Page 1

Instructions

5”

4”

WARNING

SUBJECT: PLUS 1 CONTROLLER

INSTALLATION KITS 76170-00 AND

Before inspecting or servicing any part of this machine,

shut off power source, remove key, disconnect the

battery cables and make sure all moving parts have

come to a complete stop.

76171-00

FITS MODELS: 6" CHIPPERS

These instructions will describe how to install the Plus 1

controller.

CH6670H (76624), CH611DH

(76628), CH6993H (76635)

1. CONFIRM KILL SWITCH WAS REWIRED ON CH6670H

Before installing the Plus 1 controller, confirm that the kill switch on the CH6670H has been correctly rewired as described

in Service Bulletin 07-007 (see Distributor/Dealer Tools at http://bearcatproducts.com/).

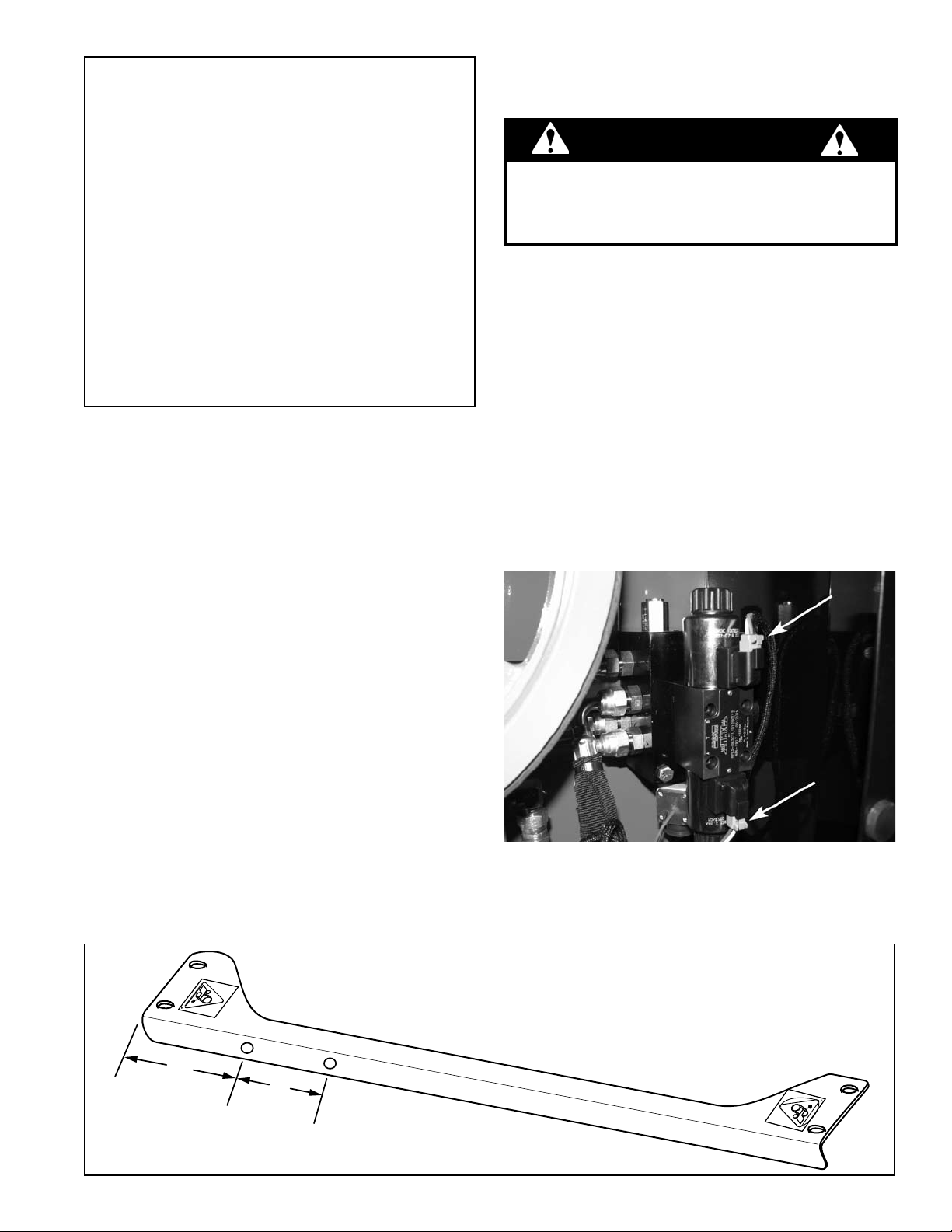

2. REMOVE SNUBBER HARNESS IF ONE WAS PREVIOUSLY INSTALLED

The Plus 1 Controller will not work if a snubber harness

was previously installed on your chipper. To check this,

look at the valve assembly (pictured at right).

