Page 1

Power Blower

Operator's Manual

MODEL: PB-755H

PB-755T

WARNING

Read rules for safe operation and all instructions carefully. ECHO provides this Operator's Manual which must be read and understood for proper and safe operation.

X7531122402

X753002812

12/08

Page 2

2

In T r o d u C T I o n

Welcome to the ECHO family. This ECHO product was designed and manufactured to provide long life and on-the-

job-dependability. Read and understand this manual. You will nd it easy to use and full of helpful operating tips and

SAFETY messages.

T h e o p e r a T o r 's m a n u a l

Read and understand this manual before operation. Keep it in a safe

place for future reference. It contains specications and information

for operation, starting, stopping, maintenance, storage and assembly

specic to this product.

Ta b l e o f Co n T e n T s

Introduction ................................................................2

- The Operator's Manual .......................................2

Safety .........................................................................3

Manual Safety Symbols and Important Information . 3

- International Symbols ......................................... 3

- Personal Condition and Safety Equipment .........3

- Equipment ...........................................................6

Emission Control .......................................................6

Description ................................................................. 7

Contents ..................................................................11

Assembly..................................................................12

- Install Blower Pipes / Stick Handle PB-755H .. 12

- Install Blower Pipes PB-755T .......................... 13

Operation ..................................................................14

- Fuel ................................................................... 14

- Starting Cold Engine .........................................16

- Starting Warm Engine .......................................17

- Stopping Engine ................................................17

- Operating Blower ..............................................18

Maintenance ............................................................. 19

- Skill Levels .......................................................19

- Maintenance Intervals .......................................19

- Air Filter ...........................................................20

- Fuel Filter ..........................................................21

- Spark Plug .........................................................21

- Cooling System .................................................22

- Exhaust System .................................................23

- Carburetor Adjustment ......................................25

Troubleshooting .......................................................26

Storage .....................................................................27

Specications ...........................................................28

Servicing Information ..............................................32

- Parts/

- Service ..............................................................32

- ECHO Consumer Product Support ...................32

- Warranty Card ................................................... 32

- Additional or Replacement Manuals ................32

Specications, descriptions and illustrative material in this

literature are as accurate as known at the time of publication, but are subject to change without notice. Illustrations

may include optional equipment and accessories, and may

not include all standard equipment.

Serial Number ........................................... 32

CopyRight© 2008 By Echo, Incorporated

All Rights Reserved.

Page 3

sa f e T y

Po w e r Bl o w e r

oP e r a t o r 's Ma n u a l

3

m a n u a l

s a f e T y s y m b o l s a n d I m p o r T a n T I n f o r m a T I o n

Throughout this manual and on the product itself, you will nd safety

alerts and helpful, informational messages preceded by symbols or

key words. The following is an explanation of those symbols and key

words and what they mean to you.

DANGER

The safety alert symbol accompanied by the word

“DANGER” calls attention to an act or condition

which WILL lead to serious personal injury or

death if not avoided.

WARNING

The safety alert symbol accompanied by the word

“WARNING” calls attention to an act or condition which CAN lead to serious personal injury or

death if not avoided.

CAUTION

The safety alert symbol accompanied by the word

“CAUTION” calls attention to an act or condition

which may lead to minor or moderate personal

injury if not avoided.

NOTE

This enclosed message provides tips for use, care and

maintenance of the unit.

IMPORTANT

The enclosed message provides information necessary for the protection of the unit.

CIRCLE AND SLASH SYMBOL

This symbol means the specic action

shown is prohibited. Ignoring these prohibitions can result in serious or fatal injury.

I n T e r n a T I o n a l s y m b o l s

Symbol form/shape

Symbol

description/application

Read and understand

Operator's Manual.

Wear eyes, ears and

head protection

Hot

Surface

Safety/Alert

DO NOT allow

ames or sparks

near fuel.

Symbol form/shape

Symbol

description/application

Fuel and oil mixture

Finger Severing

Wear hand

protection. Use

two handed.

Wear slip resis-

tant foot wear.

DO NOT smoke

near fuel.

Symbol form/shape

Symbol

description/application

Emergency stop

Carburetor adjustment

- Low speed mixture

Carburetor adjustment

- Idle speed

Choke Control

"Cold Start"

Position

(Choke Closed)

Symbol form/shape

Symbol

description/application

Ignition

ON/OFF

Primer bulb

Carburetor adjustment

- High speed mixture

Choke Control

"Run"

Position

(Choke Open)

p e r s o n a l C o n d I T I o n a n d s a f e T y e q u I p m e n T

WARNING

Power Blower users risk injury to themselves and others if the power blower is used improperly or safety precautions

are not followed. Proper clothing and safety gear must be worn when operating a blower.

Page 4

4

Physical Condition

Your judgment and physical dexterity may not be good:

• if you are tired or sick,

• if you are taking medication,

• if you have taken alcohol or drugs.

Operate unit only if you are physically and mentally well.

Eye Protection

Wear eye protection that meets ANSI Z87.1 or CE requirements whenever you operate the unit.

Hand Protection

Wear no-slip, heavy-duty work gloves to improve your grip on the blower handle. Gloves also reduce the transmission

of machine vibration to your hands.

Breathing Protection

Wear a facemask to protect against dust.

Hearing Protection

ECHO recommends wearing hearing protection whenever unit is used.

Proper Clothing

Wear snug tting, durable clothing;

• Pants should have long legs, shirts with long sleeves.

• DO NOT WEAR SHORTS,

• DO NOT WEAR TIES, SCARVES, and JEWELRY.

Wear sturdy work shoes with nonskid soles:

• DO NOT WEAR OPEN TOED SHOES,

• DO NOT OPERATE UNIT BAREFOOTED.

Keep long hair away from engine and blower intake. Retain hair with cap or net.

Hot Humid Weather

Heavy protective clothing can increase operator fatigue, which may lead to heat stroke. Schedule heavy work for early

morning or late afternoon hours when temperatures are cooler.

