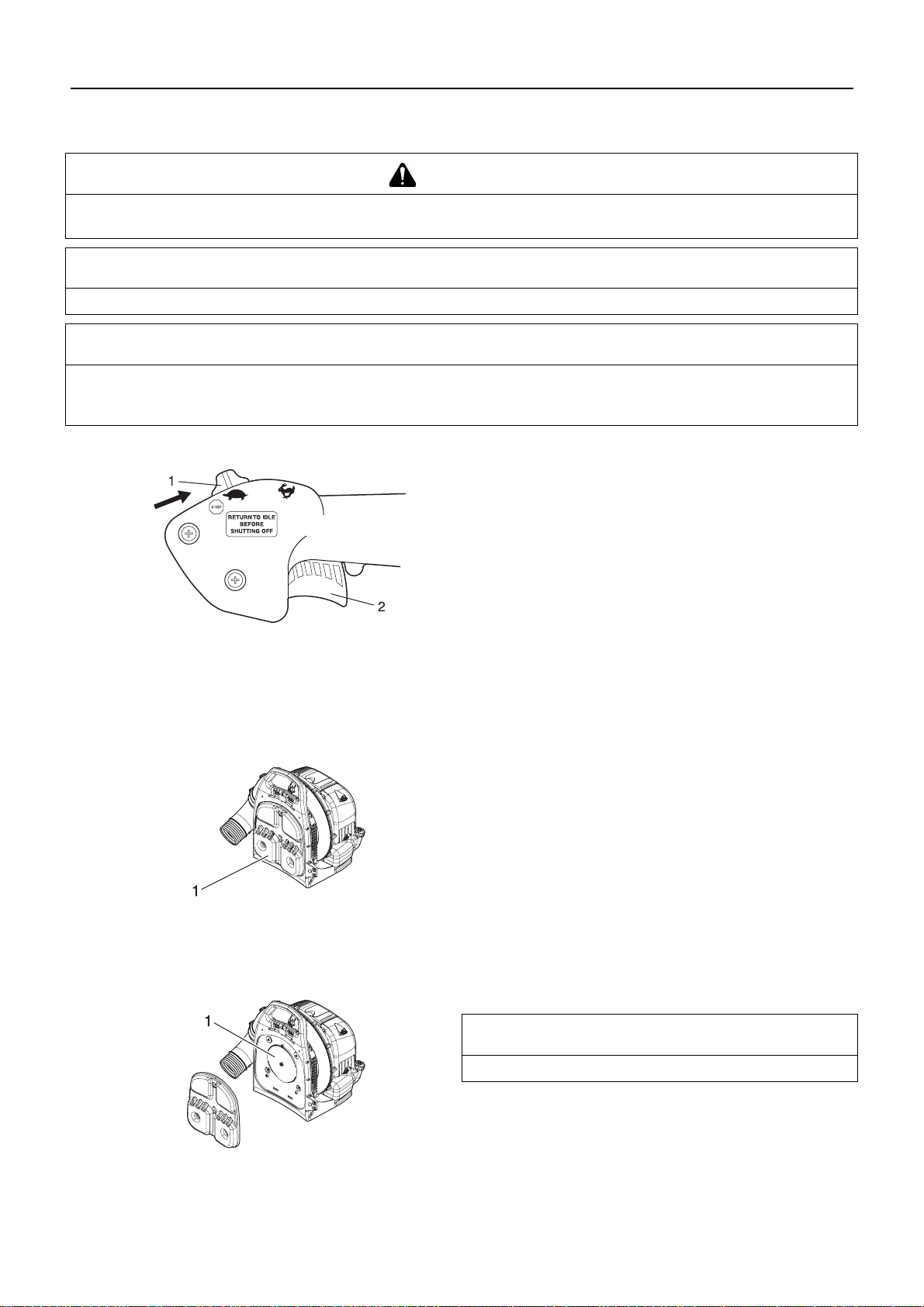

Cold weather operation

1. Back cushion

1. Intake cover

Install intake cover when you feel cold on your back.

1. Remove back cushion from frame.

2. Install intake cover on frame over air intake.

3. Install back cushion to frame over intake cover.

NOTE

Blower performance may be reduced slightly.

19

Page 22

Maintenance and care

Maintenance and care

Servicing guidelines

Area Maintenance Page Before use Monthly

Air filter Inspect/Clean/Replace 20 •

Fuel filter Inspect/Replace 21 •

Spark plug Inspect/Clean/Adjust/Replace 23 •

Carburettor Inspect 21 •

Cooling system Inspect/Clean 22 •

Exhaust system Inspect/Tighten/Clean 22 •

Starter Inspect - •

Fuel system Inspect - •

Screws, bolts and nuts Inspect/Tighten/Replace - •

IMPORTANT

Time intervals are maximum. Actual use and your experience will determine the frequency of required maintenance.

Maintenance and care

If you have any questions or problems, please contact your ECHO DEALER.