If your valve assembly looks like the one pictured,•

a snubber harness was not installed on your machine

and you may procede with Plus 1 installation.

If your valve assembly does not look like the one •

pictured because a snubber harness was connected

in the places shown by arrows, you must unplug the

connectors, remove the snubber harness, and plug

the connectors back in so that your valve assembly

looks like the one shown here.

ENGLISH FRANÇAIS

3. DRILL MOUNTING HOLES

To mount the Plus 1 controller on the engine shield brace, drill two holes 11/32" in diameter in the shield brace in the

positions shown below. They should be drilled on the side of the machine closest to the control panel. (Note: in newer

machines these holes have already been drilled.)

PN 75984-00

Rev. 081110

Page 2

4. MOUNT CONTROLLER

BUMPER

1-1/4” BOLT

2-1/4” HEX

BOLT

PLUS 1

CONTROLLER

5/16” X 3/4”

CARRIAGE

BOLT

CONTROLLER

PLATE

1/4” NYLOCK

NUT

5/16” NYLOCK NUT

ENGINE SHIELD

BRACE

7.50"

1.50"

DRILL HOLE 9/16”

IN DIAMETER

Bolt the controller plate to the engine shield brace with the (2) 3/4" carriage bolts that are provided (see figure 1.

below). Secure with two nuts.

Bolt the Plus 1 controller to the controller plate with two (2) 1" bolts, two (2) 2" hex bolts and four (4) bumpers as 2.

shown below.