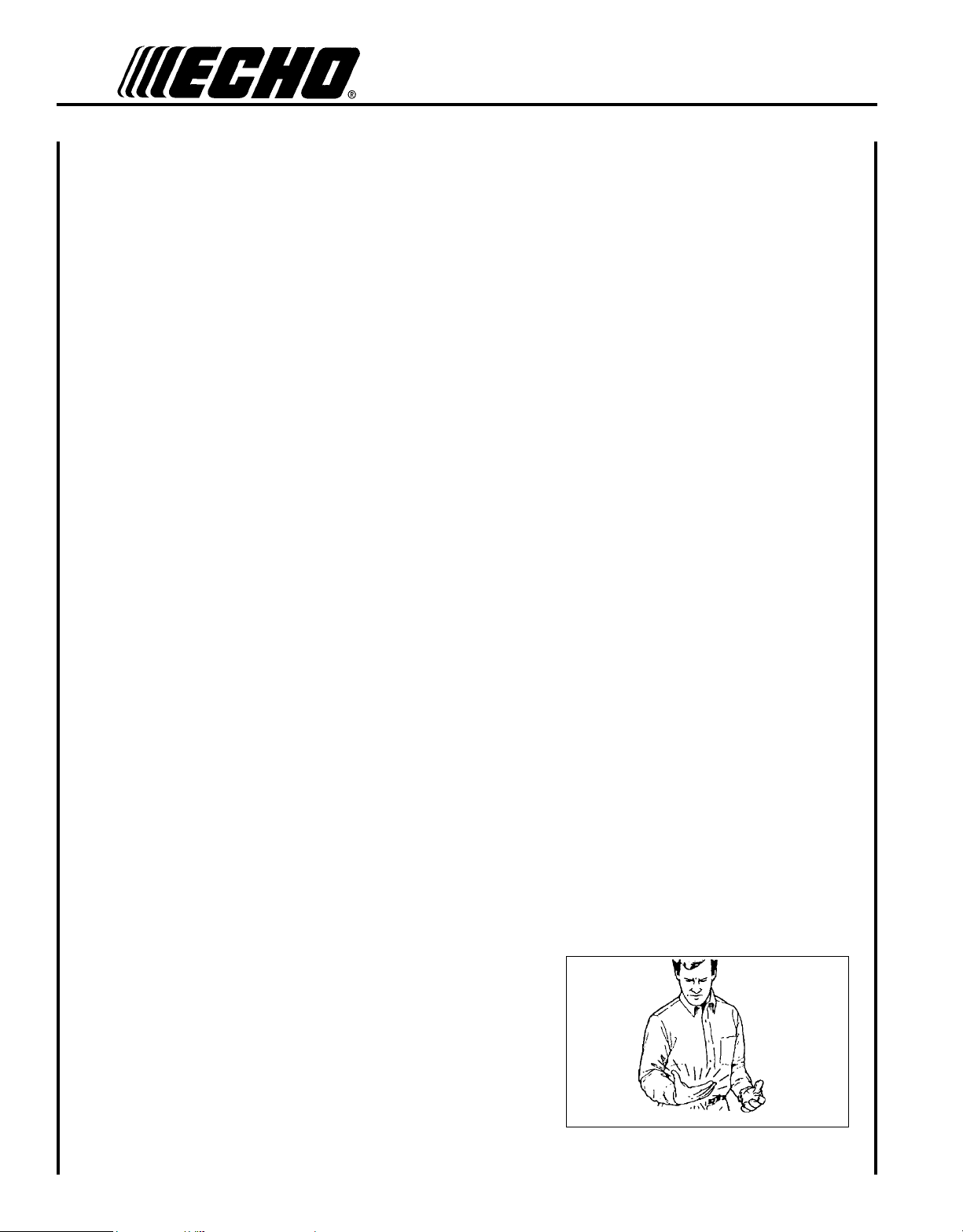

Vibration and Cold

It is believed that a condition called Raynaud’s Phenomenon, which affects the ngers of certain individuals, may be

brought about by exposure to vibration and cold. Exposure to vibration and cold may cause tingling and burning sen-

sations, followed by loss of color and numbness in the ngers. The following precautions are strongly recommended,

because the minimum exposure, which might trigger the ailment, is unknown.

• Keep your body warm, especially the head, neck, feet, ankles,

hands, and wrists.

• Maintain good blood circulation by performing vigorous arm

exercises during frequent work breaks, and also by not smoking.

• Limit the hours of operation. Try to ll each day with jobs where

operating the unit or other hand-held power equipment is not

required.

• If you experience discomfort, redness, and swelling of the ngers

followed by whitening and loss of feeling, consult your physician

before further exposing yourself to cold and vibration.

Page 5

Po w e r Bl o w e r

oP e r a t o r 's Ma n u a l

Repetitive Stress Injuries

It is believed that overusing the muscles and tendons of the ngers, hands, arms, and shoulders may cause soreness,

swelling, numbness, weakness, and extreme pain in those areas. Certain repetitive hand activities may put you at a high

risk for developing a Repetitive Stress Injury (RSI). An extreme RSI condition is Carpal Tunnel Syndrome (CTS), which

could occur when your wrist swells and squeezes a vital nerve that runs through the area.

Some believe that prolonged exposure to vibration may contribute to CTS. CTS can cause severe pain for months or

even years.

To reduce the risk of RSI/CTS, do the following:

• Avoid using your wrist in a bent, extended, or twisted position.

Instead try to maintain a straight wrist position. Also, when

grasping, use your whole hand, not just the thumb and index

nger.

• Take periodic breaks to minimize repetition and rest your hands.

• Reduce the speed and force with which you do the repetitive

movement.

• Do exercises to strengthen the hand and arm muscles.

• Immediately stop using all power equipment and consult a doc-

tor if you feel tingling, numbness, or pain in the ngers, hands,

wrists, or arms. The sooner RSI/CTS is diagnosed, the more

likely permanent nerve and muscle damage can be prevented.

5

DANGER

Do not operate this product indoors or in inadequately ventilated

areas. Engine exhaust contains poisonous emissions and can cause

serious injury or death.

Read the Manuals

• Provide all users of this equipment with the Operator’s Manual

and Safety Manual for instructions on Safe Operation.

Clear the Work Area

• Spectators and fellow workers must be warned, and children and

animals prevented from coming nearer than 15 m (50 ft.) while

the unit is in use.

• Take wind conditions into account: avoid open doors and windows.

• Do not point blower at people or animals.

Keep a Firm Grip

• Hold the front and rear handles with both hands, with thumbs

and ngers encircling the handles.

Keep a Solid Stance

• Maintain footing and balance at all times. Do not stand on slippery, uneven or unstable surfaces. Do not work in odd positions

or on ladders. Do not over reach.

Avoid Hot Surfaces

• Keep exhaust area clear of ammable debris. Avoid contact during and immediately after operation.

Page 6

6

e q u I p m e n T C h e C k

WARNING

Use only ECHO approved attachments. Serious injury may result from the use of a non-approved attachment combination. ECHO, INC. will not be responsible for the failure of cutting devices, attachments or accessories which have

not been tested and approved by ECHO. Read and comply with all safety instructions listed in this manual and safety

manual.

• Check unit for loose/missing nuts, bolts and screws. Tighten and/or replace as needed.

• Do not use blower if any part is missing or damaged.

• Have repairs done only by an authorized ECHO Service dealer.

• Do not use any attachment, accessory or replacement part unless it is recommended in this Operator's Manual.

WARNING

Moving parts can amputate ngers or cause severe injuries. Keep hands, clothing and loose objects away from all

openings.

• ALWAYS stop engine, disconnect spark plug, and make sure all moving parts have come to a complete stop

before removing obstructions, clearing debris, or servicing unit.

• DO NOT start or operate unit unless all guards and protective covers are properly assembled to unit.

• NEVER reach into any opening while the engine is running. Moving parts may not be visible through openings.

WARNING

Check fuel system for leaks due to fuel tank damage, especially if the unit is dropped. If damage or leaks are found,

do not use unit, otherwise serious personal injury or property damage may occur. Have unit repaired by an authorized

servicing dealer before using.

em I s s I o n Co n T r o l (e X h a u s T & e V a p o r a T I V e )

EPA Phase 2 / C.A.R.B. TIER III

The emission control system for the engine is EM/TWC (Engine Modication and 3-way Catalyst) and for the fuel tank

the Control System is EVAP (Evaporative Emissions) or N (for nylon tank). Evaporative emission may be applicable to

California models only.

An Emission Control Label is located on the unit. (This is an EXAMPLE ONLY, information on label varies by engine

FAMILY).

PRODUCT EMISSION DURABILITY (EMISSION COMPLIANCE PERIOD)

The 300 hour emission compliance period is the time span selected by the manufacturer certifying the engine emissions output meets applicable emissions regulations, provided that approved maintenance procedures are followed as

listed in the Maintenance Section of this manual.

ImporTanT enGIne InformaTIon

enGIne famIly: 7ehXs.0635kb dIsplaCemenT: 63.3 C C

emIssIon ComplIanCe perIod : 300 hrs.