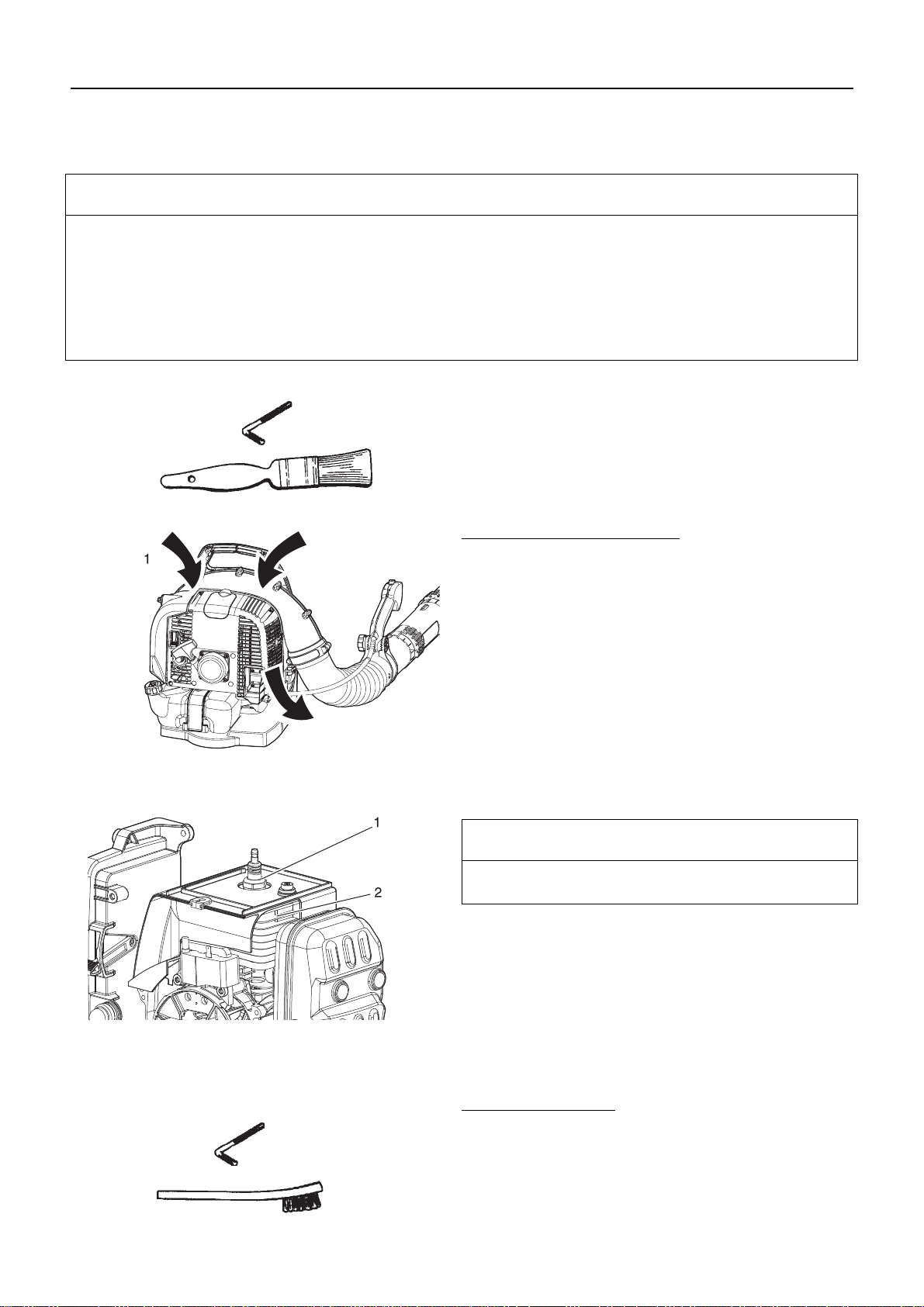

Cleaning air filter

Tools required: 25-50 mm (1-2 in.) Cleaning brush

Parts required: Air filter

1. Move choke lever to position. This prevents dirt from entering the carburettor throat when the air filter is removed.

Brush accumulated dirt from air cleaner area.

2. Remove air filter cover. Brush dirt from inside cover.

3. Remove air filter and element plate, and then lightly brush

debris from them. Replace filter if it is damaged, fuel soaked,

very dirty, or the rubber sealing edges are deformed.

4. If filter can be reused, be certain it:

Fits tightly in the air filter cavity.

Is installed with the original side out.

