Page 1

OPERATOR’S MANUAL

ENGINE CUT-OFF SAW

CSG-7410

WARNING

The engine exhaust from this product contains chemicals known to the

State of California to cause cancer, birth defects or other reproductive

harm.

Cancer and Reproductive Harm

www.P65Warnings.ca.gov

WARNING

Read the instructions carefully and follow the rules for safe

operation.

Failure to do so could result in serious injury.

ECHO, INCORPORATED

400 Oakwood Road, Lake Zurich, Illinois 60047-1564

Phone : 847-540-8400

Printed in USA

X7503954100

Page 2

INTRODUCTION

The ECHO model CSG-7410 Engine Cut-off saw is

a high-performance gasoline-powered tool designed for use with a recommended 350 x 4.7 x 20

mm (14 in. x 6/32 in. x 25/32 in.) abrasive wheel. A

water-flush attachment is available for dust control.

Use only ECHO’s wheels or other wheels having

a minimum spindle speed rating of 3820 rpm or

higher.

This manual provides the information necessary for

assembly, operation and maintenance of the cutoff saw as well as the wheels available for it. It is

important that you follow this information carefully.

WARNING

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to

the State of California to cause cancer, birth

defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement

and other masonry products, and

• Arsenic and chromium from chemically

treated lumber.

Your risk from these exposures varies,

depending on how often you do this type

of work. To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

such as those dust masks that are specially

designed to filter out microscopic particles.

WARNING

Improper use or care of this unit, or failure to

wear proper protection can result in serious

injury.

Read the rules for safe operation and instructions in this manual.

Wear eye and hearing protection and a dust

mask when operating.

Breathing in asbestos fibers can pose a

serious health risk and may cause severe

or fatal respiratory diseases such as lung

cancer. Do not use your engine cut-off saw to

cut, damage, or disturb asbestos or products

using asbestos in any form. If you believe

you might be cutting asbestos, contact your

employer immediately.

CONTENTS

Introduction ............................................ 2

Symbols and Signs ................................ 3

Packing List ........................................... 5

Nomenclature of Parts ........................... 6

Operator Safety Precautions ................. 8

Operator Safety ..................................... 10

Abrasive Wheel Types and Uses ........... 12

Preparation for Use ............................... 15

Fuel and Lubricant ................................. 18

Specifications, descriptions and illustrations in this manual were accurate at the time of publication, and

are subject to change without notice. Illustrations may include optional equipment and accessories, and

may not include all standard equipment.

Copyright

CSG-7410

©

2018

All Rights Reserved.

Emission Data ....................................... 20

Operation ............................................... 20

Cutting Instruction ................................. 23

Maintenance and Care .......................... 24

Troubleshooting ..................................... 31

Storage After Use .................................. 32

Technical Data ....................................... 34

Warranty Registration Sheet .................. 34

Notes ..................................................... 35

2

Page 3

SYMBOLS AND SIGNS

DANGER

The safety alert symbol accompanied by

the word “DANGER” calls attention to an

act or condition which WILL lead to serious

personal injury or death if not avoided.

WARNING

The safety alert symbol accompanied by

the word “WARNING” calls attention to an

act or condition which CAN lead to serious

personal injury or death if not avoided.

CAUTION

The safety alert symbol accompanied by

the word “CAUTION” calls attention to an

act or condition which may lead to minor or

moderate personal injury if not avoided.

Decals

CIRCLE AND SLASH SYMBOL

This symbol means the specific action

shown is prohibited. Ignoring these

prohibitions can result in serious or

fatal injury.

NOTE

This enclosed message provides tips for use,

care and maintenance of the unit.

IMPORTANT

The enclosed message provides information

necessary for the protection of the unit.

Locate the safety decals on your unit. The complete

unit illustration found in the “NOMENCLATURE OF

PARTS” section will help you locate them.

Make sure the decal is legible and that you

understand and follow the instructions on it. If a

decal cannot be read, a new one can be ordered

from your ECHO dealer.

3

CSG-7410

Page 4

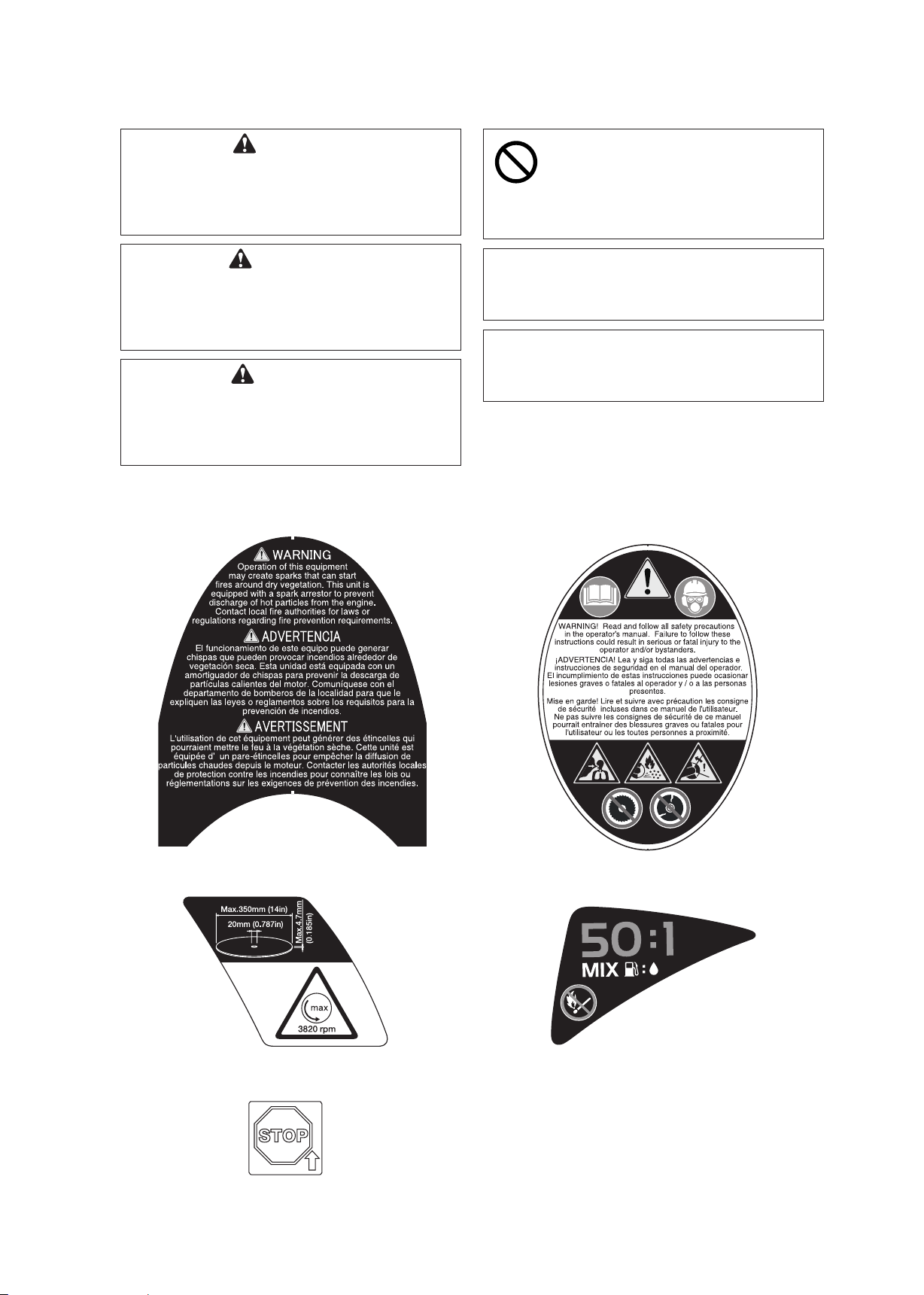

SYMBOL FORM

Symbol form/shape Symbol description/application Symbol form/shape Symbol description/application

WARNING!!

Read and follow all safety

precaution in the Operator's

Manual. Failure to follow

instructions could result in

serious personal injury.

Always wear an ear muffler,

a dust proof mask, goggles

and a helmet when operating

this machine. (ANSI Z87.1)

Choke control

Oil and gasoline mixture

Do not run the engine

indoors, or where there is

poor ventilation.

Cutting may cause sparks

from the cut-off wheel. Make

sure there is no flammable

substance nearby.

Kickback may force the

cutting-off wheel up and

back toward the operator

with a lightning-fast reaction.

Kickback can occur

whenever the upper-half of

the cutting-off wheel touches

an object while operating the

machine.

Usage of saw blades not

permitted.

L

Make sure there are no

breaks,cracks or warps.

Wheel rorating direction Max

spindle speed

Purge pump

Decompression device

Carburetor adjustment

- Low speed mixture

Carburetor adjustment

- High speed mixture

H

CSG-7410

Emergency stop

Keep away from fire.