ThIs enGIne meeTs u.s. epa ph2 eXh and 2007 and

laTer CalIfornIa eXh and eVap emIssIon reGula-

TIons for s.o.r.e. refer To oWner's manual for

maInTenanCe speCIfICaTIons and adJusTmenTs.

Page 7

Po w e r Bl o w e r

oP e r a t o r 's Ma n u a l

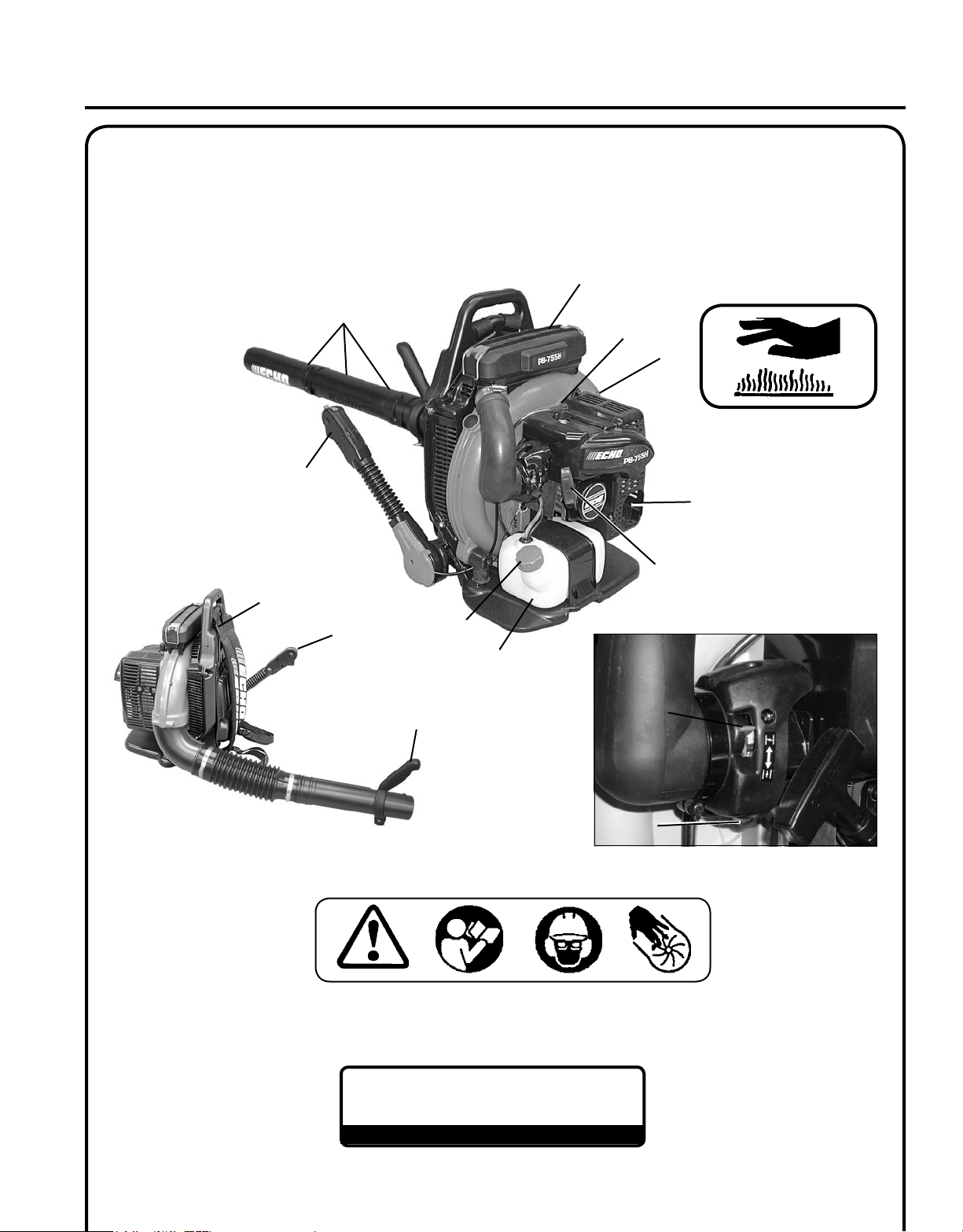

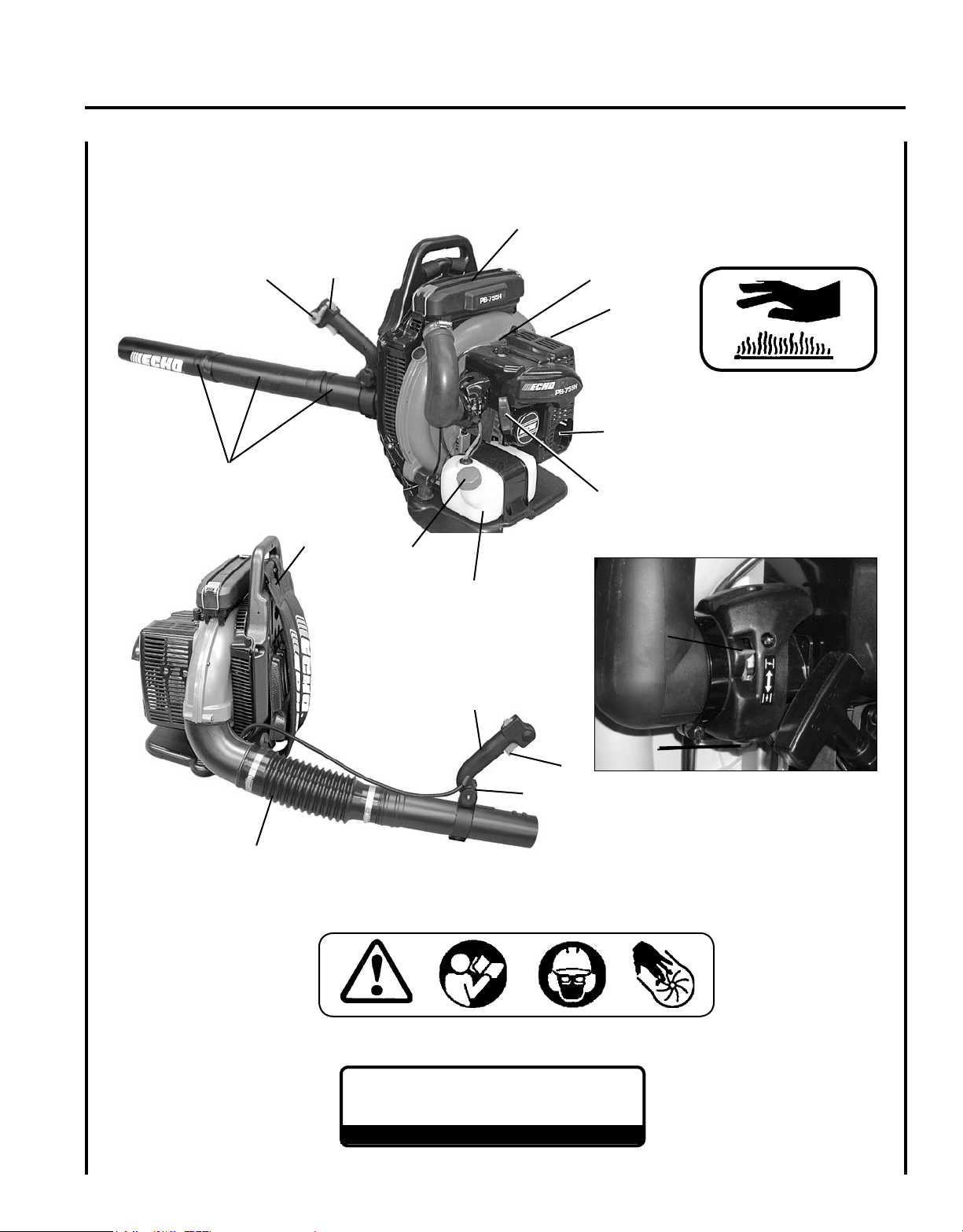

de s C r I p T I o n

PB-755H

Locate these safety decals on your unit. Make sure the decals are legible and that you understand and follow the instructions on them. If a decal cannot be read, a new one can be ordered from your ECHO dealer. See PARTS ORDERING

instructions for specic information.

