Page 1

OPERATOR'S MANUAL

MANUEL D'UTILISATION

BEDIENUNGSANLEITUNG

MANUALE ISTRUZIONI

PAS Trimmer Attachment

MODEL 99944200840

ENGLISH

FRANCAIS

DEUTSCH

ITALIANO

X7702271902

WARNING, SEE OPERATOR'S MANUAL

LÌRE SOÌGNEUSEMENT CE MANUEL AVANT

TOUTE UTÌLÌSA TÌON

ACHTUNG! BEDIENUNGSANLEITUNG LESEN

A TTENZIONE, LEGGERE IL MANUALE ISTRUZIONI

X770000151

07/04

Page 2

2

INTRODUCTION

Welcome to the ECHO family. This ECHO product was designed and manufactured to provide long life and on-the-jobdependability. Read and understand this manual and the SAFETY MANUAL you found in the same package. You will

find both easy to use and full of helpful operating tips and SAFETY messages.

THE OPERATOR'S MANUAL

Read and understand this manual before operation. Keep it in a safe

place for future reference. It contains specifications and information for

operation, starting, stopping, maintenance, storage and assembly

specific to this product.

THE ATTACHMENT OPERATOR'S MANUAL

Read and understand this manual before operation. Keep it in a safe

place for future reference. It contains specifications and information for

operation and maintenance specific to the attachment.

TABLE OF CONTENTS

Introduction ............................................................... 2

- The Operator's Manual .......................................2

Manual Safety Symbols & Important Information .....3

Safety ......................................................................... 3

- Decals .................................................................3

- International Symbols.........................................4

Safety Instructions .................................................... 4

- Personal Condition and Safety Equipment ......... 4

- Extended Operation/Extreme Conditions ............ 5

- Equipment ........................................................... 5

- Safe Operation ....................................................6

Description ................................................................6

- Contents .............................................................6

Specifications.............................................................7

Assembly ................................................................... 8

- Power Head Shaft / Lower Shaft Assembly ........8

Copyright© 2004 By Echo, Incorporated

All Rights Reserved.

- Plastic Shield Installation....................................9

- Nylon Head Installation......................................9

Operation ................................................................. 10

Maintenance ............................................................10

- Skill Levels ........................................................10

- Maintenance Intervals ...................................... 10

- Lubrication........................................................ 11

- Nylon Line Replacement ................................... 12

Declarations .............................................................14

Specifications, descriptions and illustrative material in

this literature are as accurate as known at the time of

publication, but are subject to change without notice.

Illustrations may include optional equipment and

accessories, and may not include all standard equipment.

Page 3

PAS TRIMMER ATTACHMENT

OPERATOR'S MANUAL

MANUAL SAFETY SYMBOLS & IMPORTANT INFORMATION

Throughout this manual and on the product itself, you will find safety

alerts and helpful, information messages preceded by symbols or key

words. The following is an explanation of those symbols and key words

and what they mean to you.

This symbol accompanied by the words WARNING and

DANGER calls attention to an act or condition that can lead to

serious personal injury to operator and bystanders.

IMPORTANT

IMPORTANT The enclosed message

provides information necessary for the

protection of the unit.

3

NOTE

The circle with the slash symbol means whatever is shown

within the circle is prohibited.

SAFETY

DECALS

Locate these safety decals on your unit. The complete unit illustration

found in the "DESCRIPTION" section, will help you locate them. Make

sure the decals are legible and that you understand and follow the

instructions on them. If a decal cannot be read, a new one can be ordered

from your ECHO Dealer.

NOTE This enclosed message provides

tips for use, care and maintenance of the

unit.