5. Install air filter cover.

1. Air filter cover

3. Element plate

2. Air filter

20

Page 23

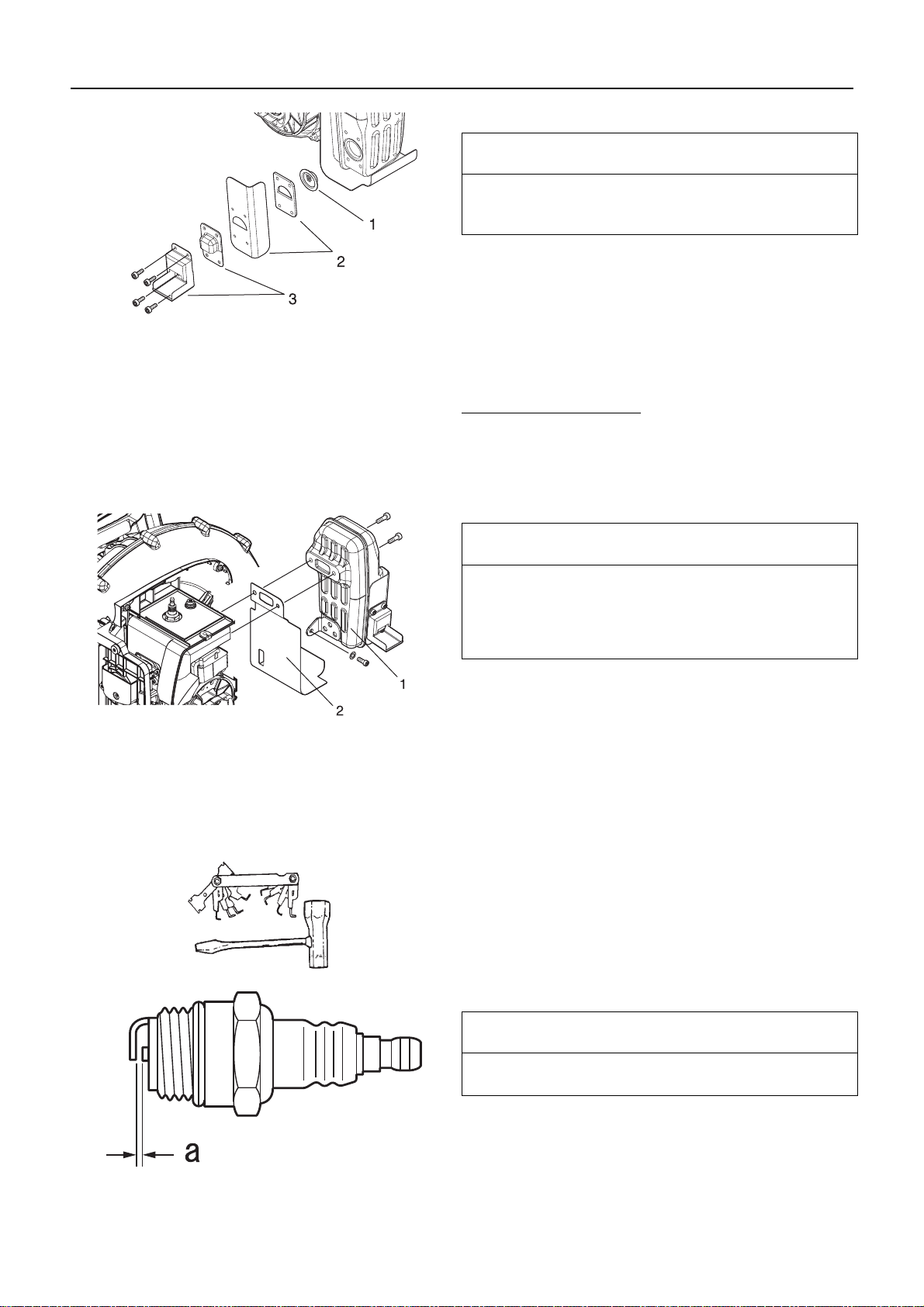

Replacing fuel filter

Maintenance and care

Tools required: 200-250 mm (8-10 in.) length of wire with

one end bent into a hook, clean rag, funnel,

and an approved fuel container

Parts required: Fuel line and filter

DANGER

Fuel is VERY flammable. Use extreme care when mixing,

storing or handling.

NOTE

If filter is excessive dirty or no longer fits properly, replace it.

1. Fuel cap

3. Fuel line

5. Fuel tank

Carburettor adjustment

2. Fuel filter

4. Fuel line hook

1. Use a clean rag to remove loose dirt from around fuel cap

and empty fuel tank.

2. Use the "fuel line hook" to pull the fuel line and filter from the

tank.

3. Remove the filter from the line and install the new filter.

Tools required: Screwdriver, tachometer (Echo P/N

99051130017)

Parts required: None

NOTE

Every unit is run at the factory and the carburettor is set in compliance with Emission Regulations. This carburettor does not

have acceleration and high speed adjustment needles. Do not

attempt to use carburettor adjustment procedures provided in

the Warranty Emissions Booklet.

1. Screw

Before Adjustment

Check that:

Air filter is clean and properly installed.

Spark arrester screen and silencer are free of carbon.

Blower pipes are installed.

1. Start engine, run at idle for one minute.

2. Complete warm up by running at full throttle for 5 minutes,

operating choke twice to clear air from carburettor chambers.

3. Check idle speed and reset if necessary. If a tachometer is

available, idle speed screw should be set to the specifications found on Page 26"Specifications" of this manual. Turn

idle screw clockwise to increase idle speed; anticlockwise to

21

Page 24

Maintenance and care

decrease idle speed.

Cooling system maintenance

IMPORTANT

To maintain proper engine operating temperature, cooling air must pass freely through the cylinder fin area. This flow of air carries combustion heat away from the engine.

Overheating and engine seizure can occur when:

Air intakes are blocked, preventing cooling air from reaching the cylinder,

or

Dust and grass build up on the out side of the cylinder. This build-up insulates the engine and prevents the heat from leaving.

Removal of cooling passage blockages or cleaning of cylinder fins is considered "Normal Maintenance". Any resultant failure

attributed to lack of maintenance is not warranted.

Tools required: Torx L-Wrench T27, Cleaning brush

Parts required: None, if you are careful.

1. Air intake

Cleaning Grill and Cylinder Fins

1. Remove accumulated debris from intake grill between backpack frame and blower housing.

2. Disconnect spark plug lead from spark plug.

3. Remove air filter cover.

4. Remove engine cover (10 screws).

5. Clean cylinder fins to allow cooling air to pass freely.

6. Reassemble parts in reverse order.

IMPORTANT

Do not over-tighten screws, otherwise mounting holes may become stripped.

1. Spark plug 2. Cylinder fins

Exhaust system

Spark Arrester Screen

Tools required: Torx L-Wrench T27, Soft metal brush

Parts required: Spark arrester screen, Gasket

22

Page 25

1. Spark arrester screen

3. Spark arrester cover

2. Gasket

Maintenance and care

IMPORTANT

Carbon deposits in silencer will cause a drop in engine output

and overheating. Spark arrester screen must be checked periodically.

1. Disconnect spark plug lead from spark plug.

2. Remove spark arrester cover, gasket, and spark arrester

screen from silencer. Replace screen if plugged with carbon

deposits.

3. Install spark arrester screen, gaskets, and cover.

4. Connect spark plug lead.

Silencer and Exhaust Port

Tools required: Torx L-Wrench T27, Wooden or plastic scraper

Parts required: Gasket

1. Silencer 2. Gasket

Check spark plug

IMPORTANT

Carbon deposits in cylinder exhaust port and silencer will

cause a drop in engine output and overheating. Silencer exhaust port must be checked periodically. Be careful not to

scratch the cylinder or piston when cleaning the cylinder exhaust port.

1. Disconnect spark plug lead from spark plug.

2. Remove engine cover (10 screws).

3. Remove silencer and gasket.

4. Clean cylinder exhaust port being careful not to scratch cylinder or piston, using a wooden or plastic scraper.

5. Install gasket and silencer.

6. Install engine cover.

Tools required: T-Wrench, Feeler gauge

Parts required: Spark plug

a: 0.6 - 0.7 mm

IMPORTANT

Use only NGK BPMR8Y spark plug otherwise severe engine

damage may occur.

1. Check plug gap. Correct gap is 0.6 mm to 0.7 mm.

2. Inspect electrode for wear.

3. Inspect insulator for oil or other deposits.

4. Replace plug if needed and tighten to 15 N·m - 17 N·m (150

kgf·cm to 170 kgf·cm).