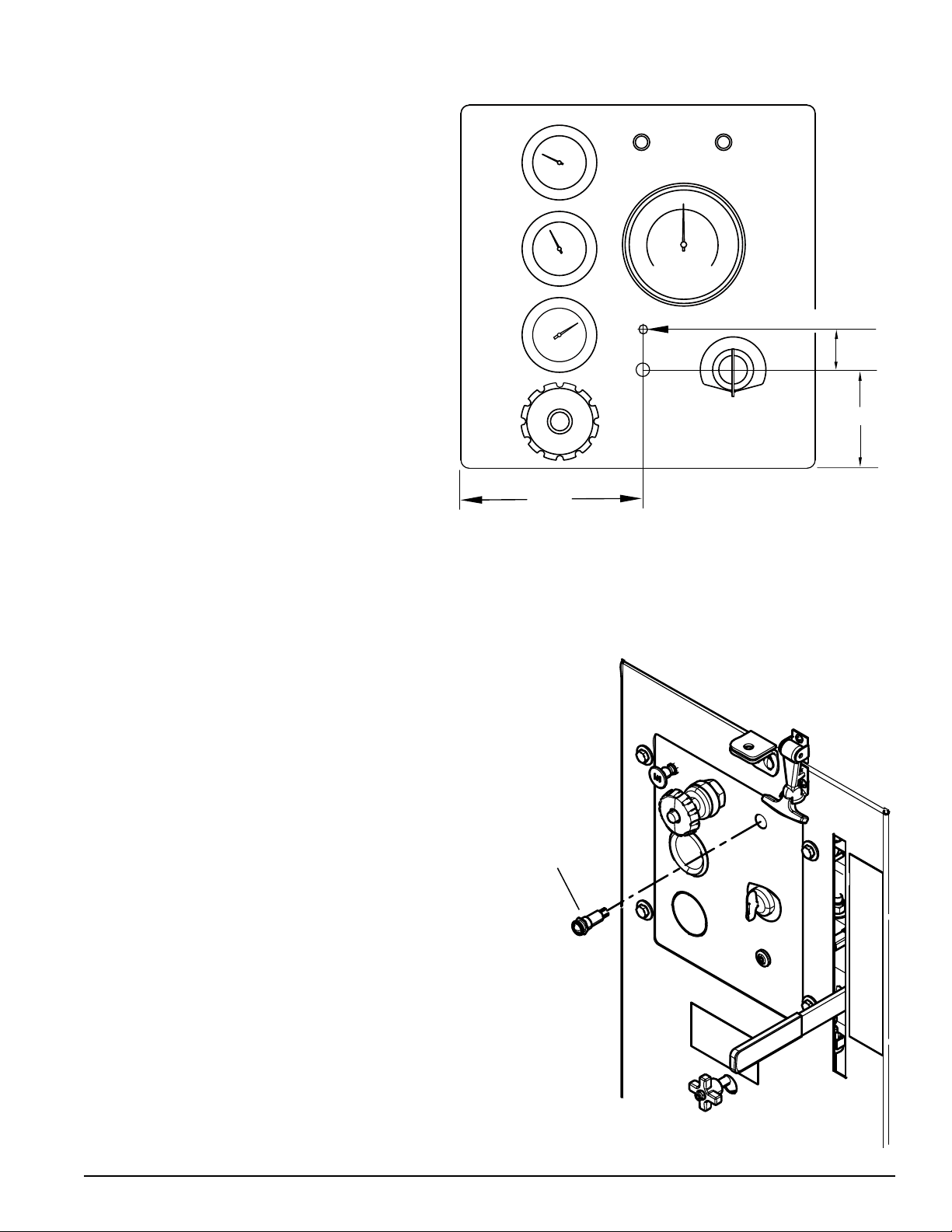

5. MOUNT THE TRI-COLOR LED

The Tri-Color LED mounts on the chipper control panel, which is located on the side of the chipper. Note that the

mounting location is different for the gas and diesel models. See Section 5.1 for gas engine models or 5.2 for diesel

engine models.

IMPORTANT

Take care not to damage the existing wiring when

drilling the hole for the LED!

5.1 - DRILL LOCATION FOR GAS ENGINE MODELS

Follow the measurements to drill a hole for the LED.

2

Instruction Sheet

Page 3

5.2 - DRILL LOCATION FOR DIESEL ENGINE MODELS

5.54"

3.00"

1.625

DRILL HOLE 9/16” IN DIAMETER

LED

Follow the measurements to drill a hole for the

LED. Drill the hole 1.625" above the Reset button

as shown.

6. INSERT THE TRI-COLOR LED

Install the tri-colored LED by unscrewing the LED hex

nut, pushing the LED into the control panel from the

front, and securing it with the hex nut from the back.

Instruction Sheet

3

Page 4

7. PLUG PLUS 1 CONTROLLER INTO MAIN HARNESS

PLUG INTO

PLUS 1

CONTROLLER

PLUG 2-PIN TO

2-PIN ON MAIN

HARNESS

PLUG 4-PIN TO

4-PIN ON MAIN

HARNESS

PLUG 6-PIN TO

6-PIN ON MAIN

HARNESS

TRIANGULAR END

(NOT USED)

CONNECT TO LED

EUROPEAN HARNESS

PLUG INTO

PLUS 1

CONTROLLER

DOMESTIC HARNESS

PLUG 4-PIN TO

4-PIN ON MAIN

HARNESS

PLUG 6-PIN TO

6-PIN ON MAIN

HARNESS

TRIANGULAR END

(NOT USED)

CONNECT TO LED

Note that the instructions for this step are different for European and Domestic machines. Choose the section below

that is correct for your machine.

DOMESTIC (US) MACHINES:

Unplug the main harness from the existing SmartRelay 1.

controller.

Locate the three connectors on the Plus 1 harness.2.

The connector with the triangular end is NOT USED.3.

Plug the 6-pin connector into the corresponding 6-pin 4.

connector on the main harness.

Plug the 4-pin connector into the 4-pin connector on 5.

the main harness.

There will be two 2-pin connectors left over on the main 6.

harness. Tape them together and out of the way.

Plug the two black and gray connectors on the other 7.

end of the Plus 1 harness to the corresponding

receptors on the Plus 1 controller.

EUROPEAN MACHINES:

Unplug the main harness from the existing SmartRelay 1.

controller.

Locate the four connectors on the Plus 1 harness.2.

The connector with the triangular end is NOT USED.3.

Plug the 6-pin connector into the corresponding 6-pin 4.

connector on the main harness.

Plug the 4-pin connector into the 4-pin connector on 5.

the main harness.

Plug the 2-pin connector into the red/black and light 6.

green 2-pin connector on the main harness.

There will be one 2-pin connector left over on the main 7.

harness. Tape it out of the way.

Plug the two black and gray connectors on the other 8.

end of the Plus 1 harness to the corresponding

receptors on the Plus 1 controller.

4

Instruction Sheet

Page 5

WHITE

BLUE

RED/YELLOW

8. HOOK UP THE LED

Connect the three wires on the Plus 1 harness to the LED as shown below.

If the wires are correctly connected, the light will flash red upon initial startup. If the light flashes green, the wires are

reversed. After initial startup, see Control Light Flash Codes chart for an explaination of all color codes.

9. OPERATION

Upon initial startup, make sure the chipper is in Neutral (Stop) position. If the chipper feed control is in any other 1.

position, the LED will flash red and forward feed will not be available.