Debris Shield Decal

P/N 89018623760

Shaft Decal

P/N 89061763630

Page 4

4

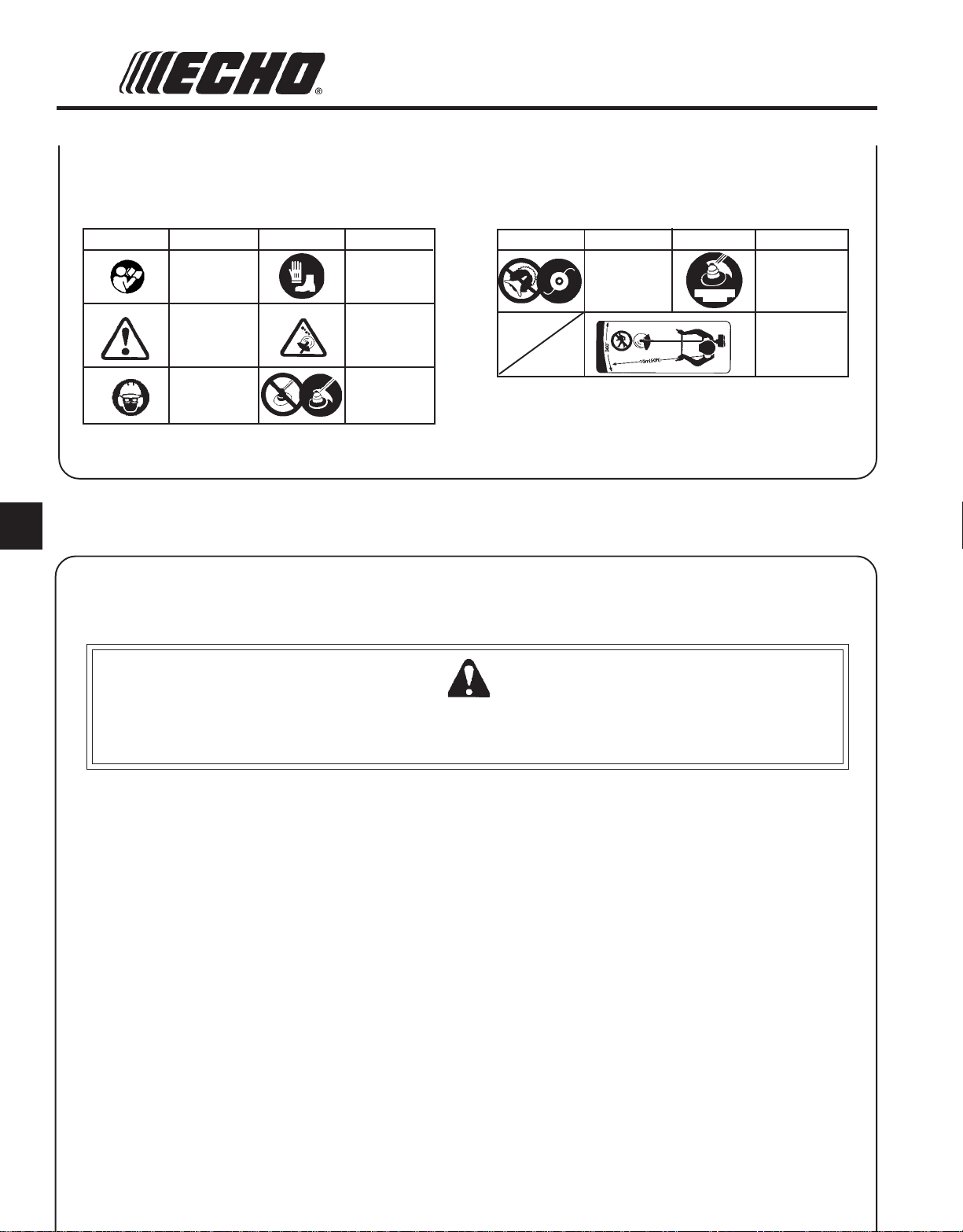

INTERNA TIONAL SYMBOLS

Symbol form/shape

Symbol

description/application

Carefully read the

operator’s manual

Safety alert

Wear eyes, ears and

head protection

Symbol form/shape

SAFETY INSTRUCTIONS

PERSONAL

CONDITION AND SAFETY EQUIPMENT

Symbol

description/application

Wear foot protection

and gloves

Warning!

