Page 1

Installation and Start-Up Instructions

Split-System

Heat Pump

HC1B

NOTE: Read the entire instruction manual before starting the installation.

Improper installation, adjustment, alteration, service, maintenance, or use can cause explosion, fire, electrical shock, or other conditions which may

cause personal injury or property damage. Consult a qualified installer, service agency, or your distributor or branch for information or assistance.

The qualified installer or agency must use factory-authorized kits or accessories when modifying this product. Refer to the individual instructions

packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses and work gloves. Use quenching cloth for brazing operations. Have fire extinguisher available. Read

these instructions thoroughly and follow all warnings or cautions attached to the unit. Consult local building codes and the National ElectricalCode

(NEC) for special installation requirements.

Recognize safety information. This is the safety-alert symbol

to the potential for personal injury.

Understand the signal word DANGER, WARNING, or CAUTION. These words are used with the safety-alert symbol. DANGER identifies the

most serious hazards which will result in severe personal injury or death. WARNING signifies hazards that could result in personal injury or death.

CAUTION is used to identify unsafe practices which would result in minor personal injury or product and property damage.

WARNING: Before installing or servicing system, always turn off main power to system. There may be more than 1

disconnect switch. Turn off accessory heater power if applicable. Electrical shock can cause personal injury or death.

PROCEDURE 1—CHECK EQUIPMENT AND JOBSITE

A. Unpack Unit

Move to final location. Remove carton taking care not to damage unit.

B. Inspect Equipment

File claim with shipping company prior to installation if shipment is damaged or incomplete. Locate unit rating plate on unit service panel. (See

Fig. 2.) It contains information needed to properly install unit. Check rating plate to be sure unit matches job specifications.

Fig. 1—Model HC1B

SAFETY CONSIDERATIONS

. When you see this symbol on the unit or in instructions and manuals, be alert

INSTALLATION

A92461

Form: IM-HC1B-02 Cancels: IM-HC1B-01 Printed in U.S.A. 2-94 Catalog No. 92-33HC-1B2