Upon initial startup, if the chipper is in Neutral position, the LED will flash green, indicating that the RPM is not high 2.

enough to chip (see Optimal Rotor and Engine RPM chart).

Increase RPM gradually until the LED is solid green. Forward feed is now available.3.

See the Control Light Flash Codes table on the following page for a complete explaination of all flash codes provided 4.

by the LED. Save these instructions for future reference.

10. OPTIONAL REMOVAL OF SMARTRELAY

Once you have used the Plus 1 controller long enough to verify that it works correctly, the SmartRelay controller can be

removed along with the box that it is located in. A plate to cover the SmartRelay opening is provided with this kit, along

with the necessary hardware.

11. OPTIMAL ROTOR AND ENGINE RPM

Chipper Model Rotor RPM Engine RPM

CH611DH (76628) 1800 3000

CH6670H (76624) 1675 3780

CH6993H (76635) 1675 3780

OPTIMAL ROTOR AND ENGINE RPM

Instruction Sheet

5

Page 6

12. CONTROL LIGHT FLASH CODES

GUIDE TO THE CONTROLLER FLASH CODES

SIGNAL FREQUENCY CAUSE ACTION TO TAKE

GREEN

Green Solid light Forward feed available. Feed materials into the chute.

Green One flash per second

Red One flash per second

Red Solid light

RPM not high enough to chip

upon initial startup.

Disk RPM dropped while

chipping.

RED

Feed bar is not in STOP upon

initial startup.

RPM dropped too low for 10

seconds.

(CE compliant models only)

Light is solid red upon startup.

(CE compliant models only)

Safety bar was activated.

(Non-CE compliant models

only) Jumper harness plug

was damaged.

AMBER

Increase RPM gradually until the green light

stops flashing.

The feed roller will automatically reverse to

regulate the feed.

Put control bar in STOP position.

Put control bar in STOP position and then

reengage.

Push reset/override button to reset.

Check connections to jumper harness plug.

Replace if plug necessary (PN 36391-00)

Amber

Amber

Amber

On for 2 seconds and

then off for 2 seconds

Solid light for 7

seconds followed by a

long pause

On for 1/2 second,

then off for 1/2 second

for a period of 8

seconds followed by a

long pause

Check the sharpness of the

chipper blades.

There is a short or open circuit

in the forward feed.

There is a short or open circuit

in the reverse feed.

Check sharpness of chipper blades. Sharpen

or flip if necessary.

To reset the controller: With the control bar

in STOP, turn the keyswitch to ON, and then

shift the control bar from reverse to reverse

and back three times within 60 seconds.

Check connections to the forward coil on the

feed hydraulic valve. Replace coil if necessary.

Check connections to the reverse coil on the

feed hydraulic valve. Replace coil if necessary.

6

Instruction Sheet

Page 7

12

1

2

3

4

5

6

7

8

9

10

11

4

PLUS 1 CONTROLLER KITS, PN 76170-00 AND 76171-00

ITEM PART NUMBER DESCRIPTION QTY

1 15238 BOLT, 1/4 X 3/4 CRG 2

2 75977-12 PLATE, CONTROLLER 1

3 36261-00 BUMPER, 1” OD WITH 1/4” STUD 4

4 15355 NUT, 1/4 NYLOCK 6

5 36258-00 CONTROLLER, PLUS 1 CHIPPER 1

6 15214 BOLT, 1/4 X 1-1/4 G5 ZP HCS 2

7 15197 BOLT, 1/4 X 2-1/4 HEX HD 2

8 75978-12 PLATE, COVER 1

9 15367 BOLT, 5/16 X 3/4 CRG 2

10 15356 NUT, 5/16 NYLOCK 2

11 15030 WASHER, 1/4 FLAT 2

12 36356-00 LED, TRI-COLOR 12V 3-TERM BASE 1

36381-00 HARNESS, 6” PLUS 1 (GAS EUROPEAN) 1

36383-00 HARNESS, 6” PLUS 1 (DIESEL EUROPEAN) 1

36397-00 HARNESS, 6” PLUS 1 (GAS DOMESTIC) 1

36398-00 HARNESS, 6” PLUS 1 (DIESEL DOMESTIC) 1

Instruction Sheet

7

Page 8

ECHO BEAR CAT

www.bearcatproducts.com

237 NW 12th Street, West Fargo, ND 58078-0849

Phone: 701.282.5520 • Toll Free: 800.247.7335 • Fax: 701.282.9522

E-mail: service@bearcatproducts.com • sales@bearcatproducts.com

Loading...

Loading...