Thrown objects!

Usage without shield

not permitted

Symbol form/shape

Symbol

description/application

DO NOT USE

BLADES - Line

Head Only

Symbol form/shape

ns10000/min

(rev/min)

Symbol

description/application

The maximum speed of

the cutting attachment

shaft in r/min

Keep bystanders away

15m

W ARNING DANGER

Trimmer/Brush Cutter users risk injury to themselves and others if the trimmer/brush cutter is used improperly

or safety precautions are not followed. Proper clothing and safety gear must be worn when operating a

trimmer/brush cutter.

Physical Condition

Your judgment and physical dexterity may not be good:

• if you are tired or sick,

• if you are taking medication,

• if you have taken alcohol or drugs.

Operate unit only if you are physically and mentally well.

Eye Protection

Wear eye protection that meets ANSI Z87.1 or CE

requirements whenever you operate the unit.

Hand Protection

Wear no-slip, heavy duty work gloves to improve your

grip on the unit handles. Gloves also reduce the transmission of machine vibration to your hands.

Hearing Protection

ECHO recommends wearing hearing protection whenever

unit is used.

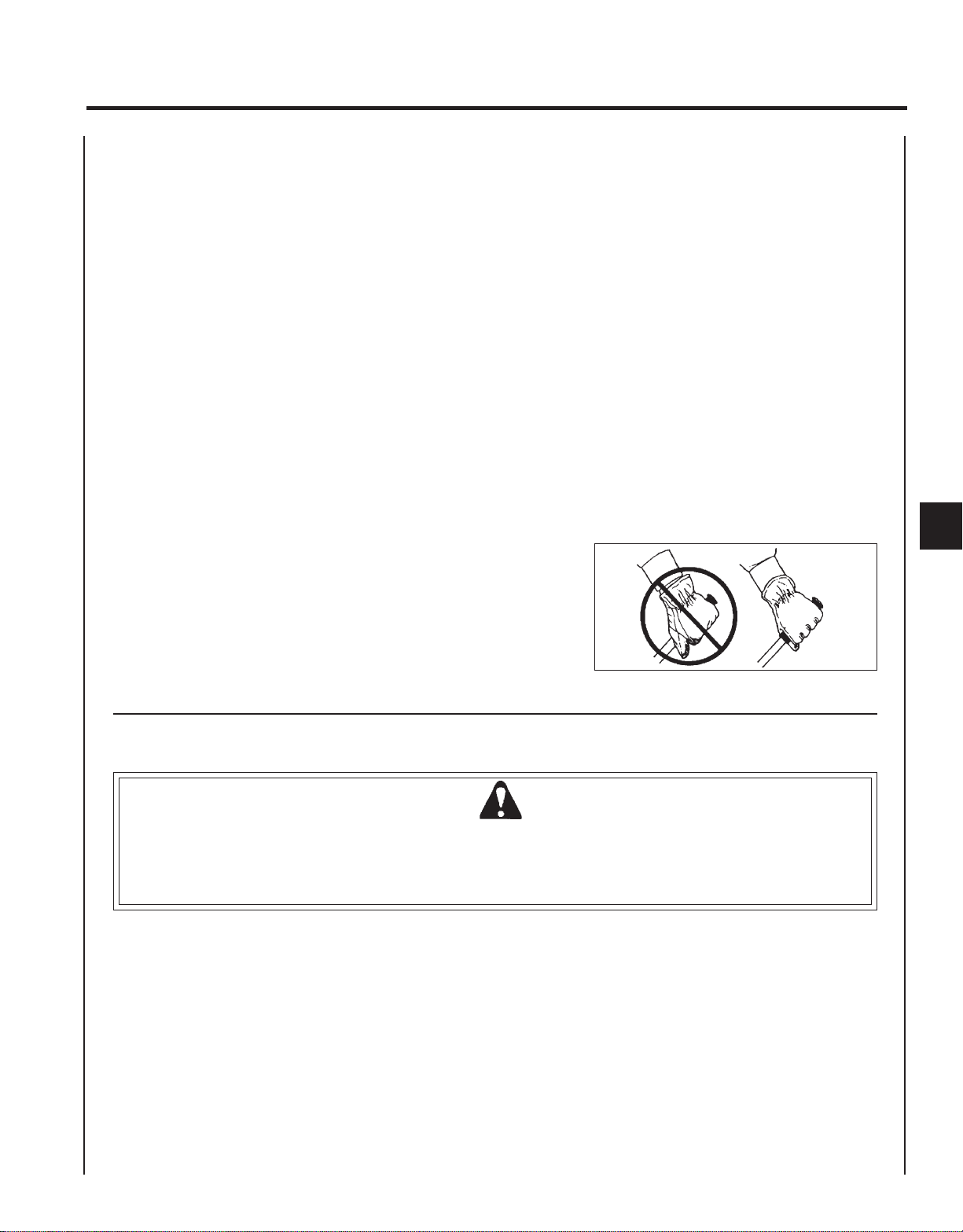

Proper Clothing

Wear snug fitting, durable clothing;

• Pants should have long legs, shirts with long sleeves.

• DO NOT WEAR SHORTS,

• DO NOT WEAR TIES, SCARVES, JEWELRY.

Wear sturdy work shoes with non-skid soles;

• DO NOT WEAR OPEN TOED SHOES,

• DO NOT OPERATE UNIT BAREFOOTED.

Hot Humid Weather

Heavy protective clothing can increase operator fatigue

which may lead to heat stroke. Schedule heavy work for

early morning or late afternoon hours when temperatures

are cooler.

Page 5

PAS TRIMMER ATTACHMENT

OPERATOR'S MANUAL

5

EXTENDED

OPERATION/EXTREME CONDITIONS

Vibration and Cold

It is believed that a condition called Raynaud’s Phenomenon, which

affects the fingers of certain individuals, may be brought about by

exposure to vibration and cold. Exposure to vibration and cold may