Carburetor adjustment

- Idle speed

T

4

Page 5

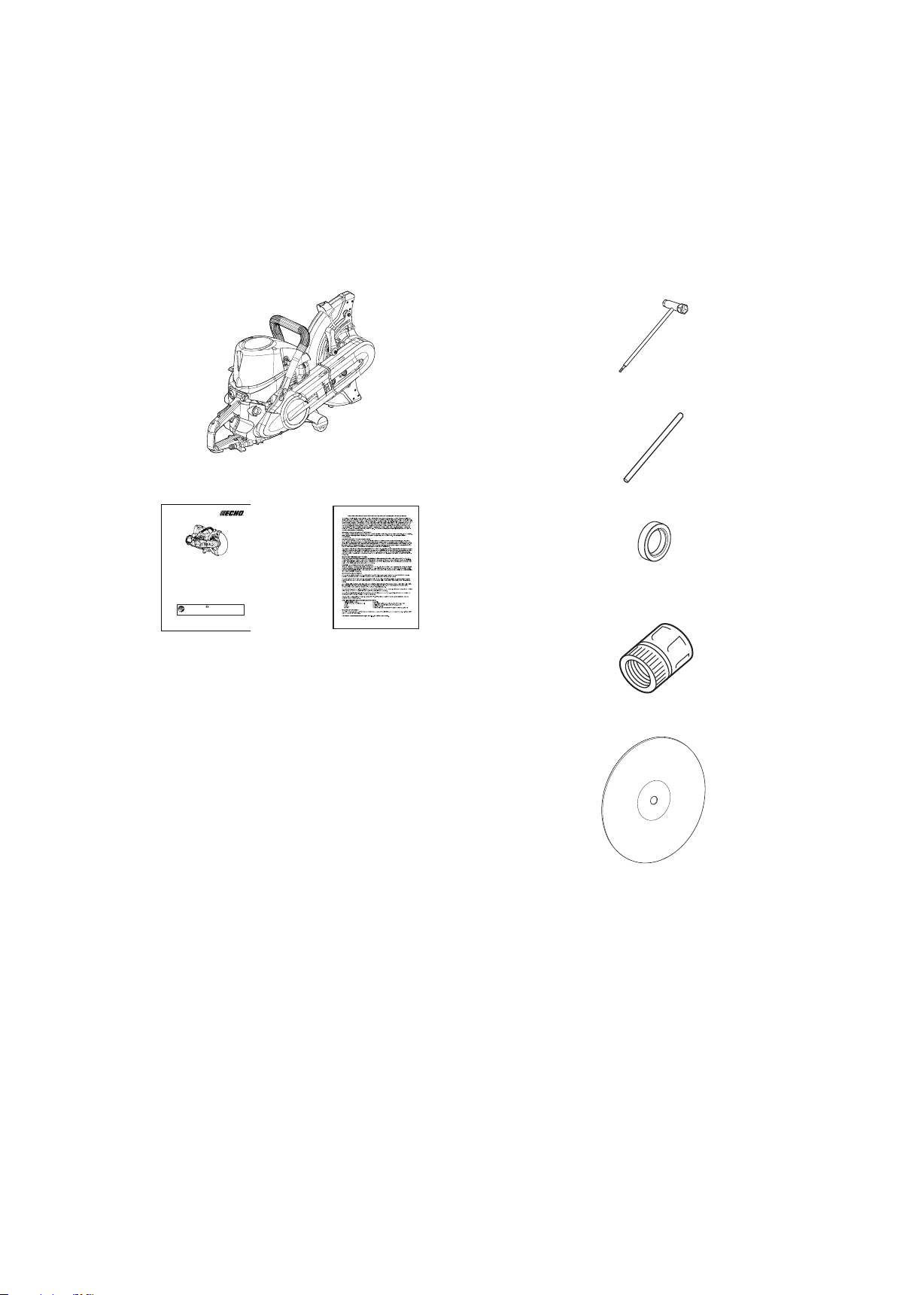

PACKING LIST

The ECHO product you purchased has been

factory pre-assembled for your convenience.

Due to packaging restrictions, wheel installation

and other assembly may be necessary.

ECHO engine cut-off saw

Operator's manual

OPERATOR’S MANUAL

ENGINE CUT-OFF SAW

CSG-7410

WARNING

Read the instructions carefully and follow the rules for safe

operation.

Failure to do so could result in serious injury.

ECHO, INCORPORATED

400 Oakwood Road, Lake Zurich, Illinois 60047-1564

Phone : 847-540-8400

Printed in USA

X750 395-410 0

Warranty sheet

• •

• •

• •

• •

• •

After opening the carton, check for damage.

Immediately notify your retailer or ECHO dealer of

damaged or missing parts.

Use the packing list to check for missing parts.

13 x 19 mm T-wrench

Bar tool

Adapter (25.4 mm)

Coupler

Wheel

5

CSG-7410

Page 6

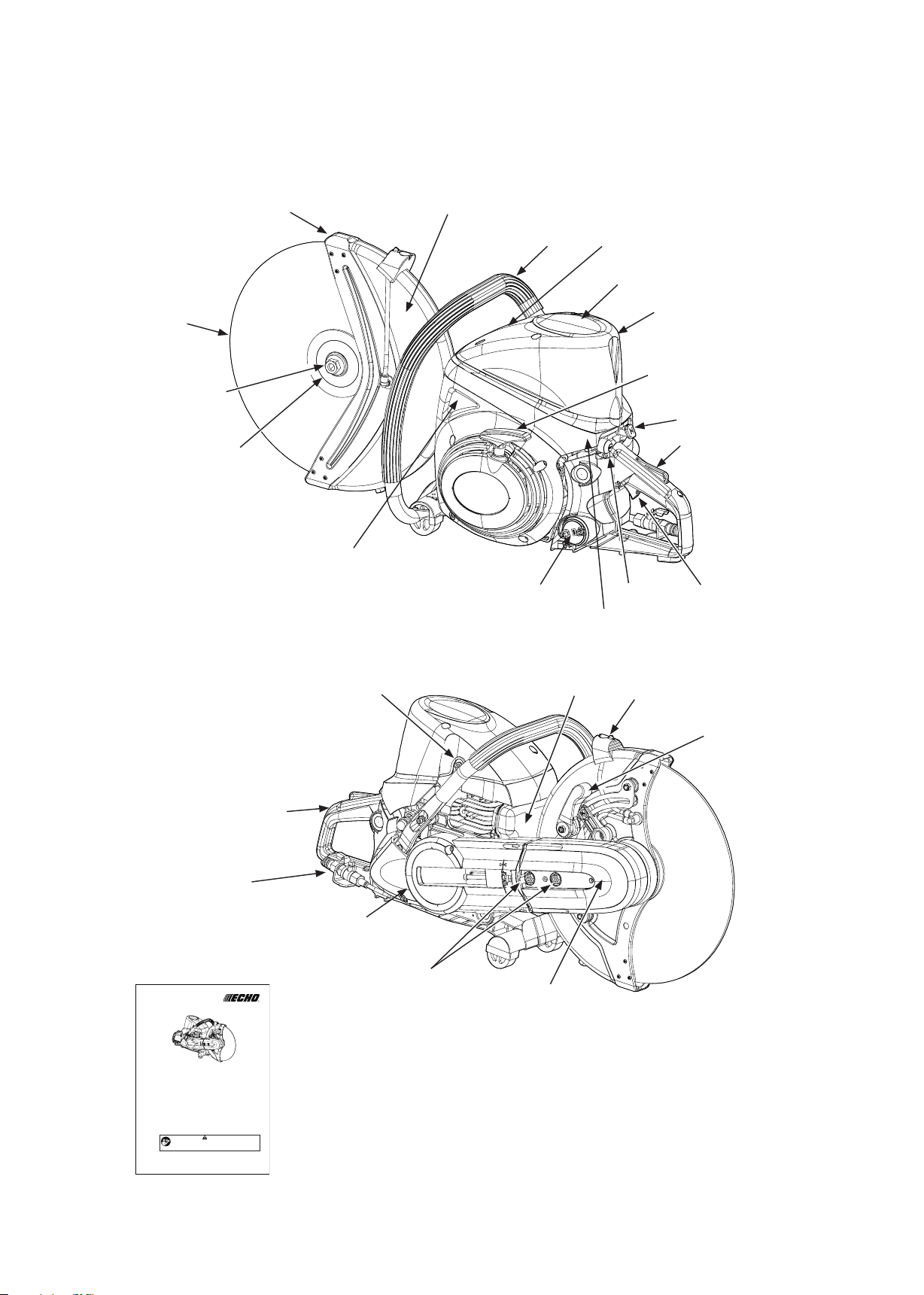

NOMENCLATURE OF PARTS

3

23

2

23

23

4

13

12

5

11

6

10

23

7

8

9

23

15

1

OPERATOR’S MANUAL

ENGINE CUT-OFF SAW

CSG-7410

14

16

22

17

18

21

20

19

CSG-7410

Read the instructions carefully and follow the rules for safe

operation.

Failure to do so could result in serious injury.

ECHO, INCORPORATED

400 Oakwood Road, Lake Zurich, Illinois 60047-1564

Phone : 847-540-8400

Printed in USA

WARNING

X750 395-410 0

6

Page 7

NOMENCLATURE OF PARTS

1. Operator's manual - Included with unit.

Read before operation and keep for future

reference to learn proper, safe operating

techniques.

2. Front handle (for the left hand) - Support

handle located at the front of the engine

housing.

3. Wheel guard - A wheel guard which is intended to protect the operator from wheel contact, and also direct debris away from the

operator.

4. Wheel - Serving as a cutting tool.

5. Wheel mouting bolt - Bolt that secures the

flange.

6. Cutter flange - Part that secures the cutting

wheel.

7. Fuel tank cap - For closing the fuel tank.

8. Momentary stop switch - Button for momen-

tarily shorting ignition voltage, causing the

engine to stop. This is NOT an ON/OFF

Ignition switch.

9. Throttle trigger - Device activated by the

operator’s finger, for controlling the engine

speed.

10. Throttle trigger lockout - A safety lever which

must be depressed before the throttle trigger

can be activated in order to prevent the

accidental operation of the throttle trigger.

11. Choke control knob - Device for enriching the

fuel/air mixture in the carburetor to aid cold

starting. Also activates fast idle throttle latch.

12. Starter grip - Pull handle slowly until starter

engages then quickly and firmly.

When engine starts, return handle slowly.

Do not let handle snap back or damage to

unit will occur.

13. Air cleaner cover - Covers air cleaner.

14. Rear handle (for the right hand) - Support

handle located towards the rear of the

engine housing.

15. Water kit - Supplies water while cutting to keep

dust from scattering.

16. Clutch cover - Protective belt and clutch when

the engine cut-off saw is in use.

17. Arm mounting bolts - Secures the cut-off saw.

18. Pulley Cover - Protects the belt and pulley.

19. Wheel guard locking knob - For use when

changing the angle of the wheel guard.

Wheel guard knob - Grip and move this knob

20.

when changing the angle of the wheel guard.

21. Spark arrestor muffler - The spark arrestor

muffler controls the exhaust noise and

prevents hot, glowing particles of carbon

from leaving the muffler.

22. Decompression device - Device for lowering

the compression in the cylinder, to aid

starting.

23. Safety labels - Device for lowering the compression in the cylinder, to aid

starting.

