Page 1

Instructions

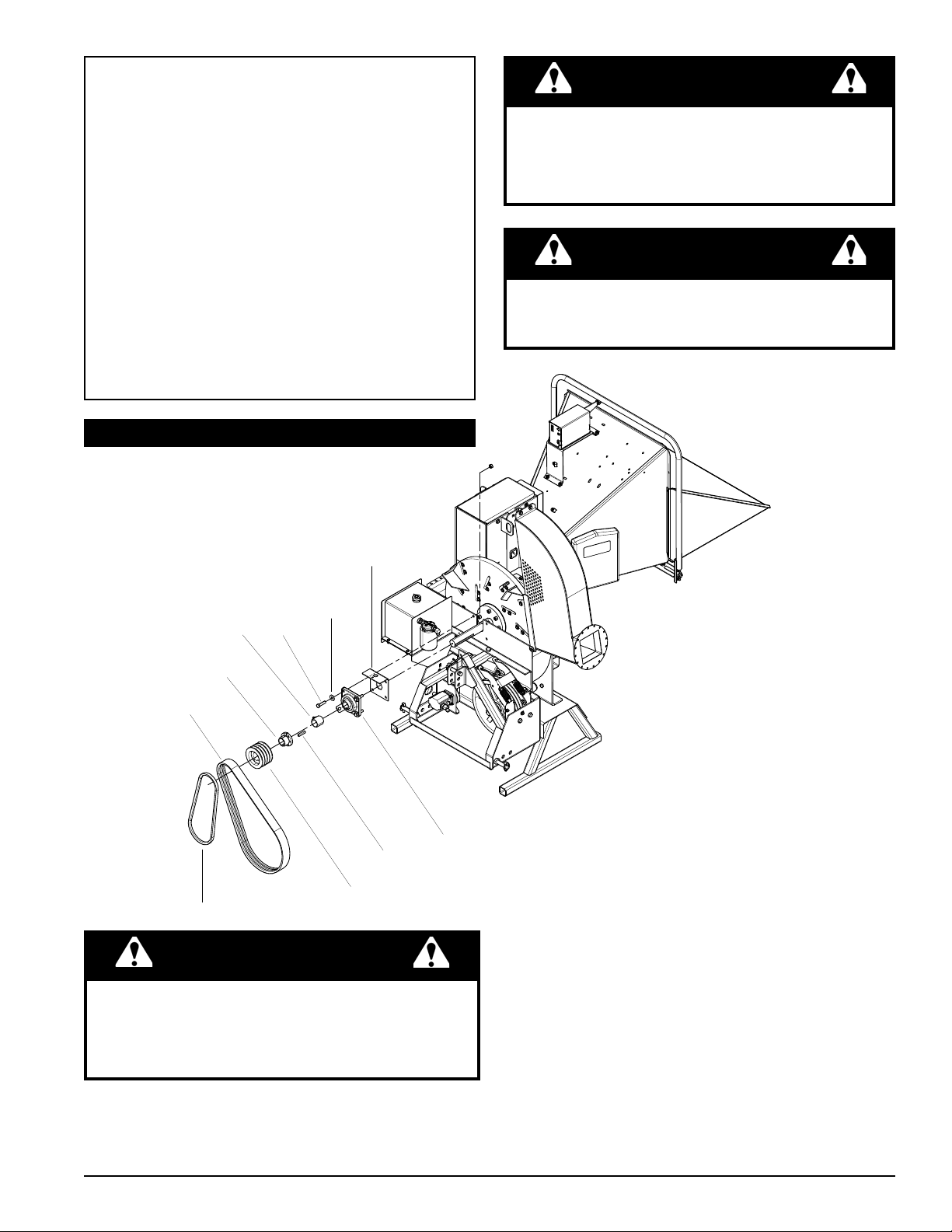

BELT

SHEAVE

BEARING

LEFT BEARING

BRACKET

KEY, 3/8”

SPACER

BUSHING

WASHER

BELT

BOLT, 1/2”

SUBJECT: 76775-00 FINE CHIP

DISK KIT – (

For replacement of

aTTENTION

While the FINE CHIP DISK KIT is designed for use in all

8" and 9" Chipper models, it is purposely designed and

recommended for use on Hydraulic Feed models.

standard and fine chipper disks.)