cause tingling and burning sensations, followed by loss of color and

numbness in the fingers. The following precautions are strongly

recommended, because the minimum exposure which might trigger the

ailment is unknown.

• Keep your body warm, especially the head, neck, feet, ankles,

hands, and wrists.

• Maintain good blood circulation by performing vigorous arm

exercises during frequent work breaks, and also by not smoking.

• Limit the hours of operation. Try to fill each day with jobs where

operating the trimmer or other hand-held power equipment is not

required.

• If you experience discomfort, redness and swelling of the fingers

followed by whitening and loss of feeling, consult your physician

before further exposing yourself to cold and vibration.

Repetitive Stress Injuries

It is believed that overusing the muscles and tendons of the fingers,

hands, arms and shoulders may cause soreness, swelling, numbness,

weakness, and extreme pain in those areas. Certain repetitive hand

activities may put you at a high risk for developing a Repetitive Stress

Injury (RSI). An extreme RSI condition is Carpal Tunnel Syndrome

(CTS), which could occur when your wrist swells and squeezes a vital

nerve that runs through the area. Some believe that prolonged exposure

to vibration may contribute to CTS. CTS can cause severe pain for

months or even years.

To reduce the risk of RSI/CTS, do the

following:

• Avoid using your wrist in a bent, extended, or twisted position. Instead, try to

maintain a straight wrist position. Also,

when grasping, use your whole hand, not

just the thumb and index finger.

• Take periodic breaks to minimize repetition

and rest your hands.

• Reduce the speed and force with which

you do the repetitive movement.

• Do exercises to strengthen the hand and

arm muscles.

• Immediately stop using all power equipment and consult a doctor if you feel

tingling, numbness, or pain in the fingers,

hands, wrists, or arms. The sooner RSI/

CTS is diagnosed, the more likely permanent nerve and muscle damage can be

prevented.