Page 2

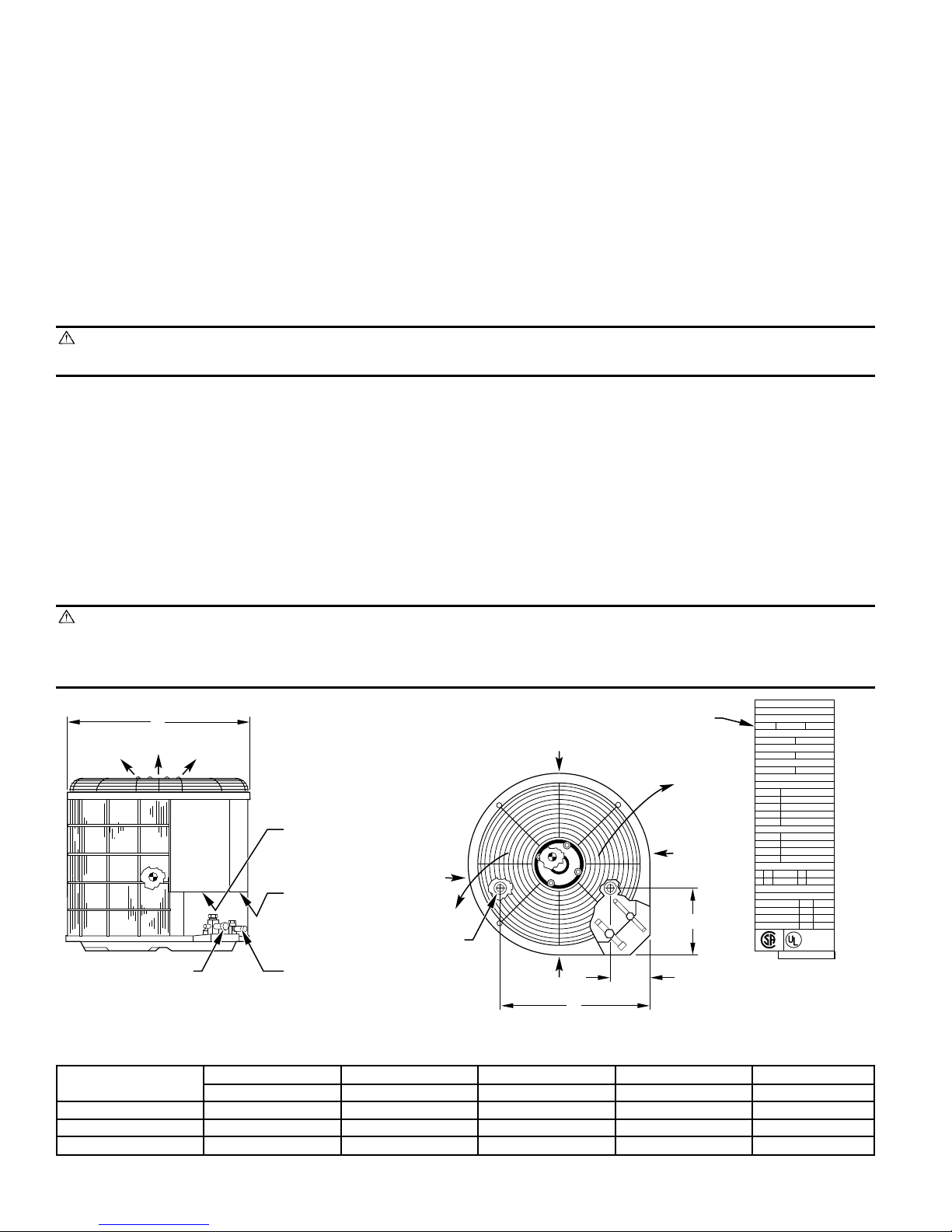

PROCEDURE 2—INSTALL ON A SOLID, LEVEL MOUNTING PAD

If conditions or local codes require the unit be attached to pad, tiedown bolts should be used and fastened through knockouts provided in unit base

pan. Refer to unit mounting pattern in Fig. 2 to determine base pan size and knockout hole location.

When installing, allow sufficient space for airflow clearance, wiring, refrigerant piping, and service. Allow 30-in. clearance to service end of unit

and 48 in. above unit. For proper airflow, a 6-in. clearance on 1 side of unit and 12 in. on all remaining sides must be maintained. Maintain a

distance of 24 in. between units. Position so water, snow, or ice from roof or eaves cannot fall directly on unit.

On rooftop applications, locate unit at least 6 in. above roof surface. Place unit above a load-bearing wall and isolate unit and tubing set from

structure.

Arrange supporting members to adequately support unit and minimize transmission of vibration to building. Consult local codes governing rooftop

applications.

PROCEDURE 3—ELEVATE UNIT

For proper drainage the heat pump must be raised off the mounting surface.