7

CSG-7410

Page 8

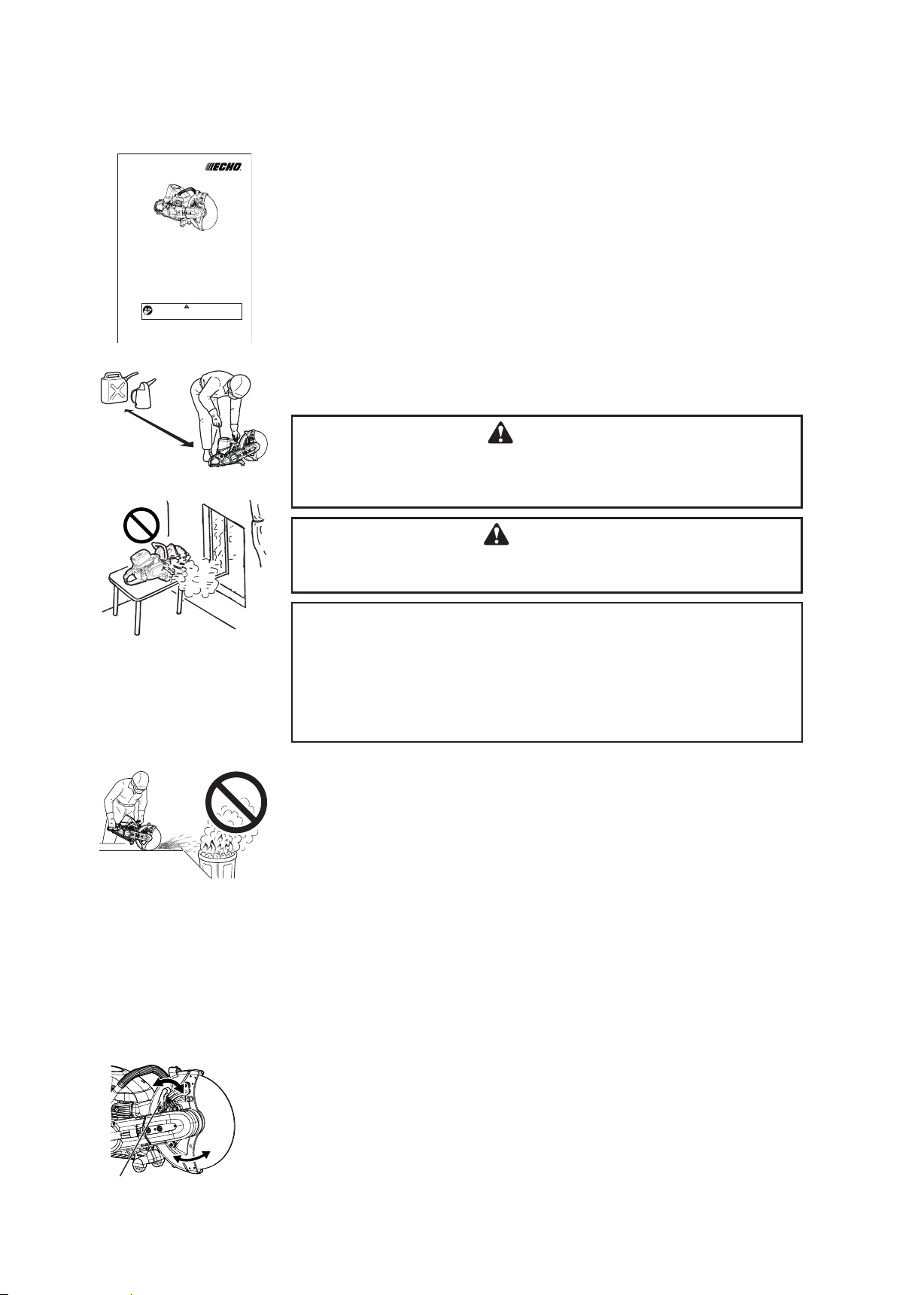

OPERATOR SAFETY PRECAUTIONS

Read this engine cut-off saw operator’s manual carefully.

Be sure you understand how to operate this saw properly before you use it.

Establish a training program for engine cut-off saw operators.

OPERATOR’S MANUAL

ENGINE CUT-OFF SAW

Read the instructions carefully and follow the rules for safe

operation.

Failure to do so could result in serious injury.

ECHO, INCORPORATED

400 Oakwood Road, Lake Zurich, Illinois 60047-1564

Phone : 847-540-8400

Printed in USA

3 m

WARNING

CSG-7410

X750 395-410 0

Use safety footwear, snug-fitting clothing and protective gloves.

Wear eye, hearing and head protection devices. Use ballistics chaps or pants

when necessary. Clothing of fire-resistant and non-meltable material should

be worn by emergency crews exposed to flames or high heat conditions.

Use caution when handling fuel. Put the fuel tank caps back tightly on both

the fuel container and the saw tank, move at least 3 m (10 ft.) from the

fueling point, and be sure there is no leakage of fuel from the fuel tank cap or

the fuel system before starting the engine. Avoid ignition from sparks.

DANGER

After refuelling, tighten fuel cap firmly and check for leakage.

In case of fuel leakage repair before starting operation since there is

a danger of fire.

WARNING

Do not run the engine indoors, or where there is poor ventilation.

Engine fumes contain deadly poisonous carbon monoxide.

IMPORTANT

Check before every use.

After refuelling, make sure fuel does not leak from around fuel pipe, fuel

grommet or fuel tank cap.

In case of fuel leakage there is a danger of fire. Stop using the machine

immediately and request your dealer to inspect or replace.

It is not permitted to fill fuel above the shoulder level of fuel tank.

Adjust Wheel guard

Wheel guard locking knob

CSG-7410

Operate this gasoline engine cut-off saw only in well-ventilated areas.

Do not store the unit with fuel in its tank, because a fuel leak could start a

fire.

Do not cause sparks in any area where there are flammable materials.

Start the engine cut-off saw on the ground with the cutting wheel completely

in the clear.

Do not drop-start the engine cut-off saw, or start it if the wheel is obstructed

by the ground or any other object.

Do not allow other persons to be closer than 9 m (30 ft.) when you are

starting or cutting with the saw. Bystanders should wear hearing and eye

protection. Do not start cutting unless you have good footing and the work

area is clear.

Do not let someone hold the work you are cutting.

Adjust the wheel guard to a position where the sparks and debris from the

wheel will be thrown away from you. Turn the wheel guard locking knob

counterclockwise, grasp the wheel guard knob and move the wheel guard to

the desired position, slowly release it and secure the wheel guard with the

locking knob. Do not operate if the wheel guard is damaged, missing from

the unit, improperly positioned, or cannot be locked in proper position.

8

Page 9

Keep to Left of

Cutting Line

Keep a firm grip on the engine cut-off saw with both hands, the right hand

on the rear handle, and the left hand on the front handle when the engine is

running. Use a firm grip with thumbs and fingers encircling the saw handles.

A firm grip will help you to keep control if the saw kickback toward you, or the

thrust of the rotating wheel pulls it away from you. Never operate the engine

cut-off saw with only one hand.

Be careful around electrical cables, sewer and gas lines to avoid cutting

them.

Keep to the left of the saw so that no part of your body is in line with the

cutting wheel. Keep all parts of your body away from the cutting wheel when

the engine is running.

Do all cutting at full throttle. Cutting at less than full speed can damage the

clutch by allowing it to slip. Accelerating from slow to full speed while the

wheel is in cutting contact may cause a violent push or pull reaction resulting

in loss of control.

It will take time for the wheel to coast to a stop after the throttle trigger is

released. Be sure to wait for rotation to stop before releasing your grip on the

saw handles. Always shut off the engine before setting down the saw.

Never leave the engine cut-off saw while the engine is running.

Put no Side

Pressure on

the Wheel

Check for Wheel

Damage

Always carry the saw with the engine stopped and the hot muffler away from

your body. Do not touch a hot muffler, wheel, cylinder cover or cylinder.

Do not touch high voltage parts such as spark plug and spark plug lead.

Remove the wheel from the saw prior to transport or storage. Store wheels

properly to avoid damage from uneven pressure, moisture and extreme

temperatures.

Do not grind on the side of an abrasive engine cut-off saw wheel, or put any

side pressure on the wheel during cutting. Avoid letting the saw tilt or wobble

off line.

Use new, properly qualified wheels of correct diameter, thickness and

mounting hole size. The wheel blotters and the mounting flanges should be

in good condition, and the mounting bolt should be tightened to the proper

torque.

Inspect the wheel carefully for cracks, edge damage and warping before use.

Do not use any wheel that has been dropped.

All adjustment and maintenance instructions in this operator’s manual

should be performed as necessary, and may be done by the saw owner. All

other service or adjustment should be performed only by a qualified ECHO

servicing dealer.

9

CSG-7410

Page 10

OPERATOR SAFETY

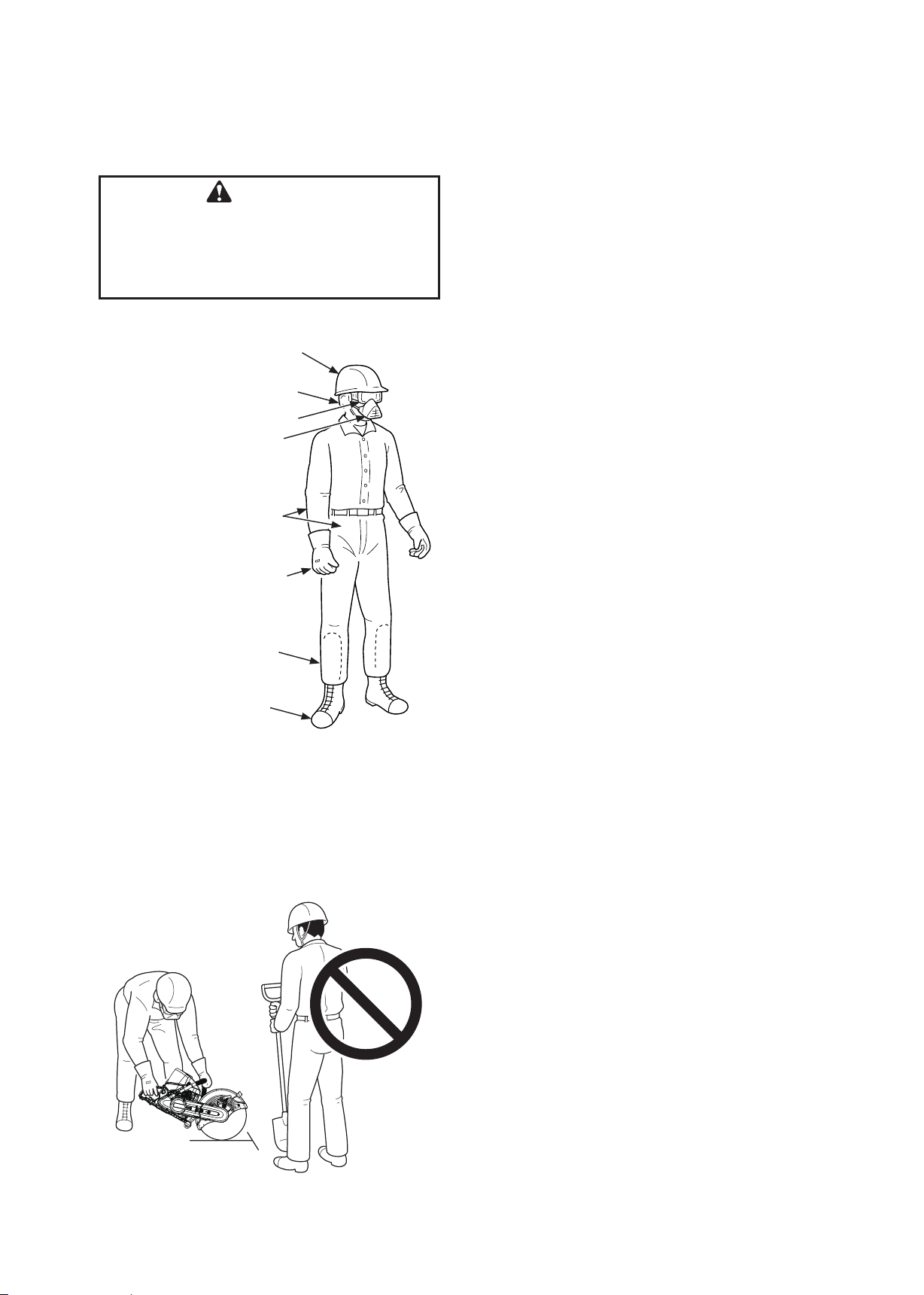

Protective Equipment

WARNING

Engine cut-off saw users risk injury if the

saw is used improperly, and / or safety precautions are not followed. Protective clothing

and safety gear must be worn when operating a engine cut-off saw.

Hard Hat

Hearing Protection

Goggles (Z 87)

Dust Mask or Respirator

Trim-Fitting

Protective Clothing

Heavy Duty non-Slip Gloves

Chaps or High Boots

for Spark Protection

You must wear eye protection goggles qualified

to the CE mark or the latest ANSI Standard Z 87.