23

Page 26

Maintenance and care

Troubleshooting table

Problem Diagnosis Cause Solution

Engine is difficult to start,

fluctuating rotation

No fuel is entering the overflow pipe

Fuel filter is clogged

Fuel system is clogged

Internal carburettor parts sticking

Clean or replace

Clean

Consult your ECHO

DEALER

or

The engine

does not start

Engine starts

but no acceleration is possible

Checking and maintenance requires specialist knowledge. If you are unable to check and maintain the product or deal with a

fault yourself, consult your ECHO DEALER. Do not attempt to dismantle the product.

Consult your ECHO DEALER in the event of a problem that is not covered in the table above, or other such concerns.

For spare parts and consumables, please use only genuine parts and designated products and components. Using parts from

other manufacturers or non-designated components may result in a malfunction.

Fuel is entering the overflow pipe

The crankshaft does not rotate

The spark plug is dirty or

damp

Fuel degradation

Carburettor problem

Internal engine malfunction Consult your ECHO

Fuel degradation

Incorrect electrode gap

Carbon deposits

Electrical fault

Dirty air filter

Dirty fuel filter

Blocked fuel passage

Carburettor adjustment problem

Spark plug problem

Blocked exhaust vent or silencer vent

Spark arrester screen plugged or normal

wear

Replace with new fuel

Consult your ECHO

DEALER

DEALER

Replace with new fuel

Adjust or Replace

Clean or Replace

Consult your ECHO

DEALER

Clean or replace

Clean or replace

Consult your ECHO

DEALER

Consult your ECHO

DEALER

Clean, Adjust or Replace

Clean

Clean or replace

24

Page 27

Maintenance and care

Long-term storage(30 days or more)

WARNING

During operation the silencer - catalytic silencer and surrounding cover become hot. Always keep exhaust

area clear of flammable debris during transportation or when storing, otherwise serious property damage

or personal injury may result.

Do not store your unit for a prolonged period of time (30 days or longer) without performing protective storage maintenance which

includes the following:

1. Store unit in a dry, dust free place, out of the reach of children.

WARNING

Do not store where fuel fumes may accumulate or reach an

open flame or spark.

1. Throttle Position / Stop

Switch Button

2. Place the Throttle Position / Stop Switch Button in the

(Stop) position.

3. Remove accumulation of grease, oil, dirt and debris from exterior of unit.

4. Perform all periodic lubrication and services that are required.

5. Tighten all screws and nuts.

6. Drain the fuel tank completely and pull the recoil starter handle several times to remove fuel from the carburettor.

7. Remove the spark plug and pour 10mL of fresh, clean ECHO

2-stroke engine oil into the cylinder through the spark plug

hole.

A. Place a clean cloth over the spark plug hole.

B. Pull the recoil starter handle 2-3 times to distribute the

oil inside the engine.

C. Observe the piston location through the spark plug hole.

Pull the recoil handle slowly until the piston reaches the

top of its travel and leave it there.

8. Fit the spark plug. (Do not connect the spark plug cap. )

9. Remove blower pipe assembly from unit.

1. Spark plug 2. Spark plug cap

Please contact your ECHO DEALER in order to dispose of the product or its parts in compliance with national laws.

25

Page 28

Specifications

Specifications

Mass: kg 9.8

External dimensions:

Length

Width

Height

Engine:

Type

Engine displacement

Maximum power

Engine speed at maximum engine power

Recommended maximum engine speed

Recommended engine idling speed

Carburettor

Ignition

Spark plug

Starter

Air Volume with straight pipe: m

mm

mm

mm

mL (cm

kW

r/min

r/min

r/min

3

/min 21.7

375

490

475

Air cooled 2-stroke single cylinder

3

)

63.3

2.85

6900

6900

2500

Diaphragm type

Flywheel magneto - CDI system

NGK BPMR8Y

Automatic recoil system

PB-770

Fuel:

Oil

Ratio 50 : 1 (2%)

Tank Capacity: L2.02

Sound pressure level: (ISO 22868) LpAeq = dB(A) 97.7

Guaranteed sound power level:

(2000/14/EC) L

Vibration levels: (ISO 22867) m/s

These specifications are subject to change without notice.

= dB(A) 112

WA

Regular grade petrol. Minimum 89 Octane unleaded

petrol is recommended. Do not use fuel containing

methyl alcohol or more than 10 % of ethyl alcohol.

Two stroke, air-cooled engine oil. ISO-L-EGD Standard (ISO/CD 13738), JASO FC,FD grade and ECHO

Premium 50 : 1 oil.

2

2.1

26

Page 29

The undersigned manufacturer:

YAMABIKO CORPORATION

7-2 SUEHIROCHO 1-CHOME

OHME; TOKYO 198-8760

JAPAN

declares that the hereunder specified new unit:

POWER BLOWER

Brand: ECHO

Type: PB-770

assembled by:

ECHO, INCORPORATED

400 Oakwood Road

Lake Zurich, Illinois 60047-1564

Declaration of conformity

Declaration of conformity

U.S.A.

complies with:

* the requirements of Directive 98/37/EC (1998) (and 2006/42/EC: from 29

* the requirements of Directive 2004/108/EC

(use of harmonized standard EN ISO 14982)

* the requirements of Directive 2002/88/EC

* the requirements of Directive 2000/14/EC

Conformity assessment procedure followed ANNEX V

Measured sound power level : 109dB(A)

Guaranteed sound power level : 112dB(A)

PB-770 Serial Number 37002001 and up

Tokyo,

October 1st 2009

YAMABIKO CORPORATION

The authorized representative in Europe

who is authorized to compile the technical file.

Company: Atlantic Bridge Limited

Address: Atlantic House, PO Box 4800,

Earley, Reading RG5 4GB, United Kingdom

th

December 2009)

K. OYURI General Manager Mr. Philip Wicks

27

Page 30

1Notes and rear cover

7-2 SUEHIROCHO 1-CHOME, OHME, TOKYO 198-8760, JAPAN

PHONE: 81-428-32-6118. FAX: 81-428-32-6145.