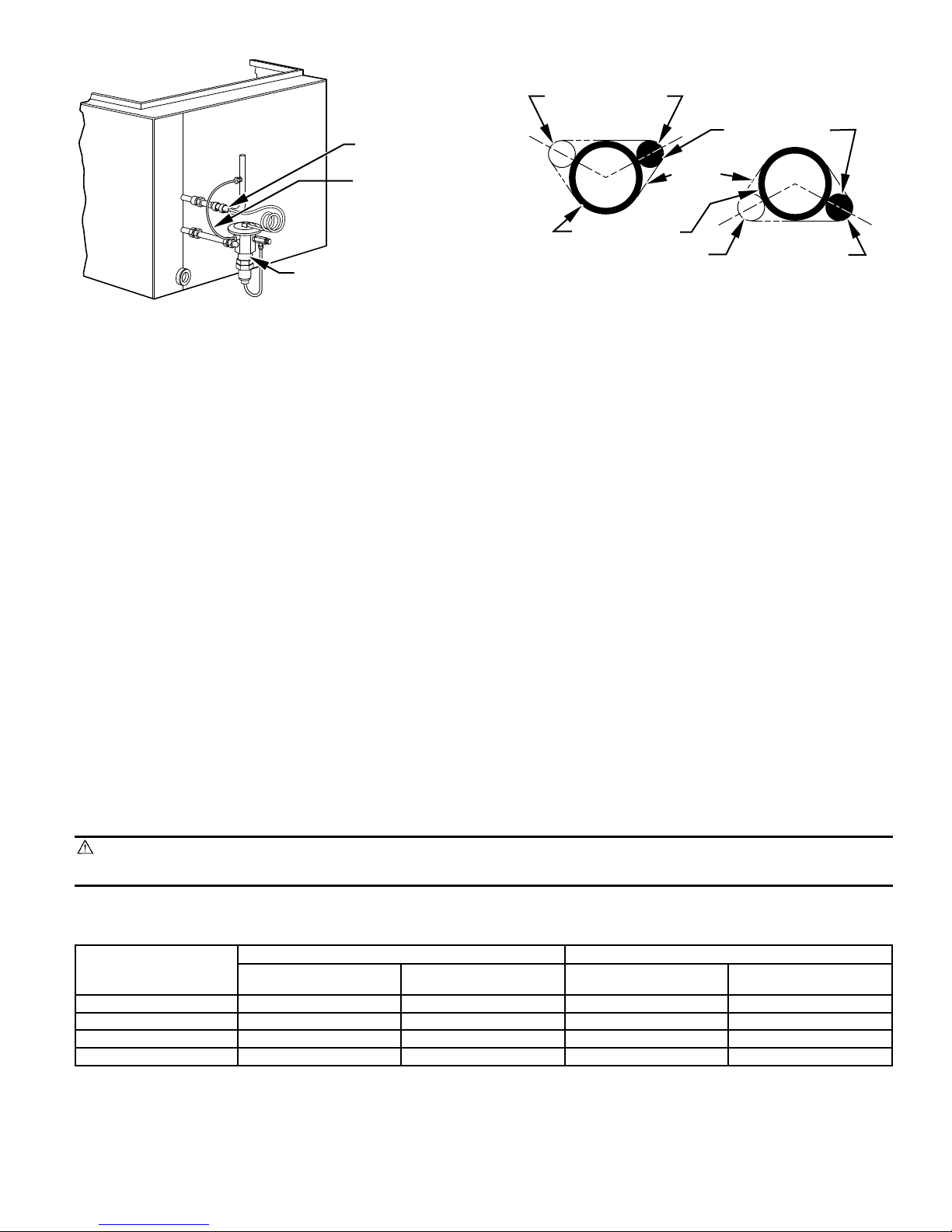

PROCEDURE 4—REPLACE INDOOR REFRIGERANT FLOW-CONTROL DEVICE PISTON WITH THERMOSTATIC EXPANSION

VALVE (TXV)

CAUTION: For proper unit operation and reliability, this unit must be installed with a field-supplied hard shutoff TXV.

Do not install with evaporator coils having capillary tube metering devices of piston.

After removing existing refrigerant flow-control device piston from indoor coil, install field-supplied bi-flow hard shutoff TXV kit.

(See Fig. 3.)

For TXV kit part number and charging instruction, refer to TXV label in your unit. If the indoor unit (fan coil) comes factory equipped with a

bi-flow hard shutoff TXV, no TXV charge is required.

Install TXV kit to indoor coil as follows:

1. Install suction tube adaptor.

2. Install liquid flare-to-sweat adaptor.

3. Connect external equalizer tube to fitting on suction tube adaptor.

4. Position sensing bulb on horizontal portion of suction tube adaptor. Secure using supplied hardware. Insulate bulb after installation. (See

Fig. 4.)

5. Leak check all connections.

CAUTION: DO NOT BURY MORE THAN 36 IN. OF REFRIGERANT TUBING IN GROUND. If any section of tubing is

buried, there must be a 6-in. vertical rise to the valve connections on the outdoor unit. If more than the recommended length

is buried, refrigerant may migrate to cooler buried section during extended periods of unit shutdown, causing refrigerant

slugging and possible compressor damage at start-up.

SERIAL

PROD

A

AIR DISCHARGE

E DIA SERVICE LINE CONN

FIELD POWER SUPPLY CONN

7

/8″ DIA HOLE WITH

1

/8″ DIA KNOCKOUT

1

3

AND 1

/8″ DIA KNOCKOUT

FIELD CONTROL POWER

SUPPLY CONN

7

/8″ DIA HOLE

TIEDOWN KNOCKOUTS

3

/8″ DIA LIQUID TUBE CONN

AIR IN

AIR

DISCHARGE

(2) PLACES

UNIT RATING

PLATE

AIR IN

AIR

DISCHARGE

AIR IN

D

AIR IN

C

B

.