EQUIPMENT

W ARNING DANGER

Use only ECHO approved attachments. Serious injury may result from the use of a non-approved attachment

combination. ECHO, INC. will not be responsible for the failure of cutting devices, attachments or accessories which

have not been tested and approved by ECHO. Read and comply with all safety instructions listed in this manual and

safety manual.

• Check unit for loose/missing nuts, bolts, and screws. Tighten and/or

replace as needed.

• Inspect shield for damage and ensure that the cut-off knife issecurely

in place. Replace if either is damaged or missing.

• Check that the cutting attachment is firmly attached and in safe

operating condition.

• Check that front loop handle and shoulder strap/ or shoulder/

waist harness are adjusted for safe, comfortable operation. See

Assembly Section for proper adjustment.

Page 6

6

SAFE OPERATION

W ARNING DANGER

Do not operate this product indoors or in inadequately ventilated

areas. Engine exhaust contains poisonous emissions and can cause

serious injury or death.

Provide Safety And Operating Instructions To All Operators

• Provide all users of this equipment with the Operator's Manual and

Safety Manual for instructions on Safe Operation.

Keep A Firm Grip

• Hold the front and rear handles with both hands with thumbs and

fingers encircling the handles

Keep A Solid Stance

• Maintain footing and balance at all times. Do not stand on slippery,

uneven or unstable surfaces. Do not work in odd positions or on

ladders. Do not over reach.

Avoid Hot Surfaces

• Keep exhaust area clear of flammable debris. Avoid contact during

and immediately after operation.

DESCRIPTION

After opening the carton, check for damage. Immediately notify your retailer or ECHO Dealer of damaged or missing

parts. Use the contents list to check for missing parts.

CONTENTS

1 - PAS Trimmer Attachment

1 - Operator's Manual

1 - Locking Tool

1 - Plastic Debris Shield

1 - Nylon Trimmer Head

1 - Safety Goggle

1 - Shield Plate

3 - 5mm x 15mm Screws (shield mounting)

Page 7

PAS TRIMMER ATTACHMENT

OPERATOR'S MANUAL

7

4

1. LOWER DRIVE SHAFT ASSEMBLY - Includes the Debris Shield Assembly, Gear Housing assembly, Flexible Drive

Cable, Nylon Cutter Head and Safety Decals.

2. PLASTIC DEBRIS SHIELD ASSEMBLY - Included in plastic bag (co-pack). MUST be installed on unit before use,

see Assembly Instructions. Shield assembly includes the Cut-Off Knife and Safety Decal. Mounts on the Gear

Housing Assembly just above the cutting attachment. Helps protect the operator by deflecting debris produced

during the trimming operation. This shield must be replaced with the steel shield for blade use.

3. CUT-OFF KNIFE - Trims line to the correct length: 127mm from head to end of line after head is tapped on the ground

during operation and the line advances. If trimmer is operated without a cut-off knife the line will become too long. If

the line is more than the listed length the operating speed will slow, the engine overheat and engine damage may

occur.

4. NYLON CUTTER HEAD - Contains replaceable nylon trimming line that advances when the trimmer head is tapped

against the ground while the head is turning at normal operating speed.

5. OPERATOR'S MANUAL - Included in plastic bag (co-pack). Read before operation and keep in a safe place for future

reference, i.e., operation, maintenance, storage and specifications.

5

SPECIFICATIONS

PAS Trimmer Attachment

MODEL ----------------------------------------------------- PAS Trimmer Attachment

Shaft Length ------------------------------------------------ 870 mm (34.3 in.)

Attachment Width ----------------------------------------- 178 mm (7.0 in.)

Attachment Height ---------------------------------------- 255 mm (10.0 in.)

Weight (dry) w/line head --------------------------------- 1.43 kg (3.15 lb.)

Drive Shaft -------------------------------------------------- 1/4" Flex Shaft

Direction of Rotation -------------------------------------- Counter clockwise viewed from the top

Cutter Head -------------------------------------------------Nylon line head (2-lines) with .095" Cross Fire™ Line

Line Capacity 6 m (20 ft.)