(Z 87 is stamped on the goggles). These goggles

also must be worn under a face screen if one is

used. A face screen should be worn when there

is a risk from flying debris.

Hearing protection should be worn. (See

“DANGER,” page 23)

Wear a respirator or dust mask (APF10) when

cutting concrete, stone, brick or other materials

where fine dust is produced while cutting. Use

water flush to keep down the dust.

Clothing should be made from fabric containing

natural fibres that resist catching fire and do not

melt. The clothing should cover as much skin

area as possible. Clothing should offer freedom

of movement, but should not be too loose or

baggy. Do not wear ties or jewellery.

Wear heavy duty boots with non-slip soles. The

boots should be high enough for shin protection,

or you should wear chaps for shin protection.

Wear non-slip, heavy duty work gloves to

improve your grip on the saw handles. The

gloves also help to reduce the transmission of

machine vibrations to your hands.

Heavy Duty Boots

with non-Slip Soles

Protecting Others

No Bystanders!

Spectators children and fellow workers must be

warned to come no nearer than 9 m (30 feet) while

the saw is in use. Shut off the saw immediately if

some one moves closer to you than 9 m (30 feet).

Persons working in the area near you should wear

the same protective equipment as the saw operator

if endangered by risky flying debris.

CSG-7410

10

Page 11

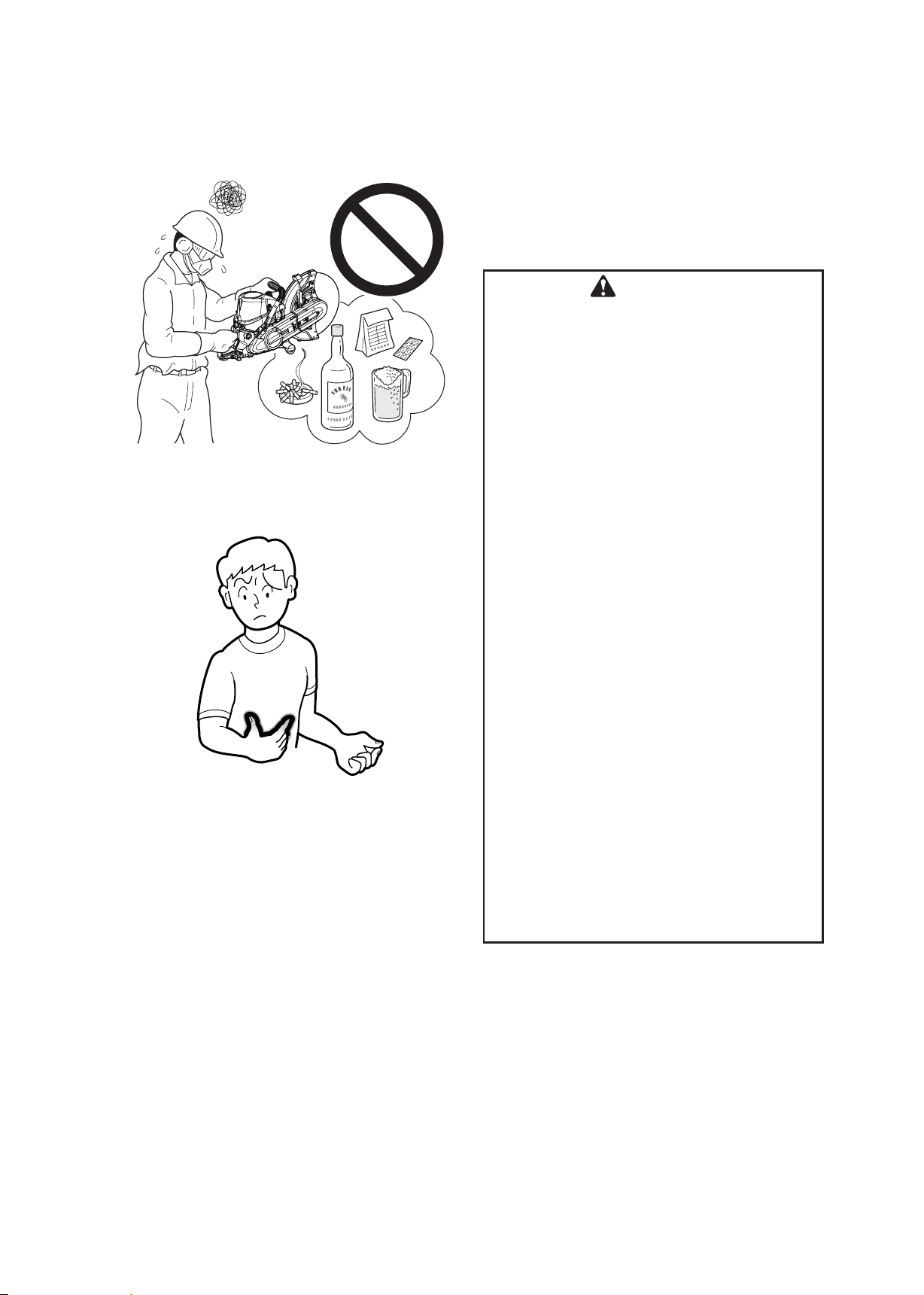

Physical Condition

Your judgment and / or dexterity may be impaired

if you are ill or have taken alcohol or other

substances known to affect the way you would

function normally. Operate only when sound in

mind and body.

WARNING

Precautions Against Vibration and Cold

It is believed that a condition called

Raynaud’s Phenomenon which affects the

fingers of certain individuals is brought

about by exposure to cold and vibration.

Accordingly, your ECHO Engine cut-off saw

has shock mounts designed to reduce the

intensity of vibration received through the

saw handles. Exposure to cold and vibration

may cause tingling and burning, followed by

loss of colour and numbness, in a person’s

fingers. We strongly recommend your

taking the following precautions because the

minimum exposure which might trigger the

ailment is unknown.

Keep your body warm – especially head,

neck, feet and ankles, and hands and

wrists.

Maintain good blood circulation by

performing vigorous arm exercises

during frequent work breaks, and also by

not smoking.

Limit the number of hours of engine cut-

off saw operation. Try to fill a part of each

work day with jobs where operating this

saw or

other hand-held power tools are not

required.

If you experience discomfort, redness and

swelling of the fingers, followed by

whitening and loss of feeling, consult your

physician before exposing yourself further

to cold and vibration.

11

CSG-7410

Page 12

ABRASIVE WHEEL TYPES AND USES

ECHO Reinforced Wheels

ECHO Wheels are labelled for the type of materials they are designed to cut.

The types of wheels identified below, and other types, may be available from ECHO dealer.

WARNING

This saw includes an abrasive wheel and a water system.

Do not use water with an abrasive wheel.

Labeled Application Primary Use Other Uses Dry or Water Flush

General purpose mild and

Metal

Ductile

Rail Track

Masonry

Diamond Wheel Rock, block, stone, tile

stainless steel: re-bar, pipe

and structural steel

Ductile or cast Iron and

concrete lined pipe

Heat treated, wear hardened

and alloyed steel

All masonry, concrete and

stone products and asphalt

Aluminum and soft

brass. Does not cut

non-metals very well

AII except very hard

metals

Not for non-metals Dry

Not for metals

Not for metal or

reinforced concrete

Dry

Dry. Does not cut well

when wet

Constant Water Flush

or Dry

Dry

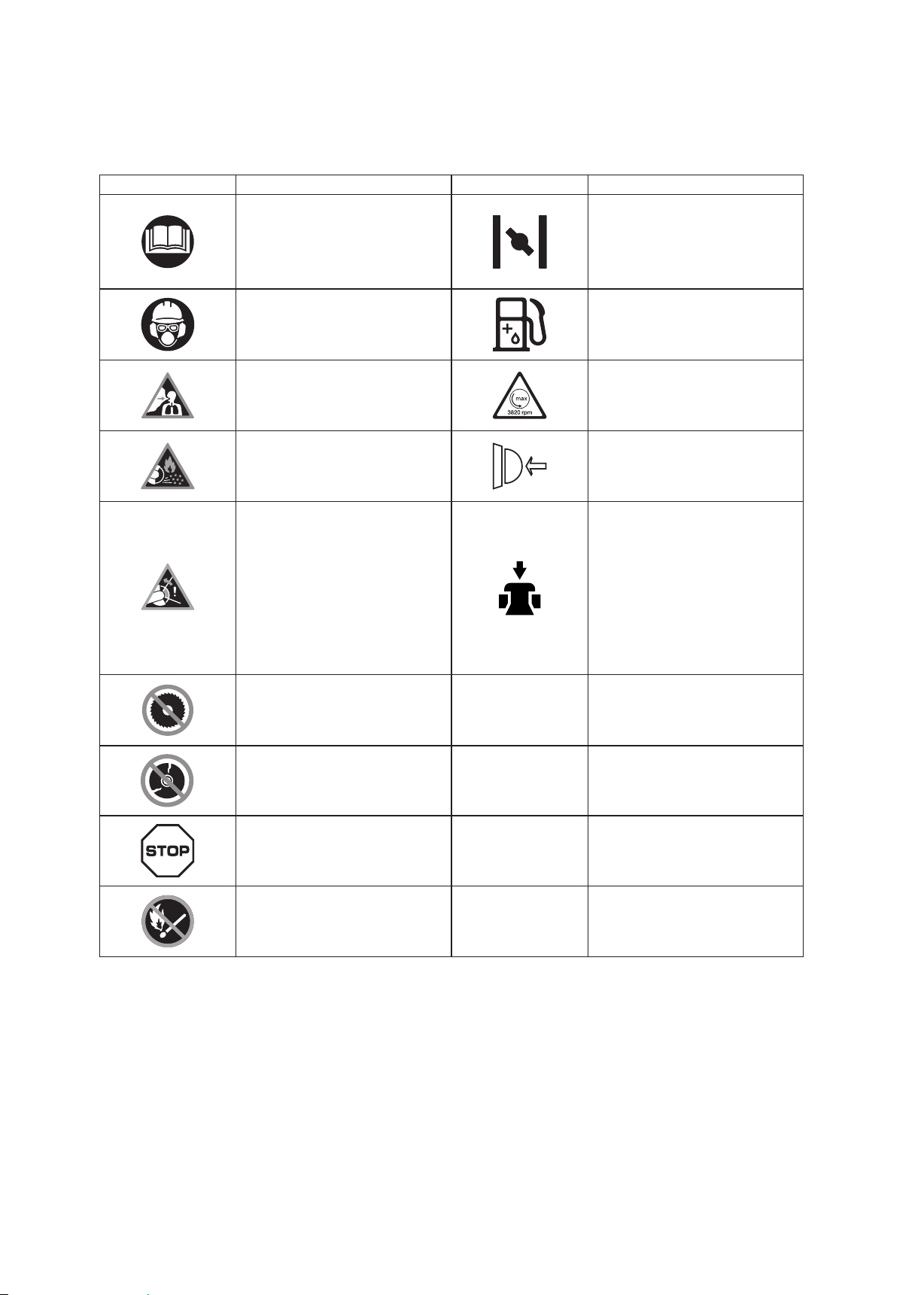

Wheel Speed Rating

This is the minimum acceptable wheel speed rating for this unit. Wheels rated

less than 3820 rpm must not be used on this engine cut-off saw.