7

12

10

11

13

14

1

9

8

Hot Decal (near mufer)

2

3

P/N 89016006361

4

7

5

General Warning Decal (located on top of blower housing)

P/N 89016009461

Sound Label (located on blower housing)

74 Category III

dB(A)

Measured at 50 ft. (15m) per ANSI B175.2

P/N X508000180

6

Page 8

8

1. AIR CLEANER - Contains replaceable air lter element.

2. SPARK PLUG - Provides spark to ignite fuel mixture.

3. SAFETY DECAL - Lists important safety precautions.

4. SPARK ARRESTOR - CATALYTIC MUFFLER / MUFFLER - The mufer or catalytic mufer controls

exhaust noise and emission. The spark arrestor screen prevents hot, glowing particles of carbon from leaving the

mufer. Keep exhaust area clear of ammable debris.

5. CHOKE - Move lever up to "Cold Start" ( ) starting position and for emergency stopping. Move lever down to

Run position ( ).

6. PURGE BULB - Pumping purge bulb before starting engine draws fresh fuel from the fuel tank, purging air from

the carburetor. Pump purge bulb until fuel is visible and ows freely in the clear fuel tank return line. Pump purge

bulb an additional 4 or 5 times.

7. RECOIL STARTER HANDLE - Pull recoil handle slowly until starter engages, then quickly and rmly. When

engine starts, return handle slowly. DO NOT let handle snap back or damage to unit will occur.

8. FUEL TANK - Contains fuel and fuel lter.

9. FUEL TANK CAP - Covers and seals fuel tank.

10. HANDLE - Rotates downward for throttle control access. Spring loaded for exible operation.

11. BLOWER PIPES - Exclusive positive locking system.

12. SHOULDER HARNESS - Used to support unit on operator's back. The straps are adjustable.

13. THROTTLE POSITION LEVER/STOP SWITCH - Combination stop switch and variable speed throttle lever.

When the lever is moved all the way forward the blower is at Wide Open Throttle (W.O.T.). When the lever is

moved rearward to detent, the blower is at idle. When the lever is moved rearward past the idle detent the blower

will stop.

14. STICK HANDLE - Provides comfortable grip for directing air ow.

Page 9

Po w e r Bl o w e r

oP e r a t o r 's Ma n u a l

PB-755T

Locate these safety decals on your unit. Make sure the decals are legible and that you understand and follow the instructions on them. If a decal cannot be read, a new one can be ordered from your ECHO dealer. See PARTS ORDERING

instructions for specic information.

11

10

12

1

Hot Decal (near mufer)

2

3

P/N 89016006361

4

5

9

13

9

8

14

15

16

17

General Warning Decal (located on top of blower housing)

6

7

P/N 89016009461

Sound Label (located on blower housing)

74 Category III

dB(A)

Measured at 50 ft. (15m) per ANSI B175.2

P/N X508000180

Page 10

10

1. AIR CLEANER - Contains replaceable air lter element.

2. SPARK PLUG - Provides spark to ignite fuel mixture.

3. SAFETY DECAL - Lists important safety precautions.

4. SPARK ARRESTOR - CATALYTIC MUFFLER / MUFFLER - The mufer or catalytic mufer controls

exhaust noise and emission. The spark arrestor screen prevents hot, glowing particles of carbon from leaving the

mufer. Keep exhaust area clear of ammable debris.

5. RECOIL STARTER HANDLE - Pull recoil handle slowly until starter engages, then quickly and rmly. When

engine starts, return handle slowly. DO NOT let handle snap back or damage to unit will occur.

6. CHOKE - Move lever up to "Cold Start" ( ) starting position and for emergency stopping. Move lever down to

Run position ( ).

7. PURGE BULB - Pumping purge bulb before starting engine draws fresh fuel from the fuel tank, purging air from

the carburetor. Pump purge bulb until fuel is visible and ows freely in the clear fuel tank return line. Pump purge

bulb an additional 4 or 5 times.

8. FUEL TANK - Contains fuel and fuel lter.

9. FUEL TANK CAP - Covers and seals fuel tank.

10. BLOWER PIPES - Exclusive positive locking system.

11. THROTTLE POSITION LEVER - Pull back to increase engine speed. Friction washers maintain throttle lever

setting.

12. STOP SWITCH - Slide switch mounted on top of handle. Move forward to run, back to stop.

13. SHOULDER HARNESS - Used to support unit on operator's back. The straps are adjustable.

14. HANDLE - Used by operator to direct and control air ow.

15. THROTTLE TRIGGER - Spring loaded to return to idle when released. During acceleration, press trigger gradually for best operating technique.

16. LOCKING KNOB - Allows operator to adjust handle position for optimum comfort and control.

17. FLEXIBLE PIPE - Allows for full range of movement.

Page 11

Co n T e n T s

PB-755H

___ 1 - Power Head

___ 1 - Flex Pipe

___ 1 - Pipe w/swivel

___ 1 - Straight Pipe

___ 1 - Straight Pipe

___ 1 - Operator's Manual

___ 1 - Warranty Registration Card

___ 1 - ECHO Emissions and Warranty Statement

___ 1 - Plastic Bag

___ 2 - Clamps w/screws

___ 1 - Stick Handle

___ 1 - Bolt 6x45

___ 1 - Washer 6

___ 1 - Wing nut

___ 1 - Echo Power Blend X TM 2-stroke oil sample

Po w e r Bl o w e r

oP e r a t o r 's Ma n u a l

11

PB-755T

___ 1 - Power Head

___ 1 - Flex Pipe

___ 1 - Pipe w/swivel

___ 1 - Straight Pipe

___ 1 - Straight Pipe

___ 1 - Operator's Manual

___ 1 - Warranty Registration Card

___ 1 - ECHO Emissions and Warranty Statement

___ 1 - Plastic Bag

___ 2 - Clamps w/screws

___ 1 - Guide Loop

___ 1 - Echo Power Blend X TM 2-stroke oil sample

Page 12

12

as s e m b l y

PB-755H

WARNING

Never perform maintenance or assembly procedures with engine

running or serious personal injury may result.

I n s T a l l b l o W e r p I p e s / s T I C k h a n d l e

1. Assemble clamps (A) onto both ends of exible pipe (B).

2. Assemble swivel pipe (C) into exible pipe (B) and tighten clamp

(A).

3. Assemble exible pipe (B) to elbow (D) on blower and tighten

clamp (A).

NOTE

A light lubricant may be used to ease assembly of exible pipe to

blower elbow.

4. Loosen wing nut (E) completely and open stick handle clamp.

5. Align notches (F) in handle clamp with tabs (G).

A

D

B

B

G

A

C

H

6. Slide stick handle onto swivel pipe (C). Stick handle should be

angled away from operator.