MODEL

ID OD

PISTON

FACTORY CHARGED R-22

LBS

VOLTSPOWER SUPPLY

PH

PERMISSIBLE VOLTAGE AT UNIT

MAX

SUITABLE FOR OUTDOOR USE

COMPRESSOR

VOLTS AC

PH

HZ

RLA

LRA

FAN MOTOR

VOLTS AC

PH

HZ

FLA

DESIGN/TEST PRESSURE GAGE

HI

kPa

PSI

LO

kPa

PSI

MINIMUM CIRCUIT AMPS

MAX OVERCURRENT PROTECTIVE DEVICE

USA

®

N/A

®

INDIANAPOLIS IN

CANADA

N/A

46206313948-401 REV A

TYPE

MAX FUSE

MAX HACR CKT-BKR

MAX CKT-BKR

CARRIER CORP

Kg

HZ

MIN

A92490

UNIT

SIZE

A B C D E

In. In. In. In. In.

018 22-1/2 18-1/2 4-1/16 8-3/16 5/8

024-036 30 23-1/2 6-1/2 10 3/4

042-060 30 23-1/2 6-1/2 10 7/8

Fig. 2—Unit Reference Drawing

—2—

Page 3

COIL

THERMOSTATIC

EXPANSION

VALVE

SENSING

BULB

EQUALIZER

TUBE

10 O'CLOCK

2 O'CLOCK

SUCTION TUBE

7

/

″ O.D. & SMALLER

8

STRAP

8 O'CLOCK

SENSING BULB

4 O'CLOCK

LARGER THAN

7/

″ O.D.

8

Fig. 3—Typical TXV Installation

A88382

Fig. 4—Positioning of Sensing Bulb

A81032

PROCEDURE 5—MAKE PIPING CONNECTIONS

Outdoor units may be connected to indoor sections using accessory tubing package or field-supplied refrigerant grade tubing of correct size and

condition. For tubing requirements beyond 50 ft, consult Long-Line Application Guideline which is available at your local distributor.

NOTE: In some cases noise in the living area has been traced to gas pulsations from improper installation of equipment.

A. Installation Recommendations

1. Locate the unit away from windows.

2. Ensure that vapor and liquid tube diameters are appropriate to the capacity of the unit. (See Table 1.)

3. Run refrigerant tubes as directly as possible by avoiding unnecessary turns and bends.

4. Leave some slack between the structure and the unit to absorb vibration.

5. When passing refrigerant tubes through the wall, seal the opening with RTV or other pliable silicon-based caulk. (See Fig. 3.)

6. Avoid direct lineset contact with water pipes, ductwork, floor joists, wall studs, floors, and walls.

7. Do not suspend refrigerant tubing from joists and studs with a rigid wire or strap which comes in direct contact with the tubing. (See Fig.

5.)

8. Ensure that tubing insulation is pliable and completely surrounds the vapor tube.

9. When necessary, use hangar straps which are 1 in. wide and conform to the shape of the tubing insulation. (See Fig. 5.)

10. Isolate the hangar straps from the insulation by using metal sleeves bent to conform to the shape of the insulation.

If refrigerant tubes or indoor coil is exposed to atmospheric conditions for longer than 5 minutes, it must be evacuated to 500 microns to eliminate

contamination and moisture in the system.

B. Outdoor Units Connected to Factory-Approved Indoor Units

Outdoor unit contains correct system refrigerant charge for operation with indoor unit of the same size when connected by 15 ft of field-supplied

or factory accessory tubing. Check refrigerant charge for maximum efficiency. (See Procedure 9—Checking Charge.)

C. Refrigerant Tubing

Connect tubing to fittings on outdoor unit vapor and liquid service valves. (See Fig. 2.)

CAUTION: To avoid valve damage while brazing, service valves must be wrapped with a heat-sinking material such as

a wet cloth.

Table 1—Refrigerant Connections and Recommended Liquid and Vapor Tube Diameters (In.)