NOTE Install U-handle and metal shield when using metal blade.

Page 8

8

ASSEMBLY

POWER

Tools Required: None

Parts Required: PAS or SRM-SB Power Head w/Shaft & Coupling.

1 . Set Power Head/Shaft Assembly on a level surface.

2 . Pull locator pin (A) out, and turn counter-clockwise 1/4 turn to lock-

out position.

3 . Carefully fit attachment drive shaft assembly into coupler (B) to decal

assembly line (C), making sure that the inner lower drive shaft

engages into the square upper drive shaft socket.

NOTE

Earlier model Power Heads may have shorter couplings. Short

couplings fit flush to decal point (E). New couplings are 120 mm

(4-3/4 in.) long, and fit flush to line (C).

NOTE

Lower bearing housing and head assembly must be in line with the

engine.

HEAD SHAFT/LOWER SHAFT ASSEMBL Y

B

D

A

B

D

A

4 . Rotate locator pin (A) 1/4 turn clockwise to engage lower shaft

hole. Insure locator pin is fully engaged by twisting lower drive

shaft. Locator pin should snap flush in coupler. Full engagement will

prevent further shaft rotation.

5 . Secure lower shaft assembly to coupler by tightening clamping

knob (D).

D

C

E

Page 9

PAS TRIMMER ATTACHMENT

PLASTIC SHIELD INSTALLATION

(For Nylon Line Operation)

Tools Required: Screwdriver.

Parts Required: Plastic Shield, Shield Plate, three (3) 5 mm x 15 mm

screws.

NOTE

The plastic shield is for use with the Nylon Line Head only.

1. Snap the shield on the bottom of the bearing housing flange.

2 . Place shield plate on shield, align holes and install three (3) screws.

OPERATOR'S MANUAL

9

NYLON LINE HEAD INSTALLATION

Tools Required: Head Locking Tool

Parts Required: Nylon Line Head.

1 . Align locking hole in upper plate (B) with notch in edge of gear

housing and insert head locking tool (A).

2 . Remove plastic sleeve from P.T.O. shaft (C).

3 . Be sure upper plate (B) remains on P.T.O. shaft.

4 . Thread line head onto P.T.O. shaft by turning it counter clockwise

until head is tight against upper plate (B).

5 . Remove locking tool (B).

A

C

B

Page 10

10

OPERATION

W ARNING DANGER

The cutting attachment should not rotate at idle. If attachment

rotates, readjust carburetor according to "Carburetor Adjustment"

instructions in this manual or see your ECHO Dealer, otherwise

serious personal injury may result.

NOTE

Refer to the power head Operator's Manual for proper and safe

operating techniques.

W ARNING DANGER

Inspect starting area for hazards such as rocks, glass, debris etc.

which could be contacted by the cutting attachment when starting.

Keep helpers and bystanders at least 15 m (50 ft.) from starting

area, otherwise serious personal injury may result.

MAINTENANCE

Your ECHO unit is designed to provide many hours of trouble-free service. Regular scheduled maintenance will help your

unit achieve that goal. If you are unsure or are not equipped with the necessary tools, you may want to take your unit to

an ECHO Service Dealer for maintenance. To help you decide whether you want to DO-IT-YOURSELF or have the ECHO

Dealer do it, each maintenance task has been graded. If a task is not listed, see your ECHO Dealer for repairs.

SKILL LEVELS

Level 1 = Easy to do. Most required tools come with unit.

Level 2 = Moderate difficulty. Some specialized tools may be required.

Level 3 = Experience required. Specialized tools are required. ECHO recommends

that the unit be returned to your ECHO dealer for service.

MAINTENANCE INTERVALS

Component/System Maintenance Procedure Skill Level Frequency

Drive Shaft Grease 1 Every 25 hours of use

Gear Housing Grease 1 Every 50 hours of use

Screws/Nuts/Bolts Inspect/Tighten/Replace 1 Before each use

Page 11

LUBRICA TION

Level 1.