7. Position stick handle (H) for comfortable operation, and tighten

wing nut (E).

8. Assemble straight pipe (I) onto swivel pipe (C), until you feel

light resistance. Do not force connection. Hold swivel pipe and

turn straight pipe clockwise, engaging positive locking channels,

until connection is rm. Do not force connection.

9. Assemble straight pipe with decal (J) to straight pipe (I) as in step

8.

NOTE

Blower use will eventually loosen pipe connections. Exclusive

positive locking system allows pipes to be tightened. If loosening

occurs, remove two straight pipes and install according to instructions 8 & 9.

F

E

G

C

I

J

Page 13

PB-755T

Po w e r Bl o w e r

oP e r a t o r 's Ma n u a l

G

13

G

WARNING

Never perform maintenance or assembly procedures with engine

running or serious personal injury may result.

I n s T a l l b l o W e r p I p e s

1. Place guide loop (G) across elbow clamp, and turn until clips

fully engage clamp band.

2. Assemble clamps (A) onto both ends of exible pipe (B).

NOTE

Clamp with cable guide loop (G) ts elbow end of exible pipe.

3. Assemble swivel pipe (C) into exible pipe (B).

NOTE

Assure throttle cable is not twisted before installing handle (E).

4. Position cable between the elbow (D) and frame and along the top

of the exible pipe. Loosen knob (H) on handle (E). Align notch

in handle with tabs (F). Install onto swivel pipe (C) past long

ridges in pipe.

5. Assemble exible pipe (B) to elbow (D) on blower and tighten

clamps (A). Position guide loop (G) on inside (blower side) of

exible tube.

A

D

G

B

B

C

G

A

E

F

H

NOTE

A light lubricant may be used to ease assembly of exible pipe to

blower elbow.

6. Clip throttle cable into throttle cable guide loop (G).

7. Move handle (E) to desired position. Tighten knob (H) hand tight.

8. Assemble straight pipe (I) onto swivel pipe (C), until you feel

light resistance. Do not force connection. Hold swivel pipe and

turn straight pipe clockwise, engaging positive locking channels,

until connection is rm. Do not force connection.

9. Assemble straight pipe with decal (J) to straight pipe (I) as in step

8.

NOTE

Blower use will eventually loosen pipe connections. Exclusive

positive locking system allows pipes to be tightened. If loosening

occurs, remove two straight pipes and install according to instructions 8 & 9.

E

H

J

E

I

C

Page 14

14

op e r a T I o n

WARNING

Moving parts can amputate ngers or cause severe injuries. Keep hands, clothing and loose objects away from all

openings. Always stop engine, disconnect spark plug, and make sure all moving parts have come to a complete stop

before removing obstructions, clearing debris, or servicing unit. Blower housing may contain shredder blades and

other sharp edges that can cause serious injuries if touched, even if engine is off and blades are not moving. Wear

gloves to protect hands from sharp edges and hot surfaces.

f u e l

NOTICE: Use of unmixed, improperly mixed, or fuel older than 90 days, (stale fuel), may cause hard starting, poor

performance, or severe engine damage and void the product warranty. Read and follow instructions in the Storage

section of this manual.

WARNING

Alternative fuels, such as E-20 (20% ethanol), E-85 (85% ethanol) or any fuels not meeting ECHO requirements are

NOT approved for use in ECHO 2-stroke gasoline engines. Use of alternative fuels may cause performance prob-

lems, loss of power, overheating, fuel vapor lock, and unintended machine operation, including, but not limited to,

improper clutch engagement. Alternative fuels may also cause premature deterioration of fuel lines, gaskets, carburetors and other engine components.

Fuel Requirements

Gasoline - Use 89 Octane [R+M/2] (mid grade or higher) gasoline known to be good quality. Gasoline may contain up to

10% Ethanol (grain alcohol) or 15% MTBE (methyl tertiary-butyl ether). Gasoline containing methanol (wood alcohol)

is NOT approved.

Two Stroke Oil - A two-stroke engine oil meeting ISO-L-EGD (ISO/CD 13738) and JASO M345/FC/FD Standards

must be used. ECHO brand premium Power Blend X TM Universal 2-Stroke Oil meets these standards. Engine problems

due to inadequate lubrication caused by failure to use an ISO-L-EGD (ISO/CD 13738) and JASO M345/FC/FD certied

oil, such as ECHO premium Power Blend X TM, will void the two-stroke engine warranty.

IMPORTANT

Echo premium Power Blend X TM Universal 2-Stroke Oil may be mixed at 50:1 ratio for application in all Echo en-

gines sold in the past regardless of ratio specied in those manuals.

Page 15

Po w e r Bl o w e r

oP e r a t o r 's Ma n u a l

Handling Fuel

DANGER

Fuel is VERY ammable. Use extreme care when mixing, storing or handling or serious personal injury may result.

• Use an approved fuel container.

• DO NOT smoke near fuel.

• DO NOT allow ames or sparks near fuel.

• Fuel tanks/cans may be under pressure. Always loosen fuel caps slowly allowing pressure to equalize.

• NEVER refuel a unit when the engine is HOT or RUNNING!

• DO NOT ll fuel tanks indoors. ALWAYS ll fuel tanks outdoors over bare ground.

• DO NOT overll fuel tank. Wipe up spills immediately.

• Securely tighten fuel tank cap and close fuel container after refueling.

• Inspect for fuel leakage. If fuel leakage is found, do not start or operate unit until leakage is repaired.

• Move at least 3m (10 ft.) from refueling location before starting the engine.

15

Mixing Instructions

1. Fill an approved fuel container with half of the required amount

of gasoline.

2. Add the proper amount of 2-stroke oil to gasoline.

3. Close container and shake to mix oil with gasoline.

4. Add remaining gasoline, close fuel container, and remix.

IMPORTANT

Spilled fuel is a leading cause of hydrocarbon emissions. Some

states may require the use of automatic fuel shut-off containers

to reduce fuel spillage.

After use

• DO NOT store a unit with fuel in its tank. Leaks can occur. Return

unused fuel to an approved fuel storage container.

Storage - Fuel storage laws vary by locality. Contact your local government for the laws affecting your area. As a precaution, store fuel in

an approved, airtight container. Store in a well-ventilated, unoccupied

building, away from sparks and ames.

IMPORTANT

Stored fuel ages. Do not mix more fuel than you expect to use in

thirty (30) days, ninety (90) days when a fuel stabilizer is added.

IMPORTANT

Stored two-stroke fuel may separate. ALWAYS shake fuel container thoroughly before each use.

Page 16

16

s T a r T I n G C o l d e n G I n e

• Recoil starter: Use short pulls - only 1/2-2/3 of rope length for starting. Do not allow the rope to snap back in. Always hold the unit

rmly.

PB-755H

1. Throttle Lever

Move throttle lever (A) to IDLE DETENT position.

PB-755T

1. Throttle Lever/Stop Switch

Move throttle lever (A) forward to idle position. Slide stop switch

(B) forward to run position.

PB-755H, PB-755T

2. Choke

Move choke (C) up to "Cold Start" position ( ).

3. Purge Bulb

Pump purge bulb (D) until fuel is visible and ows freely in the

clear fuel tank return line. Pump bulb an additional 4 or 5 times.

PB-755H

PB-755T

C

A

B

A

4. Recoil Starter

Pull recoil starter handle (E) until engine res (5 or 6 pulls maxi-

mum).

5. Choke

Move choke (C) down to run position ( ), and if necessary,

restart engine.