UNIT

SIZE

018 3/8 3/8 5/8 5/8

024-036 3/8 3/8 3/4 3/4

042 3/8 3/8 7/8 7/8

048, 060 3/8 3/8 7/8 1-1/8

Note: Tube diameters are for lengths up to 50 ft. For tubing lengths greater than 50 ft, consult your local distributor.

Connect

Diameter

D. Sweat Connection

Use refrigerant grade tubing. Service valves are closed from factory and ready for brazing. Remove plastic retainer covering threads of liquid

service valve and connect sweat/flare adapter provided to valve. (See Fig. 6.) After wrapping the service valve with a wet cloth, the tubing set can

be brazed to the service valve using either silver bearing or non-silver bearing brazing material.Consultlocalcoderequirements.Refrigeranttubing

and indoor coil are now ready for leak testing. This check should include all field and factory joints.

LIQUID VAPOR

Tube

Diameter

Connect

Diameter

—3—

Tube

Diameter

Page 4

NOTE:

AVOID CONTACT BETWEEN TUBING AND STRUCTURE

OUTDOOR WALL

THROUGH THE WALL

HANGER STRAP

(AROUND VAPOR

LINE ONLY)

INDOOR WALL

CAULK

INSULATION

VAPOR LINE

LIQUID LINE

JOIST

VAPOR LINE

INSULATION

SUSPENSION

Fig. 5—Piping Installation

1″

MIN

LIQUID

LINE

A92469

PROCEDURE 6—MAKE ELECTRICAL CONNECTIONS

WARNING: To avoid personal injury or death, do not supply power to unit with compressor terminal box cover

removed.

Be sure field wiring complies with local and national fire, safety, and electrical codes, and voltage to system is within limits shown on unit rating

plate. Contact local power company for correction of improper voltage. See unit rating plate for recommended circuit protection device.

NOTE: Operation of unit on improper line voltage constitutes abuse and could affect unit reliability. See unit rating plate. Do not install unit in

system where voltage or phase imbalance may fluctuate above or below permissible limits.

NOTE: Use copper wire only between disconnect switch and unit.

NOTE: Install branch circuit disconnect per NEC of adequate size to handle unit starting current. Locate disconnect within sight from and readily

accessible from unit, per Section 440-14 of NEC.

A. Route Ground and Power Wires

Remove access panel to gain access to unit wiring. Extend wires from disconnect through power wiring hole provided and into unit control box.

(See Fig. 2.)

WARNING: The cabinet must have an uninterrupted or unbroken ground according to NEC, ANSI/NFPA 70-1993, and

local codes to minimize personal injury if an electrical fault should occur. This may consist of electrical wire or conduit

approved for electrical ground when installed in accordance with existing electrical codes. A failure to follow this warning

could result in an electrical shock, fire, or death.

B. Connect Ground and Power Wires

Connect ground wire to ground connection in control box for safety. Connect power wiring to contactor. (See Fig. 7.)

C. Connect Control Wiring

Route 24-v control wires through control wiring grommet and connect leads to control wiring. (See Fig. 8.)

—4—

Page 5

PISTON BODY

PISTON

PISTON RETAINER

SWEAT/FLARE ADAPTER

INTERNAL STRAINER

Fig. 6—Service Valve with Sweat Adapter Tube

DISCONNECT

PER N. E. C. AND/OR

LOCAL CODES

CONTACTOR

FIELD POWER

WIRING

A92465

FIELD GROUND

WIRING

Fig. 7—Line Power Connections

GROUND

LUG

A91056

Use No. 18 AWG color-coded, insulated (35°C minimum) wires. If thermostat is located more than 100 ft from unit (as measured along the control

voltage wires), use No. 16 AWG color-coded wires to avoid excessive voltage drop.

Use furnace transformer, fan coil transformer, or accessory transformer for control power, 24-v/40-va minimum.

NOTE: Use of available 24-v accessories may exceed the minimum 40-va power requirement. Determine total transformer loading and increase

the transformer capacity or split the load with an accessory transformer as required.

NOTE: The defrost timer is factory set for 90-minute cycles. The timer can be field set for 30- and 50-minute cycles depending on defrost

conditions in your geographical location.