©

2009

X753-003 91 0

X753 112-420 0

Printed in Japan

0x0xxxx zzzz ES

28

Page 31

1Couvercle supérieur

FRANÇAIS

(Notice originale)

MANUEL D'UTILISATION

PB-770

AVERTISSEMENT

LIRE ATTENTIVEMENT LES INSTRUCTIONS ET SUIVRE LES REGLES DE SECURITE. LE NON-RESPECT DES REGLES DE SECURITE ENTRAINE UN RISQUE DE BLESSURE GRAVE.

Page 32

Information importante

2Information importante

Lire attentivement le manuel d'utilisation avant d'utiliser l'appareil pour la première fois.

Utilisation de l'appareil

Les souffleurs ECHO sont conçus pour éliminer les poussières et autres déchets, y compris les feuilles mortes.

Ne pas utiliser cet appareil pour d'autres applications que celles mentionnées ci-dessus.

Utilisateurs de l'appareil

Lire attentivement ce manuel d'utilisation et intégrer les informations qu'il contient avant d'utiliser l'appareil pour la pre-

mière fois.

Toute personne n'ayant pas lu attentivement ce manuel d'utilisation, enrhumée, fatiguée ou en mauvaise condition

physique ne doit pas utiliser cet appareil. Ne pas laisser un enfant manipuler l'appareil.

L'utilisateur est tenu pour responsable en cas d'accidents ou de risques pouvant entraîner des blessures corporelles

ou des dommages matériels.

A propos du manuel d'utilisation

Ce manuel contient les informations nécessaires au montage, à l'utilisation et à l'entretien de l'appareil. L'utilisateur

doit donc le lire attentivement et intégrer les informations qu'il contient.

Toujours conserver le manuel à portée de main.

En cas de perte du manuel ou si ce dernier a été détérioré et n'est plus lisible, s'adresser au REVENDEUR ECHO pour

en obtenir un nouveau.

Les unités utilisées dans ce manuel sont les unités SI (Système international d'unités). Les chiffres indiqués entre pa-

renthèses sont des valeurs de référence. De légères erreurs de conversion peuvent survenir dans certains cas.

Prêt ou cession de l'appareil à un tiers

Si l'appareil décrit dans ce manuel est prêté à un tiers, veiller à lui confier également le manuel d'utilisation fourni avec

l'appareil. Si l'appareil est cédé à un tiers, transmettre le manuel d'utilisation fourni avec l'appareil lors de la vente.

Renseignements

Contacter un REVENDEUR ECHO pour toute demande d'information concernant l'appareil, l'achat de consommables,

les réparations ou pour tout autre renseignement.

Remarques

ECHO se réserve le droit de modifier sans préavis le contenu de ce manuel en fonction des améliorations apportées

au produit. Il se peut que certains des schémas de ce manuel soient différents de l'appareil. Ces différences ont pour

objectif de rendre les explications plus claires.

L'appareil nécessite le montage de certains éléments.

En cas de doute, consulter un REVENDEUR ECHO.

Fabricant

YAMABIKO CORPORATION

7-2 SUEHIROCHO 1-CHOME, OHME, TOKYO 198-8760, JAPON

Représentant autorisé en Europe

Atlantic Bridge Limited

Atlantic House, PO Box 4800, Earley, Reading RG5 4GB, Royaume-Uni

2

Page 33

Table des matieres

Pour utiliser l'appareil en toute sécurité .............................................................................. 4

Etiquettes et symboles d'avertissement ........................................................................ 4

Autres indications .......................................................................................................... 4

Symboles....................................................................................................................... 4

Emplacement de l'étiquette de sécurité......................................................................... 6

Manipulation du carburant ............................................................................................. 7

Manipulation du moteur ................................................................................................. 8

Manipulation de l'appareil .............................................................................................. 9

Contenu de l'emballage .................................................................................................... 13

Description........................................................................................................................14

Avant de commencer........................................................................................................ 15

Assemblage ................................................................................................................. 15

Préparation du carburant ............................................................................................. 16

Fonctionnement du moteur ............................................................................................... 18

Démarrage du moteur.................................................................................................. 18

Arrêt du moteur............................................................................................................ 20

Fonctionnement ................................................................................................................ 21

Fonctionnement du souffleur ....................................................................................... 21

Entretien ........................................................................................................................... 23

Instructions d'entretien de l'appareil ............................................................................ 23

Entretien ...................................................................................................................... 23

Guide de dépannage ................................................................................................... 28

Remisage de longue durée (30 jours ou plus)............................................................. 29

Caractéristiques................................................................................................................30

Déclaration de conformité ................................................................................................. 31

3

Page 34

Pour utiliser l'appareil en toute sécurité

Lire attentivement cette section avant d'utiliser l'appareil pour la première fois.

Pour utiliser l'appareil e n toute sécuri té

Les mesures de précaution décrites dans cette section contiennent des informations essentielles pour la sécurité. Les

suivre scrupuleusement.

Il est également nécessaire de prendre connaissance des mesures de précaution exposées tout au long de ce manuel.

Le texte précédé d'une puce [en forme de losange] décrit les risques encourus en cas de non-respect d'une mesure de précaution.

Etiquettes et symboles d'avertissement

Les étiquettes et les symboles d'avertissement dans le manuel et sur l'appareil signalent les situations pouvant entraîner un risque

de blessure de l'utilisateur et d'autres personnes. Pour des raisons de sécurité, toujours lire et suivre attentivement les instructions

figurant sur ces étiquettes.

DANGER AVERTISSEMENT ATTENTION

Ce symbole associé au mot

« DANGER » signale une action ou

une situation présentant un risque de

blessure corporelle grave ou d'accident mortel pour l'utilisateur et les

personnes à proximité.

Ce symbole associé au mot

« AVERTISSEMENT » signale une

action ou une situation présentant un

risque de blessure corporelle grave

ou d'accident mortel pour l'utilisateur

et les personnes à proximité.