NOTE

If engine does not start after 5 pulls, move choke to "Cold Start"

position, and repeat steps 4 & 5.

NOTE

Allow engine to warm up before use.

D

C

E

Page 17

Po w e r Bl o w e r

oP e r a t o r 's Ma n u a l

17

s T a r T I n G W a r m e n G I n e

PB-755H

1. Throttle Lever

Move throttle lever (A) to IDLE DETENT position.

PB-755T

1. Throttle Lever/Stop Switch

Move throttle lever (A) forward to idle position. Slide stop

switch (B) forward to run position.

PB-755H, PB-755T

2. Recoil Starter

Pull recoil starter handle (E) and engine should start. Do not use

choke (C).

NOTE

If engine does not start after 5 pulls, use cold start procedures.

PB-755H

PB-755T

C

A

B

A

s T o p p I n G e n G I n e

PB-755H

1. Throttle Lever

Move throttle lever (A) to idle detent position and allow engine to

return to idle before shutting off engine.

2. Move throttle lever (A) to "O" (Stop) position.

PB-755T

1. Throttle Trigger/Throttle Position Lever

Release throttle trigger (C). Move throttle position lever (A)

forward to idle position and allow engine to return to idle before

shutting engine off.

2. Stop Switch

Slide stop switch (B) to Stop position.

WARNING

If engine does not stop when stop switch is moved to STOP position, close choke - COLD START position - to stall engine. Have

your ECHO dealer repair stop switch before using blower again.

E

PB-755H

PB-755T

A

A

B

C

Page 18

18

o p e r a T I n G b l o W e r

WARNING

Engine exhaust IS HOT, and contains Carbon Monoxide (CO),

a poison gas. Breathing CO can cause unconsciousness, serious

injury, or death. Exhaust can cause serious burns. ALWAYS blow

exhaust away from your face and body.

WARNING

Always wear safety glasses, hearing protection, a face lter mask and

take all safety precautions or serious personal injury may result.

Do not point the blower pipe in the direction of people or pets.

Read the Safety Section on pages 4 - 6 carefully.

IMPORTANT

To avoid engine damage due to over-revving, do not block blower

pipe opening.

1. Use only during appropriate hours.

2. Allow the engine to warm up at a fast idle for a few minutes.

3. PB-755H

Set engine speed with throttle lever (A).

PB-755T

Control engine speed with throttle trigger (C), or throttle position

lever (A). Rotate throttle position lever forward for lower speed,

back for higher speed.

4. Use lower speed to blow dry leaves from walks, patios and drives.

5. Additional speed may be necessary to clean grass and leaves from a

lawn or ower bed.

6. Higher speed may be necessary to move gravel, dirt, snow, bottles

or cans from a driveway, street, parking lot or stadium.

PB-755H

PB-755T

A

C

A

NOTE

Never use a higher speed setting than necessary to perform a task.

Remember, the higher the engine speed, the louder the blower noise.

Minimize dust by using blower at lower speeds and by dampening material with water/mist when necessary. Keep debris on your

property.

Be Smart - be a good neighbor.

Page 19

Po w e r Bl o w e r

COMPONENT / SYSTEM

MAINTENANCE

PROCEDURE

REQ'D

SKILL

LEVEL

DAILY OR

BEFORE USE

EVERY

REFUEL

3 MONTHS

OR 90

HOURS

YEARLY

600 HOURS

Air Filter Inspect/Clean

1 I / C * R *

Choke Shutter Inspect/Clean

1 I / C

Fuel Filter Inspect/Replace

1 I * I / R *

Fuel Cap Gasket Inspect/Replace

1

I *

Fuel System Inspect/Replace

1 I (1) * I (1) *

Spark Plug Inspect/Clean/Replace

1 I / C / R *

Cooling System Inspect/Clean

2 I / C

Muffler Spark Arrestor Inspect/Clean/Replace

2 I / C / R *

Cylinder Exhaust Port Inspect/Clean/Decarbon

2 I / C

Recoil Starter Rope Inspect/Clean

1 I / C *

Screws/Nuts/Bolts Inspect/Tighten/Replace

1 I *

MAINTENANCE PROCEDURE LETTER CODES: I = INSPECT, R = REPLACE, C = CLEAN

IMPORTANT NOTE - Time intervals shown are maximum. Actual use and your experience will determine the

frequency of required maintenance.

MAINTENANCE PROCEDURE NOTES:

(1) Low evaporative fuel tanks DO NOT require regular maintenance to maintain emission integrity.

* All recommendations to replace are based on the finding of damage or wear during inspection.

oP e r a t o r 's Ma n u a l

19

ma I n T e n a n C e

WARNING

Moving parts can amputate ngers or cause severe injuries. Keep hands, clothing and loose objects away from all

openings. Always stop engine, disconnect spark plug, and make sure all moving parts have come to a complete stop

before removing obstructions, clearing debris, or servicing unit. Allow unit to cool before performing service. Wear

gloves to protect hands from sharp edges and hot surfaces.

Your ECHO blower is designed to provide many hours of trouble free service. Regular scheduled maintenance will help

your blower achieve that goal. If you are unsure or are not equipped with the necessary tools, you may want to take your

unit to an ECHO Service Dealer for maintenance. To help you decide whether you want to DO-IT-YOURSELF or have

the ECHO Dealer do it, each maintenance task has been graded. If task is not listed, see your ECHO Dealer for repairs.

s k I l l l e V e l

Level 1 = Easy to do. Common tools may be required.

Level 2 = Moderate difculty. Some specialized tools may be required.

ECHO offers REPOWERTM Maintenance Kits and Parts to make your maintenance job easier.

m a I n T e n a n C e I n T e r V a l s

Page 20

20

a I r f I l T e r

Level 1.

Tools required: 25 - 50mm (1 - 2 in.) cleaning brush

Parts required: Tune Up Kit

NOTE

Always brush dirt and debris away from air cleaner area prior to

cleaning air lter.

1. Brush dirt off air cleaner area. Keep dirt away from engine and

air intake grid.

2. Remove air lter cover. Brush dirt from inside cover and away

from edges of air lter.

3. Check air lter seal for tight t with air lter case.

4. Remove air lter from case. Use care to prevent dirt and debris

from falling into air lter case.

5. Inspect lter element and seal. Replace lter if any of these prob-

lems are present:

•Air lter seal does not t tightly against case

•Air lter seal is distorted, worn, or damaged

•Air lter element has holes or other damage

•Air lter element is saturated with dirt

•Air lter element is soaked with fuel mix

6. If air lter is in good condition and can be cleaned and reused,

lightly brush debris from air lter element, or blow lter element

clean using low pressure (40 psi or less) compressed air directed

at inside of lter.

IMPORTANT

When using compressed air, always direct air stream at inside sur-

face of lter so dust and debris will be blown out of lter. Keep air

nozzle 6 - 8 inches away from lter to prevent damage to lter.

7. Install air lter in case, and replace cover.

NOTICE

Actual replacement interval for air lter depends on operating conditions. Operation in dustier applications requires more frequent

cleaning and replacement. Continued operation with a damaged

or excessively dirty lter will allow dirt and debris to enter engine,

and result in poor performance, rapid engine wear, and premature

engine failure.

Page 21

Po w e r Bl o w e r

oP e r a t o r 's Ma n u a l

21

f u e l

Level 1.

Tools required: 200 - 250 mm (8 - 10 in.) length of wire with one end

bent into a hook, clean rag, funnel, and an approved

fuel container

Parts required: Repower

f I l T e r

TM

Tune Up Kit

DANGER

Fuel is VERY ammable. Use extreme care when mixing, storing

or handling.