PROCEDURE 7—INSTALL ELECTRICAL ACCESSORIES

Refer to the individual instructions packaged with the kits or accessories when installing.

PROCEDURE 8—START-UP

1. If equipped with a crankcase heater, energize a minimum of 24 hrs before starting unit. To energize heater only, set thermostat at OFF

position and close electrical disconnect to outdoor unit.

WARNING: Service valve gage ports are equipped with Schrader valves. To prevent personal injury, wear safety

glasses and gloves when handling refrigerant.

2. Fully open liquid and vapor service valves.

3. Unit is shipped with valve stem(s) front seated and caps installed. Replace stem caps after system is opened to refrigerant flow. Replace

caps finger-tight and tighten additional 1/6 turn using a backup wrench on valve body flats to prevent distortion of sheet metal.

4. Close electrical disconnects to energize system.

5. Set room thermostat at desired temperature.

—5—

Page 6

6. Set room thermostat at HEAT or COOL and fan switch at ON or AUTO, as desired. Operate unit for 15 minutes. Check system refrigerant

charge. (See Procedure 9—Checking Charge.)

WARNING: Relieve pressure and recover all refrigerant before system repair or final unit disposal to avoid personal

injury or death. Use all service ports and open all flow-control devices, including solenoid valves.

A. Sequence of Operation

NOTE: Defrost control board in scroll compressor units is equipped with 5-minute lockout timer which may be initiated upon any interruption

of power.

NOTE: With power supplied to indoor and outdoor units, transformer is energized.

COOLING

On a call for cooling, the thermostat makes circuits R-O, R-Y, and R-G. Circuit R-O energizes the reversing valve, switching it to cooling position.

Circuit R-Y energizes the contactor, starting outdoor fan motor and compressor circuit. R-G energizes the indoor unit blower relay, starting the

indoor blower motor on high speed.

When the thermostat is satisfied, its contacts open, de-energizing the contactor and blower relay. Compressor and motors should stop.

HEATING

On a call for heating, the thermostat makes circuits R-Y and R-G. Circuit R-Y energizes contactor, starting outdoor fan motor and compressor.

Circuit R-G energizes the indoor blower relay, starting the blower motor on high speed.

Should the temperature continue to fall, R-W2 is made through the second-stage room thermostat bulb. Circuit R-W2 energizes a sequencer,

bringing on the first bank of supplemental electric heat and providing electrical potential to the second heater sequencer (if used). If the outdoor

temperature falls below the setting of the outdoor thermostat (field-installed option), the contacts close to complete the circuit and bring on the

second bank of supplemental electric heat.

When the thermostat is satisfied, its contacts open, de-energizing the contactor and sequencer. All heaters and motors should stop.

DEFROST

The defrost control is a time/temperature control which includes a field-selectable (quick-connects located at board edge) time period between

defrost cycles (30, 50, and 90 minutes), factory set at 90 minutes.

The electronic timer and the defrost cycle will start only when the contactor is energized and the defrost thermostat is closed.

The defrost mode is identical to the cooling mode except that the outdoor fan motor stops and second-stage heat is turned on to continue warming

the conditioned space.

PROCEDURE 9—CHECKING CHARGE

Factory charge is shown on unit rating plate. (See Fig. 2.)

CAUTION: Compressor damage may occur if system is overcharged.

Adjust charge in cooling mode by following procedure shown on the superheat charging tables on unit. Check charge in heating mode by following

procedure shown on heating check chart on unit.

CAUTION: Do not vent refrigerant to atmosphere. Recover during system repair or final unit disposal.

CARE AND MAINTENANCE

For continued high performance and to minimize possible equipment failure, it is essential that periodic maintenance be performed on this

equipment.

PROCEDURE 1—BEFORE YOU REQUEST A SERVICE CALL

Check the indoor and outdoor disconnect switches. Verify that circuit breakers are in ON position and that fuses have not blown.

Check for sufficient airflow. Check the air filter(s) for any accumulation of dirt. Check for blocked return-air or supply-air grilles. Be sure grilles

are open and unobstructed.