Read Label on The

Wheel

Maximum Allowable Wheel Speed

The wheel rotates at the same speed as the spindle (arbour) on which it is

mounted. The wheel must never be allowed to rotate faster than 3820 rpm if

the wheel speed is rated at 3820 rpm.

CSG-7410

12

Page 13

Wheel Blotters and Mounting Flanges

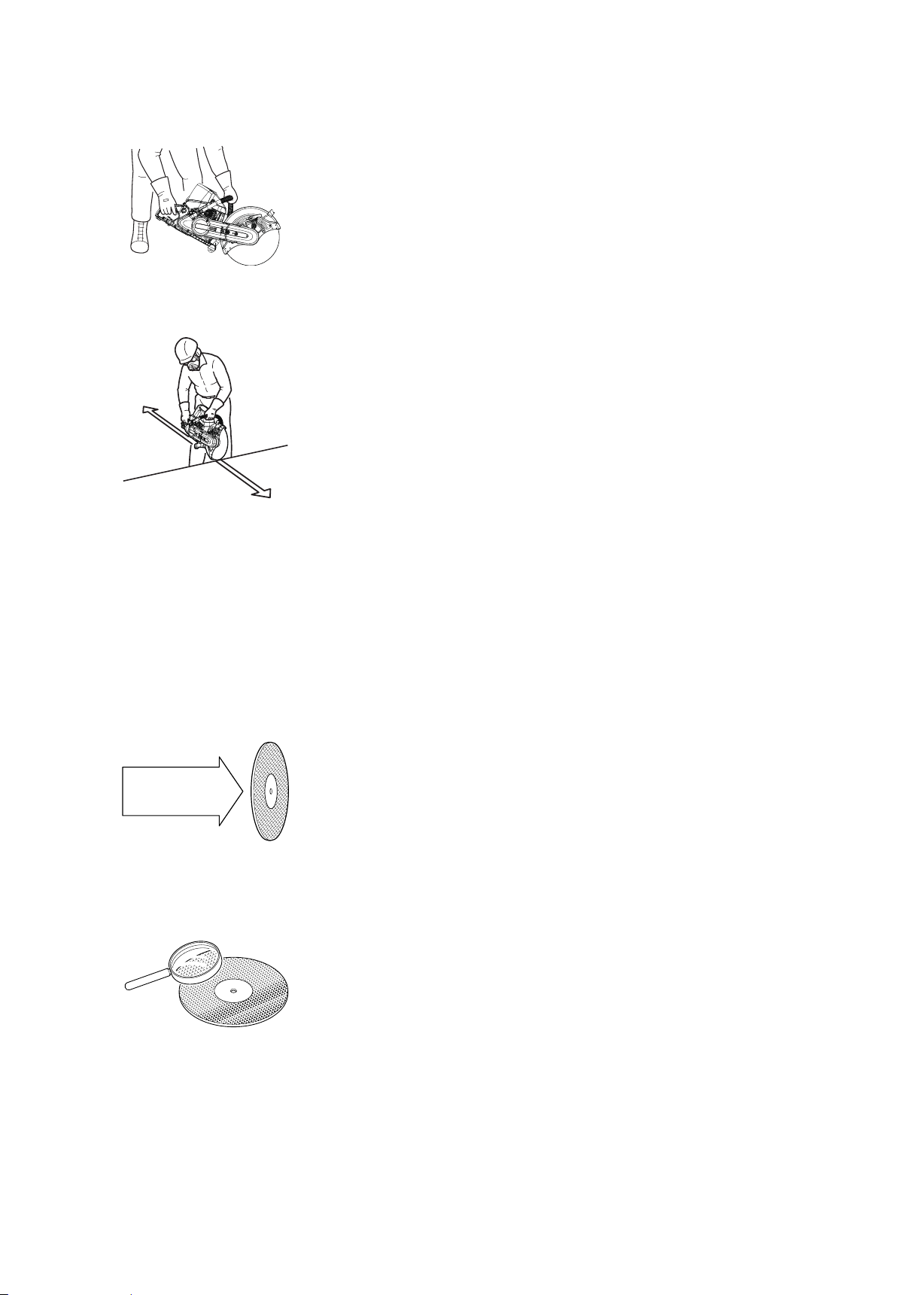

Blotter 108 mm

20 mm

(25.4 mm)

350 mm

Abrasive Wheel: 350 mm (13.8 in.)

Diamond Wheel: 350 mm (13.8 in.)

Refer to Chart

Wheel Diameter Mounting Hole Diameter Thickness

Emergency Applications

Do not grind with a cut-off wheel or put pressure on the sides.

Do not mount wheel if blotters are damaged. Do not destroy

cushioning effect by making mounting bolts too tight.

Never fasten while applying your weight.

Otherwise the thread could be broken.

Proper torque is 25 N•m (250 kgf•cm) - 30 N•m (300 kgf•cm).

Examine wheel carefully before use.

Do not use if wheel is warped, damp, cracked, chipped or cutting

area shows heat discolouration.

Dropping a wheel can easily damage it.

Discard a wheel if you drop it.

Wheel blotters attached to both sides of reinforced

wheels are cushions needed to equalize the

pressure of the mounting flanges from wear if

slippage between the wheel and the flanges

occurs. The blotters are 108 mm (4 1/4 in.)

diameter. Take care that the blotters do not become

gouged or deeply scratched and that there is no

foreign material on them when mounting the wheel.

Wheel Dimensions

20 mm

(25.4 mm with Adapter)

20 mm

(25.4 mm with Adapter)

Max. 4.7 mm (6/32 in.)

Max. 4.7 mm (6/32 in.)

WARNING

Ring Testing Wheels

Centre Line

45°

45°

45°

“Tap” Here

45°

Cracks or defects in a wheel may not be visible. To help in verifying that a

wheel is OK to use, a “ring test”. Perform the ring test immediately before

mounting all new or used wheels.

Put your finger through the mounting hole to support the wheel. Use a nonmetallic handle of any small tool or a small piece of wood to lightly tap (do

not hit) the wheel in the locations shown in the illustration. Do not tap wheel

on the edge. Wheels without cracks will make a ringing sound, wheels with

cracks, or concealed cracks, will make a dull “clunk”.

IMPORTANT

If a wheel being “ring tested” is dirty or damp or

is tapped at the vertical centre line, the resulting

sound will be muffled and not reliable.

13

CSG-7410

Page 14

Facts About Abrasive Wheel

ECHO wheels are made by laying a strong fibre mesh material into a form,

pouring a mixture of resin and the abrasive grit particles over the mesh,

and adding a second layer of mesh over the mixture. Then the resin and

reinforcing mesh are bonded together and cured.

The wheel’s ability to cut certain materials are due to the type abrasive, size

of the grit and it’s spacing. The reinforcement on both sides adds strength

and rigidity.

Always read the label on the wheel. If the wheel does not cut well, it may be

the wrong type for the material. Forcing it to cut may result in shattering of

the wheel and serious injury to the operator.

Do not use water with an abrasive wheel.

Do not grind with a cut-off wheel or put pressure on the sides.

Use only ECHO reinforced wheels, or wheels approved for this saw

by ECHO.

Wheels that are too thick or fit the arbour improperly may shatter,

causing serious personal injury. So may wheels of low speed rating

or those that are cracked, warped, out-of-round or edge-damaged.

WARNING

Put no Side

Pressure on

the Wheel

A wheel can stand a lot of cutting pressure as long as the pressure is straight

on and not from the side of the wheel. This is why you always must make

only straight line cuts.

Saws intended for forcible entry should be equipped with new wheels for

each use. If the used wheels can pass the ring test (page 13) and close

inspection, they may be use in training emergency crews.

Handling and Storage of Wheels

Check every wheel for warping, cracks and broken edges before mounting

on the saw.

Warped wheels do not cut properly and may be stressed to the point of

breaking. Always store your wheels laying flat, on a dry surface. When

stacking many wheels, place cardboard or paper spacers between them as a

cushion.

Moisture and heat both can cause wheel damage. Do not let wheels lie in the

sun or expose them to high heat. Keep wheels dry at all times, and store in

an area of low humidity and moderate temperature. Protection from moisture

damage applies during water-flush cutting.

CSG-7410

14

Page 15

PREPARATION FOR USE

How to Install the Wheel

Replacing the Adapter

Install the adapter that fits the inside diameter of the cutting wheel. When

shipped, an adapter with an outside diameter of 20 mm is mounted. If the

inside diameter of the cutting wheel to be used is 25.4 mm, replace the

adapter as follows.

1. Insert the bar tool.

2. Rotate the drive shaft until the hole in the large pulley and the bar tool

aligned.

Bar Tool

3. Unscrew wheel mounting bolt with the 19 mm end of the box wrench or

your fingers.

Remove wheel bolt and outer flange, leaving inner flange in place.

4. The adapter is held to the drive shaft with a snap ring. Insert a tool like a

small slotted screwdriver in the gap and remove the snap ring.

Adapter

Bar Tool

Snap ring

Flange

Bolt

Adapter

5. Replace with an adapter that fits the inside diameter of the cutting wheel

to be used.

6. Press the snap ring in until it reaches the groove in the drive shaft and

secures the adapter. If the snap ring is deformed, replace it with a new one.

Installing a Cutting Wheel

1. Insert the bar tool.

Rotate the drive shaft until the hole in the large pulley and the bar tool

aligned.

2. Unscrew wheel mounting bolt with the 19 mm end of the box wrench or

your fingers.

3. Remove wheel bolt and outer flange, leaving inner flange in place.

4. Confirm the direction of rotation of the cutting wheel and mount it so its

centre hole fits over the adapter mounted on the drive shaft.

Cutting Wheel

Tighten

5. Align the hole in the cutter flange with the drive shaft and press it on.

6. Finger tighten the wheel bolt and then tighten it fully with a socket wrench.

Tighten it to a torque of 25 to 30 N・m.

7. Remove the bar tool and rotate the cutting wheel by hand; make sure it is

straight and wobble-free.

15

CSG-7410

Page 16

Before tightening, check that flanges are properly seated and not

cocked on the mount or bolt threads. Do not make bolt so tight

as to destroy the cushion supplied by the wheel blotters. Do not

use pneumatic, electric-powered tools or one’s body weight for

tightening. Otherwise the thread could be broken. Do not tighten

more than 30 N•m (300 kgf•cm).

NOTE

Arm may be removed and remounted with wheel on the outboard side of

the arm as required for certain procedures.

Adjusting the Wheel Guard Angle

WARNING

Wheel guard knob

Never operate the machine without the wheel guard in place.

1. The wheel guard can be adjusted to prevent debris from flying off and hitting the

operator.

2. Turn the wheel guard locking knob counterclockwise, grasp the wheel guard

knob and move the wheel guard to the desired position, then slowly release it and

Wheel guard

Wheel guard

Locking knob

secure the wheel guard with the locking knob.