1. Use a clean rag to remove loose dirt from around fuel cap and

empty fuel tank.

2. Use the “fuel line hook” to pull the fuel line and lter from the

tank.

3. Remove the lter from the line and install the new lter.

s p a r k p l u G

Level 1.

Tools required: 19mm Spark Plug deep socket, Feeler gauge

Parts Required: Repower

IMPORTANT

Use only NGK BPM-8Y spark plug (BPMR-8Y in Canada)

otherwise severe engine damage may occur.

1. Remove spark plug , and check for fouling, worn and rounded

center electrode.

2. Clean the plug or replace with a new one. DO NOT sand blast to

clean. Remaining sand will damage engine.

3. Adjust spark plug gap by bending outer electrode.

4. Tighten spark plug to 150-170 kgf • cm (130-150 in • lbf).

TM

Tune Up Kit

0.65 mm

(0.026 in.)

Page 22

22

C o o l I n G s y s T e m

Level 2.

Tools required: 25 - 50mm (1 - 2 in.) cleaning brush, Cross Head

Screwdriver

Parts Required: None, if you are careful.

IMPORTANT

To maintain proper engine operating temperatures, cooling air must

pass freely through the cylinder n area. This ow of air carries combustion heat away from the engine.

Overheating and engine seizure can occur when:

• Air intakes are blocked, preventing cooling air from reaching the

cylinder.

• Dust and grass build up on the outside of the cylinder. This build up

insulates the engine and prevents the heat from leaving.

Removal of cooling passage blockages or cleaning of cooling ns is

considered “Normal Maintenance.” Any failure attributed to lack of

maintenance is not warranted.

Cleaning Grill

1. Remove accumulated debris from intake grill between backpack

frame and blower housing.

Cleaning Cylinder Fins

1. Remove spark plug and engine cover (four screws), pull cover

away from engine.

2. Clean cylinder ns (A) to allow cooling air to pass freely.

3. Install engine cover and spark plug.

A

Page 23

e X h a u s T s y s T e m

Spark Arrestor Screen

Level 2.

Tools required: Cross Head Screwdriver

Parts Required: Spark arrestor screen, Gaskets

WARNING

Do not perform maintenance on engine or mufer until engine and

mufer are completely cool, otherwise serious personal injury may

result.

Po w e r Bl o w e r

oP e r a t o r 's Ma n u a l

23

IMPORTANT

Carbon deposits in mufer will cause a drop in engine output and

overheating. Spark arrestor screen must be checked periodically.

1. Remove spark plug and engine cover (four screws).

2. Remove spark arrestor covers (A), gaskets (B), and spark arrestor

screen (C) from mufer. Replace screen if plugged with carbon

deposits.

NOTE

When cleaning carbon deposit, be careful not to damage the cata-

lytic element inside mufer.

3. Install spark arrestor screen and cover.

4. Install spark plug and engine cover.

C

B

A

Page 24

24

Exhaust Port Cleaning

Level 2

Tools required: Wood or plastic scraper, Cross Head Screwdriver,

4 & 5mm Hex Wrench

Parts Required: As needed: Mufer gasket

1. Remove spark plug lead from spark plug, and remove engine

cover (5 screws).

2. Place piston at top dead center. Remove mufer (A) and mufer

gasket (B ).

3. Use a wood or plastic scraping tool to clean deposits from cylinder exhaust port.

IMPORTANT

Never use a metal tool to scrape carbon from the exhaust port.

Do not scratch the cylinder or piston when cleaning the exhaust

port. Do not allow carbon particles to enter the cylinder.

4. Inspect mufer gasket, and replace if damaged.

5. Install mufer gasket and mufer.

6. Tighten mufer mounting bolts (or nuts) to 80-95 in•lbf

(90-110 kgf•cm).

7. Start engine, and warm to operating temperature.

8. Stop engine, and re-tighten mounting bolts (or nuts) to specications.

9. Install engine cover and attach spark plug lead.

Page 25

Po w e r Bl o w e r

oP e r a t o r 's Ma n u a l

25

C a r b u r e T o r

a d J u s T m e n T

Engine Break-In

New engines must be operated a minimum duration of two tanks of fuel

break-in before carburetor adjustments can be made. During the breakin period your engine performance will increase and exhaust emissions

will stabilize. Idle speed can be adjusted as required.

High Altitude Operation

This engine has been factory adjusted to maintain satisfactory starting,

emission, and durability performance up to 1,100 feet mean sea level

(MSL) (96.0 kPa and below). To maintain proper engine operation and

emission compliance above 1,100 feet MSL the carburetor may need to

be adjusted by an authorized ECHO service dealer.

IMPORTANT

If the engine is adjusted for operation above 1,100 feet MSL, the

carburetor must be re-adjusted when operating the engine below

1,100 feet MSL, otherwise severe engine damage can result.

Level 2.

Tools required: Screwdriver, tachometer (Echo P/N 99051130017)

Parts required: None.

NOTE

Do not adjust carburetor unless necessary. If you have difculty,

see your ECHO dealer.

Before Adjustment

Check that:

• Air lter is clean and properly installed.

• Spark arrestor screen is free of carbon.

• Blower pipes are installed.

1. Start engine, run at idle for one minute.

2. Complete warm up by running at full throttle for 5 minutes, operating choke twice to clear air from carburetor chambers.

3. Check idle speed and reset if necessary. If a tachometer is avail-

able, idle speed screw (A) should be set to the specications

found on Page 28 "Specications" of this manual. Turn idle

screw (A) clockwise to increase idle speed; counter clockwise to

decrease idle speed.

A

4. Use a tachometer to adjust idle speed to specications found on

page 28.

Page 26

26

TRAHCGNITOOHSELBUORT

melborPkcehCsutatSesuaCydemeR

-sknarcenignE

/drahstrats

t'nseod

trats

roterubractaleuFroterubractaleufoNdeggolcreniartsleuF

deggolcenilleuF

roterubraC

ecalperronaelC

ecalperronaelC

relaedohcEruoyeeS

rednilyctaleuFrednilyctaleufoNroterubraCrelaedohcEruoyeeS

leufhtiwtewrelffuMhcirooterutxiMleuFekohcnepO

retlifriaecalper/naelC

roterubractsujdA

relaedohcEruoyeeS

dnetakrapS

eriwgulpfo

krapsoNffohctiwspotS

melborp

lacirtcelE

hctiwskcolretnI

NOothctiwsnruT

relaedohcEruoyeeS

relaedohcEruoyeeS

gulptakrapSkrapsoNtcerrocnipagkrapS

nobrachtiwderevoC

leufhtiwdeluoF

evitcefedgulP

).ni620.0(mm56.ottsujdA

ecalperronaelC

ecalperronaelC

gulpecalpeR

,snurenignE

roseidtub

tonseod

etarelecca

ylreporp

retlifriAytridretlifriAraewlamroNecalperronaelC

retlifleuFytridretlifleuFseudiser/stnanimatnoCni

leuf

ecalpeR

tnevleuFdeggulptnevleuFleufniseudiser/stnanim

atnoCecalperronaelC

gulPkrapSnrow/ytridgulPraewlamroNecalperrotsujdadnanaelC

roterubraCtnemtsujdareporpmInoitarbiVtsujdA

metsySgnilooCmetsysgnilooC

deggulp/ytrid

ninoitarepodednetxE

snoitacolytsud/ytrid

naelC

neercSrotserrAkrapSneercsrotserrakrapS

deggulp

raewlamroNecalpeR

seodenignE

knarcton

A/NA/NmelborpenignelanretnIrelaedohcEruoyeeS

,snurenignE

t'nseodrewolb

sirokrow

nevenu/kaew

epiprewolBdeggolcepiPsirbedfopu-dliuBgolcnU

esool

epiPnoitarbiVnethgiT

degamadepiPesusiM/raeWecalpeR

Tr o u b l e s h o o T I n G

DANGER

Fuel vapors are extremely ammable and may cause re and/or explosion. Never test for ignition spark by grounding spark plug near cylinder plug hole, otherwise serious personal injury may result.