Autres indications

Outre les étiquettes et les symboles d'avertissement, ce manuel contient les symboles d'explication suivants :

« ATTENTION » signale une situation potentiellement dangereuse qui,

si elle n'est pas évitée, peut entraîner

une blessure légère à modérée.

REMARQUE IMPORTANT

Le cercle barré indique

une interdiction.

Ce type de message fournit des

conseils relatifs à l'utilisation et à l'entretien de l'appareil.

Le texte dans l'encadré où figure le

mot « IMPORTANT » donne des informations importantes concernant

l'utilisation, la vérification, l'entretien

et le remisage de l'appareil décrit

dans ce manuel.

Symboles

De nombreux symboles d'explication sont utilisés dans ce manuel et sur l'appareil lui-même. S'assurer d'avoir bien compris la signification de chacun de ces symboles.

Forme des symboles Description / application des

symboles

Lire attentivement le manuel

d'utilisation

Port obligatoire de protections

pour les yeux, les oreilles et la

tête

Alerte / sécurité

Arrêt d'urgence

Forme des symboles Description / application des

symboles

Mélange d'essence et d'huile

Pompe d'amorçage (charge

d'amorçage)

Réglage du carburateur - Mélange bas régime

Réglage du carburateur - Mélange haut régime

4

Page 35

Pour utiliser l'appareil en toute sécurité

Forme des symboles Description / application des

symboles

Risque de sectionnement des

doigts

Ne pas utiliser l'appareil dans

des endroits mal aérés

Attention aux risques d'incendie

Attention aux risques de choc

électrique

Niveau de puissance sonore

garanti

Forme des symboles Description / application des

symboles

Réglage du carburateur - Régime de ralenti

Commande de starter en position « Démarrage à froid »

(starter fermé)

Commande de starter en position « Marche » (starter

ouvert)

Régime de ralenti

Régime maximal

Interrupteur ON / OFF

(marche / arrêt)

Démarrage du moteur

Attention aux températures

élevées

5

Page 36

Pour utiliser l'appareil en toute sécurité

Emplacement de l'étiquette de sécurité

L'étiquette de sécurité ci-dessous figure sur l'appareil décrit dans ce manuel. S'assurer de bien comprendre la signification de

l'étiquette avant d'utiliser l'appareil.

Si l'étiquette devient illisible avec le temps ou si elle s'est décollée ou a été déchirée, contacter un REVENDEUR ECHO pour

obtenir une nouvelle étiquette et la coller à l'emplacement indiqué sur les illustrations ci-dessous. Veiller à ce que l'étiquette soit

toujours lisible.

1. Etiquette de sécurité (Numéro de pièce X505002310)

2. Etiquette de sécurité (Numéro de pièce 89016009461)

6

Page 37

Pour utiliser l'appareil en toute sécurité

Manipulation du carburant

DANGER

Toujours effectuer le ravitaillement à l'écart de toute flamme

Le carburant est hautement inflammable et entraîne un risque d'incendie en cas de mauvaise manipulation. Rester extrêmement vigilant lors du mélange, du stockage ou de la manipulation du carburant. Toute erreur entraîne un risque

de blessure corporelle grave. Observer scrupuleusement les règles de sécurité suivantes.

Il est interdit de fumer lors du ravitaillement. Effectuer le ravitaillement à l'écart de toute flamme.

Il est interdit de ravitailler l'appareil lorsque le moteur est chaud ou en marche.

En effet, le carburant risque de s'enflammer et de provoquer un incendie, entraînant ainsi un risque de brûlure.

A propos du réservoir et du point de ravitaillement

Utiliser un réservoir de carburant agréé.

Les bidons/réservoirs de carburant peuvent être sous

pression. Toujours desserrer le bouchon du réservoir

de carburant de façon progressive pour permettre l'égalisation de la pression.

NE JAMAIS remplir les réservoirs de carburant dans un

endroit fermé. TOUJOURS remplir les réservoirs de carburant à l'extérieur, à même le sol.

Tout déversement de carburant entraîne un risque

d'incendie

Respecter les règles de sécurité suivantes lors du

ravitaillement :

Ne pas remplir le réservoir de carburant jusqu'en haut.

Remplir le réservoir jusqu'au niveau recommandé (jusqu'à l'épaulement du réservoir de carburant).

Essuyer le carburant renversé en cas de débordement

ou de trop plein du réservoir.

Une fois le ravitaillement effectué, revisser fermement

le bouchon du réservoir de carburant.

Tout déversement de carburant, s'il s'enflamme, entraîne un

risque d'incendie et de brûlure.

Ne pas démarrer le moteur à l'endroit où le ravitaillement a été effectué

Il ne faut pas démarrer le moteur à l'endroit où le ravitaillement a été effectué. S'éloigner d'au moins 3 mètres

de l'endroit où le ravitaillement a été effectué avant de

démarrer le moteur.

Les fuites de carburant qui peu-

vent survenir lors du ravitaillement

entraînent un risque d'incendie si

le carburant s'enflamme.

Toute fuite de carburant entraîne un risque d'incendie

Après le ravitaillement, toujours

vérifier qu'il n'y a pas de fuite ou d'écoulement de carburant au niveau du tuyau de carburant, du passe-tuyau

de carburant ou autour du bouchon du réservoir de carburant.

En cas de fuite ou d'écoulement de carburant, interrompre immédiatement l'utilisation de l'appareil et contacter un REVENDEUR ECHO pour effectuer les

réparations nécessaires.

Toute fuite de carburant entraîne un risque d'incendie.

1. Réservoir de carburant

2. Epaulement

7

Page 38

Pour utiliser l'appareil en toute sécurité

Manipulation du moteur

AVERTISSEMENT

Démarrage du moteur

Veiller à bien respecter les mesures de précaution suivantes lors du démarrage du moteur :

Vérifier que tous les écrous et toutes les vis sont bien

serrés

Vérifier qu'il n'y a pas de fuite de carburant

Ne pas essayer de démarrer le moteur avec l'appareil

sur l'épaule

Placer l'appareil sur une surface plane et dans un endroit bien aéré

Etablir un périmètre de sécurité autour de l'appareil et

s'assurer que personne ni aucun animal ne se trouve à

proximité.