* Never operate the machine without the guard stopper in place.

Reverse Mounting the Cutter Arm

When shipped the cutting wheel is mounted so it is near the center of gravity of

the machine. The cutting wheel can be moved to a position outside the machine

by reverse mounting the cutter arm.

Reverse mounting the cutter arm compromises the balance of

Pipe

the machine and makes it difficult to operate. Do not use it in the

reversed state except when necessary.

WARNING

WARNING

Guard Stopper

Wheel guard knob

Nozzle

CSG-7410

1. Remove the cutting wheel.

2. Remove the 2 screws and remove the guard stopper.

3. Remove both of the pipes connected to the pipe connector. Remove the pipe

connector after removing the nut mounted on the wheel guard.

4. Mount the pipe connector in the lower hole in the wheel guard.

Pipe

connector

5. Loosen the nut that holds the nozzle in place.

6. Remove the wheel guard knob mounted on the wheel cover.

16

Page 17

Locking Knob

7. Loosen the nut of the locking knob and reinstall it after changing the angle of

the knob.

8. Change the angle of the wheel guard.

Tension screw

Cutter arm

Pulley cover

Pulley cover

Belt

Pulley

Bolt

9. Loosen the tension screw until its tip cannot be seen, then remove the 2 pulley

cover bolts.

10. Remove the pulley cover.

11. Remove the cutter arm from the crankcase. Remove the belt at the same time.

12. Reverse the cutter arm and mount it in the long hole in the crankcase.

13. Put the belt on the pulley.

14. Put the pulley cover into the cutter arm. Make sure the pulley cover is not mis-

aligned when putting it into the arm.

15. Finger tighten the 2 pulley cover bolts, then back them off about 1 turn. Adjust

the tightness of the belt.

16. Tighten the 2 pulley cover bolts. Note: Tighten it to a torque of 23 to 27N・m (230

to 270 kgf・cm).

17. Change the nozzle angle and then tighten the nut.

18. Insert the 2 pipes into the pipe connector.

19. Mount the knob on the top of the wheel guard.

20. Install the guard stopper on the guard (above the cutting arm).

17

CSG-7410

Page 18

FUEL AND LUBRICANT

FUEL

WARNING

Diesel fuels and alternative fuels, such as

E-15 (15% ethanol), E -85 (85% ethanol) or

any fuels not meeting ECHO requirements

are NOT approved for use in ECHO 2-stroke

gasoline engines. Use of diesel or alternative

fuels may cause performance problems, loss

of power, overheating, fuel vapor lock, and

unintended machine operation, including, but

not limited to, improper clutch engagement.

Diesel or alternative fuels may also cause

premature deterioration of fuel lines, gaskets,

carburetors and other engine components.

Fuel Requirements

Gasoline - Use 89 Octane [R+M/2] (mid grade or

higher) gasoline known to be good quality. Gasoline

may contain up to 10% Ethanol (grain alcohol) or 15%

MTBE (methyl tertiary-butyl ether). Gasoline containing methanol (wood alcohol) is NOT approved. Use of

ECHO brand fuel is recommended to extend engine

life in all air-cooled 2-stroke and 2/4-stroke hybrid

engines.

Two Stroke Oil - A two-stroke engine oil meeting ISO-LEGD (ISO/CD 13738) and J.A.S.O. FD Standards must

be used. ECHO brand 2-stroke oils meet these standards. Engine problems due to inadequate lubrication

caused by failure to use an ISO-L-EGD (ISO/CD 13738)

and J.A.S.O. M345-FD certified oil, such as ECHO brand

2-stroke oils, will void the two-stroke engine warranty.

WARNING

2-Stroke engine oil contains petroleum

distillates and other additives that may be

harmful if swallowed. Heated oil can release

vapors that can cause flash fire, or ignite

with explosive force. Read and follow the oil

manufacturer’s instructions, and observe all

safety warnings and precautions for handling

flammable liquids. For more detailed safety and

first aid information, visit www.echo-usa.com

for a copy of the Material Safety Data Sheet.

• KEEP OUT OF REACH OF CHILDREN.

• If swallowed, do not induce vomiting. CALL

PHYSICIAN OR A POISON CONTROL

CENTER IMMEDIATELY.

• WEAR SAFETY GLASSES when mixing or

handling.

• AVOID repeated or prolonged skin contact

• AVOID inhaling oil mists or vapors.

NOTICE

ECHO brand 2-stroke oils may be mixed at

50:1 ratio for application in all ECHO engines

sold in the past regardless of ratio specified

in those manuals.

Handling Fuel

DANGER

Fuel is VERY flammable. Use extreme care

when mixing, storing or handling, or serious

personal injury may result.

Use an approved fuel container. Mark fuel

containers as containing 2-stroke mixture

fuel.

• DO NOT smoke near fuel.

• DO NOT allow flames or sparks near fuel.

• Fuel tanks/cans may be under pressure.

Always loosen fuel caps slowly allowing

pressure to equalize.

• NEVER refuel a unit when the engine is

HOT or RUNNING!

• DO NOT fill fuel tanks indoors. ALWAYS

fill fuel tanks outdoors over bare ground.

• DO NOT overfill fuel tank. Wipe up spills

immediately.

• Securely tighten fuel tank cap and close

fuel container after refueling.

• Inspect for fuel leakage. If fuel leakage is

found, do not start or operate unit until

leakage is repaired.

• Move at least 3 m (10 ft.) from refueling

location before starting the engine.

DANGER

Gasoline vapor is heavier than air, and can

travel along the ground to nearby sources of

ignition such as electrical motors, pilot lights,

and hot or running engines. Vapors ignited

by an ignition source can flash back to the

fuel container, resulting in an explosion,

fire, serious or fatal injuries, and extensive

property damage.

CSG-7410

18

Page 19

Mixing Instructions

1. Fill an approved fuel container with half of the required amount of gasoline.

2. Add the proper amount of 2-stroke oil to gasoline.

3. Close container and shake to mix oil with gasoline.

4. Add remaining gasoline, close fuel container, and

remix.

Fuel to Oil Mix – 50:1 Ratio

US Metric

Gas Oil Gas Oil

gal. fl.oz. L cc

1 2.6 5 100

2 5.2 10 200

5 13 25 500

NOTICE

Stored fuel ages. Do not mix more fuel than

you expect to use in 30 days, 90 days when a

fuel stabilizer is added.

Stored two-stroke fuel may separate.

ALWAYS shake fuel container thoroughly

before each use.

Used oil and gasoline, and soiled towels are

hazardous waste materials. Disposal laws

vary by locality.

EMISSION DATA

EMISSION CONTROL

(EXHAUST and EVAPORATIVE)

EPA 2010 and Later and/or C.A.R.B. TIER III

The emission control system for the engine is EM

(engine modification) and, if the second to last

character of the Engine Family on the Emission

Control Information label (sample below) is “C”, “K”,

or “T”, the emission control system is EM and TWC

(3-way catalyst). The fuel tank/fuel line emission

control system is EVAP (evaporative emissions).

Evaporative emissions for California models may

only be applicable to fuel tanks.

An Emission Control Label is located on the

engine ( example only, information on label varies

by engine family).

PRODUCT EMISSION DURABILITY

(EMISSION COMPLIANCE PERIOD)

The 300 hours emission compliance period is

the time span selected by the manufacturer

certifying the engine emissions output meets

applicable emissions regulations, provided that

approved maintenance procedures are followed

as listed in the Maintenance Section of this

manual.

EMISSION CONTROL INFORMATION

ENGINE FAMILY: #EHXS.0735RA DISPLACEMENT: 73.5 cc

EMISSION COMPLIANCE PERIOD: 300 Hours

THIS ENGINE MEETS U.S. EPA EXH/EVP EMISSION

REGULATIONS FOR MODEL YEAR **** REFER TO OWNER’S MANUAL FOR MAINTENANCE SPECIFICATIONS AND ADJUSTMENTS.

***XXXX

19

CSG-7410

Page 20

OPERATION

Safe Starting Techniques

Set saw down on level ground with wheel in the clear. Grasp front handle

with left hand, and hold down rear handle with toe of your boot. Never “dropstart” the saw.

Wheel will rotate when engine is started at fast idle throttle latch setting. Keep cutting wheel in the clear.

IMPORTANT

Check unit for loose nuts, bolts and screws before starting.

Make sure the wheel guard is securely in place.

Always clear work area of debris before starting operation.

Always hold the unit firmly.

When pulling starting rope, use short pulls, 1/2 to 2/3 of rope length.

Do not allow the starter grip to snap back against the housing.

WHEN THE ENGINE IS COLD

WARNING

Decompression device

Primer pump

Choke

Starter grip

Throttle trigger lockout

1. Fill the fuel tank with fuel mixture. It is not permitted to fill fuel above the

shoulder level of fuel tank.

2. Press the decompression device.

3. Push primer pump until fuel is visible in primer pump.

4. Pull out choke all the way (engages the fast idle throttle latch setting).

5. Securely hold the engine cut-off saw. Pull starter grip briskly, but only 1/2

to 2/3 its full length. Pulling rope to the end may damage the starter.

6. Push in the choke the first time engine fires, and crank until engine starts

and runs. In cold weather you should keep the choke out just a little until

the engine gets very warm. But, do not operate with the choke out.

7. Squeeze and release trigger when engine runs to release the fast idle

throttle latch setting. You now have trigger control of the throttle speed.

CSG-7410

Throttle trigger

20

Page 21

WHEN THE ENGINE IS WARM

Starter grip

1. Fill the fuel tank with fuel mixture. It is not permitted to fill fuel above the

shoulder level of fuel tank.

2. Press the decompression device.

3. Securely hold the engine cut-off saw. Pull starter grip briskly, but only 1/2

to 2/3 its full length. Pulling rope to the end may damage the starter.

Choke

RUNNING

Stopping Engine

Momentary stop switch

Choke

* If the engine is hard to start, pull the choke to engage the fast idle throttle

latch setting, then return the choke to its normal position (this opens the

throttle slightly).

If it still fails to start, revert to the WHEN ENGINE IS COLD starting

procedure.

1. Once the engine starts, allow it to warm up for 2 to 3 minutes at idling (i.e.

low speed).

2. Warming the engine helps to lubricate its internal workings more smoothly.

Allow the engine to warm up fully, especially when it is cold.

WARNING

Momentary stop switch automatically returns to run position. Engine

can start unintentionally when starter handle is pulled. Always

remove spark plug lead from spark plug before pulling starter

handle, otherwise severe personal injury may result.

Release throttle trigger and allow engine to idle.

Push the momentary stop switch.

The engine stops with just one press of the stop switch. It is not necessary to hold the

switch until it stops.

If engine does not stop, pull choke control knob out fully to stop engine. The choked

engine will slow to a stop. Be sure to keep the wheel in the clear until all movement stops.

Dust Suppression

Close

Open

Coupler

WARNING

With trigger latched, wheel will rotate as soon as engine starts. Keep

wheel in the clear.

Wheel will rotate for some time after the trigger is released. Keep

wheel in the clear until all movement stops.