MODELS: 8" aND 9" CHIPPErS;

CH8670H, CH8993H, CH8540,

CH9540H, CHF9540H, CH911DH,

CH922DH

rEMOVaL OF DISK

WarNING

The chipping blades are sharp! Use care when

working on the machine to avoid injury.

WarNING

Before inspecting or servicing any part of this machine,

shut off power source, remove key, disconnect the

battery cables and make sure all moving parts have

come to a complete stop.

Rotate discharge to the right side of the machine. 1.

Remove the two 3/8" retaining bolts holding the access

cover to the main frame assembly. Tilt the access cover

open to allow access to the rotor.

Instruction Sheet

Remove upper and lower belt guards.2.

Loosen the bolts holding the hydraulic pump bracket to 3.

the 3-point, slide the bracket up and remove hydraulic

pump belt.

Remove the idler tensioning springs, and remove the 4.

1/2" bolt holding the idler pulley in place.

Remove the drive belt.5.

Taking the bolts out of the bushing and reinserting 6.

them into the empty holes, slowly tighten each bolt in

a rotating clockwise direction to remove the bushing

and sheave from the rotor shaft.

Loosen the set screw holding the spacer in place and 7.

remove. If rear bearing does not need to be removed

go to step 11.

Lift up the feed roller and insert the retaining pin to 8.

hold in place.

PN 76772-00

Rev. 080510

Page 2

Remove the protective cap.9.