Retirer tout obstacle éventuel

Démarrer le moteur avec la manette d'accélérateur en

position démarrage/marche

Maintenir fermement l'appareil au sol lors du démarrage

du moteur

Le non-respect de ces mesures de précaution entraîne un

risque d'accident et de blessure grave, voire mortelle.

Une fois le moteur démarré, vérifier que l'appareil

n'émet aucun son ou vibration anormal(e).

Lorsque le moteur est démarré, vérifier que l'appareil

n'émet aucun son ou vibration anormal(e). Ne pas utiliser l'appareil en cas de son ou vibration anormal(e).

Contacter un REVENDEUR ECHO pour effectuer les réparations nécessaires.

La chute ou la rupture accidentelle de pièces entraîne un ris-

que de blessure grave.

Ne pas toucher les composants sous haute tension

ou sous haute température lors du fonctionnement

de l'appareil

Ne pas toucher les composants sous haute tension ou

sous haute température suivants lors du fonctionnement

de l'appareil et pendant la phase qui suit l'arrêt de l'appareil.

Silencieux, cylindre et autres composants

sous haute température

Il existe un risque de brûlure en cas de contact

avec un composant sous haute température.

Bougie d'allumage, fil de la bougie et

autres composants sous haute tension

Il existe un risque de choc électrique en

cas de contact avec un composant sous

haute tension pendant le fonctionnement

de l'appareil.

Toxicité des fumées d'échappement

Les fumées d'échappement du moteur contiennent des

gaz toxiques. Ne pas utiliser l'appareil dans un endroit

fermé, dans une serre en plastique ou dans tout autre

endroit mal aéré.

Il existe un risque d'intoxication due aux fumées d'échappe-

ment.

Arrêter le moteur pour la vérification et l'entretien de

l'appareil

Respecter les mesures de précaution suivantes lors de la

vérification et de l'entretien de l'appareil après utilisation :

Couper le moteur et attendre qu'il refroidisse avant la

vérification ou l'entretien de l'appareil.

Il existe un risque de brûlure.

Retirer le protecteur de bougie avant d'effectuer les

opérations de vérification ou d'entretien

Il existe un risque d'accident en cas de démarrage intem-

pestif de l'appareil.

Vérification de la bougie d'allumage

Respecter les mesures de précaution suivantes lors de la

vérification de la bougie d'allumage.

En cas d'usure des électrodes ou des bornes, ou en cas

de fissure de la céramique, procéder au remplacement

de ces composants.

L'essai de l'étincelle (destiné à vérifier si la bougie d'allumage émet une étincelle) doit être effectué par un professionnel. Contacter un REVENDEUR ECHO.

L'essai de l'étincelle ne doit pas être effectué à proximité du trou de bougie.

L'essai de l'étincelle ne doit pas être effectué à proximité de flaques de carburant ou de gaz inflammables

Ne pas toucher les parties métalliques de la

bougie d'allumage

La bougie d'allumage ris-

que de provoquer un incendie ou un choc

électrique.

Le bon réflexe en cas d'incendie ou de fumée

Si le moteur prend feu ou si de la fumée s'échappe de

l'appareil à un autre endroit que la sortie d'échappement, la première chose à faire est de s'éloigner de l'appareil pour éviter tout risque de blessure.

A l'aide d'une pelle, jeter du sable ou un

autre matériau équivalent sur les flammes

pour éviter que l'incendie ne se propage,

ou éteindre les flammes avec un extincteur.

Ne pas céder à la panique permet d'éviter que l'incendie ne

se propage et donc de limiter l'étendue des dégâts.

8

Page 39

Pour utiliser l'appareil en toute sécurité

Manipulation de l'appareil

Mesures de précaution générales

AVERTISSEMENT

Manuel d'utilisation

Lire attentivement le manuel d'utilisation

avant d'utiliser l'appareil pour la première fois afin d'éviter toute erreur d'utilisation.

Le non-respect de cette mesure de précau-

tion entraîne un risque d'accident ou de

blessure grave.

Ne pas détourner l'appareil de son utilisation normale

Utiliser l'appareil uniquement pour les tâches décrites

dans ce manuel d'utilisation.

Le non-respect de cette règle de sécurité entraîne un risque

d'accident ou de blessure grave.

Ne pas modifier l'appareil

Aucune modification ne doit être apportée à l'appareil.

Le non-respect de cette règle de sécurité entraîne un risque

d'accident ou de blessure grave. Tout dysfonctionnement dû

à une modification de l'appareil n'est pas couvert par la garantie du fabricant.

Prêt ou cession de l'appareil à un tiers

Si l'appareil est prêté à un tiers, veiller à lui confier également le manuel d'utilisation fourni avec l'appareil.

Si l'appareil est cédé à un tiers, transmettre le manuel

d'utilisation fourni avec l'appareil lors de la vente.

Le non-respect de cette règle de sécurité entraîne un risque

d'accident ou de blessure grave.

Savoir réagir en cas de blessure

Même si les cas de blessure ou d'accident restent exceptionnels, l'utilisateur doit savoir réagir à ces situations.

Kit de premiers secours

Serviettes et lingettes (pour arrêter les saignements)

Sifflet ou téléphone portable (pour appeler de l'aide)

Si l'utilisateur n'est pas capable de prodiguer les premiers

soins ou d'appeler à l'aide, la blessure peut s'aggraver.

Ne pas utiliser l'appareil avant d'avoir effectué les

opérations de vérification et d'entretien nécessaires

Il ne faut pas utiliser l'appareil avant d'avoir effectué les

opérations de vérification et d'entretien nécessaires.

Veiller à ce que l'appareil soit vérifié et entretenu régulièrement.

Le non-respect de cette règle de sécurité entraîne un risque

d'accident ou de blessure grave.