WARNING

Do not use with wheels that are not designed to be used with water-flush cutting.

Doing so may damage the wheel while it is being used.

1. Use water-flush cutting when doing work that generates a lot of dust, such

as cutting concrete.

2. Attach a water hose with a coupler on it to the joint of the engine cut-off

saw.

3. Make sure the liquid cock is in the closed position before turning the water

faucet on.

4. Adjust the water flow with the liquid cock.

5. After cutting, turn off the water and let the wheel spin itself dry.

IMPORTANT

Make sure there are no water leaks before use.

Use as little water as possible to sufficiently suppress generation of dust.

21

CSG-7410

Page 22

CUTTING INSTRUCTION

Sequence after Starting Engine

1. Squeeze and release trigger to unlatch it and take control of the throttle.

2. Let engine warm to operating temperature before doing any cutting.

3. Take cutting stance on left side of saw. Never get any part of your body

behind the saw. Hold the saw firmly with both hands. Throttle up to cutting

speed and make gentle wheel contact with the work.

Cutting Asphalt, Tar and Reinforced Materials

Old, cold and hardened asphalt paving can be cut with a masonry wheel with

good results and little trouble with tarring of the wheel. Fresh asphalt and

tarred surfaces can gum up the wheel and slow its cutting action. Some tar

or resin-impregnated materials also may present problems of this sort.

Masonry containing metal reinforcement is best cut with a masonry wheel

which can cut through the reinforcing steel better than a wheel designed for

metal can cut the masonry. Expect faster than normal wheel wear.

Do not raise saw above chest height, because the saw is hard to

control when held up high, and dust or sparks will fall on you.

Wear hearing protection. Without it you risk hearing loss,

especially where bounce-back of sound waves off nearby surfaces

increases the noise.

Do not take awkward or risky operating positions. Find solid

footing for both feet, and always hold the saw firmly with both

hands. Never make one-handed cuts.

Kickback safety precautions

Kickback may force the cutting-off wheel up and back toward the

operator with a lightning-fast reaction. Kickback can occur whenever

the upper-half of the cutting-off wheel touches an object while operating the machine. This may cause the cutting wheel to touch the

Rotational kickback

Linear kickback

operator, resulting in serious injury

Rotational kickback

Cutting with the upper part of the cutting wheel generates kickback

from the material being cut; this causes the tip of the cutting wheel

to kick back from the rotation and is extremely dangerous. Always

cut with the bottom of the cutting wheel.

DANGER

DANGER

CSG-7410

Linear kickback

When cutting with the bottom of the cutting wheel, the machine may

generate a force that pulls the machine forward. Always hold the

handle firmly while working.

22

Page 23

Cutting Technique

Keep Wheel

Moving

Cut in a

Straight Line

Roll Pipe to Cut 360° Around

Follow Snap Line

Saw will Bind

in Crocked Cut

The main objectives are to avoid overheating the

wheel, and to prevent it from being pinched or

trapped or stressed in any way.

Adjust position of wheel guard to direct the

discharge away from you.

Prepare to make straight cuts only. Use a snap-

line to mark long cuts, and follow the marked line

carefully.

Take a balanced, comfortable stance on the left

side of the saw. Hold saw firmly with both hands.

Always throttle up to cutting speed before letting

the wheel make contact. The saw may be jerked

forward, causing loss of control, if wheel is in

contact during throttling up. Carefully let cutting

edge of wheel make light contact with the work.

Do not push or bounce the wheel onto the work.

Hold saw steady. Do not let it tilt or wobble.

Do not let the wheel stop in one place, but keep

it moving - in one direction, or back and forth,

along the line of cut. Cutting in one spot causes

heat build-up which can damage or glaze the

wheel. Too much cutting pressure also causes

overheating.

Cut as shallow and straight a groove as you can.

If you cut a curve, the wheel will start to bind as

the cut deepens.

Go over and over the groove you have started

until the cut is completed.

On cuts of long duration, remove saw from cut

often to let the wheel cool.

Never put any side pressure on a engine cut-off

saw wheel, grind on the side of it or use it to flick

away debris.

When cutting large diameter pipe, cut 360

degrees around and try not to cut through. If a

large segment of the wheel breaks through, the

wheel may catch and kick out at lightning-fast

speed.

Before cutting materials which are not supported

along their entire length, provide support to

prevent binding. Also be aware that the top

section will settle on the wheel if a column is cut

in two.

Try not to Let Wheel Break

Through in One Place

Be careful not to cut your own legs in the

downward cutting. Be particularly careful at the

end of cutting.

NOTE

Always cut at full throttle. Cutting at less than full

throttle may harm the clutch as it will overheat

during slippage.

23

CSG-7410

Page 24

MAINTENANCE AND CARE

Your ECHO engine cut-off saw is designed to

provide many hours of trouble free service. Regular

scheduled maintenance will help your engine cutoff saw achieve that goal. If you are unsure or are

not equipped with the necessary tools, you may

want to take your unit to an ECHO Service Dealer

for maintenance. To help you decide whether you

want to DO-IT-YOURSELF or have the ECHO Dealer do it, each maintenance task has been graded.

If the task is not listed ask your ECHO dealer for

repairs.

SKILL LEVELS

Level 1 = Easy to do. Most required tools come

with unit.

Level 2 = Moderate difficulty. Some specialized

tools may be required.

WARNING

Momentary stop switch automatically

returns to run position. Engine can start

unintentionally. Always remove spark plug

lead from spark plug before assembling

or performing maintenance procedures or

serious personal injury can result.

MAINTENANCE INTERVALS

Component / system Maintenance procedure

Required Skill

level

Daily or Before

use

Every refuel

Air Filter Inspect / Replace 1 I R *

Every 50 hours

or Yeary

Every 100

hours

Fuel System Inspect / Clean / Replace 1 I * I *

Fuel Filter Inspect / Replace 1 I / R *

Fuel Cap Gasket Inspect / Replace 1 I * R *

Wheel Inspect / Replace 1 I I

Wheel guard Inspect / Clean 1 I / C

Flange Inspect / Clean / Replace 1 I / C *

Belt Inspect / Tensioning / Replace 1 I I / R *

Clutch Inspect / Replace 2 I *

Spark Plug Inspect / Clean / Replace 1

Cooling System Inspect / Clean 1 I / C

Muffler Spark Arrestor Inspect / Clean / Replace 2 I

Cylinder Exhaust Port Inspect / Clean / Decarbon 2 I / C

Recoil Starter Rope Inspect / Clean 2 I / C *

Screws / Nuts / Bolts Inspect / Tighten / Replace 1 I *

Maintenance Procedure Letter Codes:

I = Inspect

C = Clean

R = Replace

Maintenance Procedure Notes:

* = All recommendations to replace are based

on the finding of damage or wear during

inspection.

When replacing parts, always use ECHO

genuine parts. Using non genuine parts may

result in serious injury.

IMPORTANT

Time intervals shown are maximum.

Actual use and your experience will determine

the frequency of required maintenance.

WARNING

I / C / R *

I / C / R *

CSG-7410

24

Page 25

Air Filter

The air filters of this product are designed to

be maintenance-free for a long period of time.

However, in the following cases the main and sub

air filters should be replaced.

・If engine output drops markedly

・After 1 year or 50 hours of operation

IMPORTANT

Do not attempt to clean the main or sub air filters

with compressed air.

Bolts (A)

Air Cleaner

Cover

Sub air filter

Grommets

Bolt (B)

Main air filter

Filter case

Filter case

Choke knob

Air Filter Replacement Procedure

1. Remove the 4 grommets on the air cleaner cover.

2. Remove the 4 bolts securing the air cleaner

cover and then remove the cover.

3. Remove the main and sub air filters. The sub air

filter can be removed by pulling out the choke

and lifting up the filter case and then pressing on

the filter from the under side.

4. Put the filter case back in position.

5. Install new sub and main air filters. Replace both

filters at the same time.

6. Install the air cleaner cover and tighten its 4

bolts. Tighten the 3 bolts (A) and then the bolt (B).

7. Make sure the grommets are facing the right way

when installing them on the air cleaner cover.

25

CSG-7410

Page 26

Spark Plug

Spark plug

Spark plug lead

1. Remove air cleaner cover.

2. Remove spark plug lead.

3. Remove spark plug.

4. The proper spark plug for this engine is NGK

BPMR7A. The firing gap between the electrodes

should be adjusted to 0.65 mm (0.026 in) before

use.

5. Install the spark plug. Proper tightness with a

cold engine is 17 to 19 N•m (170 to 190 kgf•cm).

6. Many failed plugs can be restored by filing or

scraping the electrodes down to bare metal,

cleaning all deposits off the porcelain insulation

around the centre electrode, then setting the

gap.

0.65 mm (0.026 in)

Replace Fuel Filter

Fuel Filter

Fuel Tank Cap

WARNING

Fuel vapours are extremely flammable and

may cause fire and/or explosion. Never test

for ignition spark by grounding spark plug

near cylinder plug hole, otherwise serious

personal injury may result.

(Check Periodically)

1. Do not allow dust to enter fuel tank.

2. Clogged filter will cause difficulty in starting

engine or abnormalities in engine performance.

3. Pull the fuel filter out through fuel inlet port with

a piece of steel wire or the like.

4. When the filter is dirty, replace it. Do not attempt

to clean the filter.

5. When the inside of the fuel tank is dirty, rinsing

the tank out with petrol can clean it.

WARNING

Check condition of fuel cap and gasket. Be

sure the cap fits tightly and there is no fuel

leak.

CSG-7410

NOTE

Federal EPA regulations require all model year

2012 and later gasoline powered engines produced

for sale in the United States to be equipped with a

special low permeation fuel supply hose between

the carburetor and fuel tank. When servicing model

year 2012 and later equipment, only fuel supply

hoses certified by EPA can be used to replace

the original equipment supply hose. Fines up to

$37,500 may be enforced for using an un-certified

replacement part.

26

Page 27

Carburetor Adjustment

Idle adjusting screw

High speed needle (H)

Low speed needle (L)

Every unit is run at the factory and the carburetor is

set in compliance with Emission Regulations.

In addition, the carburetor is equipped with “H” (High

Speed) and “L” (Low Speed) needle adjustment

limiters that prevent settings outside acceptable

limits.

1. Before adjusting carburetor clean or replace air

filter and muffler “Spark Arrestor Screen”.

2. Install the wheel.

3. Start engine and run several minutes to bring to

operating temperature.

Flash choke twice during warm-up to clear any

air from the fuel system.

4. Stop engine.

Turn “L” speed needle counterclockwise (CCW)

to stop.

Turn “H” speed needle midway between full

clockwise (CW) stop and CCW stop.

5. Idle Speed Adjustment:

• Start engine, turn “Idle” speed adjustment

screw CW until the wheel begins to turn, then

turn screw out CCW until the wheel stops

turning.

Turn screw out, CCW, an additional 1 + ½

turn.

High Altitude Operation

This engine has been factory adjusted to maintain

satisfactory starting, emission, and durability

performance up to 1100 feet above sea level (ASL)

(96.0 kPa).