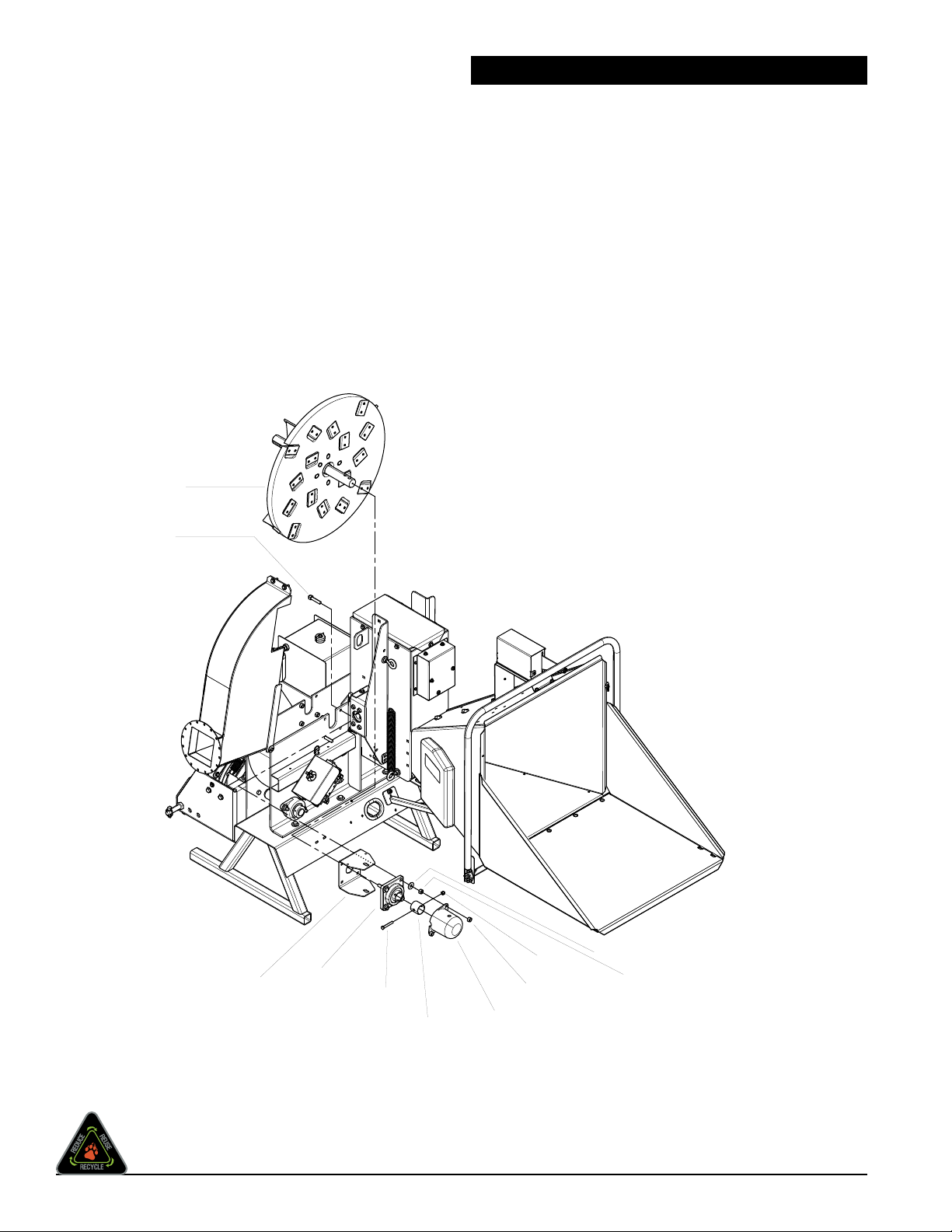

FINE CHIP DISK

BOLT,1/2”

WASHER

NUT, 1/2”

SHAFT CAP

LOCK NUT, 1/2”

NUT, 3/8”

BOLT 3/8”

COLLAR

BRACKET,

DISC LOCK

BEARING

Remove the 3/8" bolt holding the retaining spacer and 10.

remove the spacer.

Remove the four 1/2" bolts on each rotor bearing and 11.

loosen the two set screws on each bearing. (Note: You

may have to clean the shaft with emery cloth.)

Remove old disk and replace with Fine Chip Disk. 12.

NOTE: Approximate weight of disk is 260 lbs (118

kg).

Put the bolts back in the bearings and slide into place. 13.

Tighten bolts to 75 ft-lbs (102 Nm). Slide rear collar

back into place (noting that the offset bolt hole should

be toward the bearing) insert and fasten 3/8" bolt.

INSTaLL OF FINE CHIP DISK

Taking a rubber mallet, tap the rotor shaft until the rear 14.

collar is tight against the rear bearing. Tighten the bolt

and lock the set screws on both bearings. Torque to

160 inch-lbs (20 Nm). Reinstall front collar and tighten

the cap screw. Make sure the speed sensor is aligned

and gapped properly. Reinstall the rear rotor protective

cap.

Slide the bushing on and tighten set screw, then slide 15.

the sheave on. Insert bolts into the sheave and tighten in

a clockwise direction. Torque to 108 inch-lbs (12 Nm).

Check the alignment of pulleys with a straight edge and 16.

adjust if needed. If adjustment is needed, adjust the

jackshaft bushing and sheave.

Replace the drive belt.17.

Replace the idler and tighten. Reinstall tensioning 18.

springs.

Bolt the hitch support back in its original position.19.

Close cover and replace bolts.20.

Replace the hydraulic pump belt. Readjust hydraulic 21.

pump belt tension by sliding the hydraulic pump in the

mounting slots. Tighten bolts. The belt tension should

be set to have a deflection of 1/4" with 5.5 lbs of force

applied.

Replace belt guard and resume operation.22.

ECHO BEar CaT

www.bearcatproducts.com

237 NW 12th Street, West Fargo, ND 58078-0849

Phone: 701.282.5520 • Toll Free: 800.247.7335 • Fax: 701.282.9522

E-mail: service@bearcatproducts.com • sales@bearcatproducts.com

Start tractor engine and engage PTO drive clutch (see 23.

tractor owner’s manual). Increase engine speed to

rated PTO RPM position and test unit. If readjustment

of pulleys and belt tension is needed, shut machine off

Instruction Sheet

and adjust as necessary.

Loading...

Loading...