9

Page 40

Pour utiliser l'appareil en toute sécurité

Précautions d'utilisation

AVERTISSEMENT

Utilisateurs de l'appareil

L'appareil ne doit pas être utilisé si :

l'utilisateur est fatigué

l'utilisateur a consommé de l'alcool

l'utilisateur prend des médicaments

la personne qui souhaiter utiliser l'appareil est enceinte

l'utilisateur est en mauvaise

condition physique

l'utilisateur n'a pas lu le manuel

d'utilisation

la personne qui souhaite utiliser

l'appareil est un enfant

Le non-respect de ces règles de sé-

curité entraîne un risque d'accident.

Couper le moteur pour se déplacer

Dans les exemples de déplacement décrits ci-dessous,

couper le moteur et se déplacer en gardant l'appareil sur

l'épaule.

Se déplacer vers le lieu de travail

Se déplacer vers un autre endroit tout en travaillant

Quitter le lieu de travail

Le non-respect de ces mesures de précaution entraîne un

risque de brûlure ou de blessure grave.

Pour transporter l'appareil dans une voiture, vider le réservoir de carburant, placer l'appareil en position verticale et s'assurer qu'il est bien calé pour éviter qu'il ne

se déplace lors du trajet.

Rouler en voiture avec du carburant dans le réservoir de

carburant entraîne un risque d'incendie.

Environnement d'utilisation et fonctionnement de

l'appareil

Ne pas utiliser l'appareil :

en cas de pluie, de tonnerre ou de probabilité élevée

d'éclairs.

sur des pentes raides ou sur une surface instable et

glissante.

la nuit ou dans des endroits mal éclairés.

Toute chute, dérapage ou utilisation incorrecte de l'appareil

entraîne un risque de blessure grave pour l'utilisateur.

Utilisation de l'appareil

Veiller à bien respecter les mesures de précaution suivantes lors de l'utilisation de l'appareil.

Les personnes n'ayant pas de rapport avec le travail effectué et les animaux sont interdits sur le lieu de travail.

Ne pas diriger le tuyau de soufflage vers des personnes

ou des animaux.

Ne pas utiliser l'appareil sur une surface instable.

Tenir la poignée fermement.

Afin d'éviter toute nuisance sonore pour le voisinage,

ne pas utiliser l'appareil tard le soir ou tôt le matin.

Le non-respect de ces règles de sécurité entraîne un risque

d'accident ou de blessure.

Attention à ne pas se faire prendre dans la turbine

Veiller à ce que des cheveux ne se prennent pas dans la

turbine.

Ne jamais placer sa main entre le moteur et le cadre de

l'étui de transport lorsque l'appareil fonctionne.

La pression de l'air soufflé par la turbine risque de repousser

la main vers la turbine et donc d'entraîner une blessure grave.

Exposition aux vibrations et au froid

Les personnes exposées aux vibrations et au froid peuvent être victimes du phénomène de Raynaud, une affection qui touche les doigts. L'exposition à des vibrations et

au froid peut provoquer une sensation de picotement et de

brûlure, suivie d'une cyanose et d'un engourdissement

des doigts. Il est vivement recommandé de respecter les

mesures de précaution suivantes car le seuil d'exposition

minimum pouvant provoquer l'apparition de ce phénomène reste inconnu à ce jour.

Limiter la perte de chaleur corporelle, en protégeant en

priorité la tête, le cou, les pieds, les chevilles, les mains

et les poignets.

Stimuler la circulation sanguine en interrompant le travail régulièrement pour remuer énergiquement les bras,

et éviter de fumer.

Limiter le nombre d'heures d'utilisation. Essayer d'intégrer à l'emploi du temps de la journée des tâches ne nécessitant pas l'utilisation du souffleur ou d'une autre

machine portative.

En cas d'inconfort, de rougeur et de gonflement au niveau des doigts, suivis d'un blanchiment et d'une perte

de sensibilité, consulter un médecin avant de s'exposer

à nouveau au froid et aux vibrations.

Le non-respect de ces instructions peut être dangereux pour

la santé.

10

Page 41

Pour utiliser l'appareil en toute sécurité

AVERTISSEMENT

Lésions attribuables au travail répétitif

Une trop grande sollicitation des muscles et des tendons

des doigts, des mains, des bras et des épaules peut entraîner l'apparition d'inflammations, de gonflements, d'engourdissements, d'une sensation de faiblesse ou d'une

douleur aiguë dans ces parties du corps. L'apparition de

lésions attribuables au travail répétitif (LATR) est très fréquente chez les personnes pratiquant certaines activités

manuelles répétitives. Pour réduire le risque d'apparition

de LATR, respecter les mesures de précaution suivantes :

Eviter de plier, d'étirer ou de tordre le poignet pendant

le travail.

Faire des pauses régulières pour réduire l'effet répétitif

et pour reposer ses mains. Effectuer le mouvement répétitif plus lentement et en faisant moins d'effort.

Faire des exercices de musculation des mains et des

bras.

En cas de picotements, d'engourdissement ou de douleur dans les doigts, les mains, les poignets ou les bras,

consulter un médecin. Plus les LATR sont diagnostiquées précocement, plus les chances d'empêcher les

lésions nerveuses et musculaires irréversibles sont

grandes.

Le non-respect de ces instructions peut être dangereux pour

la santé.

Couper immédiatement le moteur en cas d'anomalie

Si l'appareil se met à vibrer soudainement ou émet des

bruits anormaux, couper immédiatement le moteur. Ne

pas utiliser l'appareil en cas de son ou vibration anormal(e). Contacter un REVENDEUR ECHO pour effectuer

les réparations nécessaires.

L'utilisation prolongée de pièces endommagées entraîne un

risque d'accident ou de blessure grave.

11

Page 42

Pour utiliser l'appareil en toute sécurité

Equipement de protection

AVERTISSEMENT

Port d'un équipement de protection

Toujours porter des vêtements et un équipement de

protection adaptés pour utiliser le souffleur. Veiller surtout à toujours porter des lunettes de sécurité, un masque anti-poussière et un casque de protection anti-bruit

pour travailler avec l'appareil.