To maintain proper engine operation and emission

compliance above 1100 feet ASL the carburetor

may need to be adjusted by an authorized ECHO

service dealer.

IMPORTANT

If the engine is adjusted for operation above

1100 feet ASL, the carburetor must be

readjusted when operating the engine below

1100 feet ASL, otherwise severe engine damage

may result.

WARNING

Cutting attachment must not move when unit

is idling.

6. Accelerate to full throttle for 2 - 3 seconds to

clear any excess fuel in the engine, then return

to idle.

Accelerate engine to full throttle to check for

smooth transition from idle to high speed.

7. Check idle speed and reset if necessary as

described in item 5.

If a tachometer is available idle speed should be

set to 2800 rpm.

CAUTION

When starting, idling adjustment speed

should be adjusted not to rotate the wheel.

Correct idle speed is adjusted 2800 rpm.

Or 1 + ½ turn CCW from the point the wheel

stops moving.

When you experience trouble with the

carburetor, contact your dealer.

27

CSG-7410

Page 28

Cylinder Fins

Cylinder fins

Muffler Spark Arrestor

Spark arrestor screen

Bolts

Spark arrestor screen cover

1. Check periodically.

2. Clogged fins will result in poor engine cooling.

3. Remove dirt and dust from between fins to let

cooling air pass easily.

1. Remove air cleaner cover and remove spark

plug lead.

2. Remove the cutter arm. (See page 30.)

3. Remove spark arrestor screen cover and screen

from muffler body.

4. Clean carbon deposits from muffler components.

5. Replace screen if it is cracked, or has holes

burned through.

6. Assemble components in reverse order.

NOTE

Carbon deposits in muffler will cause drop in

engine output. Spark arrestor screen must be

checked periodically.

Clutch and Maximum Speed Checks

Clutch

Slipping of the clutch under a cutting load is not the only thing that can

happen to a clutch. Another problem may appear during setting of the

Carburetor for proper idling speed. The clutch may be at fault if an adjustment

high enough for stable idling results in wheel rotation. Such a condition

should be checked out by your servicing dealer before any further use of the

saw.

Speed

To ensure the wheel does not over speed, the engine no load speed

must be adjusted to a maximum of 9950 rpm. Use a tachometer to

measure speed. If engine speed exceeds 9950 rpm, have the unit serviced by your nearest ECHO servicing dealer before further use.

Whenever activated, the vibration-sensitive governor in the Carburetor high

speed fuel circuit supplies more fuel than the engine can burn. Consequently,

the engine has to purge itself of the extra fuel and slows down in the process.

Proper high speed adjustment (see page 28) of the Carburetor should result

in engine high speed, no load, operation within the desired range. This range

is 9750 rpm ± 200 rpm, which is required for the proper wheel spindle speed

range of 3700 – 3820 rpm.

WARNING

CSG-7410

28

Page 29

Belt Change and Adjustment

Adjusting the Belt

Washer

Tension screw

Water-flush

pipe

Tension screw

Mark

Bolt

Pipe connector

Pulley cover

Adjust the belt if it becomes loose.

1. Loosen the 2 pulley cover bolts about 1 turn.

2. Turn the tension screw so the washer lines up

with the mark on the clutch cover.

3. Tighten the 2 pulley cover bolts. Note: Tighten to

a torque of 23 to 27N・m (230 to 270 kgf・cm).

Replacing the Belt

Replace the belt when it becomes very worn

(peeling, turning, cuts, cracking, etc.)

1.Disconnect the water-flush pipe from the pipe

connector.

2. Loosen the tension screw and then remove the

2 pulley cover bolts.

Pulley

(small)

Clutch cover

Belt

Cutter arm

Belt

Clutch cover

3. Remove the pulley cover along its rail.

4. Loosen the clutch cover bolt and then remove

the clutch cover.

5. Remove the old belt and then remove the cutter

arm.

6. Put the new belt on the small pulley.

7. While pulling the belt in the direction of the cutter,

install the clutch cover and fasten it with its bolt.

29

CSG-7410

Page 30

Flange

Bolt

Cutter arm

Belt

Large pulley

8. Fit the cutter arm into the long hole in the

crankcase and then put the belt on the large

pulley.

9. Put the pulley cover on along the outside of the

cutter arm. Make sure the pulley cover is not

misaligned when putting it into the arm.

10. Tighten the 2 pulley cover bolts and then back

them off 1 turn. Adjust the tightness of the belt.

11. Tighten the 2 pulley cover bolts. Note: Tighten

to a torque of 23 to 27N・m (230 to 270 kgf・cm).

12. Insert the water-flush pipe into the pipe

connector.

13. The belt stretches after being replaced, so

readjust its tension after operating the machine.

1. Check for wear, cracks and broken pieces.

2. Replace with a new one if anything is abnormal.

Wheel Guard

Wheel guard locking knob

1. Make sure it does not touch the cutting wheel, as

a result of deformation or rattling.

2. Consult your dealer if the wheel guard moves

back and forth even when the wheel guard

locking knob is tightened.

3. Consult your ECHO dealer if there is any wear or

cracking.

Wheel guard

CSG-7410

30

Page 31

Troubleshooting Cutting Problems

Trouble Probable Cause Remedy

Wheel stops when cutting pressure

is applied

Wheel stops when cutting pressure

is applied

Poor cutting – wheel discolored at

outer area

1. Bearing down too hard

2. Binding in crooked cut

3. Binding in closing cut

4. Loose belt

Belt worn beyond the limit Replace belt

Heat damage

1. Ease up cutting pressure

2. Lay out and follow a straight line

3. Support material so cut will open

4. Increase belt tension

Replace wheel.

Do not cut long in one spot.

Water flush when recommended.

Troubleshooting Engine Problems

Trouble Probable Cause Remedy

1. Out of fuel 1. Fill fuel tank

2. Engine flooded 2. Remove spark plug

• Push in and hold the momentary STOP

switch

• Crank the engine to expel the fuel

• Install clean, dry, properly gapped spark plug

Engine will not start

Engine hard to start

Engine misses

Engine overheats

and / or stalls under

cutting load

3. Fuel filter clogged 3. Install clean fuel filter.

Check that fuel pick-up line is not leaking or

clogged.

Clean fuel tank.

4. Air filter blocked 4. Replace air filter element

5. Spark plug fouled or cracked 5. Replace plug.

6. Ignition magneto or spark

plug wire faulty

1. See reasons under “will not

start”

2. Water in fuel or fuel has gone

stale or sour

3. Engine not getting the proper

fuel / air mixture

4. Carburetor out of adjustment 4. See “Carburetor Adjustment” or seek

1. Dirt in Carburetor or fuel line 1. Contact nearest authorized servicing dealer

2. Carburetor out of adjustment 2. Adjust, or seek dealer service

3. Weak or intermittent spark 3. Contact nearest authorized servicing dealer

1. Not enough oil 1. Use proper amount of oil in fuel mixture

2. Air passages around cylinder

clogged

3. Carburetor main adjustment

is set too “Lean”

6. Contact nearest authorized ECHO servicing

dealer

1. See remedies above

2. Fill tank with clean, fresh fuel mixture

3. If over-choked and flooded:

• Remove spark plug

• Push in and hold the momentary STOP

switch

• Crank the engine to expel the fuel

• if not choked enough, set controls properly

for starting

authorized dealer for adjustment

2. Clean air intake grid on starter side, flywheel,

cylinder fins and surrounding area

3. See “Carburetor Adjustment” or seek

authorized dealer for adjustment

31

CSG-7410

Page 32

STORAGE AFTER USE

WARNING

Momentary stop switch automatically

returns to run position. Engine can start

unintentionally when starter handle is pulled.

Always remove spark plug lead from spark

plug before pulling starter handle, otherwise

severe personal injury may result.

• Inspect and adjust every part of the engine cutoff saw.

- Completely clean every part and repair if

necessary.

- Apply thin coating of oil on metal parts to

prevent rust.

• Remove wheel.

• Drain fuel tank, pull starter slowly a few times to

drain fuel from carburetor.

• Pour a small amount of clean motor oil into spark

plug hole, pull starter and crank the engine until

piston reaches: TOP DEAD CENTER.

• Store in a dry area, free from dust.

WARNING

Do not store in an enclosure where fuel

fumes may accumlate or reach an open flame

or spark.

CAUTION

Do not lend or rent your engine cut-off saw

without the Operator's Manual.

NOTE

• For future reference, you should keep this

Operator's Manual.

• If this Operator's Manual has become illegible

or is lost, please purchase a new one from your

ECHO dealer.

CSG-7410

32

Page 33

TECHNICAL DATA

Model

External dimensions : Without cutting wheel

Length × Width × Height mm (in) 620 × 240 × 407 (24.4 x 9.4 x 16.0)

Mass : Without cutting wheel and empty tank kg (lb) 10.7 (23.6)

Volume :

Fuel tank mL

(US fl. oz.)

Fuel ( Mixture ratio ) 50:1 ratio with ECHO band oil,

Engine :

Type Air-cooled, two-stroke, single cylinder

Engine displacement

Carburetor Diaphragm type, Inner vent type

Magneto Flywheel magneto, CDI type

Spark plug NGK BPMR7A

Starter Recoil starter

Clutch Centrifugal type

Maximum shaft brake power kW 3.2

Wide open throttle speed rpm 9650 (9350-9750)

Idle speed rpm 2800 (2600-3000)

Throttle control Throttle trigger with throttle lockout

Cutting device :

Belt 6PJ-808

Pulley ratio 2.57 : 1

Belt tensioner Coil Spring system

Wheel mm (in.) 350 × 4.7 × 20 (14 x 6/32 x 25/32)

Maximum cut-off wheel speed rpm 3820

Flange outside diameter mm 100

Wheel fastener tightening torque N•m 25 - 30

Maximum spindle speed rating rpm 3820

Sound pressure level : measured at 15 m (50 ft) dB(A) 78.2

Other device :

Vibration reduction system Rubber mounted between the engine

mL (cu.in.)

700 (23.67)

ISO-L-EGD (ISO/CD 13738), JASO

M345-FC/FD two-stroke, air-cooled engine oil.

Use 89 octane unleaded. Do not use fuel

containing methyl alcohol, more than

10% ethyl alcohol or 15% MTBE.

gasoline engine

73.5 (4.49)

and the handles

CSG-7410

* Technical data subject to change without notice.

33

CSG-7410

Page 34

WARRANTY REGISTRATION SHEET

Thank you for choosing ECHO Power Equipment

Please go to http://www.echo-usa.com/Warranty/Register-Your-ECHO to register your new product on-line.

It’s FAST and EASY! NOTE: your information will never be sold or misused by ECHO, Inc. Registering

your purchase enables us to contact you in the unlikely event of a service update or product recall, and

verifies your ownership for warranty consideration.

If you do not have access to the Internet, you can complete the form below and mail to:

ECHO Inc., Product Registration, PO Box 1139, Lake Zurich IL 60047.

CSG-7410

34

Page 35

NOTES

35

CSG-7410

Page 36

C72715001001 – C72715999999

Loading...

Loading...