Page 27

Po w e r Bl o w e r

oP e r a t o r 's Ma n u a l

sT o r a G e

WARNING

During operation the mufer or catalytic mufer and surrounding cover become hot. Always keep exhaust area clear

of ammable debris during transportation or when storing, otherwise serious property damage or personal injury may

result.

Long Term Storage (Over 30 Days)

Do not store your unit for a prolonged period of time (30 days or longer) without performing protective storage maintenance which includes the following:

1. Store unit in a dry, dust free place, out of the reach of children.

7. Remove the spark plug and pour 7cc (1/4 oz.) of

DANGER

Do not store in enclosure where fuel fumes may ac-

cumulate or reach an open ame or spark.

fresh, clean ECHO 2-stroke engine oil into the cylinder through the spark plug hole.

A. Place a clean cloth over the spark plug hole.

27

2. Place the stop switch in the "STOP" position.

3. Remove accumulation of grease, oil, dirt and debris

from exterior of unit.

4. Perform all periodic lubrication and services that are

required.

5. Tighten all screws and nuts.

6. Drain the fuel tank completely and pull the recoil

starter handle several times to remove fuel from the

carburetor.

B. Pull the recoil starter handle 2-3 times to

distribute the oil inside the engine.

C. Observe the piston location through the spark

plug hole. Pull the recoil handle slowly until the

piston reaches the top of its travel and leave it

there.

8. Install the spark plug (do not connect ignition cable).

9. Remove blower pipe assembly from unit.

Page 28

28

sp e C I f I C a T I o n s

MODEL ---------------------------------------------------- PB-755H, PB-755T

Length ------------------------------------------------------ 375 mm (14.8 in.)

Width -------------------------------------------------------- 485 mm (19 in.)

Height ------------------------------------------------------- 527 mm (20.8 in.)

Weight (dry) (PB-755H) --------------------------------- 11.8 kg (26.2 lb.)

Weight (dry) (PB-755T) ---------------------------------- 11.8 kg (26.2 lb.)

Engine Type ------------------------------------------------ Air cooled, two-stroke, single cylinder gasoline engine

Displacement ----------------------------------------------- 63.3 cc (3.86 cu. in.)

Bore ---------------------------------------------------------- 48.0 mm (1.89 in.)

Stroke -------------------------------------------------------- 35.0 mm (1.38 in.)

Carburetor--------------------------------------------------- Walbro w/primer bulb

Ignition System -------------------------------------------- Flywheel Magneto, capacitor discharge ignition type

Spark Plug -------------------------------------------------- NGK BPM-8Y Gap 0.65 mm (0.026 in.)

Exhaust System -------------------------------------------- Spark Arrestor - Catalytic Mufer / Mufer

Fuel ---------------------------------------------------------- Mixed (Gasoline and Two-stroke Oil)

Fuel/Oil Ratio ---------------------------------------------- 50 : 1 Power Blend X TM ISO-L-EGD (ISO/CD 13738) and

J.A.S.O. M345- FC/FD, two-stroke, air-cooled engine oil.

Gasoline ----------------------------------------------------- Use 89 Octane unleaded. Do not use fuel containing methyl

alcohol, more than 10% ethyl alcohol or 15% MTBE. Do not use

alternative fuels such as E-20 or E-85.

Oil ------------------------------------------------------------ Power Blend X TM Premium Universal 2-Stroke Oil

Fuel Tank Capacity ---------------------------------------- 2.0 lit. (67.7 US . oz.)

Recoil Starter System ------------------------------------- Automatic Recoil Starter Centrifugal Type

Idle Speed -------------------------------------------------- 2400 - 3200 (RPM)

Wide Open Throttle Speed ------------------------------- 6800 - 7300 (RPM)

Maximum Air Speed (Measured at pipe end) --------- 329.9 KM/H (205 mph)

Average Air Volume (Measured at pipe end) ---------- 17.6 m3/min. (620 cu. ft./min.)

Sound Level at 50 ft. dB(A) scale per ANSI B175.2 - 74 dB(A)

Page 29

n o T e s

Po w e r Bl o w e r

oP e r a t o r 's Ma n u a l

29

Page 30

30

n o T e s

Page 31

n o T e s

Po w e r Bl o w e r

oP e r a t o r 's Ma n u a l

31

Page 32

se r V I C I n G In f o r m a T I o n

p a r T s

Genuine ECHO Parts and ECHO REPOWER™ Parts and Assemblies

for your ECHO products are available only from an Authorized ECHO

Dealer. When you do need to buy parts always have the Model Num-

ber, Type and Serial Number of the unit with you. You can nd these

numbers on the engine housing. For future reference, write them in the

space provided below.

Model No. _____________ Type _________SN. ______________

/s e r I a l n u m b e r

s e r V I C e

Service of this product during the warranty period must be performed

by an Authorized ECHO Service Dealer. For the name and address of

the Authorized ECHO Service Dealer nearest you, ask your retailer or

call: 1-800-432-ECHO (3246). Dealer information is also available on

our Web Site. When presenting your unit for Warranty service/repairs,

proof of purchase is required.

e C h o C o n s u m e r p r o d u C T s u p p o r T

If you require assistance or have questions concerning the application, operation or maintenance of this product you may call the ECHO

Consumer Product Support Department at 1-800-673-1558 from 8:30

am to 4:30 pm (Central Standard Time) Monday through Friday. Before

calling, please know the model and serial number of your unit to help

your Consumer Product Support Representative.

DEALER?

Call

1-800-432-ECHO

1-800-432-3246

or

www.echo-usa.com

CONSUMER PRODUCT

SUPPORT

1-800-673-1558

8:30 - 4:30 Mon - Fri C.S.T.

W a r r a n T y r e G I s T r a T I o n

To ensure trouble free warranty coverage it is important that you register your ECHO equipment on-line at www.echo-usa.com. Other registration options are by automated phone at 1-800-432-3246 or by lling

out the warranty registration card supplied with your unit. Registering

your product conrms your warranty coverage and provides a direct

link between you and ECHO if we nd it necessary to contact you.

a d d I T I o n a l o r r e p l a C e m e n T m a n u a l s

Safety Manuals in English/Spanish or English/French are available, free of charge, from your ECHO dealer or at www.

echo-usa.com.

Operator's and Parts Manuals are available by:

• Downloading free from www.echo-usa.com

• Purchasing from your Echo Dealer.

• Manuals are available by sending a written request stating the model number and serial number of your Echo unit, part

number of the manual, your name and address, and mail to the address below.

Safety Videos are available from your Echo dealer. A $5.00 shipping charge will be required for each video.

ECHO, INCORPORATED

400 Oa k w O O d RO a d

La k e Zu R i c h , iL 60047

(H) P08511001001/P08511999999

(H) P10012001001/P10012999999

www.echo-usa.com

(T) P08611001001/P08611999999

(T) P10812001001/P10812999999

Loading...

Loading...