Check settings of your indoor thermostat. If you desire cooling, see that the temperature control selector is set below room temperature and the

SYSTEM switch is on the COOL or AUTO position. If you require warmth, be sure the temperature control selector is set above room temperature

and the SYSTEM switch is at HEAT or AUTO. The FAN switch should be set at ON for continuous blower operation or AUTO if you wish blower

to function only while the unit is operating.

If your comfort system still fails to operate, contact your servicing dealer for troubleshooting and repairs. Specify your apparent problem, and state

the models and serial numbers of your equipment. (You should record them on your warranty.) With this information your dealer may be able to

offer helpful suggestions over the telephone or save valuable time through knowledgeable preparation for the service call.

PROCEDURE 2—REGULAR DEALER MAINTENANCE

In addition to the routine maintenance you perform, your home comfort system should be inspected regularly by a properly trained service

technician. The inspection (preferably twice each year, but at least once every year) should include the following:

Routine inspection of air filter(s). Replacement or cleaning as required.

Inspection and cleaning of the blower wheel, housing, and motor as required.

—6—

Page 7

Inspection and, if required, cleaning of indoor and outdoor coils.

Inspection of the indoor coil drain pan, plus the primary and secondary drain lines. If supplied, the auxiliary drain pan and line should be inspected

at this time. Service should include cleaning if required.

A check of all electrical wiring and connections.

A check for secure physical connections of individual components within units.

Operation check of the heat pump system to determine actual working condition. Necessary repair and/or adjustment should be performed at this

time.

Your servicing dealer may offer an economical service contract that covers seasonal inspections. Ask for further details.

FOR THE RECORD

Record the models and serial numbers of your new equipment in the spaces provided on your warranty. This information is necessary should you

ever require information or service.

—7—

Page 8

SYSTEMS WITHOUT OUTDOOR THERMOSTATS

THERMOSTAT

SUBBASE

C

W

2

L

G

Y

E

O

R

INDOOR

SPLICE

CONNECTION

C

W

2

G

R

OUTDOOR

SPLICE

CONNECTION

C

W

2

Y

O

R

DEFROST

BOARD

THERMOSTAT

SUBBASE

C

W

2

L

G

Y

E

O

R

INDOOR

TERMINAL

BOARD

W

3

C

W

2

L

G

Y/Y

2

Y

1

E

O

R

OUTDOOR

SPLICE

CONNECTION

FACTORY WIRING

FIELD WIRING

FIELD SPLICE

USED WITH FD3, FF1, FA4, FB4, FC4, FH4 FAN COILS USED WITH FK4B FAN COIL

DEFROST

BOARD

C

W

2

Y

O

R

A91326

SYSTEMS WITH ONE OUTDOOR THERMOSTAT SYSTEMS WITH TWO OUTDOOR THERMOSTATS

THERMOSTAT

SUBBASE

C

W

2

L

G

Y

E

O

R

INDOOR

SPLICE

CONNECTION

W

3

C

W

E

2

G

R

OUTDOOR

SPLICE

CONNECTION

C

W

2

Y

O

R

DEFROST

BOARD

ODT

THERMOSTAT

SUBBASE

C

W

2

L

G

Y

E

O

R

EHR

INDOOR

SPLICE

CONNECTION

W

3

C

W

2

G

E

R

OUTDOOR

SPLICE

CONNECTION

SHR

C

W

SHR

Y

O

R

2

FACTORY WIRING

FIELD WIRING

OUTDOOR THERMOSTAT

ODT

EMERGENCY HEAT RELAY

EHR

FIELD SPLICE

USED WITH FB4, FB5, FC4, FA4, FH4 FAN COILS USED WITH FB4, FB5, FC4, FA4, FH4 FAN COILS

REMOVE WIRES FROM CRIMP NUT IN INDOOR FAN COIL WHEN INSTALLING OUTDOOR THERMOSTATS.

IMPORTANT: WHEN USING OUTDOOR THERMOSTATS, W2 MUST BE ENERGIZED WHEN REQUESTING

SUPPLEMENTAL HEAT.

DEFROST

BOARD

ODT

ODT

© 1994 RESCO P.O. Box 1667, Indianapolis, IN 46206 34002r

Fig. 8—Typical Circuit Connections

—8—

A91327

Catalog No. 92-33HC-1B2

Loading...

Loading...