Tools Required: 8 mm Open End Wrench, Screwdriver, Clean Rag

Parts Required: Lithium Base Grease.

Gear Housing

1 . Clean all loose debris from gear box.

2 . Remove plug (A) and check level of grease.

3 . Add grease if necessary, DO NOT over fill.

PAS TRIMMER ATTACHMENT

OPERATOR'S MANUAL

11

4 . Install plug (A).

Drive Shaft (Lower)

IMPORTANT

Lower and upper drive shaft must be lubricated with high temperature automotive grease every 25 hours of operation, otherwise drive

shaft assembly overheating and failure can result.

1 . Loosen two (2) screws (B) and remove center locating screw (C).

Pull gear box and shield from drive shaft housing.

2 . Pull flexible cable from the drive shaft housing, wipe clean and

re-coat with a thin coating [15 ml (1/2 oz.)] of Lithium Base Grease.

3 . Slide the flexible cable back in the drive housing. DO NOT get

dirt on the flex cable.

4. Install the gear housing and shield assembly.

IMPORTANT

Flat edge of washers (D) must be against drive shaft.

A

D

Page 12

12

NYLON LINE REPLACEMENT

Level 1.

Parts Required: ECHO 0.095 in. Nylon Trimmer Line 6 m (20 ft.) long.

1. Shut engine off. Lay unit on the ground with head assembly up.

2 . Hold drum (A) and turn spool (B) CW (clockwise) until it stops.

Pull spool from drum. DO NOT push in on spool when turning.

3 . Use one piece of new nylon line (C) 6 m (20 ft.) long and thread

through the molded loop (D) on the spool. Pull line tight and

adjust so one end is 15 cm (6 in.) longer than the other.

4 . Hold the spool, opening toward you. Place index finger between

the two strands and wind line, tightly and evenly, in direction of

arrow (E) marked "CC".

Page 13

5 . Stop when approximately 15-20 cm (6-8 in.) line (C) remains and

place ends of line in notches (F) in spool (B).

6 . Feed ends of line through housing eyelets (G) and place spool (B)

over drive (H). Align pegs (I) on drive with notches in spool, and

push spool into drum.

PAS TRIMMER ATTACHMENT

OPERATOR'S MANUAL

F

H

I

G

I

13

7 . Pull on both lines until they come free from notches (F) in spool.

8 . Hold drum (A) firmly and turn spool (B) CCW (counterclockwise)

until it stops. DO NOT push in on spool when turning.

9 . Pull both lines out and trim to cut-off knife length.

G

Page 14

14

DECLARATION “CE” OF CONFORMITY

The undersigned manufacturer:

KIORITZ CORPORA TION

7-2 SUEHIROCHO 1-CHOME

OHME ; TOKYO 198-871 1

JAPAN

declares that the hereunder specified new unit:

PRO ATTACHMENT

Brand :ECHO

Type : PAS-2400

assembled by:

ECHO, INCORPORA TED

400 Oakwood Road

Lake Zurich, Ilinois 60047-1564

U.S.A.

complies with:

*the requirements of Directive 98/37/EC (1998)

*the requirements of Directive 89/336/EEC

(use of harmonized standards EN 50081-1, EN 50082-1, EN 55014 & EN 55022)

*the requirements of Directive 2002/88/EC

*the requirements of Directive 2000/14/EC

Conformity assessment procedure followed ANNEX V

Measured sound power level :106 dB(A)

Guaranteed sound power level : 109 dB(A)

SERIES

Tokyo,

May 1st 2004

GB

Page 15

NOTES

PAS TRIMMER ATTACHMENT

OPERATOR'S MANUAL

15

Page 16

KIORITZ CORPORATION

7-2 SUEHIROCHO 1-CHOME, OHME, TOKYO, 198-8711, JAPAN

PHONE: 81-428-32-6118 FAX: 81-428-32-6145

ECHO, INCORPORATED

400 OAKWOOD ROAD

LAKE ZURICH, IL 60047

GB

X770-000 151

X770227-1902

Loading...

Loading...